Copper-based repair alloy and preparation method thereof

A filling and alloying technology, applied in the field of alloys, can solve the problems of reducing the value of silver products, loose surface of silver jewelry, insufficient hardness, etc., and achieve the effect of proper control of trace element composition, good anti-darkness and discoloration ability, and improved anti-discoloration ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A kind of preparation method of the copper-base jointing alloy of promoting the apparent quality of silver product of the present invention, it comprises the following steps:

[0040] Step 1, preparing a binary master alloy with trace elements Si, Ge, In, Ce, Al and copper, and preparing a master alloy with Al-Y;

[0041] Step 2: analyzing and determining the component content of each component in the above binary master alloy, and determining the additive weight of the binary master alloy ingredients according to the content of trace elements. Cu, Zn, and Sn are smelted under an inert gas protective atmosphere, and then the master alloy with trace elements is mixed and smelted, and the Al-Y master alloy is added last;

[0042] Step 3: Control the furnace temperature at 800-1100°C, let it stand still for more than 20 minutes, and then carry out granulation to produce joint alloy particles.

[0043] The copper-based jointing alloy of the invention is applicable to the p...

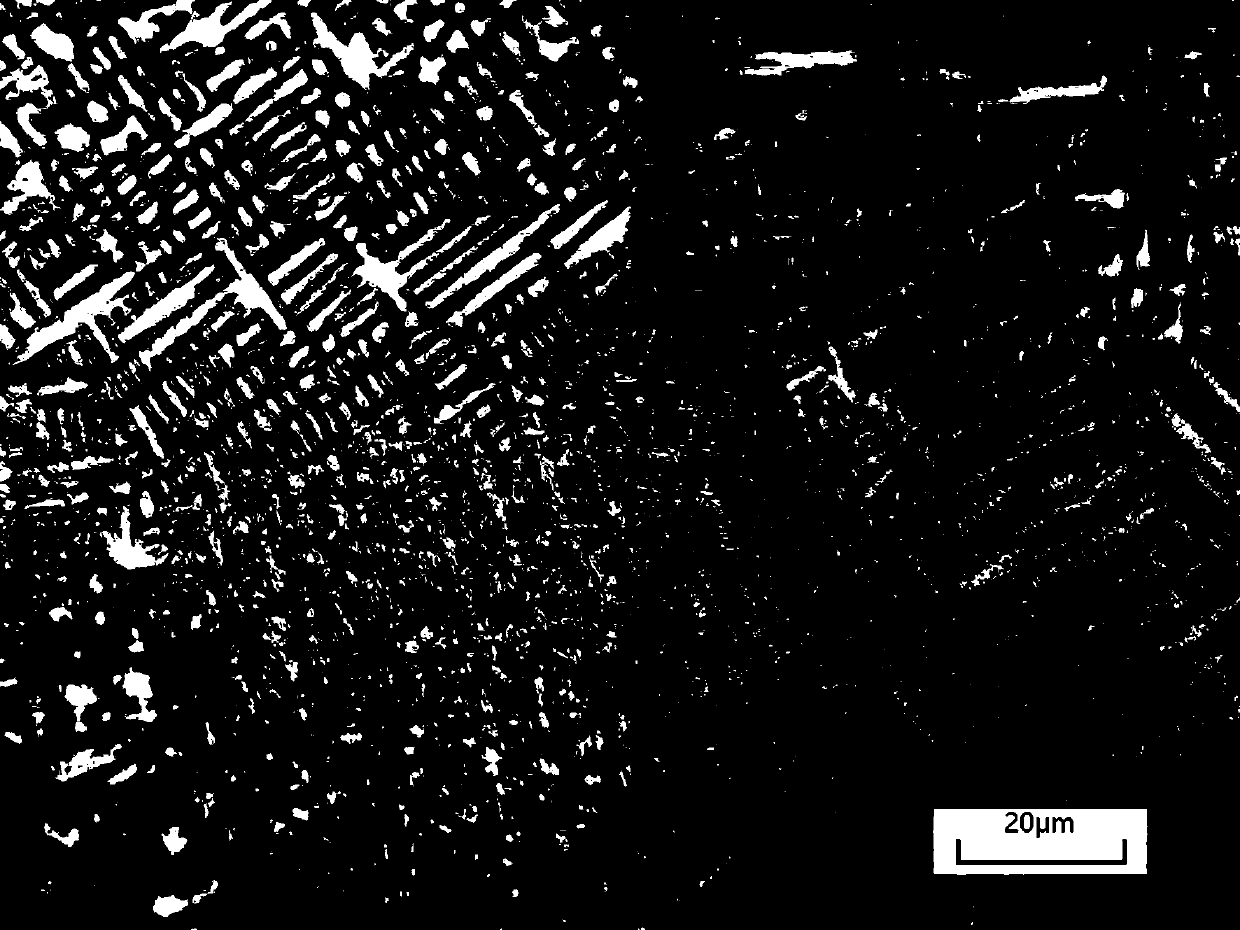

Embodiment 1

[0056] A copper-based jointing alloy to improve the apparent quality of silver products, the following composition is designed according to the mass percentage: Cu: 65%; Zn: 25%; Sn: 4.5%; Si: 1.5%; Ge: 0.08%; In: 2 %; Ce: 0.3%; Al: 1.57%; Y: 0.05%.

[0057] In the above-mentioned jointing alloys, Cu can improve the hardness and strength of silver products through solid solution strengthening, but if the content is too high (≥50%), red marks will easily appear and affect the appearance quality, which needs to be adjusted by adding Zn, Sn and trace elements; Zn can lower the melting point of the alloy and increase the whiteness of the silver alloy. When the mass percentage of Zn is 25%, it forms a solid solution with higher solubility with Cu in the alloy; Sn can lower the melting point of the alloy and increase the fluidity of the alloy. When the Zn is 25 %, the tendency of Sn to segregate on the surface of the product to form brittle phases and intermetallic compounds is weak...

Embodiment 2

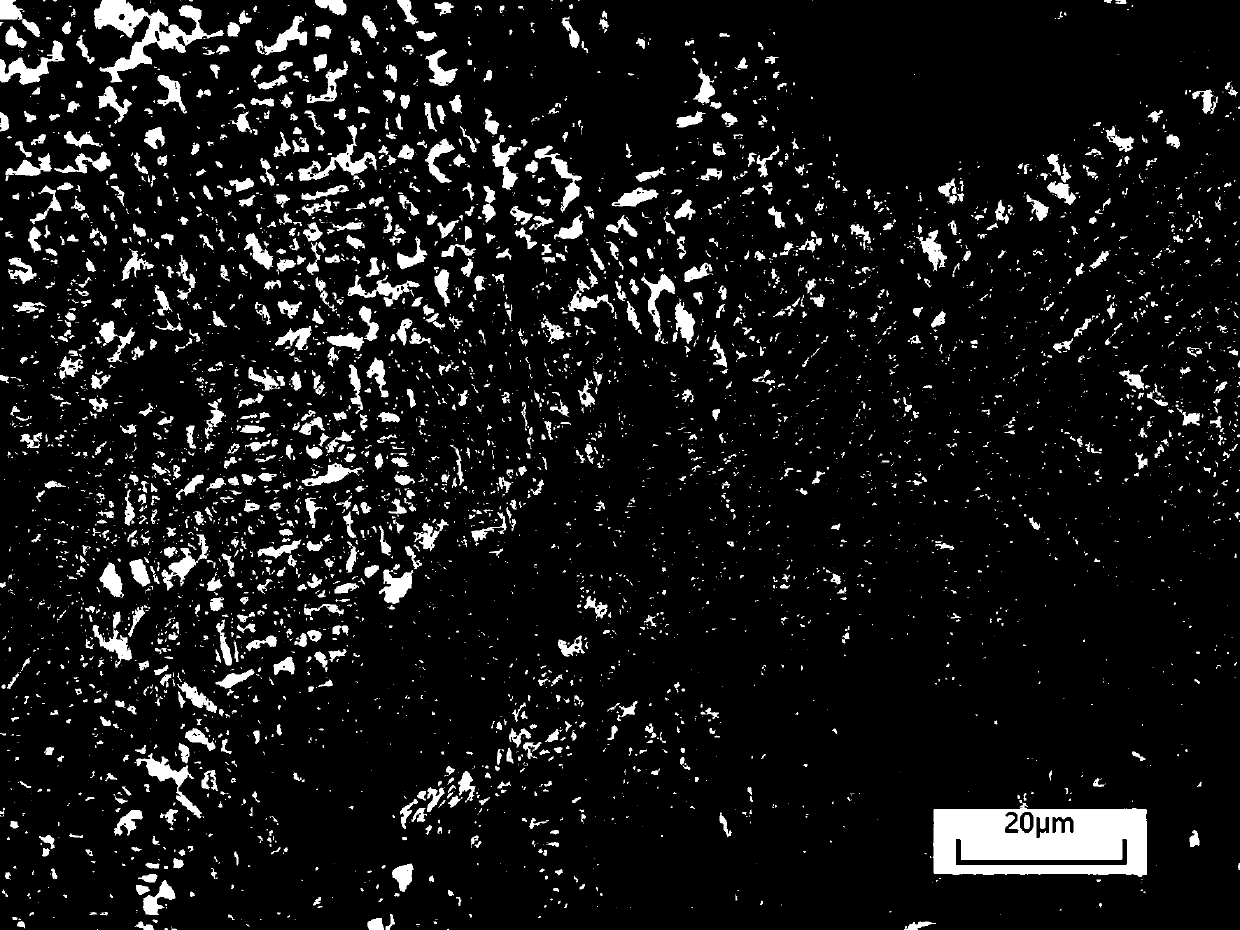

[0062] A copper-based jointing alloy to improve the apparent quality of silver products, the following composition is designed according to the mass percentage: Cu: 62.48%; Zn: 30%; Sn: 3%; Si: 1.6%; Ge: 1.2%; In: 0.7 %; Ce: 0.2%; Al: 0.8%; Y: 0.02%.

[0063] Among the above-mentioned jointing alloys, Cu can improve the hardness and strength of silver products through solid solution strengthening; Zn can reduce the melting point of the alloy and increase the whiteness of the alloy. α phase and (α+β) phase; Sn can lower the melting point of the alloy and increase the fluidity of the alloy, the content is preferably 3%; trace elements Si and Ce can purify the grain boundary and avoid oxide inclusions, the preferred composition range is Si: 1.6%, Ce: 0.2%; Al and Y can improve the anti-oxidation and discoloration ability of silver products, the preferred composition range Al: 0.8%; Y: 0.02; In can refine the grain and improve the mechanical properties, the preferred composition r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com