Wrapping paper and manufacturing method thereof, and wrapping plate with wrapping paper and manufacturing method thereof

A manufacturing method and packaging paper technology, applied in the field of papermaking, can solve the problems of increasing the labor intensity of workers, restricting the development of solid wood packaging, and the heavy quality of solid wood packaging, so as to achieve the effects of promoting resource recycling, reducing labor intensity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

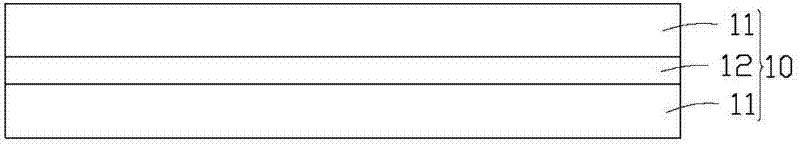

[0015] The packaging paper provided by the present invention and its manufacturing method, the packaging board with the packaging paper and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings.

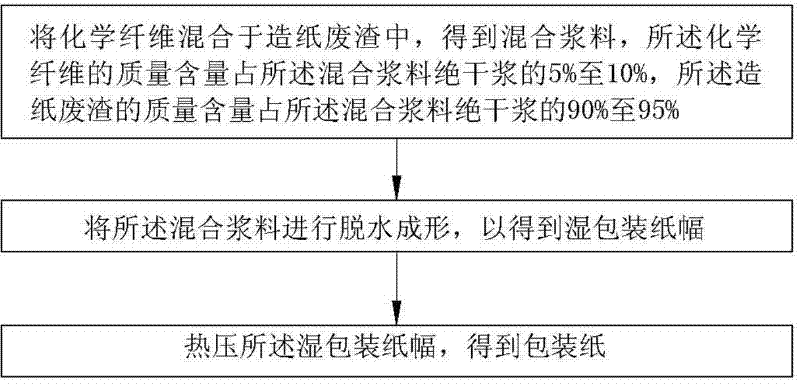

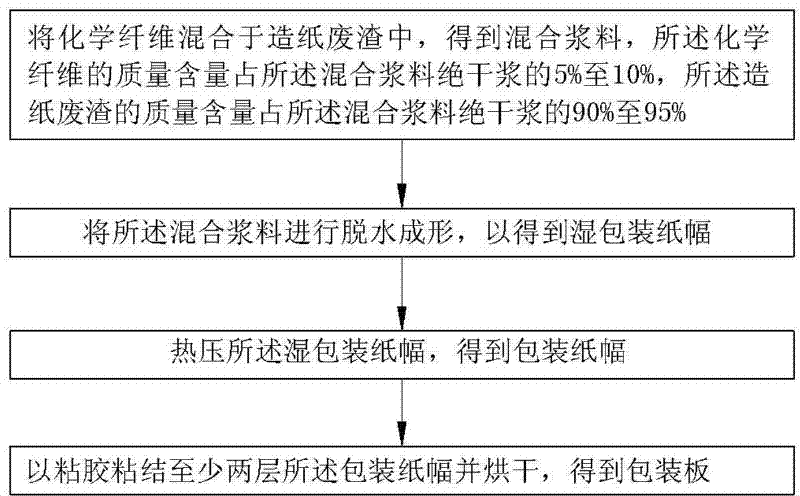

[0016] see figure 1 , The invention provides a method for manufacturing wrapping paper and the prepared wrapping paper.

[0017] The manufacturing method of described wrapping paper comprises the following steps:

[0018] In the first step, chemical fiber is mixed with papermaking waste residue to obtain a mixed slurry, the mass content of the chemical fiber accounts for 5% to 10% of the dry pulp of the mixed slurry, and the mass content of the papermaking waste residue accounts for 5% to 10%. 90% to 95% of the dry pulp of the above-mentioned mixed pulp.

[0019] The papermaking waste residue can be waste residue from papermaking, coating and other processes in the papermaking process, and mainly includes paper fiber, fille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com