Method for preparing powder metallurgy of titanium-aluminium alloy target material

A titanium-aluminum alloy and powder metallurgy technology, applied in the field of powder metallurgy preparation, can solve the problems of small size, porosity, segregation, bubbles, etc., and achieve the effect of large size, good compactness and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

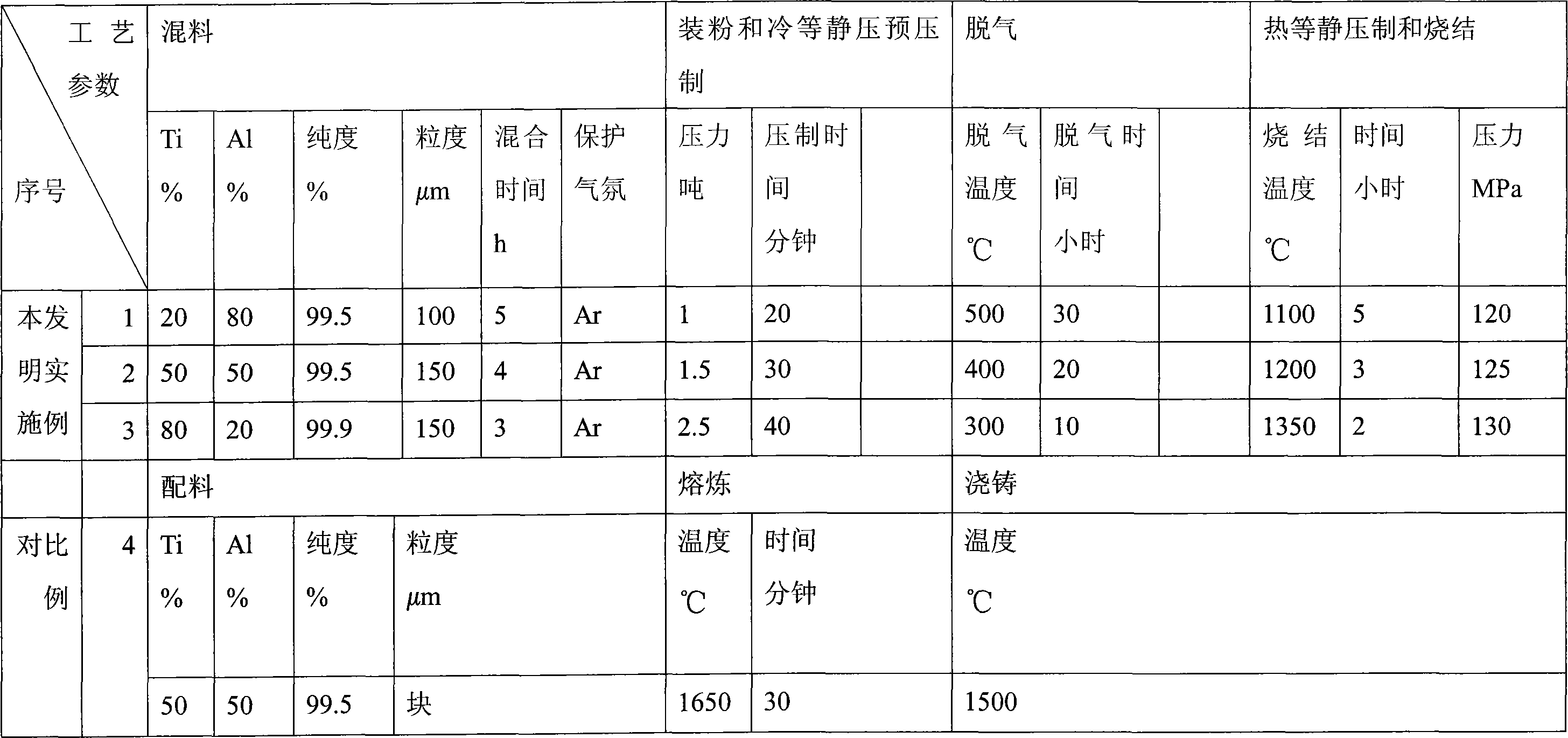

[0030] Using the composition and preparation method of the present invention, three batches of titanium-aluminum alloy targets were prepared. Table 1 is a comparison table of composition, process steps and process parameters between the present invention and the prior art. Table 2 is the comparison table of the present invention and the prior art. The performance comparison table of the final finished products of the prior art comparative examples; for convenience of comparison, the comparative examples are listed in the above table simultaneously, wherein, serial numbers 1-3# are embodiments of the present invention, and 4# is the prior art comparative examples.

[0031] Table 1 is the comparative table of composition, process steps and process parameters of the present invention and the prior art

[0032]

[0033] Table 2 is a comparison table of final product performance parameters between the embodiment of the present invention and the prior art comparative example

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com