Surface coating method of cathode material for lithium-ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as increasing the contact between electrolyte and electrode materials, increasing processing procedures and production costs, and being unable to control uniform carbon coating. , achieve good commercial application prospects, improve electrochemical performance, and improve the effect of reducing tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

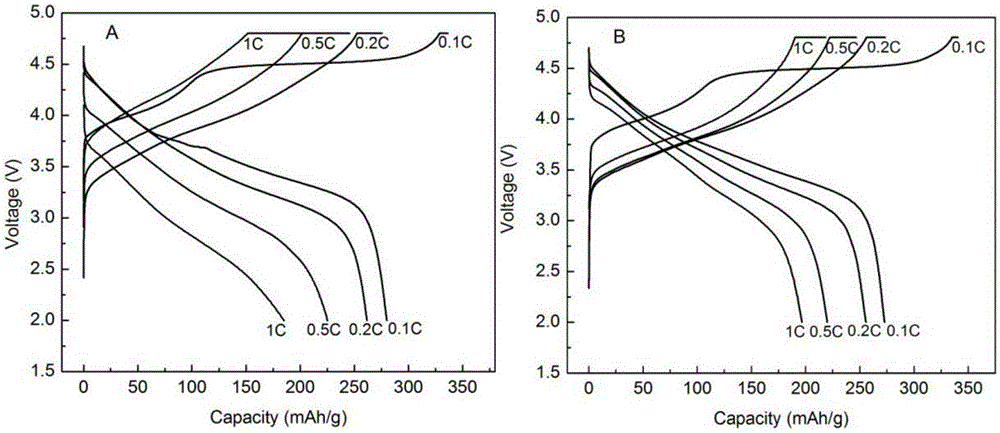

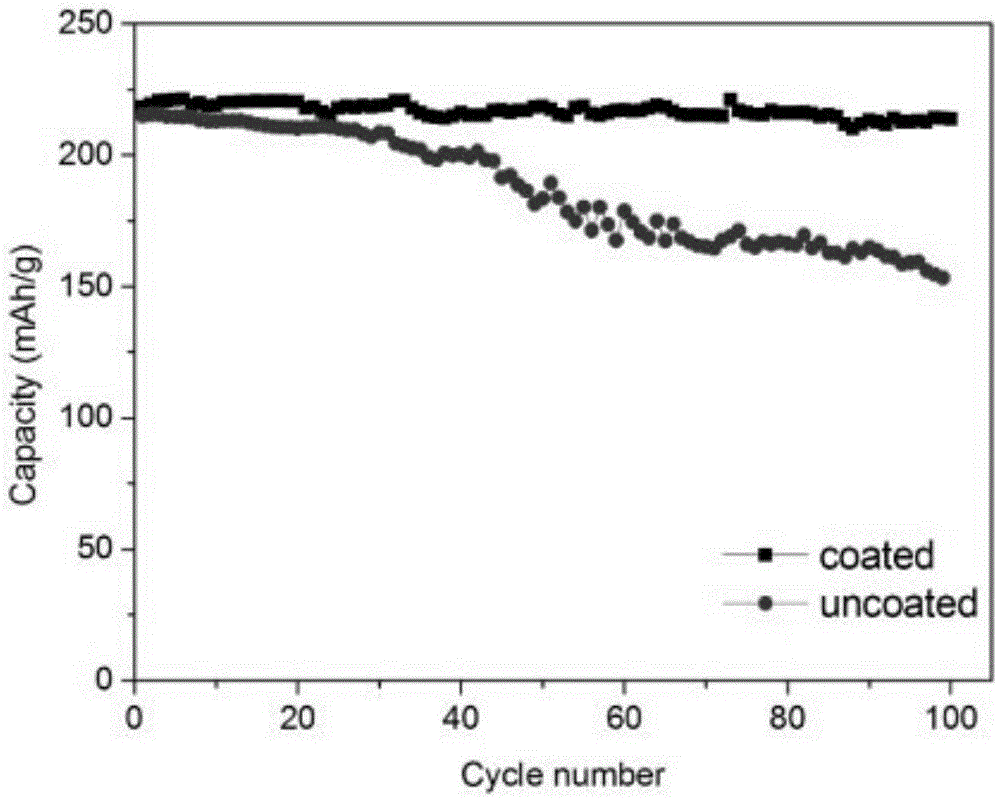

[0025] Example 1: Preparation of Li-MgO and carbon-coated Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2

[0026] The ground Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2 Add in a solution containing magnesium acetate and LiOH, wherein magnesium accounts for 2% of the total mass of the positive electrode material, and Li accounts for 0.2% of the total mass of the positive electrode material. The mixed solution is ultrasonicated for 2h, then stirred at 60°C until dry, and finally at 80°C ℃ in an oven for 12 hours; the dried samples were heated in a tube furnace at 1 ℃ / min to 130 ℃ and maintained for 1 hour, and then heated to 600 ℃ at 2 ℃ / min and maintained for 2 hours. During the whole process, the tube furnace O 2 . When the sample coated with Li-MgO dropped to room temperature, the gas was switched to CH 4 , O 2 and CO 2 The mixed gas, where CH 4 , O 2 and CO 2 The volume ratio is 5:1:4, then the temperature is raised to 500°C for 1 hour, and finally it is lowered to room temperat...

Embodiment 2

[0029] Example 2: Preparation of Li-MgO and carbon-coated LiMn 0.2 Ni 0.6 co 0.2 o 2

[0030] The ground LiMn 0.2 Ni 0.6 co 0.2 o 2 Add in a solution containing magnesium acetate and LiOH, wherein magnesium accounts for 2% of the total mass of the positive electrode material, and Li accounts for 0.2% of the total mass of the positive electrode material. The mixed solution is ultrasonicated for 2h, then stirred at 60°C until dry, and finally at 80°C ℃ in an oven for 12 hours; the dried samples were heated in a tube furnace at 1 ℃ / min to 130 ℃ and maintained for 1 hour, and then heated to 600 ℃ at 2 ℃ / min and maintained for 2 hours. During the whole process, the tube furnace O 2 . When the sample coated with Li-MgO dropped to room temperature, the gas was switched to CH 4 , O 2 and CO 2 The mixed gas, where CH 4 , O 2 and CO 2 The volume ratio is 5:1:4, then the temperature is raised to 500°C for 1 hour, and finally cooled to room temperature.

Embodiment 3

[0031] Example 3: Preparation of Li-MgO and carbon-coated Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2

[0032] The ground Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2Add in a solution containing magnesium acetate and LiOH, wherein magnesium accounts for 5% of the total mass of the positive electrode material, and Li accounts for 0.5% of the total mass of the positive electrode material. The mixed solution is ultrasonicated for 2h, then stirred at 60°C until dry, and finally at 80°C ℃ in an oven for 12 hours; the dried samples were heated in a tube furnace at 1 ℃ / min to 130 ℃ and maintained for 1 hour, and then heated to 600 ℃ at 2 ℃ / min and maintained for 2 hours. During the whole process, the tube furnace O 2 . When the sample coated with Li-MgO dropped to room temperature, the gas was switched to CH 4 , O 2 and CO 2 The mixed gas, where CH 4 , O 2 and CO 2 The volume ratio is 5:1:4, then the temperature is raised to 500°C for 1 hour, and finally it is lowered to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com