Preparation and application of hollow nickel disulfide ball

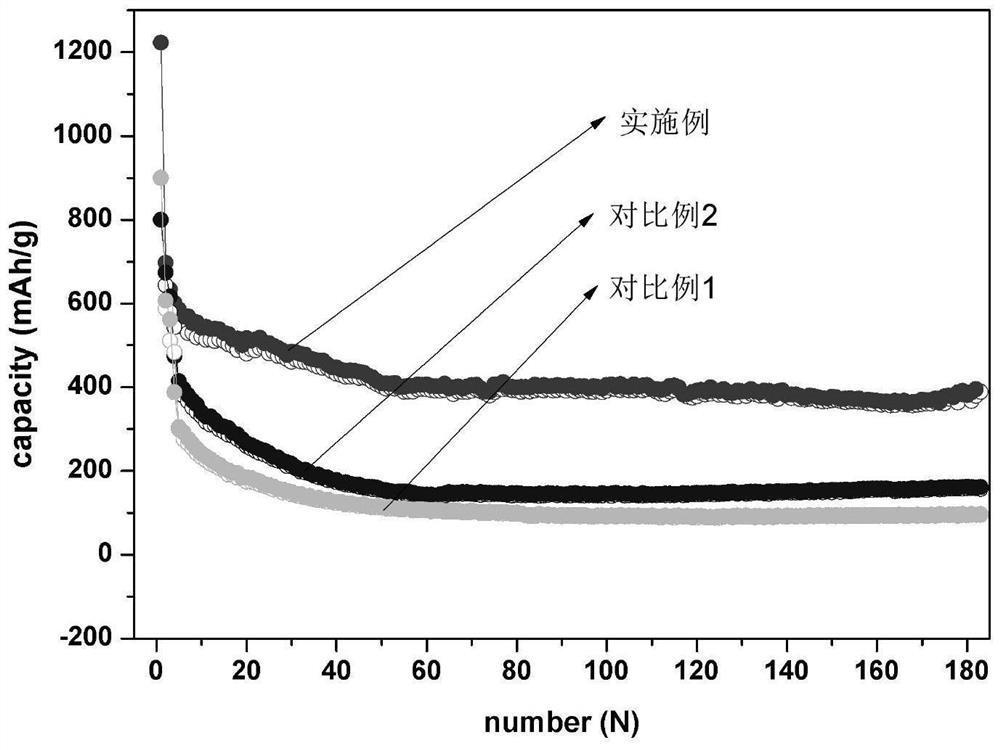

A disulfide and hollow technology, which is used in the preparation and application of hollow nickel disulfide balls, can solve the problems of electrode crushing, large volume expansion, poor conductivity, etc., and achieve the effects of preventing by-products, low cost, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

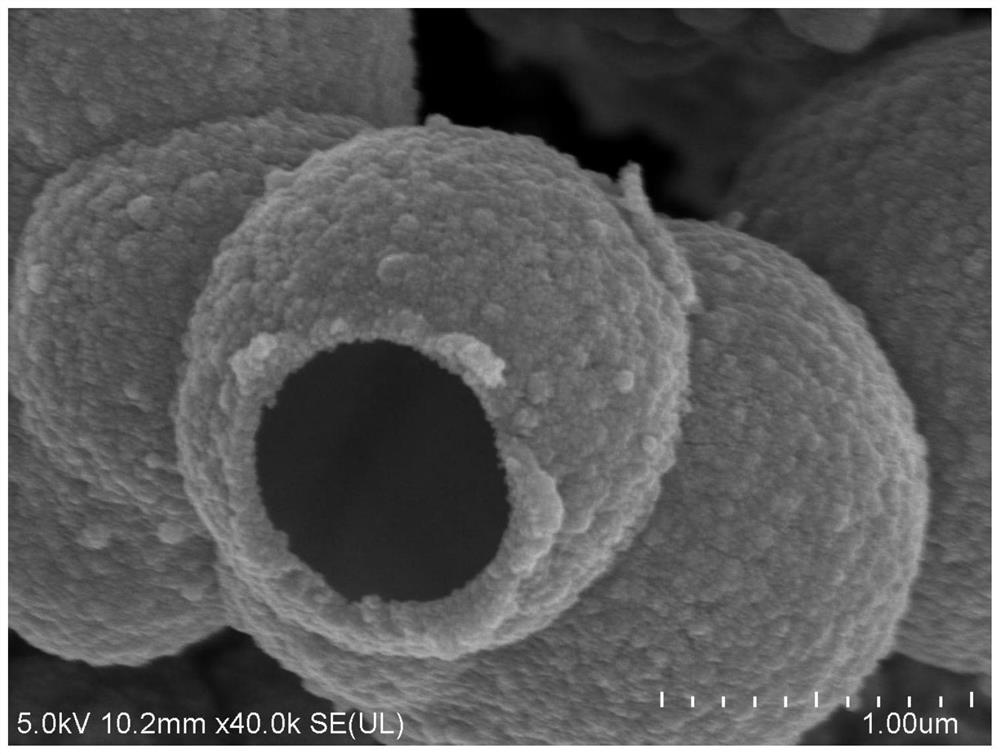

Embodiment 1

[0042] 1) After mixing nickel chloride hexahydrate, urea and L-cysteine at a molar ratio of 1:1:4, stir magnetically for 5 minutes to completely dissolve them in 20 mL of deionized water to obtain a mixed solution;

[0043] 2) Add 50 mL of deionized water into the obtained mixed solution, and ultrasonically clean it for 1 hour;

[0044] 3) Pour the solution obtained in step 2) into a 100mL polytetrafluoroethylene-lined high-temperature and high-pressure reactor, and react at 120°C for 24h;

[0045] 4) When the reaction solution in step 3) is cooled to room temperature, centrifuge at a speed of 3500r / min for 5min;

[0046] 5) Wash the centrifuged solution three times with 30mL deionized water, and then three times with 30mL ethanol solution;

[0047] 6) Put the precipitate washed in step 5) into a vacuum drying oven at 60° C. for 24 hours to dry to obtain the product hollow nickel disulfide balls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com