SBS modified asphalt and preparation method thereof

A technology of modified asphalt and matrix asphalt, which is applied in building components, building insulation materials, buildings, etc. It can solve the problem of high modification process requirements for modified equipment, affecting the production quality of modified asphalt, and the long distance between the construction site and the factory, etc. problems, to achieve the effect of easy implementation of quality monitoring, excellent road performance, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

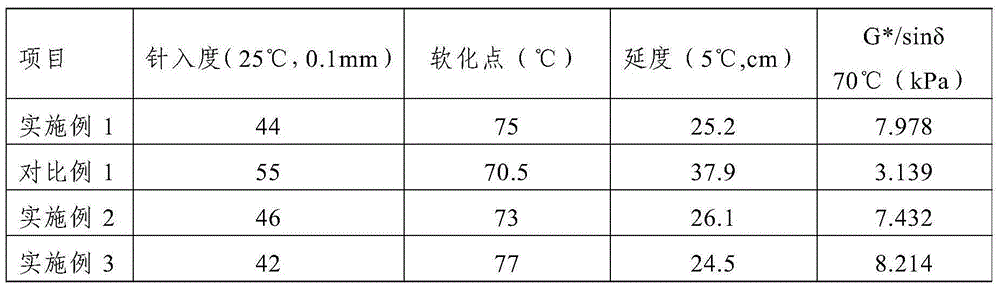

Embodiment 1

[0020] The SBS modified asphalt in this example is made from the following raw materials in parts by weight: 100 parts of base asphalt, 3 parts of SBS asphalt modifier, 1.2 parts of RET asphalt modifier, 0.5 part of polyphosphoric acid, 3 parts of compatibilizer, stable 0.1 part of agent; the compatibilizer is furfural extract oil, and the stabilizer is sulfur.

[0021] The preparation method of the present embodiment SBS modified asphalt comprises the following steps:

[0022] Step 1. Heat the base asphalt to 160°C, then add a compatibilizer and stir for 15 minutes to obtain a mixture; the base asphalt is preferably 70#A grade road petroleum asphalt;

[0023] Step 2. Add SBS asphalt modifier and RET asphalt modifier and stir for 15 minutes under the condition that the temperature of the mixed material in step 1 is 165°C. After stirring, shear the mixed material for 30 minutes at a temperature of 175°C. , then add stabilizer and continue shearing for 25min, after shearing, ad...

Embodiment 2

[0031] The SBS modified asphalt in this example is made from the following raw materials in parts by weight: 100 parts of base asphalt, 2.5 parts of SBS asphalt modifier, 1.5 parts of RET asphalt modifier, 0.3 parts of polyphosphoric acid, 3.5 parts of compatibilizer, stable 0.13 part of agent; Described compatibilizer is furfural extract oil, and described stabilizing agent is sulfur.

[0032] The preparation method of the present embodiment SBS modified asphalt comprises the following steps:

[0033] Step 1. Heat the base asphalt to 155°C, then add a compatibilizer and stir for 20 minutes to obtain a mixture; the base asphalt is preferably 70#A grade road petroleum asphalt;

[0034]Step 2: Add SBS asphalt modifier and RET asphalt modifier and stir for 18 minutes when the temperature of the mixed material in step 1 is 170°C, and then shear the mixed material for 35 minutes at a temperature of 170°C , then add stabilizer and continue shearing for 20min, after shearing, add po...

Embodiment 3

[0036] The SBS modified asphalt in this example is made from the following raw materials in parts by weight: 100 parts of base asphalt, 3.5 parts of SBS asphalt modifier, 1 part of RET asphalt modifier, 0.5 part of polyphosphoric acid, 3 parts of compatibilizer, stable 0.1 part of agent; the compatibilizer is furfural extract oil, and the stabilizer is sulfur.

[0037] The preparation method of the present embodiment SBS modified asphalt comprises the following steps:

[0038] Step 1. Heat the base asphalt to 165°C, then add a compatibilizer and stir for 18 minutes to obtain a mixture; the base asphalt is preferably 70#A grade road petroleum asphalt;

[0039] Step 2: Add SBS asphalt modifier and RET asphalt modifier and stir for 20 minutes when the temperature of the mixed material in step 1 is 175°C, and then shear the mixed material for 32 minutes at a temperature of 180°C , then add stabilizer and continue shearing for 23min, after shearing, add polyphosphoric acid, then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com