A kind of production method of composite coating strapping for gold and silver jewelry packaging

A technology of composite coating and production method, which is applied in the direction of metal material coating process, coating, superimposed layer coating, etc., can solve the problems of easy aging of paint film, reduction of decorative effect, cracking and falling off, etc., and achieve bright colors , reduce the cost of raw materials, and improve the effect of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below:

[0038] Table 1 is the list of cold rolling and annealing process parameters of each embodiment of the present invention and comparative examples;

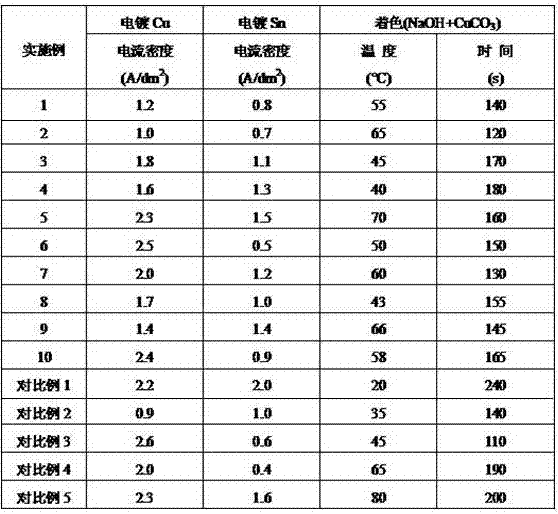

[0039] Table 2 is the tape making process parameter list (orange red strap) of each embodiment of the present invention and comparative example;

[0040] Table 3 is the tape making process parameter list (blue-black strap) of each embodiment of the present invention and comparative example;

[0041] Table 4 is the product performance list (orange-red strap) corresponding to each embodiment of Table 2 and comparative examples of the present invention;

[0042] Table 5 is a product performance list (blue-black strap) corresponding to each embodiment and comparative example in Table 3 of the present invention.

[0043] Each embodiment of the present invention is produced according to the following steps:

[0044] A method for producing a composite plated strap for gold an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com