Patents

Literature

58 results about "Silver jewelry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

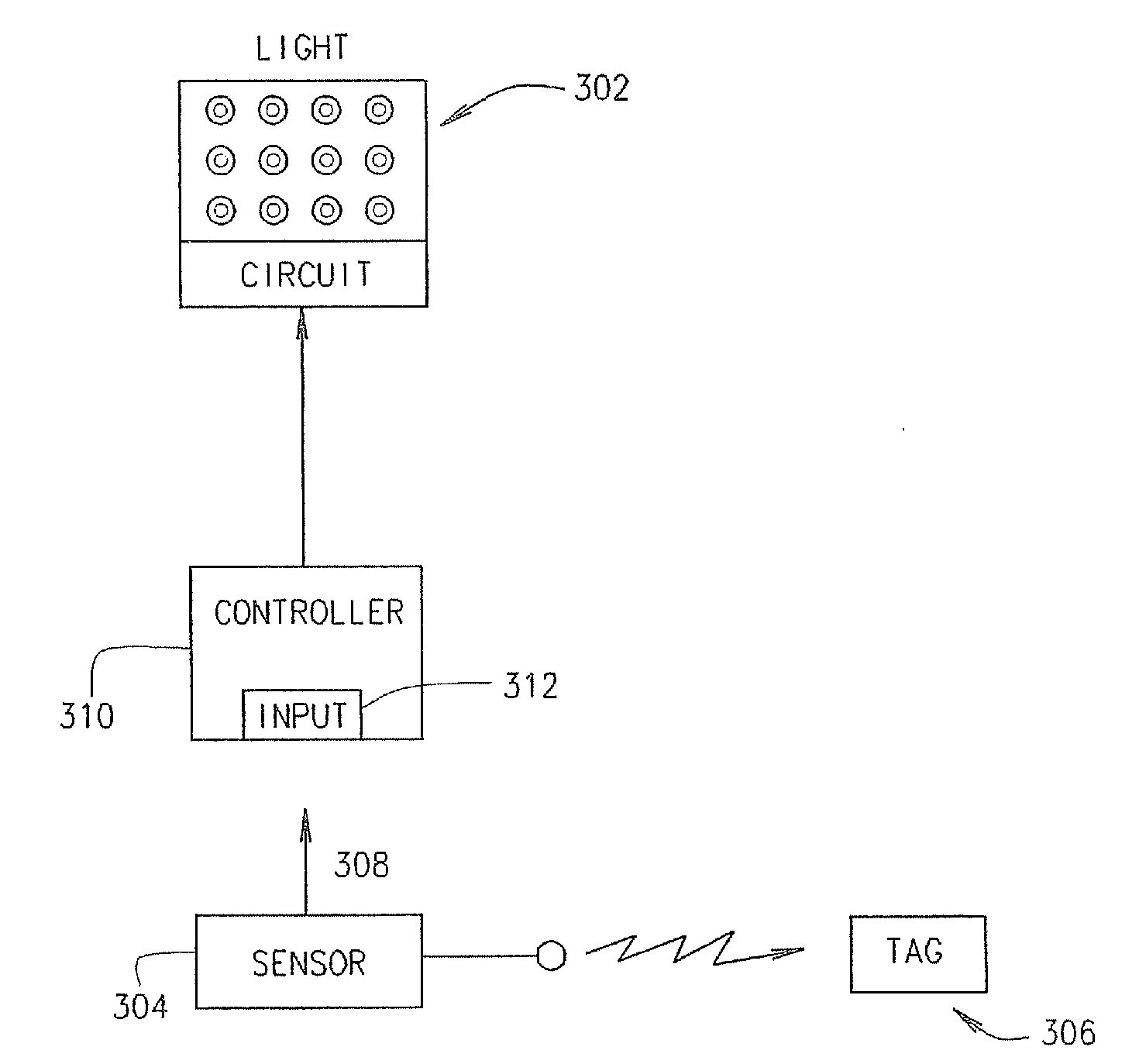

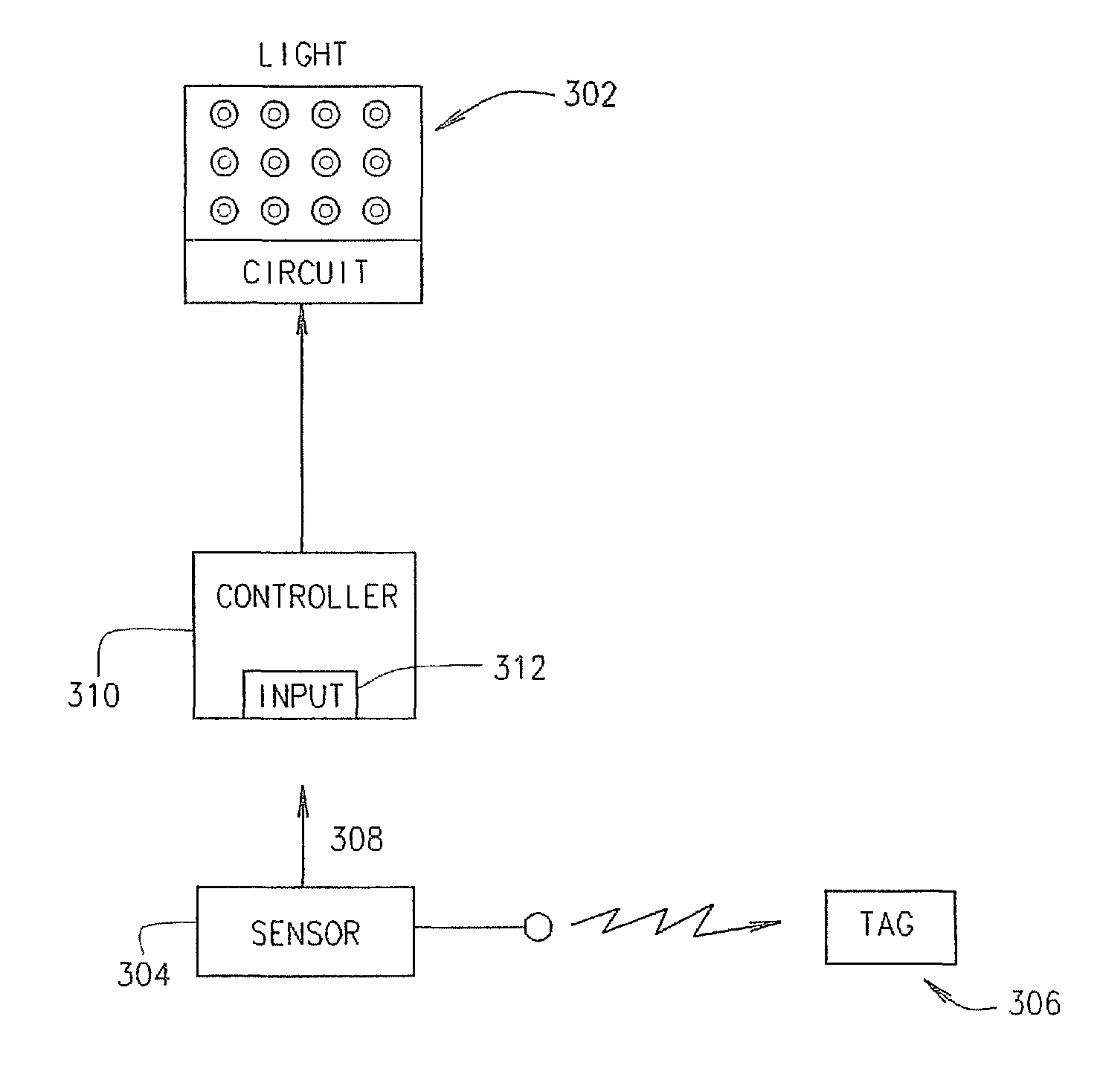

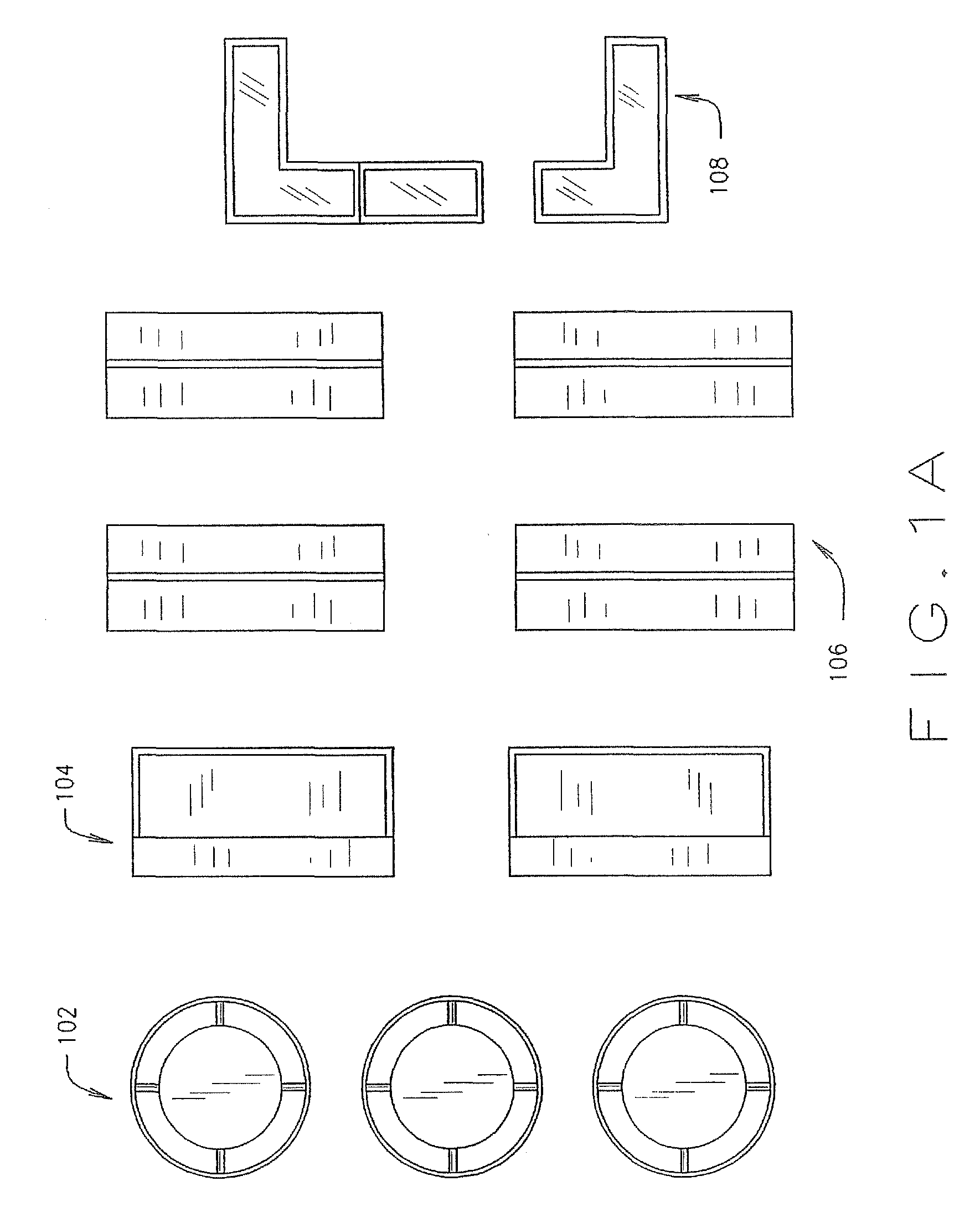

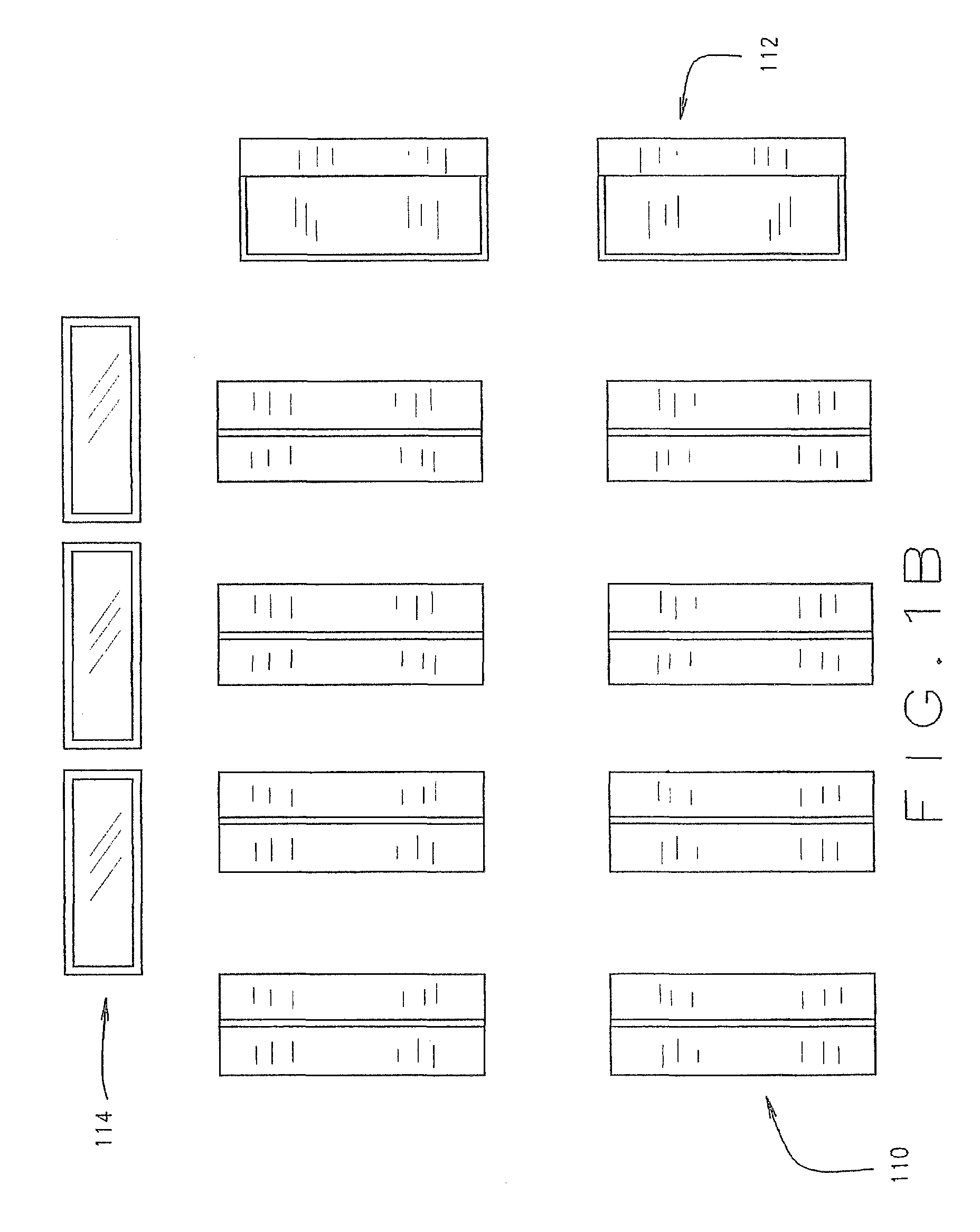

Adjustable lighting for displaying products

InactiveUS20080012722A1Reduce power consumptionStable and controllableElectric signal transmission systemsElectroluminescent light sourcesRed meatUltrasonic sensor

A system and method for controlling a variable light source where a variation in the light source can be triggered by utilizing a product identifier, such as for example RFIDs associated with the product being displayed to tell the controller to control the variable display case lighting to vary its color / intensity to change the lighting to best showcase the product; or utilizing UPC codes, scanned using a handheld device to accomplish the same objective; or utilizing motion / infrared / ultrasonic sensors particularly when lighting is to be turned off to conserve on power consumption. For example, red meat and poultry each may require their respective different lighting to be best displayed; thus red meat products may have a different RFID than poultry items; and gold jewelry items may have a different RFID than sterling silver jewelry items.

Owner:WALMART APOLLO LLC

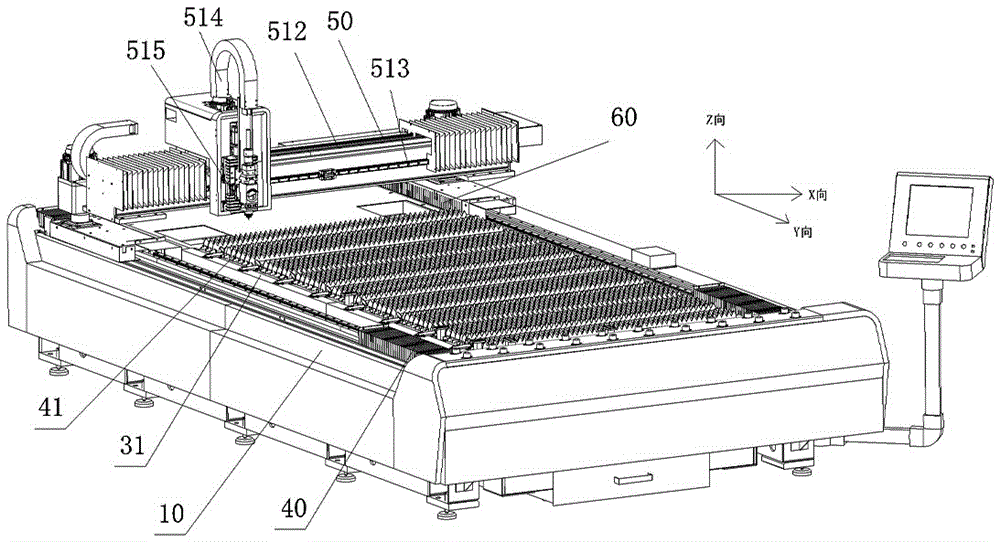

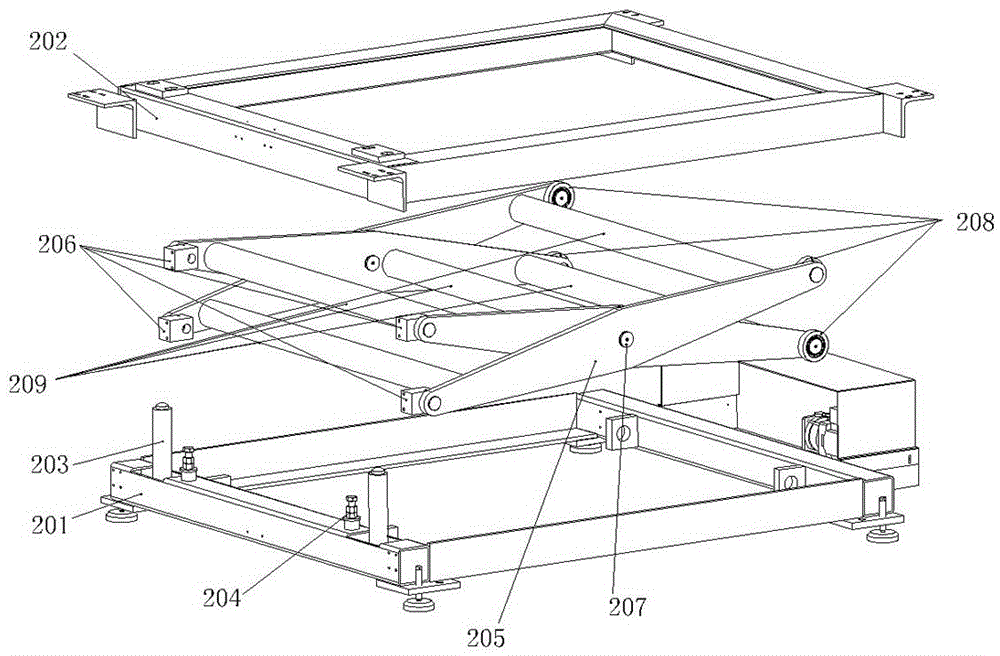

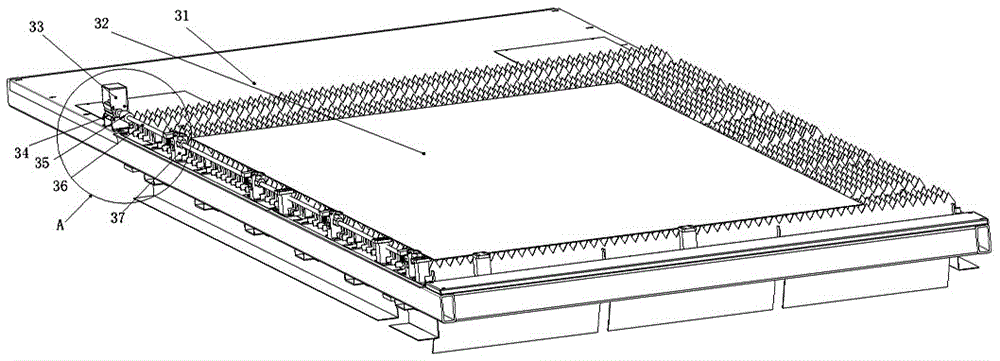

Laser cutting machine

InactiveCN105414773ALarge processing rangeHigh precisionLaser beam welding apparatusEngineeringLaser cutting

The invention relates to the field of machines and laser equipment, in particular to a laser cutting machine for the industries of automobile accessories, hardware tools, medical devices, instruments and meters, optical communication devices, gold and silver jewelries, craft gifts, packaging printing, mechanical equipment, and the like. The laser cutting machine comprises a machine tool body. The laser cutting machine is characterized in that the machine tool body is internally provided with a lifting mechanism; a working platform assembly is arranged above the lifting mechanism and comprises a working platform and a working platform needle plate arranged on the working platform; a plate clamping mechanism is arranged at the Y-axis direction side edge of the working platform; a plurality of plate universal translation supporting mechanisms parallel to the X-axis direction side edge of the working platform are arranged on the working platform needle plate; a cross beam is arranged above the X-axis direction side edge of the working platform; an air exhaust and dust removal mechanism is arranged below the cross beam; and the outer side of the working platform needle plate is enclosed by the air exhaust and dust removal mechanism.

Owner:DONGGUAN GLORYSTAR LASER TECH

Adjustable lighting for displaying products

InactiveUS8248214B2Reduce power consumptionStable and controllableElectric signal transmission systemsElectroluminescent light sourcesUltrasonic sensorProduct Identifier

A system and method for controlling a variable light source where a variation in the light source can be triggered by utilizing a product identifier, such as for example RFIDs associated with the product being displayed to tell the controller to control the variable display case lighting to vary its color / intensity to change the lighting to best showcase the product; or utilizing UPC codes, scanned using a handheld device to accomplish the same objective; or utilizing motion / infrared / ultrasonic sensors particularly when lighting is to be turned off to conserve on power consumption. For example, red meat and poultry each may require their respective different lighting to be best displayed; thus red meat products may have a different RFID than poultry items; and gold jewelry items may have a different RFID than sterling silver jewelry items.

Owner:WALMART APOLLO LLC

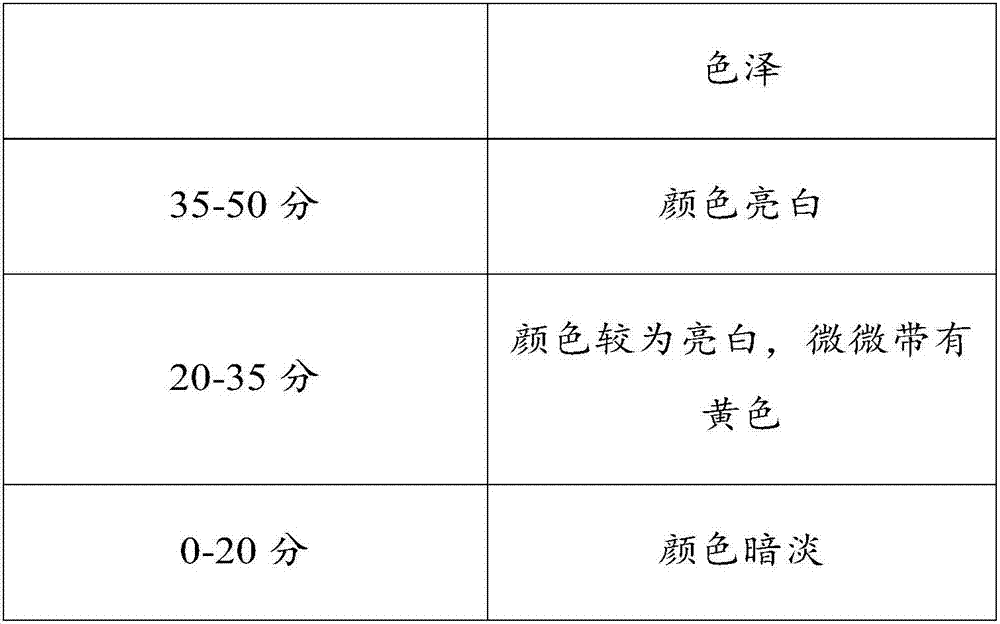

Silver alloy and method for preparing high-temperature transparent enamel decorating silver jewelry by using silver alloy

Owner:GUANGZHOU PANYU POLYTECHNIC

Pure-silver wiredrawing knitted flower welding method

The invention discloses a pure-silver wiredrawing knitted flower welding method, which comprises the following steps of: grinding a pure-silver soldering lug or welding rod into pure-silver powder; putting the pure-silver powder in a copper disc; adding borax and pure water, wherein the mass ratio of the pure-silver powder to the borax is 10:0.8; heating the copper disc with fire; boiling water in the copper disc; after the water in the copper disc is boiled, heating for 5-10 seconds to fully dissolve the borax in the boiling water; putting a filament accessory which needs to be welded in the copper disc liquid to be dipped for 15-25 seconds; taking out the filament accessory after 15-25 seconds; welding the filament accessory on the corresponding position of a silverware; and baking with flame of 500-700DEG C. People can not see the welding mark of a silver jewelry welded with the method, and the appearance of the silver jewelry is smooth and flat.

Owner:丹寨县国春银饰有限责任公司

electrical contact metal protector

The present invention relates to electrical contact metal protective agents. The invention relates to a surface protective agent mainly used for electronic components and a preparation method thereof. 5.0% lubricant, the balance is solvent, made by mixing and heating. The selected materials are environmentally friendly materials, which will not pollute the environment during production, preparation and use. The protective agent composition of the invention is closely combined with the metal surface, and has strong wear resistance, lubrication, rust resistance, mildew resistance and corrosion resistance. It maintains a good insulating or conductive state during work, and will not cause instant arc sparks to burn the circuit due to poor contact. It can be widely used in electronic and electrical components, connectors, aluminum alloy conductive oxidation and protection of gold and silver jewelry surfaces.

Owner:罗英 +1

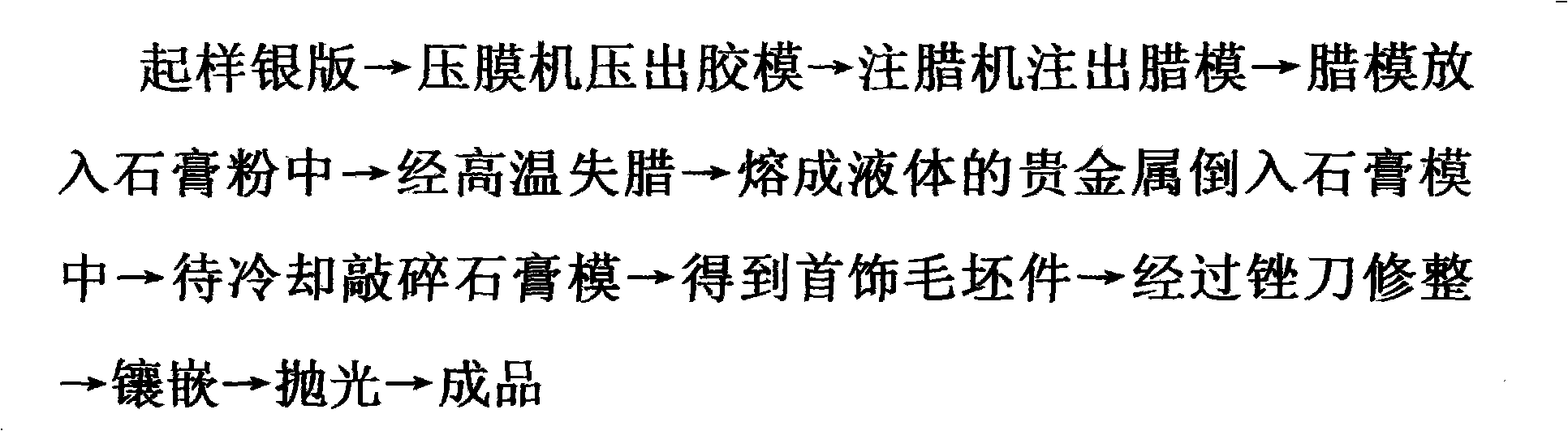

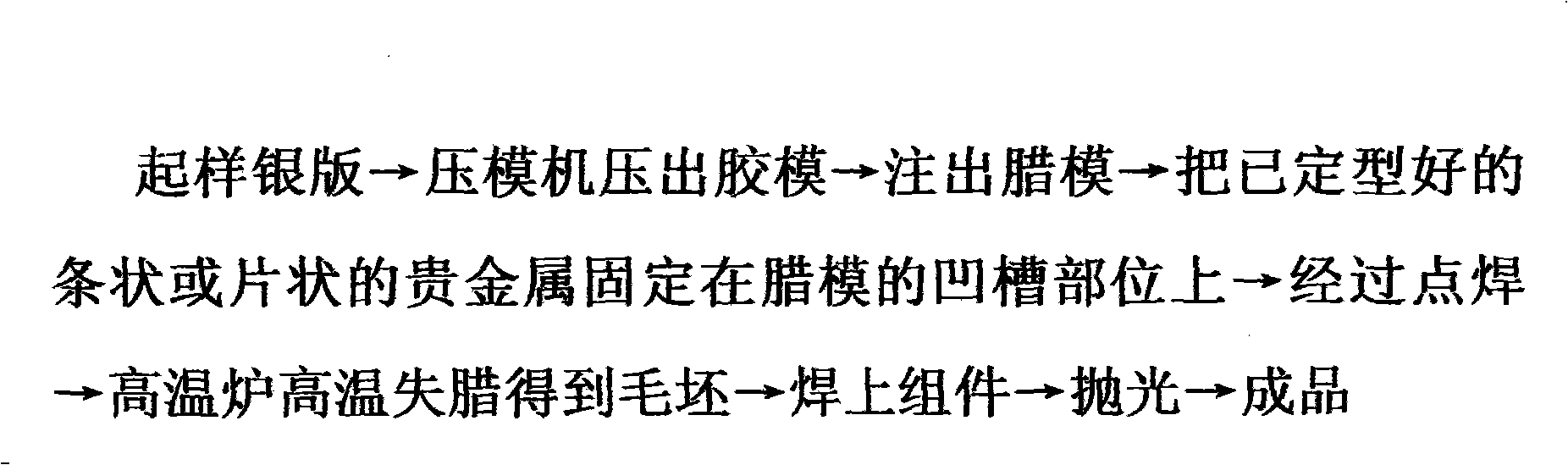

Processing technology of silver jewelry

The invention discloses a processing technology of silver jewelry, which includes following steps: (1) silver melting: hammering large silver material blocks to crush the silver material blocks and melting the crushed silver material blocks on a furnace; (2) forging, wherein the crushed silver material block is forged to form a required shape of center; (3) material cutting: cutting silver sheets with comparison of a designed silver jewelry design pattern; (4) manufacturing of a lead support: inversely placing the crudely processed silver sheets in a sand box with injection of molten lead thereinto and cooling the molten lead; (5) pattern carving: carving patterns on the processed semi-product according to the requirement in the design pattern; (6) welding: dipping the joints of the silver jewelry to be welded and performing welding with a welding gun; (7) silver washing: because that the surface of the silver jewelry may be blackened or stained with impurities after repeated hammering and roasting, heating the silver jewelry at a high temperature on fire, soaking the silver jewelry in an acidic solution, taking out the silver jewelry and soaking the silver jewelry in clear water, brushing the silver jewelry with a copper brush to enable the silver jewelry to be white and bright; and (8) inspection and storage of finish products in storerooms. The processing technology is simple to carry out. The silver jewelry produced through the technology is high in glossiness. The technology saves cost for manufacturers and can satisfy consumer demand.

Owner:卢家雄

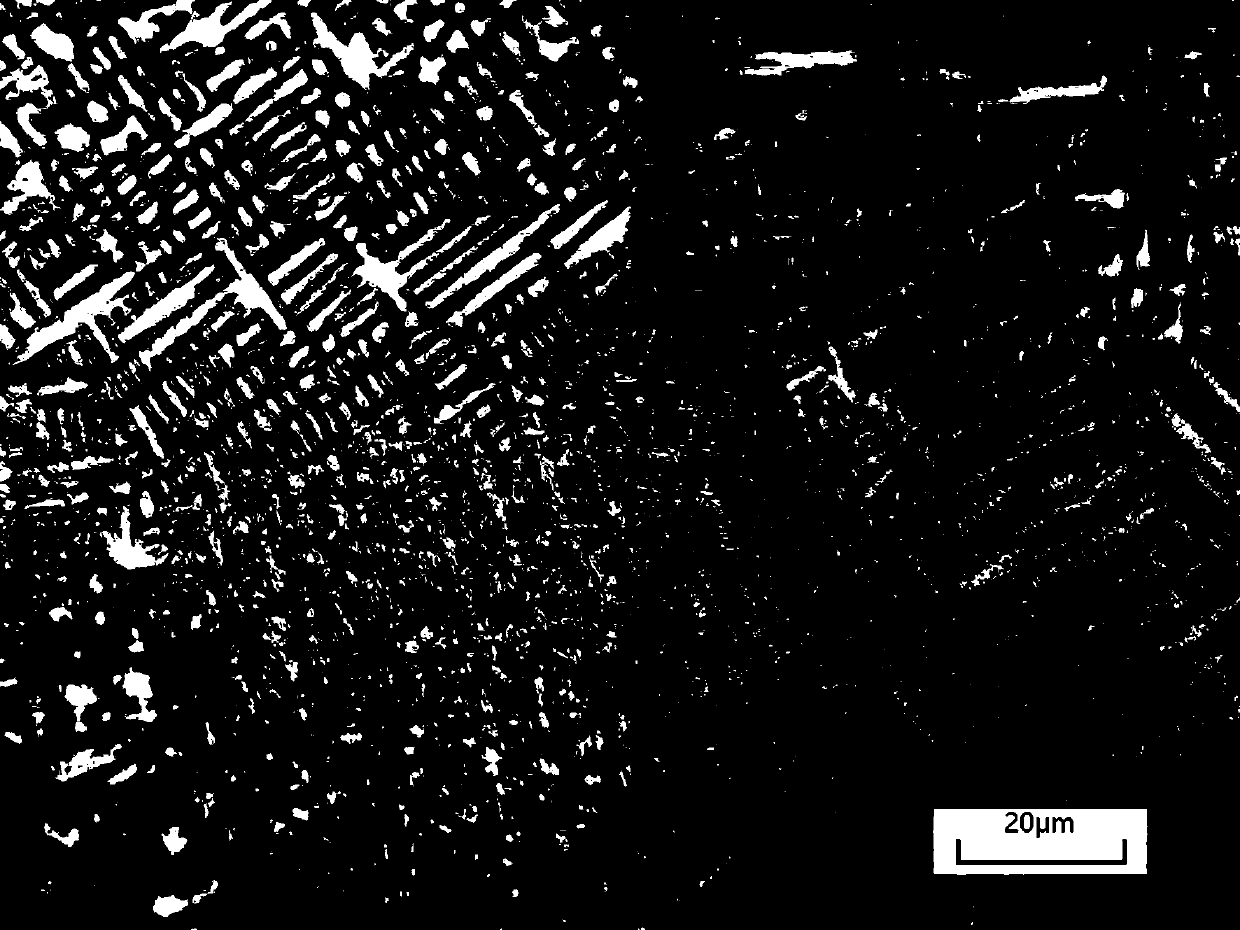

Silver-germanium jewelry alloy

The invention relates to a silver jewelry alloy, and in particular relates to a silver-germanium jewelry alloy, belonging to the technical field of nonferrous metals. In the alloy silver jewelry components, the mass ratio of silver to germanium is 1: (0.081-1), and the purities of various component raw materials are more than 99.9%-99.99%. Silver and germanium are melted in a vacuum furnace with the vacuum degree of 0-5Pa and the temperature of 1150 DEGC-1200 DEG C; and the mixture is kept at the constant temperature for 1-1.2 hours, then evenly stirred, cast in a mould, and cooled at the speed of 20-30 DEG C / min so as to obtain the finished alloy product. According to the invention, the production process is simple and is easy to operate, the produced alloy sliver jewelry is brighter in color, is harder and durable in fire-resistant scale cinder, and has a certain health function on a human body.

Owner:宣威市泓澔金属科技有限公司

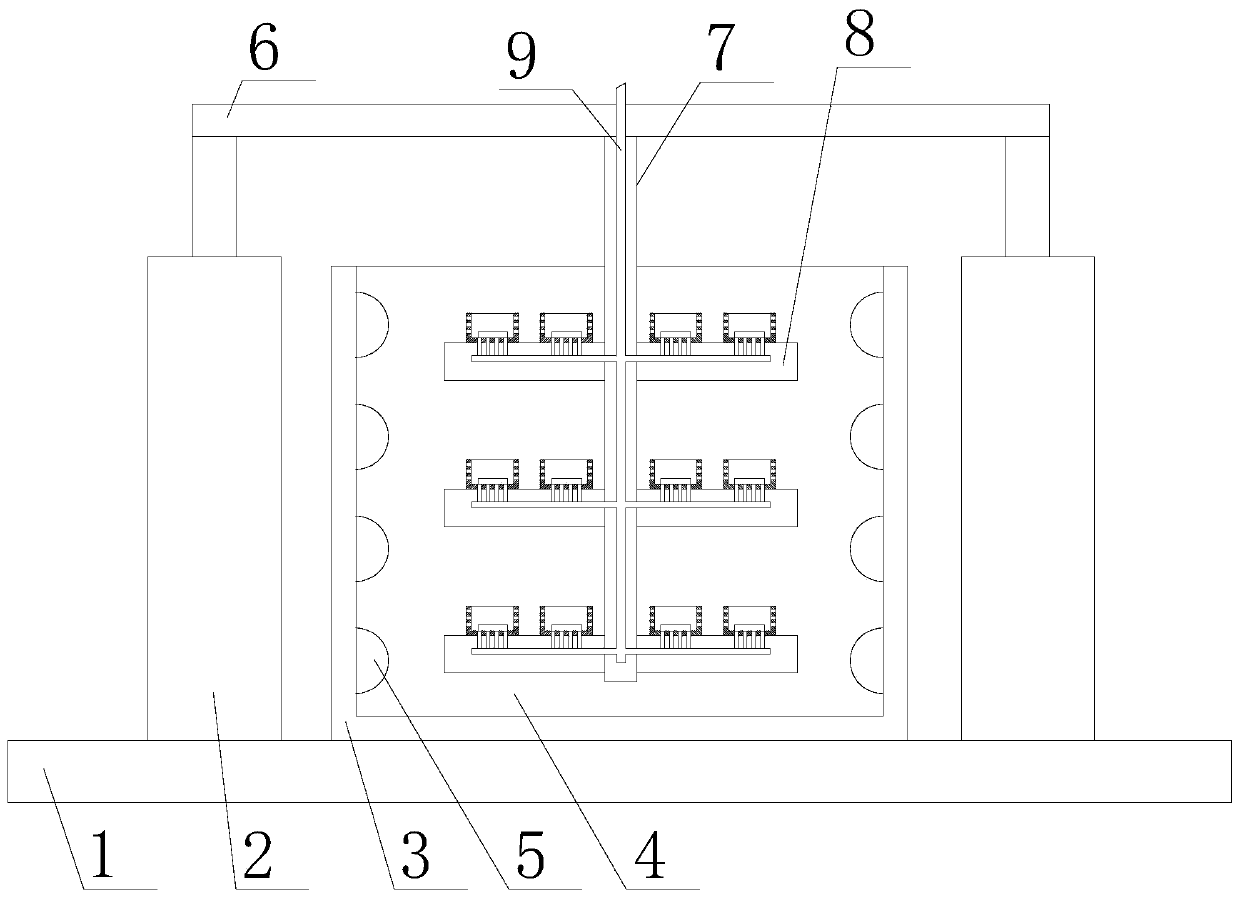

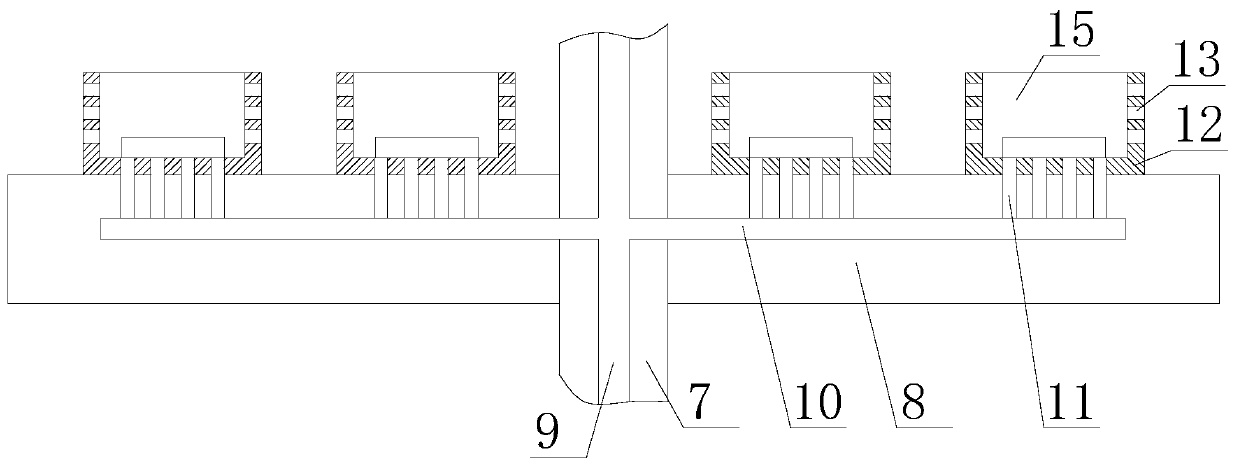

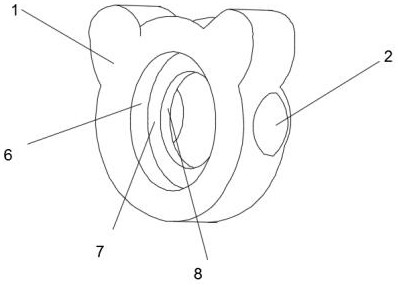

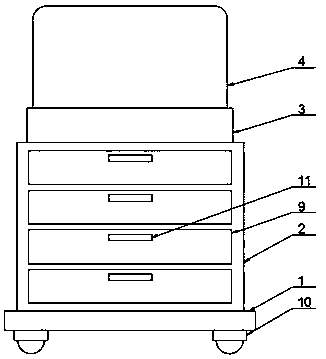

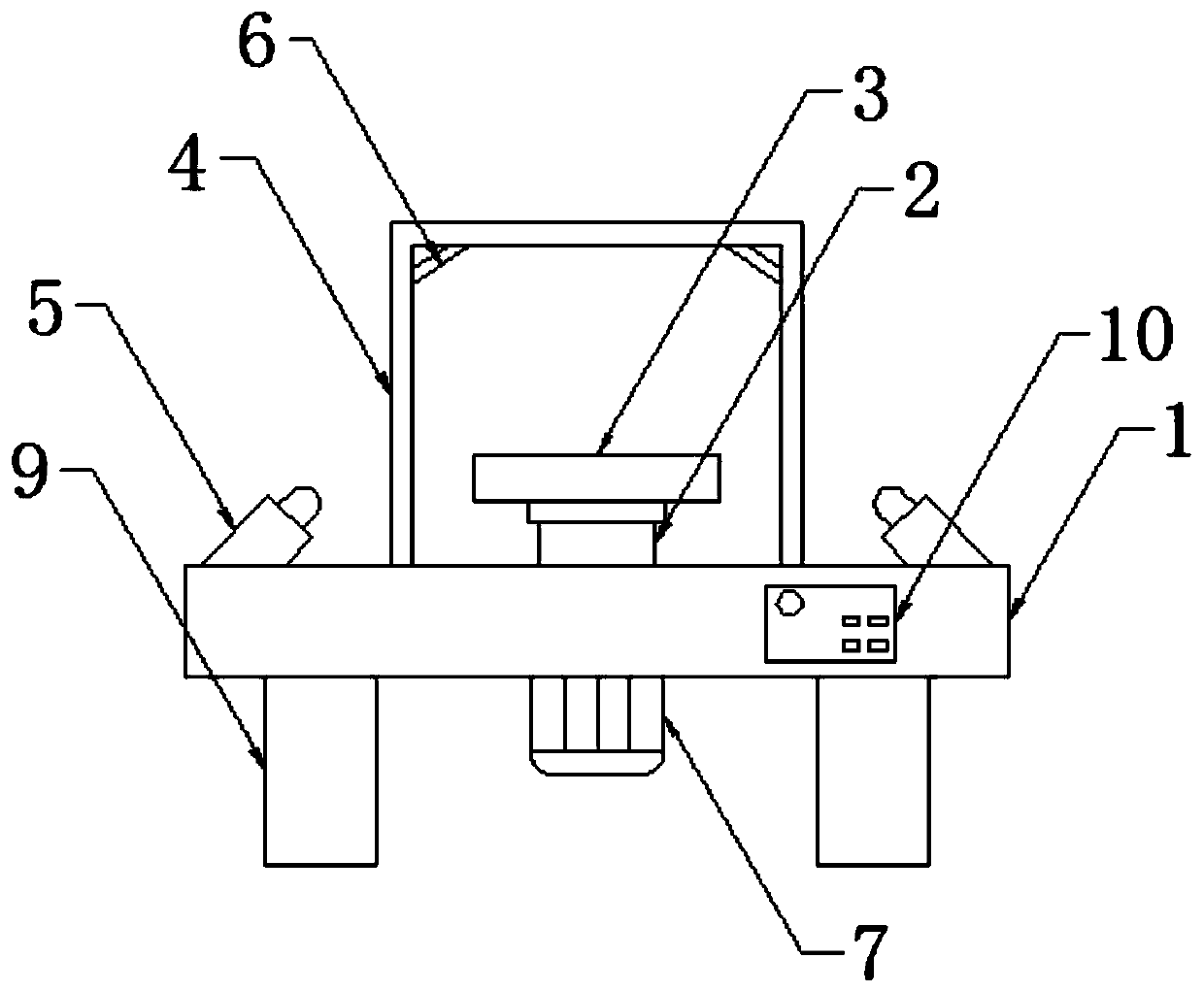

Silver ornament cleaning device

ActiveCN110813907AImprove cleaning efficiencyImprove work efficiencyCleaning using liquidsStructural engineeringMechanical engineering

The invention discloses a silver ornament cleaning device, and relates to the field of silver ornament machining. The device comprises a base, a driving part, a cleaning part, ultrasonic generators, aconnecting plate, a connecting column, a supporting disc and placing blocks. The cleaning part is fixed to the base, the cleaning part is internally provided with a cleaning groove with an upward opening, cleaning liquid is contained in the cleaning groove, the multiple ultrasonic generators are arranged on the side wall in the cleaning groove, the driving part is fixed to the base, an output shaft of the driving part is fixedly connected with the connecting plate, the connecting plate is located above the cleaning part, one end of the connecting column is fixed to the lower side face of theconnecting plate, the connecting column right faces the cleaning groove, the side face of the connecting column is fixedly provided with multiple supporting discs, the multiple placing blocks are arranged on the upper end face of the supporting disc, and placing grooves with upward openings are formed in the placing blocks. During cleaning, multiple pieces of silver ornament can be placed in the placing grooves at one time, the driving part drives the silver ornament into the cleaning liquid, through ultrasonic waves, the silver ornament is cleaned, in the cleaning process, the cleaning efficiency is high, and work efficiency is improved.

Owner:张家界湘西白银艺术博物馆有限公司

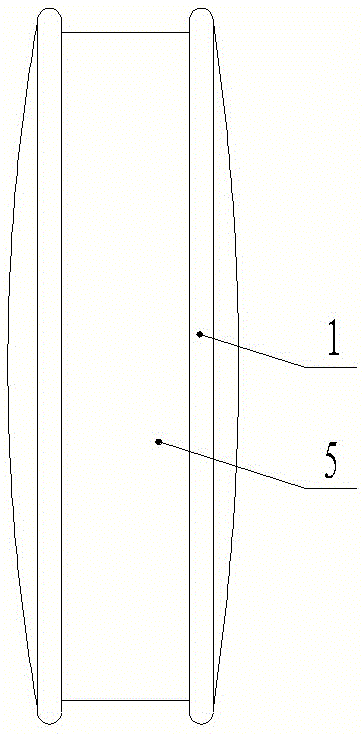

Production method of composite plated tie for packaging gold and silver jewelries

A production method of a composite plated tie for packaging gold and silver jewelries comprises the following steps: carrying out cold rolling, carrying out routine degreasing, and annealing; making a belt: uncoiling, cutting to form strips, and burring; electroplating Cu at normal temperature; carrying out first time water washing, and drying; electroplating Sn or Zn at normal temperature; carrying out second time water washing, and drying; coloring; carrying out third time water washing, and drying; and routinely reeling. The thickness, the tensile strength and the elongation percentage of the above produced product are 0.1mm, 800-830MPa and 8-9% respectively. A uniform and compact Cu-Sn or Cu-Zn composite plated layer with strong adhesion and with the thickness of 3-5[mu]m is formed on the surface of the product; and the colored product has brilliant orange red or blue black appearance, and the gloss loss rate of the composite plated layer 540d later does not exceed 5%, so binding and packaging needs of gold finger rings, necklaces, bracelets, ruby, sapphire and other gold and silver jewelries are met.

Owner:武汉钢铁有限公司

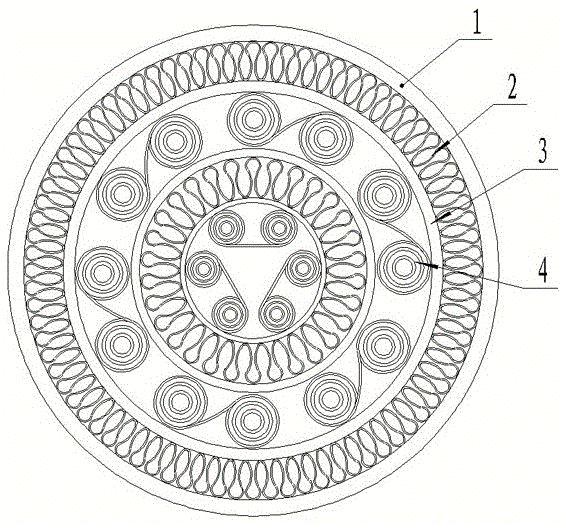

Production method of sun drum silver ornament

InactiveCN105620155APrevent oxidationEvenly distributedDecorative surface effectsOrnamental structuresEngineeringSoldering

The invention discloses a production method of a sun drum silver ornament, belongs to a production method of a silver ornament, and aims to provide a silver ornament production method with convenient and simple production, high efficiency and delicate and beautiful ornament patterns. The production method comprises the steps of weaving of patterns by using silver wires, combination and welding of the patterns to form hollowed drum surfaces, and welding of the drum surfaces with a drum body to form a drum shape; the silver wires include fine round wires, square wires, twisted wires and flat wires; one of the silver wires is selected to wind a drum ring; one or several silver wires are selected to wind decoration rings with different diameters, lace rings with different diameters and decoration patterns; all parts are dip in borax water; the drum ring and all the decoration rings are taken out and arranged in a concentric circle manner; all the lace rings and all the decoration patterns are arranged between the drum ring and the decoration rings or between the adjacent decoration rings; silver welding powder is spread in the connecting places of all the parts for gas welding to obtain the drum surfaces; and the two drum surfaces are welded at two ends of the drum body. The silver ornament, produced by the method, is delicate and beautiful in patterns, fine and uniform in crators and free of pseudo soldering.

Owner:GUIZHOU TOURISM CO LTD

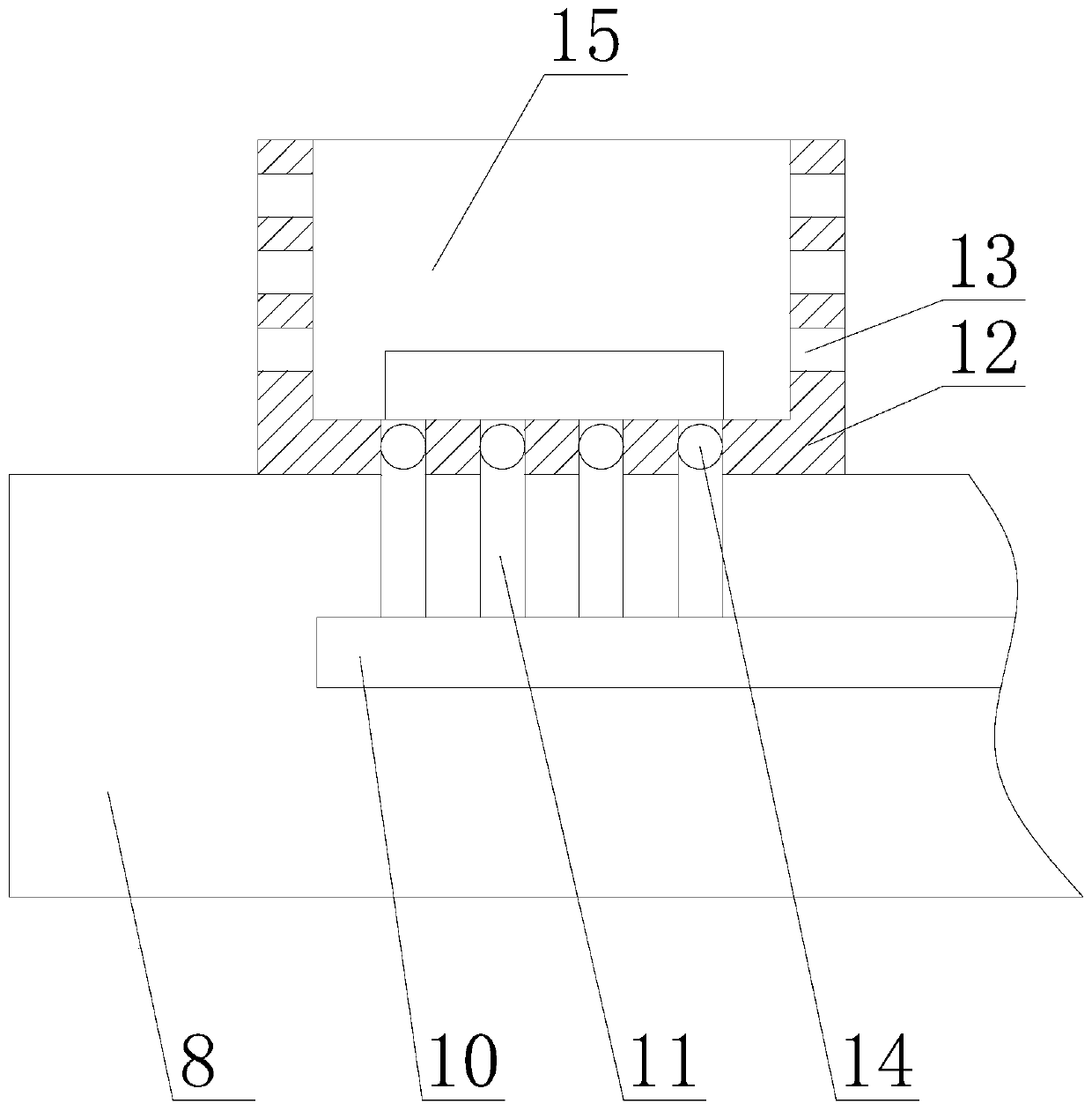

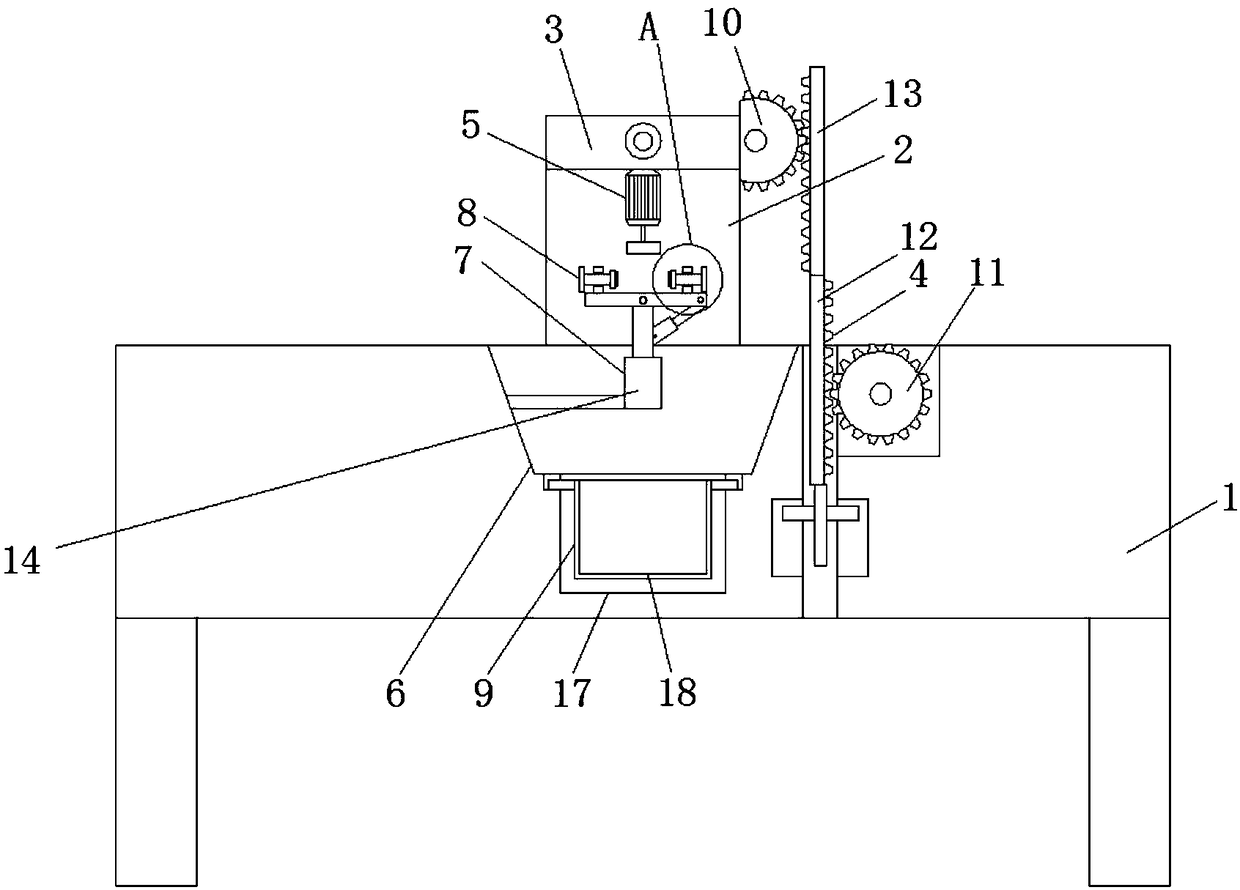

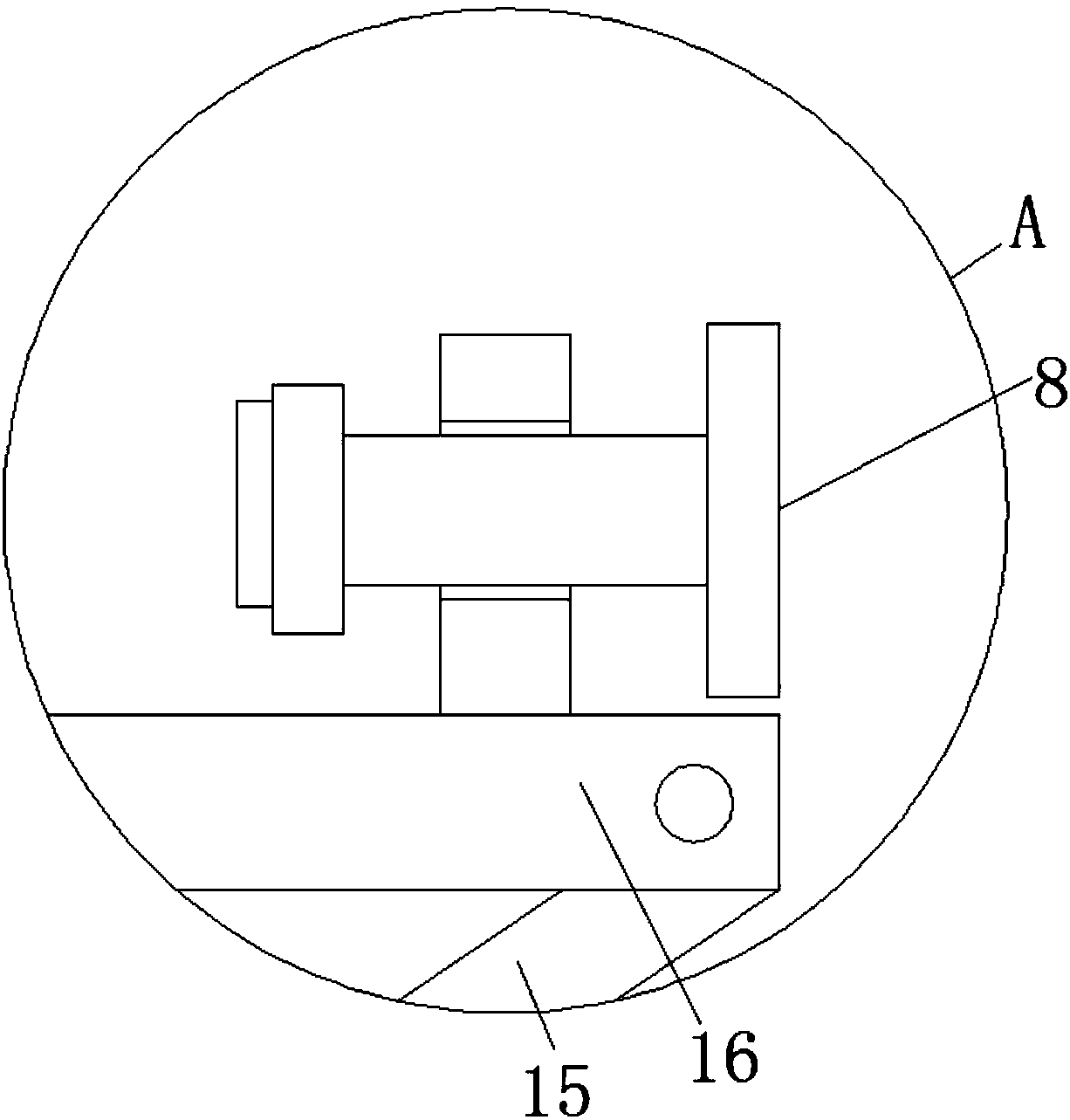

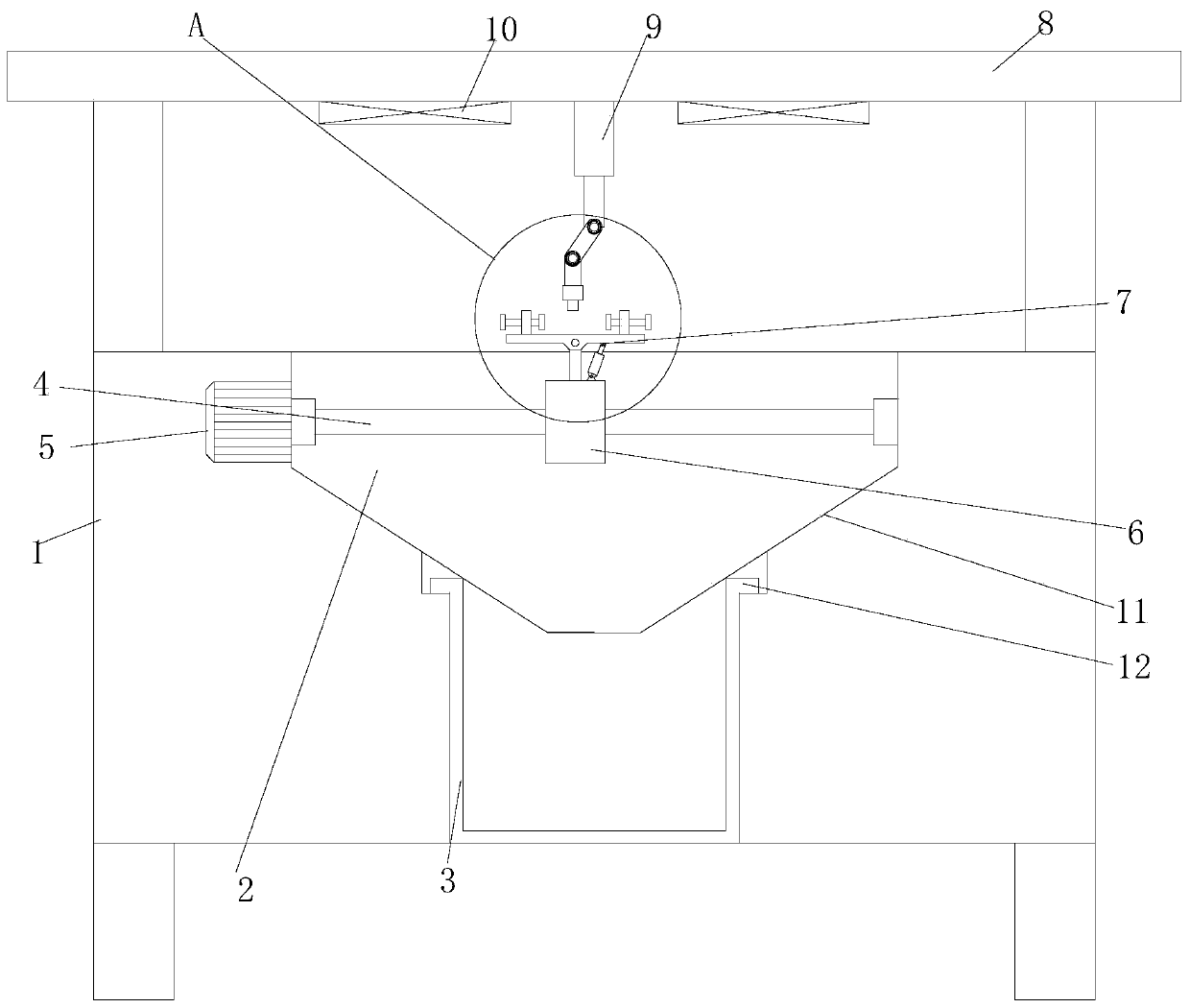

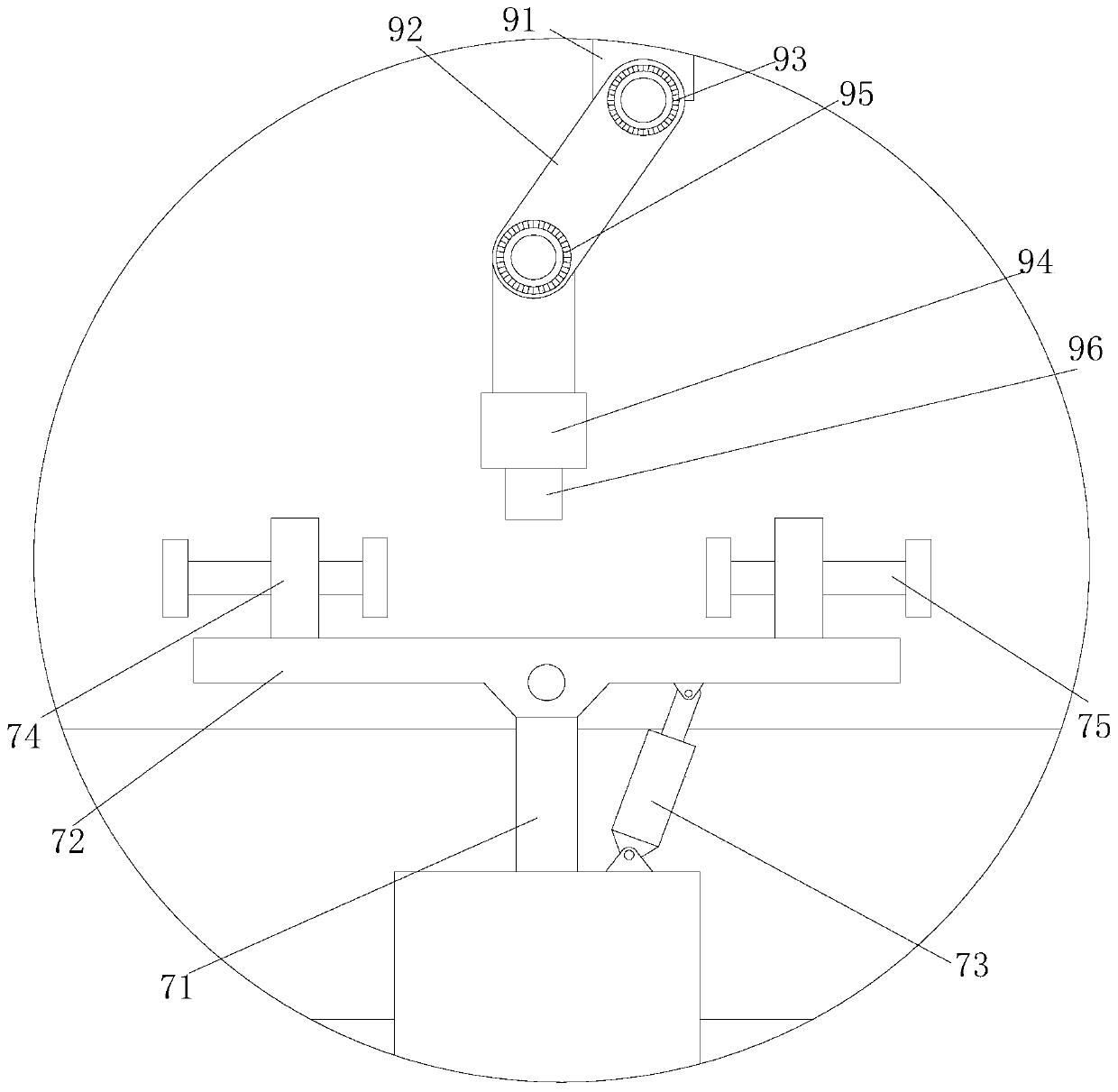

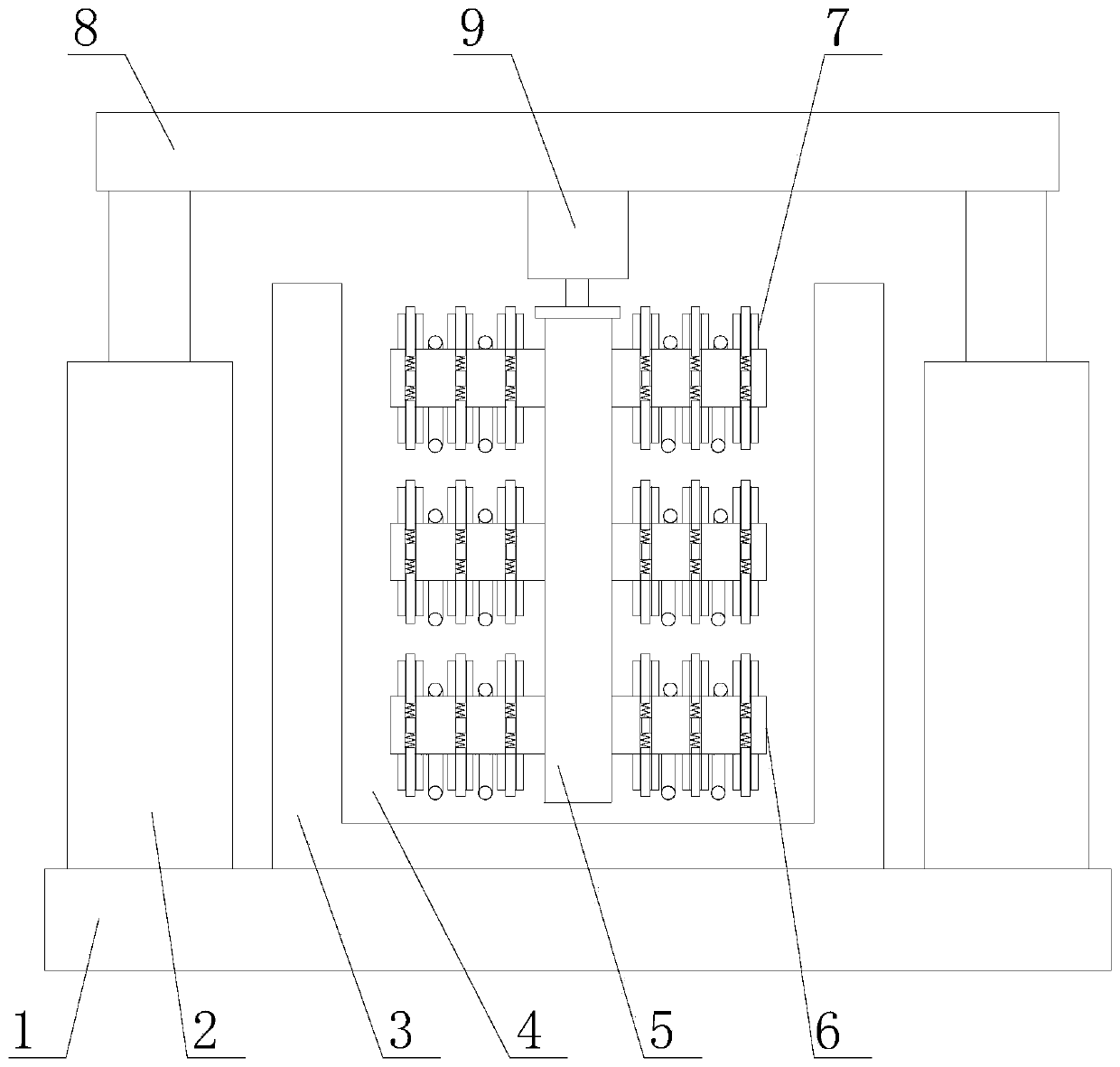

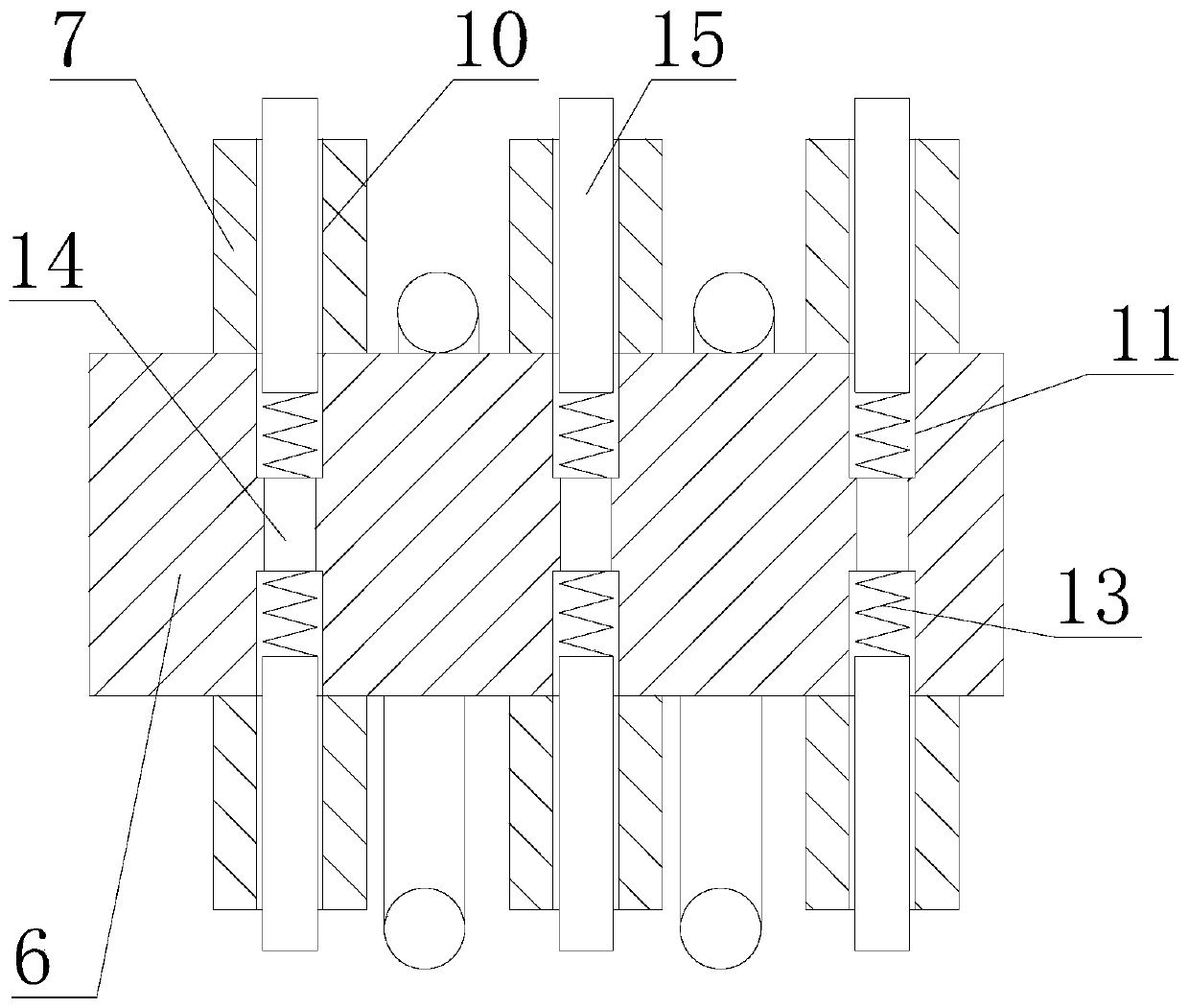

Polishing machining table for Miao silver jewelry

PendingCN108500835ANearbyIncrease the polishing areaGrinding carriagesGrinding bedsTransverse planeEngineering

The invention discloses a polishing machining table for Miao silver jewelry. The polishing machining table comprises a working table. The rear side of the top of the working table is fixedly connectedwith a supporting plate. The top of the front face of the supporting plate is rotationally connected with a transverse plate. A drive mechanism is arranged on the right side of the top of the workingtable. The bottom of the transverse plate is fixedly connected with a polishing mechanism. A collection tank is arranged at the position, corresponding to the polishing mechanism, of the top of the working table. The tank wall on the left side of the collection tank is fixedly connected with a fixed mechanism. The left side and the right side of the top of the fixed mechanism are fixedly connected with clamps. A recycling mechanism is arranged at the position, located below the fixed mechanism, in the collection tank. The right side face of the transverse plate is fixedly connected with a tooth plate engaged with the drive mechanism. According to the polishing machining table for the Miao silver jewelry, the silver jewelry can be polished at multiple angles, and the polished face is larger; the structure is simple, and operation is convenient; and scraps generated during polishing can be recycled, and use and popularization are facilitated.

Owner:余金龙

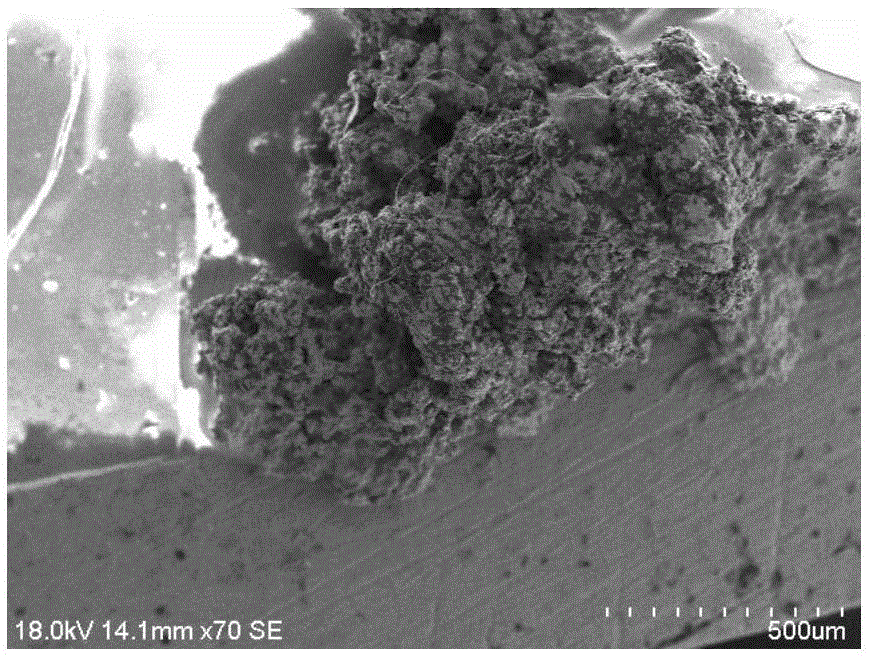

Copper-based repair alloy and preparation method thereof

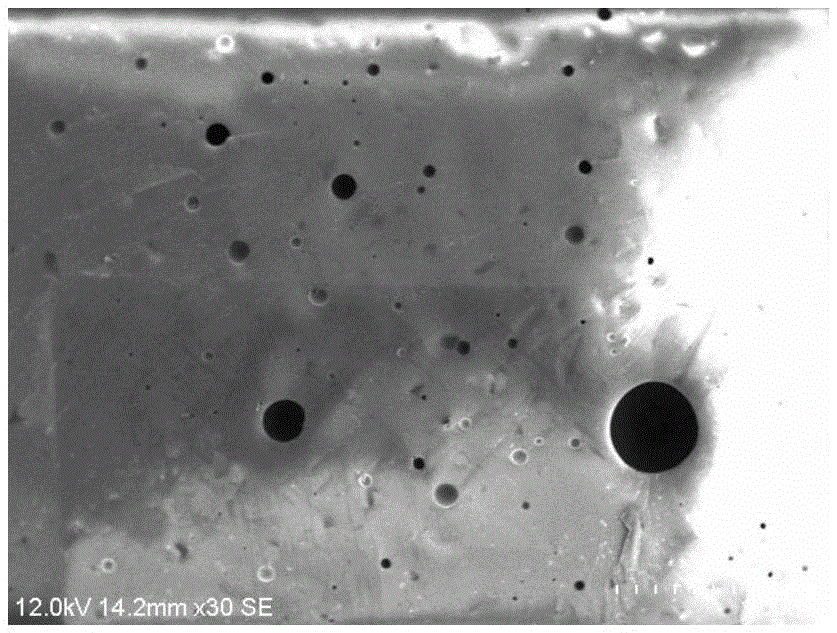

The invention provides a copper-based repair alloy and a preparation method thereof. The copper-based repair alloy comprises 20% to 70% of Cu, 20% to 70% of Zn, 0 to 5% of Sn, 0.2% to 6% of Si, 0.02%to 5% of Ge, 0.2% to 5% of In, 0.01% to 0.5% of Ce, 0.1% to 2.5% of Al and 0.01% to 0.7% of Y. Except for the main elements including the Cu, the Zn and the Sn, the trace elements are added in the form of intermediate alloys in the preparation process, wherein the Si, the Ge, the In, the Ce and the Al are added in the form of copper-based master alloys, and the Y is added in the form of an Al-Y intermediate alloy. Through inert gas for protection of mixing and smelting, a pelletizing device is used for preparing near-spherical repair particles. 925 silver jewelry prepared by using the copper-based repair alloy has few surface defects, the anti-vulcanization dullness and discoloration performance is good, the requirements for the hardness and white brightness of wax setting are met, and thestrength requirements pull wires and pressing sheets can be met.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Process for preparing multifunctional dishcloth

The invention relates to a process for preparing multifunctional dishcloth. The preparation process comprises the following steps: drying camellia seeds, grinding into powder, taking 10g of powder, drying Sophora flavescens, milling into powder, taking 5g of Sophora flavescens powder, and sewing to keep the mixture of both powders in the dishcloth. The dishcloth of the invention has the following beneficial effects: (1) the raw materials are natural without any chemical additives or residues; (2) by adopting the composition formula of camellia seed powder and Sophora flavescens powder, the skin is cleaned synchronously in the dish washing process, fungi on skin is sterilized, so as to prevent skin disease and keep skin health and the composition formula is safe; the oil contamination is removed quickly, the residual pesticide on vegetables are decomposed, and bacteria are killed; (3) the product is provided with the functions of dishcloth and detergent without repetitive use of dishcloth and bacteria are avoided, so that the dishcloth is convenient and sanitary; (4) the dishes can be cleaned by the dishcloth in one time through water, so that water and labor are saved; the camellia seeds can decompose naturally without polluting the environment; and (5) the dishcloth further can be applied for cleaning gold and silver jewelry without corrosion.

Owner:胡军卫

Silver jewelry and processing method thereof

InactiveCN107502909AEfficient removalImprove production efficiencyJewelleryCelluloseDioxyethylene Ether

The invention provides a silver jewelry and a processing method thereof, and relates to the field of jewelry processing. The processing method of the silver jewelry comprises the following steps: silver is cast after melting, and is finished after preprocessing to obtain an initial sample; the qualified initial sample is polished to clean to obtain the silver jewelry; a cleaning agent is adopted to clean; the cleaning agent comprises 20-30 weight parts of hydroxyethyl cellulose with a concentration of 5%, 3-8 weight parts of borax, 50-60 weight parts of de-ionized water, 3-10 weight parts of silicon dioxide, 3-7 weight parts of polyoxyethylene lauryl ether, 2-3 weight parts of octadecyl sulfylpropionate, 1-2 weight parts of lauryl sodium sulfate, and 1-2 weight parts of white spirit; and the silver jewelry is excellent in gloss, is beautiful and elegant, and satisfies the demands of customers. The processing method of the silver jewelry is simple in processing process and convenient to operate.

Owner:贵州印象苗族银饰刺绣有限公司

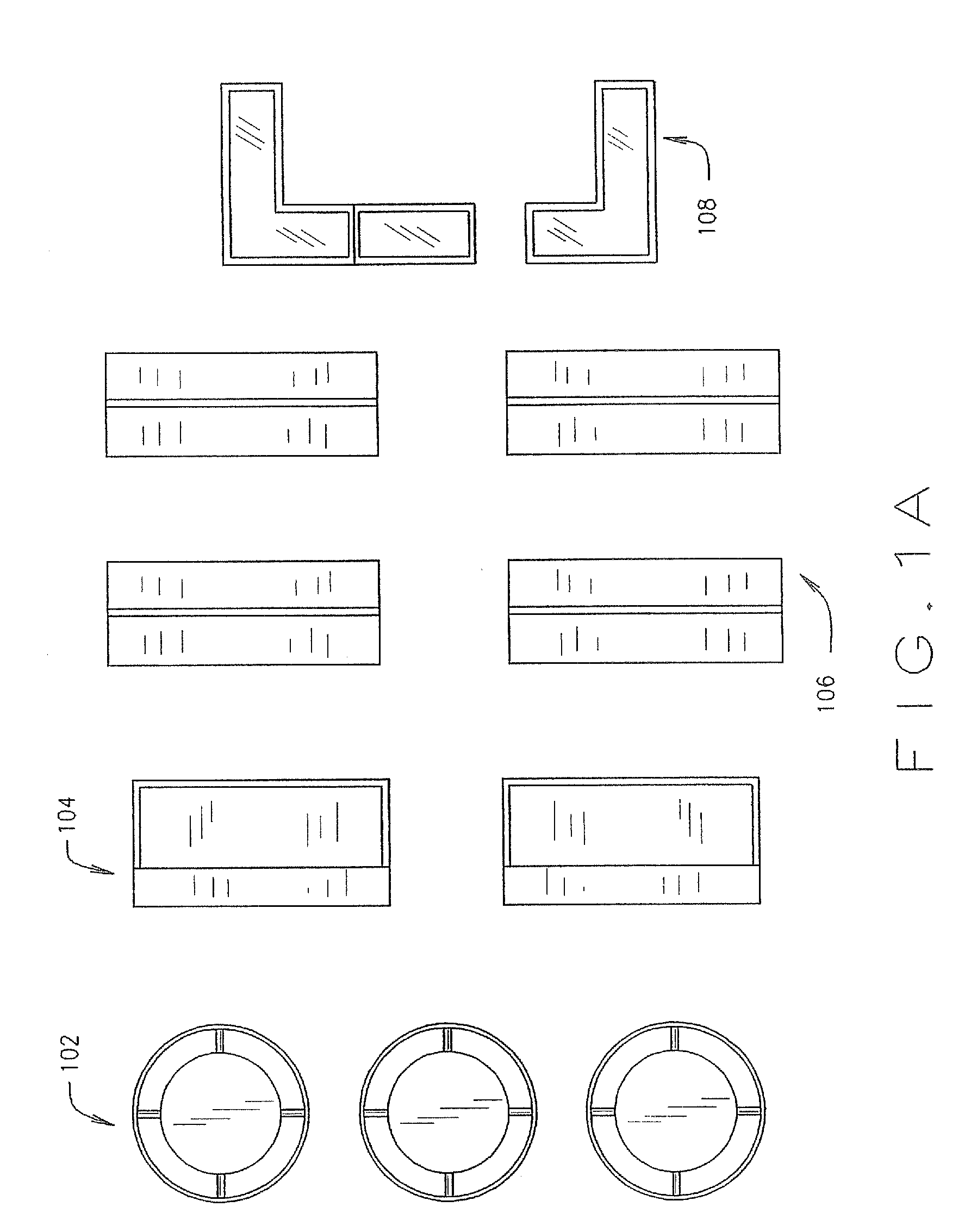

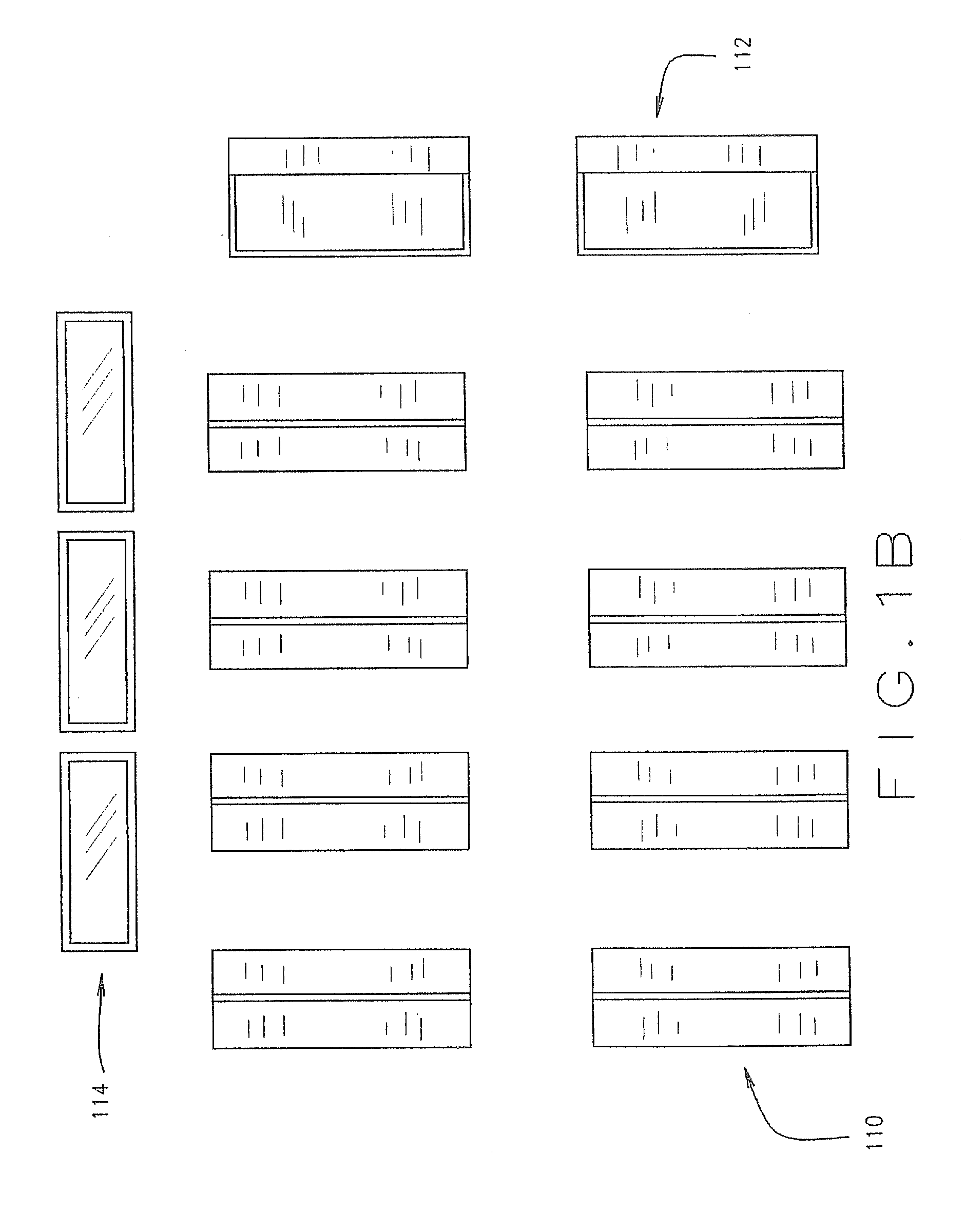

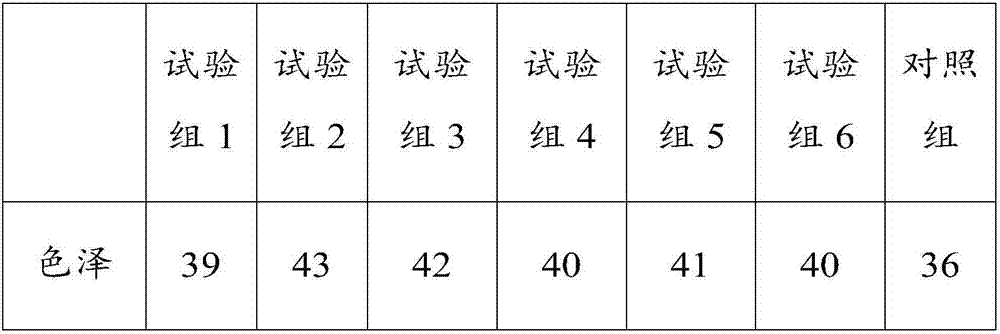

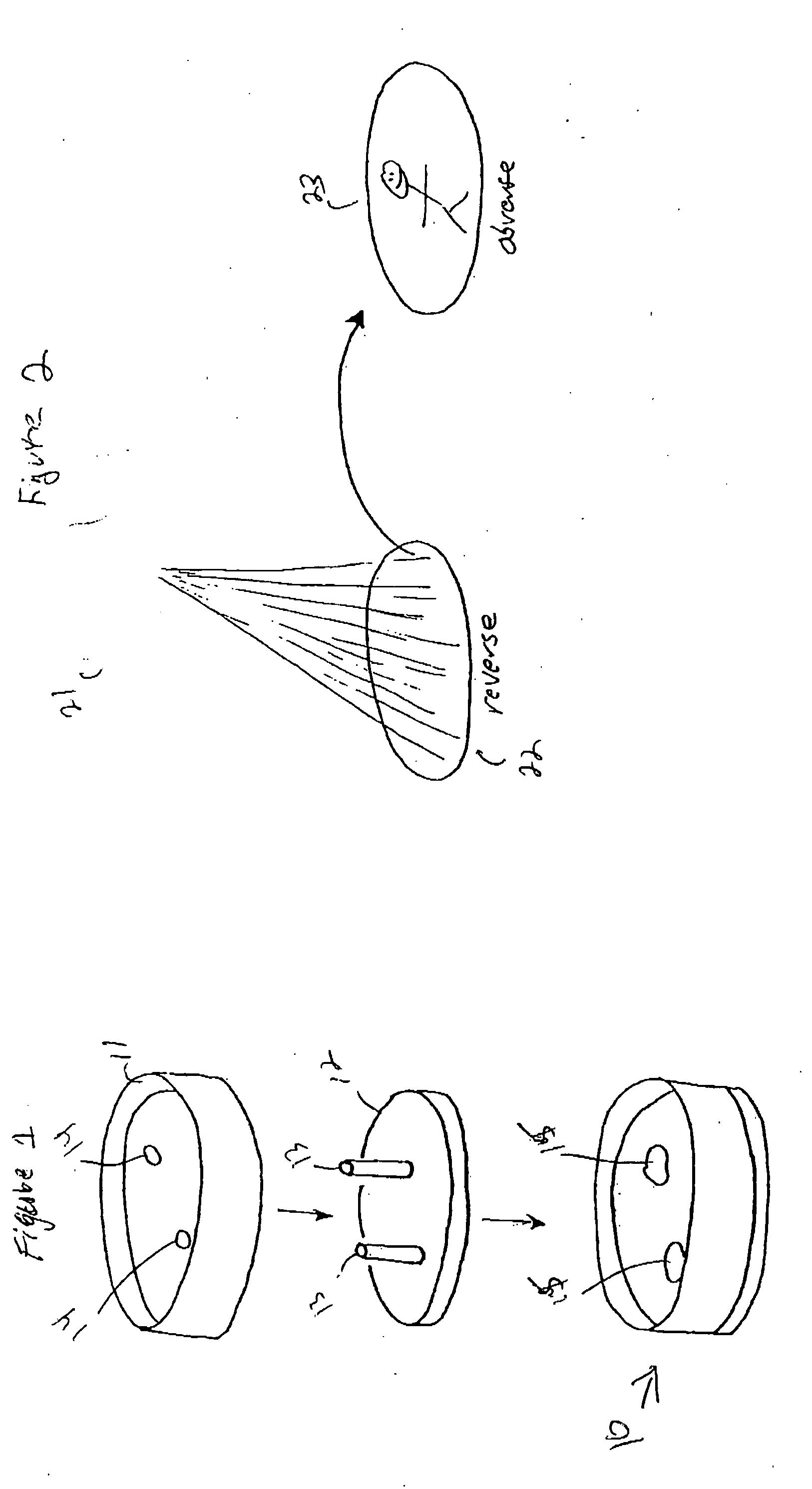

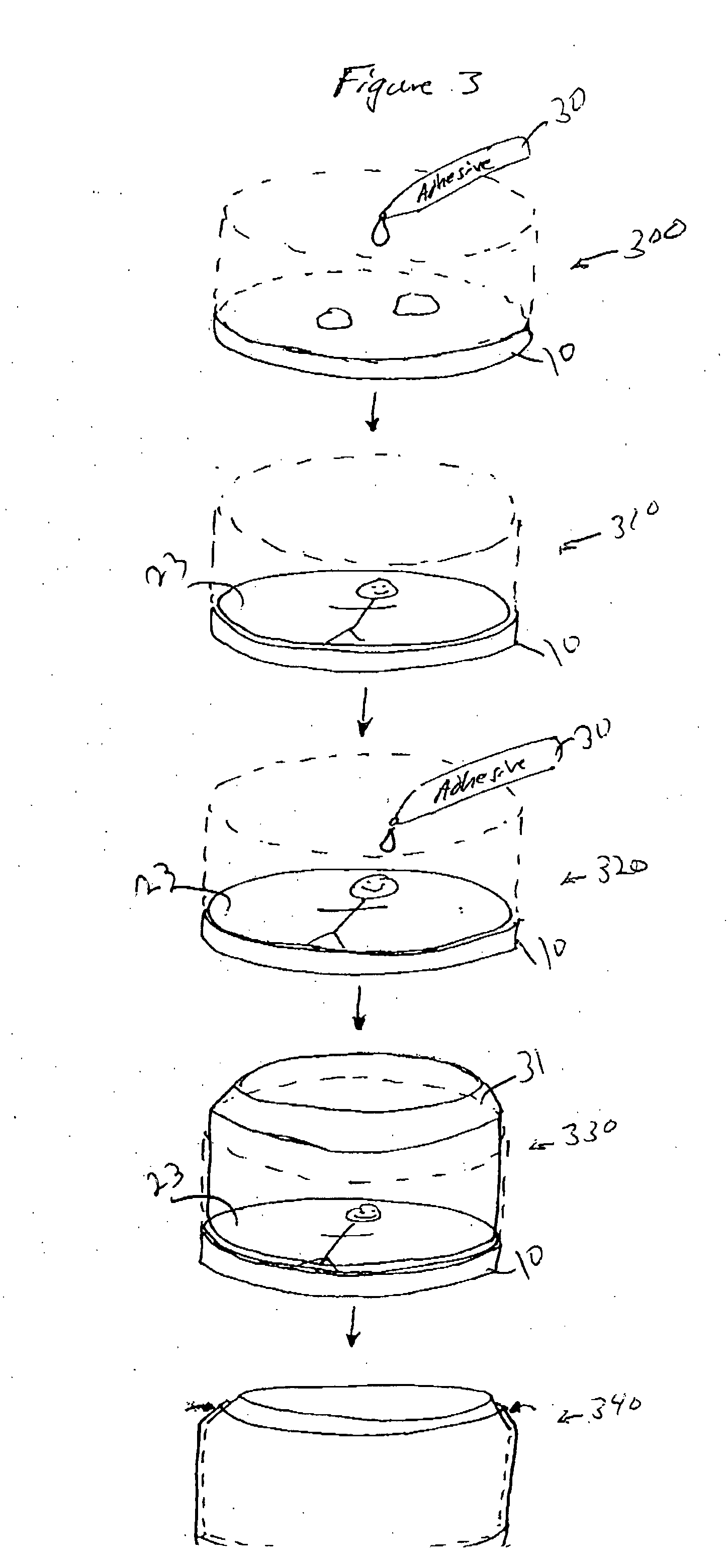

Water-proof photographic charms

InactiveUS20060090342A1Large image sizeMetal rolling stand detailsJewelleryEngineeringWater resistant

The invention comprises a water-proof photographic charm. In one embodiment, a handcrafted gold or silver jewelry base is provided for the charm, and a proprietary process is used to combine a photograph with the charm to produce a water resistant photographic charm. The charms may be mounted on a bracelet, necklace, earrings, or other piece of jewelry. The photograph is adjusted to size for cropping and display quality. A hand beveled crystal seal is used to protect the image from the elements and, at the same time, enhance image size by providing a magnifying effect.

Owner:IMAGE UNDER GLASS

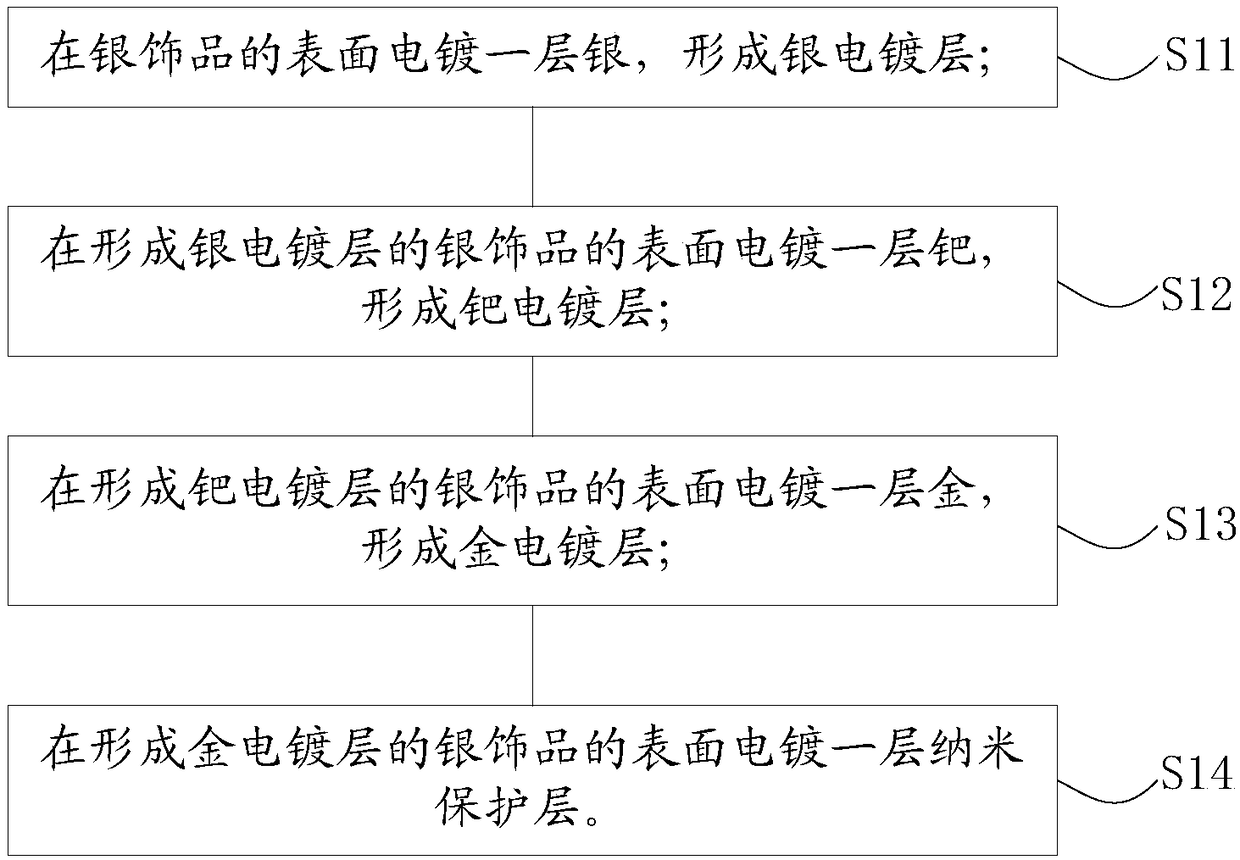

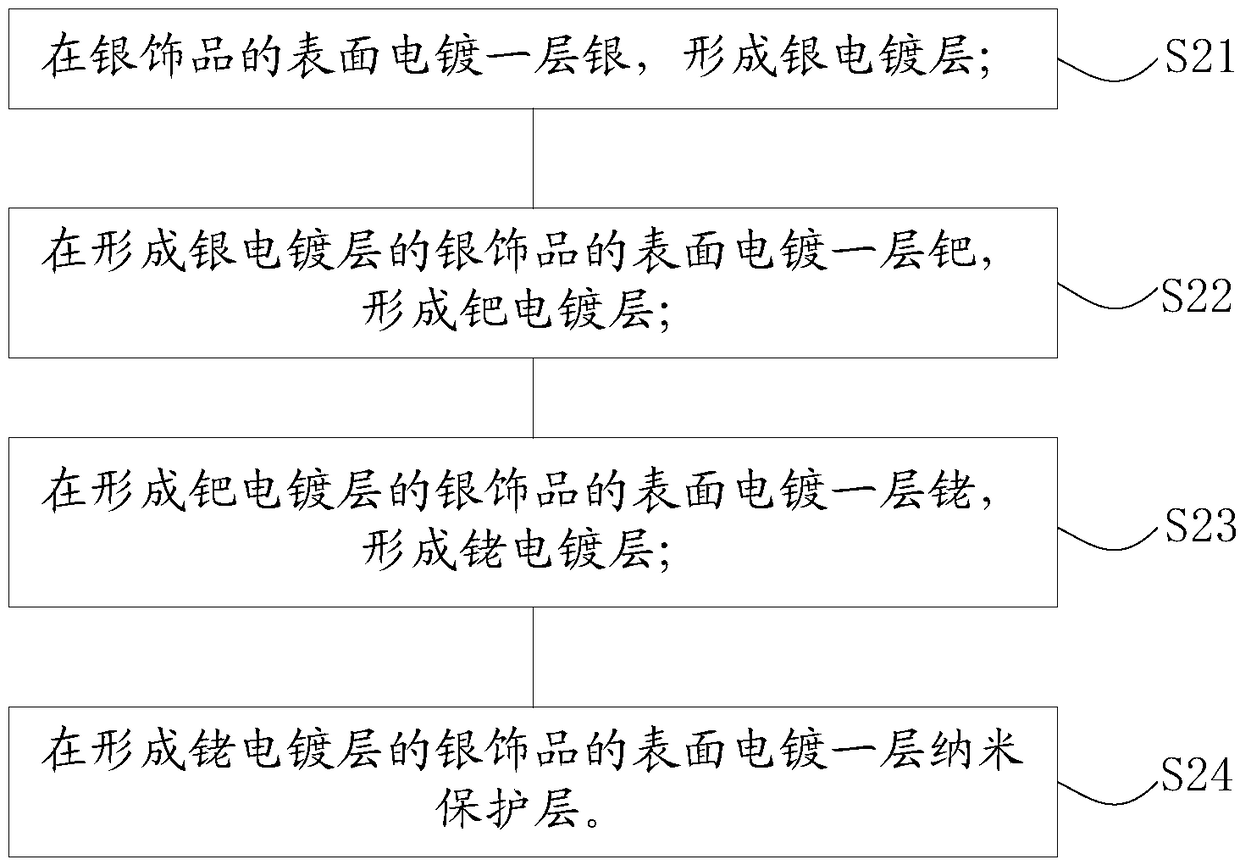

Electroplating anti-black method of silver ornament

The invention provides an electroplating anti-black method of silver ornament. The electroplating anti-black method of silver decoration comprises the following steps that a layer of silver is electroplated on the surface of a silver ornament, and a silver electroplating layer is formed; a layer of palladium is electroplated on the surface of the silver ornament forming the silver electroplating layer to form a palladium electroplating layer; a gold layer is electroplated on the surface of the silver ornament forming the palladium electroplating layer to form a gold electroplating layer, or arhodium layer is electroplated on the surface of the silver ornament forming the palladium electroplating layer to form a gold electroplating layer; and a layer of nano protective layer is electroplated on the surface of the silver ornament forming the gold electroplating layer or the rhodium electroplating layer. The method has the beneficial effects that the silver protection layer, the palladium protection layer, the gold protection layer or the rhodium protection layer and the nano protection layer are electroplated on the silver ornament in sequence, it is guaranteed that the silver ornament is not easy to oxidize in a wearing process, so that the occurrence of blackening conditions of the silver ornament can be avoided.

Owner:深圳市广福来珠宝实业有限公司

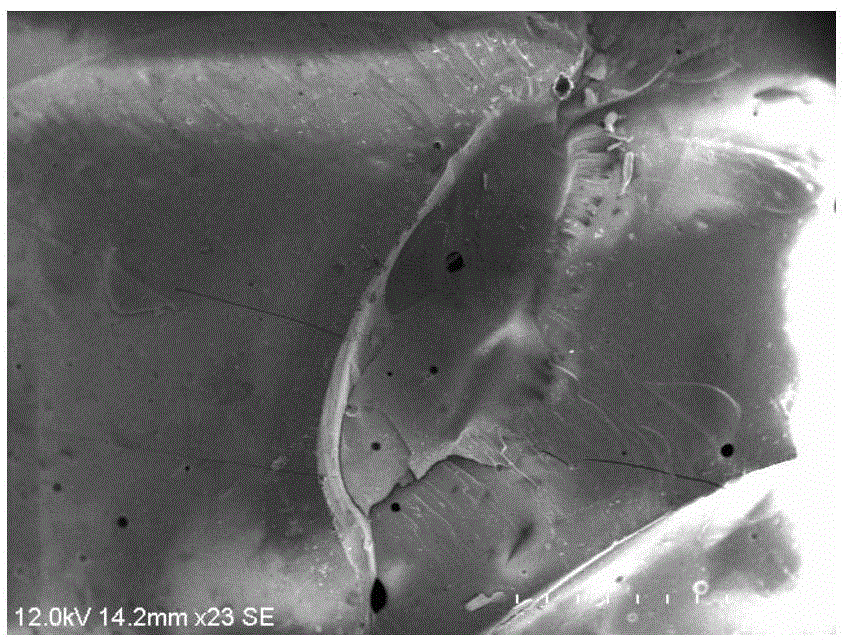

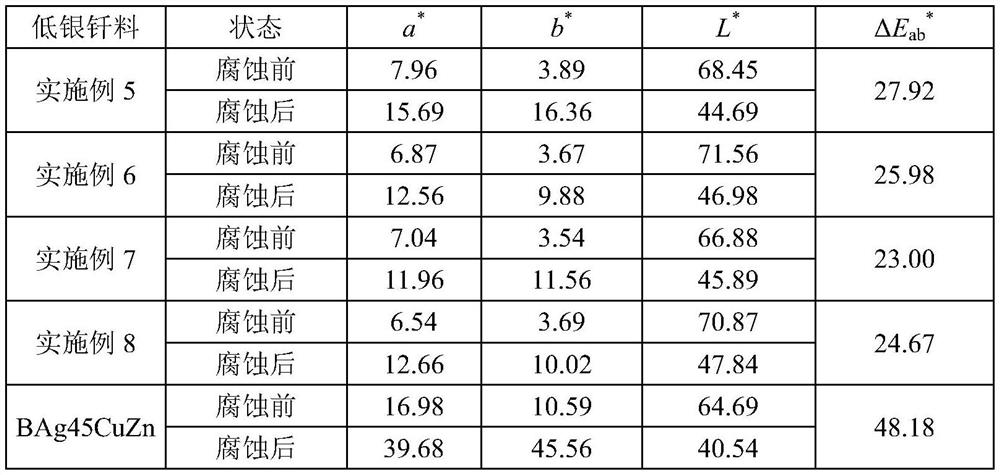

Low-silver brazing filler metal for welding pure silver jewelry and preparation method of low-silver brazing filler metal

PendingCN114473292ALow soldering temperatureImprove liquidityWelding/cutting media/materialsSoldering mediaFiller metalSilver jewellery

The invention relates to low-silver brazing filler metal for welding pure silver jewelry and a preparation method of the low-silver brazing filler metal, and belongs to the technical field of silver jewelry welding materials. The low-silver brazing filler metal for pure silver jewelry welding is composed of the following elements of, by mass, 60%-70% of Ag, 6%-15% of Zn, 0.1%-4% of Sn, 0.2%-1.2% of Si, 0.2%-0.8% of Ge, 0.5%-2% of microelements and the balance Cu. The trace element is selected from one or any combination of Ni, Co, Ce, Au, Pt, Pd, Ir and Mo. The melting temperature of the low-silver brazing filler metal for welding the pure silver jewelry is 650-780 DEG C, the brazing temperature is 680-800 DEG C, and the low-silver brazing filler metal for welding the pure silver jewelry has the advantages that the welding temperature is low, the fluidity of brazing filler metal melt is good, and turbulent flow and air holes are not prone to occurring in the welding process, and is suitable for low-temperature repair welding and secondary welding of the pure silver jewelry.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

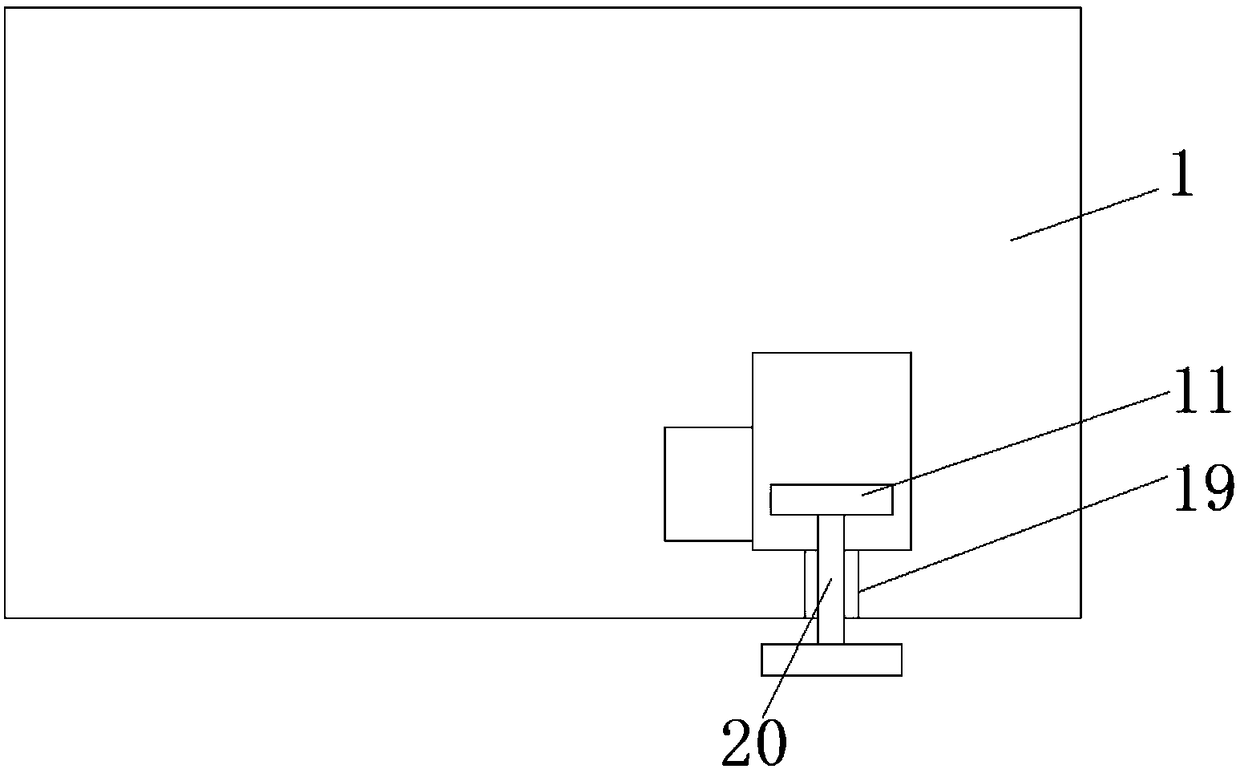

Silver ornament polishing device

InactiveCN110834262AAvoid fixationImprove securityGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a silver ornament polishing device. The device comprises a working table, wherein a groove is formed in the middle of the working table, the bottom of the groove is detachablyprovided with a collecting box, a screw rod is arranged in the groove in the horizontal direction, one end of the screw rod is provided with a driving motor for driving the screw rod to rotate, a driving block is arranged on the screw rod in a threaded transmission mode, a clamping assembly is arranged on the upper portion of the driving block, the upper portion of the working table is provided with a cross beam, the middle of the cross beam is provided with a polishing assembly, and the two sides of the polishing assembly are provided with draught fans. According to the device, a connecting rod, a first locking piece and a second locking piece are arranged so that the angle of a polishing brush can be adjusted, and then the different surfaces of a silver ornament can be polished; and a clamping piece is arranged, so that the situation that the silver ornament is fixed by an operator through hands is avoided, and the safety of polishing is improved.

Owner:张家界湘西白银艺术博物馆有限公司

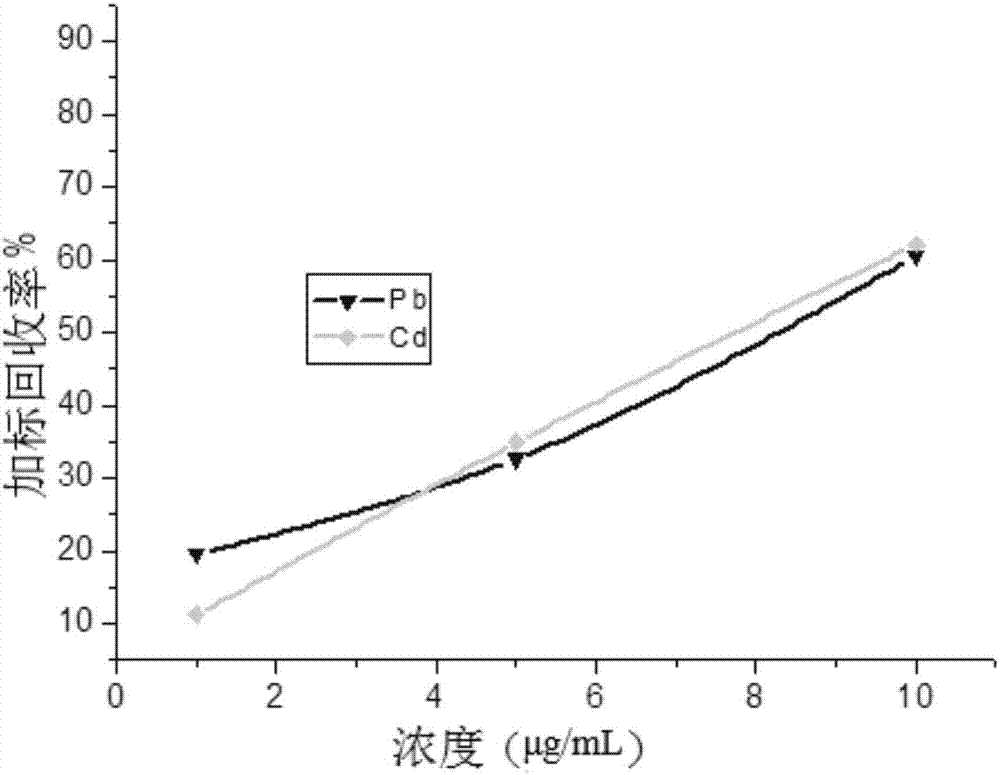

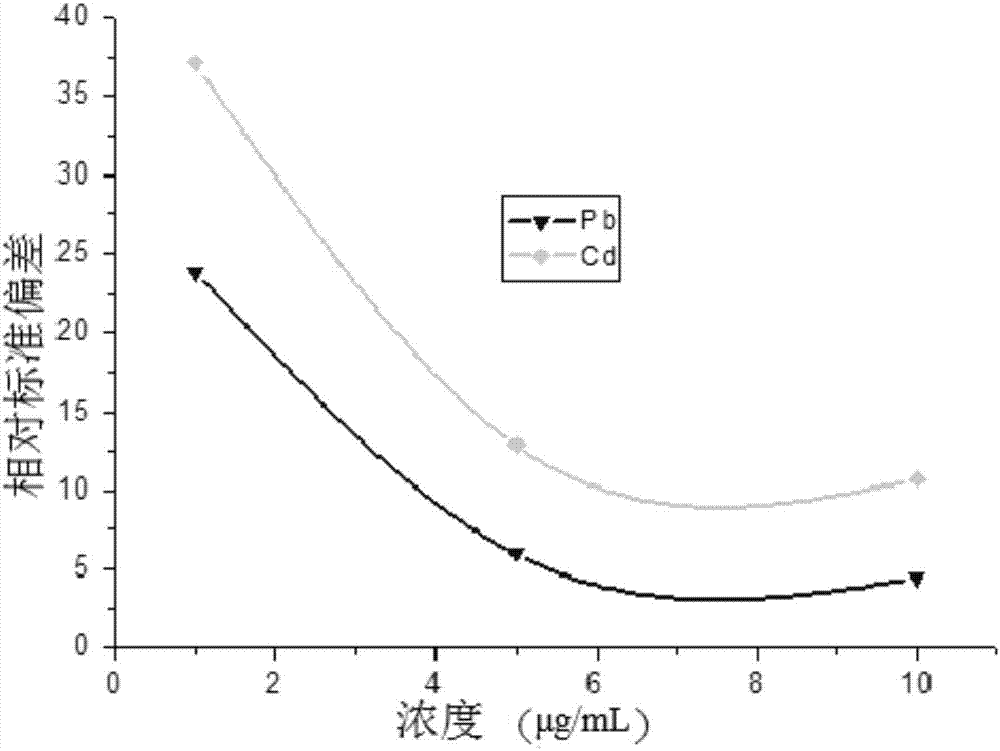

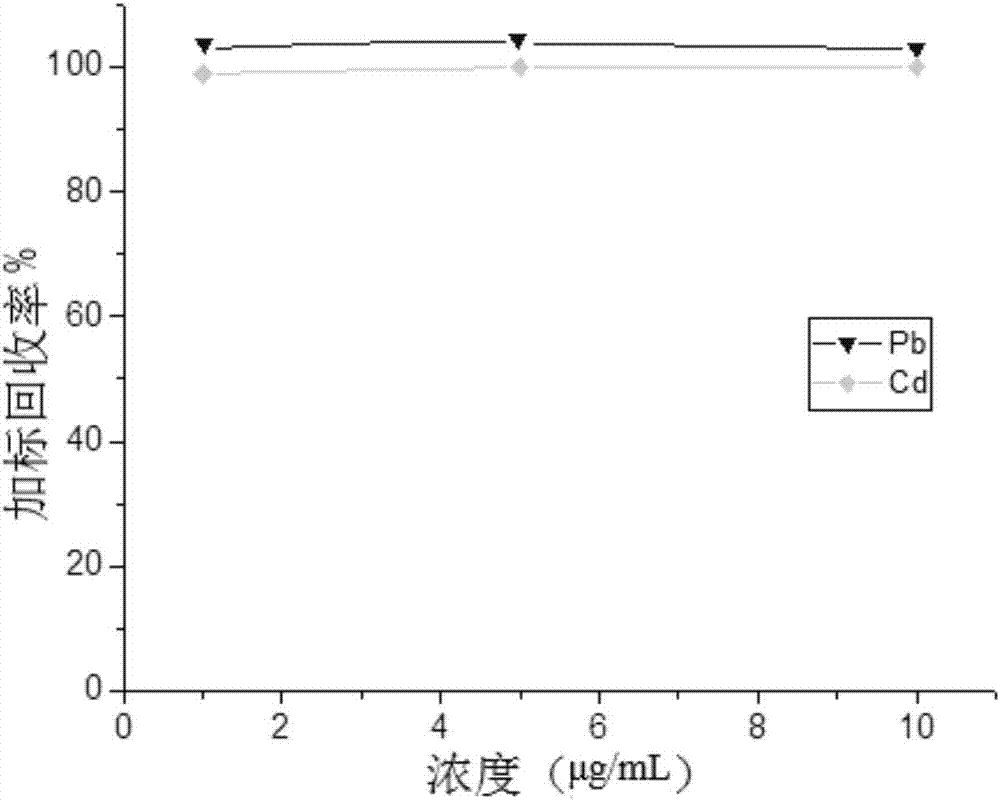

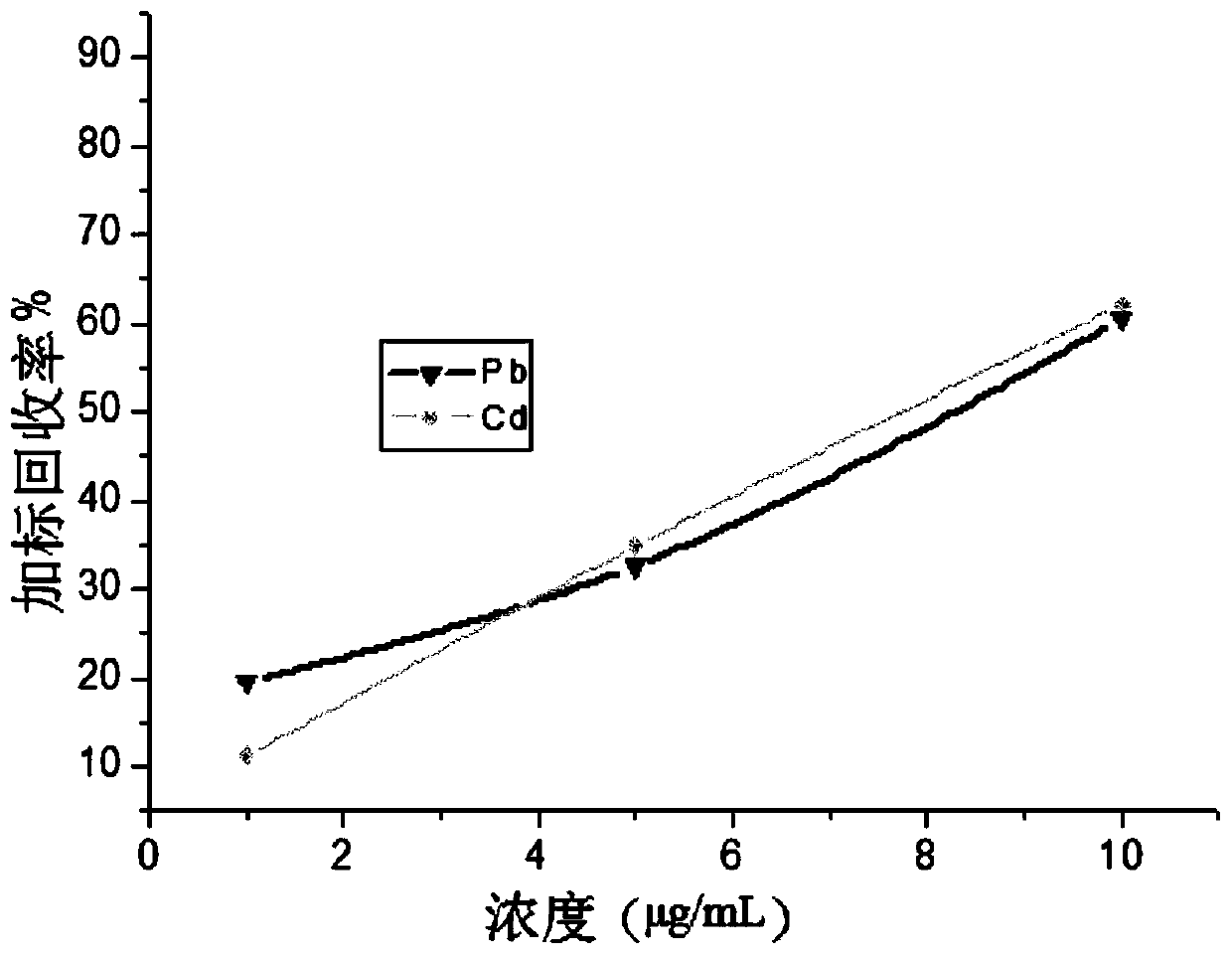

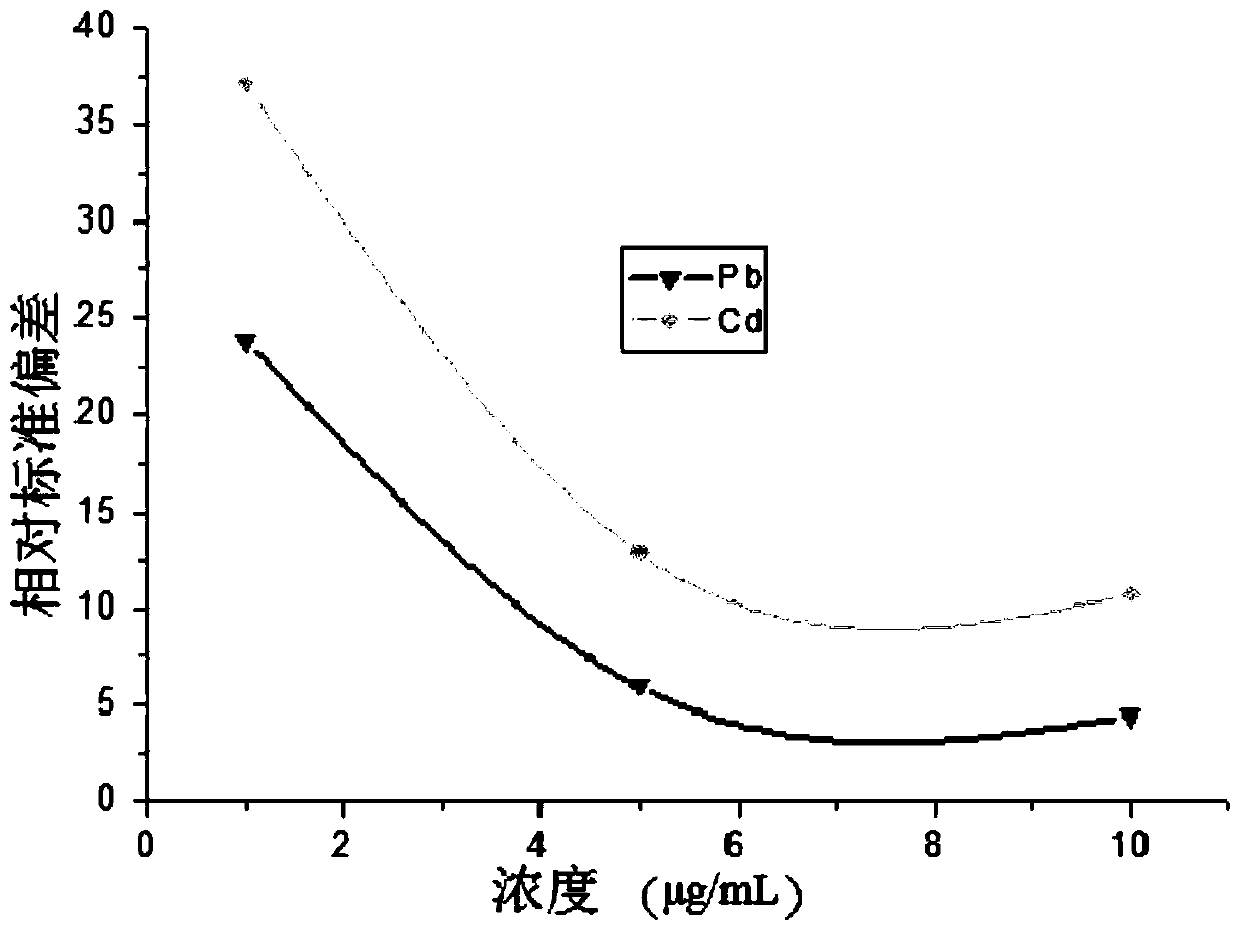

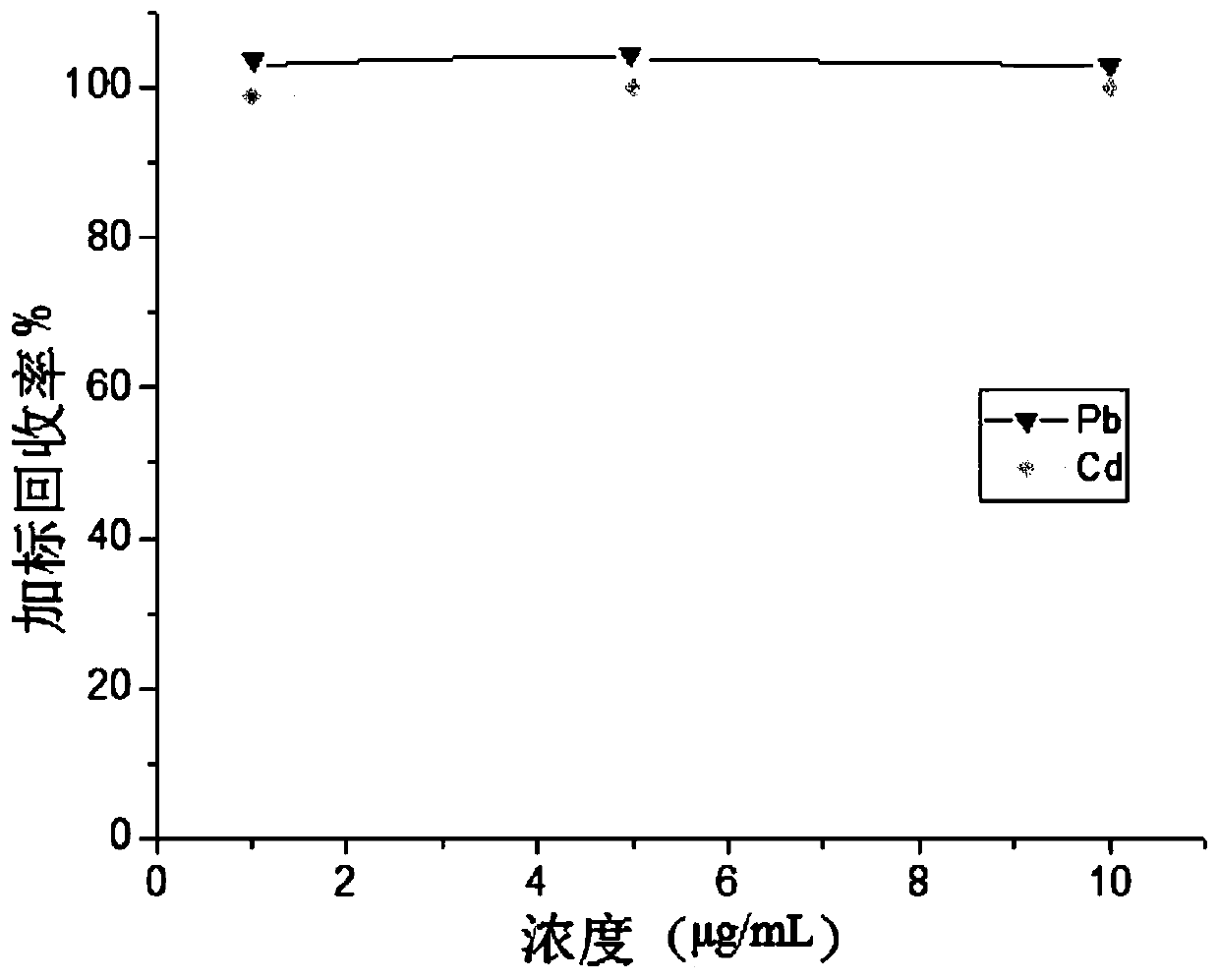

Method for determination of lead and cadmium content in silver jewelry

ActiveCN107328762AAccurate detectionHigh recovery rateAnalysis by thermal excitationPotassium thiocyanateSilver chloride

The invention relates to a method for determination of lead and cadmium content in silver jewelry and belongs to the field of precious metal analysis. The method comprises dissolving a silver sample to be detected through nitric acid to obtain a silver nitrate solution, adding a thiocyanate solution into the silver nitrate solution so that the silver nitrate is completely precipitated to form silver rhodanide, filtering to remove silver rhodanide precipitates, collecting the filtrate and determining lead and cadmium contents. Potassium thiocyanate is used as a precipitating agent and can solve the problem that lead and cadmium contents cannot be accurately determined because of silver chloride precipitate adsorption effects on lead and cadmium. The method realizes accurate determination of two element contents of silver jewelry.

Owner:SHANDONG MEASUREMENT SCI RES INST

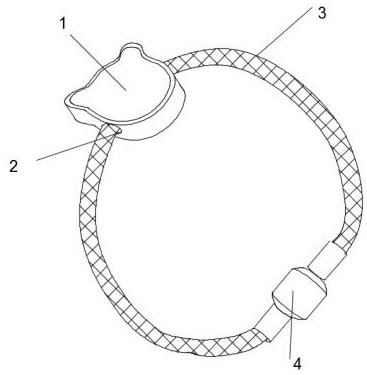

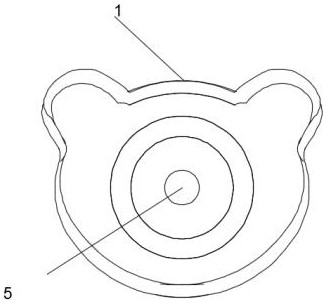

Anti-interference precious metal jewelry with built-in chip

InactiveCN112315146ASolve out of powerSolve the problem of not working without the mobile phoneWatch chainsOrnamental chainsInterference resistanceEngineering

The invention relates to the technical field of gold and silver jewelries, and discloses an anti-interference precious metal jewelry with a built-in chip. The jewelry comprises a metal jewelry body, athrough hole is arranged in the metal jewelry body in a penetrating manner, a wearing bracelet is inserted in the through hole, a snap ring is arranged on the wearing bracelet, and a rear cover is arranged on the back surface of the metal jewelry body; a rear cover groove is formed in the metal jewelry body, a mounting groove is formed in one side of the rear cover groove, a sealing groove is formed in one side of the mounting groove, a metal plate is arranged in the mounting groove, and a groove is formed in the metal plate. According to the precious metal jewelry with the anti-interferencebuilt-in chip, through the built-in chip, a product is not only separated from a power supply, but also can be separated from a mobile phone to be directly used for payment, entrance guard, membershipand other functions; meanwhile, GPS positioning can be recognized by a terminal, and later tracking can be conducted under the condition that the jewelry is lost and stolen; the hidden chip is not exposed on the surface, and can resist high temperature, water and corrosion.

Owner:上海驰零文化发展有限公司

A method for determining the content of lead and cadmium elements in silver ornaments

ActiveCN107328762BAccurate detectionHigh recovery rateAnalysis by thermal excitationPotassium thiocyanatePotassium

The invention relates to a method for determination of lead and cadmium content in silver jewelry and belongs to the field of precious metal analysis. The method comprises dissolving a silver sample to be detected through nitric acid to obtain a silver nitrate solution, adding a thiocyanate solution into the silver nitrate solution so that the silver nitrate is completely precipitated to form silver rhodanide, filtering to remove silver rhodanide precipitates, collecting the filtrate and determining lead and cadmium contents. Potassium thiocyanate is used as a precipitating agent and can solve the problem that lead and cadmium contents cannot be accurately determined because of silver chloride precipitate adsorption effects on lead and cadmium. The method realizes accurate determination of two element contents of silver jewelry.

Owner:SHANDONG MEASUREMENT SCI RES INST

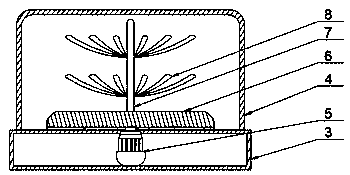

Display cabinet for gold and silver jewelry selling

InactiveCN110811240AEasy to displayImprove publicityShow cabinetsShow shelvesElectric machineEngineering

The invention discloses a display cabinet for gold and silver jewelry selling, and specifically relates to the technical field of jewelry selling. The display cabinet comprises a first box body, wherein a second box body is fixedly arranged at the top end of the first box body; a motor is fixedly arranged at the bottom end in the second box body; a protective cover is fixedly arranged at the top end of the second box body; a support table is arranged in the protective cover; the top end of an output shaft of the motor penetrates through the second box body and extends into the protective cover; the bottom end of the support table is fixedly connected with the top end of the output shaft of the motor; the bottom end of the support table is movably connected with the top end of the second box body through a bearing; a vertical rod is fixedly arranged at the top end of the support table; the vertical rod is arranged in the protective cover; two storage racks are fixedly arranged at the outer end of the vertical rod; and the storage racks are arranged in the protective cover. The support table can rotate in real time, gold and silver jewelry can be displayed in all directions, the propaganda effect is better, and the use effect is preferable.

Owner:徐州启承文化经纪有限公司

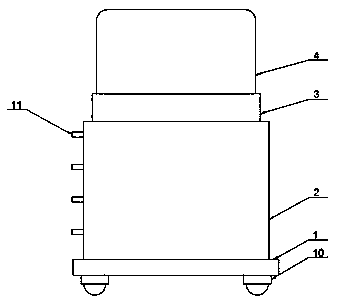

Processing device for silver ornament

InactiveCN110899215AMechanization of the cleaning processImprove work efficiencyCleaning using liquidsCouplingElectric machinery

The invention discloses a processing device for a silver ornament, which relates to the field of silver ornament processing. The device comprises a base, a driving part, a cleaning part, a rotating shaft, supporting rods, blocking discs, a connecting rod and a motor, wherein the cleaning part is fixed on the base; a cleaning tank with an upward opening is arranged in the cleaning part; the cleaning tank is filled with cleaning liquid; the driving part is fixed on the base; an output shaft of the driving part is fixedly connected with the end part of the connecting rod; the connecting rod is positioned above the cleaning part; the motor is fixed on the lower side face of the connecting rod; an output shaft of the motor is connected with one end of the rotating shaft through a coupler; the rotating shaft vertically faces the cleaning tank; the side face of the rotating shaft is fixedly connected with one ends of a plurality of supporting rods; a plurality of blocking discs are arranged on the side faces of the supporting rods; the center positions of the blocking discs are fixedly connected with the supporting rods; gaps are formed between the adjacent blocking discs; and the gaps are used for containing silver ornaments. Through the device, the cleaning process is mechanized, and therefore the working efficiency is improved, and the cleaning effect is guaranteed.

Owner:张家界湘西白银艺术博物馆有限公司

Blue low-silver alloy with stamping resistance and high elastic modulus for Tibetan silver jewelries and process thereof

InactiveCN108796294AUnchanged for a long timeWith self-healing functionSolid state diffusion coatingSocial benefitsAlloy

Owner:GUANGZHOU YUZHI TECH CO LTD

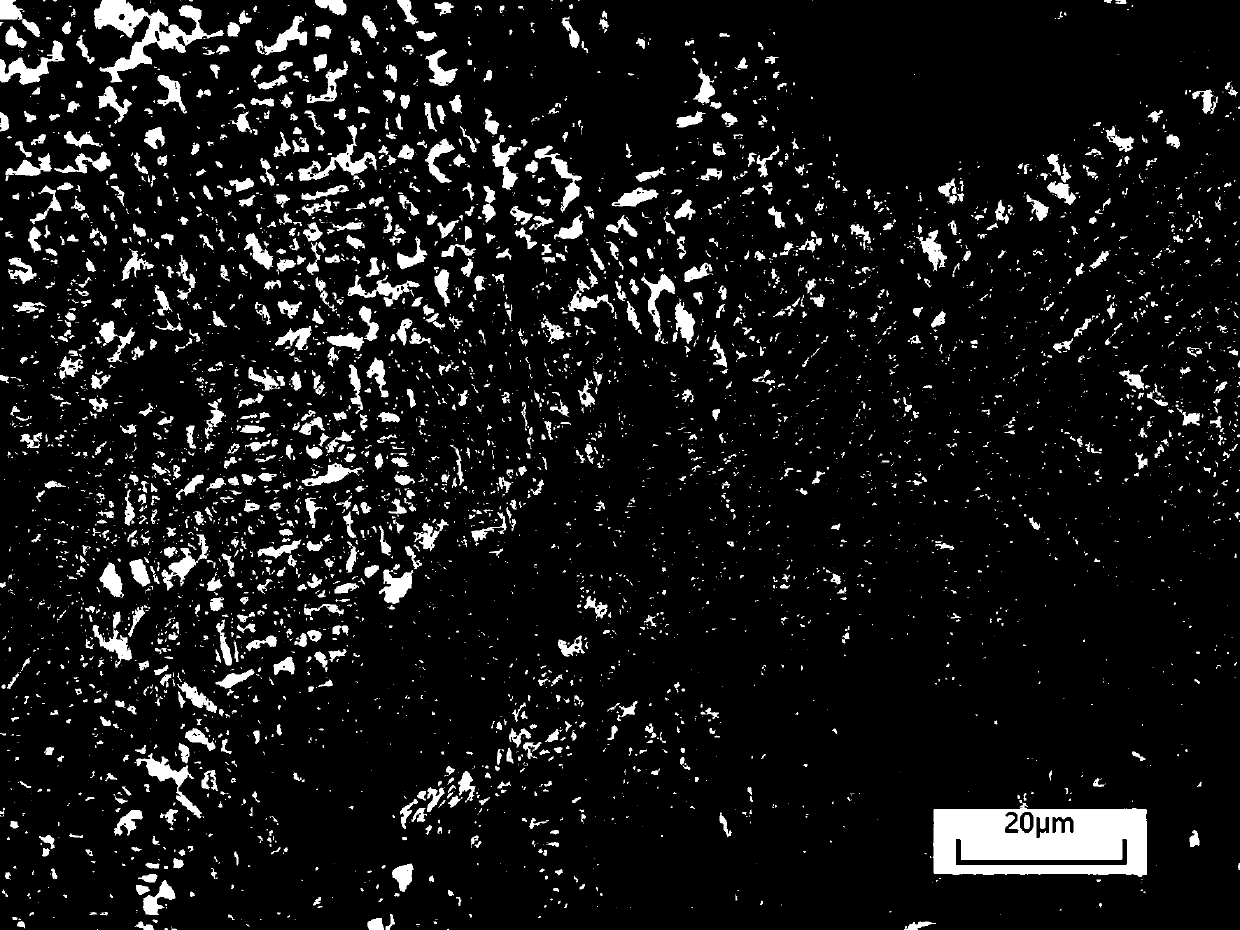

Novel low-silver-content alloy with blue luster, corrosion resistance and color change resistance for Miao silver jewelry

InactiveCN108796337AUnchanged for a long timeWith self-healing functionSolid state diffusion coatingSocial benefitsAlloy

The invention discloses a novel low-silver-content alloy with blue luster, corrosion resistance and color change resistance for Miao silver jewelry. The novel low-silver-content alloy comprises, by weight, 0.4%-0.6% of B, 1.8%-2.5% of Li, 0.4%-0.6% of Mo, 0.3%-0.5% of W, 1.2%-1.5% of Sc, 4.0%-6.0% of Ni, 40.0%-50.0% of Ag and the balance copper. The material supplies a materials science solution for a Miao silver alloy in China, therefore, a Miao silver product can have the blue luster after being machined, and the alloy has the excellent corrosion resistance and color change resistance. Through implementation and industrialization of the material, the product updating and industry upgrading requirements in the jewelry industry in China can be effectively met, and the plenteous economic gains and social benefits can be achieved while industry problems are solved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Pure-silver wiredrawing knitted flower welding method

The invention discloses a pure-silver wiredrawing knitted flower welding method, which comprises the following steps of: grinding a pure-silver soldering lug or welding rod into pure-silver powder; putting the pure-silver powder in a copper disc; adding borax and pure water, wherein the mass ratio of the pure-silver powder to the borax is 10:0.8; heating the copper disc with fire; boiling water in the copper disc; after the water in the copper disc is boiled, heating for 5-10 seconds to fully dissolve the borax in the boiling water; putting a filament accessory which needs to be welded in the copper disc liquid to be dipped for 15-25 seconds; taking out the filament accessory after 15-25 seconds; welding the filament accessory on the corresponding position of a silverware; and baking with flame of 500-700DEG C. People can not see the welding mark of a silver jewelry welded with the method, and the appearance of the silver jewelry is smooth and flat.

Owner:丹寨县国春银饰有限责任公司

Manufacturing process of silver-germanium infrared health-care ornament

PendingCN114231774ARealize manufacturingBroaden Design FeasibilityAdditive manufacturing apparatusIncreasing energy efficiency3d patterningMetal forming

The invention belongs to the technical field of metal material additive manufacturing, and particularly relates to a manufacturing process of a silver-germanium infrared health-care ornament, which comprises the following steps: firstly, uniformly mixing Ag alloy powder and Ge powder, and then obtaining a green body of which the shape completely conforms to a pre-designed 3D pattern by adopting an adhesive spraying 3D printing metal forming technology; and degreasing and sintering to obtain a silver-germanium sintered part, and finally carrying out molding post-processing to finally obtain the finished product silver-germanium ornament. The defects that in the germanium-silver alloy machining process, materials are large in brittleness, high in hardness, poor in flexibility and ductility, prone to brittle failure and scrapping and difficult to machine into delicate and exquisite products are overcome; and the 3D printing technology is applied to design and manufacturing of germanium-silver ornaments, one-time forming of complex three-dimensional design products is achieved, the design feasibility of germanium-silver products is greatly widened, and the germanium-silver ornaments have great application value when being applied to health-care products such as ornaments, waistbands, neck bands, bracelets, kneecaps and pillows.

Owner:DONGGUAN JINGWEI NEW MATERIALS CO LTD

Display stand for selling gold and silver

InactiveCN111214044AIncrease brightnessImprove aestheticsShow cabinetsShow shelvesGlass coverMaterials science

The invention discloses a display stand for selling gold and silver. The display stand comprises a bottom plate, wherein a bearing mechanism is arranged in the middle of the top end of the bottom plate, irradiation lamps are fixedly installed at the corners of the bottom end of the bottom plate, the top end of the bottom plate and the exterior of the bearing mechanism are sleeved with a transparent glass cover, and light scattering mirrors are obliquely and fixedly connected to the four corners of the top part of the inner wall of the transparent glass window. By means of the arrangement of the irradiation lamps, the transparent glass window and the light scattering mirrors, light rays entering the transparent observation window can be evenly projected to the gold and silver jewelry afterbeing scattered by the light scattering mirrors, the brightness degree of the gold and silver jewelry is improved, and therefore the attractiveness of the gold and silver jewelry is improved, and thedisplay effect is improved.

Owner:永兴县三分地环保信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com