Lithium ion battery positive electrode material coated with amorphous passivation layer and with stable surface and preparation method thereof

A lithium-ion battery and cathode material technology, applied in the field of electrochemical energy storage, can solve problems such as difficulty in fully exerting its role, and achieve the effects of facilitating industrial production, simple and efficient operation steps, and improving film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

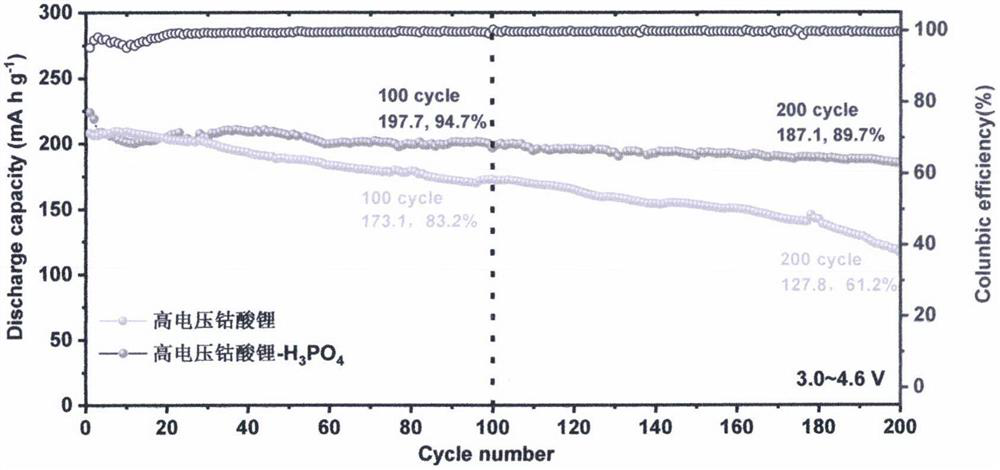

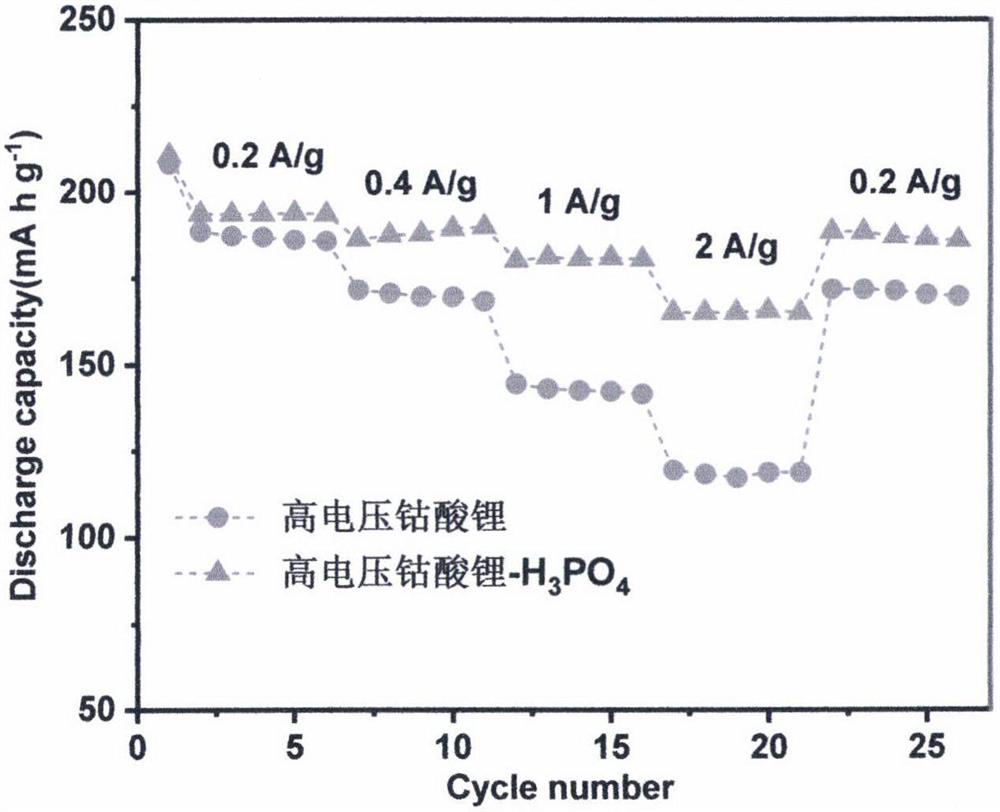

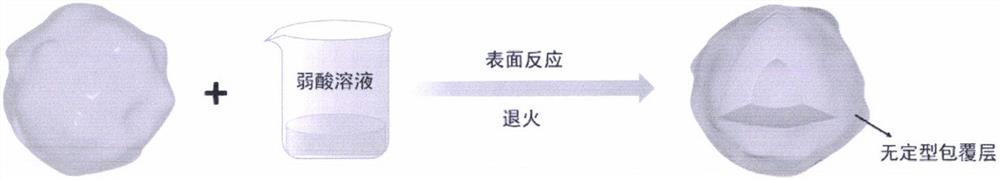

[0027] A method for preparing surface-passivated high-voltage lithium cobalt oxide. Weigh 0.1g of anhydrous H 3 PO 4 In a 10mL beaker, add 4mL of absolute ethanol and stir to disperse evenly, then add 2.0g of lithium cobaltate prepared by a solid-phase method, continue stirring at room temperature for 12 hours, filter and wash once with ethanol, and dry The final product was placed in a crucible, placed in a muffle furnace, raised to 600°C at a rate of 5°C / min and kept at a temperature of 6 hours, and then cooled naturally. The obtained material is the surface-modified high-voltage lithium cobalt oxide material.

[0028] The electrochemical performance of the cathode material was evaluated using CR2016 button cell. The negative pole of the button battery is 1 mm in thickness and a metal lithium sheet with a diameter of 15 mm, and the positive electrode adopts surface-modified LiCoO in Example 1. 2 material, conductive acetylene black, and binder polyvinylidene fluoride (PV...

Embodiment 2

[0030] A method for preparing a surface-passivated NCM ternary cathode material. Weigh 0.1g H 3 BO 3 In a 10mL beaker, add 4mL of absolute ethanol and stir to dissolve it completely, then add 2.0g of LiNi prepared by coprecipitation 0 33 co 0.33 mn 0.33 o 2 After stirring continuously for 6 hours in a water bath at 50°C, filter and wash with ethanol for 2-3 times, place the dried product in a crucible, put it in a muffle furnace, and raise the temperature to 600 at a rate of 5°C / min. ℃ and keep warm for 6 hours, then cool down naturally. The obtained material is the surface-modified NCM ternary cathode material.

[0031] The method for evaluating the electrochemical performance of the NCM ternary positive electrode material surface-treated with boric acid is the same as in Example 1.

Embodiment 3

[0033] A method for preparing a surface-passivated NCM high-nickel ternary positive electrode material. Weigh 0.1g H 3 PO 2 (Hypophosphorous acid) in a 10mL beaker, add 4mL of absolute ethanol and stir to dissolve completely, then add 2.0g of LiNi prepared by solid phase method 0.8 co 0.1 mn 0.1 o 2 After stirring continuously for 2 hours at room temperature, filter and wash with ethanol for 2-3 times, place the dried product in a crucible, put it in a tube furnace, and heat it at a rate of 5°C / min in an Ar gas atmosphere Raise to 700°C and keep it warm for 6 hours, then cool down naturally. The obtained material is the surface-modified NCM ternary cathode material.

[0034] The electrochemical performance evaluation method of the NCM high-nickel ternary positive electrode material treated with hypophosphorous acid is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com