Preparation method and application of single-crystal high-nickel ternary material with completely modified surface

A high-nickel ternary material and single crystal technology, applied in chemical instruments and methods, electrical components, nickel compounds, etc., can solve the problems of diffusion path damage, low Coulombic efficiency, active material exposure, etc., to improve cycle performance and The effect of high rate performance, simple and reliable process method, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a MgB 2 The preparation method of the single crystal high-nickel ternary material with completely modified surface comprises the following steps:

[0029] 1) Weigh 200 g of Ni 0.8 co 0.1 mn 0.1 (OH) 2 , then weigh lithium hydroxide according to the lithium source: the molar ratio of the ternary precursor is 1.05, then put it into the mixer and mix it evenly, and place the evenly mixed mixture in the pre-oxygenated atmosphere furnace, set the calcining program, first at 480 °C for 5 h, then at 750 °C for 15 h, with a heating rate of 5 °C / min;

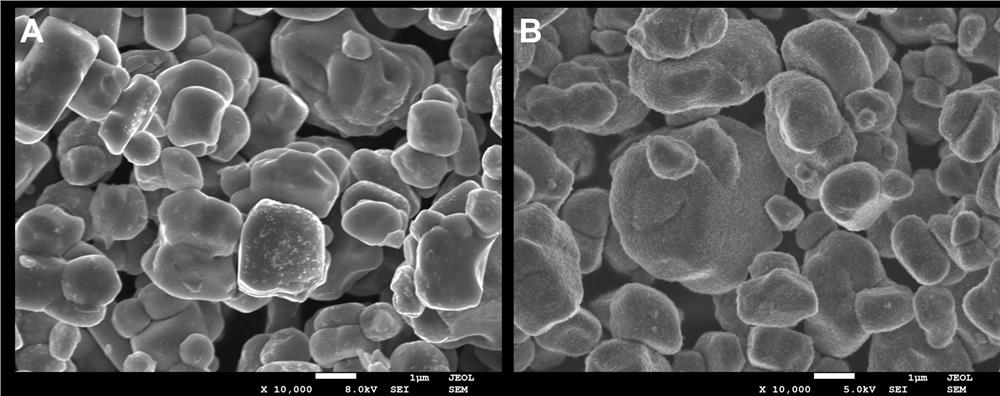

[0030] 2) The high-nickel ternary material obtained in step 1) is crushed, and then passed through a 400-mesh sieve to obtain a single-crystal high-nickel ternary material with uniform particle size dispersion;

[0031] 3) Weigh 100 g of the single crystal high-nickel ternary material obtained in step 2), add it to a 5 L vacuum stirred reactor, add 2 L, 0.009 M Mg(NO 3 ) 2 in anhydrous ethanol solution, slowly stirred for 1...

Embodiment 2

[0034] A kind of Co 2 The preparation method of the fully modified single crystal high-nickel ternary material of B surface comprises the steps:

[0035] 1) Weigh 200 g of Ni 0.8 co 0.1 mn 0.1 (OH) 2 , then weigh lithium hydroxide according to the lithium source: the molar ratio of the ternary precursor is 1.05, then put it into the mixer and mix it evenly, and place the evenly mixed mixture in the pre-oxygenated atmosphere furnace, set the calcining program, first at 480 °C for 5 h, then at 750 °C for 15 h, with a heating rate of 5 °C / min;

[0036] 2) The high-nickel ternary material obtained in step 1) is crushed, and then passed through a 400-mesh sieve to obtain a single-crystal high-nickel ternary material with uniform particle size dispersion;

[0037] 3) Weigh 100 g of the single crystal high-nickel ternary material obtained in step 2), add it to a 5 L vacuum stirred reactor, add 2 L, 0.009 M Mg(NO 3 ) 2 in anhydrous ethanol solution, slowly stirred for 1 h, pass...

Embodiment 3

[0040] A method for preparing a single crystal high-nickel ternary material with a fully modified FeB surface, comprising the following steps

[0041] 1) Weigh 200 g of Ni 0.8 co 0.1 mn 0.1 (OH) 2 , then weigh lithium hydroxide according to the lithium source: the molar ratio of the ternary precursor is 1.05, then put it into the mixer and mix it evenly, and place the evenly mixed mixture in the pre-oxygenated atmosphere furnace, set the calcining program, first at 480 °C for 5 h, then at 750 °C for 15 h, with a heating rate of 5 °C / min;

[0042] 2) The high-nickel ternary material obtained in step 1) is crushed, and then passed through a 400-mesh sieve to obtain a single-crystal high-nickel ternary material with uniform particle size dispersion;

[0043] 3) Weigh 100 g of the single crystal high-nickel ternary material obtained in step 2), add it to a 5 L vacuum stirred reactor, add 2 L, 0.009 M Fe(NO 3 ) 2 in anhydrous ethanol solution, slowly stirred for 1 h, passed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com