A kind of preparation method of ultra-thin glass

An ultra-thin glass, glass technology, applied in the field of glass, can solve the problems of softness, light transmission and touch sensitivity that need to be further improved, unable to completely wrap the screen, low toughness and softness, etc., to improve the anti-embroidery cleaning function , The effect of reducing glass surface defects and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

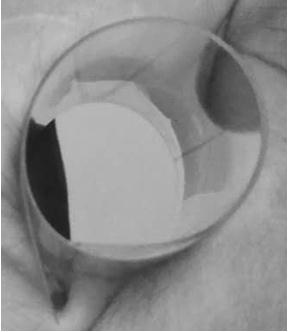

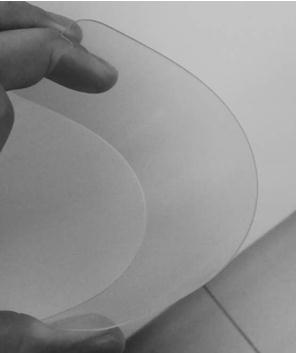

Image

Examples

Embodiment 1

[0034] A preparation method of ultra-thin glass, comprising the following steps:

[0035] (1) Take the glass, soak the glass in the thinning etchant, and perform the first thinning treatment on the glass;

[0036] (2) Grinding and polishing the thinned glass on both sides;

[0037] (3) Lay the glass that has been ground and polished on both sides on the carrier glass, and then soak it in the thinning etchant, and perform the second thinning treatment on the glass to obtain ultra-thin glass.

[0038] Further, the cross-sectional area of the carrier glass is the same as that of the glass that has been ground and polished on both sides, and its thickness is thicker than that of the glass that has been ground and polished on both sides.

[0039] Further, in the step (1) and step (3), the thinning etchant includes the following raw materials in parts by weight: 1 part of hydrofluoric acid, 5 parts of ammonium fluoride, and 94 parts of water.

[0040] Further, in the step (1), t...

Embodiment 2

[0050] In this embodiment, a method for preparing ultra-thin glass includes the following steps:

[0051] (1) Take the glass, soak the glass in the thinning etchant, and perform the first thinning treatment on the glass;

[0052] (2) Grinding and polishing the thinned glass on both sides;

[0053] (3) Lay the glass that has been ground and polished on both sides on the carrier glass, and then soak it in the thinning etchant, and perform the second thinning treatment on the glass to obtain ultra-thin glass.

[0054] Further, the cross-sectional area of the carrier glass is the same as that of the glass that has been ground and polished on both sides, and its thickness is thicker than that of the glass that has been ground and polished on both sides.

[0055] Further, in the step (1) and step (3), the thinning etchant includes the following raw materials in parts by weight: 0.8 parts of hydrofluoric acid, 4 parts of ammonium fluoride, and 90 parts of water.

[0056] Further,...

Embodiment 3

[0066] In this embodiment, in the step (2), the thinning etchant includes the following raw materials in parts by weight: 0.12 parts of hydrofluoric acid, 6 parts of ammonium fluoride, and 98 parts of water.

[0067] Further, in the step (1), the first thinning treatment is performed on the glass to reduce the thickness of the glass to 0.16 mm.

[0068] Further, in the step (3), the glass is subjected to a second thinning treatment to reduce the thickness of the glass to 0.03 mm, and a glass with a thickness of 0.03 mm is prepared.

[0069] Further, in the step (2), the specific operation of grinding and polishing includes the following steps:

[0070] A1. Polishing: place the glass in a polishing machine and use polishing liquid to polish;

[0071] A2. Ultrasonic cleaning: Ultrasonic cleaning of polished glass;

[0072] A3. Drying: Dry the ultrasonically cleaned glass.

[0073] Further, in the step A1, the polishing liquid is composed of the following raw materials in part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com