Patents

Literature

98results about How to "Low tap density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

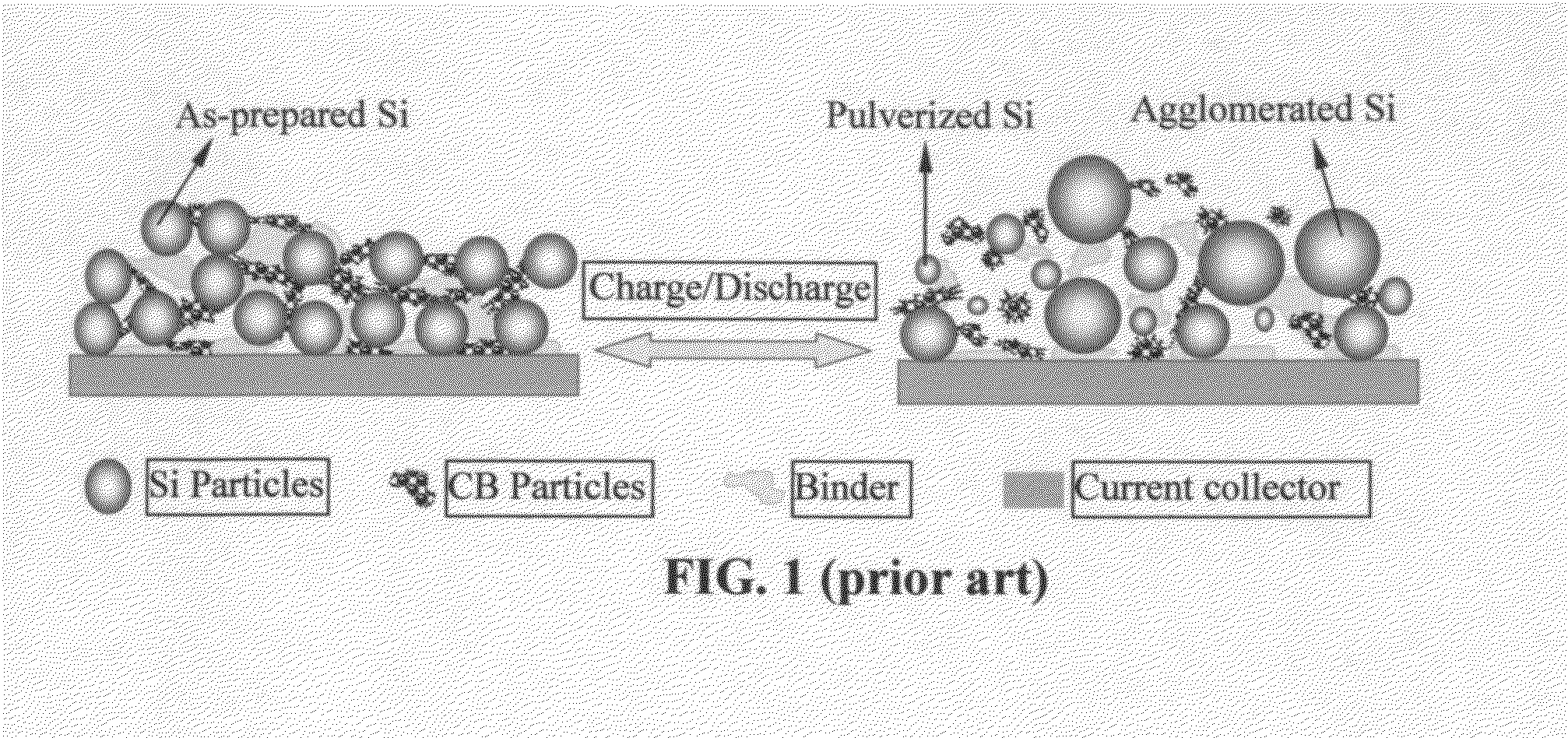

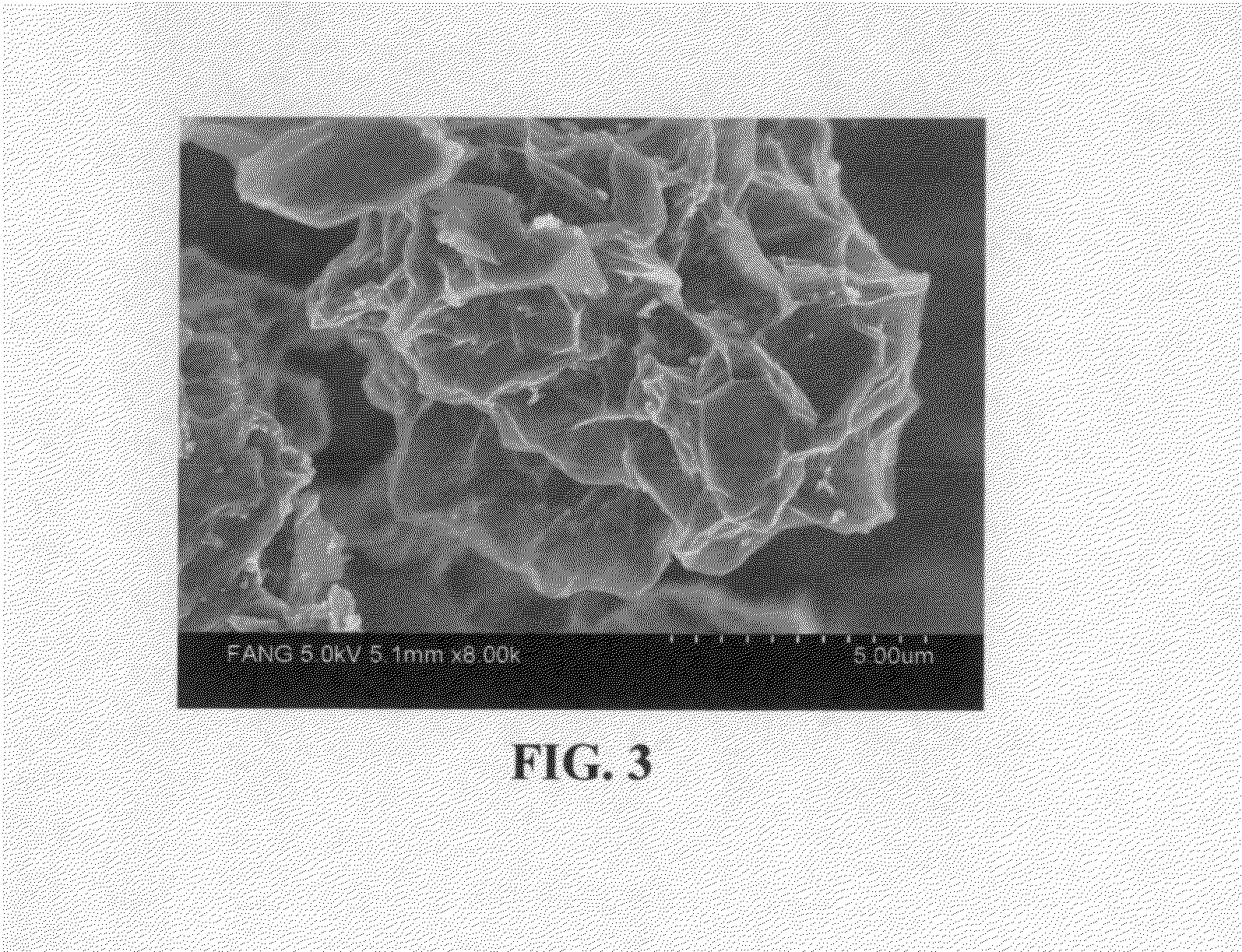

Graphene-enhanced anode particulates for lithium ion batteries

ActiveUS20120064409A1Enhanced Li-ion insertionIncrease capacityNon-metal conductorsMaterial nanotechnologyParticulatesMicroparticle

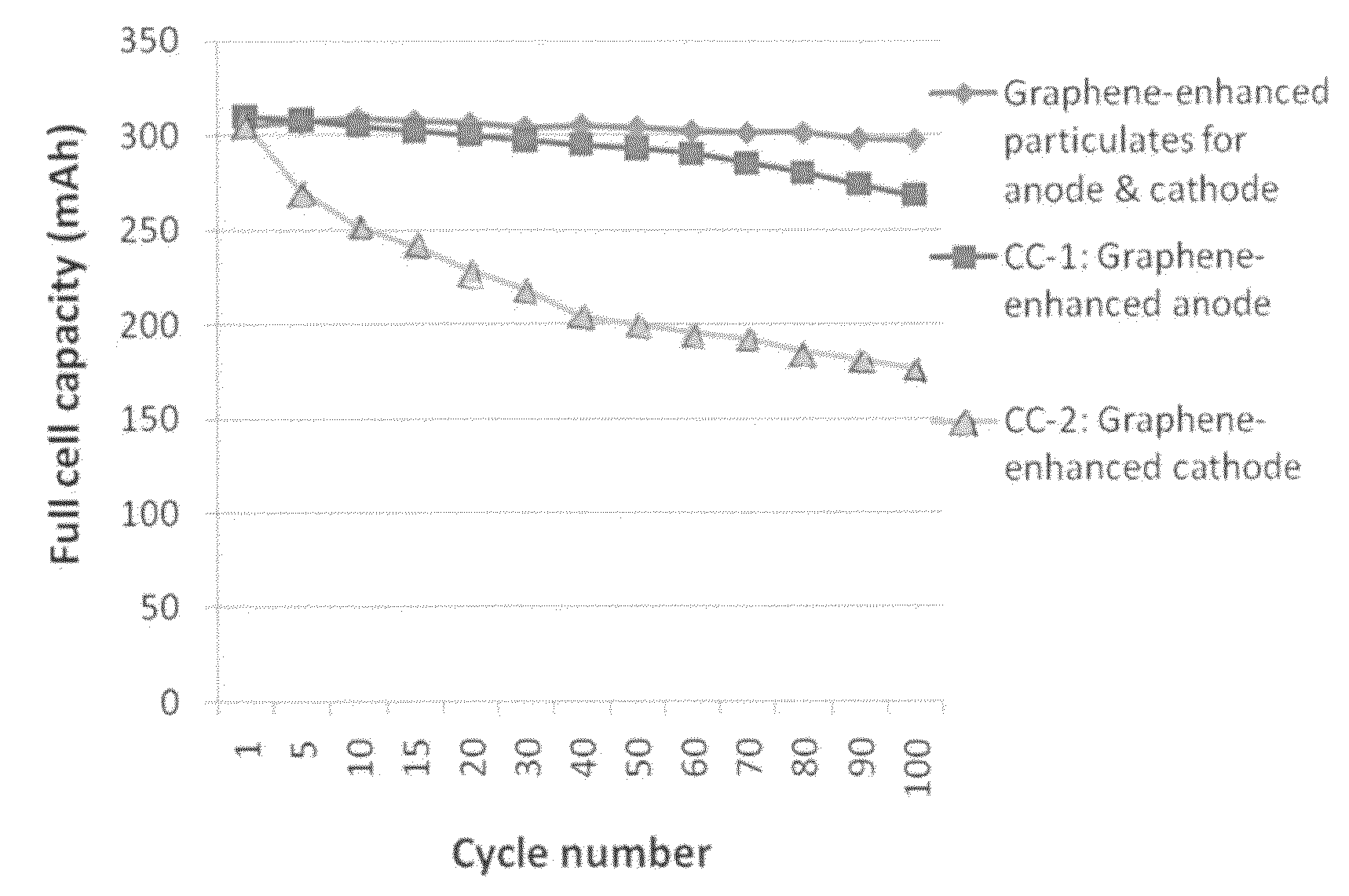

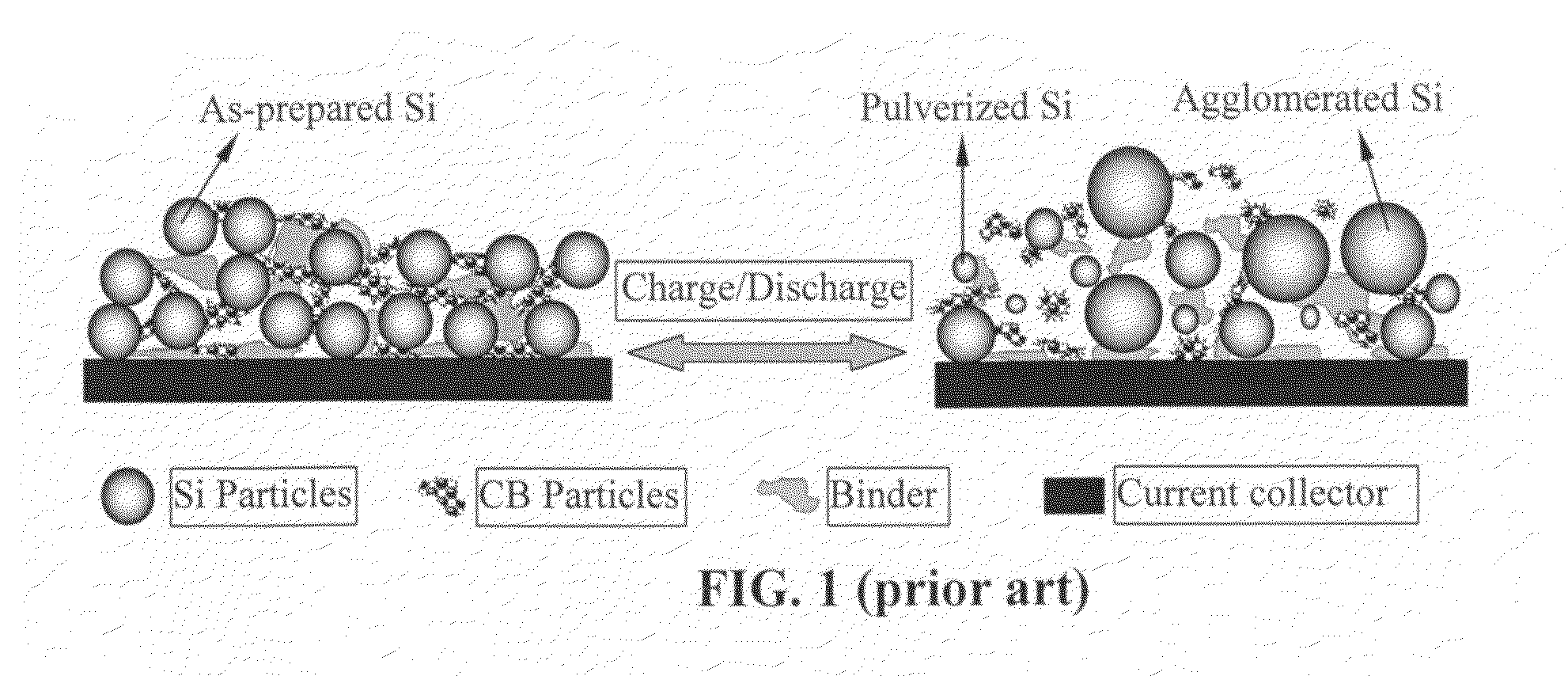

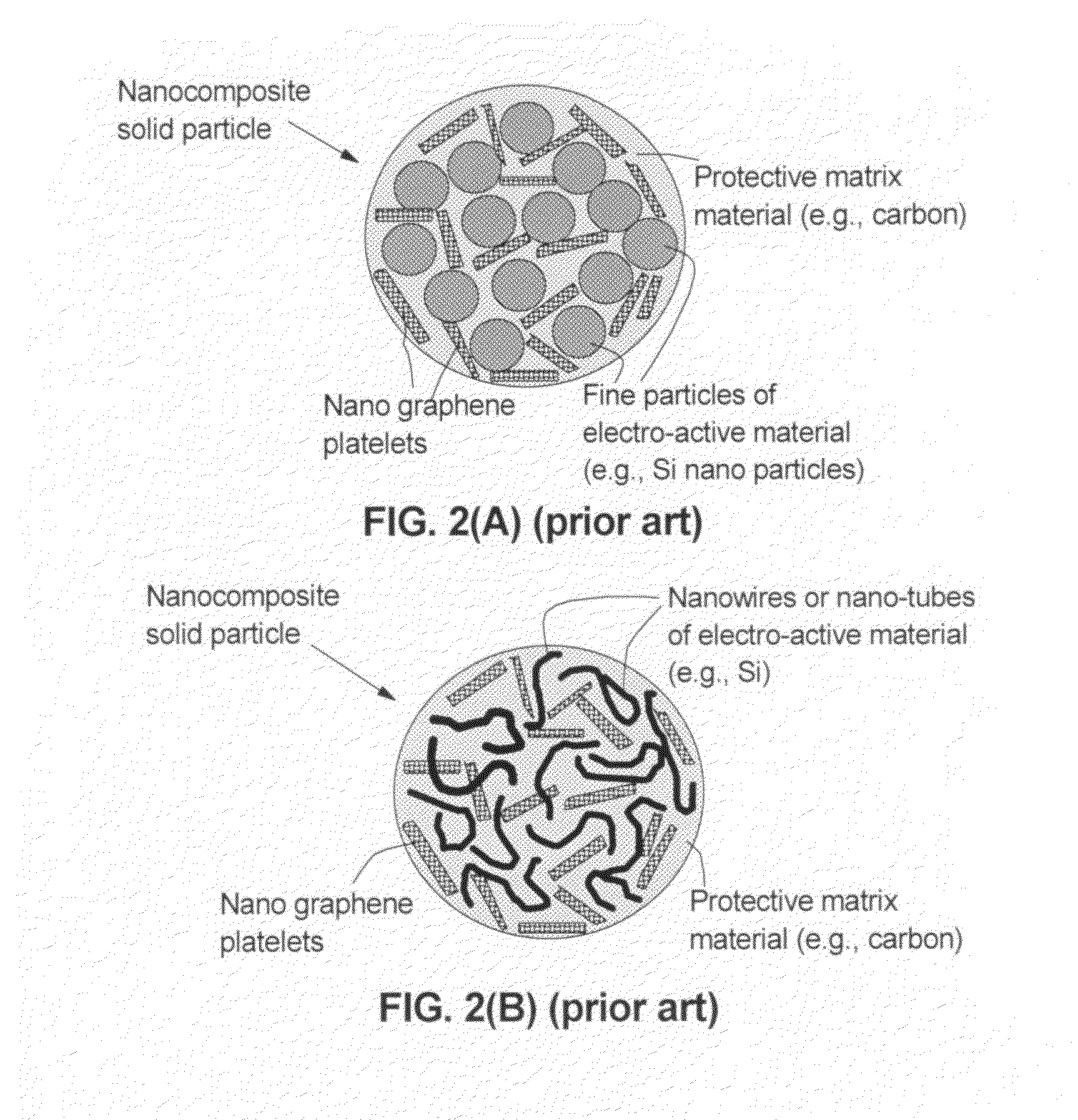

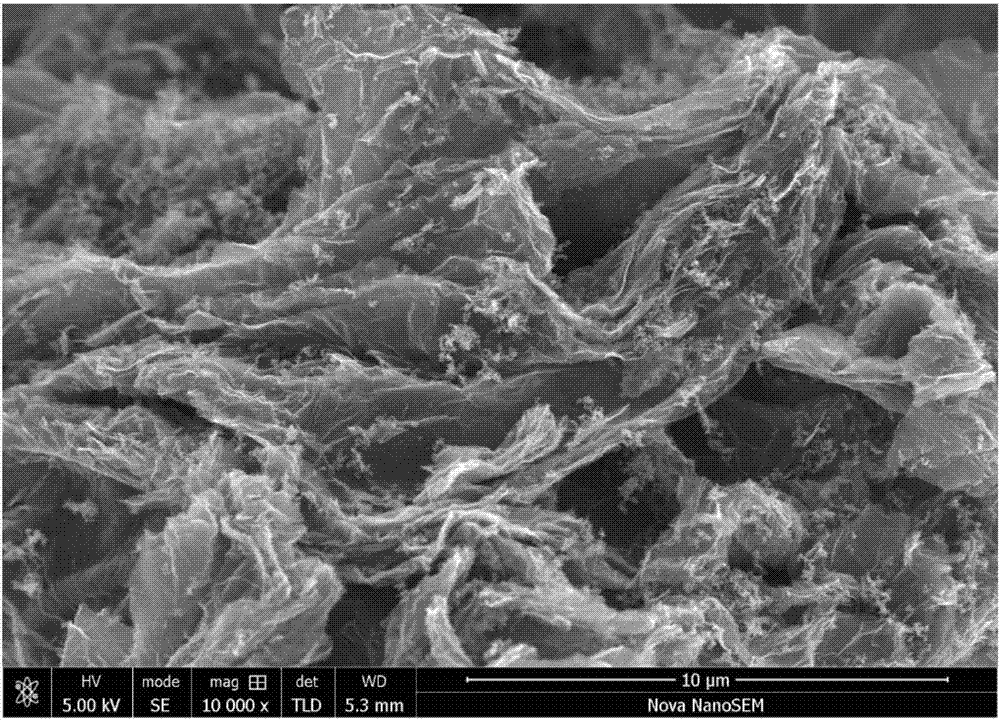

A nano graphene-enhanced particulate for use as a lithium-ion battery anode active material, wherein the particulate is formed of a single sheet of graphene or a plurality of graphene sheets and a plurality of fine anode active material particles with a size smaller than 10 μm. The graphene sheets and the particles are mutually bonded or agglomerated into the particulate with at least a graphene sheet embracing the anode active material particles. The amount of graphene is at least 0.01% by weight and the amount of the anode active material is at least 0.1% by weight, all based on the total weight of the particulate. A lithium-ion battery having an anode containing these graphene-enhanced particulates exhibits a stable charge and discharge cycling response, a high specific capacity per unit mass, a high first-cycle efficiency, a high capacity per electrode volume, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD +1

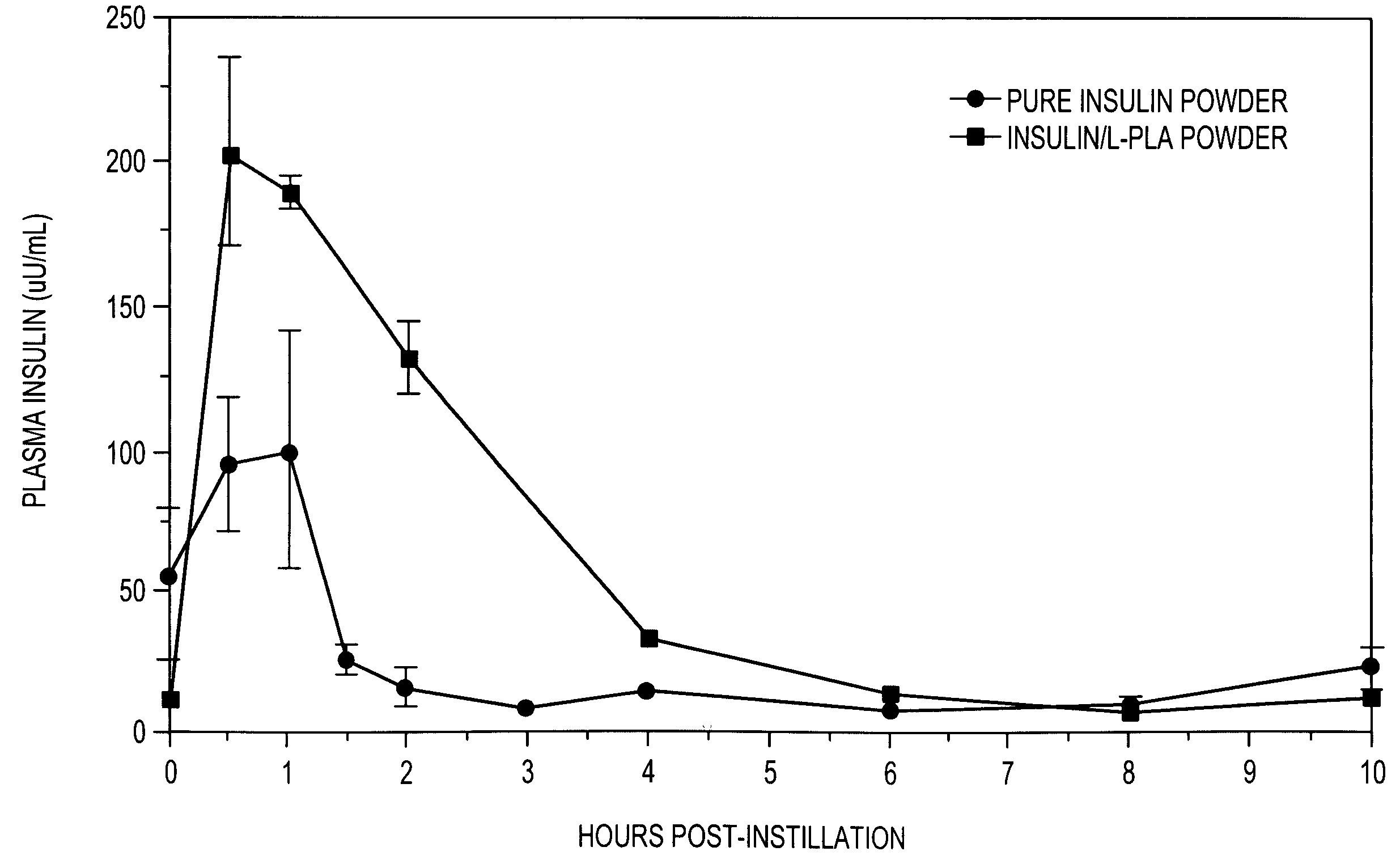

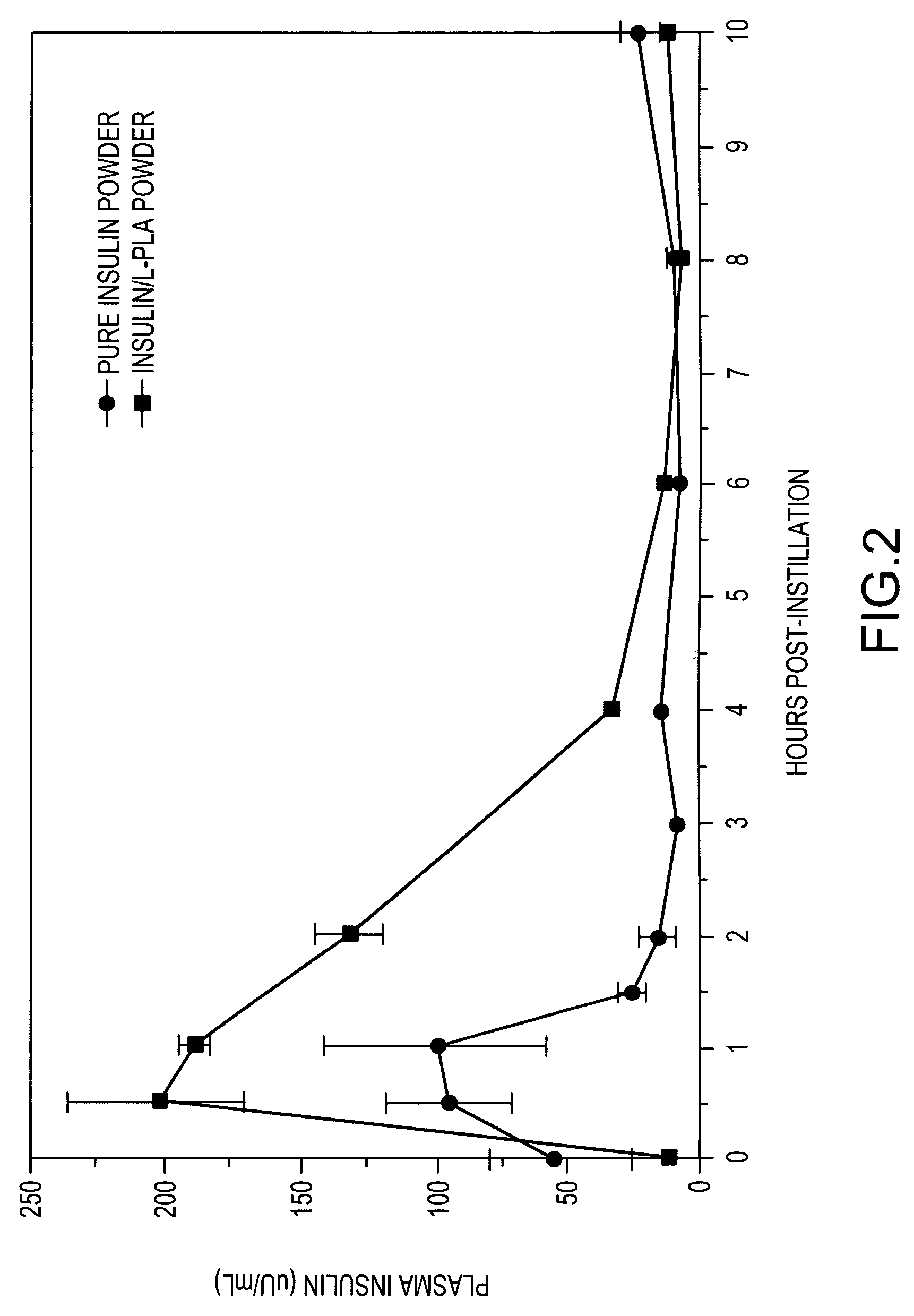

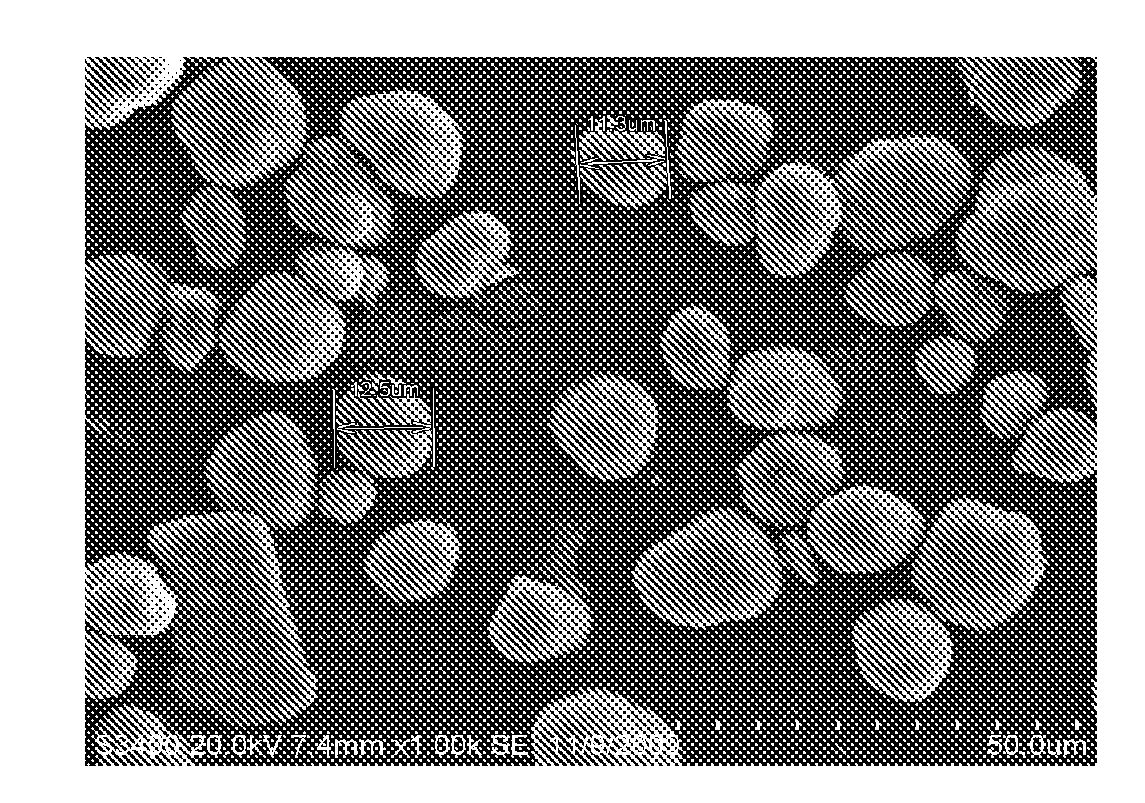

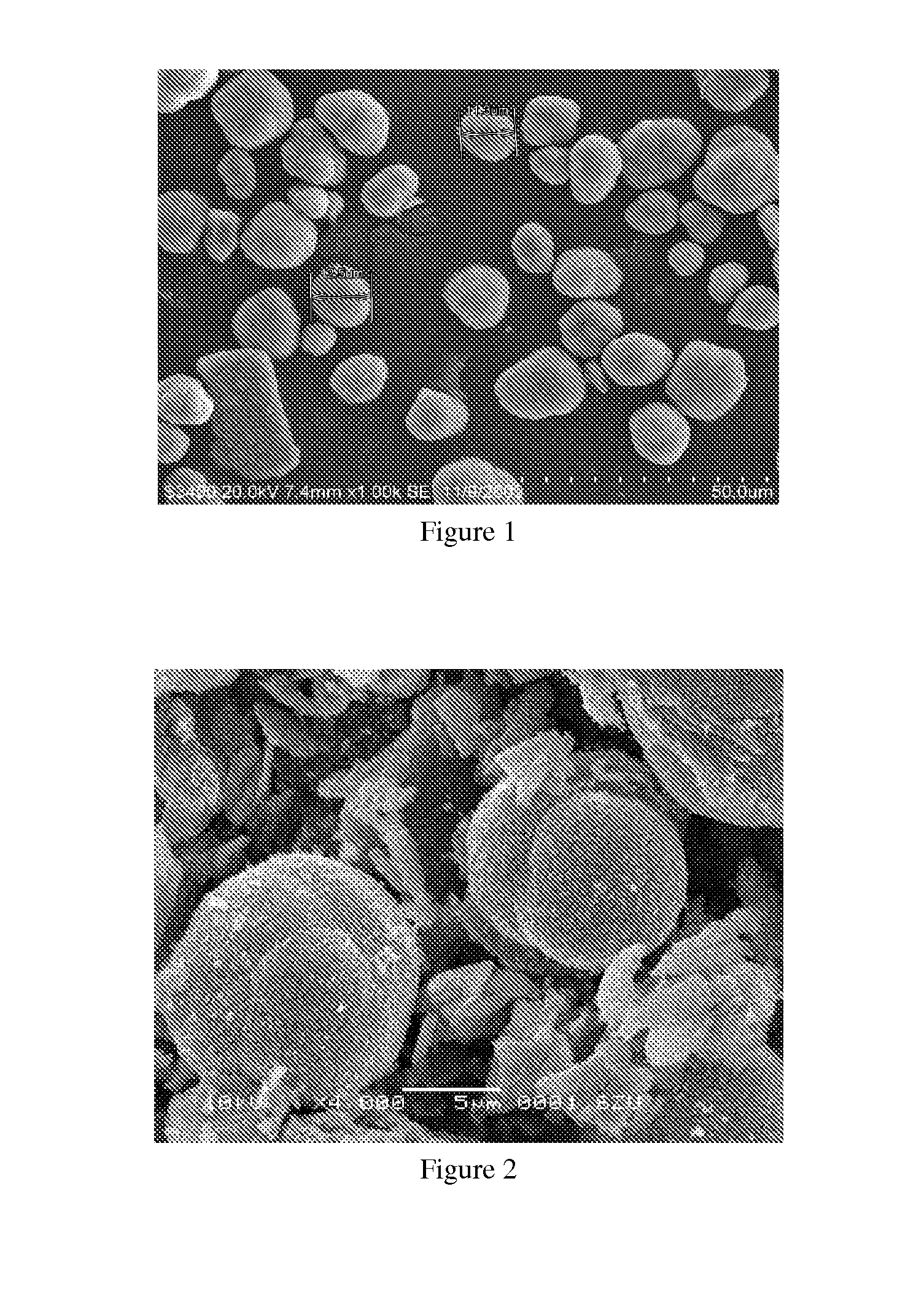

Insulin highly respirable microparticles

ActiveUS7625865B2High percentage of pharmaceutical activityHigh pHPowder deliveryPeptide/protein ingredientsMicroparticleVolumetric Mass Density

The invention describes novel dried powders of peptide therapeutic agent useful for producing highly respirable aerosols and the methods for their manufacture. Insulin is the peptide therapeutic agent in the preferred embodiment. The powders of insulin prepared for pulmonary administration are characterized by the peculiar structure and shape of the microparticles that allow the powder to flow and to be easy aerosolized. Typical dry powder of insulin described in this patent show corrugated, nonagglomerated microparticles with a low tapped density. The mean geometric diameter (particle size) ranges between 1.0 and 10.0 micron and the mass median aerodynamic diameter (MMAD) ranges between 1.0 and 4.0 micron. These insulin pulmonary powders exhibit in vitro a very high respirable fraction (>75%).

Owner:UNIV DEGLI STUDI DI PARMA

Particulate drug-containing products and method of manufacture

InactiveUS7125566B2Improve featuresEfficiently aerosolizedBiocidePowder deliveryParticulatesOrganic solvent

Provided is a compressed anti-solvent technique for manufacture of drug-containing powders for pulmonary delivery. The drug is processed in a cosolvent system including two or more mutually soluble organic solvents. Also provided are powders manufacturable by the manufacture method, including powders of substantially pure drug and powders including a biocompatible polymer for pulmonary sustained drug release applications. Also provided are packaged products including drug-containing powder in a container that is receivable by and operable with a dry powder inhaler to produce an aerosol including dispersed drug-containing particles when the inhaler is actuated.

Owner:ENDO PHARMA COLORADO

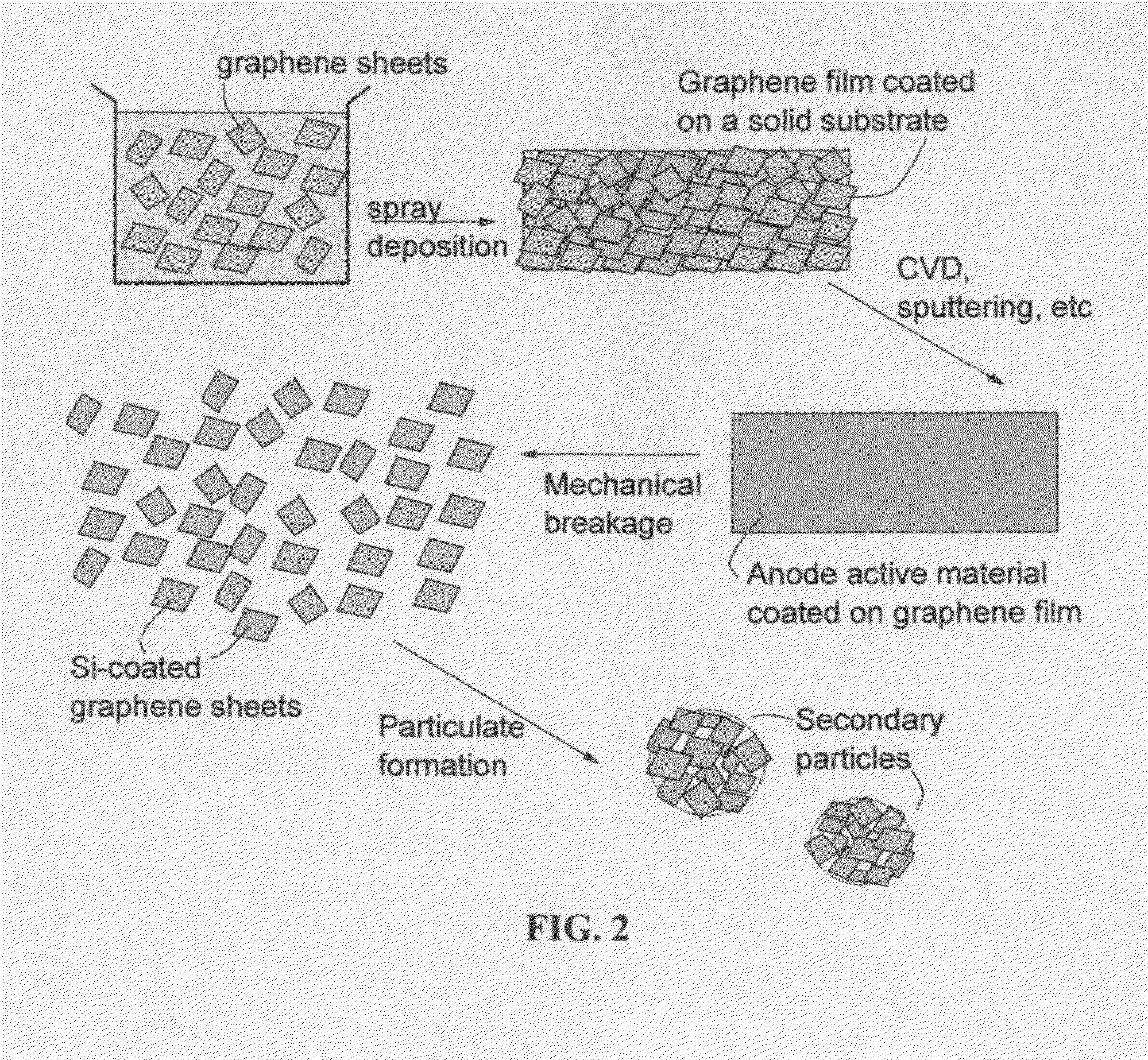

Anode containing active material-coated graphene sheets and lithium-ion batteries containg same

ActiveUS20150044564A1Enhanced Li-ion insertionIncrease capacityNegative electrodesSecondary cellsGrapheneLithium-ion battery

The present invention provides an anode electrode of a lithium-ion battery, comprising an anode active material-coated graphene sheet, wherein the graphene sheet has two opposed parallel surfaces and at least 50% area of one of the surfaces is coated with an anode active material and wherein the graphene material is in an amount of from 0.1% to 99.5% by weight and the anode active material is in an amount of at least 0.5% by weight (preferably at least 60%), all based on the total weight of the graphene material and the anode active material combined.

Owner:GLOBAL GRAPHENE GRP INC

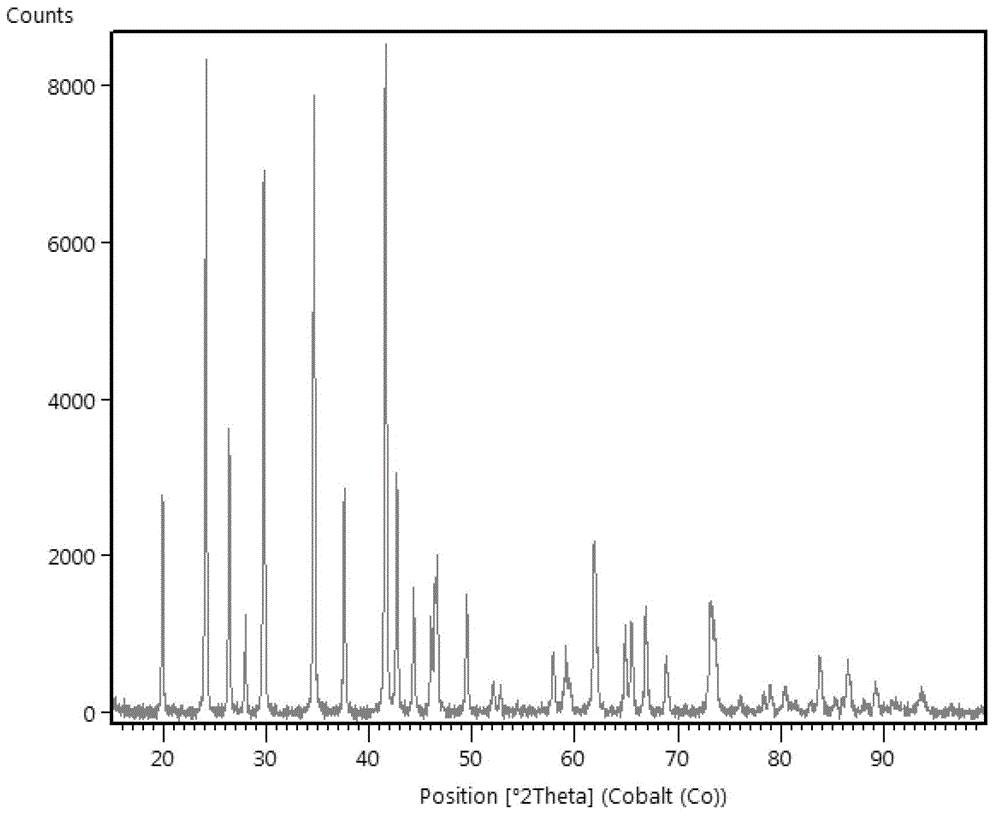

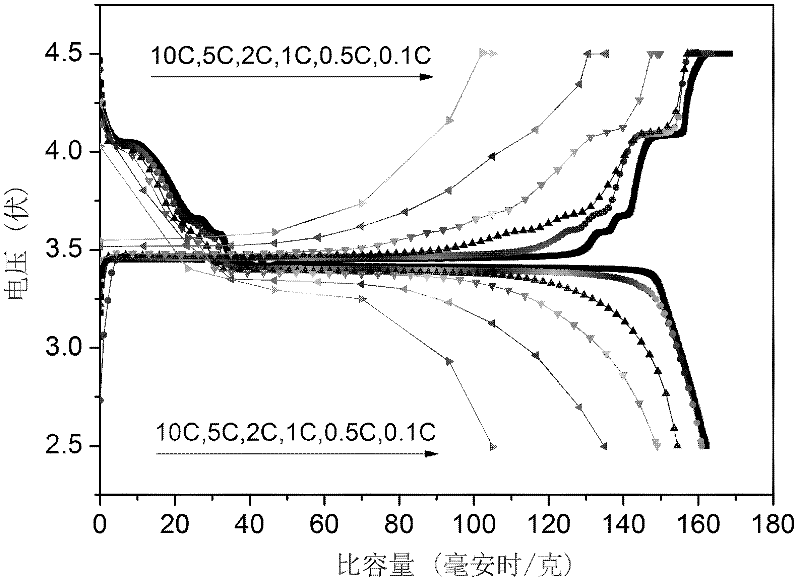

Lithium iron phosphate composite material, production method and use thereof

InactiveUS20130177784A1Improve conductivityHigh charge-discharge rateElectrode thermal treatmentSecondary cells charging/dischargingParticulatesIron salts

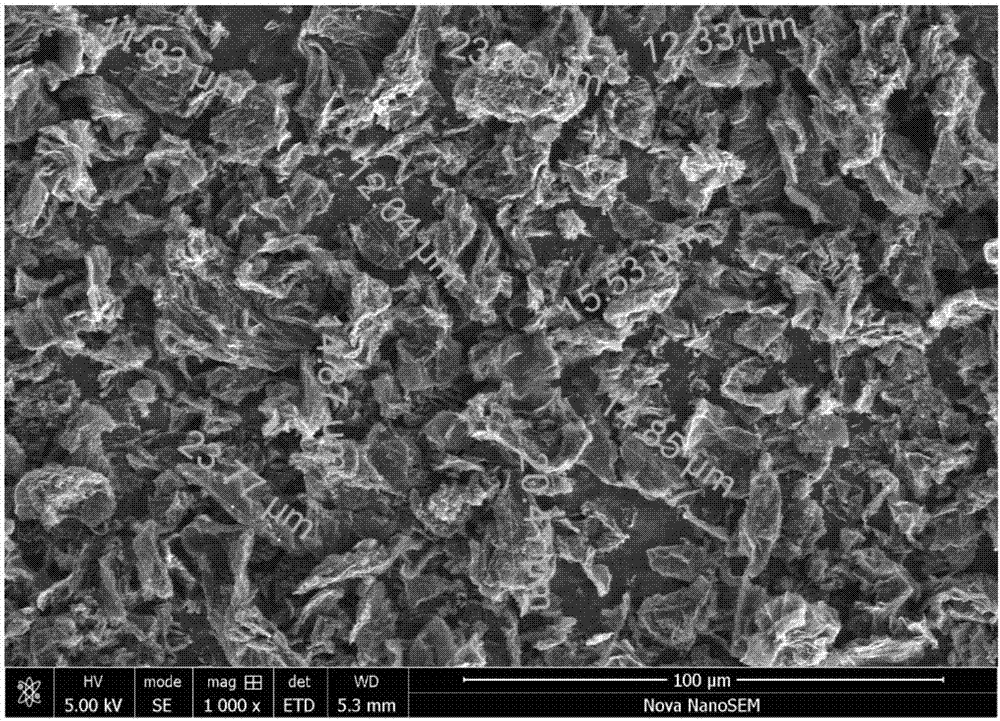

Provided are a lithium iron phosphate composite material, the production method thereof and the use thereof The lithium iron phosphate composite material has a micro-size particle structure, which contains nano-size grains of lithium iron phosphate and graphene inside, and bears nano-carbon particulates outside. The lithium iron phosphate composite material has the properties of high conductivity, high-rate charge / discharge performance and high tap density. The production method comprises: preparing an iron salt mixed solution according to the mole ratio of P:Fe=1:1; adding the above solution into an organic carbon source aqueous solution, followed by mixing and reacting, so as to obtain nano-iron phosphate covered with organic carbon source; adding the above nano-iron phosphate covered with organic carbon source and a lithium source compound into an aqueous solution of graphene oxide, agitating, mixing, and then spray drying, so as to obtain a precursor of lithium iron phosphate composite material; calcinating said precursor in a reduction atmosphere and cooling naturally, so as to obtain said lithium iron phosphate composite material. The material is used for lithium ion battery or positive electrode material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Anode material for lithium ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an anode material for a lithium ion battery. The anode material is in a laminated structure, and the expression of the anode material is Li1+zNixMnyA1-x-yO2; the anode material further comprises a metal oxide or a metal fluoride coated on the surface of the Li1+zNixMnyA1-x-yO2. Compared with the prior art, according to the Li1+zNixMnyA1-x-yO2 provided by the invention, although x is greater than 0.5, and an appropriate synthetic process is adopted, the structure thereof is extremely stable, and the cycle performance of the anode material for the lithium ion battery containing the anode material is good; moreover, the content of Ni is high, thus the specific capacity of the anode material disclosed by the invention is higher and achieves more than 130 mAh / g; moreover, the material is in the laminated structure, so that the multiplying performance is good, and the lithium ion battery can be quickly charged or discharged.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

High-density and small-particle size nickel-cobalt-manganese hydroxide and preparation method thereof

InactiveCN107640792AHigh density and small tap densityLow tap densityCell electrodesSecondary cellsHigh densityManganese

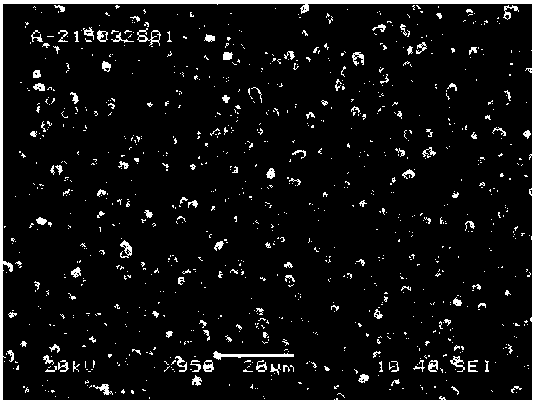

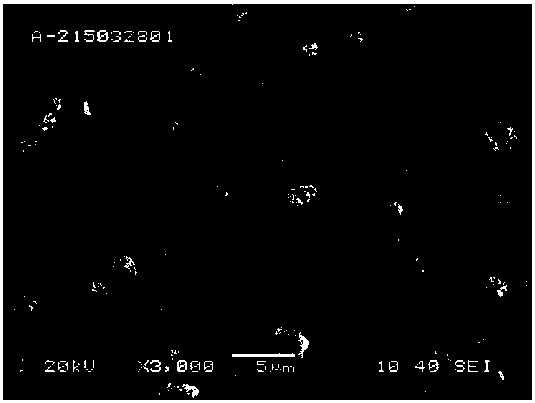

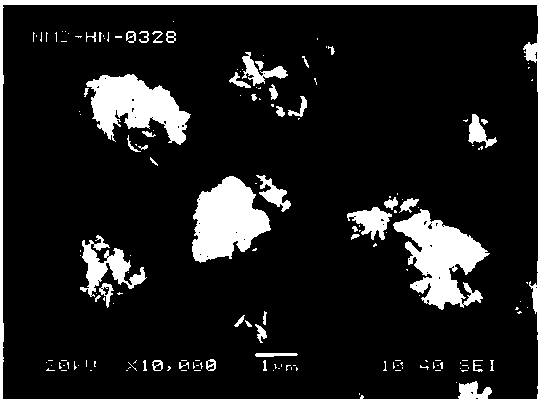

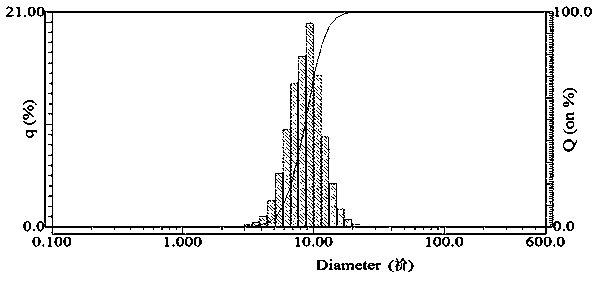

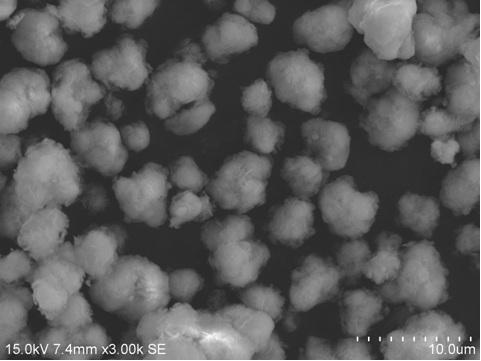

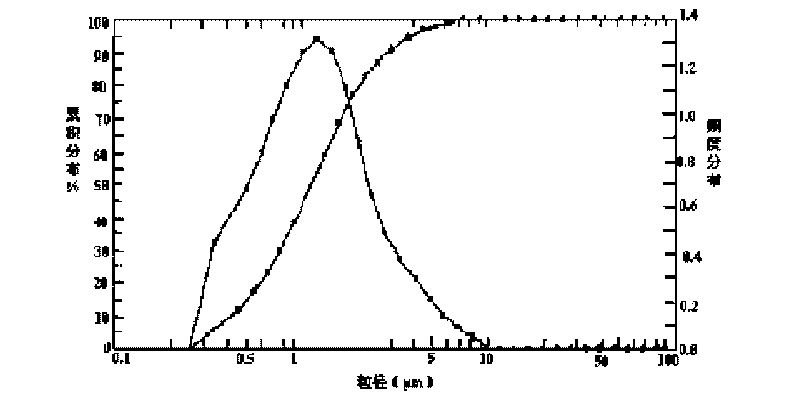

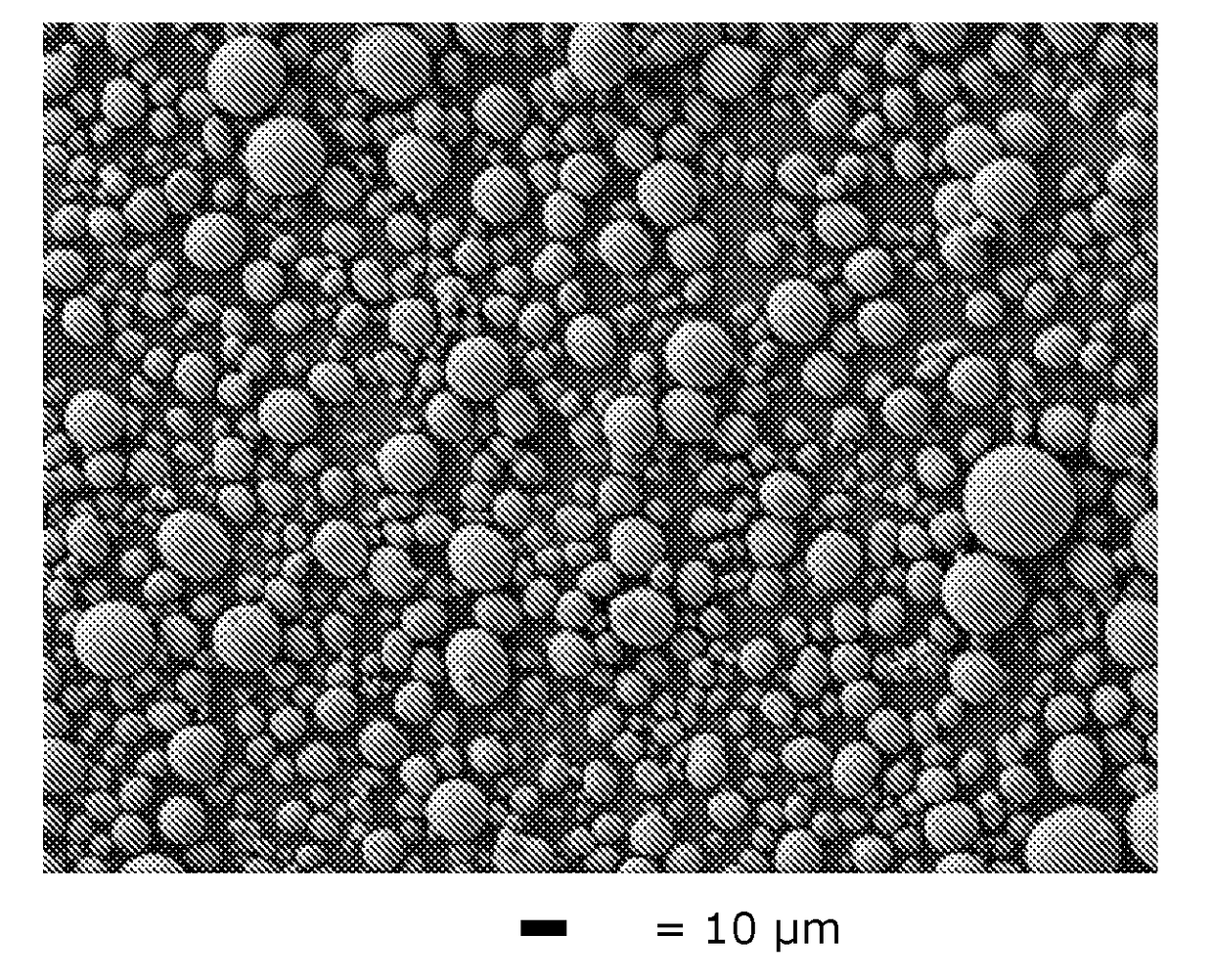

The invention discloses a high-density and small-particle size nickel-cobalt-manganese hydroxide and a preparation method thereof. For the high-density and small-particle size nickel-cobalt-manganesehydroxide provided by the invention, a general chemical formula is NixCoyMnz(OH)2, wherein x+y+z=1, x is larger than or equal to 0.3 and smaller than or equal to 0.8, y is larger than or equal to 0.1and smaller than or equal to 0.4, and z is larger than or equal to 0.1 and smaller than or equal to 0.4; the particle sizes are d10 larger than or equal to 2 microns, d50 equal to 2.5-4 microns and d90 smaller than or equal to 6 microns, the tap density is larger than or equal to 1.4g / cm<3>, the specific surface area is 5-20m<2> / g, and the shape is spherical or spheroidal. The invention also discloses the preparation method of the high-density and small-particle size nickel-cobalt-manganese hydroxide. The preparation method is strong in controllability, can stably control the particle sizes ineach production batch without using a surfactant and is low in production cost, high in efficiency and good in physicochemical index of a final product.

Owner:ZHUJI PAWA NEW ENERGY

Process for preparing a positive electrode material for lithium ion battery

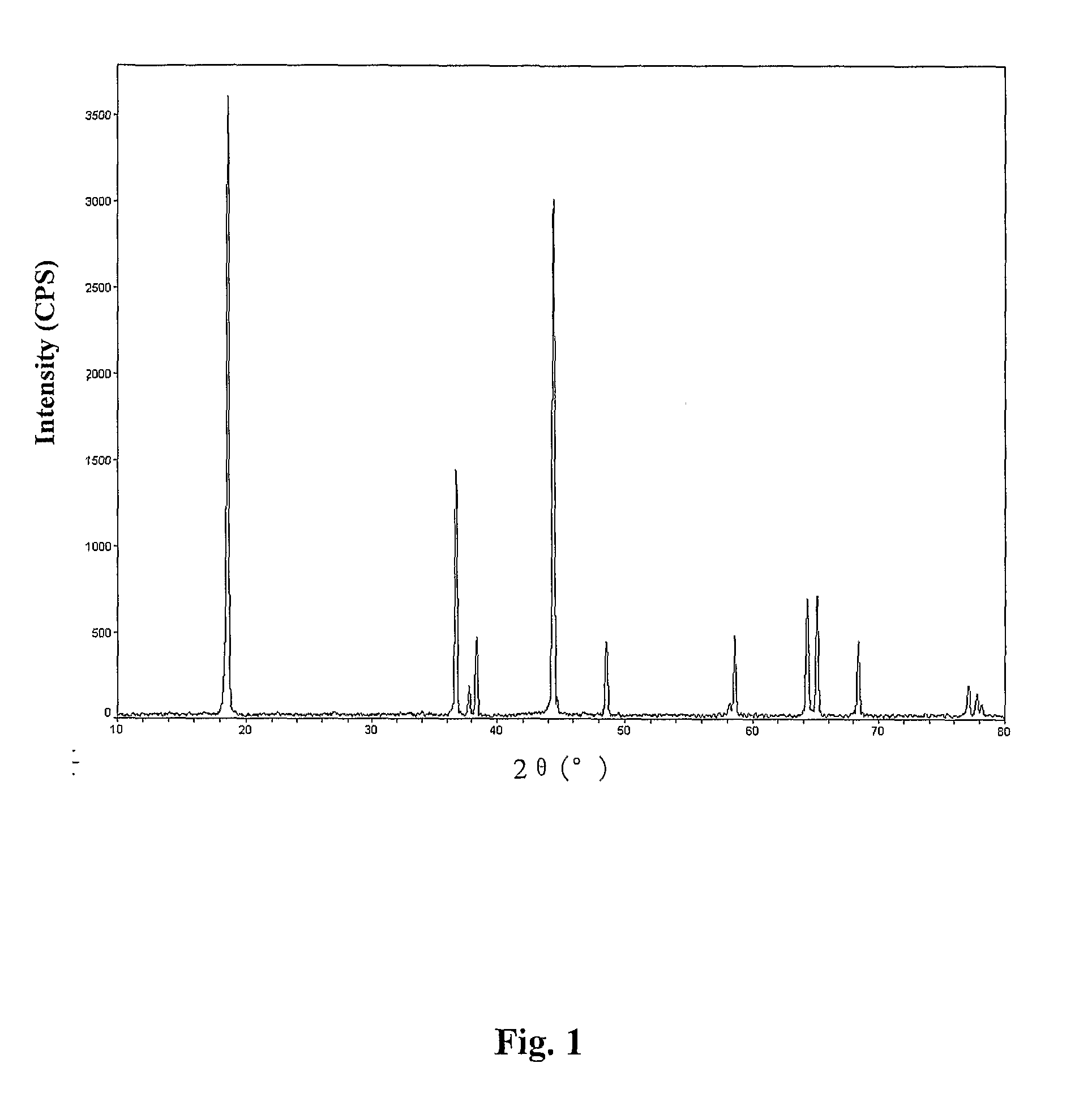

InactiveUS20090146115A1High tap densityLow tap densityElectrode thermal treatmentFinal product manufactureManganeseLithium compound

A process for preparing lithium-nickel-manganese-cobalt composite oxide used as a positive electrode material for the lithium ion battery, comprising subjecting a mixture containing a lithium compound and nickel-manganese-cobalt hydroxide to a first-stage sintering and a second-stage sintering, wherein said process further comprises adding a binder and / or binder solution after the first-stage sintering, and the mixture of the binder and / or binder solution and the product of first-stage sintering is sintered in said second-stage sintering. The tap density and volume specific capacity of the positive electrode material lithium-nickel-manganese-cobalt composite oxide prepared by the present process, come up to 2.4 g / cm3 and 416.4 mAh / cm3, respectively. Besides, the positive electrode material lithium-nickel-manganese-cobalt composite oxide prepared by the present process possesses the advantages of high specific capacity and good cycle stability.

Owner:BYD CO LTD

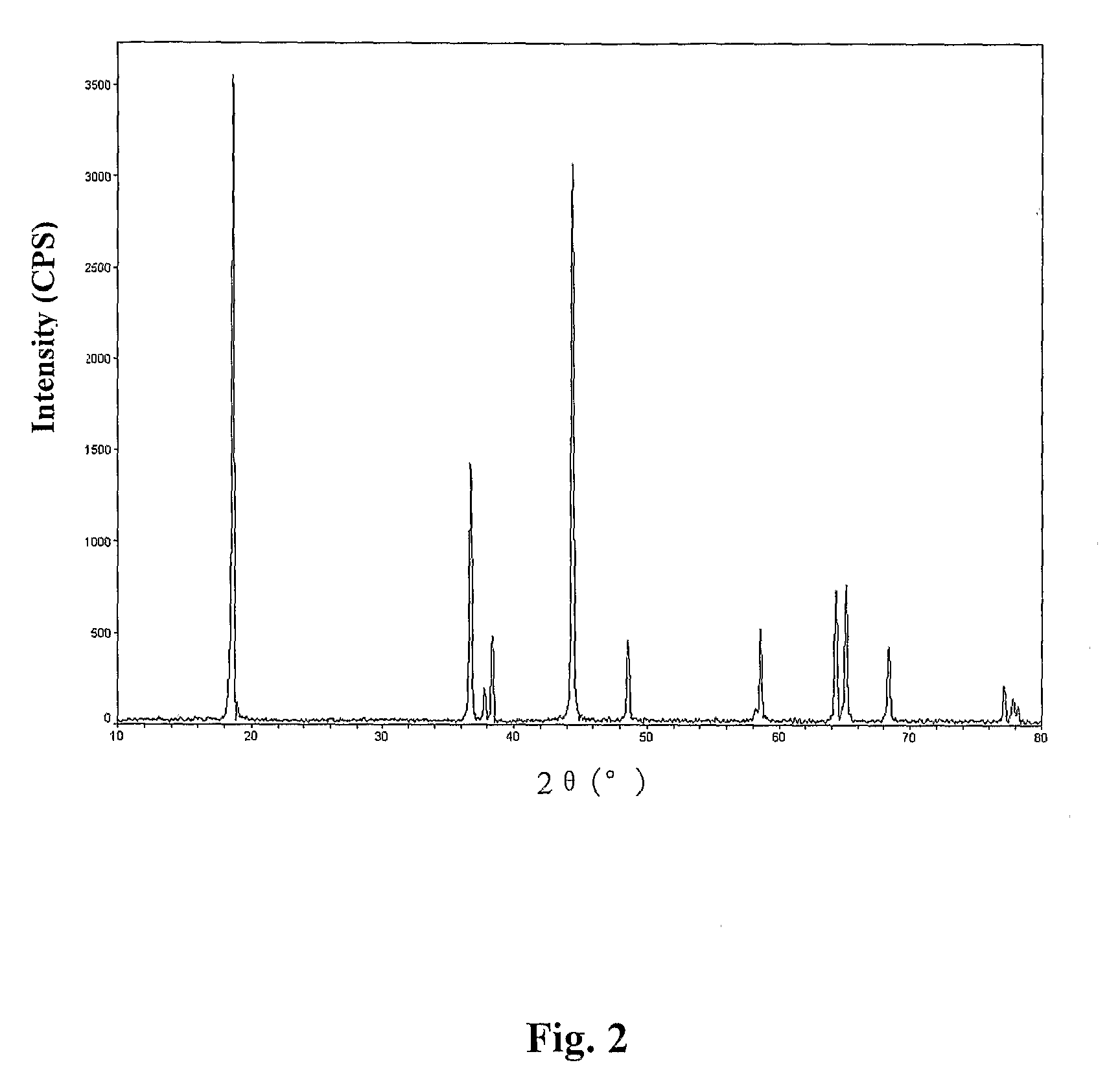

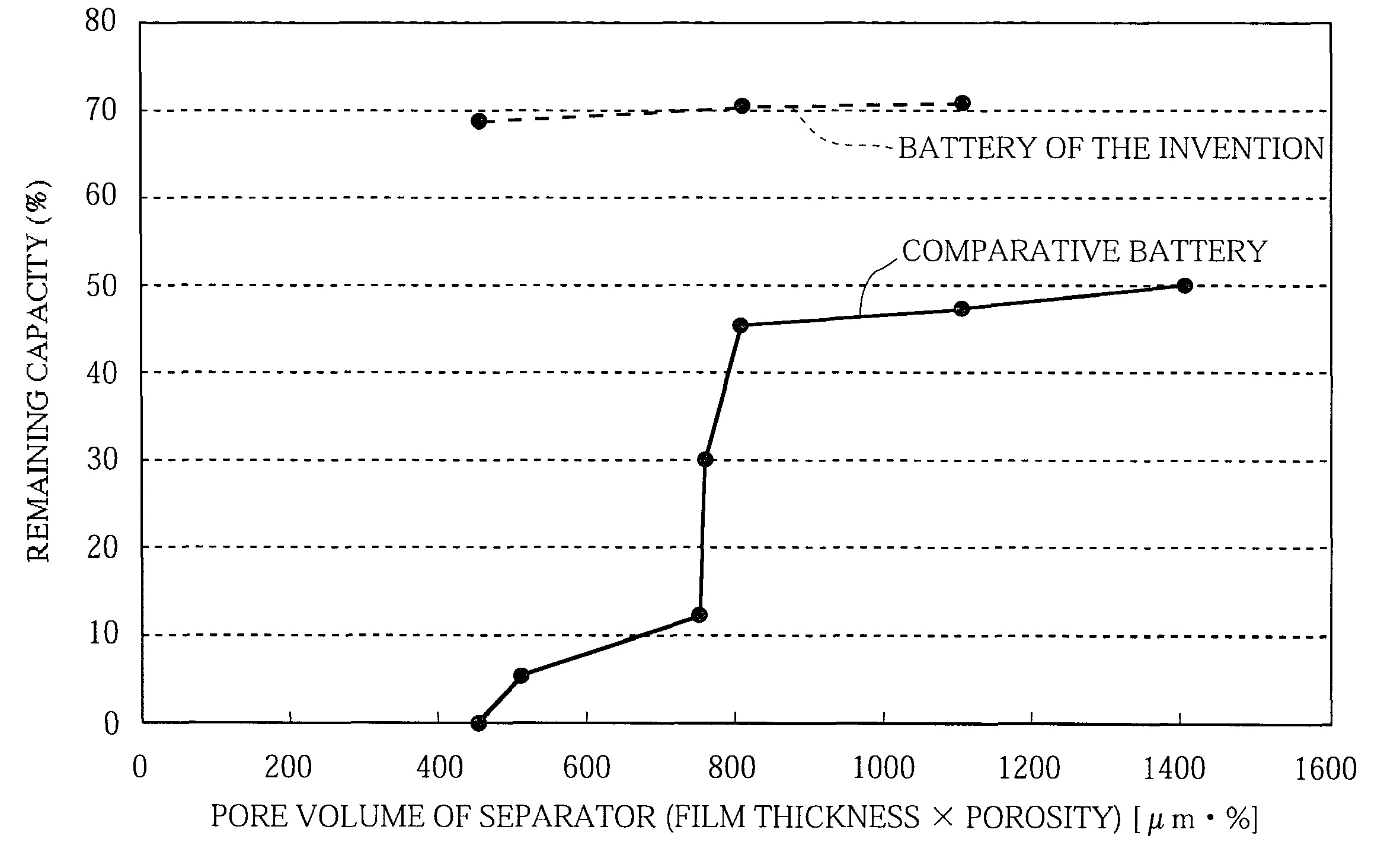

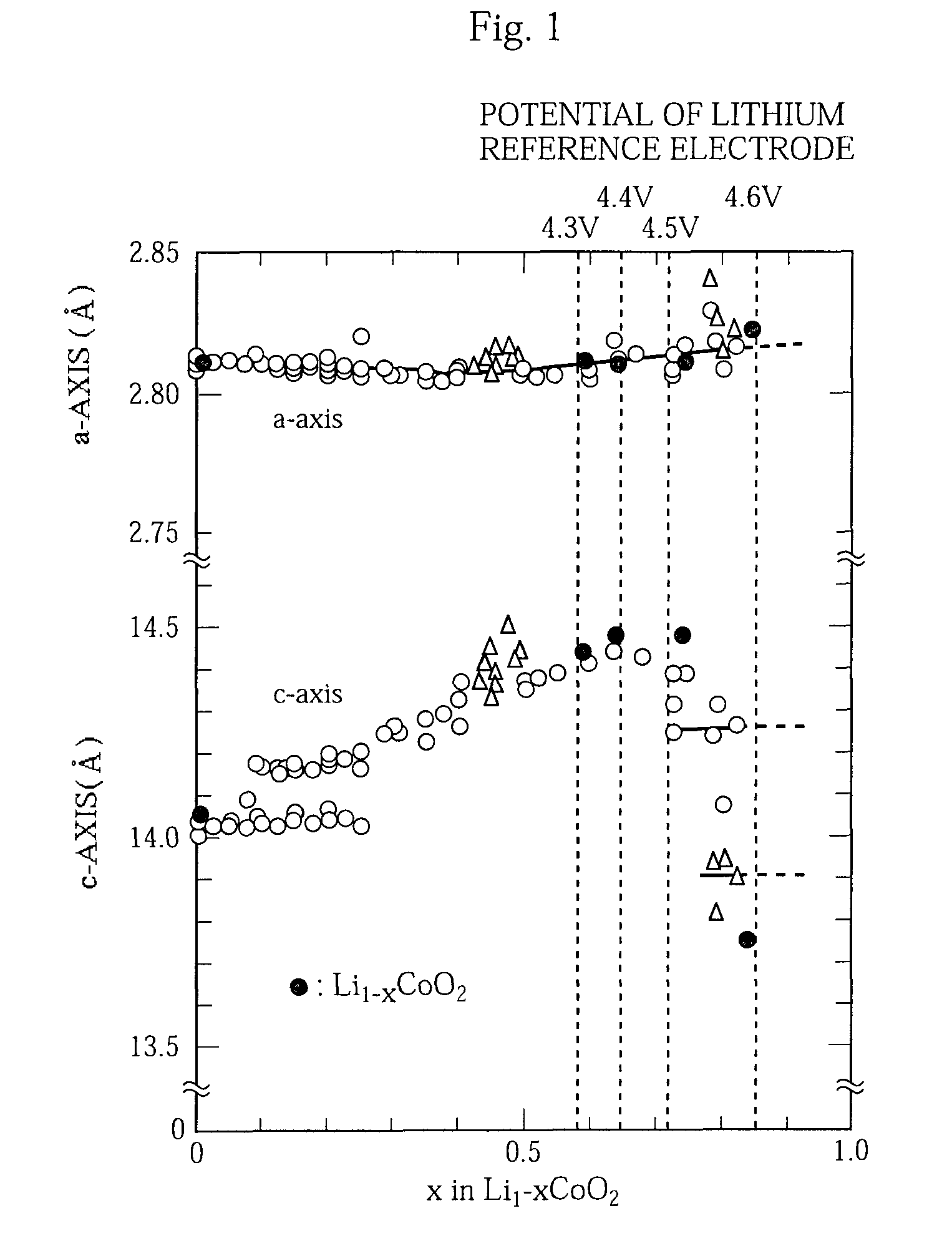

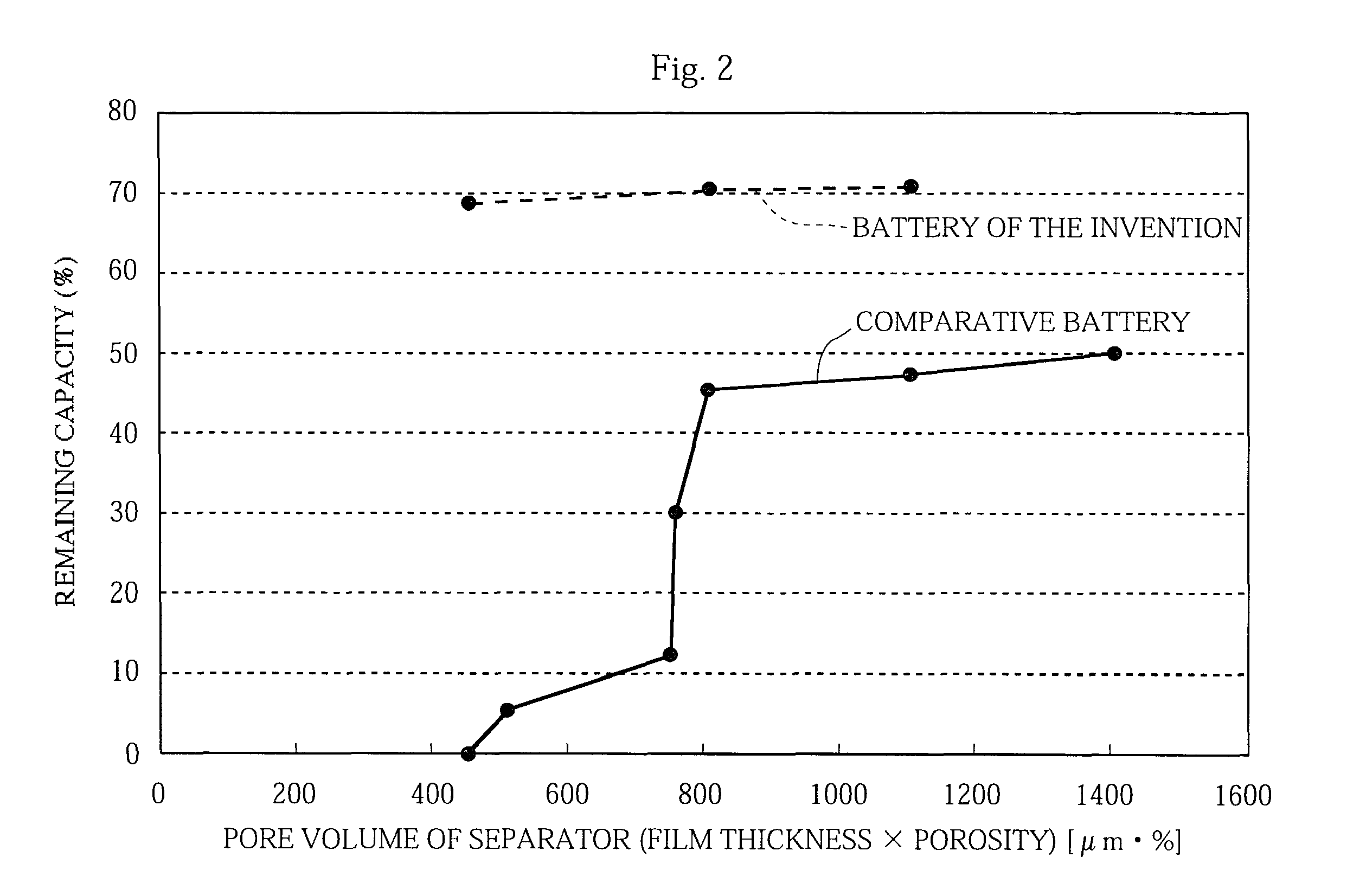

Non-aqueous electrolyte battery and method of manufacturing the same

InactiveUS20090197181A1Low tap densityIncrease battery capacityCell seperators/membranes/diaphragms/spacersFinal product manufactureFiller particleEngineering

[Problem] A non-aqueous electrolyte battery is provided that shows good cycle performance and good storage performance under high temperature conditions and exhibits high reliability even with a battery configuration featuring high capacity. A method of manufacturing the battery is also provided.[Means for Solve the Problem] A non-aqueous electrolyte battery includes: a positive electrode having a positive electrode active material layer containing a positive electrode active material; a negative electrode having a negative electrode active material; a separator interposed between the positive electrode and the negative electrode; an electrode assembly including the positive electrode, the negative electrode, and the separator; and a non-aqueous electrolyte impregnated in the electrode assembly, characterized in that: the positive electrode active material contains at least cobalt or manganese; and a coating layer is formed on a surface of the positive electrode active material layer, the coating layer including filler particles and a binder.

Owner:SANYO ELECTRIC CO LTD

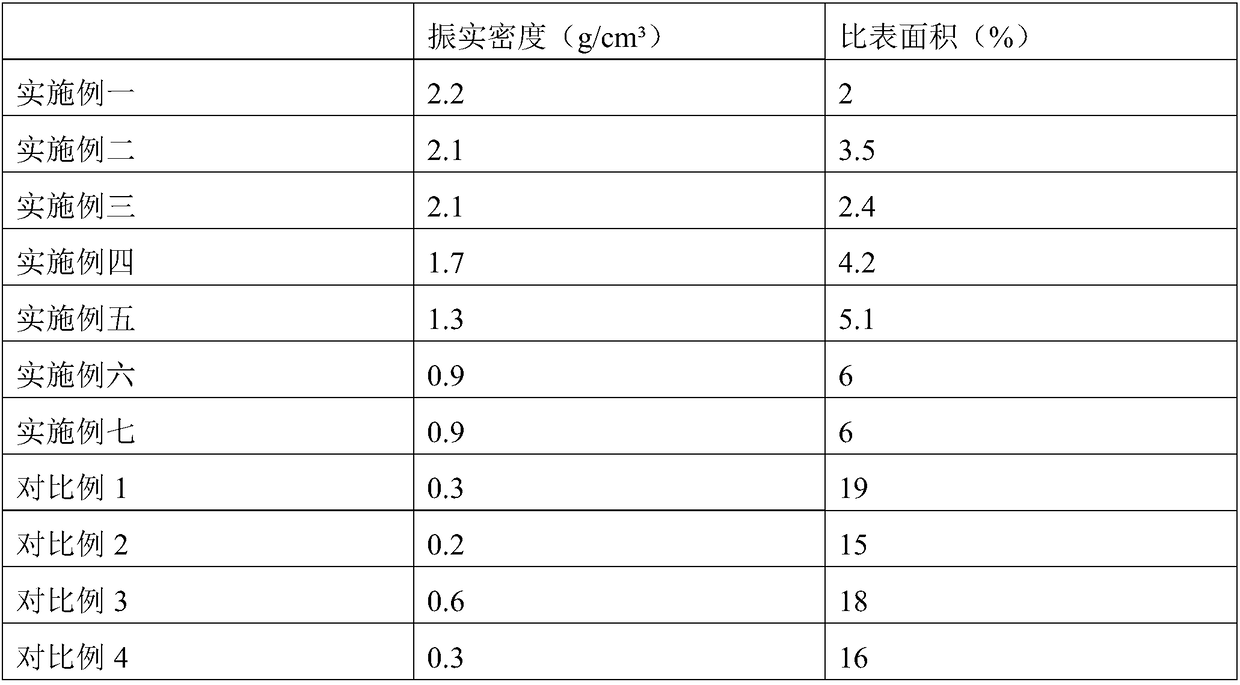

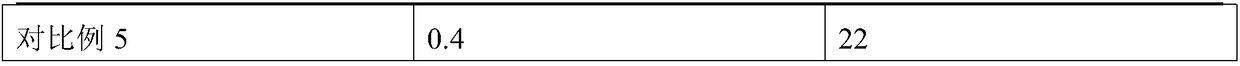

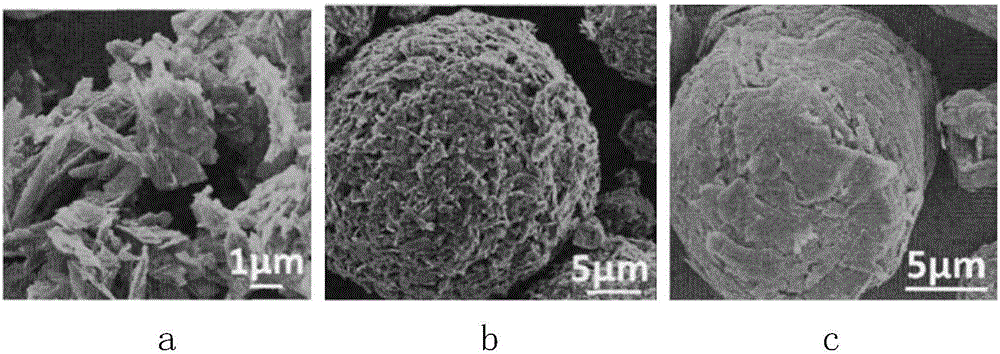

Preparation method for artificial graphite negative electrode material for lithium ion battery

InactiveCN105958070ALow tap densityHigh tap densityCell electrodesSecondary cellsEnvironmental resistanceLithium-ion battery

Disclosed is a preparation method for an artificial graphite negative electrode material for a lithium ion battery. Artificial graphite coke powder with small grain diameter and an organic carbon source are taken as the raw materials; the raw materials are subjected to procedures of mixing, high-temperature treatment, graphitization treatment, sieving and the like; the coke powder and the organic carbon source are mixed in a heating environment, and the effects of coating, mixing and holding, secondary pelleting and the like can be achieved; the small-particle coke powder can form secondary particles under the cohesive action of the organic carbon source; therefore, the problem of anisotropy of the material is solved, and the tap density of the material is improved; meanwhile, the artificial graphite negative electrode material is capable of lowering the material turnover and equipment residual loss, high in yield, simple in procedures, low in energy consumption, environment-friendly, uniform in the coating effect on the surface of the material, and high in consistency; and in addition, the prepared negative electrode material has the characteristics of isotropy, low iron impurity content, low initial irreversible capacity, small volume expansion, high absorbency, high circulation performance, high performance cost ratio, excellent comprehensive performance and the like.

Owner:田东

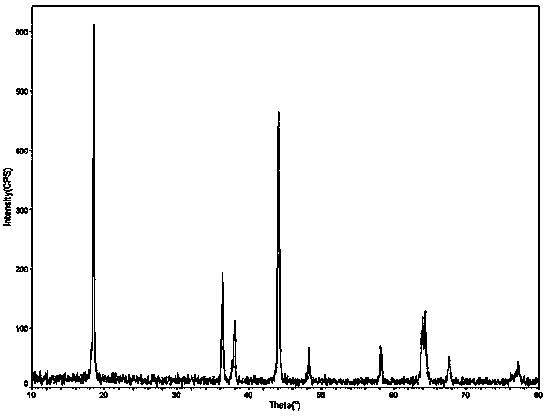

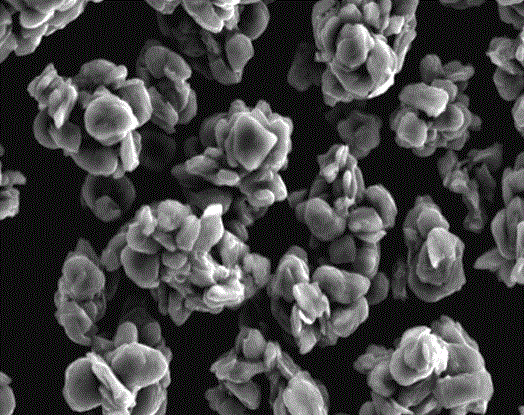

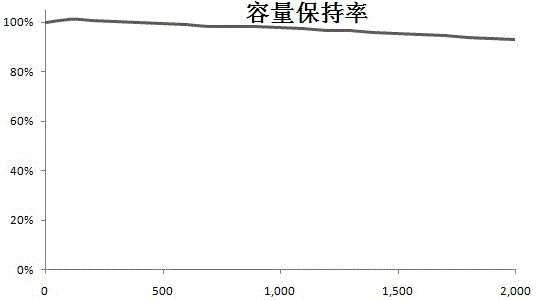

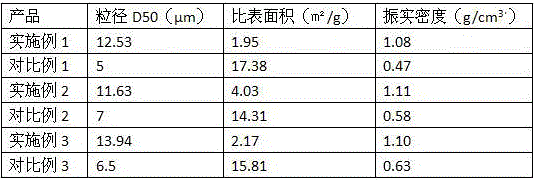

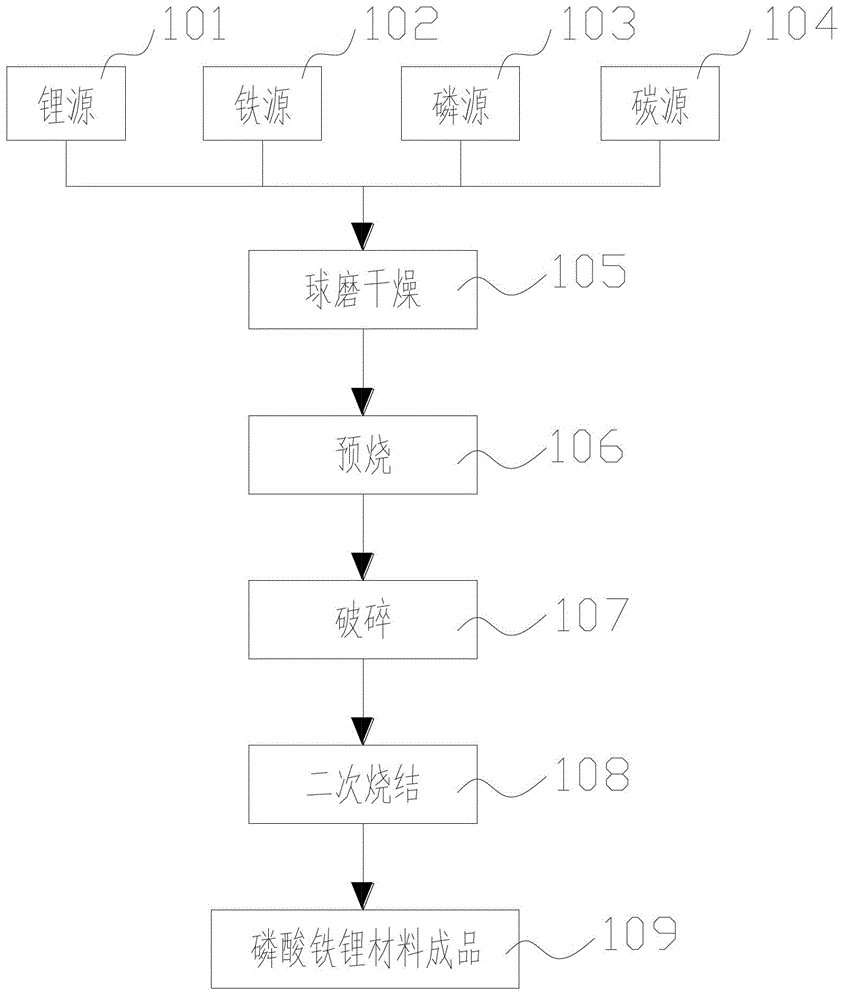

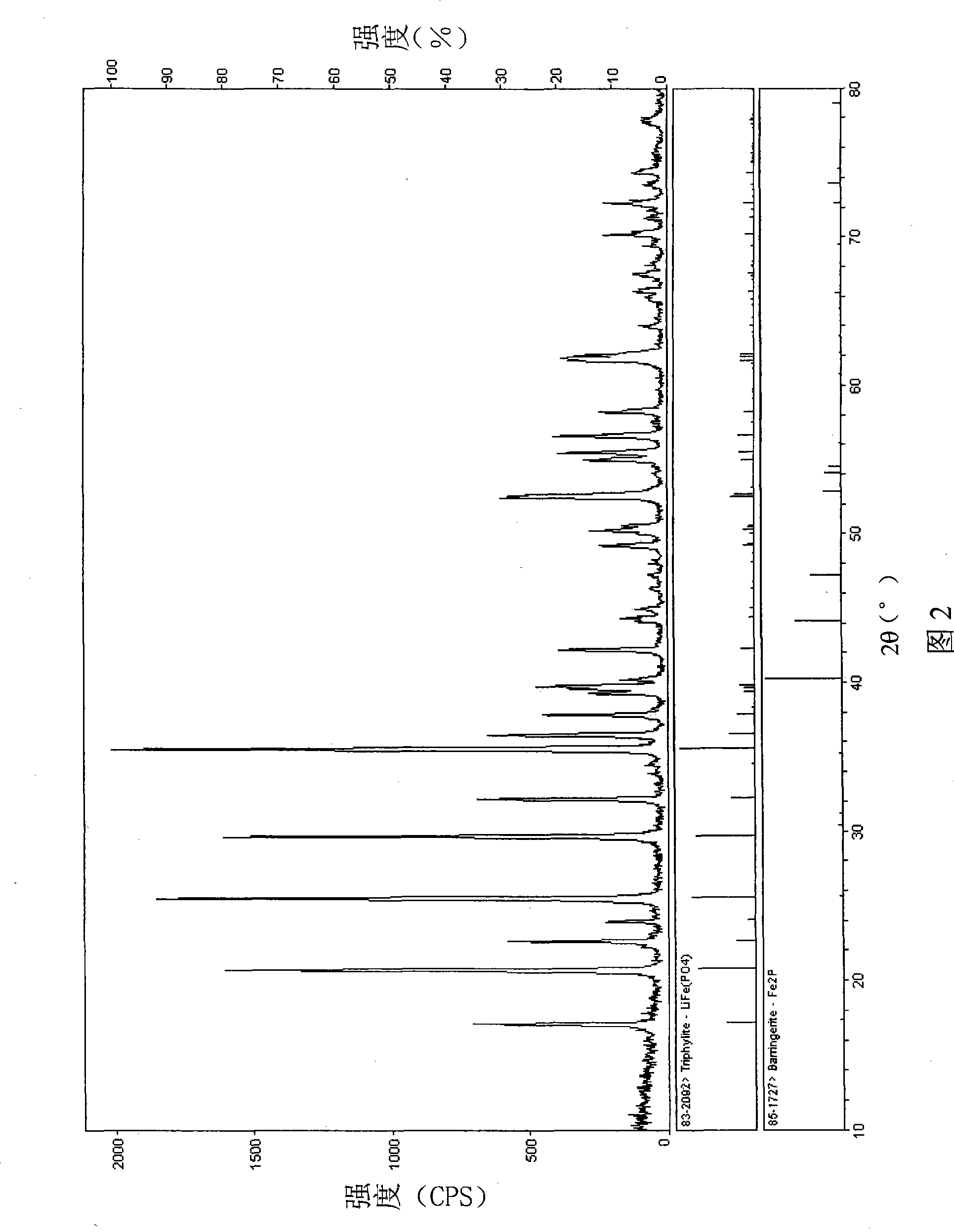

Method for preparing lithium iron phosphate material

ActiveCN102745663ASteps to reduce doping modificationSimple production processPhosphorus compoundsLithium iron phosphateBall mill

The invention discloses a method for preparing a lithium iron phosphate material. The method comprises the following steps of: mixing raw materials for preparing the lithium iron phosphate material, wherein the raw materials include a lithium source, an iron source, a phosphorus source and a carbon source, and the iron source is a mixture of ferrous iron and ferric iron; performing ball milling and drying on the mixed raw materials: putting the mixed raw materials into a ball mill for performing ball milling, and drying; pre-burning the ball-milled and dried raw materials to obtain a precursor of the lithium iron phosphate material; crushing the precursor of the lithium iron phosphate material obtained by pre-burning; and performing secondary sintering on the crushed precursor of the lithium iron phosphate material to obtain a finished lithium iron phosphate material. The lithium iron phosphate material prepared with the method has the advantages of high specific capacity, appropriate tap density, appropriate specific surface area, excellent circulating performance and excellent processing performance.

Owner:SICHUAN JINWANGTONG ELECTRONICS SCI & TECH

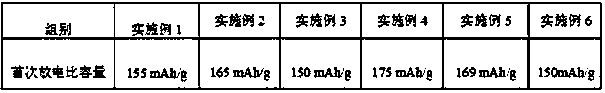

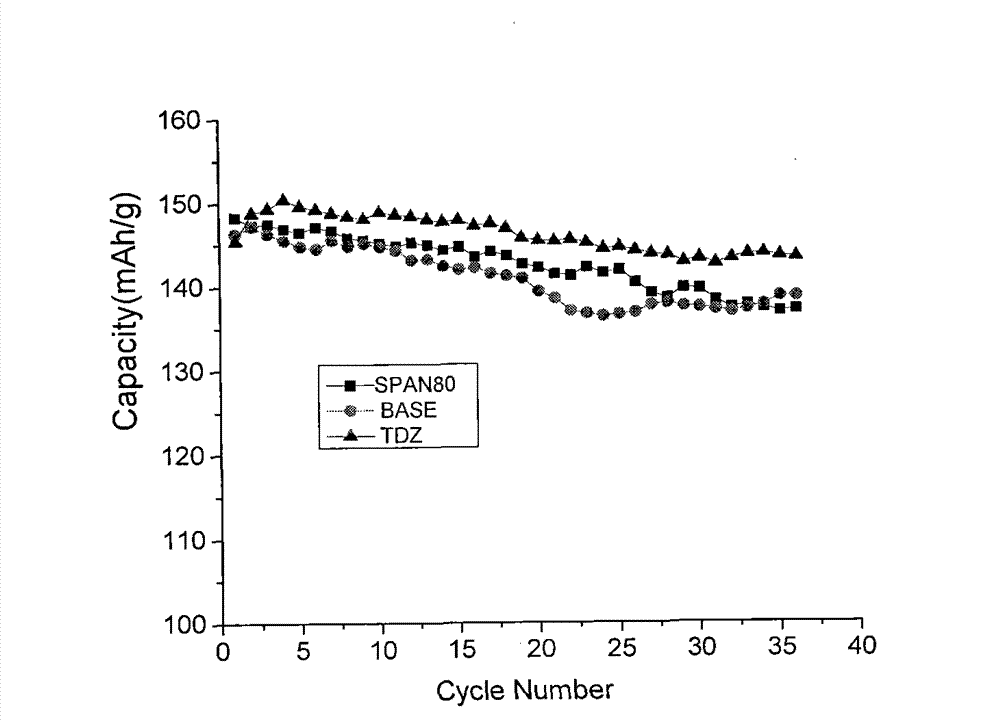

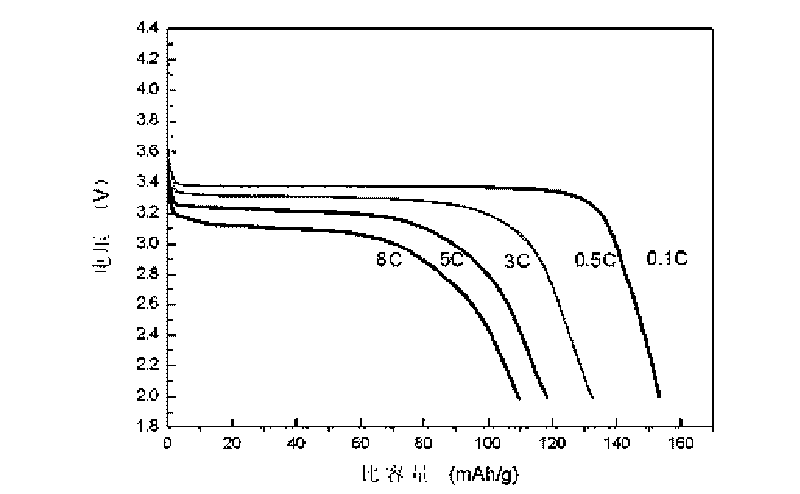

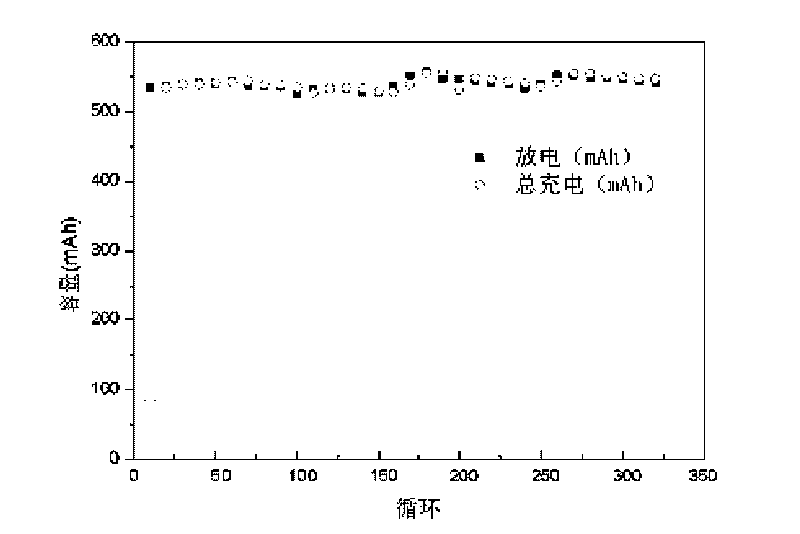

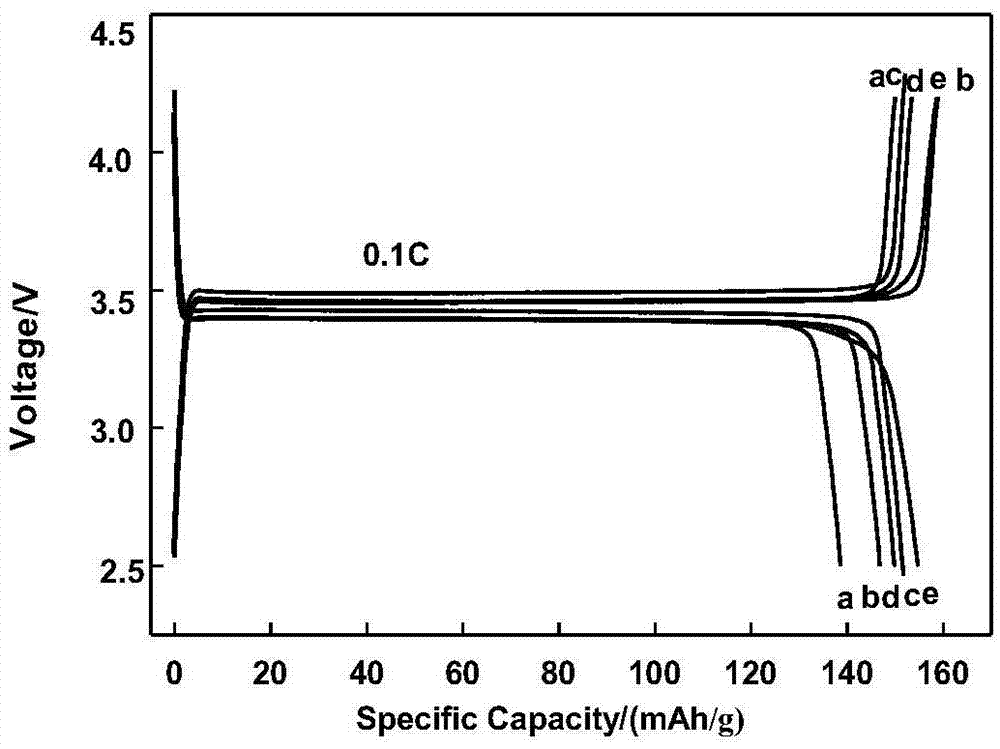

Preparation method of lithium iron phosphate material anode sheet

ActiveCN102956894AImprove adhesionWell mixedCell electrodesSecondary cellsLithium iron phosphateSodium-ion battery

The invention relates to a coating method of a lithium iron phosphate material anode sheet, belonging to the technical field of preparation of a lithium ion battery. The invention aims to provide a preparation method of a superfine and nano lithium iron phosphate material anode sheet to improve an anode coating performance, improve a battery discharging performance and prolong the cycle life. The lithium iron phosphate material anode sheet prepared by the preparation method disclosed by the invention is coated uniformly; the surface of the lithium iron phosphate material anode sheet is smooth and has no grains; the surface density is obviously improved; and a discharging specific capacity of a prepared semi-battery under a 0.1 C multiplying power is more than 145 mAh / g and a discharging specific capacity under a 1C multiplying power is more than 135 mAh / g. According to the preparation method disclosed by the invention, the performance of a pole sheet can be improved through optimizing a slurry formula and adding an additive for increasing the bonding property; and the operation process is simple and the cost is low. The preparation method has the very great propelling effect on the actual application of superfine lithium iron phosphate and nano-scale lithium iron phosphate.

Owner:内蒙古三信科技发展有限公司

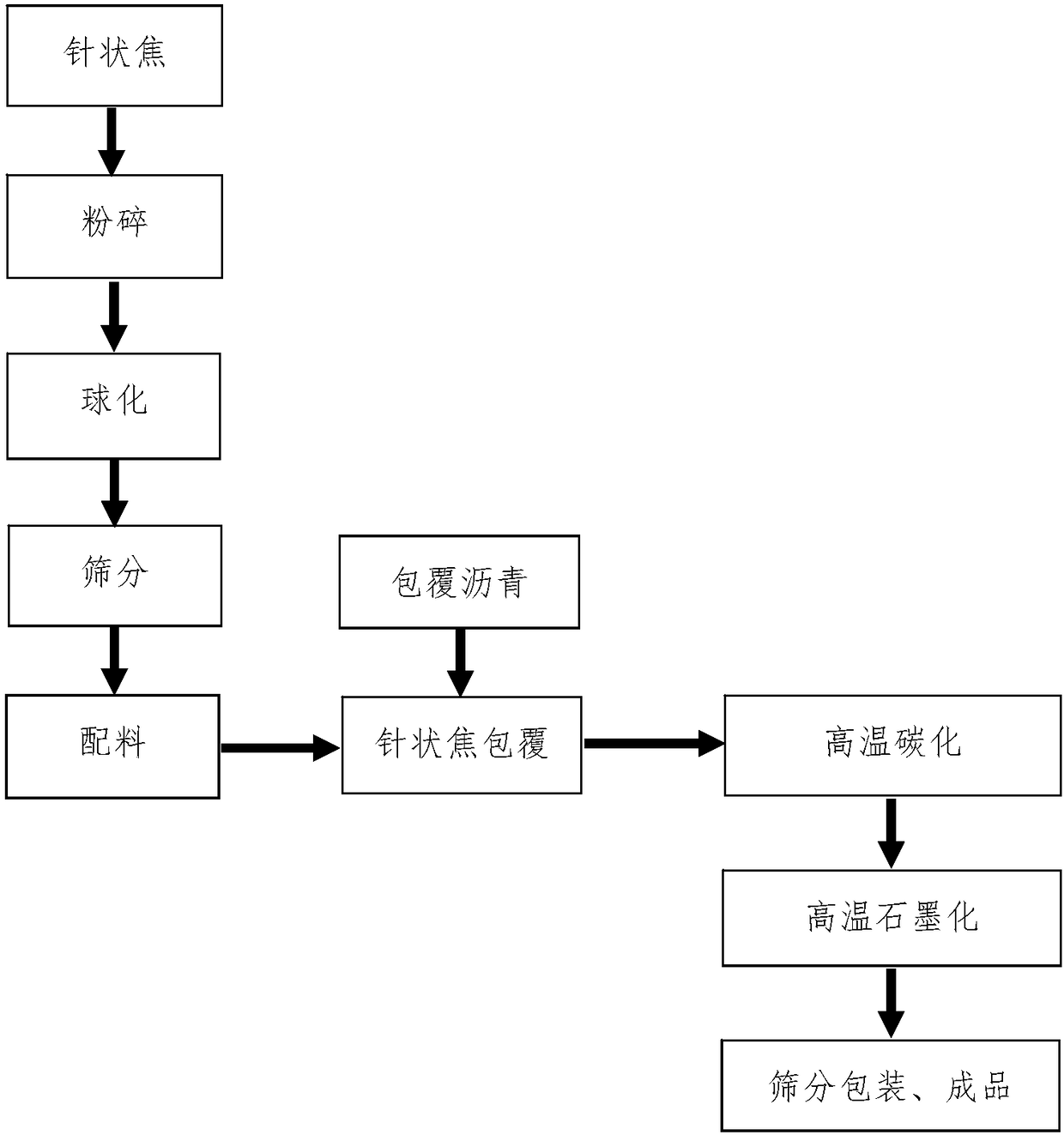

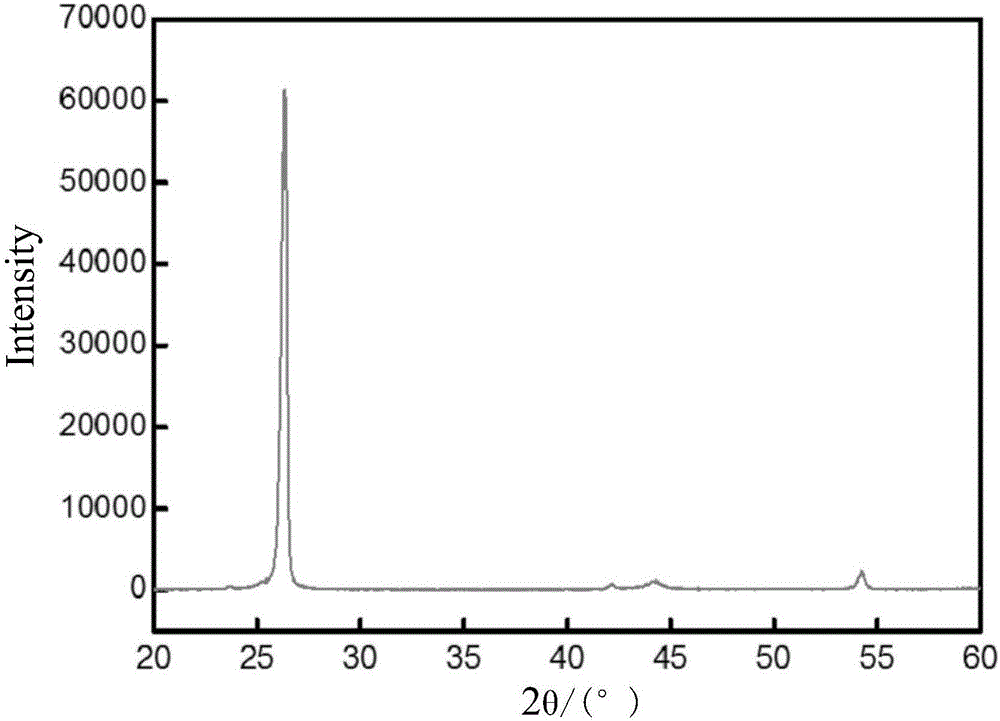

Method for producing graphite negative-electrode material by using needle coke, and negative-electrode material

ActiveCN108328613AExcellent preparation performanceLarge specific surface areaCarbon compoundsCell electrodesLithiumGraphite

The invention specifically relates to a method for producing a graphite negative-electrode material by using needle coke, and the negative-electrode material, belonging to the field of graphite negative-electrode materials. According to the method, needle coke is subjected to crushing, spheroidizing, screening, batching, coating, graphitization and screening successively so as to obtain the graphite negative-electrode material. In the step of batching, 10 to 15 parts of needle coke with a particle size in a range of 10 to 15 [mu]m, 50 to 55 parts of needle coke with a particle size in a rangeof 15 to 25 [mu]m and 20 to 35 parts of needle coke with a particle size in a range of 25 to 30 [mu]m. The invention has the beneficial effects that needle coke with three different particle sizes isused for preparing the carbon negative-electrode material, and small-particle-size needle coke which is large in specific surface area, short in the path that lithium ions take to enter particle centers and small in resistance is mixed with larger-particle-size needle coke which is small in specific surface area, long in the path that lithium ions take to enter particle centers and large in resistance, so the advantages of the small-particle-size needle coke and the larger-particle-size needle coke complement each other; and thus, the coated integral needle coke has large tap density and smallspecific surface area, and better facilitates preparation of the negative-electrode material with excellent performance.

Owner:衢州市衢发瑞新能源材料有限公司

Positive pole active substance containing lithium iron phosphate, preparation, positive pole and battery thereof

InactiveCN101453019AAvoid reduction in tap densityHigh unit mass specific capacity and capacity retentionElectrode manufacturing processesActive material electrodesNanometreCarbon source

The invention provides an anode active substance containing lithium iron phosphate. The anode active substance contains lithium iron phosphate particles and nanometer carbon, wherein the anode active substance also contains ferrous phosphide. The invention also provides a method for preparing the anode active substance containing the lithium iron phosphate; the preparation method comprises: under the environment of inert gas, a mixture is pre-sintered for 6 to 10 hours at a temperature of between 400 and 500 DEG C and is sintered for 8 to 30 hours at a temperature of between 650 and 850 DEG C; and the mixture contains a lithium source compound, a ferrous compound, an organic carbon source and a phosphor source, wherein the mixture also contains nanometer iron powder. The invention also provides an anode and a cell containing the anode active substance. The ferrous phosphide in the anode active substance containing the lithium iron phosphate has larger density than carbon so as to effectively avoid the reduction of tap density of the electrode material caused by the addition of the carbon source, and make unit mass specific capacity and capacity retention rate of the anode active substance high.

Owner:海宁市盐官工业投资有限公司

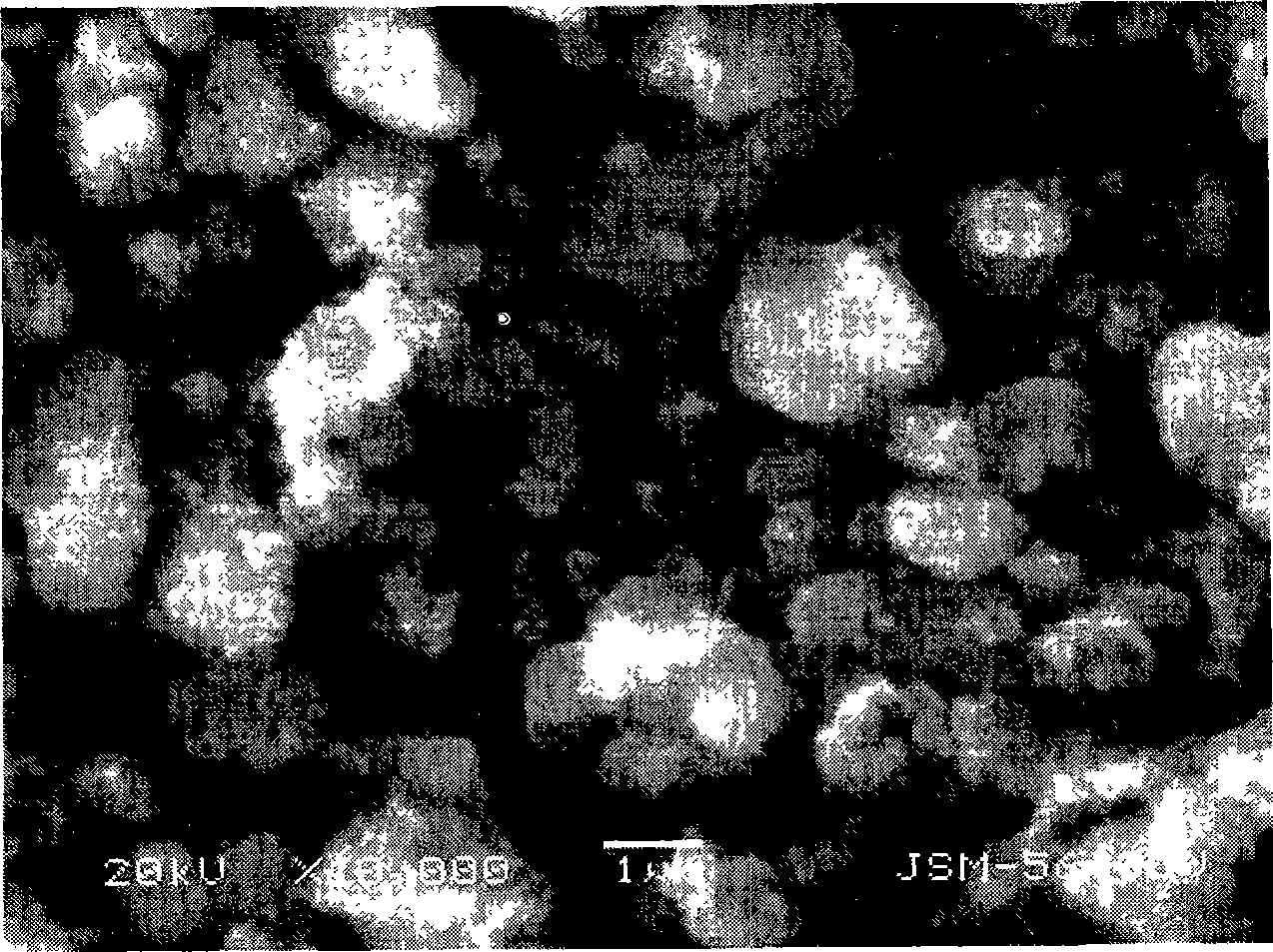

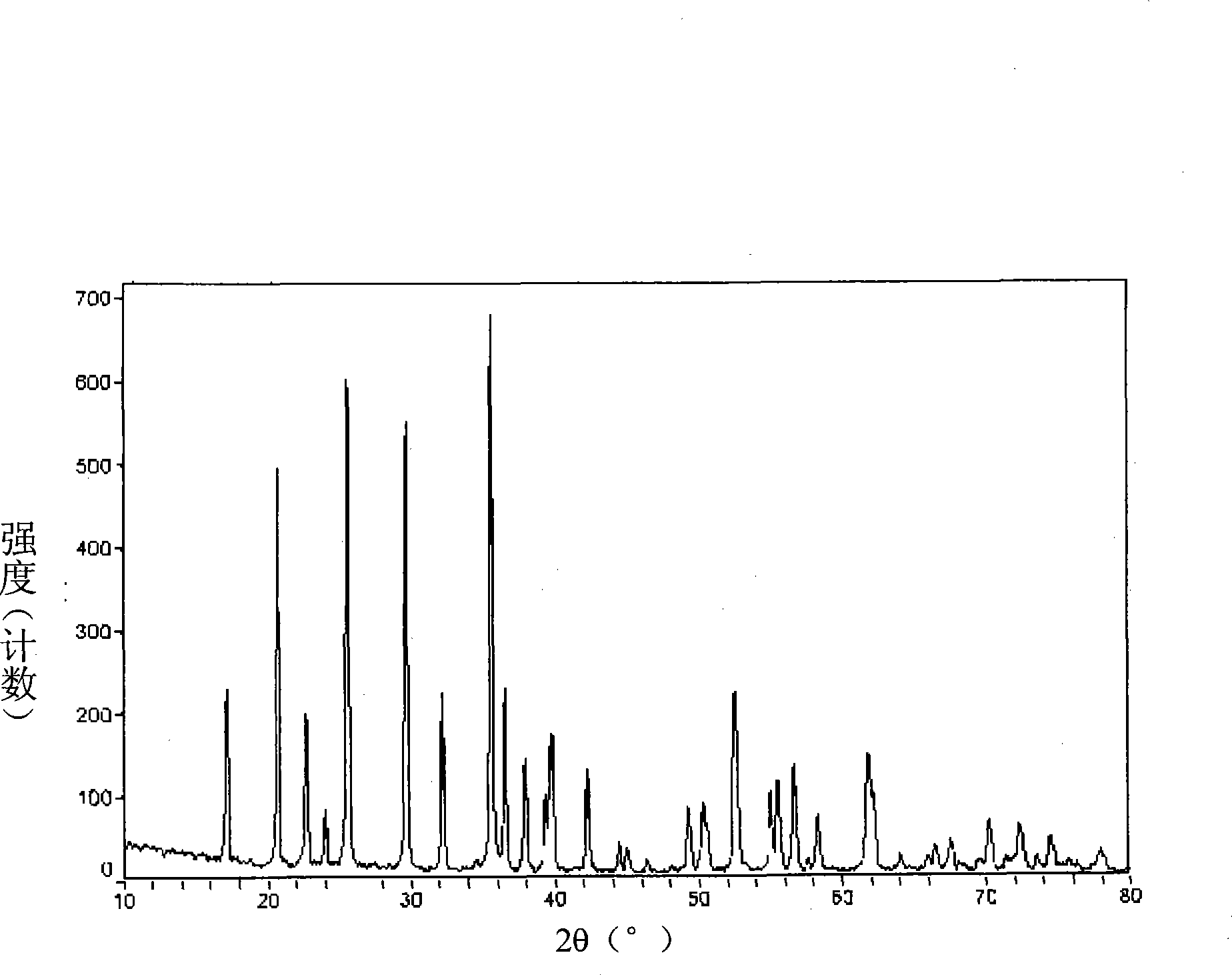

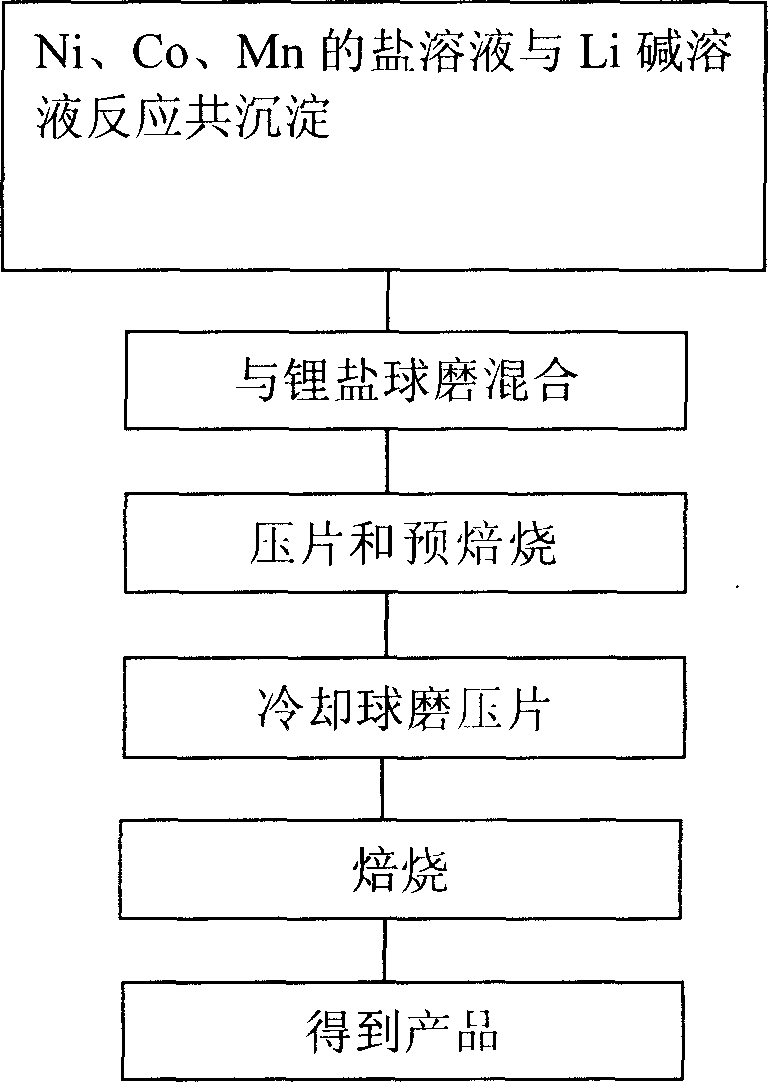

Method for producing anode active material containing lithium, magnesium compound oxide

InactiveCN1741302AStructural Precise TailoringSimple structureElectrode manufacturing processesLithium compoundsMANGANESE ACETATENickel salt

A method for preparing positive electrode multielement active material containing lithium / manganese composite oxide includes directly using lithium hydroxide coprecipitation to prepare M ( OH )2 , mixing it with lithium salt in grinding , forming plate by pressing , prebaking , cooled ball grinding , forming plate by pressing and backing . In the method , applied nickel salt is nickel acetate or nickel nitrate , applied cobalt salt is cobalt acetate or cobalt nitrate, applied manganese salt is manganese nitrate or manganese acetate and applied lithium salt is lithium carbonate or lithium acetate .

Owner:HEBEI UNIV OF TECH

Preparation method of sphere-like manganese-rich ternary precursor

PendingCN111498908ASimple process operationReduce manufacturing costCell electrodesSecondary cellsSulfuric acidParticle-size distribution

The invention discloses a preparation method of a sphere-like manganese-rich ternary precursor. The method comprises the following steps: mixing and dissolving nickel sulfate, cobalt sulfate and manganese sulfate to prepare a nickel-cobalt-manganese sulfate mixed solution, adding the nickel-cobalt-manganese sulfate mixed solution and a precipitant solution into a reaction kettle in a parallel flowmanner, adding a complexing agent in a parallel flow manner, controlling the pH value to be 6.8-10.0, the reaction temperature to be 40-80 DEG C and the stirring speed to be 200-800 r / min, and agingthe obtained turbid liquid in the reaction kettle for 5-20 hours after the solution is dropwise added; and after aging is finished, filtering and washing the turbid liquid, and finally, carrying out vacuum drying at 80 DEG C for 10-20 hours to obtain the sphere-like manganese-rich ternary precursor. The sphere-like manganese-rich ternary precursor prepared by the method is good in sphericity degree, narrow in particle size distribution, uniform in particle size, high in tap density, simple in process method and less in pollution.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

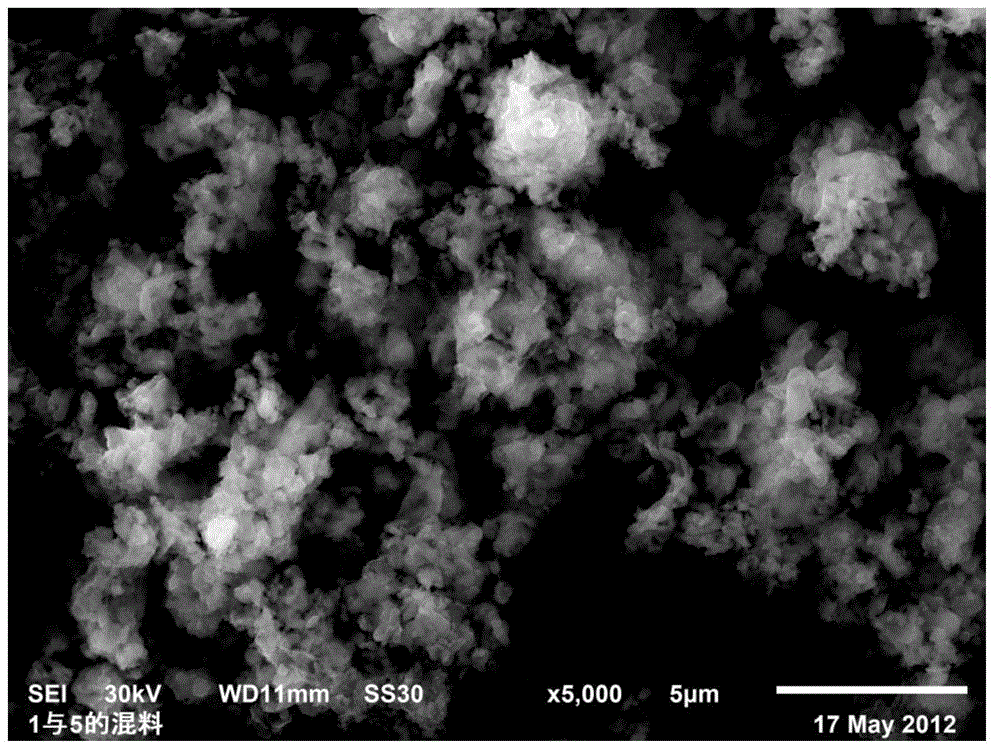

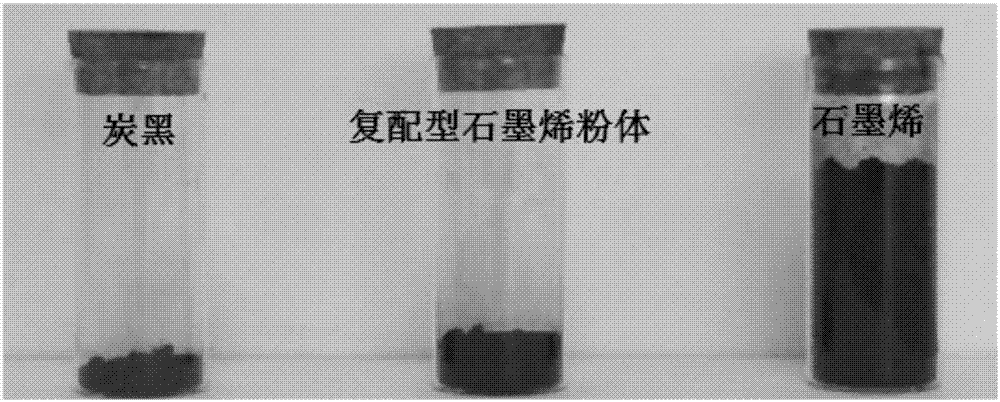

Carbon black and graphene powder composite conductive agent and preparation method and applications thereof

The invention discloses a preparation method of a carbon black and graphene powder composite conductive agent. The preparation method comprises the following steps: forming a graphite oxide / carbon black composite system: adding carbon black powder during the oxidation process of graphite to obtain the graphite oxide / carbon black composite system; and reducing the graphite oxide / carbon black composite system to obtain the graphene / carbon black powder conductive agent. The carbon black is added during the graphite oxide preparation process. The mixture is subjected to low temperature thermal expansion and high temperature reduction in sequence to prepare the conductive agent in one step. No surfactant or reducing agent is added. No difficult technology such as hydrothermal technology is used. The preparation method is close to a graphene preparation technology. The technology is simple, and the operation is easy.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

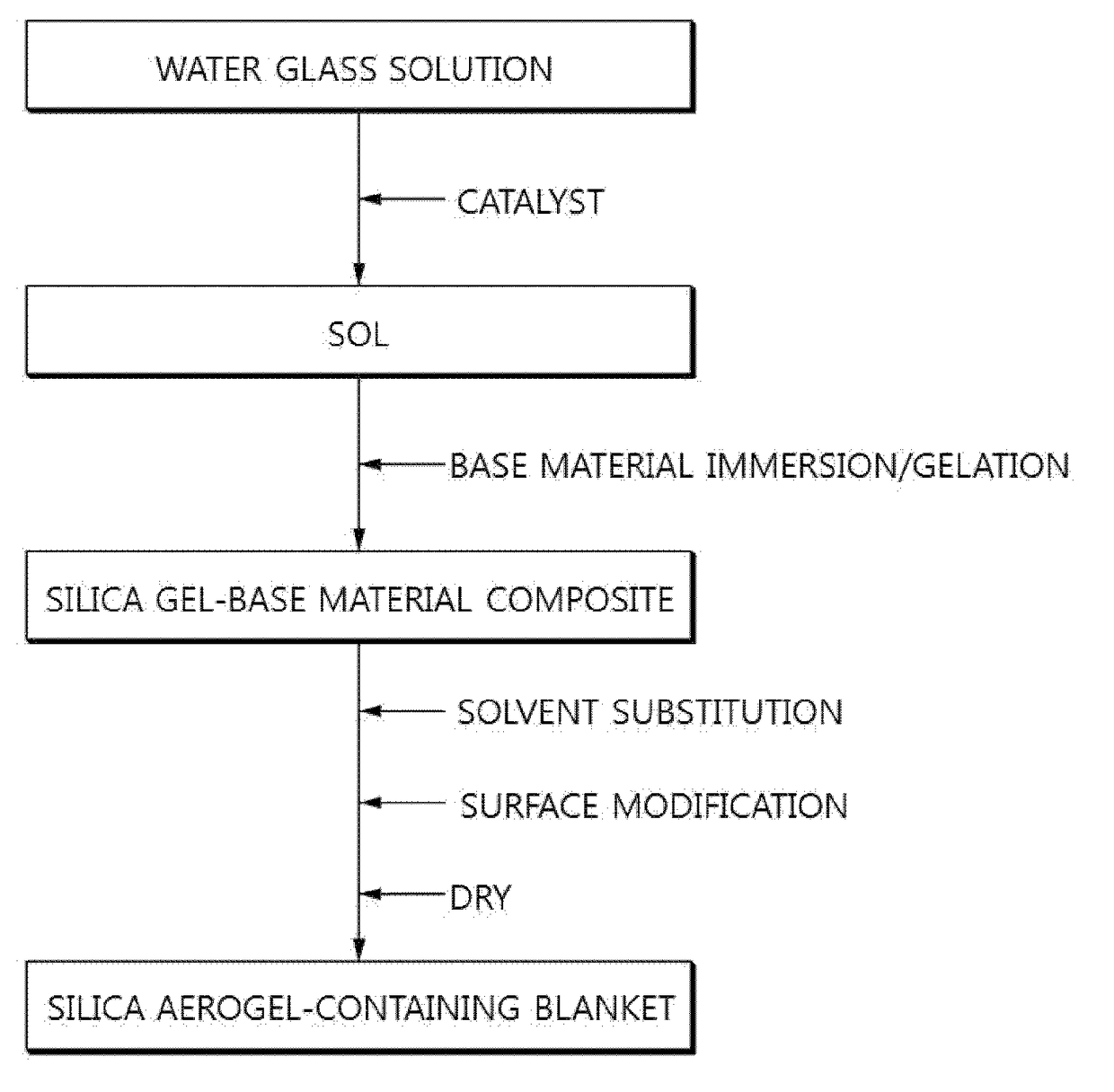

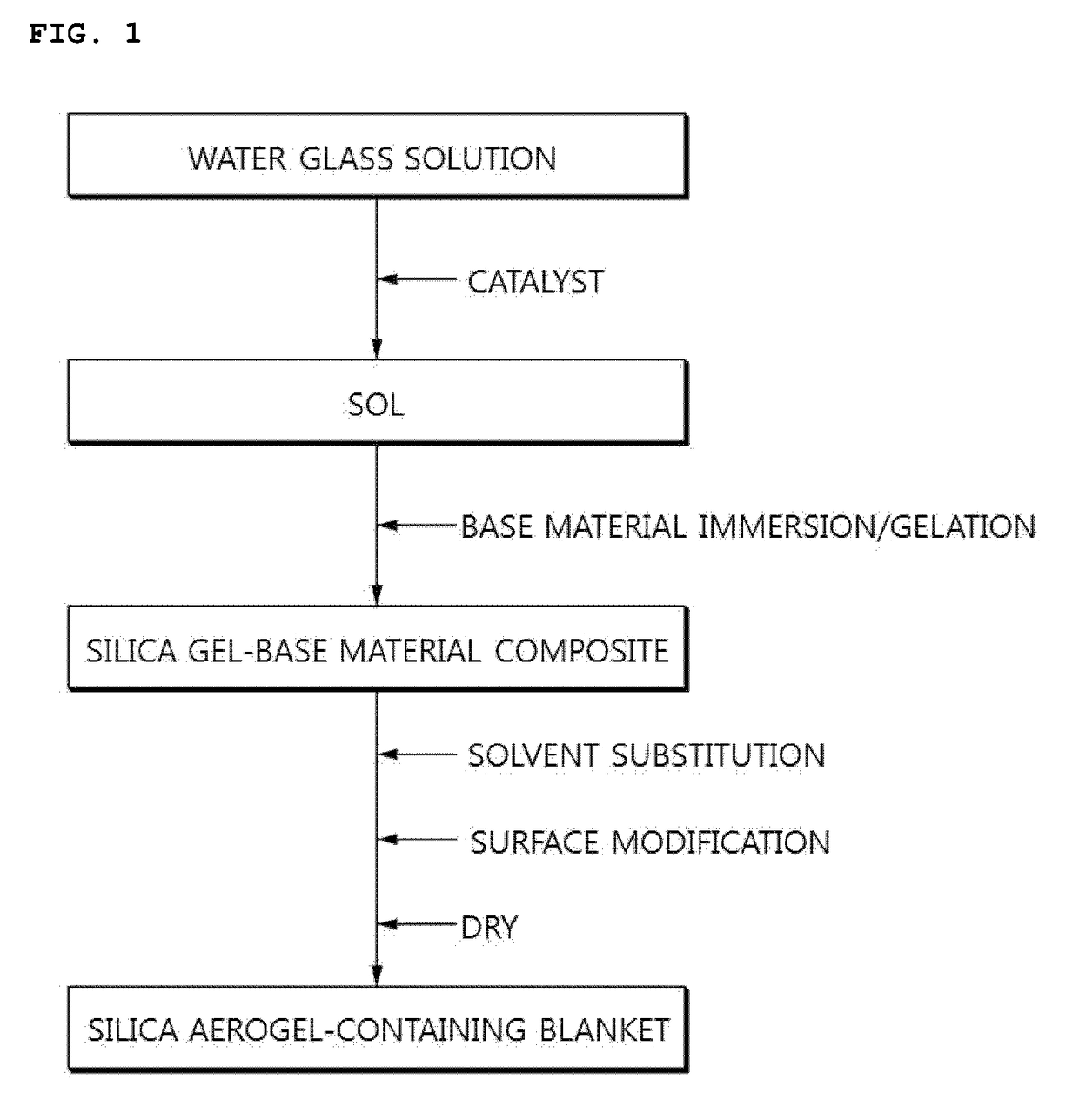

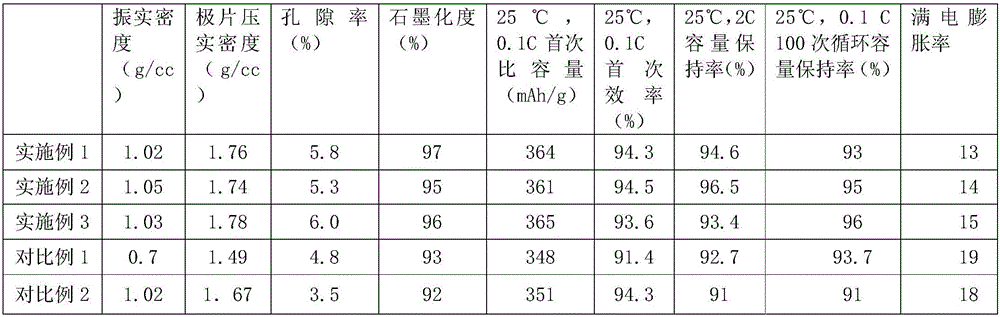

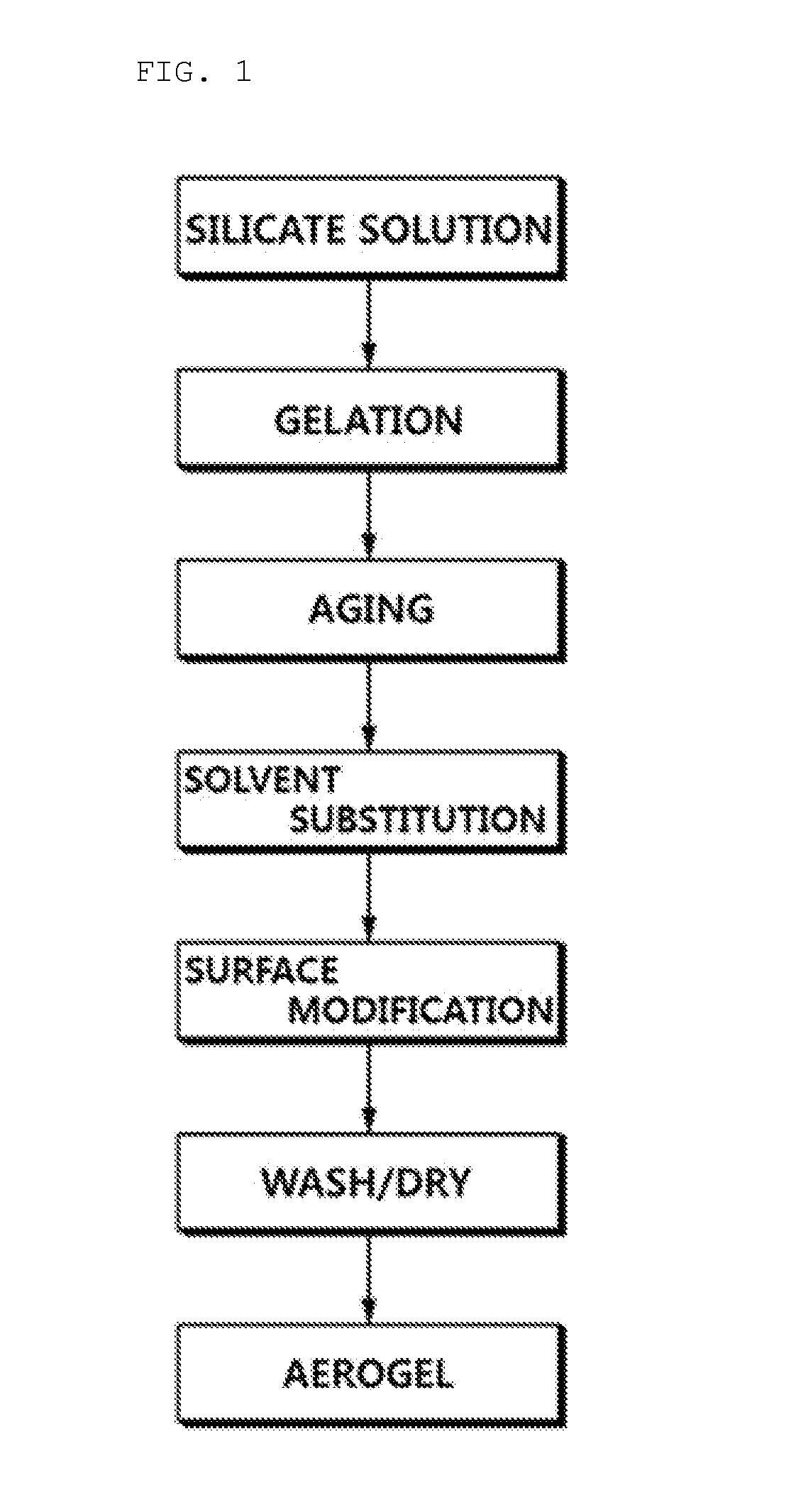

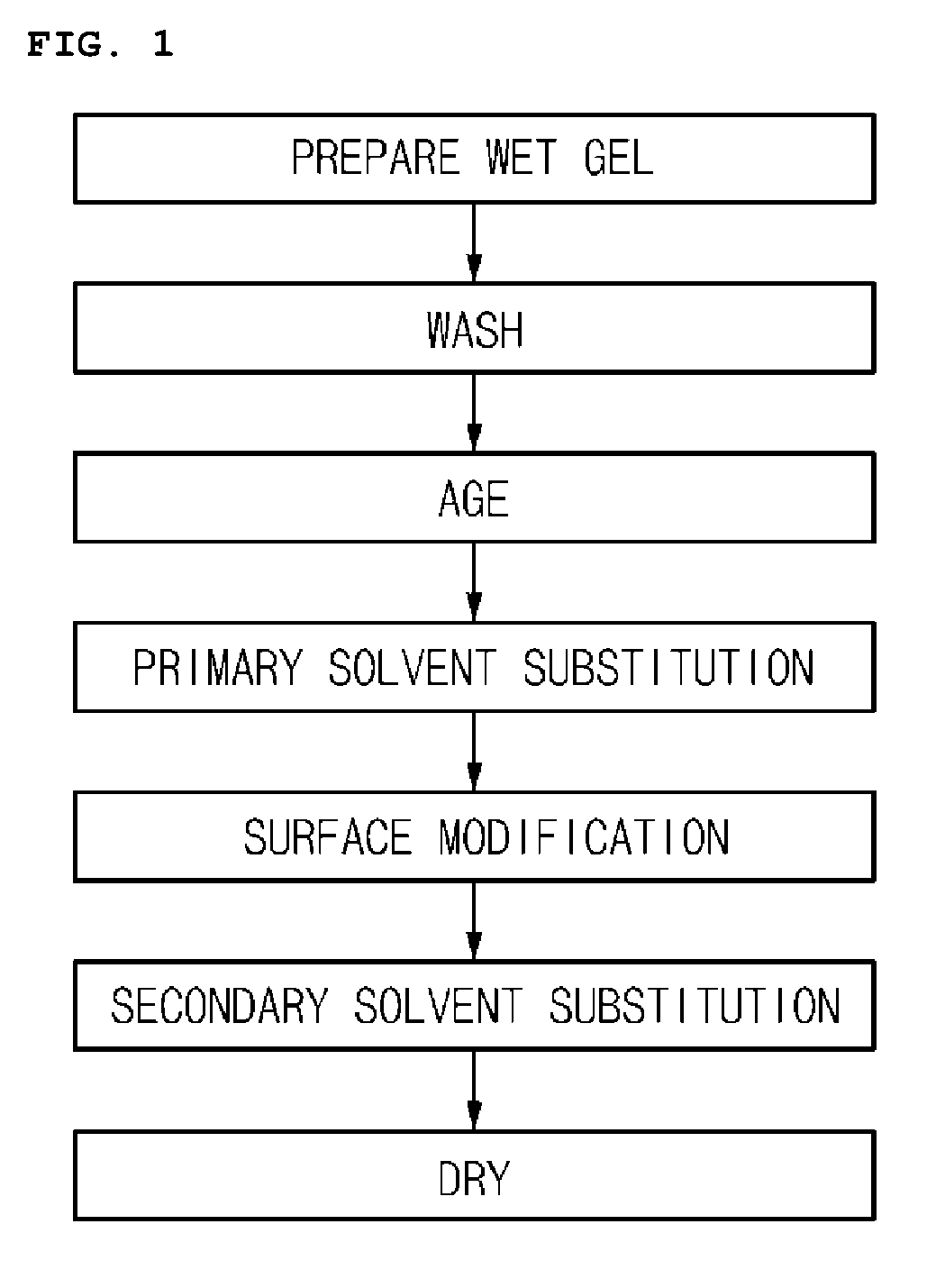

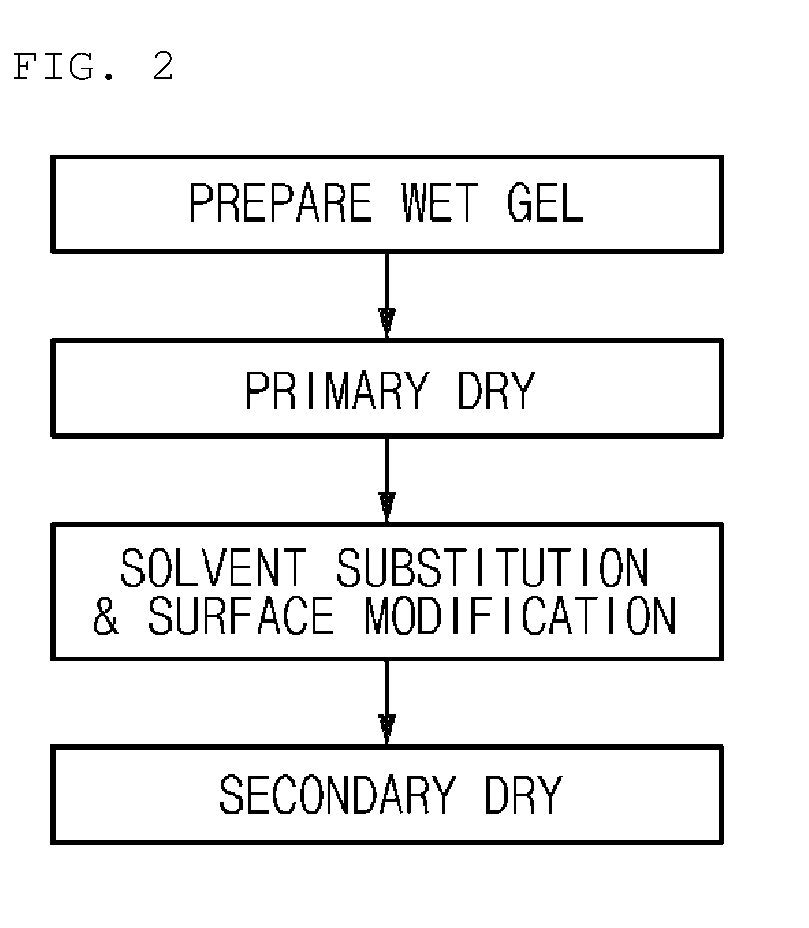

Preparation method of silica aerogel-containing blanket and silica aerogel-containing blanket prepared by using the same

ActiveUS20180010726A1Easy to prepareReduce the amount requiredLiquid surface applicatorsThermal insulationPorosityPolymer science

Provided are a preparation method of a silica aerogel-containing blanket which includes mixing a water glass solution, a polar organic solvent, and a silazane-based surface modifier to prepare a sol, preparing a silica gel-base material composite by immersion and gelation of a base material for a blanket in the sol, and drying the silica gel-base material composite, and a silica aerogel-containing blanket prepared by using the preparation method.A silica aerogel-containing blanket having a high degree of hydrophobicity as well as excellent physical properties, particularly, low tap density, high porosity, and excellent mechanical flexibility may be prepared by the minimal use of a surface modifier without a surface modification step by the above method.

Owner:LG CHEM LTD

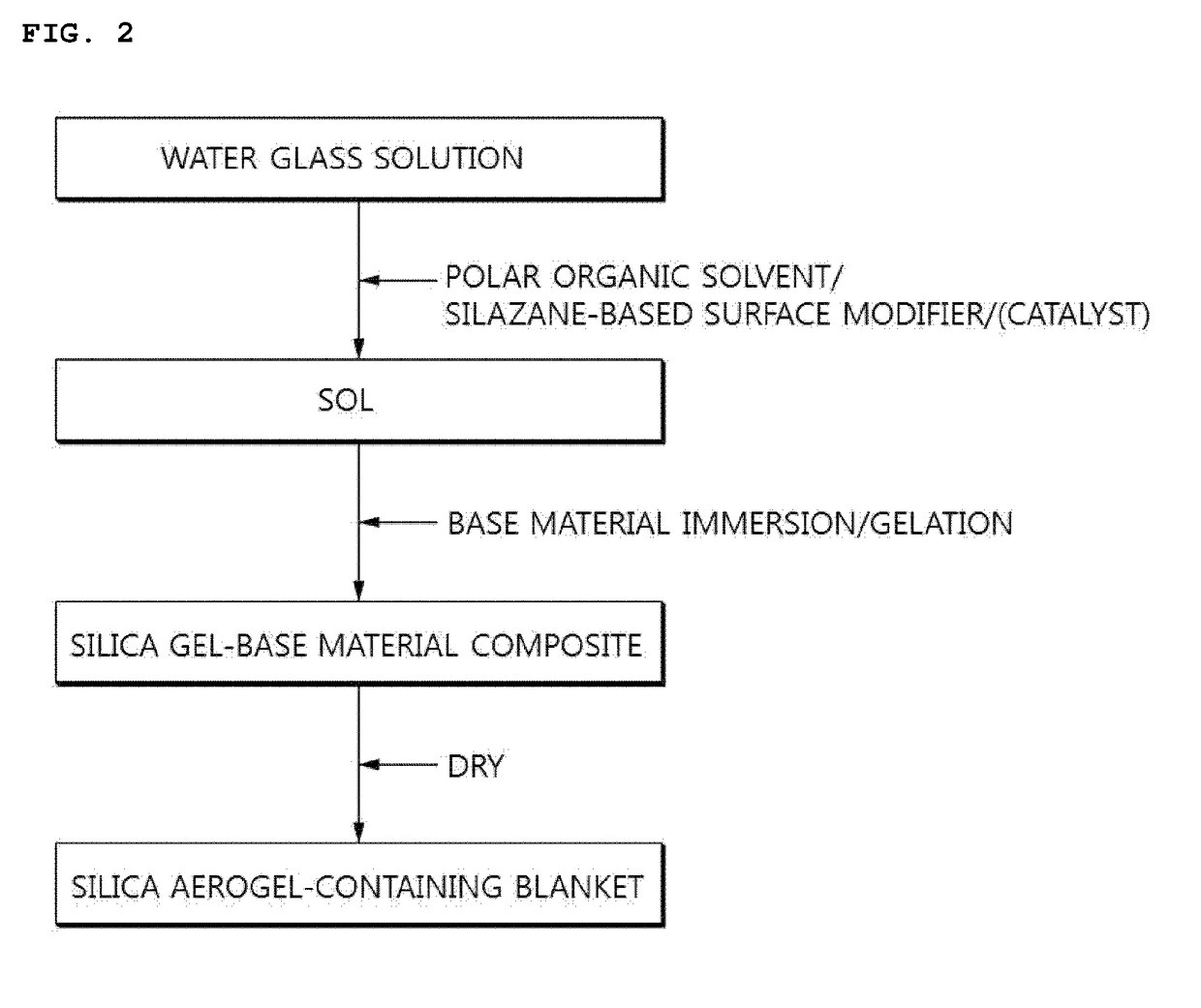

Preparation method of high-performance graphite negative electrode material for lithium ion battery

InactiveCN105789627AEasy to processImprove cycle performanceCell electrodesSecondary cellsHigh rateMass ratio

The invention discloses a preparation method of a high-performance graphite negative electrode material for a lithium ion battery. The method comprises the following steps of 1) collecting petroleum coke micropowder in a shaper and a grinder in normal graphite production, and mixing the petroleum coke micropowder, ground expanded graphite powder, raw mesocarbon microbeads and an adhesive in a mixer for 0.5-3 hours according to a mass ratio of 1 to (0.01-0.3) to (0.7-1.5) to (0.1-0.2) to form a solid-phase coated mixture, wherein the frequency of the mixer is 30-50HZ; and 2) graphitizing the solid-phase coated mixture obtained in the step 1) to obtain the high-performance graphite negative electrode material for the lithium ion battery. The method is simple and feasible; micropowder wastes in a dust collector are recycled, so that the cost is reduced; the method is easy for large-scale industrial production; and the obtained graphite negative electrode material has the characteristics of high energy density, good liquid absorption and retention performance, good cycle performance, good isotropic performance, good high-rate charge / discharge performance and low expansion rate in a charge / discharge process.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

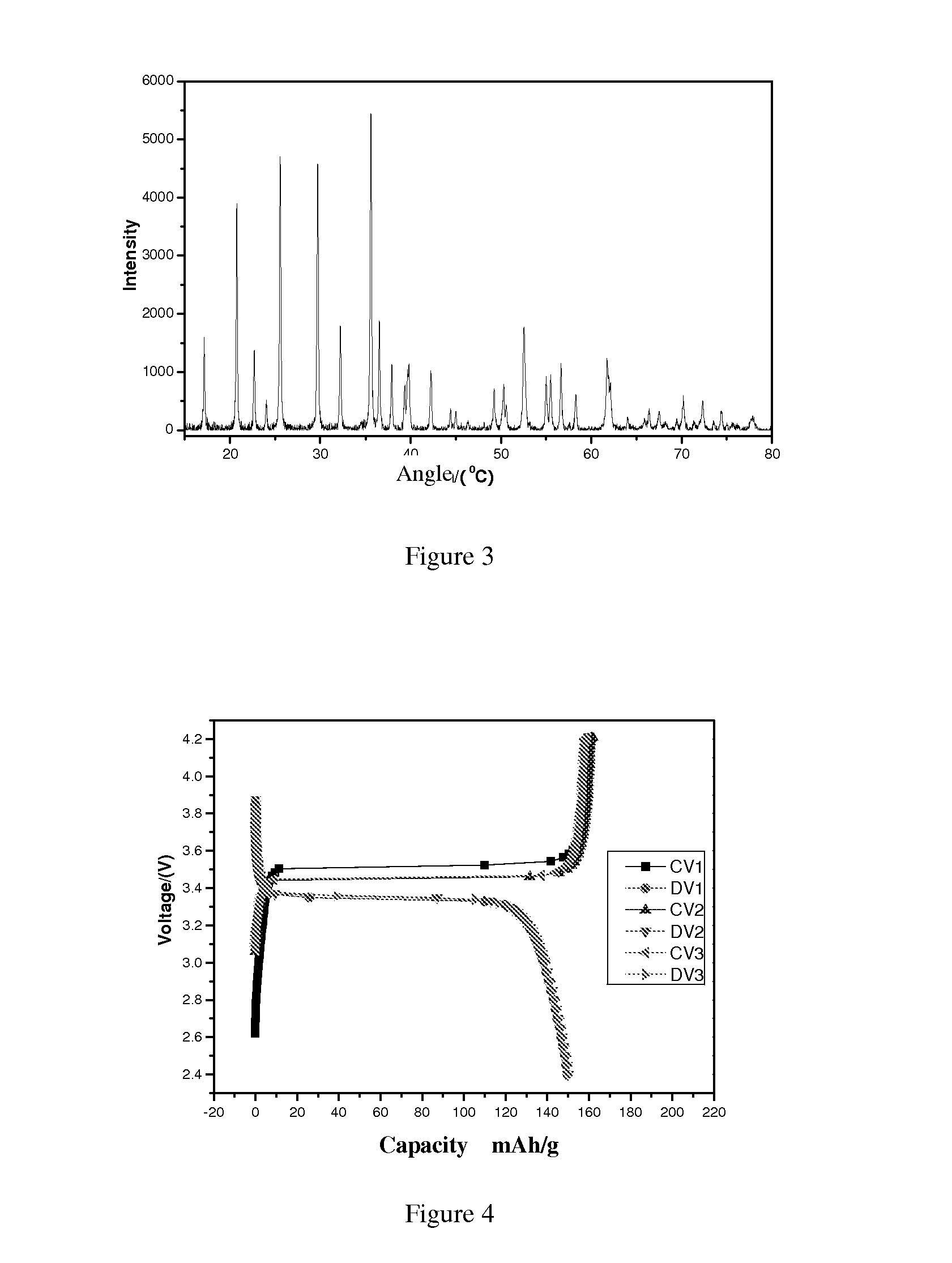

Oxygen vacancy-contained and Fe site-doped lithium ferric phosphate and rapid solid-phase sintering method thereof

ActiveCN101764226AImprove electronic conductivityImprove ionic conductivityFinal product manufactureCell electrodesLithium iron phosphateOxygen vacancy

The invention relates to an oxygen vacancy-contained and Fe site-doped lithium ferric phosphate as a lithium ion anode material and a rapid microwave sintering preparation method thereof. The formula of the invention product is LiFe1-x-aMeaMxPO4-yNz, wherein Me is one or more of Mg, Mn or Nd, and M is one or more of Li, Na, K, Ag, Cu; 0<=x<=0.1, 0<a<=0.1, 0<y<=0.5, 0<=z<=0.5 (4.9), wherein x and z can not be 0 at the same time. The rapid microwave sintering preparation method of the invention has high production efficiency, low energy consumption, good stability of prepared product batches, as well as excellent rate capability and cycle performance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

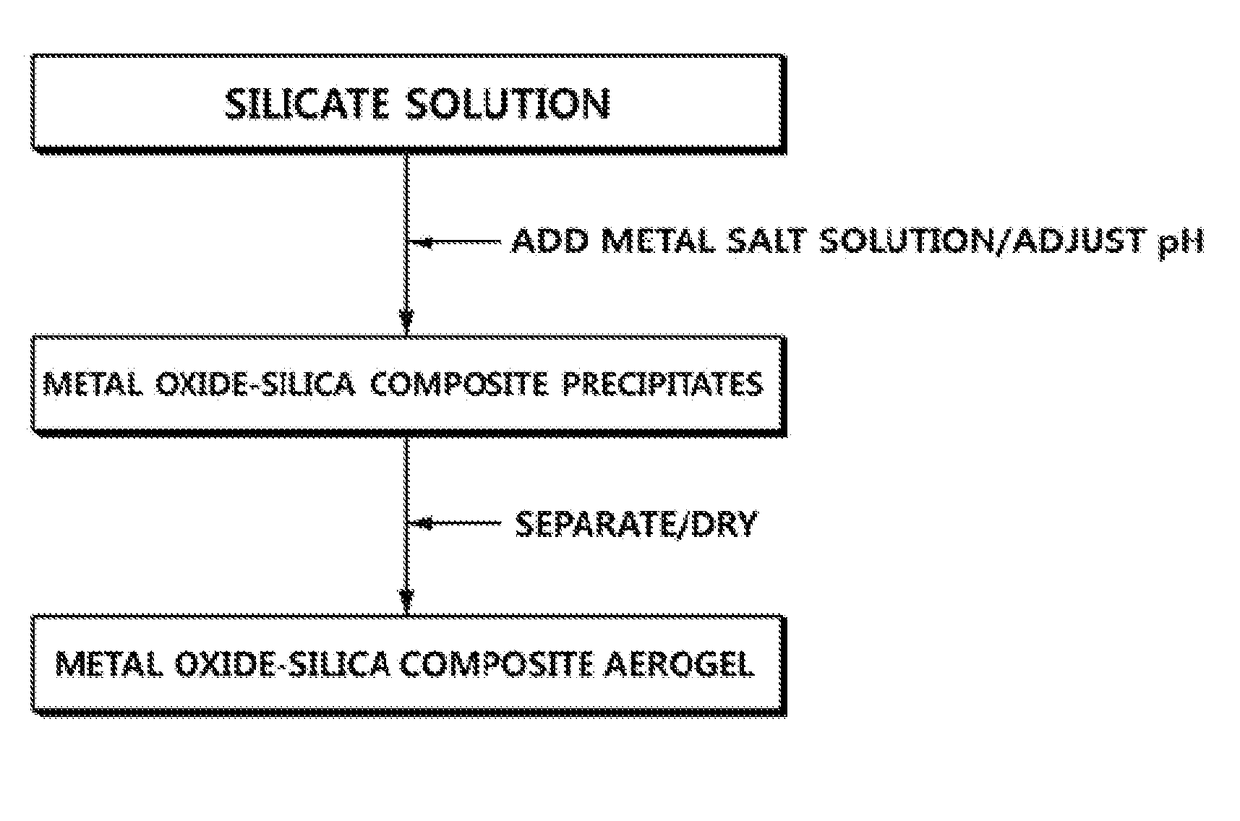

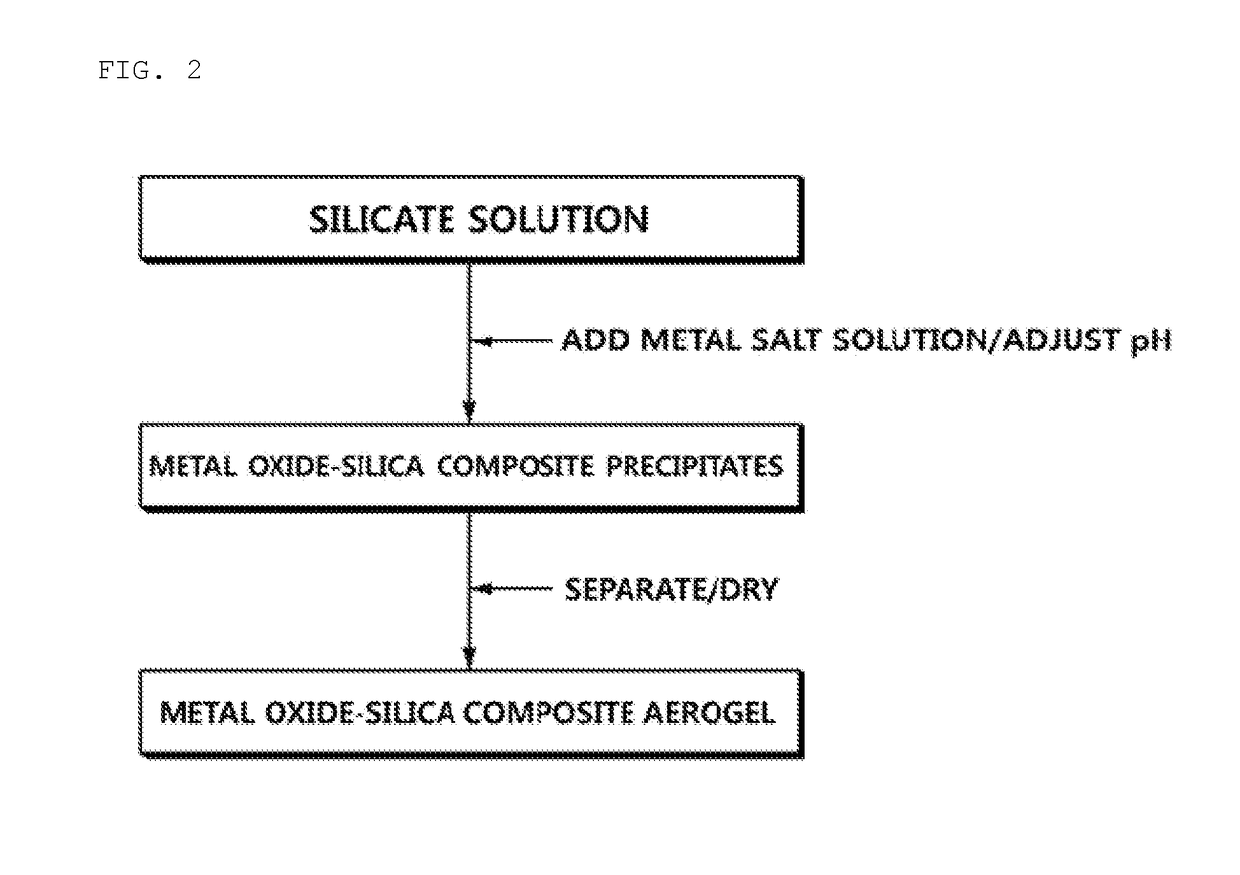

Method of preparing metal oxide-silica composite aerogel and metal oxide-silica composite aerogel prepared by using the same

ActiveUS20180127278A1Low shrinkageGood physical propertiesSilicaOther chemical processesVolumetric Mass DensitySolvent

Provided are a method of preparing a metal oxide-silica composite aerogel, which includes preparing metal oxide-silica composite precipitates by adding a metal salt solution to a silicate solution and performing a reaction, and washing the metal oxide-silica composite precipitates with a washing solvent having a surface tension at 20±5° C. of 30 mN / m or less and drying the washed metal oxide-silica composite precipitates, and a metal oxide-silica composite aerogel having increased specific surface area and pore properties as well as tap density, which is significantly reduced by a maximum of 78.6% in comparison to a composite aerogel prepared by using water as a typical washing solvent, prepared by the method.

Owner:LG CHEM LTD

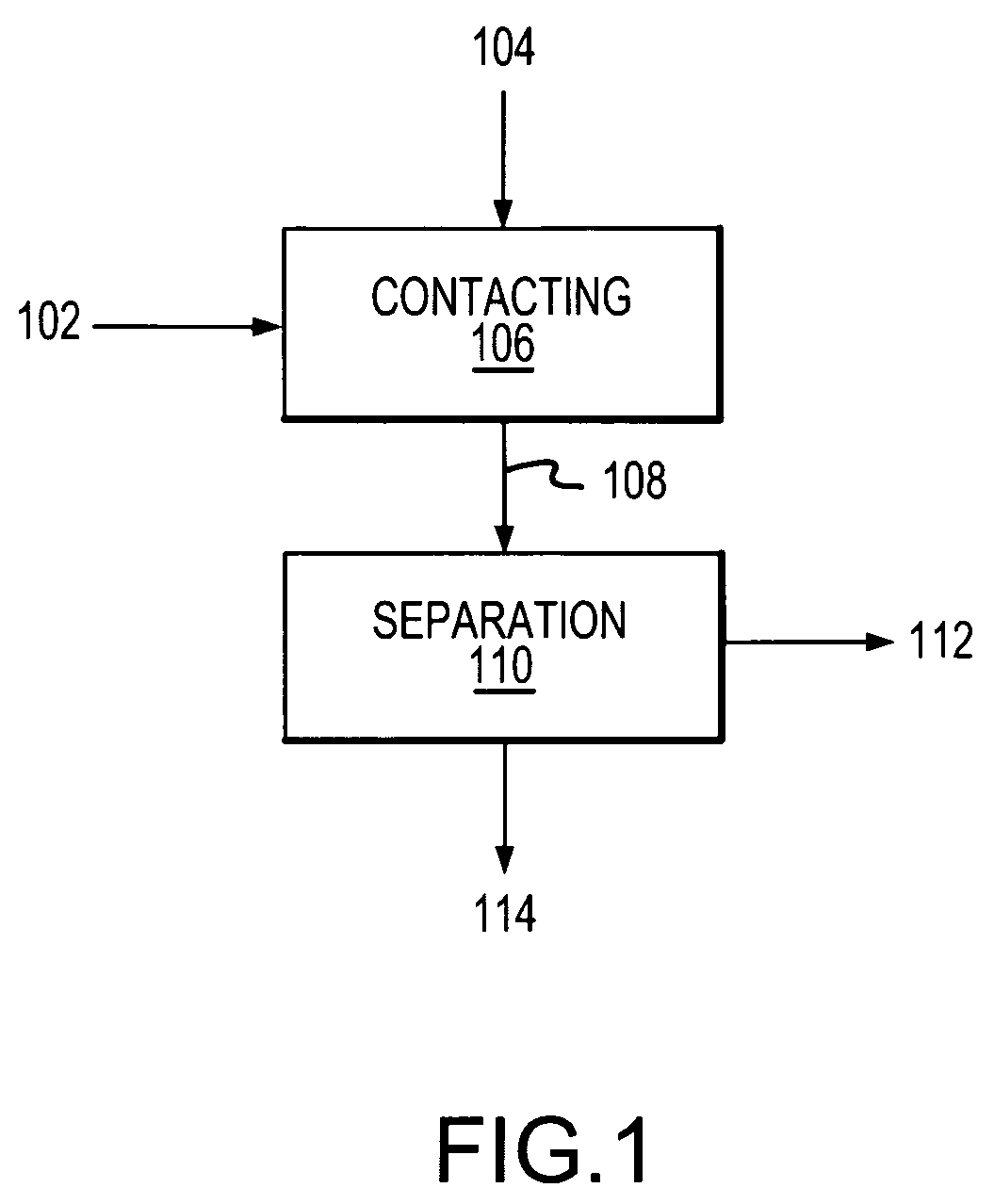

Method of preparing metal oxide-silica composite aerogel and metal oxide-silica composite aerogel prepared by using the same

ActiveUS20180127279A1Good physical propertiesLow tap densitySilicaOther chemical processesVolumetric Mass DensitySilicon dioxide

Provided are a method of preparing a metal oxide-silica composite aerogel which includes preparing a silicate solution by dissolving water glass at a concentration of 0.125 M to 3.0 M, after adding and mixing a metal salt solution having a metal ion concentration of 0.125 M to 3.0 M to the silicate solution, precipitating metal oxide-silica composite precipitates by adjusting a pH of a resulting mixture to be in a range of 3 to 9, and separating and drying the metal oxide-silica composite precipitates, wherein the metal salt solution includes a magnesium (Mg)-containing metal salt in an amount such that an amount of magnesium ions is greater than 50 mol % based on a total mole of metal ions in the metal salt solution, and a metal oxide-silica composite aerogel having low tap density and high specific surface area prepared by the method.

Owner:LG CHEM LTD

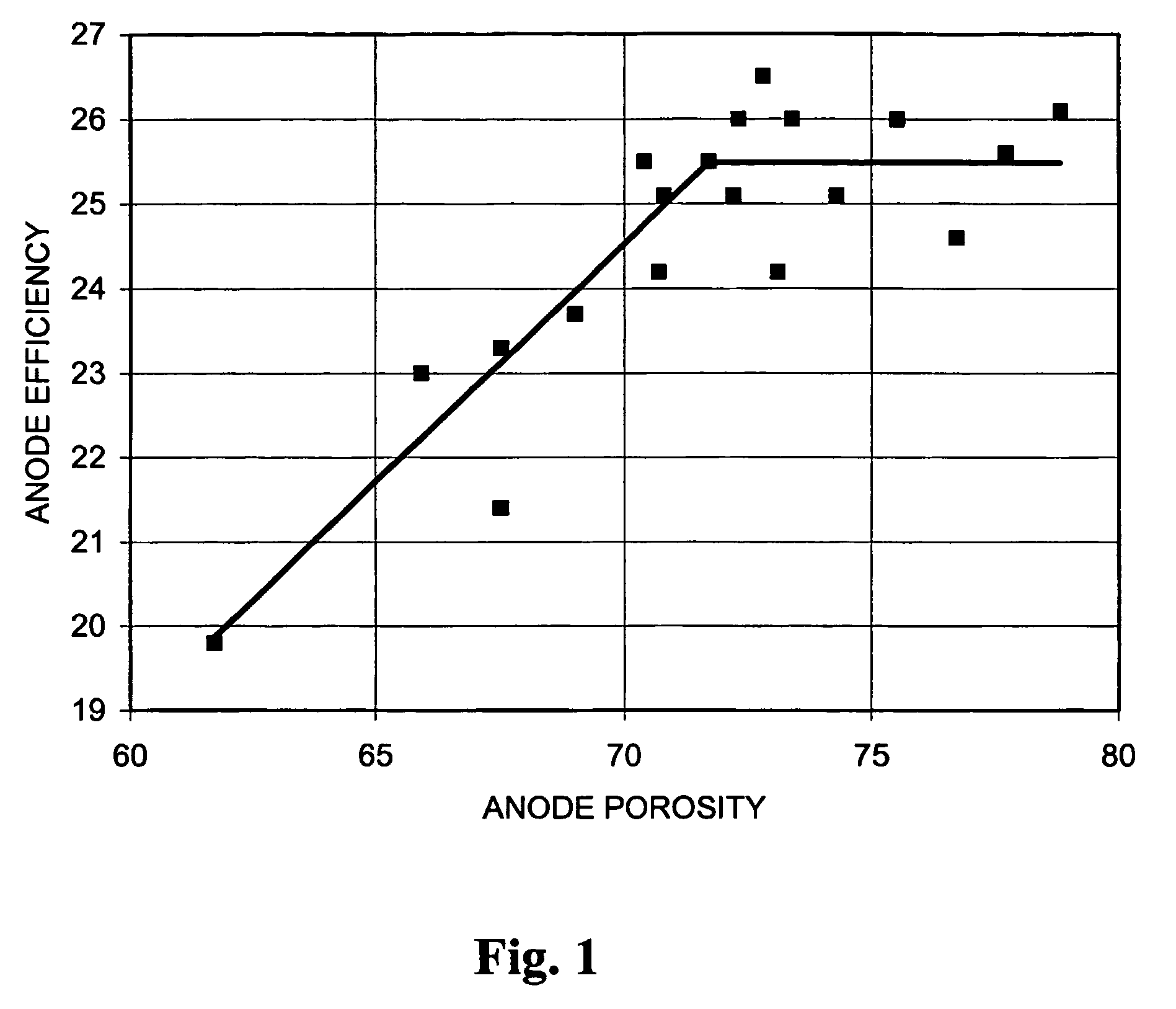

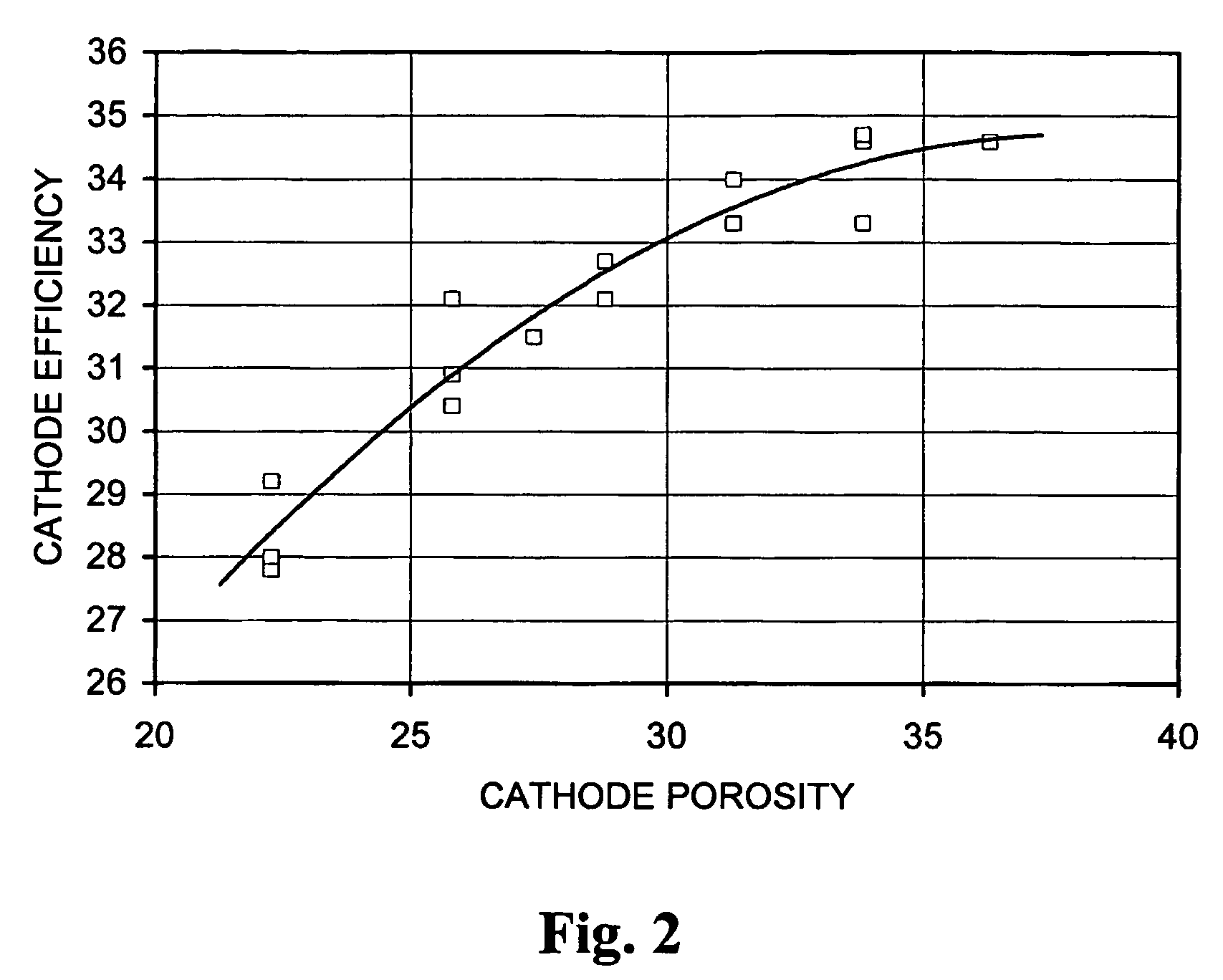

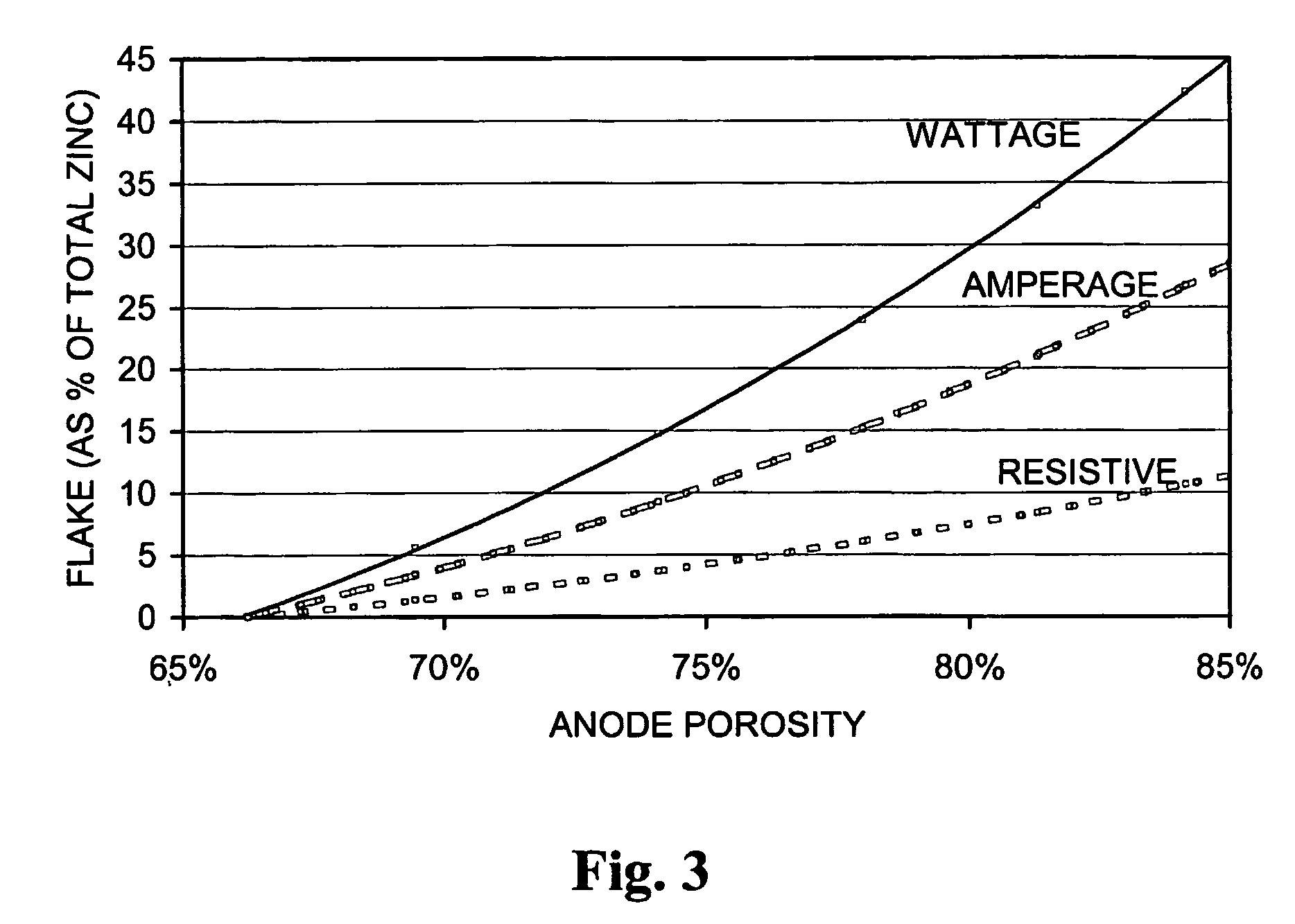

Optimised alkaline electrochemical cells

InactiveUS7232628B2Improve performanceReducing quantity of activeAlkaline accumulatorsActive material electrodesPorosityMetallurgy

Owner:ENERGIZER BRANDS

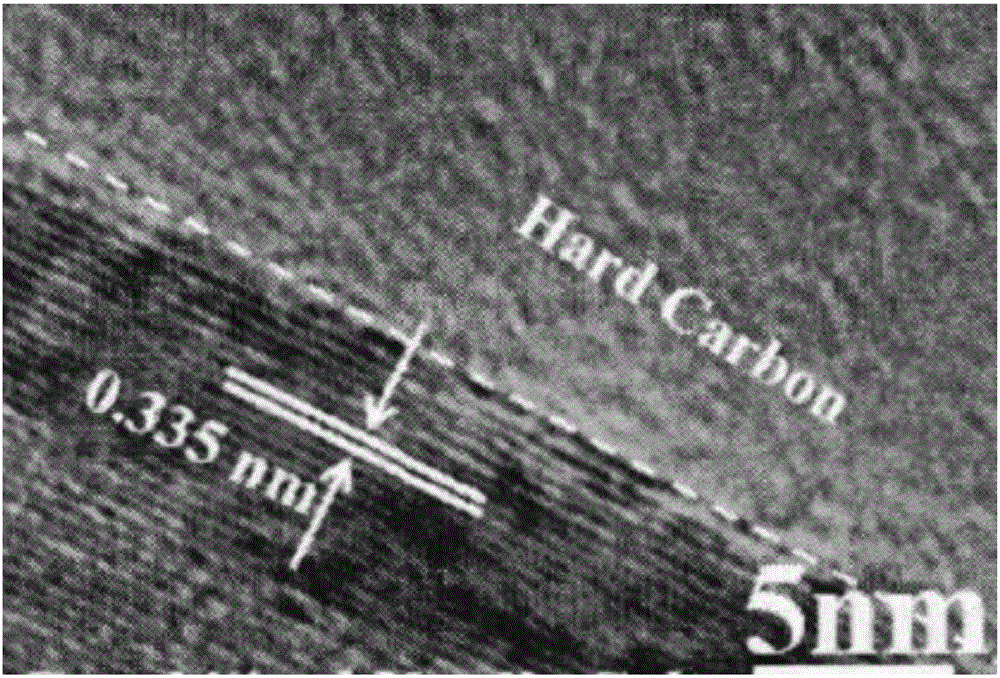

Preparation method of graphitized carbon negative electrode material

PendingCN106848258AIncrease electron densityImprove electronic conductivityCell electrodesGrapheneSucroseMetallurgy

The invention provides a preparation method of a graphitized carbon negative electrode material. The preparation method comprises the following steps: 1) calcining fatty acid in a nitrogen atmosphere at the temperature of 600-800 DEG C for 6-8h and cooling, so as to obtain amorphous carbon; 2) calcining the amorphous carbon in a nitrogen atmosphere at the temperature of 2,500-2,800 DEG C for 4-6h and cooling, so as to obtain graphitized carbon; 3) dispersing the graphitized carbon and a certain amount of nitrogenous polymers into anhydrous ethanol, uniformly mixing the mixture, atomizing to form balls and collecting precursors with a cyclone separator; 4) carbonizing the precursors in a nitrogen atmosphere at the temperature of 800-1,000 DEG C for 2-4h and cooling, so as to obtain porous graphitized carbon; 5) dispersing the porous graphitized carbon and a certain amount of sucrose into deionized water, uniformly mixing the mixture and performing air blast drying on the mixture at the temperature of 120-150 DEG C; carbonizing the mixture in a nitrogen atmosphere at the temperature of 800-1,000 DEG C for 2-3h and cooling, so as to obtain N-doped carbon-coated porous graphitized carbon.

Owner:OPTIMUM BATTERY CO LTD

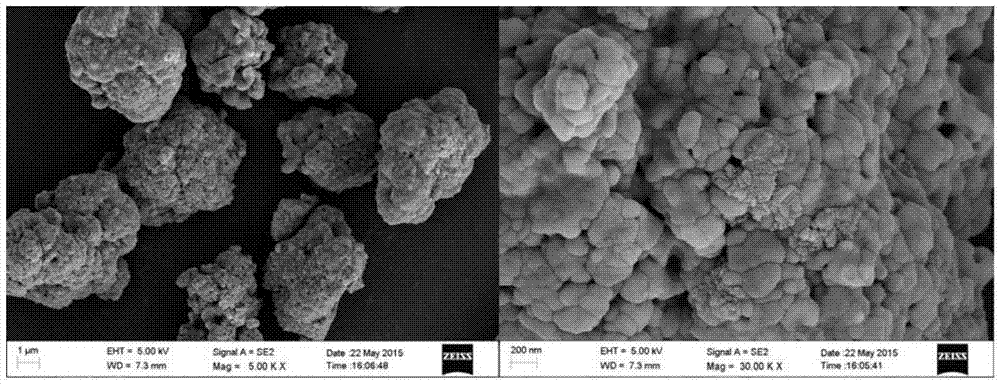

Spherical micro-nano ferric phosphate/carbon composite material and preparation method thereof

ActiveCN105449208AHas a spherical structureAchieve wrappingCell electrodesSecondary cellsPhosphateCarbon composites

The invention discloses a spherical micro-nano ferric phosphate / carbon composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing aqueous solution of ferric salt and a phosphorous compound, wherein the mole ratio of the ferric element to the phosphorus element is (0.9-1.2): 1, and the solution concentration is 0.2-5 mol / L; (2) dispersing a high polymer material binder in the solution in the step (1), wherein the dosage of the high polymer material binder is 0.5-90 wt / % of the ferric salt; (3) adding the solution prepared in the step (2) into a reaction still, continuously adding alkali solution to ensure that the pH in the reaction still is kept in 2-4, and reacting at a temperature of 20-90DEG C for 1-60 hours to obtain a crystal water-containing spherical micro-nano ferric phosphate / carbon composite material; and (4) under an inert atmosphere, roasting the spherical micro-nano ferric phosphate / carbon composite material prepared in the step (3) at a temperature of 300-800DEG C for 3-12 hours, and cooling to obtain the product. According to the preparation method, the coating of carbon materials is realized, and a crucial role is played in subsequently preparing high-density high-performance lithium ion battery LiFePO4 anode materials.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

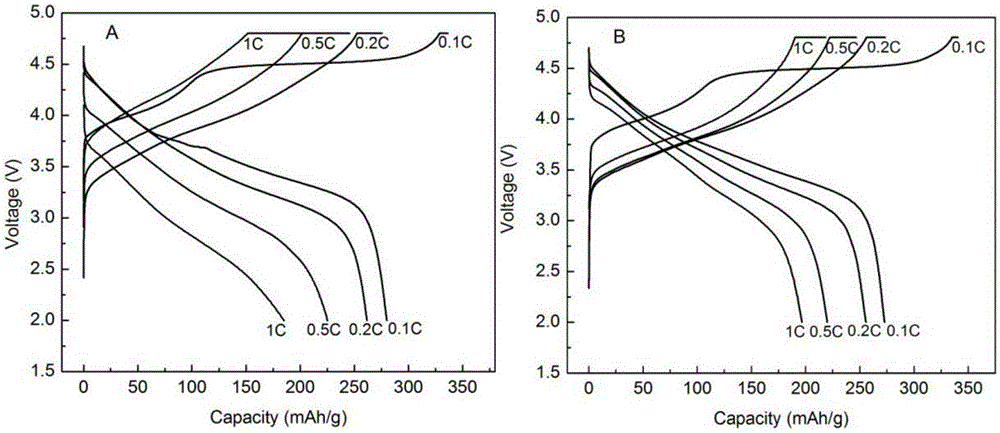

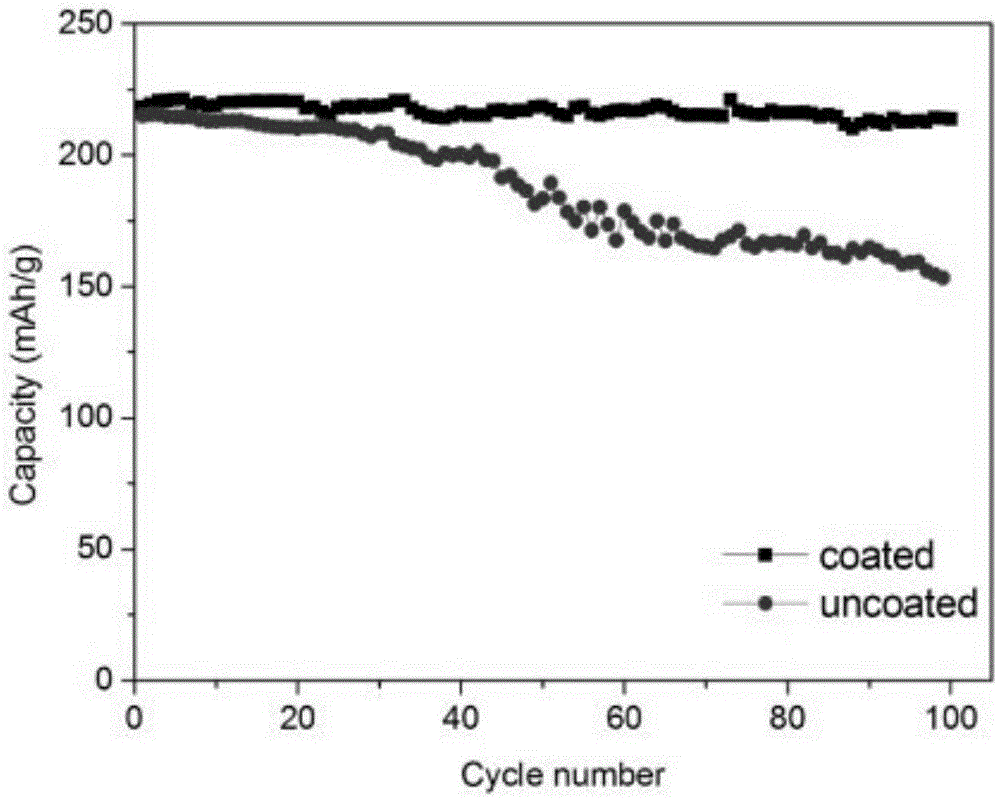

Surface coating method of cathode material for lithium-ion battery

ActiveCN105322176AImproved tap density reductionImproved cycle performance and rate performanceCell electrodesSecondary cellsLithium compoundCarbon coating

The invention discloses a surface coating method of a cathode material for a lithium-ion battery. The method comprises the following steps: adding the cathode material for the lithium-ion battery to a magnesium salt solution, simultaneously adding a certain amount of lithium compound, carrying out ultrasound for 30-180 minutes, stirring the solution at 50-80 DEG C until dry, and putting the sample into a drying oven at 80 DEG C for drying; slowly heating the dried sample to 110-130 DEG C in a tube furnace, maintaining the temperature for 1-2 hours, heating the sample to 500-600 DEG C at the speed of 2 DEG C / min, maintaining the temperature for 2 hours, and introducing an oxidizing atmosphere to the tube furnace in the overall process; and burning the sample in the tube furnace. According to the cathode material for the lithium-ion battery, oxide coating is combined with carbon coating; and the amount of the oxide can be reduced, so that reduction of the conductivity caused by the oxide coating is well improved; meanwhile, reduction of the tap density caused by traditional carbon coating can also be improved; and the rate capability and the cycle performance of the material are improved. The carbon coating is carried out on the cathode material for the lithium-ion battery by a catalysis method; the coated carbon is uniform and controlled in thickness; and meanwhile, reduction of the cathode material caused by coated carbon can be reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Modified kieselguhr and preparation method thereof, and indoor decorative material containing modified kieselguhr and preparation method thereof

The invention provides modified kieselguhr of which the tap density is 450-490 kg / m<3> and a preparation method thereof. The method comprises the following specific steps: acquiring kieselguhr; and adding sodium carbonate into the kieselguhr, heating, then activating at a high temperature of 900-1100 DEG C, and crushing. The modified kieselguhr provided by the invention has the characteristics of high whiteness, low tap density and high strength and has favorable adsorption property and heat-insulating property. Besides, the invention also provides an indoor decorative material containing the modified kieselguhr of which the tap density is 450-490 kg / m<3>, calcium hydroxide, sepiolite and film-forming assistant, and provides a preparation method thereof. The material is low in organic substance content, is nonvolatile, has high whiteness, low tap density and high strength, and ensures that the material can not volatilize harmful gas while ensuring favorable adsorption property and heat-insulating property, thereby being safer and more environment-friendly.

Owner:长白朝鲜族自治县天宝硅藻土功能制品有限公司

Carbonate Precursors for Lithium Nickel Manganese Cobalt Oxide Cathode Material and the Method of Making Same

ActiveUS20170309894A1Reduce energy densityLow tap densityElectrode thermal treatmentLi-accumulatorsManganeseSlurry

A method for producing a M-carbonate precursor of a Li-M oxide cathode material in a continuous reactor, wherein M=NixMnyCozAn, A being a dopant, with x>0, y>0, 0≦z≦0.35, 0≦n≦0.02 and x+y+z+n=1, the method comprising the steps of: —providing a feed solution comprising Ni-, Mn-, Co- and A-ions, and having a molar metal content M″ feed, —providing an ionic solution comprising either one or both of a carbonate and a bicarbonate solution, the ionic solution further comprising either one or both of Na- and K-ions, —providing a slurry comprising seeds comprising M′-ions and having a molar metal content M′ seeds, wherein M′=Nix′Mny′Coz′A′n′, A′ being a dopant, with 0≦x′≦1, 0≦y′≦1, 0≦z′≦1, 0≦n′≦1 and x′+y′+z′+n′=1, and wherein the molar ratio M′ seeds / M″ feed is between 0.001 and 0.1, —mixing the feed solution, the ionic solution and the slurry in the reactor, thereby obtaining a reactive liquid mixture, —precipitating a carbonate onto the seeds in the reactive liquid mixture, thereby obtaining a reacted liquid mixture and the M-carbonate precursor, and —separating the M-carbonate precursor from the reacted liquid mixture.

Owner:UMICORE AG & CO KG +1

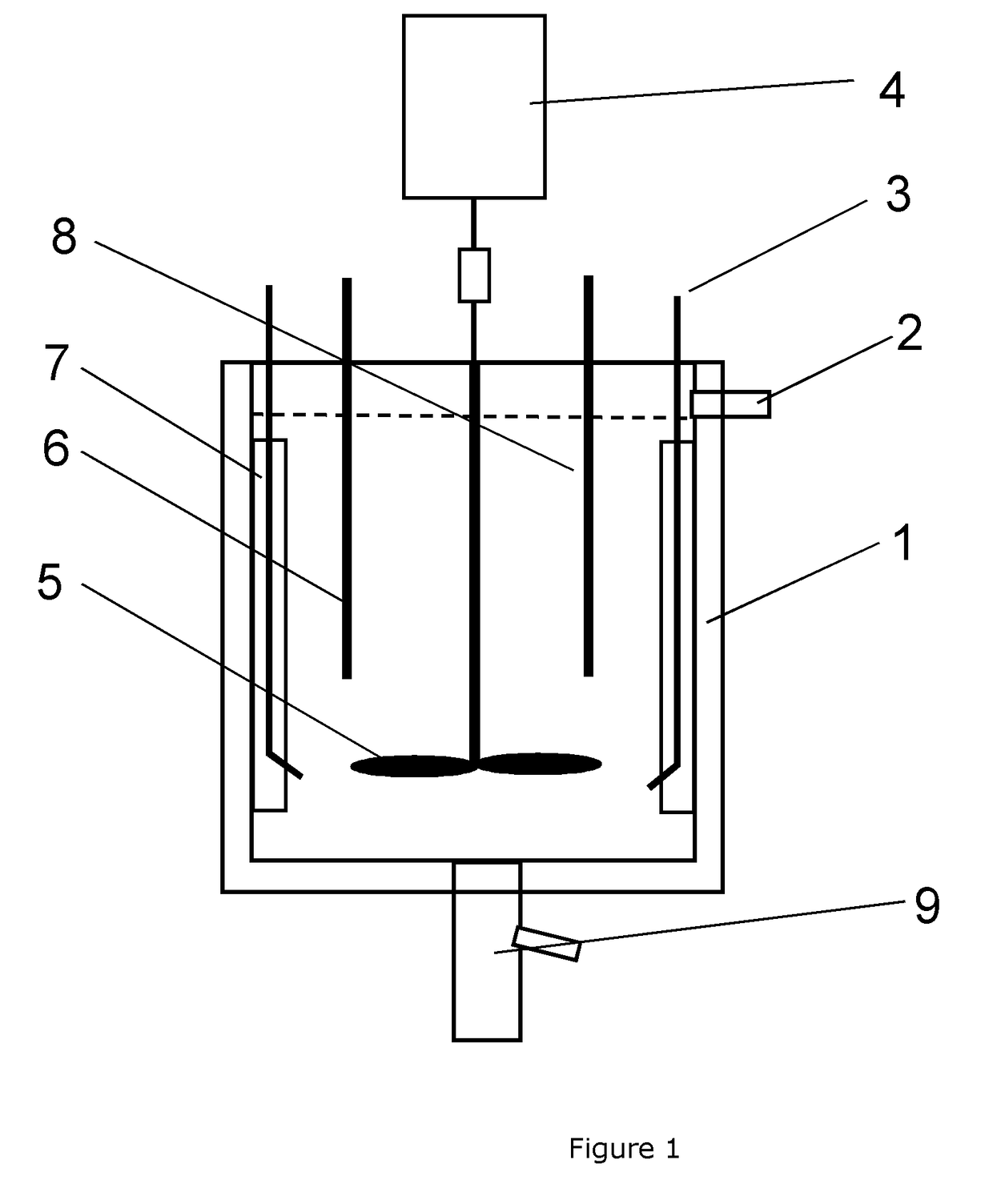

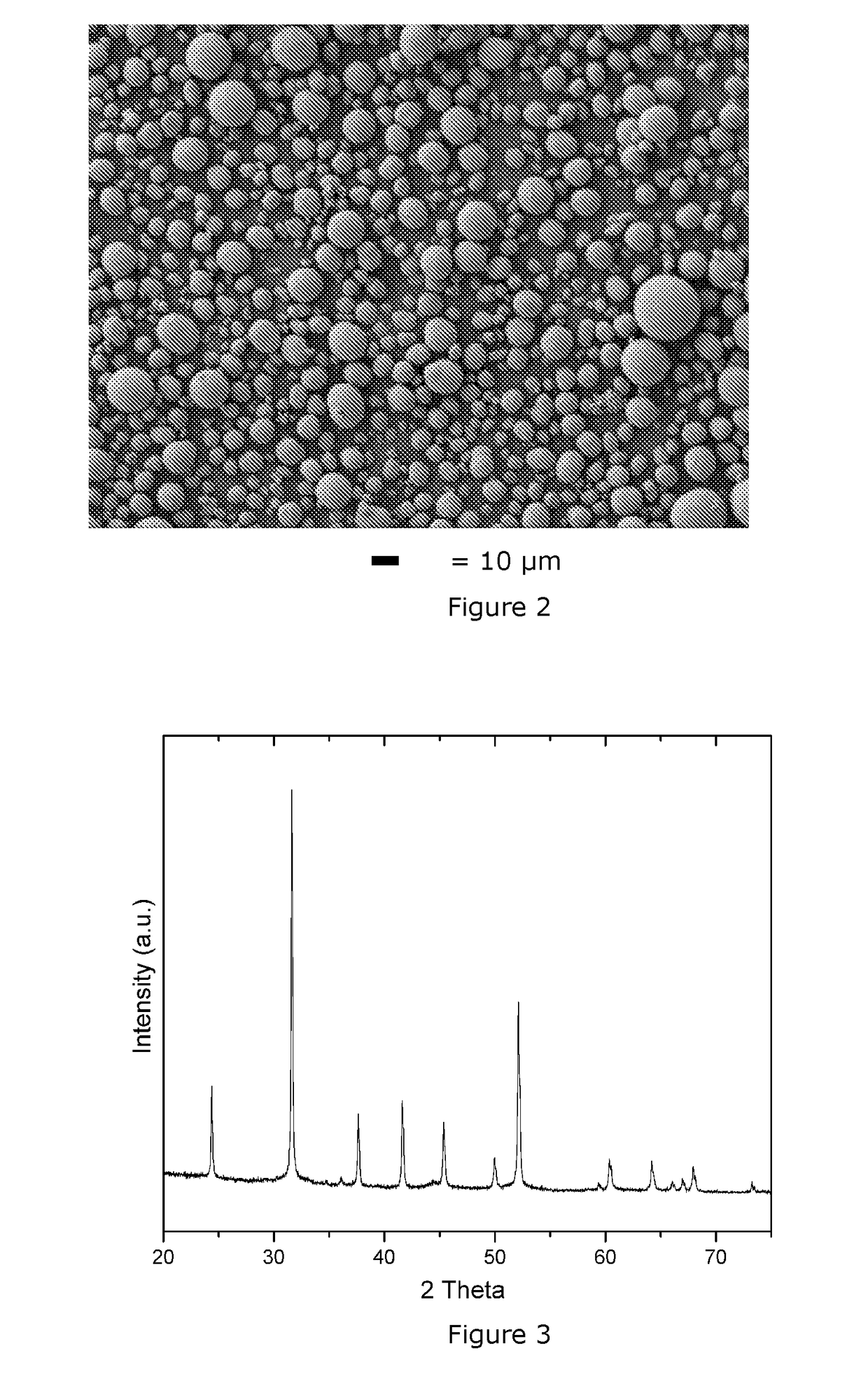

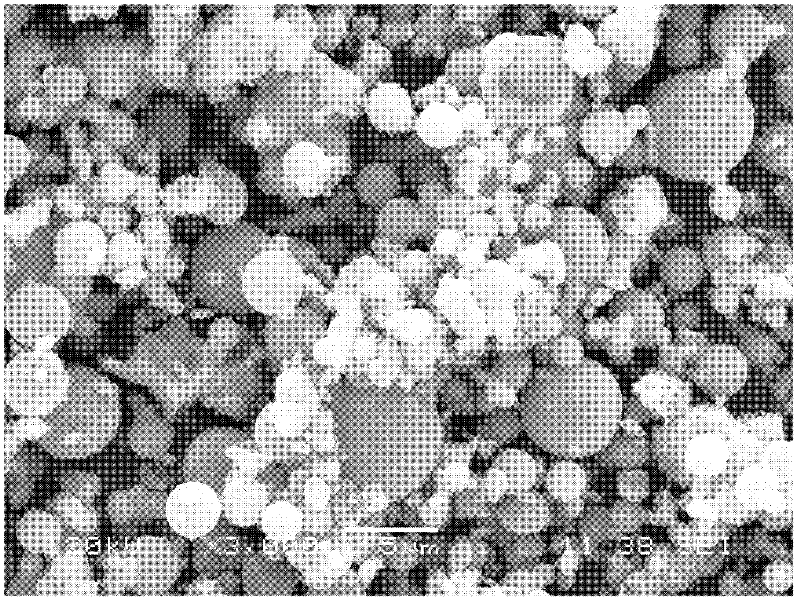

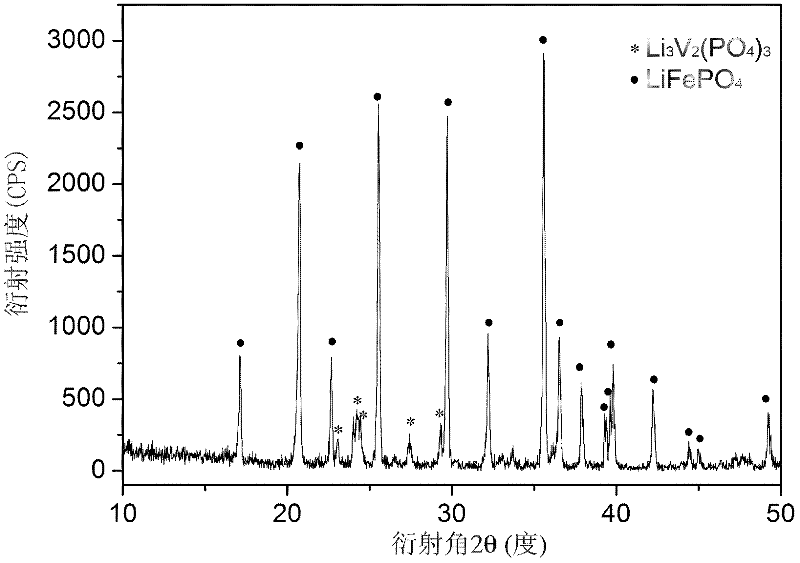

Method for improving tap density of composite anode material xLiFePO4.yLi3V2(PO4)3 of lithium ion battery

ActiveCN102244244AImprove electrochemical performanceHigh tap densityCell electrodesPhosphoric acidSodium-ion battery

The invention discloses a method for improving the tap density of a composite anode material xLiFePO4.yLi3V2(PO4)3 of a lithium ion battery. A combined sol gel-spray drying-carbon thermal reduction method is adopted to prepare the composite anode material xLiFePO4.yLi3V2(PO4)3 of the lithium ion battery, comprising the following concrete steps: mixing a lithium source, an iron source and a vanadium source with phosphate groups in a stoichiometric ratio; adding a solvent and a coordinating agent containing carbon to stir to form sols; carrying out spray drying on the sols; and roasting the obtained powder for 2-24 hours in an argon or nitrogen atmosphere at the temperature of 500-850 DEG C to obtain the composite anode material xLiFePO4.yLi3V2(PO4)3. The tap density of the prepared composite material is 1.50-2.00g / cm<3> and the electrochemical performance of the prepared composite material is good.

Owner:CENT SOUTH UNIV

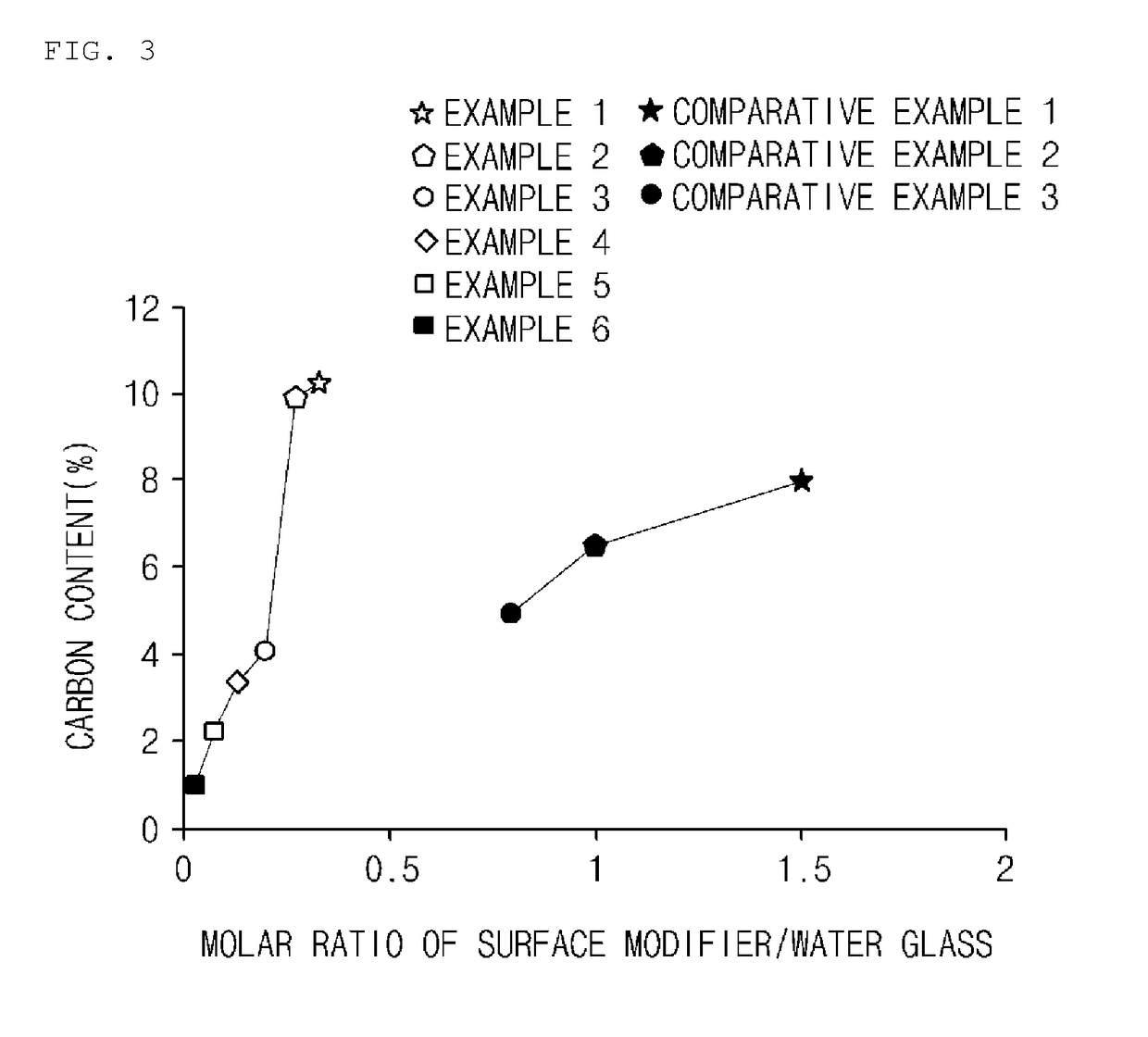

Method for preparing hydrophobic metal oxide-silica composite aerogel, and hydrophobic metal oxide-silica composite aerogel prepared thereby

ActiveUS20170305749A1Improve efficiencyIncrease productivityAerogel preparationSilicon compoundsProduction rateEffective surface

The present invention relates to a method of preparing a hydrophobic metal oxide-silica composite aerogel, in which a degree of hydrophobicity may be controlled while having a high specific surface area and a low tap density, and a hydrophobic metal oxide-silica composite aerogel prepared thereby. The preparation method according to the present invention may not only have excellent productivity and economic efficiency due to a relatively simpler preparation process and shorter preparation time than the related art, but may also perform an effective surface modification reaction by using a small amount of a surface modifier. Thus, since the surface modification reaction may be easily performed by using only a very small amount of the surface modifier, a hydrophobic metal oxide-silica composite aerogel containing about 1 wt % to 2 wt % of carbon may be prepared.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com