Patents

Literature

389results about How to "No segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

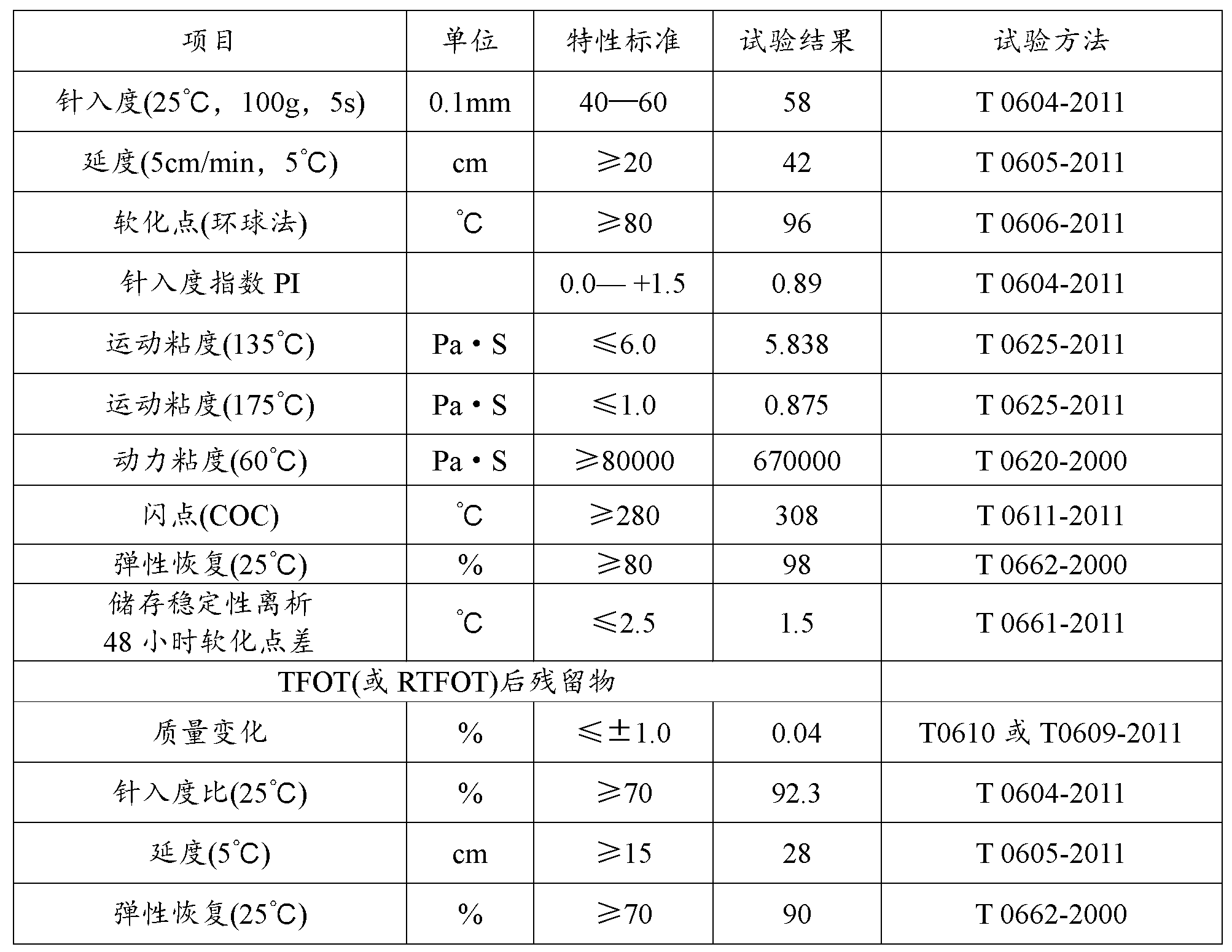

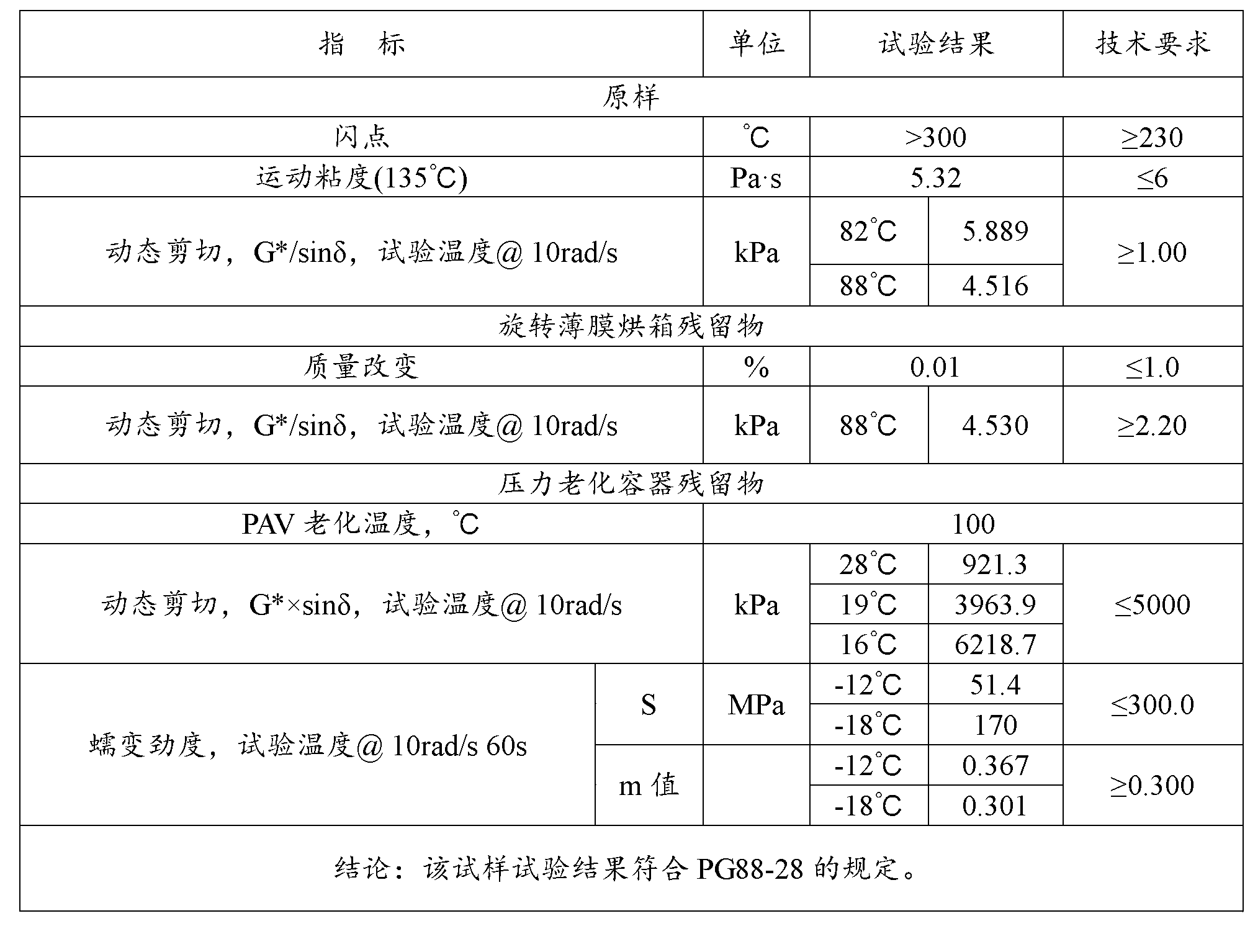

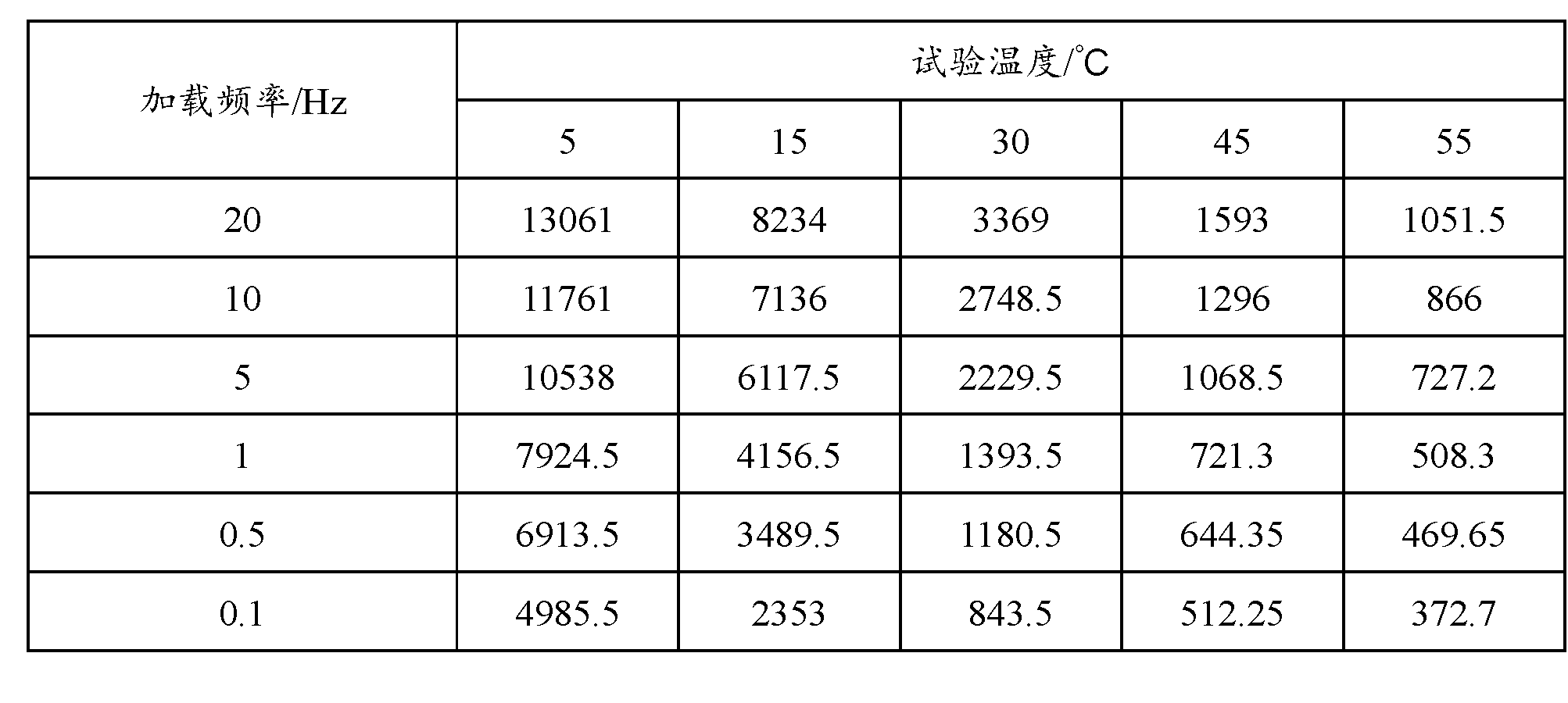

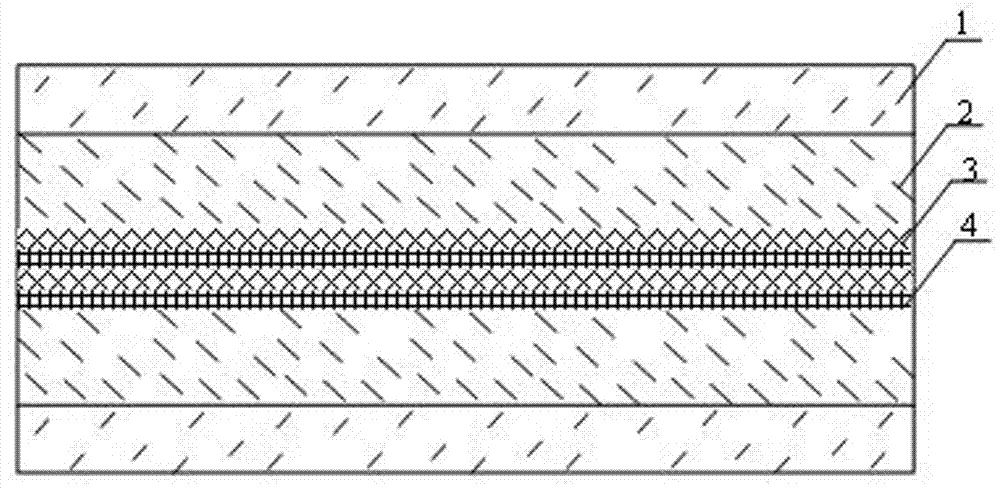

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

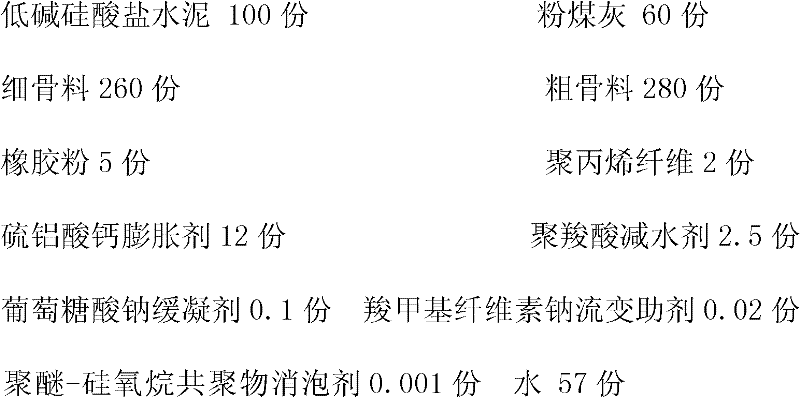

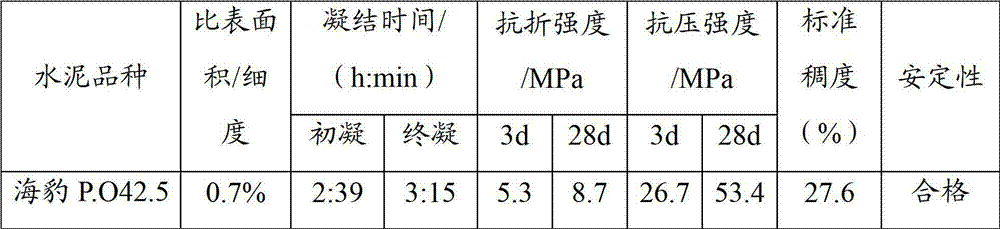

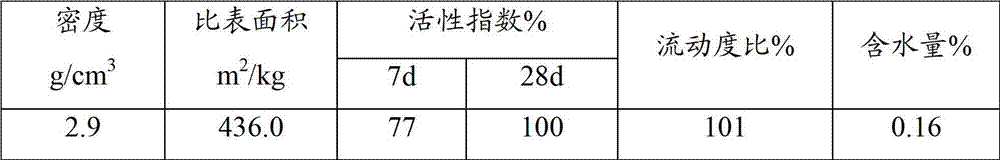

Self-compacting concrete mixture for plate-type ballastless track of railway

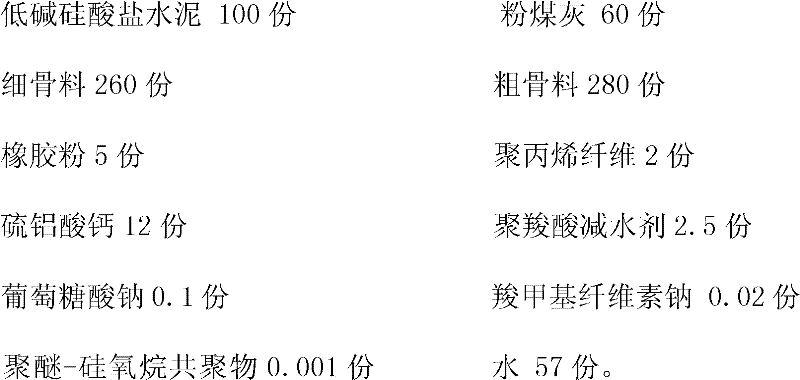

The invention discloses a self-compacting concrete mixture for a plate-type ballastless track of a railway, which is composed of the following ingredients in part by weight: 100 parts of cement, 20-80 parts of mineral admixture, 200-300 parts of fine aggregate, 250-350 parts of coarse aggregate, 2-10 parts of parts of rubber powder, 1-3 parts of polypropylene fiber, 10-25 parts of expansion agent, 1.0-3.0 parts of water reducing agent, 0.1-1 part of retarder, 0.01-0.05 parts of rheology accessory agent, 0.001 part of antifoaming agent and 60-80 parts of water; and the self-compacting concretemixture is prepared by blending and stirring the materials. The self-compacting concrete mixture disclosed by the invention has the advantages of large flow state, self-compacting property, non-segregation, low shrinkage, high anti-cracking property and vibration adsorption, and the like, so that the self-compacting concrete mixture can be used as filler between a rail board and a soleplate in a plate-type ballastless track and can also be used as filler between a turnout board and the soleplate in a turnout structure.

Owner:SOUTHWEST JIAOTONG UNIV

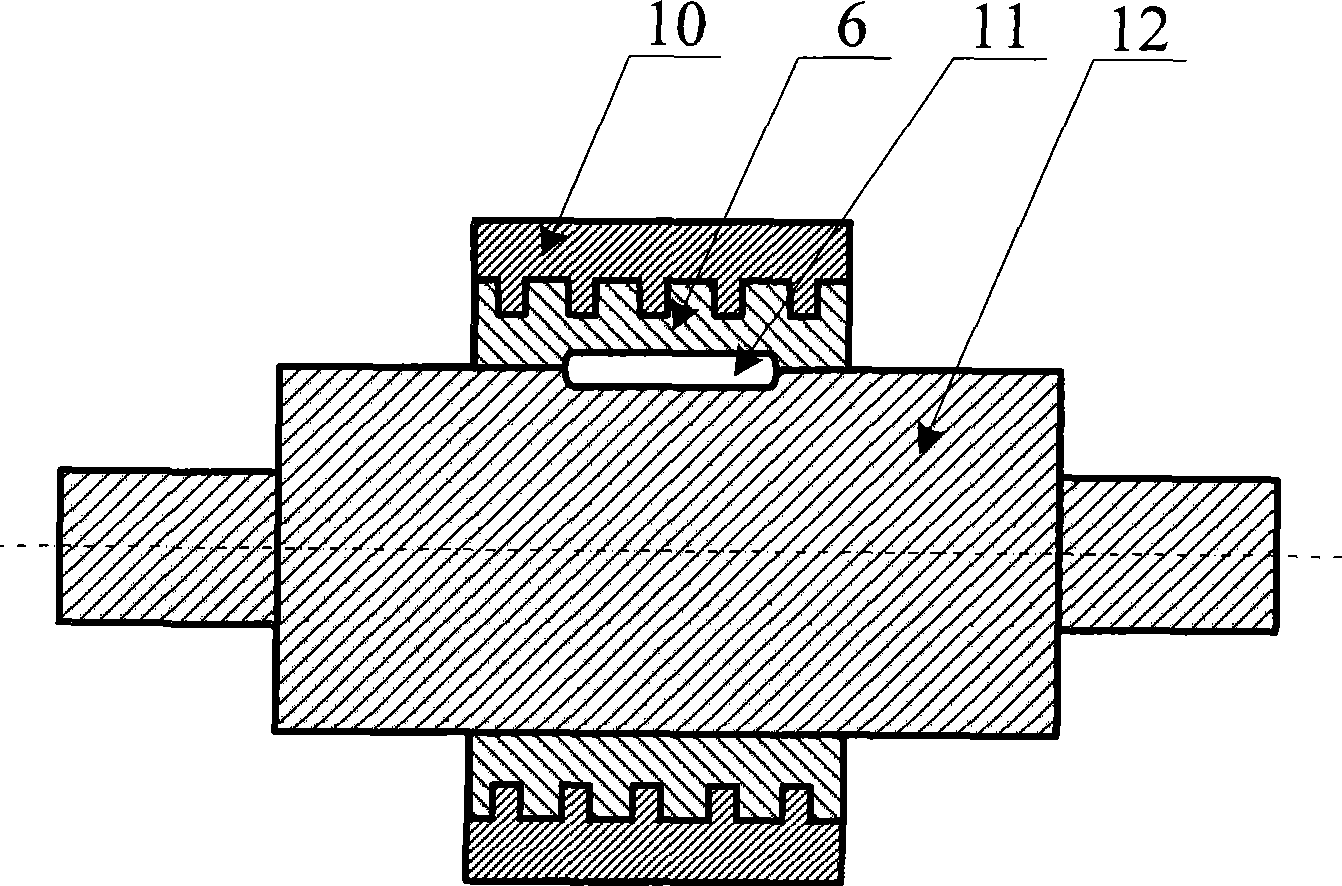

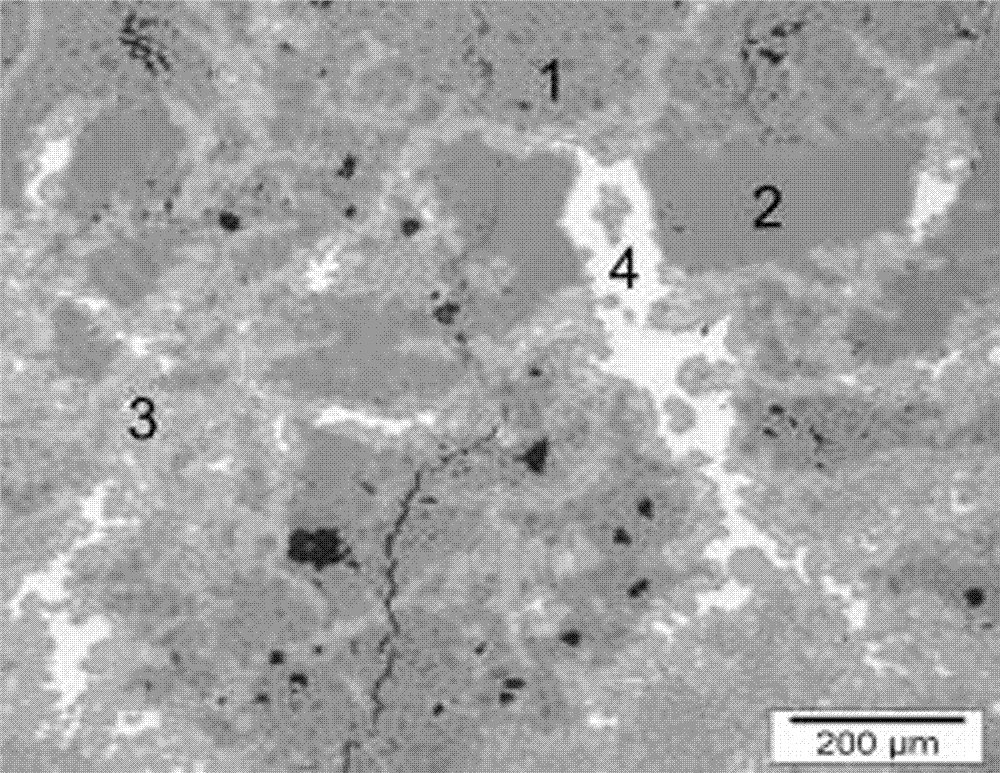

Method for preparing powder metallurgy of titanium-aluminium alloy target material

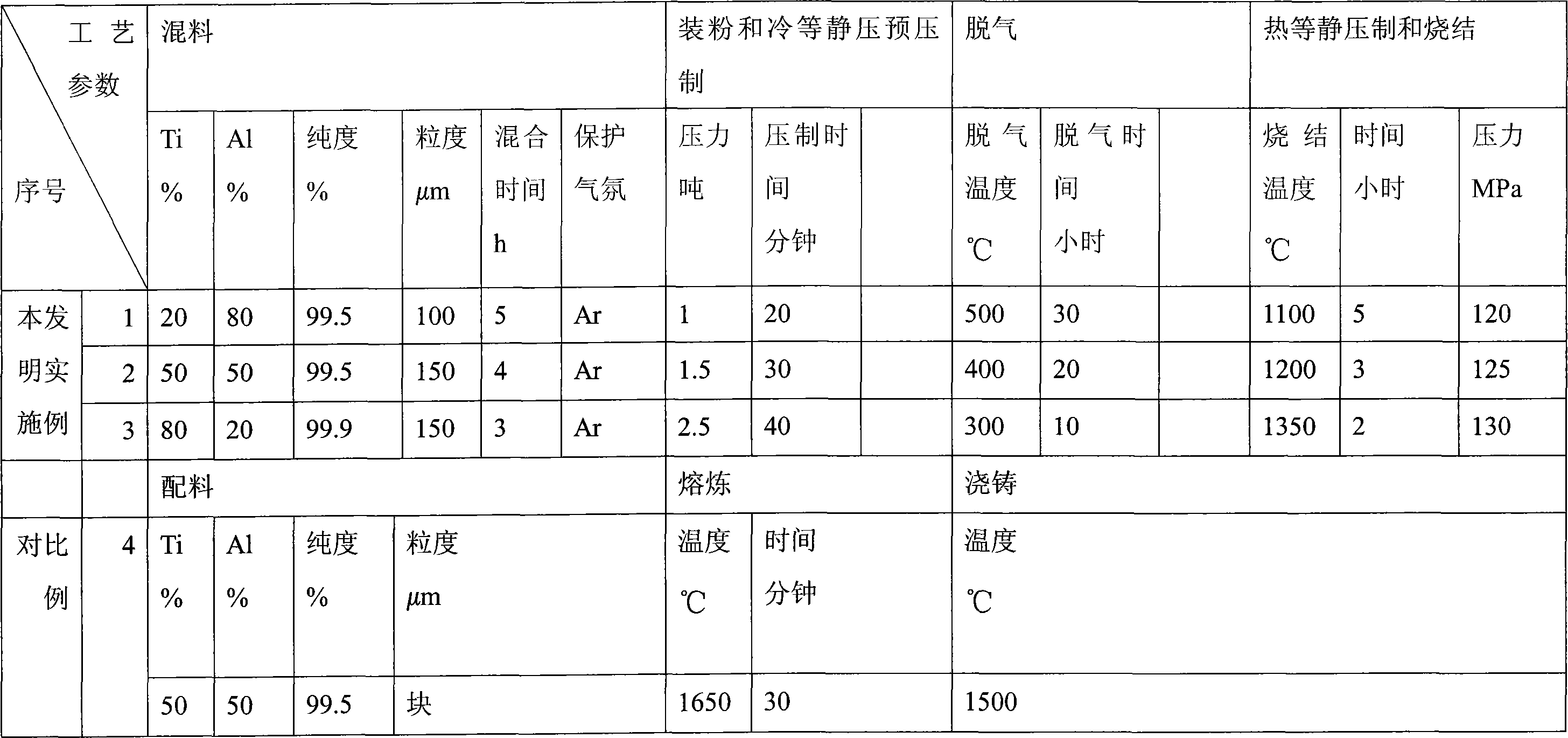

The invention belongs to the preparing field of powder metallurgy, in particular to the powder metallurgy preparing method for titanium aluminum alloy target material. The components of the titanium aluminum alloy target material relates to: Ti to Al is equal to 80 percent to 20 percent or Ti to Al is equal to 20 to 80 percent. The powder metallurgy preparing method for the titanium aluminum alloy target material is to adopt a pulverization method to acquire the titanium aluminum alloy or mix the titanium powder and the aluminum powder and then pre-pressing through powder mounting and isostatic cool pressing, and then carries out hot isostatic pressing forming after the technique of desaeration and finally carries out sintering process and machining to acquire the titanium aluminum alloy target material. Compared with the exiting casting target material, the titanium aluminum alloy target material of the invention has the advantages of good compactness, no air holes, no loosening and aliquation, uniform component, petty crystal particle, big specification dimension, etc., and is suitable for hard coat needed by various tools and dies.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

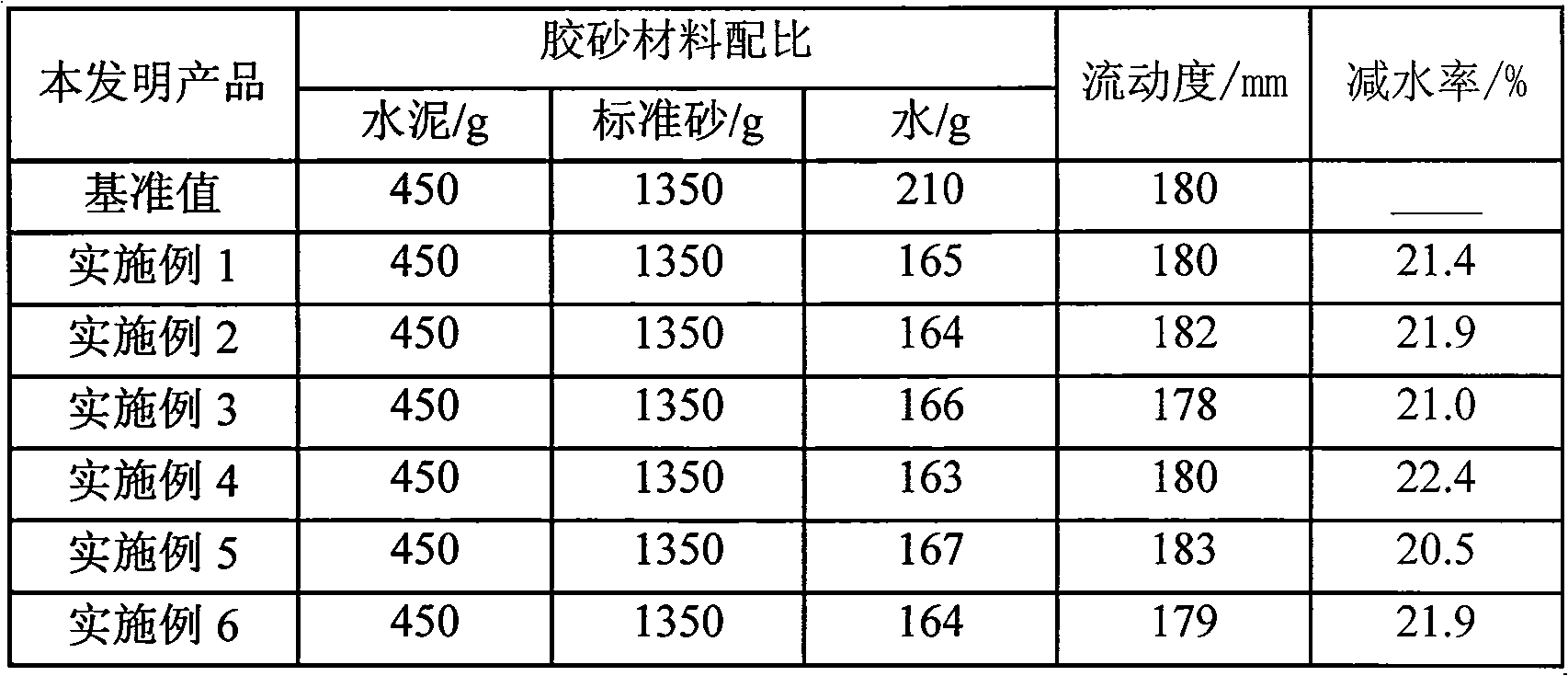

Modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate and preparation method thereof

The invention relates to a method for preparing a modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate, belonging to the field of concrete water-reducing agents. The invention adopts acetone and formaldehyde as condensation monomers and lignosulfonate as a modifying agent and carries out sulfonating and condensation reactions under an alkaline condition to produce anovel high-efficiency concrete water-reducing agent. The preparation method of the novel high-efficiency concrete water-reducing agent comprises the following steps: (1) adding a sulfonating agent, acetone and water to a reactor, increasing the temperature to 25-65 DEG C and reacting for 0.1-1.5 hours; (2) dipping part of formaldehyde solution for 0.25-2.5 hours, increasing the temperature to 70-95 DEG C and reacting for 1-6 hours; and (3) decreasing the temperature to below 60 DEG C, adding the lignosulfonate and the rest of the formaldehyde solution to the reactor, using an alkaline regulator to regulate a pH value of the system to be 8.0-14.0, increasing the temperature to 70-98 DEG C, reacting for 1-5 hours and decreasing the temperature before discharging. The modified aliphatic high-efficiency water-reducing agent is suitable for producing commercial concrete which has similar color as normal concrete and has smaller collapsed slump loss. By adjusting the process, such as proportioning raw materials, and the like and effectively utilizing the lignosulfonate, the invention not only decreases the product cost, but also lessens environmental pollutants and has favorable industrialized prospects.

Owner:NANJING FORESTRY UNIV

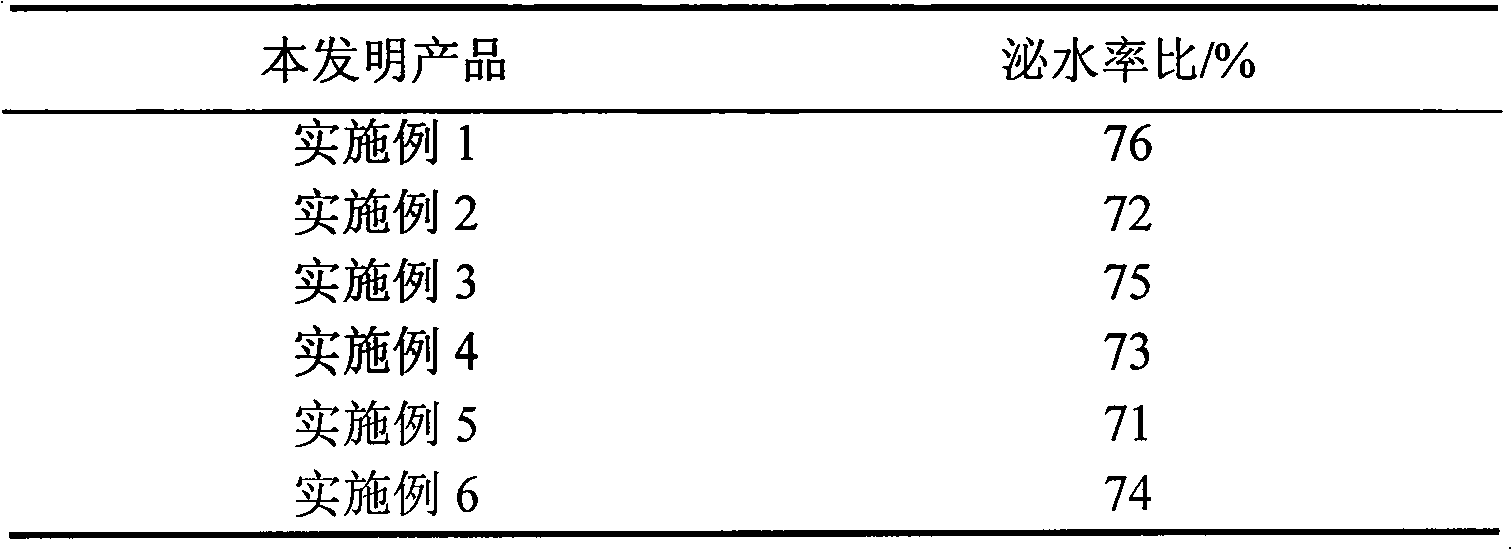

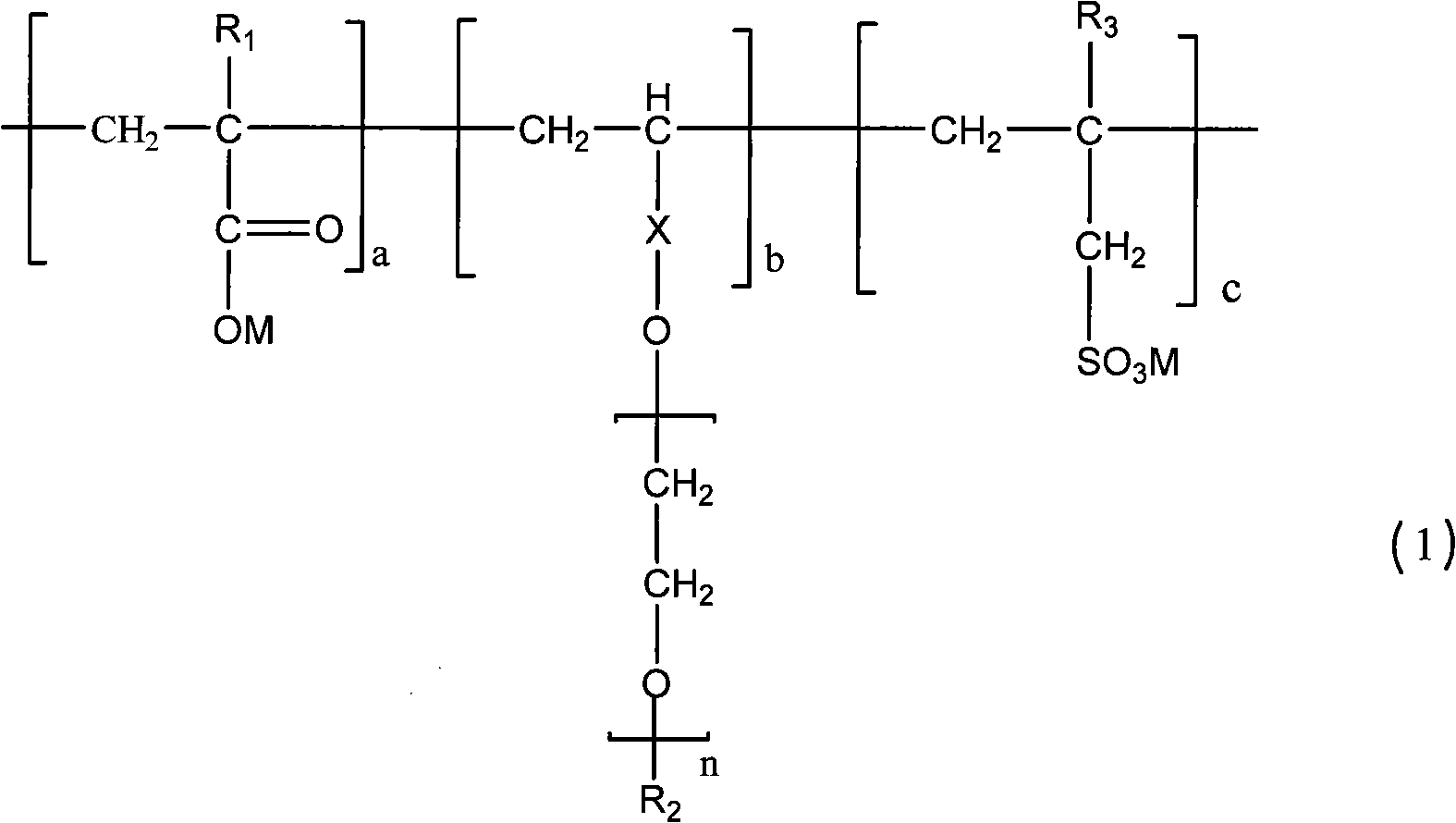

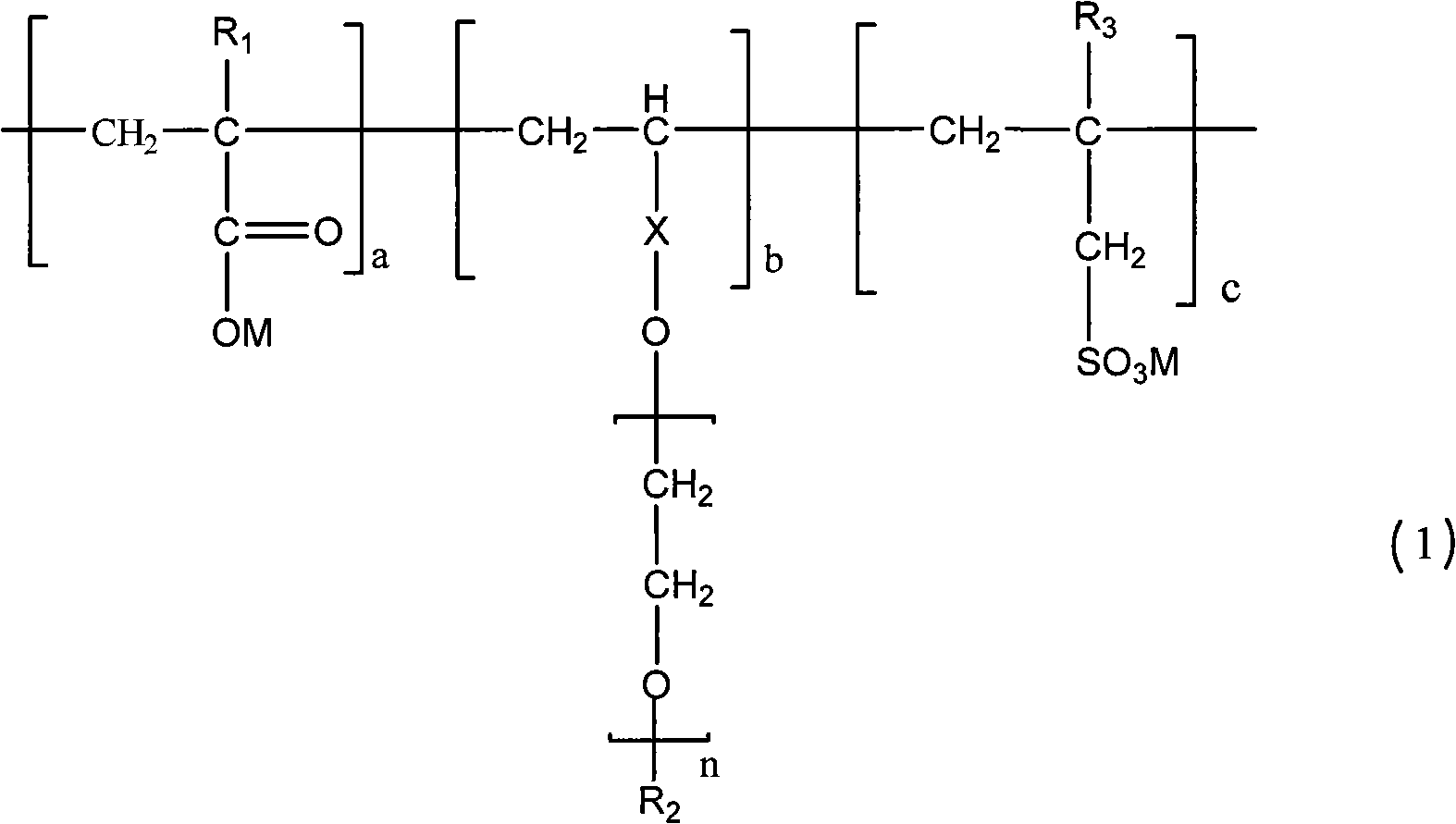

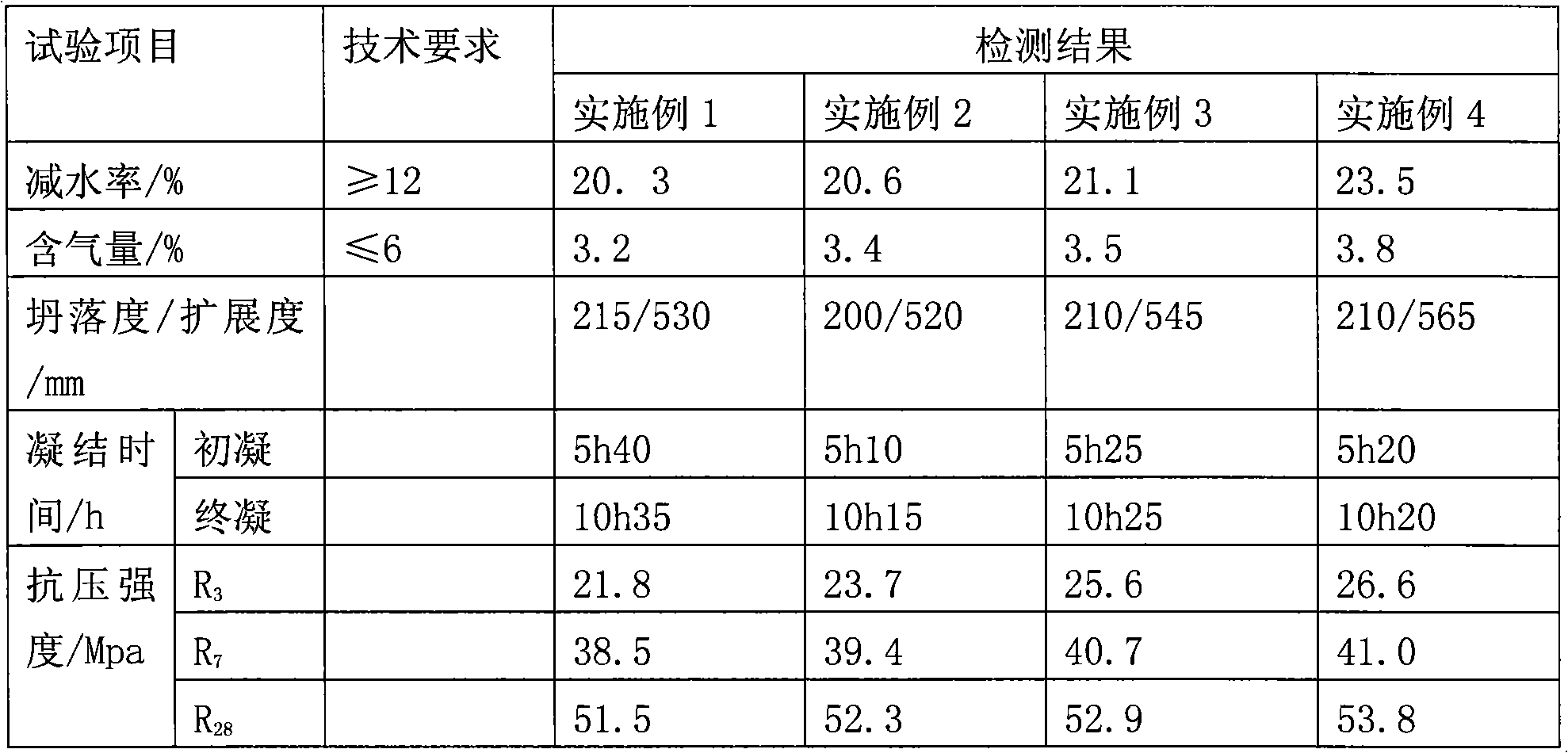

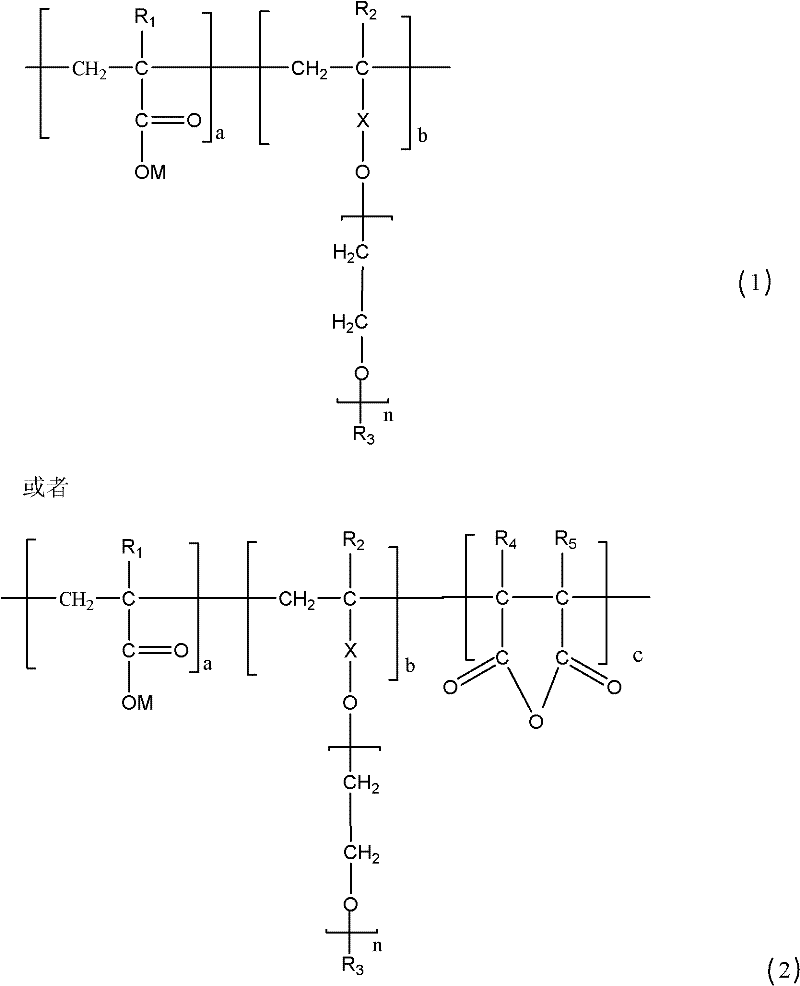

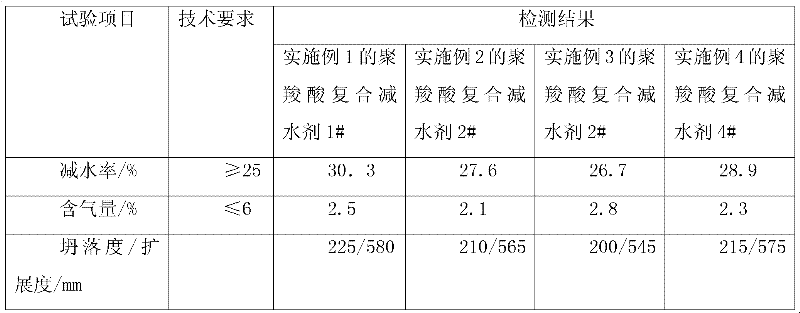

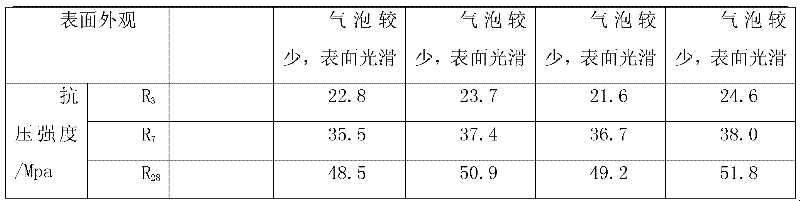

Polycarboxylate composite water reducing agent suitable for low-cementitious material concrete and preparation method thereof

The invention relates to a polycarboxylate composite water reducing agent suitable for low-cementitious material concrete and a preparation method thereof. The polycarboxylate composite water reducing agent suitable for the low-cementitious material concrete is characterized by comprising the following components in percentage by mass: 15 to 25 percent of polycarboxylic high-performance water reducing agent, 1 to 5 percent of retarder, 0 to 0.10 percent of defoaming agent, 0.01 to 0.3 percent of air entraining agent, 0.3 to 0.5 percent of preservative and the balance of water, wherein the mass solid content of the polycarboxylic high-performance water reducing agent is 40 percent. The polycarboxylate composite water reducing agent is applied to the concrete, and has the water reducing rate over 20 percent by comparing the concrete with reference concrete; and the prepared concrete has the advantages of good workability, no dissociation or bleeding, and good freezing resistance and infiltration resistance, and can be used for preparing concrete with various strength grades between C20 and C40.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Composite roller for high vanadium high speed steel and its production process

The invention offers the high V super-speed steel complex roller and its producing craft. The roller includes roller heart and roller shell, the roller heart uses low metal alloy steel or middle carbon steel to produce, the shell uses high V super-speed steel, whose main element is : C: 1.8--3.5A%, V: 7--12%, Cr: 4--5%, Mo: 2--4%, Ni: 0.5--1.5%, other is Fe. The producing craft is: melt and cast the heart and shell by responding heat way. The roller in the invention has good whet feature, high rate of feature and price, using safely. Fine roller, high strength of combination, no crush in use; it can reduce the stop times. It efficiently increase the roller tenacity and whet feature, solve the problems in the heart leaving foundry, and solve the problems of complicated craft and high cost.

Owner:HENAN UNIV OF SCI & TECH +1

Tail sealing grease for shield tunneller

The invention discloses a sealing grease for a shield tail of a shield tunneller, which comprises by weight the following components: basic oil 17.5-19 portions, thickener 8-15 portions, waterproof sealing material 58-65 portions, lubricant 1.5-3 portions, antioxidant 1-2 portions, anti-rust agent 0.5-1.5 portions, and tackifier 4-6 portions. The invention is of low cost, strong adhesion, good sealing performance, good pumping effect, environmental friendliness, good lubrication and steadiness, is resistant to aging and oxidation, free from separation and dry contracting during the quality warranty period of the product.

Owner:刘延鹏

Method for preparing polysilicon in high purity in use for solar cell

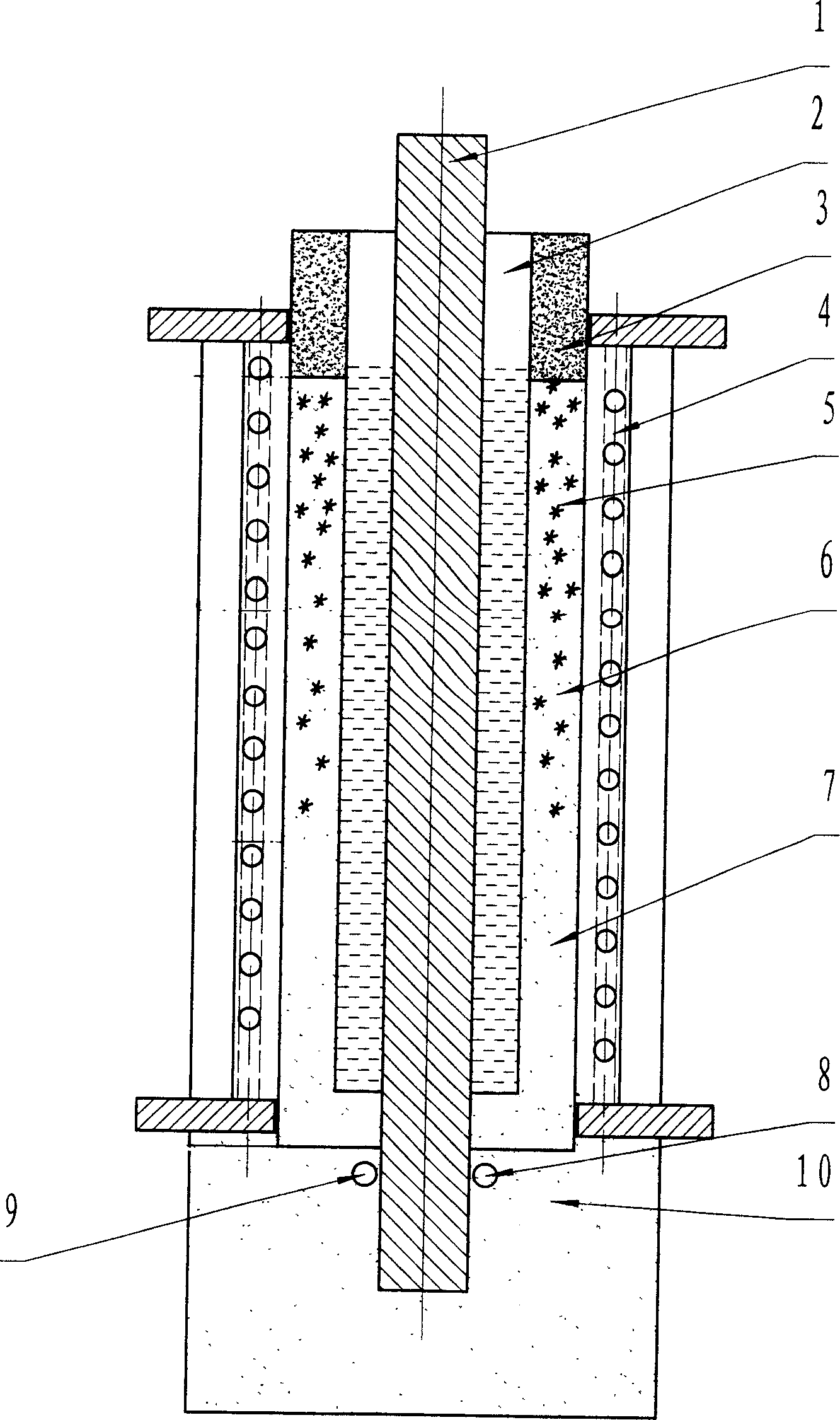

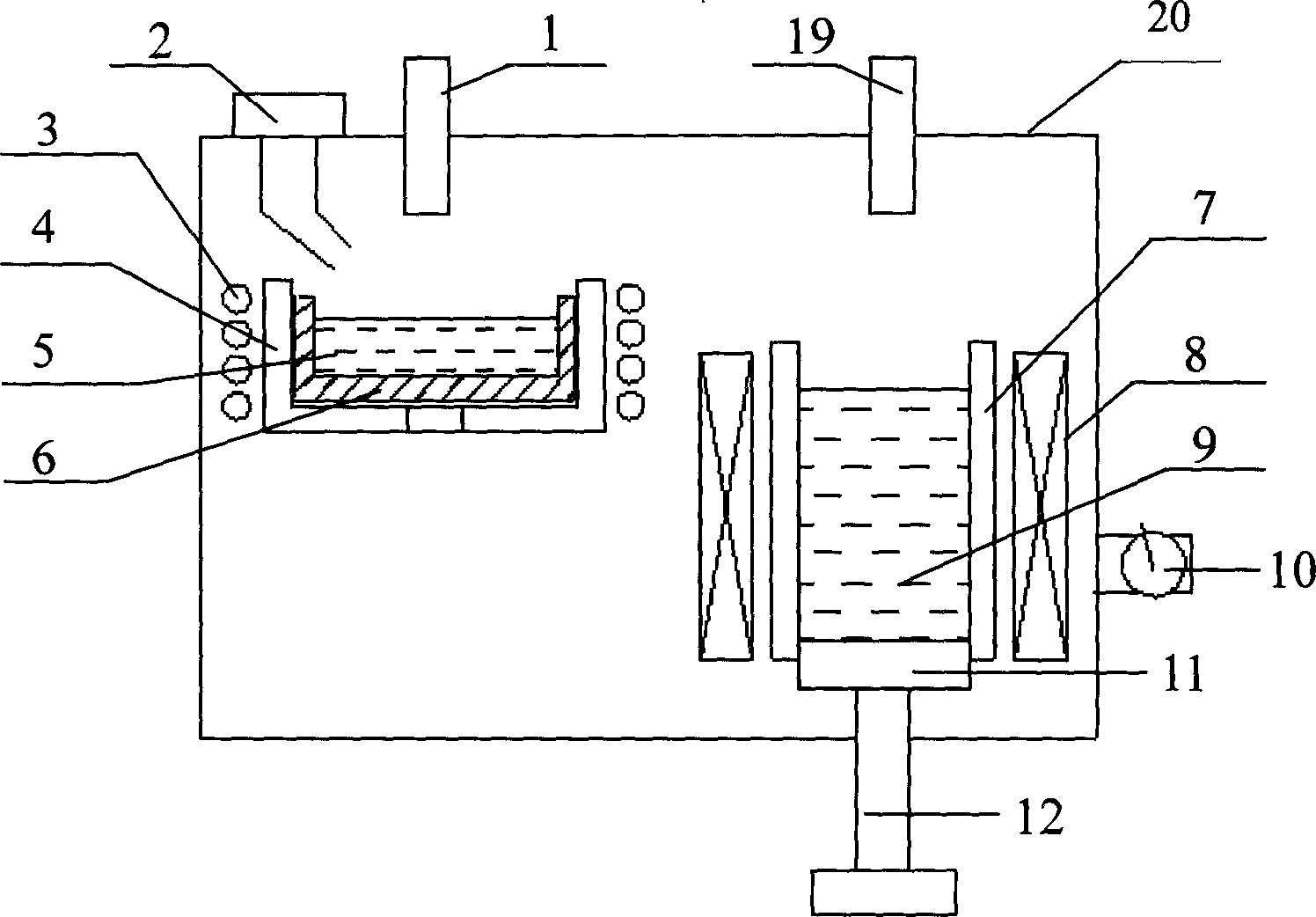

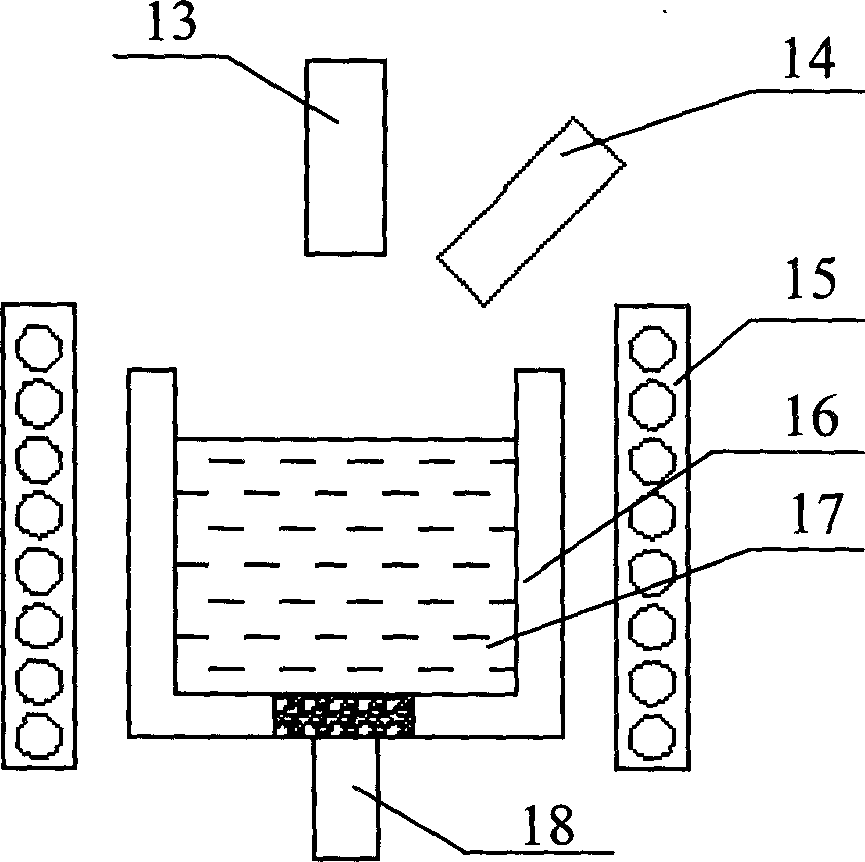

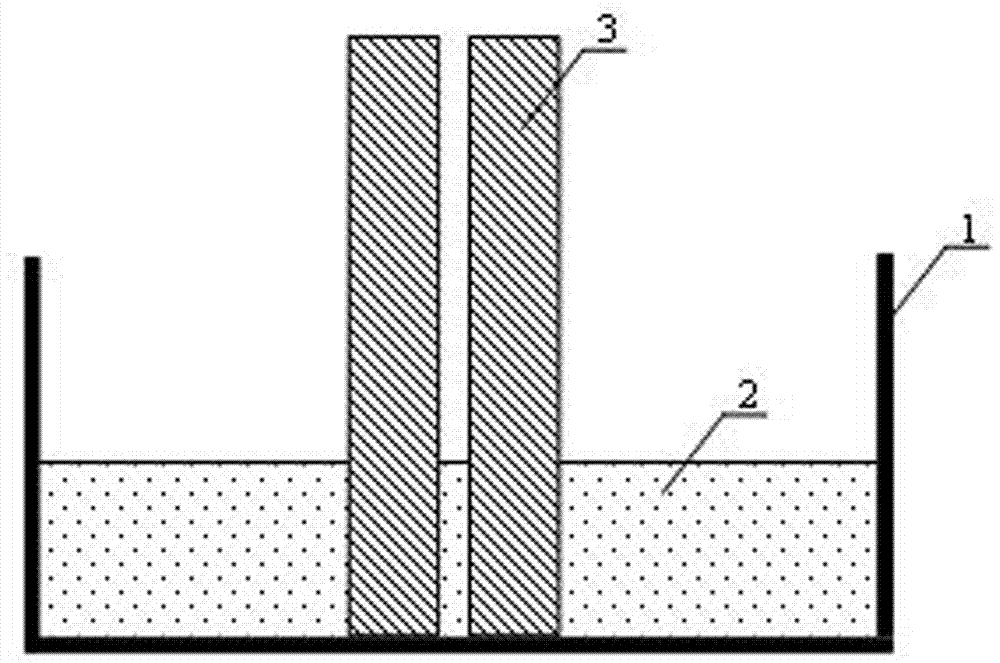

InactiveCN1873062ANo crackNo segregationPolycrystalline material growthSingle crystal growth detailsSemiconductor materialsElectromagnetic theory

This invention discloses method and device for preparing high purity polycrystalline silicon for solar cells. This invention combines vacuum electromagnetic induction smelting, plasma oxidation and purification, and oriented-solidification to prepare high purity silicon ingots for solar cells. The method comprises: (1) applying an alternative electromagnetic field (Q is J2 / sigma) at the outer side of solid silicon according to electromagnetic theory; (2) smelting to remove impurities such as P in liquid silicon according to chemical equilibrium theory; (3) performing oriented-solidification according to metal solidification theory that the elements whose equilibrium distribution coefficients are less than 1 can be enriched at the last solidification site, and thus discharged from the liquid. This invention has such advantages as simple equipment, rapid and convenient smelting and purification, uniform solidification, no cracking, no segregation.

Owner:DALIAN UNIV OF TECH

Ultrahigh-strength concrete and preparation method thereof

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

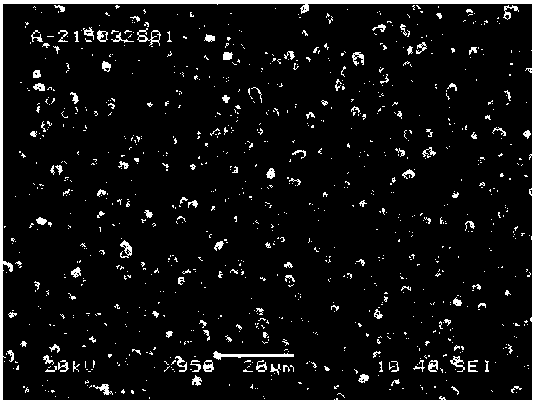

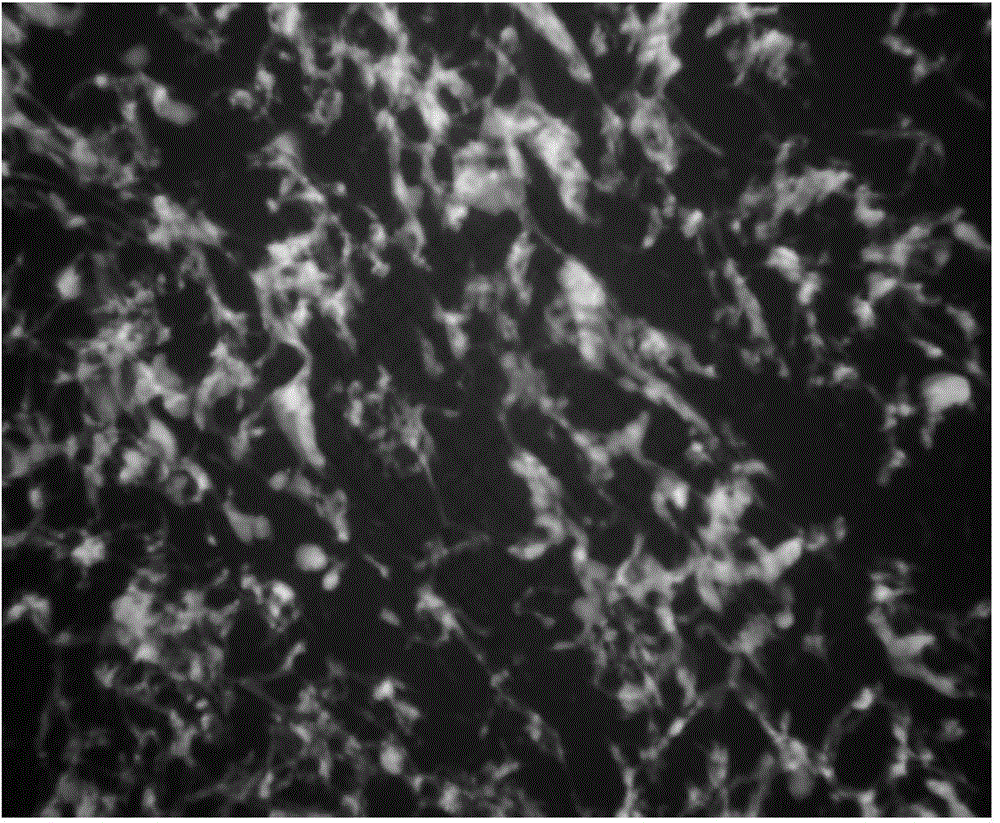

Preparing method for fine sheet metal magnetically soft alloy powder

ActiveCN104858441AImprove permeabilityHigh strengthInorganic material magnetismMicrometerGranularity

The invention relates to a preparing method for fine sheet metal magnetically soft alloy powder and belongs to the technical field of metal and alloy powder preparation. The method comprises the steps that two or three of Fe, Si, Al, Ni and Mo are selected as raw materials to carry out alloy distributing; a medium-frequency induction furnace is adopted for carrying out alloy smelting; a two-flow atomization method is adopted for carrying out atomizing on a melt, and alloy powder approximately spherical is prepared; by means of mechanical milling, flattening is carried out on the alloy powder; annealing treatment is carried out on the obtained sheet powder, and by means of an ultrasonic vibrating sieve, the fine sheet metal magnetically soft alloy powder is prepared. The powder prepared through the method, the granularity ranges from 10 micrometers to 100 micrometers, the average thickness ranges from 0.1 micrometer to 5 micrometer, the radial thickness ratio ranges from 50 to 500, and the powder flattening rate reaches 90%. According to the method, the powder preparing process is simple, the production efficiency is high, the production cost is low, the quality of the magnetically soft powder core can be effectively improved, and the manufacturing cost is reduced.

Owner:有研增材技术有限公司

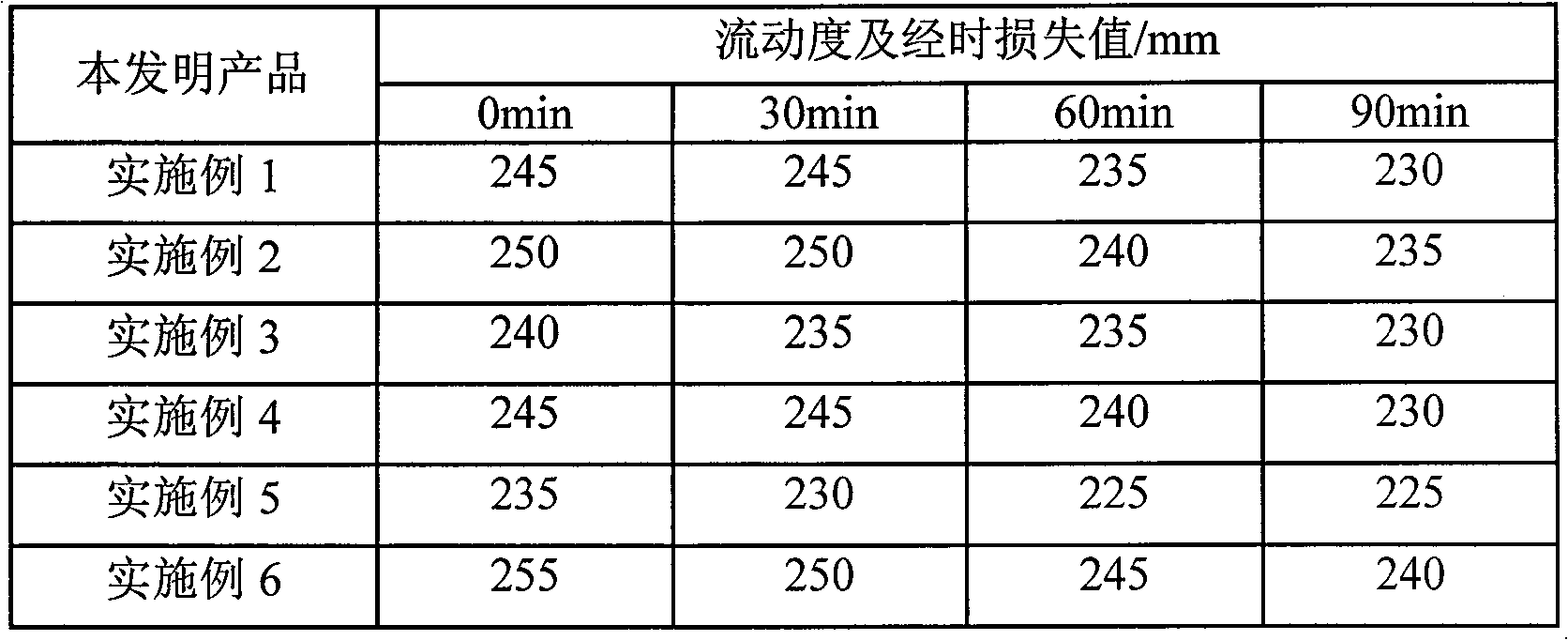

Composite polycarboxylic acid water reducing agent

The invention belongs to the technical field of concrete additives, in particular relates to a water reducing agent, and more particularly a composite polycarboxylic acid water reducing agent. The composite polycarboxylic acid water reducing agent is characterized by being prepared from the following components in percentage by mass: 8-28.6 percent of polycarboxylic acid high-performance water reducing agent, 0.5-7.36 percent of inhibiting agent, 0.001-0.15 percent of functional aid, 0.01-0.65 percent of preservative and the balance of water, wherein the total mass percentage of the components is 100 percent. The composite polycarboxylic acid water reducing agent is applied to freshly mixed concrete. After a template coated with waste engine oil or rosinate soap is dismantled, the surface of hardened concrete is smooth, air bubbles are reduced remarkably, and the construction requirement is fully met. By adopting the composite polycarboxylic acid water reducing agent, the problem of a large quantity of air bubbles on the surface of concrete, produced after the use of demolding agents such as waste engine oil or rosinate soap and the like is solved.

Owner:CHINA STATE CONSTR ENG CORP TIANJIN +1

Method for producing wear-resistant composite roller

InactiveCN101412105ANo crackingImprove bindingRollsMetal rolling arrangementsInterference fitSurface layer

The invention relates to a method for manufacturing a wear resistant composite roll, which belongs to the technical field of steel rolling. The most difficult problems in the technology transfer of the prior combined composite roll are the improvement on the processability of an outer-layer roll sleeve and the improvement on the processing efficiency. The method comprises the following steps: opening a groove on the outer surface of a roll collar inner sleeve, washing the roll collar inner sleeve by using diluted hydrochloric acid and alcohol, then painting borax on the surface of the roll collar inner sleeve and in the groove, and air-drying the roll collar inner sleeve and placing the roll collar inner sleeve in a casting mould; pouring outer layer wear resistant molten metal through a bottom pouring method to obtain an imbedded composite roll sleeve; and combining the imbedded composite roll sleeve with a cast steel or forged steel rolling shaft through splines and integrating the imbedded composite roll sleeve and the cast steel or forged steel rolling shaft through interference fit so as to obtain the wear resistant composite roll. The composite roll has the advantages of high hardness for the outer surface layer, good wear resistance, high roll core strength, good tenacity, firm combinations between the roll sleeve and the roll core and between the roll sleeve outer surface layer and the roll collar inner sleeve and the like.

Owner:BEIJING UNIV OF TECH

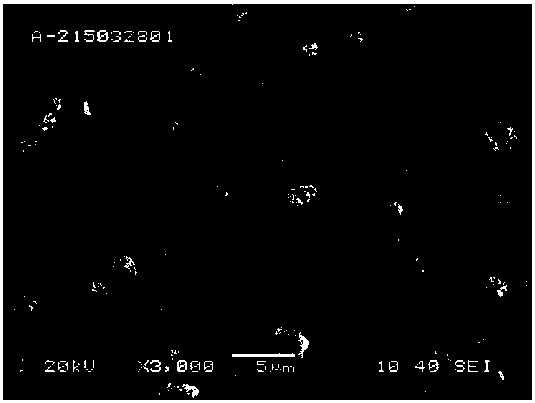

High-density and small-particle size nickel-cobalt-manganese hydroxide and preparation method thereof

InactiveCN107640792AHigh density and small tap densityLow tap densityCell electrodesSecondary cellsHigh densityManganese

The invention discloses a high-density and small-particle size nickel-cobalt-manganese hydroxide and a preparation method thereof. For the high-density and small-particle size nickel-cobalt-manganesehydroxide provided by the invention, a general chemical formula is NixCoyMnz(OH)2, wherein x+y+z=1, x is larger than or equal to 0.3 and smaller than or equal to 0.8, y is larger than or equal to 0.1and smaller than or equal to 0.4, and z is larger than or equal to 0.1 and smaller than or equal to 0.4; the particle sizes are d10 larger than or equal to 2 microns, d50 equal to 2.5-4 microns and d90 smaller than or equal to 6 microns, the tap density is larger than or equal to 1.4g / cm<3>, the specific surface area is 5-20m<2> / g, and the shape is spherical or spheroidal. The invention also discloses the preparation method of the high-density and small-particle size nickel-cobalt-manganese hydroxide. The preparation method is strong in controllability, can stably control the particle sizes ineach production batch without using a surfactant and is low in production cost, high in efficiency and good in physicochemical index of a final product.

Owner:ZHUJI PAWA NEW ENERGY

Preparation method of silicon-aluminium alloy hollow rotary target for vacuum sputtering coating

InactiveCN102352483AUnique Semiconductor PropertiesImprove matchVacuum evaporation coatingSputtering coatingSputteringSilicon

The invention discloses a preparation method of a silicon-aluminium alloy hollow rotary target for vacuum sputtering coating. The method comprises the following flows: mixing silicon powder and aluminum powder as raw materials, charging, performing high-vacuum heating for degassing and sealing welding, performing hot isostatic pressing and machining and obtaining the finished product. The method is a technology capable of obtaining the high-quality silicon-aluminium alloy hollow rotary target; and the method has the advantages that technological parameters can be controlled easily, technological process is short, product yield is high and raw material utilization rate is high. The prepared silicon-aluminium alloy target has wide application prospect in functional plating and decoration coating.

Owner:METALINK SPECIAL ALLOYS CORP

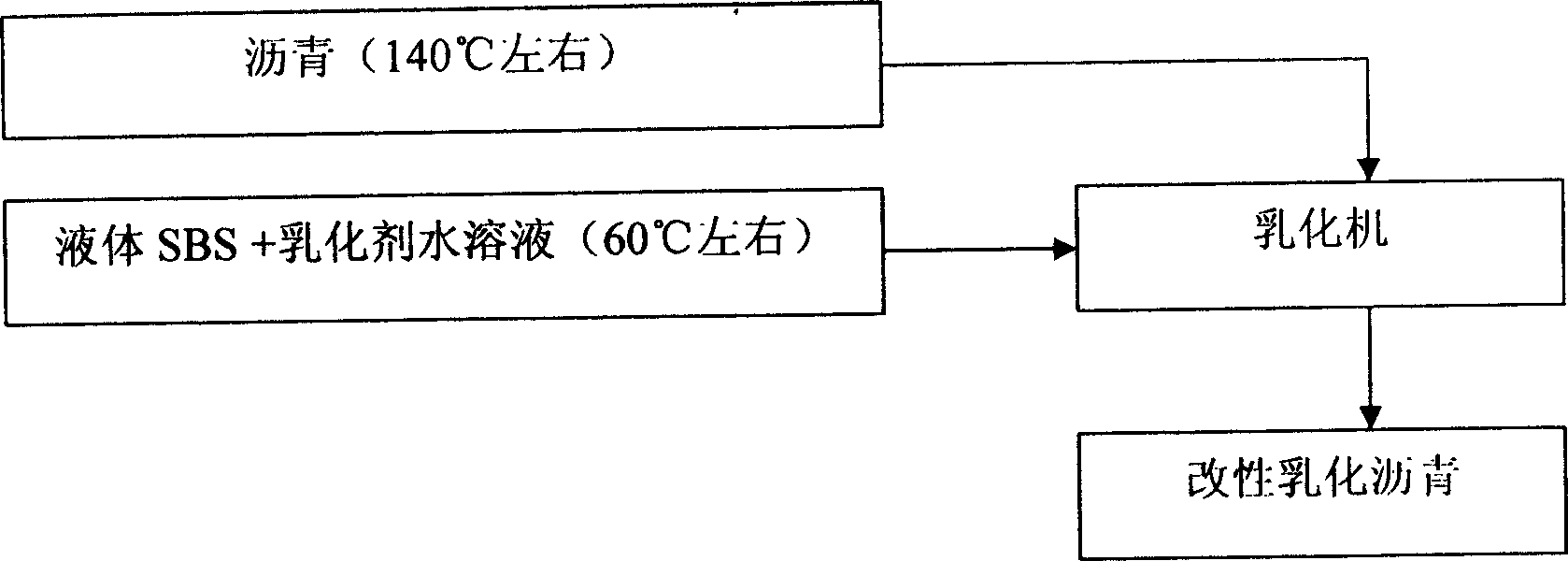

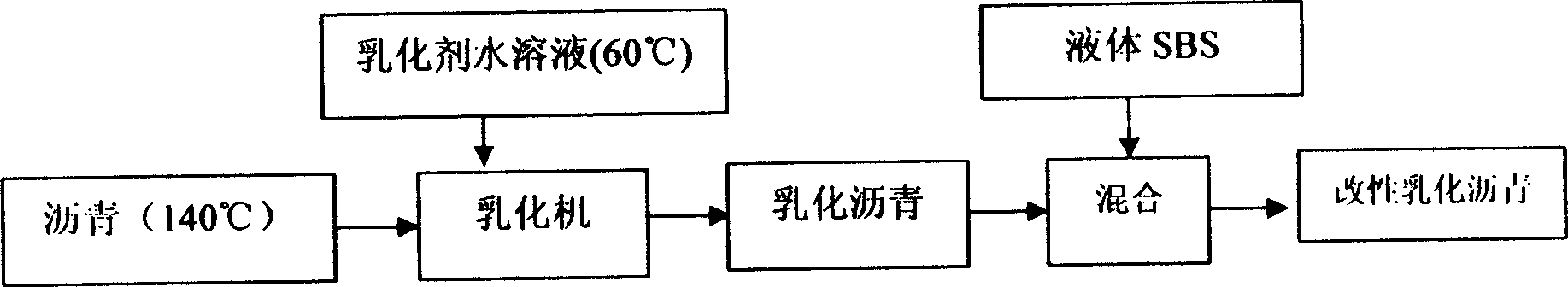

Manufacturing method of liquid asphalt modifier

A liquid asphalt modified able to be directly sprayed into asphalt at the road construction site is prepared from solid SBS through dissolving it in organic solvent, adding surfactant and water, emulsifying, and recovering organic solvent from SBS emulsion.

Owner:SHANXI PROVINCIAL RES INST OF COMM

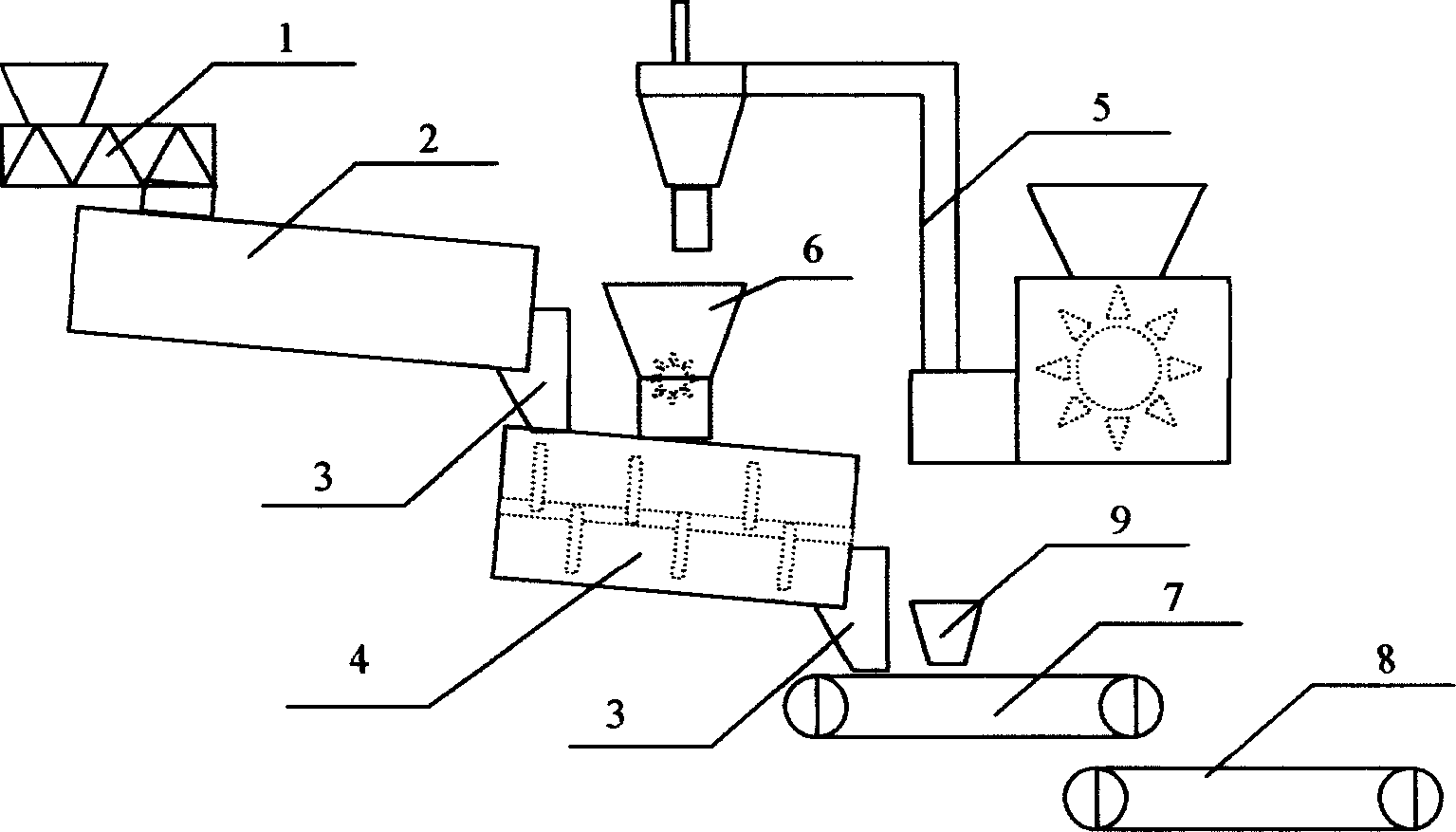

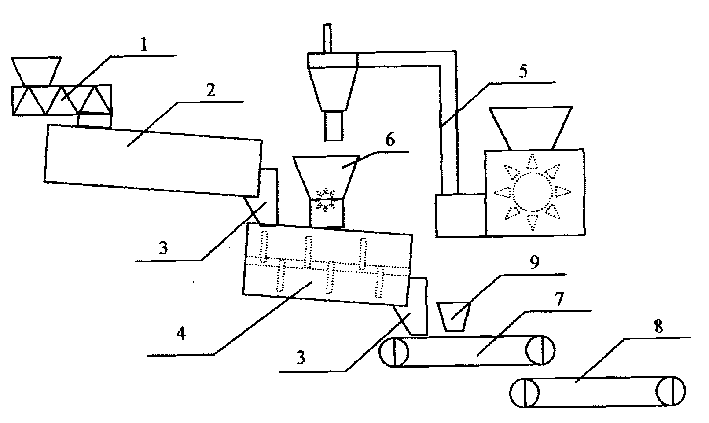

Waste plastic processing method for increasing coke strength and its apparatus system

The invention publishes a kind of process method of plastic waste to improve coke's intensity and the setting system. It relates to technique and setting of plastic waste. The characteristic of process method of the plastic waste follows this. teat the plastic waste by hot-melt method and then carbonize it with coal blending by special ratio to improve the quality of coke. The setting system is composed by feedway, breaking plant, heat flux plant, hot-melt plant, carrying vehicle and coking and coal blending mixing device. The invention's advantage rest with that many complicated working processes are not needed such as air sizing and graining because of hot-melt process. It can solve the problem that mixture of plastic and coal liquating is not odds and can reduce or eliminate the use of additives. So the quality of coke can be improved by plastic waste or additives and the the working cost and operating cost can be reduced by far.

Owner:SHOUGANG CORPORATION

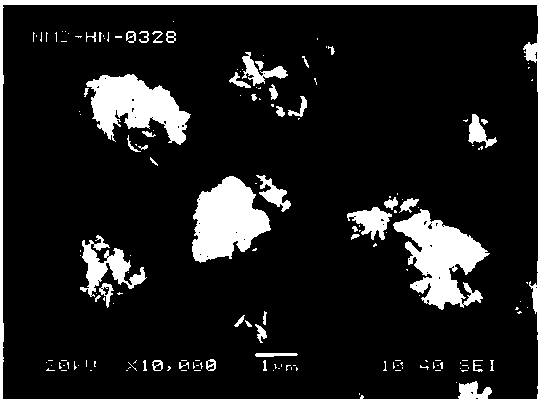

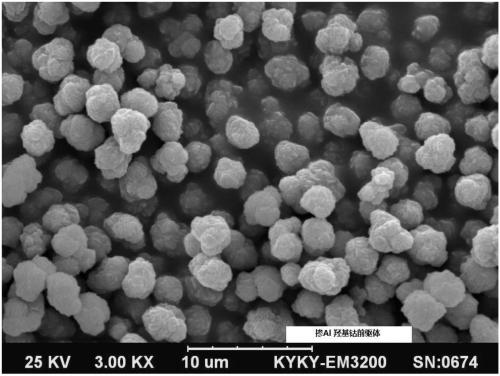

Preparation method of small-particle-size uniform-aluminum-doped spherical tricobalt tetraoxide

ActiveCN109354075ASolve segregationGuaranteed repair and growthCell electrodesSecondary cellsGranularityCobalt(II,III) oxide

The invention relates to a preparation method of a lithium ion battery positive electrode material precursor, in particular to a preparation method of small-particle-size uniform-aluminum-doped spherical tricobalt tetraoxide. The preparation method includes following steps: 1, adding soluble aluminum salt and EDTA disodium into a cobalt salt solution to prepare a cobalt-aluminum mixed salt complexsolution; 2, injecting pure water into a reaction kettle to serve as base liquid, blowing in air, adding a small amount of sodium hydroxide solution to adjust pH, and rising temperature; 3, adding the cobalt-aluminum mixed salt complex solution and the sodium hydroxide solution into the reaction kettle for settling reaction while stirring; 4, sampling every 2h to measure granularity till reaching2-5um after more than 40h of reaction, and filtering and washing a material after the granularity reaches a target value; 5, thermally decomposing aluminum-doped hydroxyl cobalt after being washed sectionally to finally obtain small-particle-size uniform-aluminum-doped spherical tricobalt tetraoxide with uniform distribution of aluminum from inside to outside, tricobalt tetraoxide is compact andadhesion-free spherical particles in morphology, tap density is 2.0-2.7g / cm3, and laser granularity distribution is narrow.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

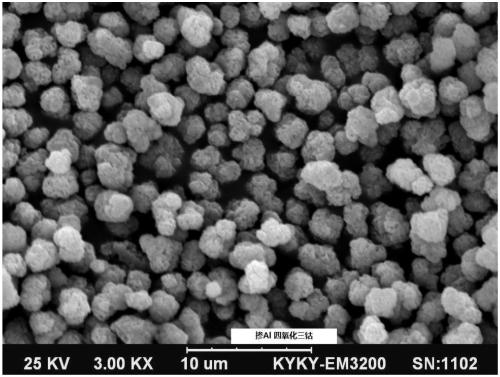

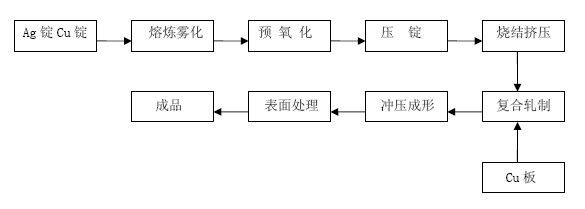

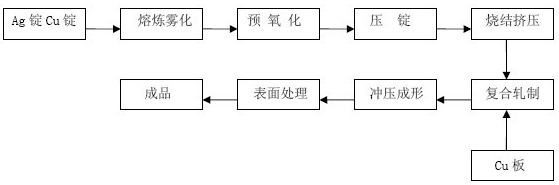

Silver copper oxide/copper composite electrical contact material and preparation process thereof

ActiveCN102054598AGuaranteed uniformityGrain refinementContactsMetal rolling arrangementsCopper oxideHigh pressure water

The invention discloses a silver copper oxide / copper composite electrical contact material and a preparation process thereof. The process comprises the following steps: mixing silver and copper according to certain proportions, and then, smelting the mixture in an intermediate frequency furnace; then, carrying out alloy atomization by using high pressure water atomizing equipment; baking after atomization to obtain powder; screening; putting the screened powder into an internal oxidization furnace for oxidizing at certain temperature and oxygen pressure; carrying out isostatic cool pressing after oxidization to form a billet; sintering and extruding to form a plate; and then, carrying out composite rolling with copper to obtain a finished product. Because the formula and process disclosed by the invention are reasonable, the produced electrical contact has the characteristics of high conductivity, uniform and fine tissue, high bonding strength between a working layer and a welding layer, fusion welding resistance, electrical arc erosion resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

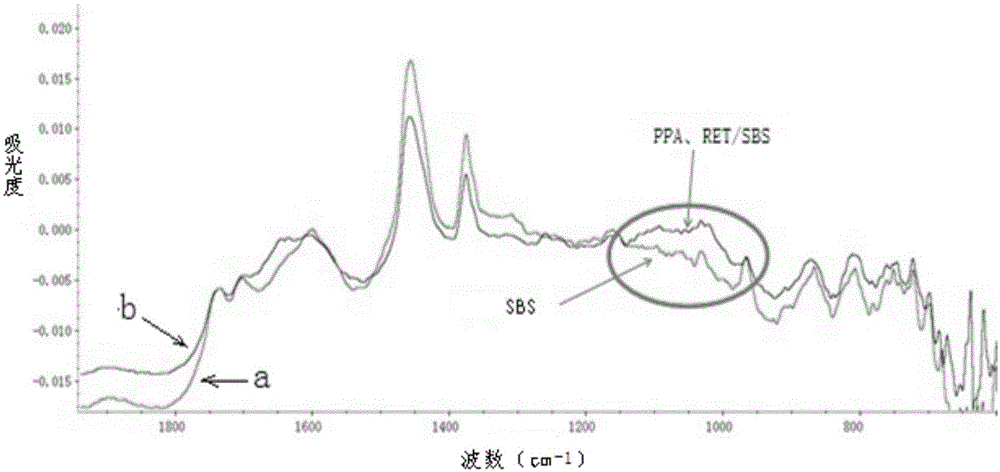

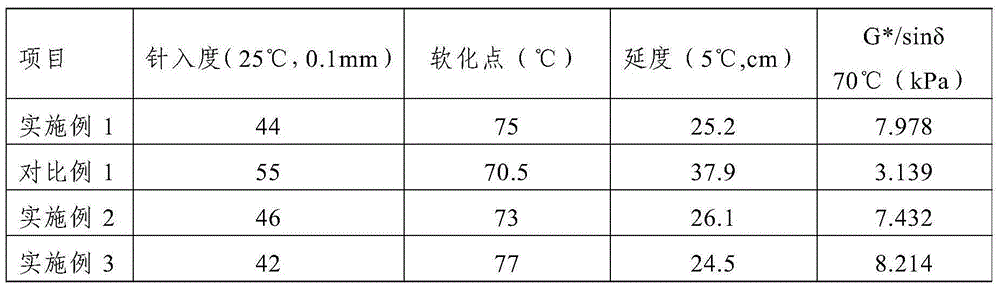

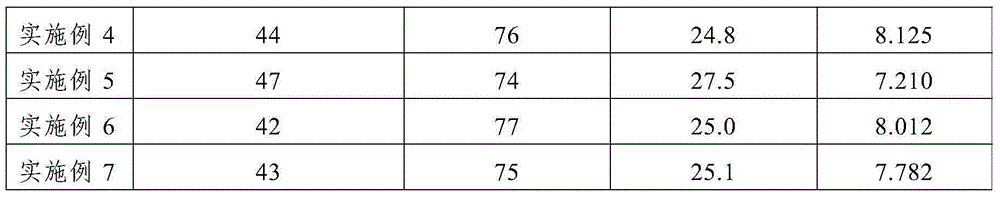

SBS modified asphalt and preparation method thereof

ActiveCN105038280AGood storage stabilityImprove stabilityBuilding insulationsPhosphoric acidHeat stability

The invention discloses SBS modified asphalt. The SBS modified asphalt is prepared with, by weight, 100 parts of matrix asphalt, 2.0-3.5 parts of SBS asphalt modifier, 1-2 parts of RET asphalt modifier, 0.2-0.5 part of polyphosphoric acid, 3-4 parts of compatilizer and 0.1-0.15 part of stabilizer. In addition, the invention further discloses a method for preparing the SBS modified asphalt. The method comprises the steps of 1, heating the matrix asphalt, adding the matrix asphalt into the compatilizer, stirring the mixture uniformly, and obtaining mixed materials; 2, adding the SBS asphalt modifier and the RET asphalt modifier into the mixed materials, stirring the mixture uniformly, conducting cutting, adding the stabilizer, continuing cutting, adding polyphosphoric acid, stirring the mixture uniformly, and obtaining the SBS modified asphalt. The SBS modified asphalt is chemical stabilization type SBS modified asphalt, great high temperature performance and anti-track performance are achieved, and the heat stability of the SBS modified asphalt is superior to that of traditional SBS modified asphalt.

Owner:CHANGAN UNIV

C / C-SiC composite material and preparation method and application thereof

ActiveCN107266075AConsistent performanceHigh hardnessFriction liningActuatorsCompression moldingFiber

The present invention discloses a C / C-SiC composite material and a preparation method and application thereof. The C / C-SiC composite is a multilayer symmetrical gradient structure, the symmetrical multilayer gradient structure comprises from the inner layer to the outer layer in turn a middle layer, a longitudinally-symmetrical second layer short-cut carbon fiber reinforced silicon carbide layer and a longitudinally-symmetrical first layer short-cut carbon fiber reinforced silicon carbide layer, the carbon fiber content of the first layer short-cut carbon fiber reinforced silicon carbide layer is lower than that of the second layer short-cut carbon fiber reinforced silicon carbide layer, and the middle layer is a 90 DEG and 45 DEG plain carbon fiber cloth interlaced superposed reinforced toughened interlayer. The C / C-SiC composite is prepared from short-cut carbon fiber, plain carbon fiber cloth, phenolic resin and industrial silica fume as raw materials by compression molding, curing, carbonization and infiltration. Products prepared by the C / C-SiC composite material have high density, excellent mechanical property, oxidation resistance, friction and wear resistance and fatigue resistance, and are suitable for the fields of high end industries such as high speed and high energy transportation vehicles.

Owner:HUNAN UNIV OF TECH

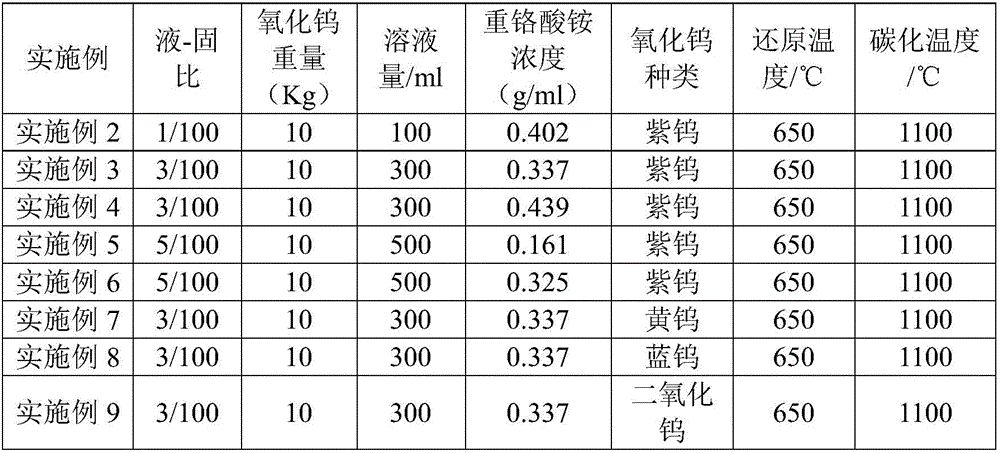

Method of preparing chromium-containing ultrafine WC powder through solid-liquid doping method

The invention discloses a method of preparing a chromium-containing ultrafine WC powder through a solid-liquid doping method. The method successively includes the steps of: preparing an ammonium dichromate solution; adding a certain amount of the ammonium dichromate solution to tungsten oxide powder, mixing the components to achieve solid-liquid mixing doping; performing hydrogen reduction, carbon blending, carbonization, cooling, ball milling and sieving to obtain the chromium-containing ultrafine WC powder. The method solves technical problems of non-uniform distribution, large granularity and unsatisfactory effect of inhibiting increase of granularity of WC grains of distribution of Cr3C2 in ultrafine WC powder and hard alloy. When the mixed powder is used for preparing the ultrafine hard alloy, the Cr3C2 has more significant effect of inhibiting the increase of granularity of carbonization grains than a conventional method.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Wet process for building 3t intermediate frequency electric furnace

The invention relates to a wet process for building a 3t intermediate frequency electric furnace. By the process, 3t of materials can be melted, and the service life is prolonged. The process comprises the following steps of: (1) manufacturing a steel crucible die which has a shape of a truncated hollow cone; (2) paving an insulation layer and a thermal insulation layer by using two layers of asbestos cloth; (3) paving a furnace bottom, namely paving two layers of asbestos cloth at the furnace bottom in a staggered mode; (4) paving a furnace wall, namely paving two layers of asbestos cloth next to the inner wall of an induction coil from top to bottom, ensuring that each layer is flat and does not have any wrinkle, adhering longitudinal joints for lapping by using water glass, staggering joints of two adjacent layers, and adhering the asbestos cloth which stretches out of the upper plane to a fireproof brick plane at an upper opening of the furnace by using the water glass; (5) preparing a furnace lining material from refined quartz sand; (6) manually knotting a furnace lining, brushing a layer of water glass before filling, and tamping a filler; and (7) baking the furnace and sintering, namely baking only by using firewood after the furnace is built by the wet process, adding 50 to 60kg of firewood into a hearth for several times, and completely combusting to bake the furnace lining.

Owner:HANGZHOU ZHONGQIANG ROLLER

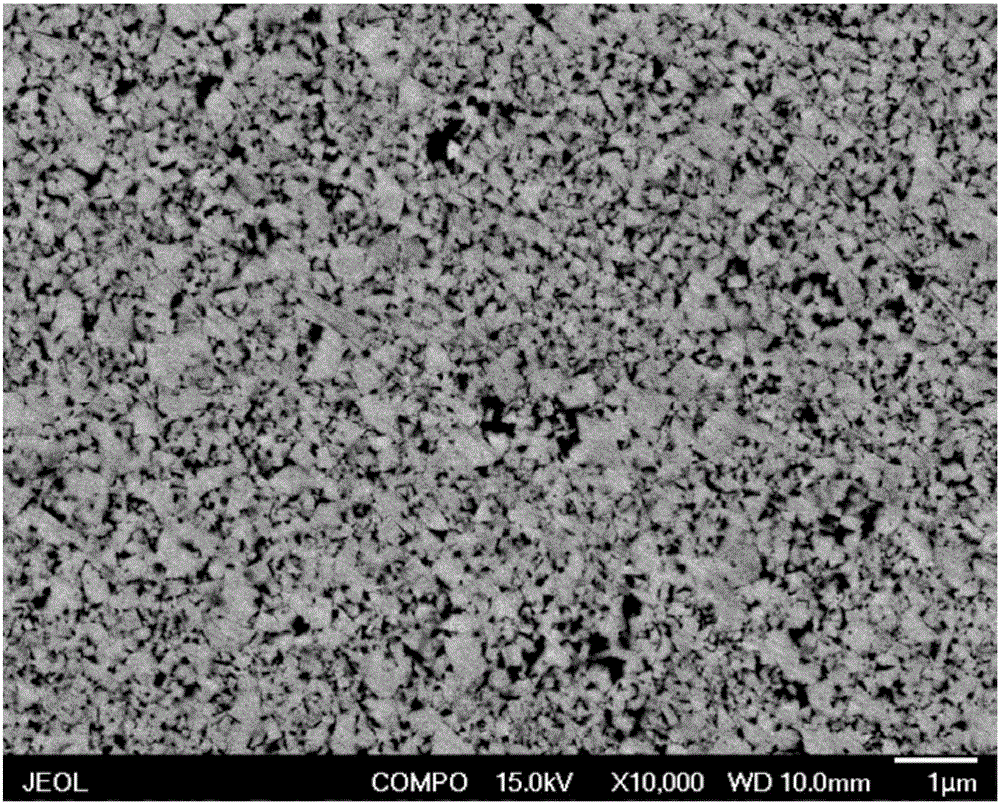

Preparation method of molybdenum-niobium alloy sputtering target

ActiveCN105441884AEasy to prepareSave raw materialsVacuum evaporation coatingSputtering coatingHot isostatic pressingSurface grinding

The invention discloses a preparation method of a molybdenum-niobium alloy sputtering target. The method comprises the following steps: (1) molybdenum powder and niobium powder are put in a mixing tank of a mixing machine for uniformly mixing to obtain mixed powder; (2) the cold isostatic pressing is performed for the mixed powder to obtain a slab; and the slab is pre-sintered under the vacuum or hydrogen atmosphere protection condition to obtain a molybdenum-niobium alloy prefabricated blank; (3) the surface of the molybdenum-niobium alloy prefabricated blank is turned and milled; and the hot isostatic pressing is performed to obtain a molybdenum-niobium alloy part; and (4) the mechanical processing and the surface grinding are performed for the molybdenum-niobium alloy part to obtain the molybdenum-niobium alloy sputtering target. The preparation method is simple in process, and saves raw materials; the introduction of impurity elements can be reduced in the preparation process; the prepared molybdenum-niobium alloy sputtering target is uniform in components, free of segregation and fine in grains; the theoretic density can reach above 99%; the oxygen mass content is lower than 500 ppm; and the requirements of the sputtering target can be preferably satisfied.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Thermal-storage-stabilized rubber-powdery asphalt composition and its preparation

ActiveCN1896143AStorage stableSolve compatibility and stability issuesBuilding insulationsAsphaltGrinding - action

A heat-stored stabilized rubber powder-asphalt composition and its production are disclosed. The composition consists of asphalt 65-95wt%, 1-30wt% rubber powder 1-30wt%, compatibilizer 0-30wt% and auxiliary 0.01-5wt%. The process is carried out by mixing asphalt with rubber powder and compatibilizer, reacting at 100-240degree under high-speed shear agitating or gel grinding action for 0.2-4hrs, adding into auxiliary and re-reacting for 0.3-6hrs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Super retarding concrete and application thereof

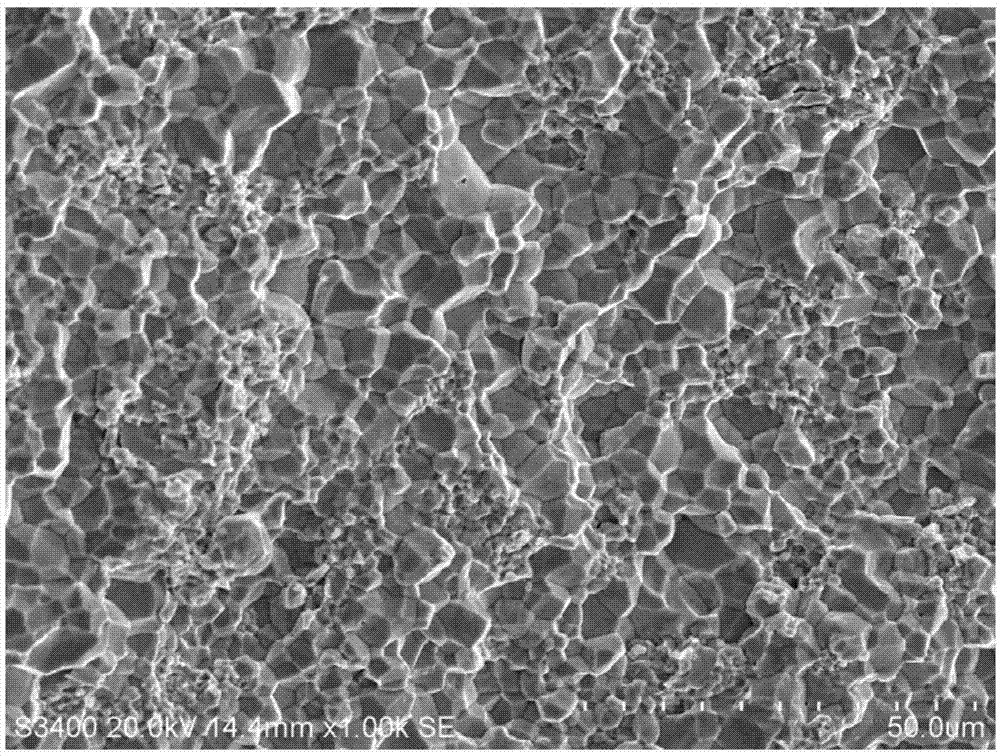

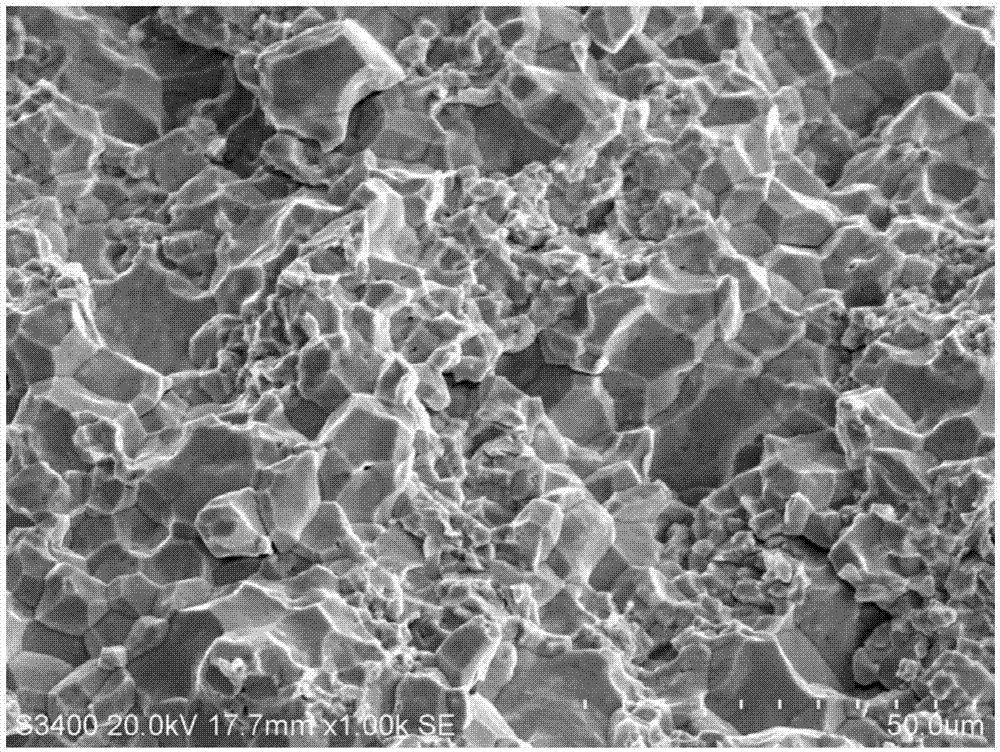

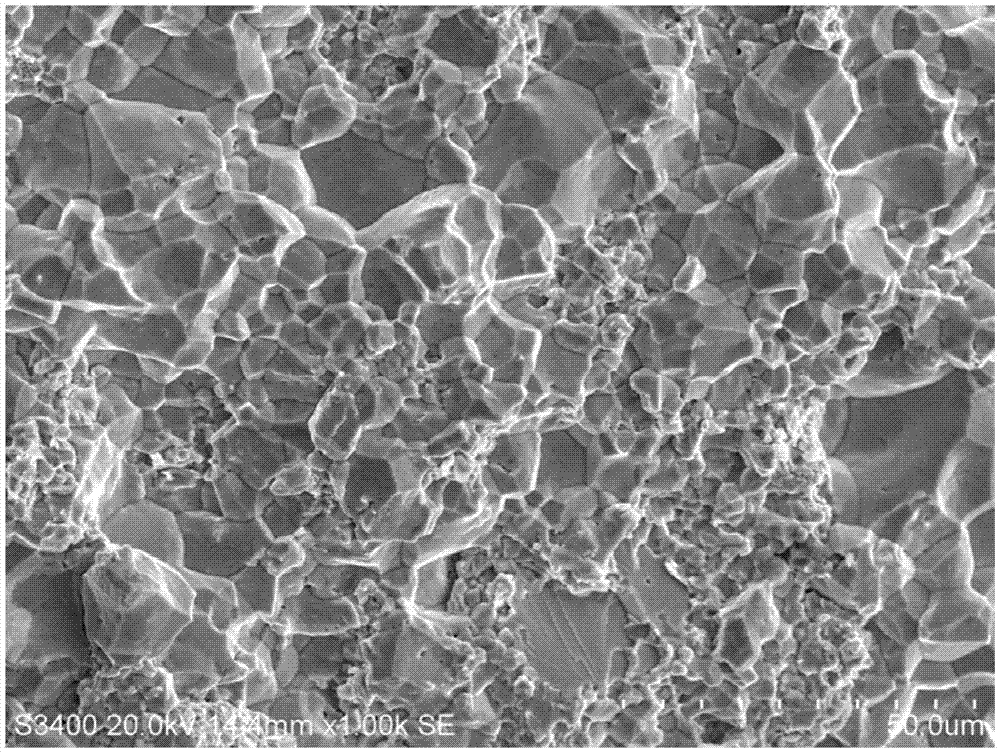

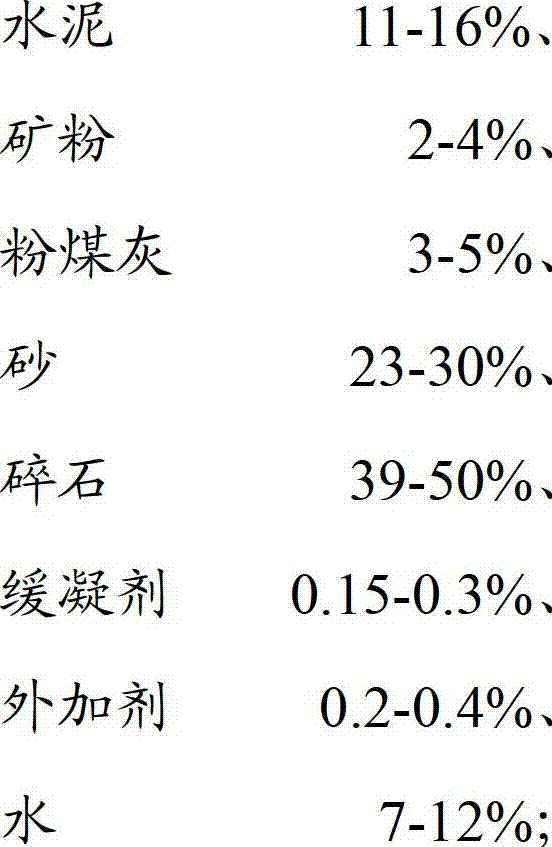

InactiveCN102924017ASufficient late strengthProlong clotting timeCrushed stoneUltimate tensile strength

The invention provides super retarding concrete which comprises the following components by weight percentage: 11-16 percent of cement, 2-4 percent mineral powder, 3-5 percent of coal ash, 23-30 percent of sand, 39-50 percent of crushed stone, 0.15-0.3 percent of retardant, 0.2-0.4 percent of additive and 7-12 percent of water, wherein the sum of the percentage contents of all components is 100 percent. The super retarding concrete greatly prolongs the setting time under condition of ensuring adequate long-term strength, has the advantages of good cohesiveness and water retention, and avoids segregation and bleeding phenomenon before or after being poured.

Owner:上海市建筑构件制品有限公司

Sliver-oxide ternary alloy electrical contact material and production method thereof

InactiveCN102747248AImprove electrical contact performanceImprove wear resistanceSolid state diffusion coatingElectric switchesWire rodLow voltage

The invention discloses a sliver-oxide ternary alloy electrical contact material and a production method thereof. The sliver-oxide ternary alloy electrical contact material comprises, by weight percent, 6%-24% of total ternary alloy oxides, 0.72%-5% of total added element oxides, and the balance of silver. The production method includes smelting the raw materials to obtain ingots by stepwise smelting process or atomizing to produce alloy powder; performing rolling and temperature differential oxidation, or high energy ball milling and temperature differential oxidation; and performing isostatic pressing to obtain primary ingots, subjecting the primary ingots to sintering, hot re-pressing and hot extrusion to obtain wires or strips, and thereby obtaining highly dispersible organizational structure with even and small crystal grains. The obtained material is high in conductivity, low in temperature rise, high in welding resistance, high in arc suppressing and high in electric corrosion resistance, electrical life is prolonged greatly, advantages of comprehensive property are highlighted, and the demands of high-end low-voltage electric appliances are fully met.

Owner:浙江乐银合金有限公司 +1

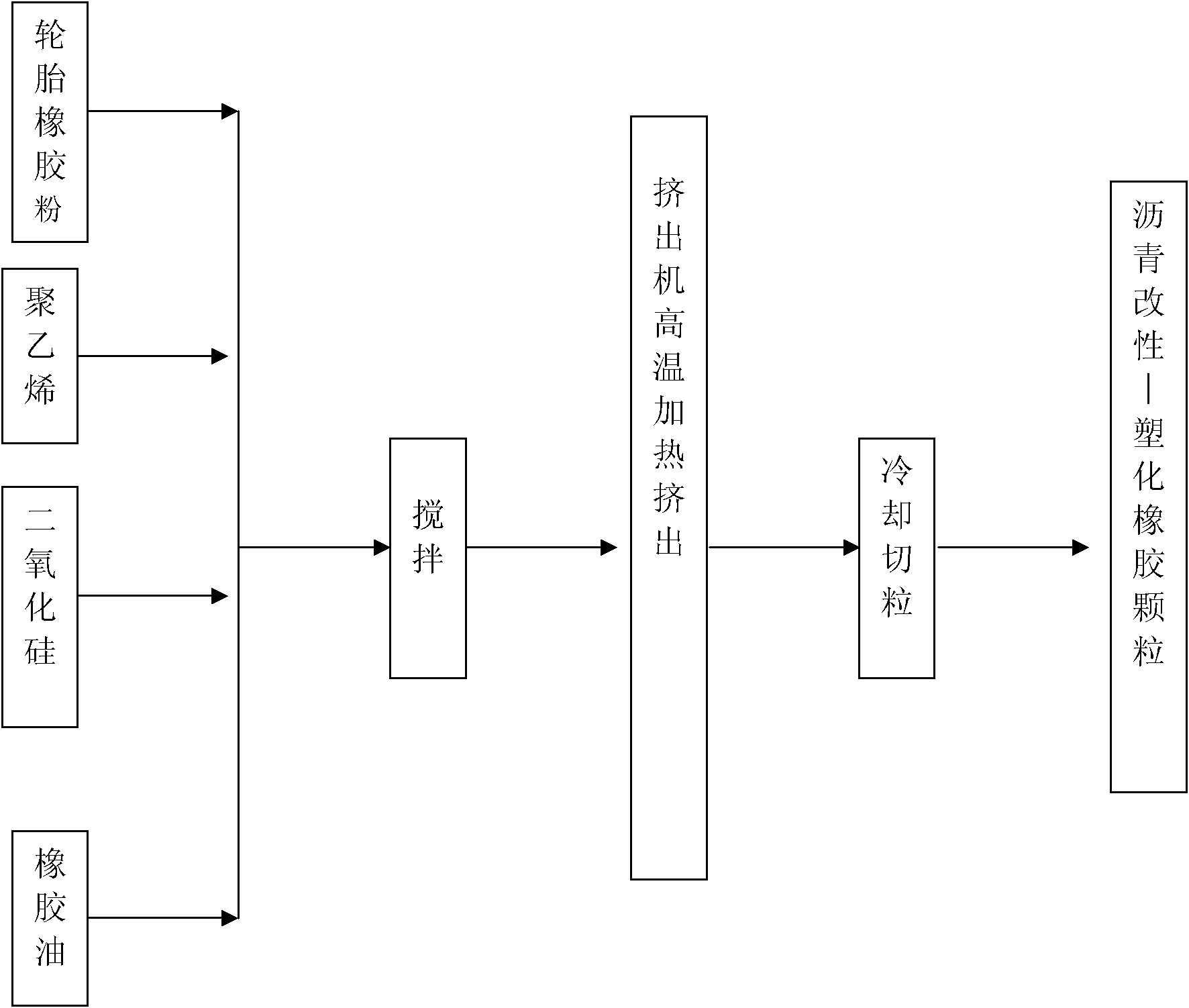

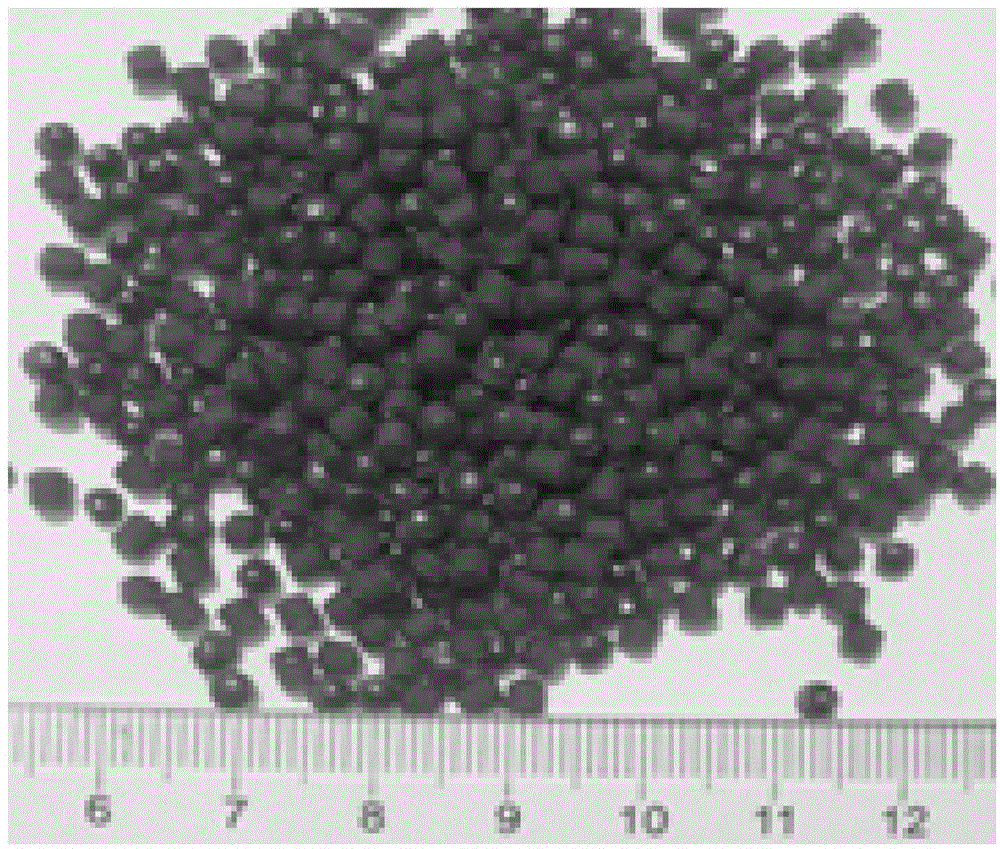

Asphalt modifier and preparation method thereof

InactiveCN101979440AGood compatibilityGood dispersionIn situ pavingsBuilding insulationsPolymer scienceSilicon dioxide

The invention aims to provide an asphalt modifier and a preparation method thereof, which overcome the disadvantages of nonuniform modification, serious pollution and hidden danger caused by adding rubber powder into asphalt and solve the technical problem of the modification and prefabrication of the rubber powder. The invention provides the asphalt modifier. The asphalt modifier is characterized by comprising the following components of: tire rubber powder, polyethylene, silicon dioxide and rubber oil, wherein the components are stirred, heated, extruded, cooled and cut to obtain plasticized rubber sticky particles, namely the asphalt modifier. The plasticized rubber sticky particle product of the invention greatly reduce high-temperature processing and pollution of rubber asphalt; the produced rubber asphalt sticky particles are a directly thrown type novel internal modification material and can be directly thrown into the asphalt and stones for mixing; and the asphalt modifier is odorless, can reduce secondary pollution, and has better meltability than that of rubber powder modified asphalt. The rubber asphalt particles are black sticky particles and are easy to package and transport.

Owner:无锡市同义路面新材料有限公司 +1

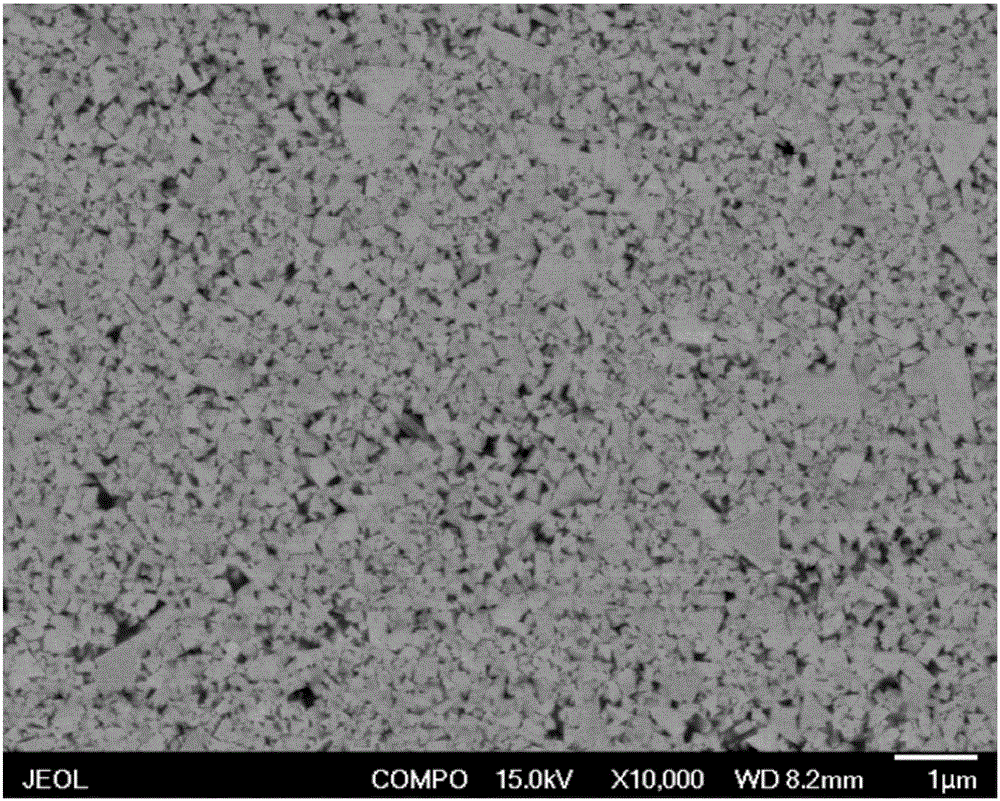

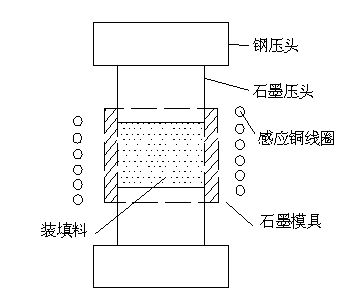

Preparing method for Ti-Si alloy target materials

InactiveCN102699325AWide ingredient ratioUniform compositionVacuum evaporation coatingSputtering coatingCrystalliteHot pressing

The invention discloses a preparing method for Ti-Si alloy target materials. According to the method, silica powder and titanium powder are taken as raw materials, are mixed mechanically according to a certain proportion, filled into a graphitic mould, and are treated with vacuum induction hot pressing sintering to prepare the Ti-Si alloy target materials with different ingredients and sizes. The Ti-Si alloy target materials prepared according to the method has the advantages that the grains are fine; the ingredients are uniform; segregation is avoided; the cost is low; the density is high; and mass production is realized.

Owner:METALINK SPECIAL ALLOYS CORP

Method for producing aluminum-magnesium alloy by utilizing liquid aluminum cathode method

The invention discloses a method for producing an aluminum-magnesium alloy by utilizing a liquid aluminum cathode method. The method is used for high-efficiently producing the high-quality aluminum-magnesium alloy. The method comprises the following steps of dissolving the high-purity magnesium oxide (MgO) in an electrolyte system consisting of Na3PO3-MgF2-NaCl in an electrolytic cell under the electrolytic temperature of 850DEG C to 900DEG C, wherein the aluminum liquid which is formed by melting a high-purity aluminum ingot is used as a liquid cathode; and applying a coil magnetic field with the intensity of 30mT to 40mT outside the electrolytic cell so as to enable the aluminum liquid to rotate under the electrolytic conditions that the anode current density is 0.47 to 0.52A / cm<2> and the high-purity graphite is adopted as an anode, reducing the magnesium ions on the rotating aluminum liquid cathode into elemental magnesium under the electromagnetic stirring effect to be uniformly dispersed into the aluminum liquid so as to form the aluminum-magnesium alloy product, and producing CO2 gas on the anode. The alloy prepared through the method is uniform in components and contains no impurity. The production process is continuous and easy to control.

Owner:UNIV OF SCI & TECH LIAONING

Direct-adding type instant SBS (Styrene Butadiene Styrene) modifier as well as preparation method and application thereof

The invention discloses a direct-adding type instant SBS (Styrene Butadiene Styrene) modifier prepared from the following raw materials in parts by mass: 60-85 parts of SBS, 5-25 parts of ethylene-vinyl acetate copolymer (EVA), 5-10 parts of naphthenic oil, 1-3 parts of a compatilizer and 2-4 parts of an antioxidant. The SBS modifier disclosed by the invention can be directly added into a blending tower (a process for directly adding the modifier into the blending tower is called a 'dry method' according to industry habits) to quickly melt with an aggregate and base asphalt during short-time mixing, thereby achieving micron-scale dispersion and giving play to a modification effect which is the same as that of a wet method.

Owner:BEIJING ZHONGLU PAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com