Patents

Literature

709results about "Metal borides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

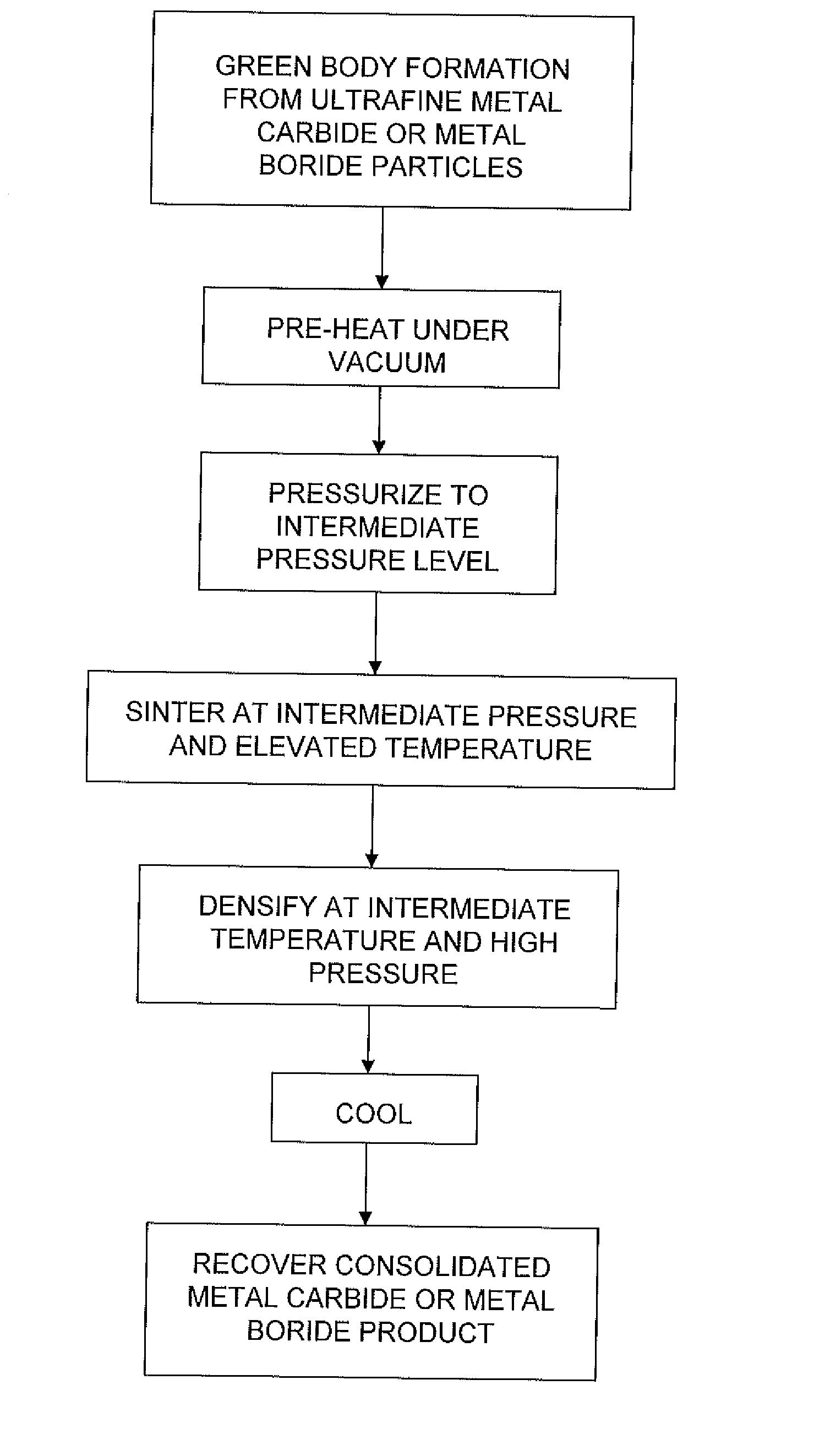

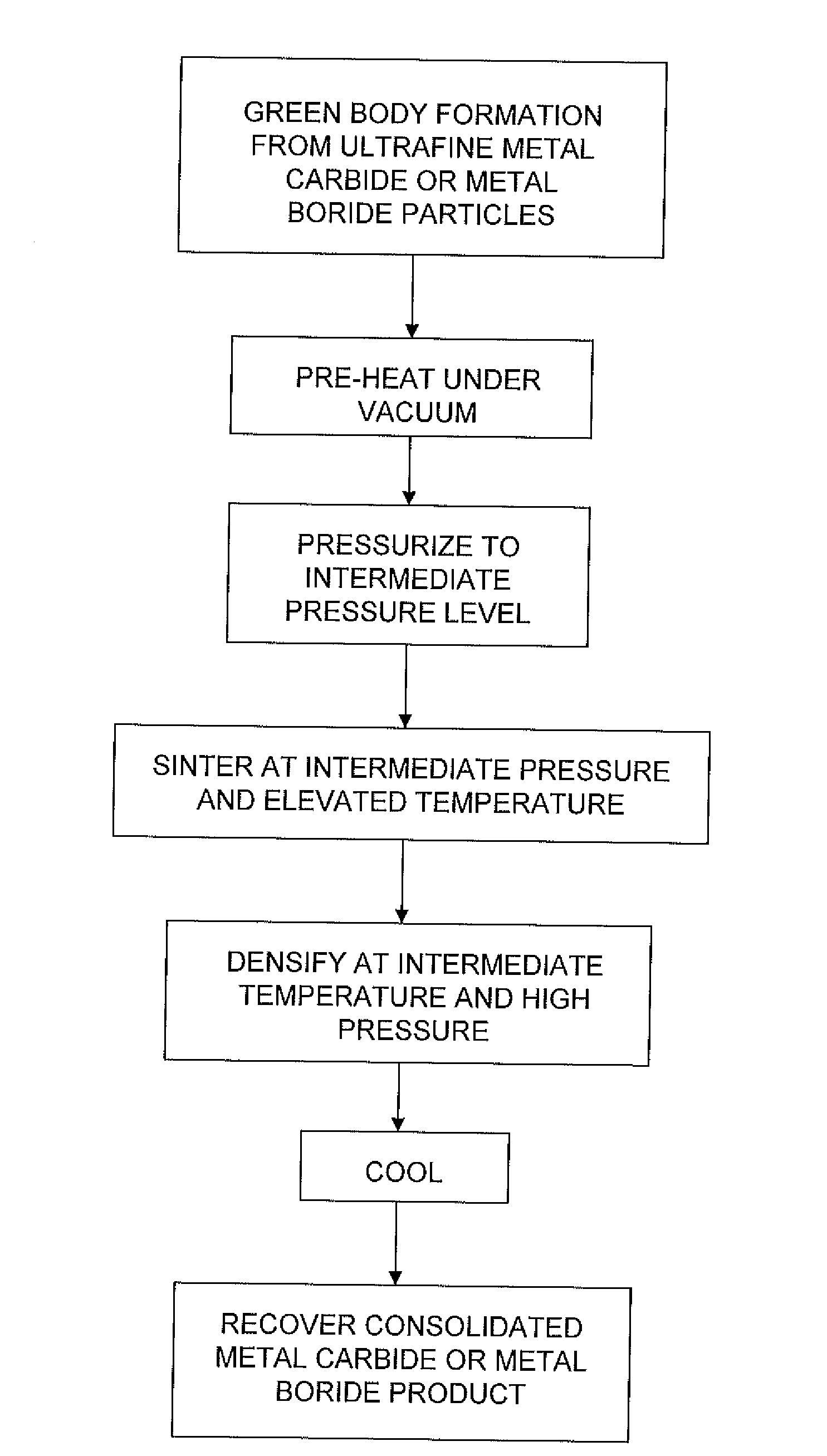

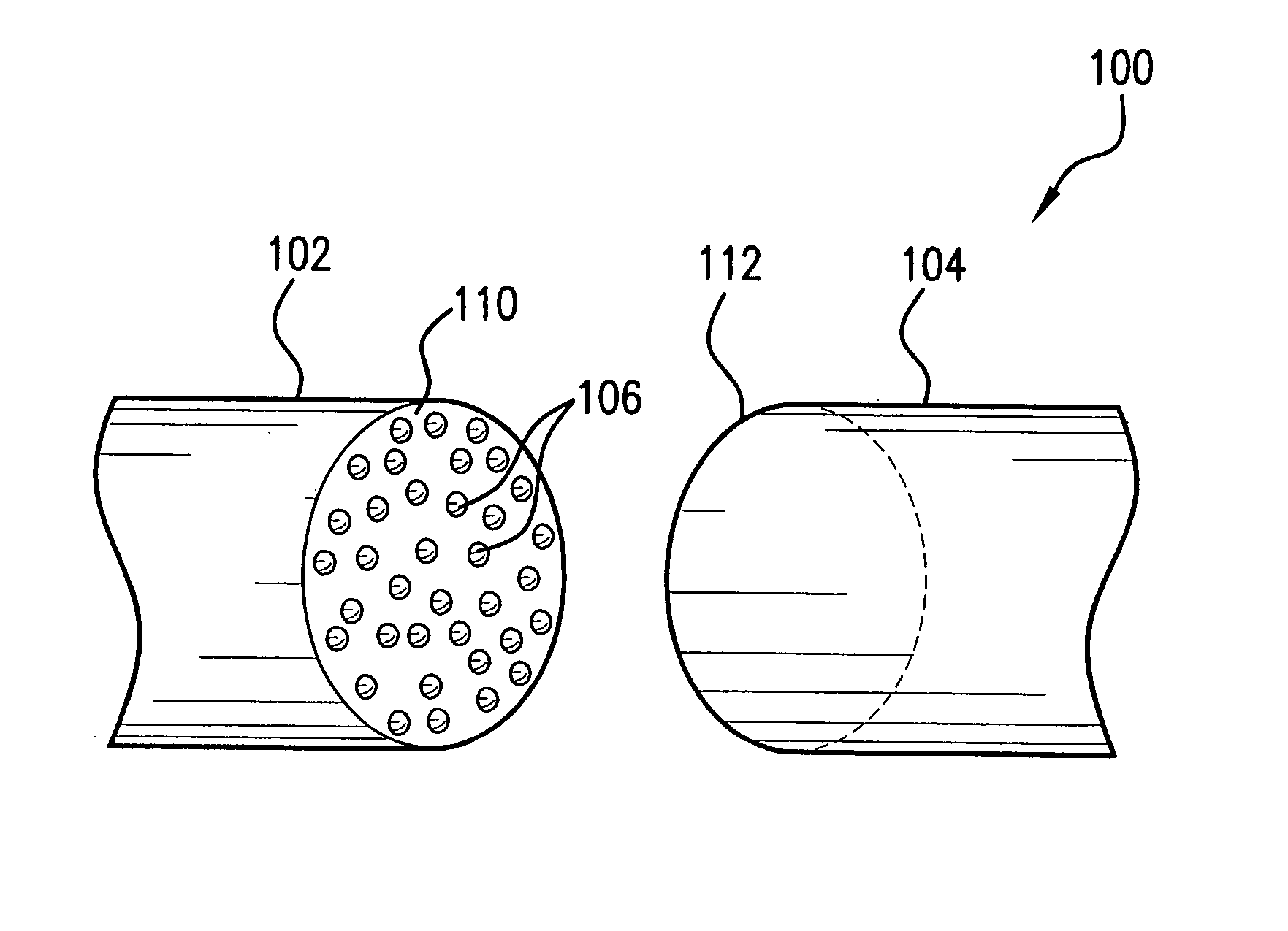

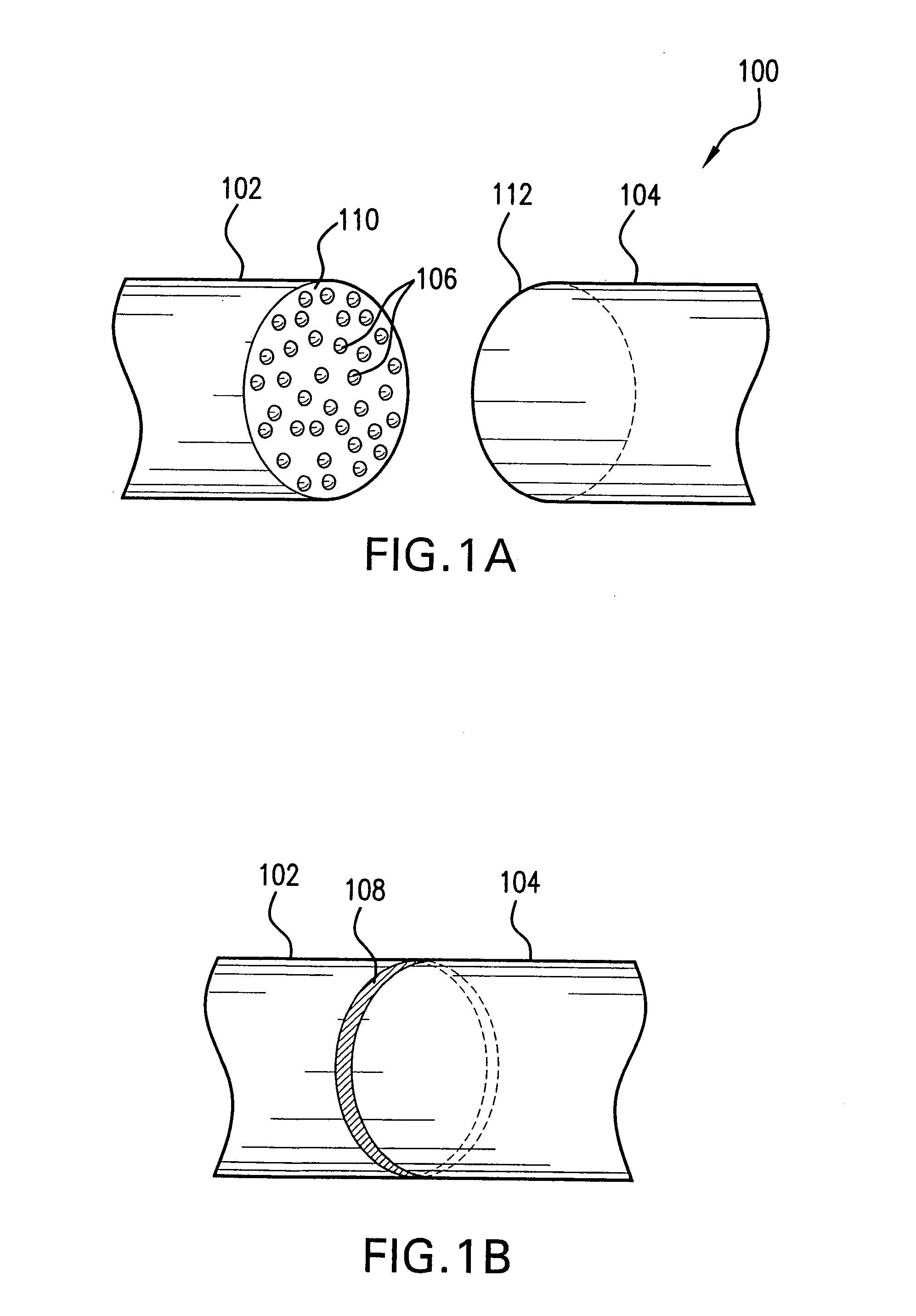

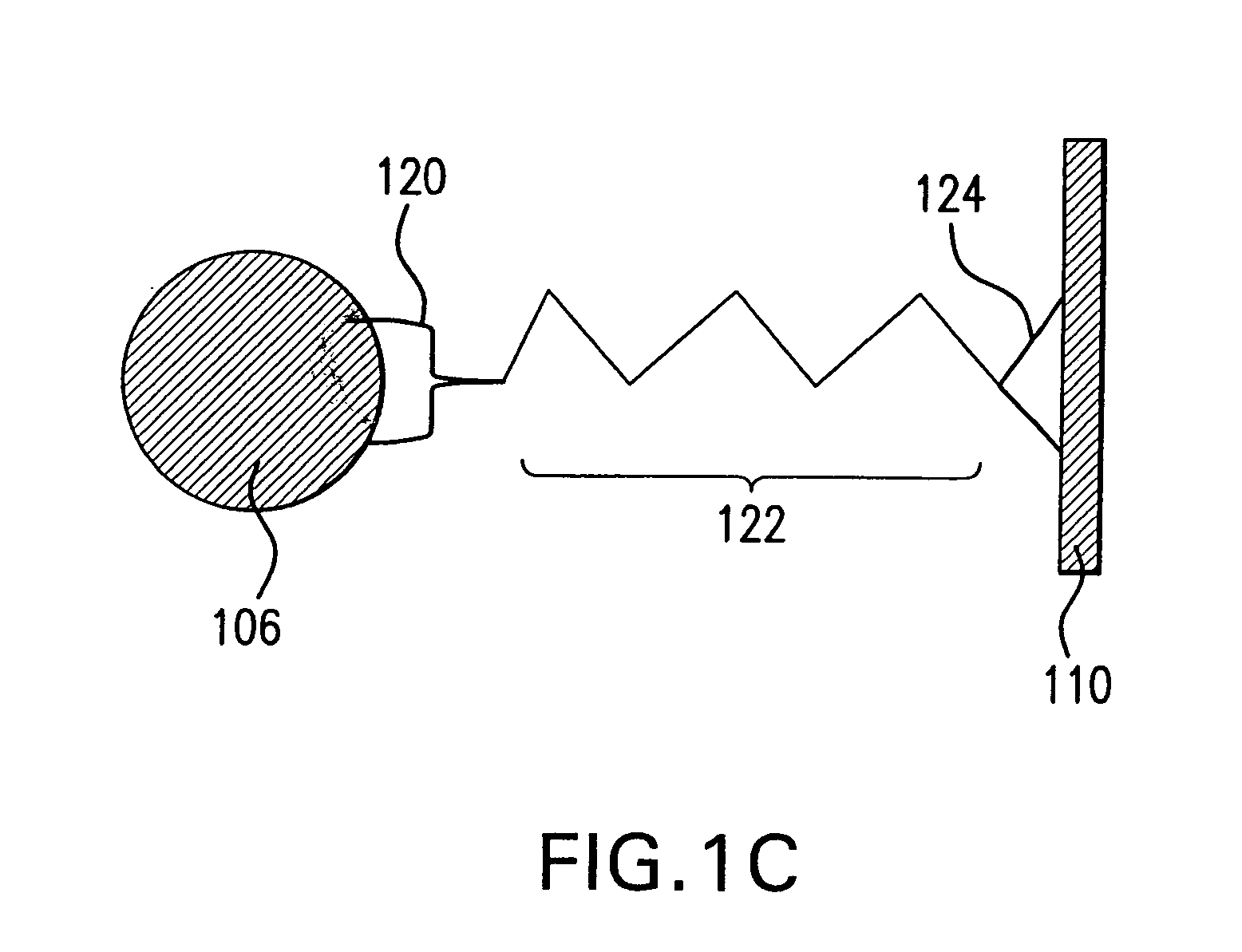

Method of consolidating ultrafine metal carbide and metal boride particles and products made therefrom

Ultrafine metal carbide or metal boride particles are consolidated by a method including sintering at intermediate pressures. A green body comprising the ultrafine metal carbide or metal boride particles may be preheated under vacuum and then pressurized to the intermediate sintering pressure. After sintering, the article may be densified at an intermediate temperature below the sintering temperature, and at an elevated pressure above the intermediate sintering temperature. The resultant consolidated metal carbide or metal boride article may then be cooled and used for such applications as armor panels, abrasion resistant nozzles, and the like.

Owner:PPG IND OHIO INC

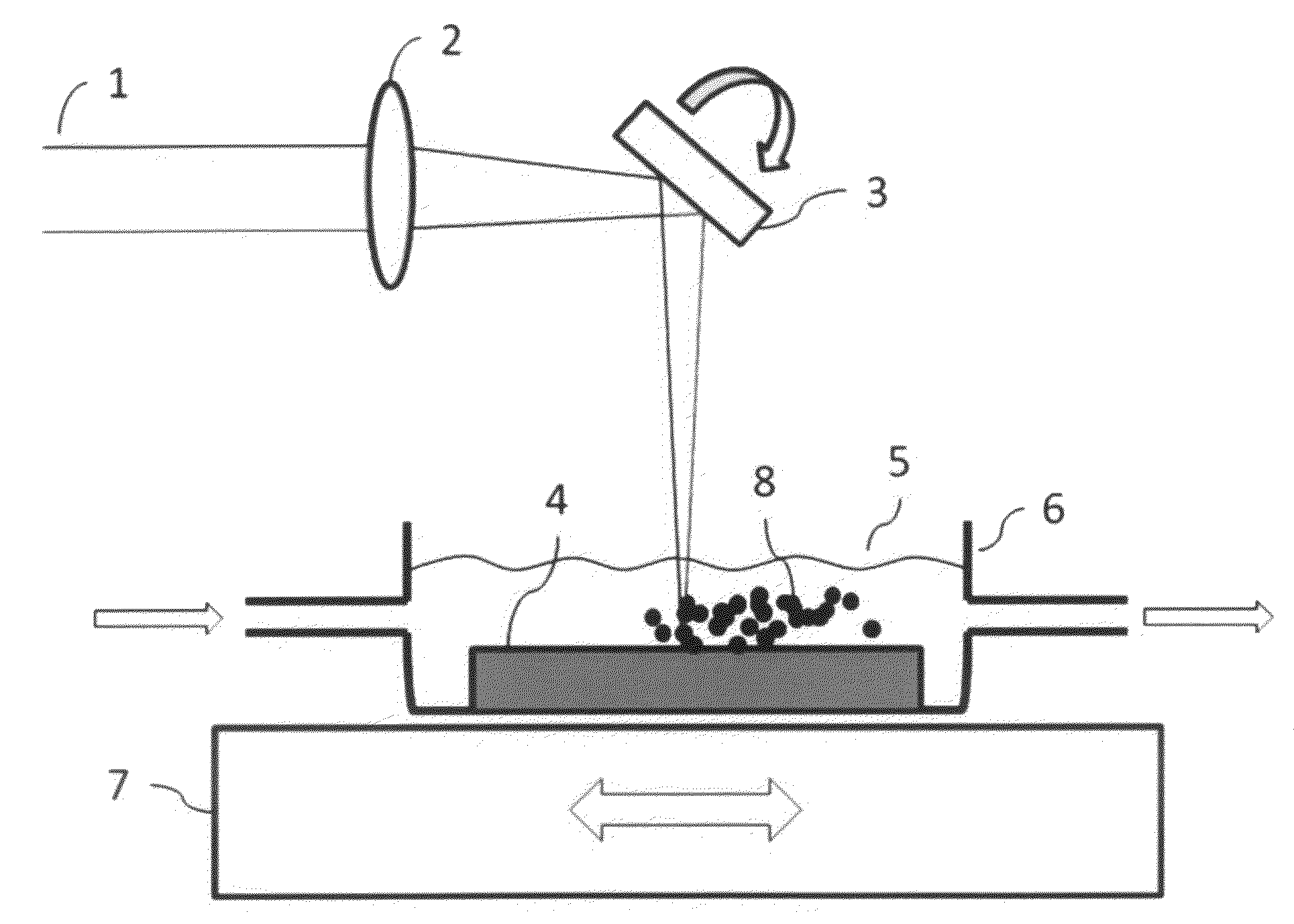

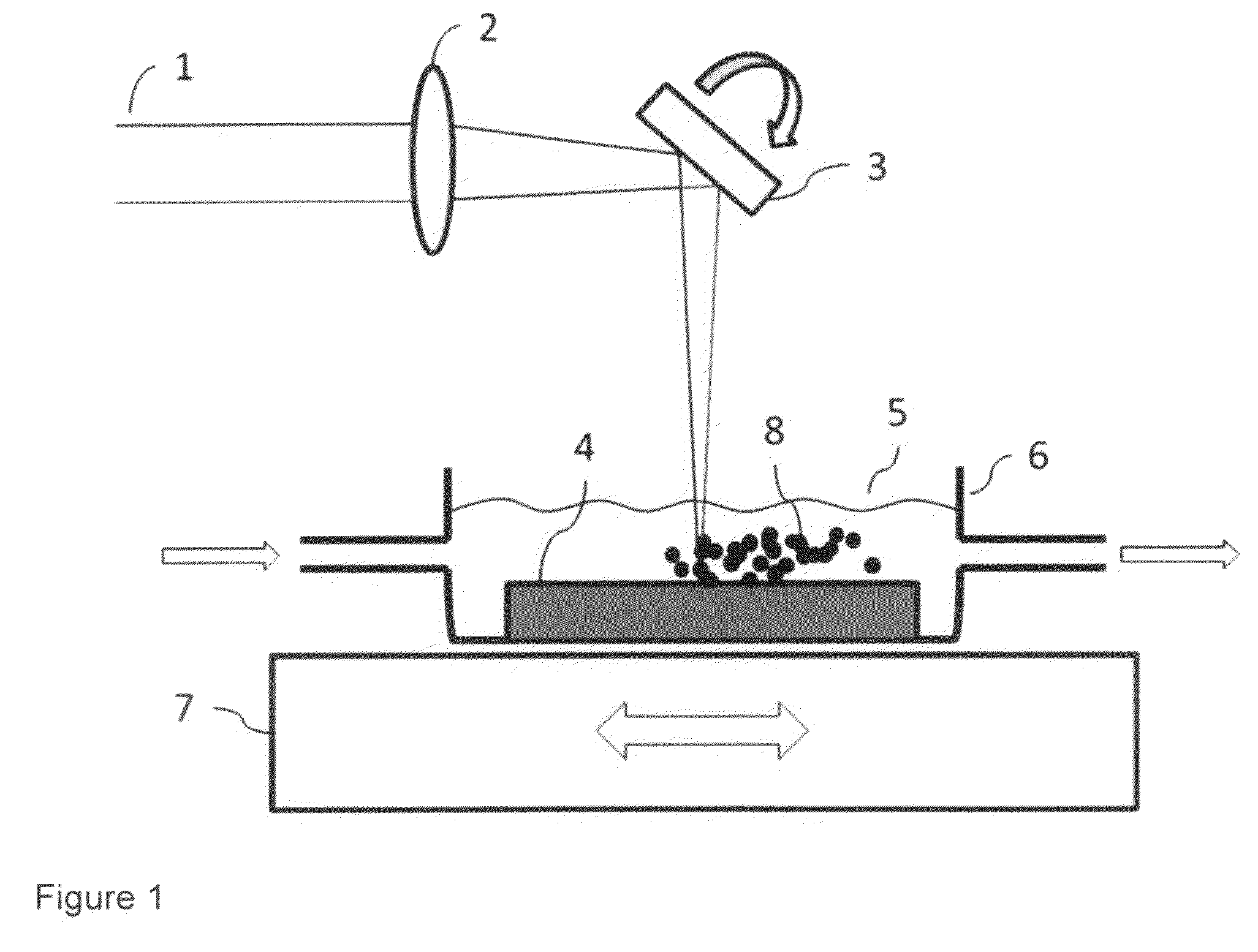

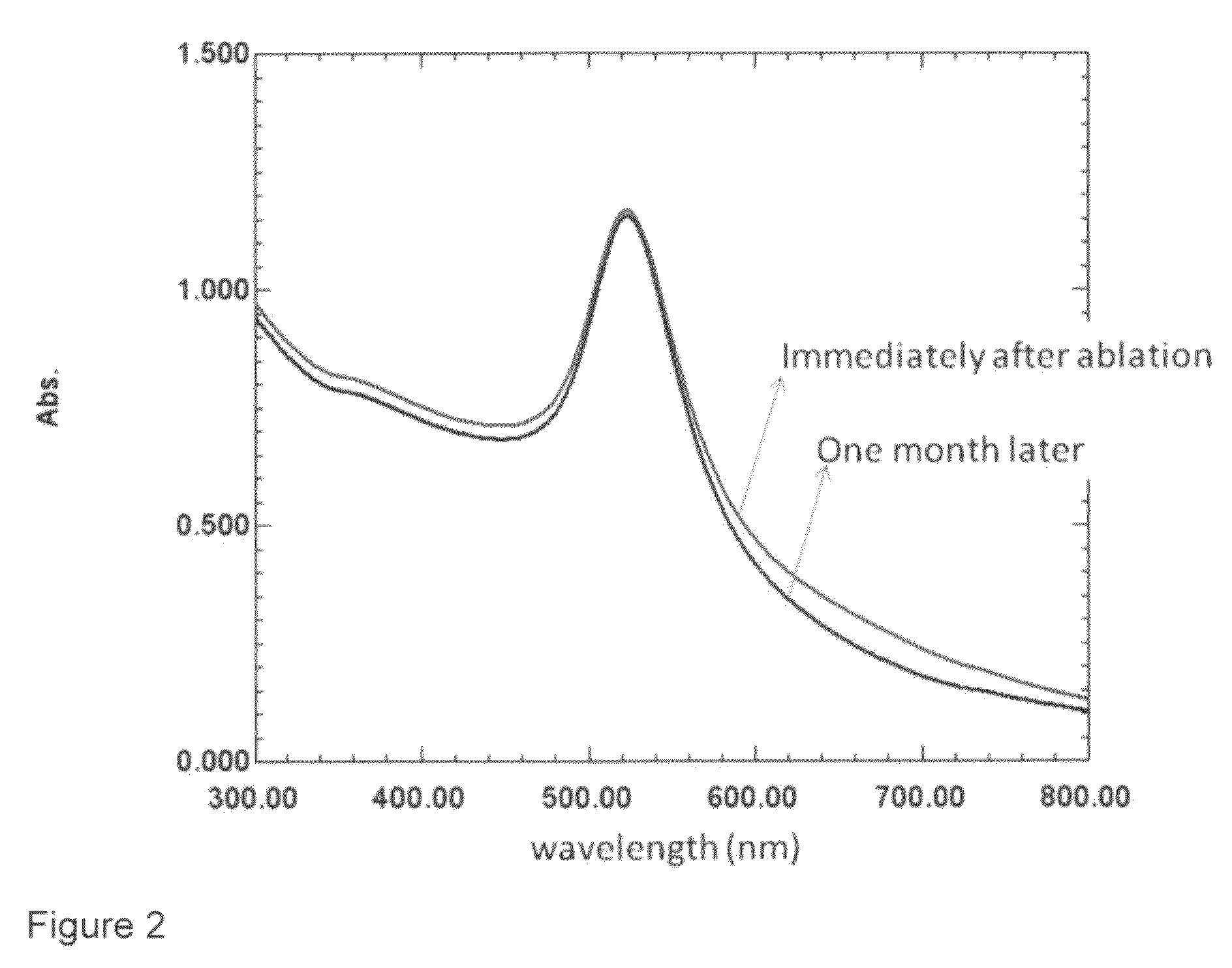

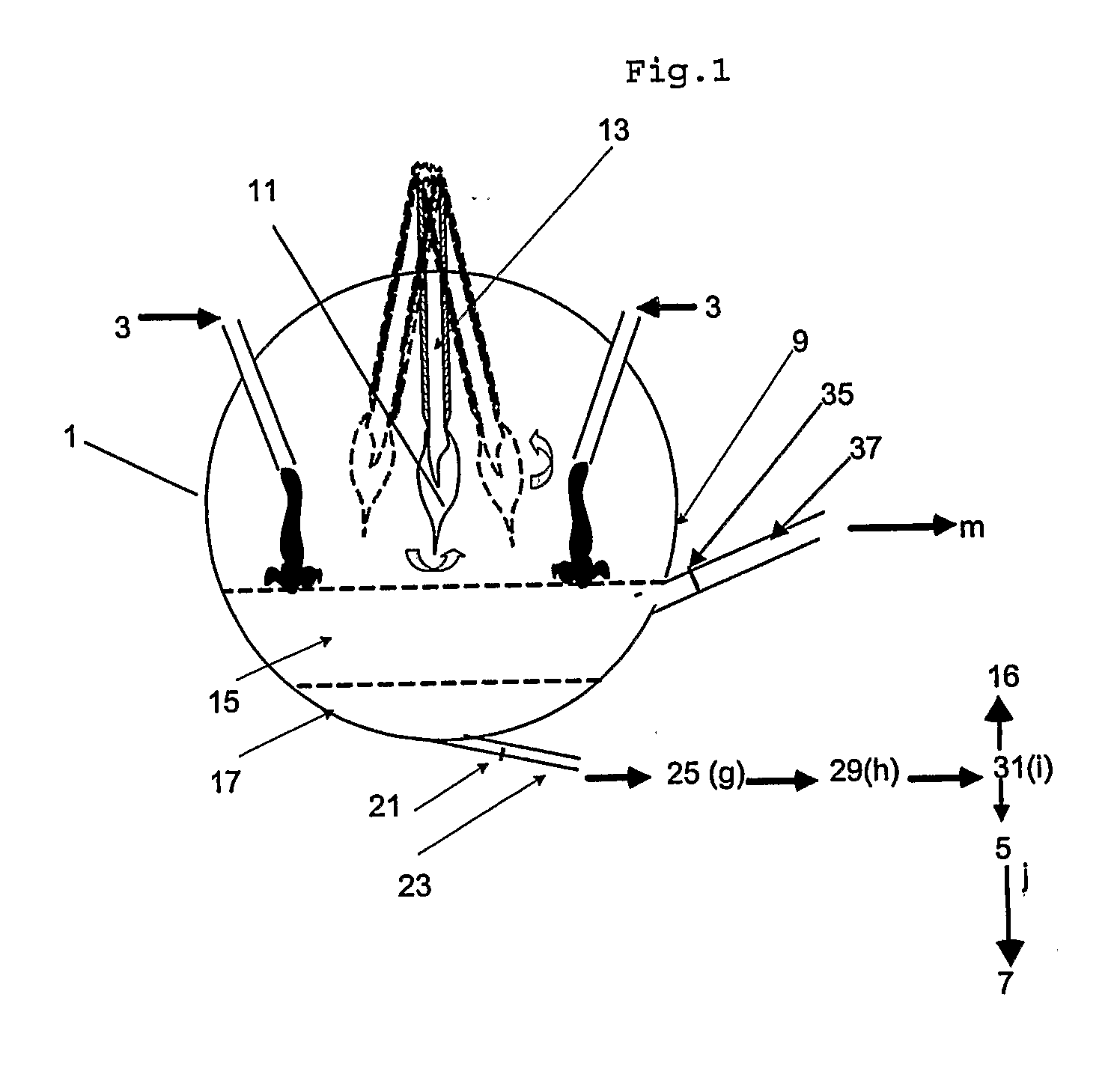

Production of metal and metal-alloy nanoparticles with high repetition rate ultrafast pulsed laser ablation in liquids

ActiveUS20100196192A1Prevent coagulationFaster throughputMaterial nanotechnologyOther chemical processesUltrashort laserFocal volume

Various embodiments include a method of producing chemically pure and stably dispersed metal and metal-alloy nanoparticle colloids with ultrafast pulsed laser ablation. A method comprises irradiating a metal or metal alloy target submerged in a liquid with ultrashort laser pulses at a high repetition rate, cooling a portion of the liquid that includes an irradiated region, and collecting nanoparticles produced with the laser irradiation and liquid cooling. The method may be implemented with a high repetition rate ultrafast pulsed laser source, an optical system for focusing and moving the pulsed laser beams, a metal or metal alloy target submerged in a liquid, and a liquid circulating system to cool the laser focal volume and collect the nanoparticle products. By controlling various laser parameters, and with optional liquid flow movement, the method provides stable colloids of dispersed metal and metal-alloy nanoparticles. In various embodiments additional stabilizing chemical agents are not required.

Owner:IMRA AMERICA

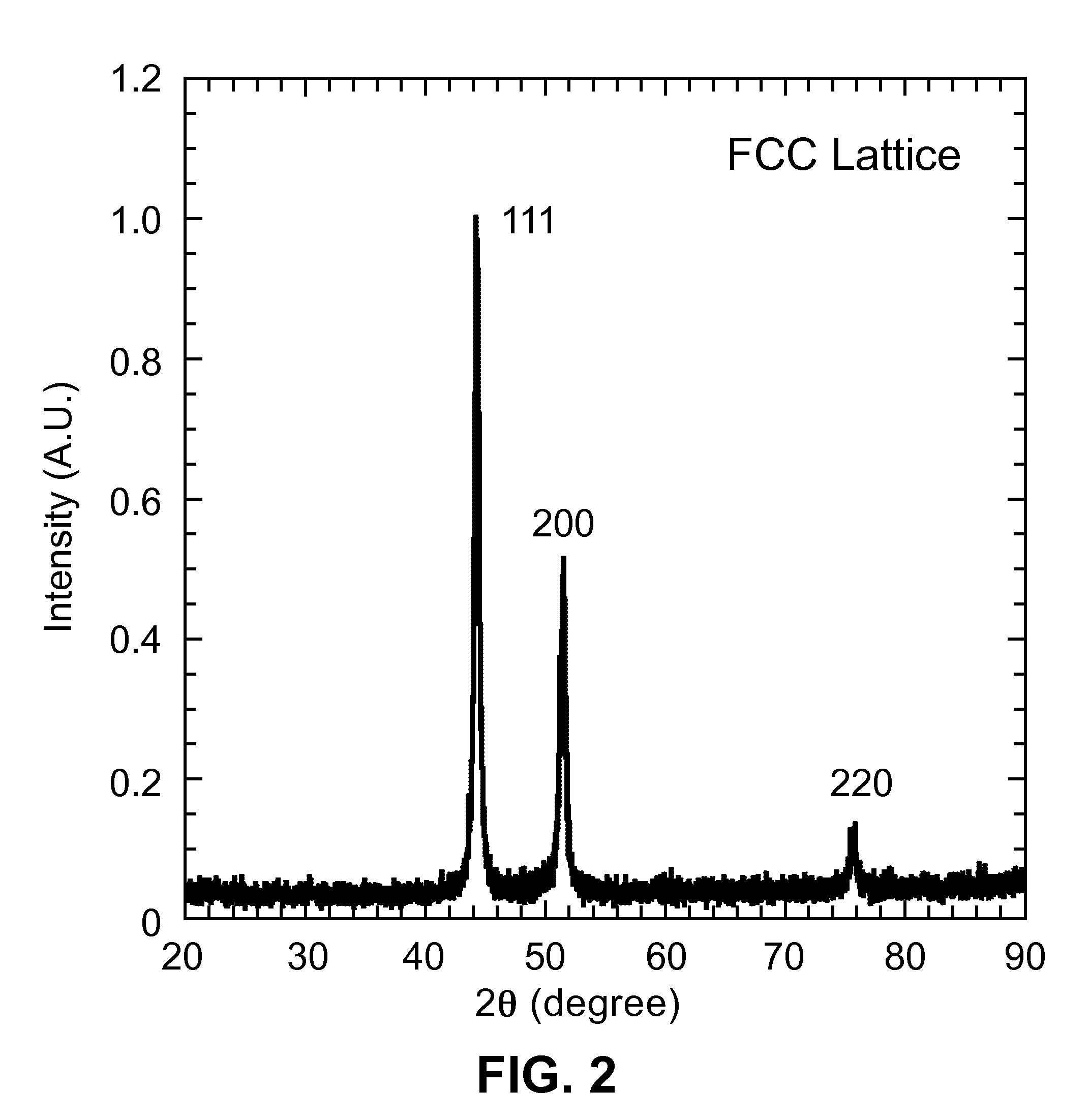

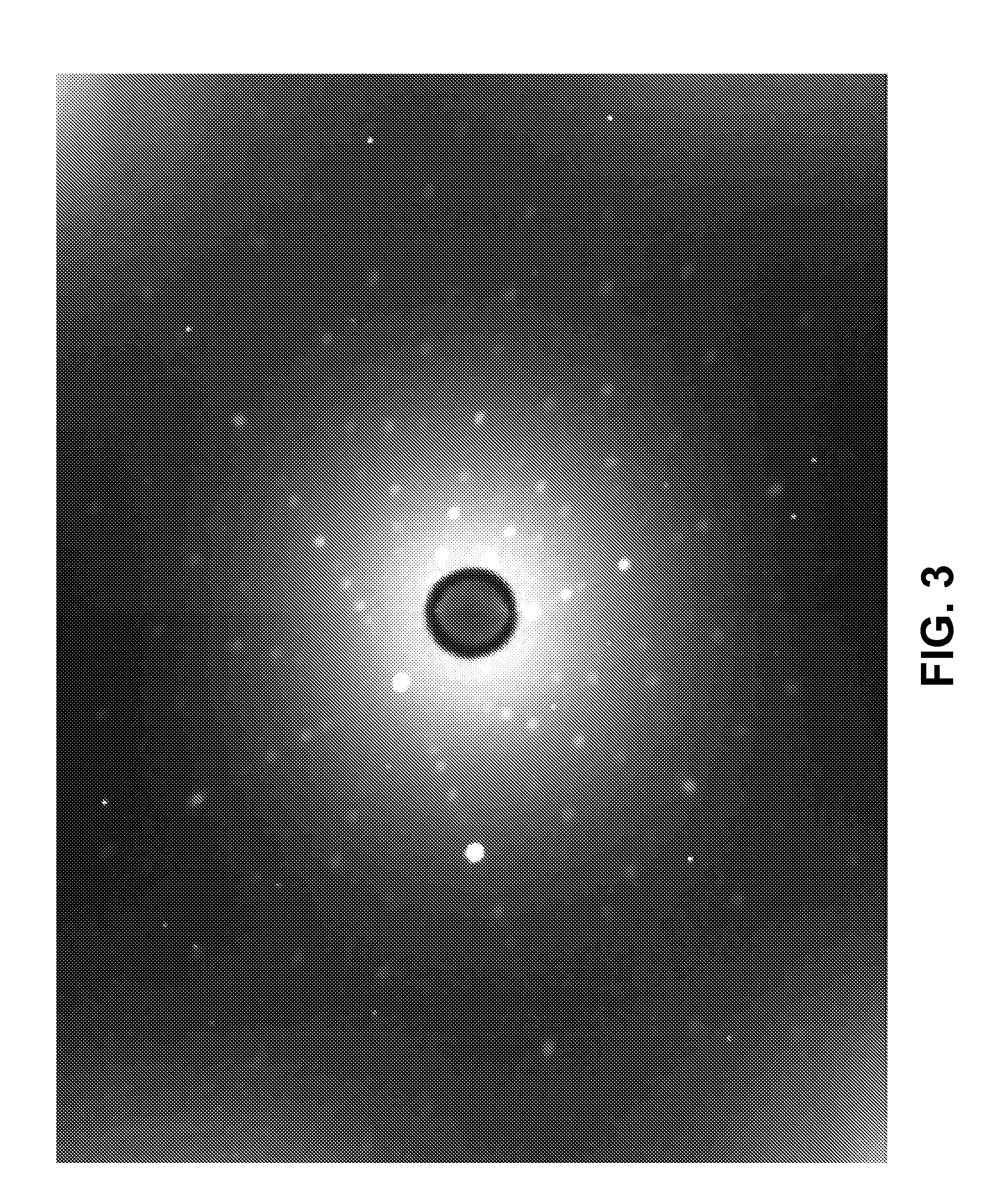

Multi-Component Solid Solution Alloys having High Mixing Entropy

A multi-component high-entropy alloy includes a composition selected from the following group: VNbTaTiMoWRe, VNbTaTiMoW, VNbTaTiMoRe, VNbTaTiWRe, VNbTaMoWRe, VNbTiMoWRe, VTaTiMoWRe, NbTaTiMoWRe, VNbTaTiMo, VNbTaTiW, VNbTaMoW, VNbTiMoW, VTaTiMoW, NbTaTiMoW, VNbTaTiRe, VNbTaMoRe, VNbTiMoRe, VTaTiMoRe, NbTaTiMoRe, VNbTaWRe, VNbTiWRe, VTaTiWRe, NbTaTiWRe, VNbMoWRe, VTaMoWRe, NbTaMoWRe, VTiMoWRe, NbTiMoWRe, TaTiMoWRe, wherein relative amounts of each element vary by no more than ±15 atomic %.

Owner:UT BATTELLE LLC

Titanium boride coatings on titanium surfaces and associated methods

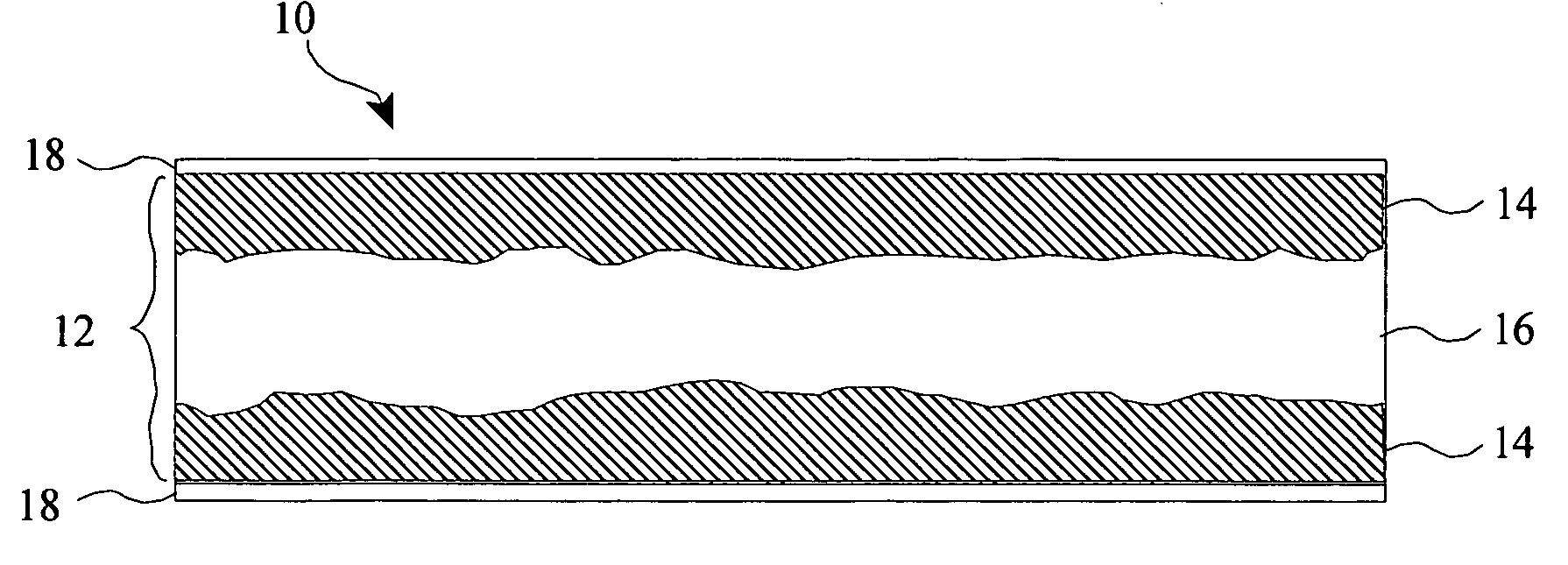

InactiveUS7264682B2High wear and corrosion and oxidation resistanceResistance to galling and seizureSolid state diffusion coatingMetal boridesBorideTitanium surface

Owner:UNIV OF UTAH RES FOUND

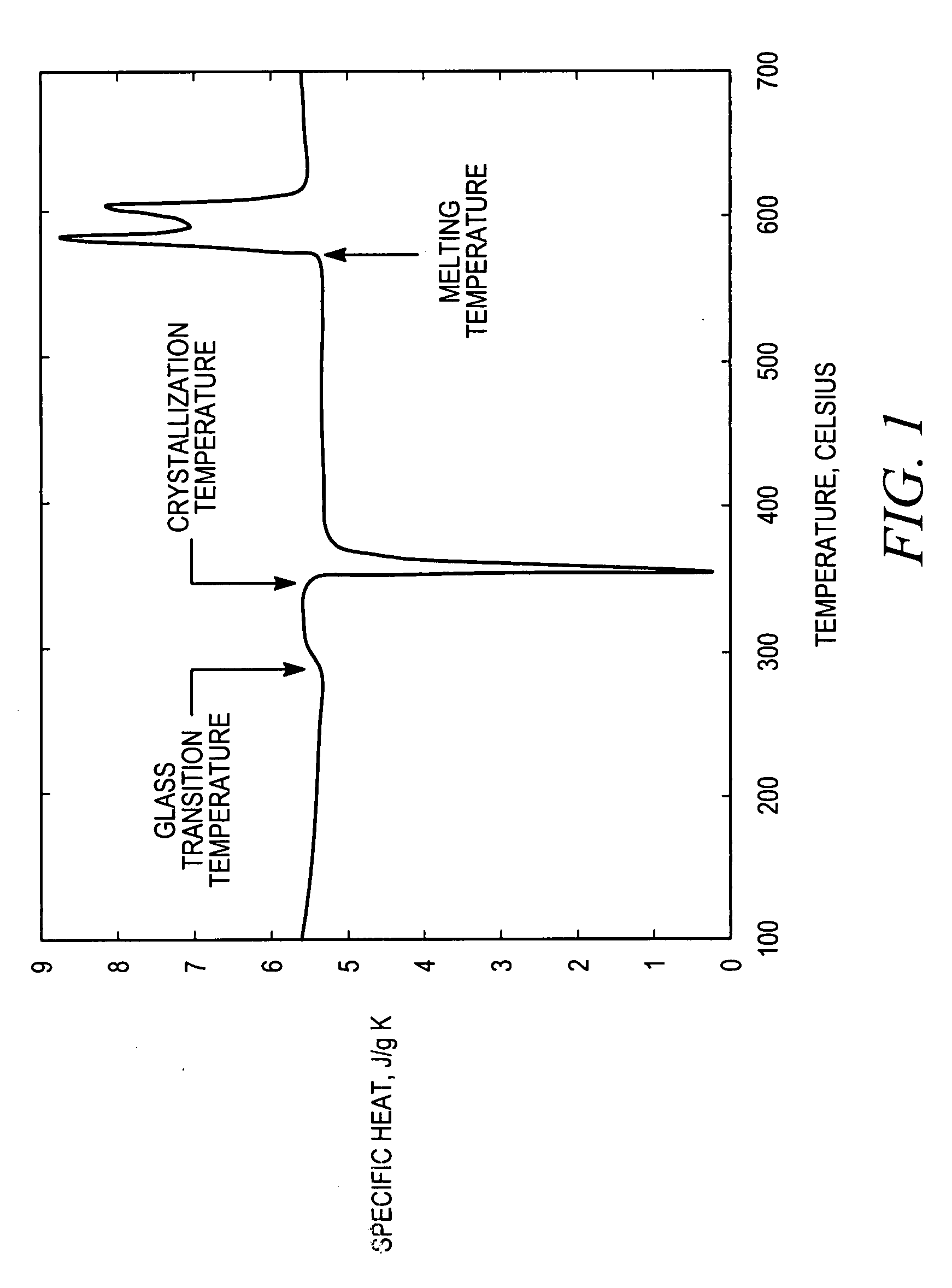

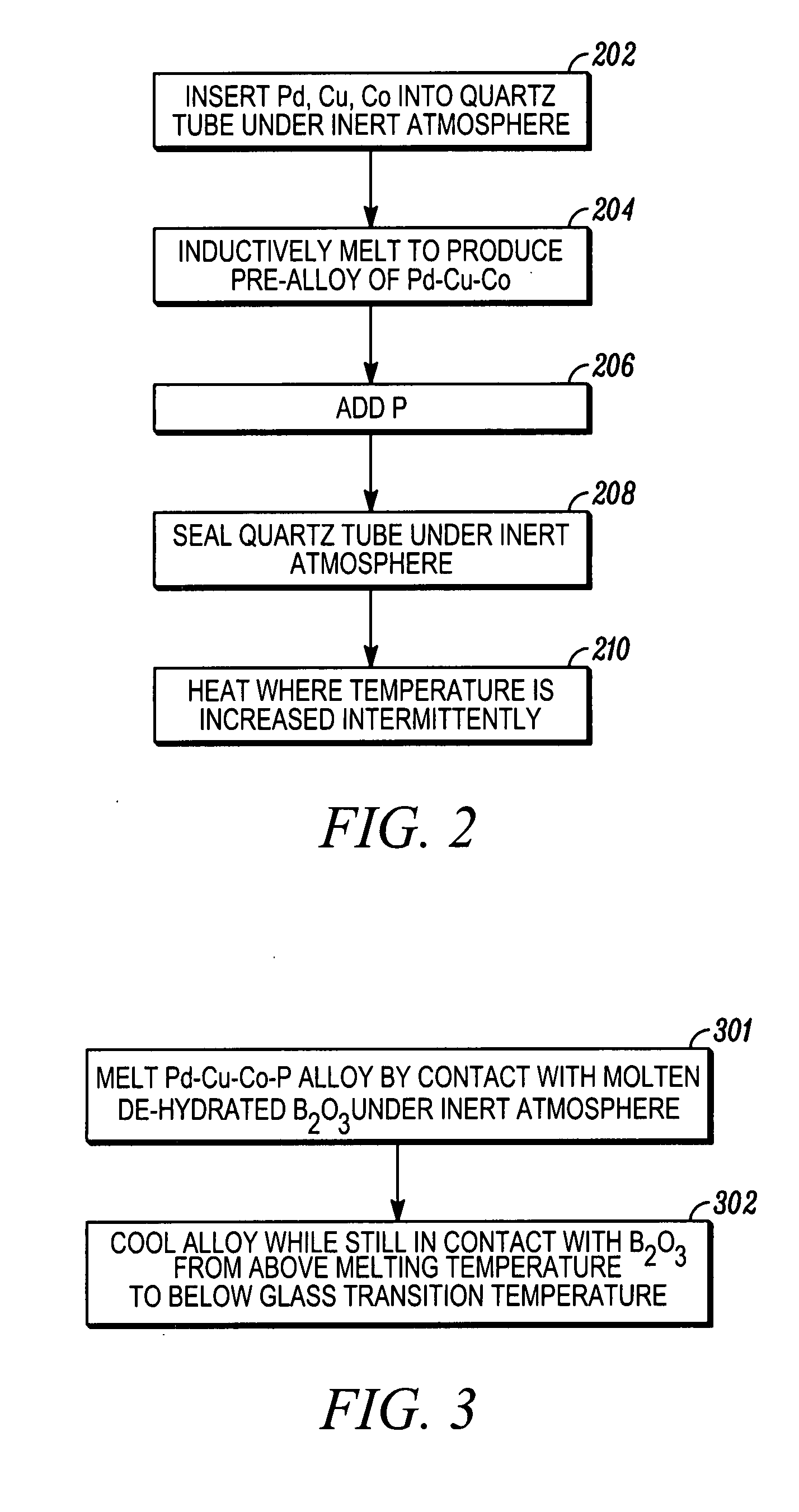

Metallic glass alloys of palladium, copper, cobalt, and phosphorus

Metallic glass alloys of palladium, copper, cobalt, and phosphorus, that are bulk-solidifying having an amorphous structure. Other embodiments are described and claimed.

Owner:CALIFORNIA INST OF TECH

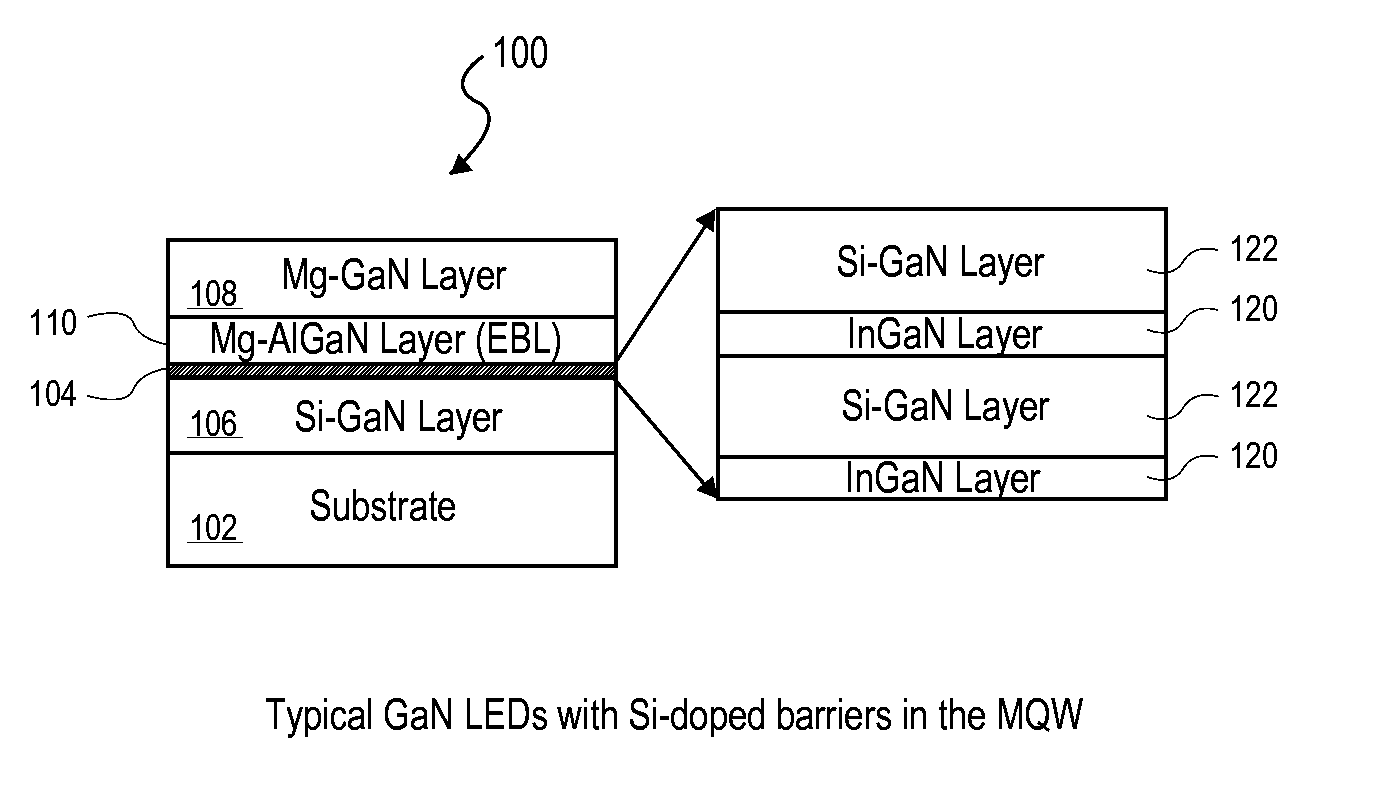

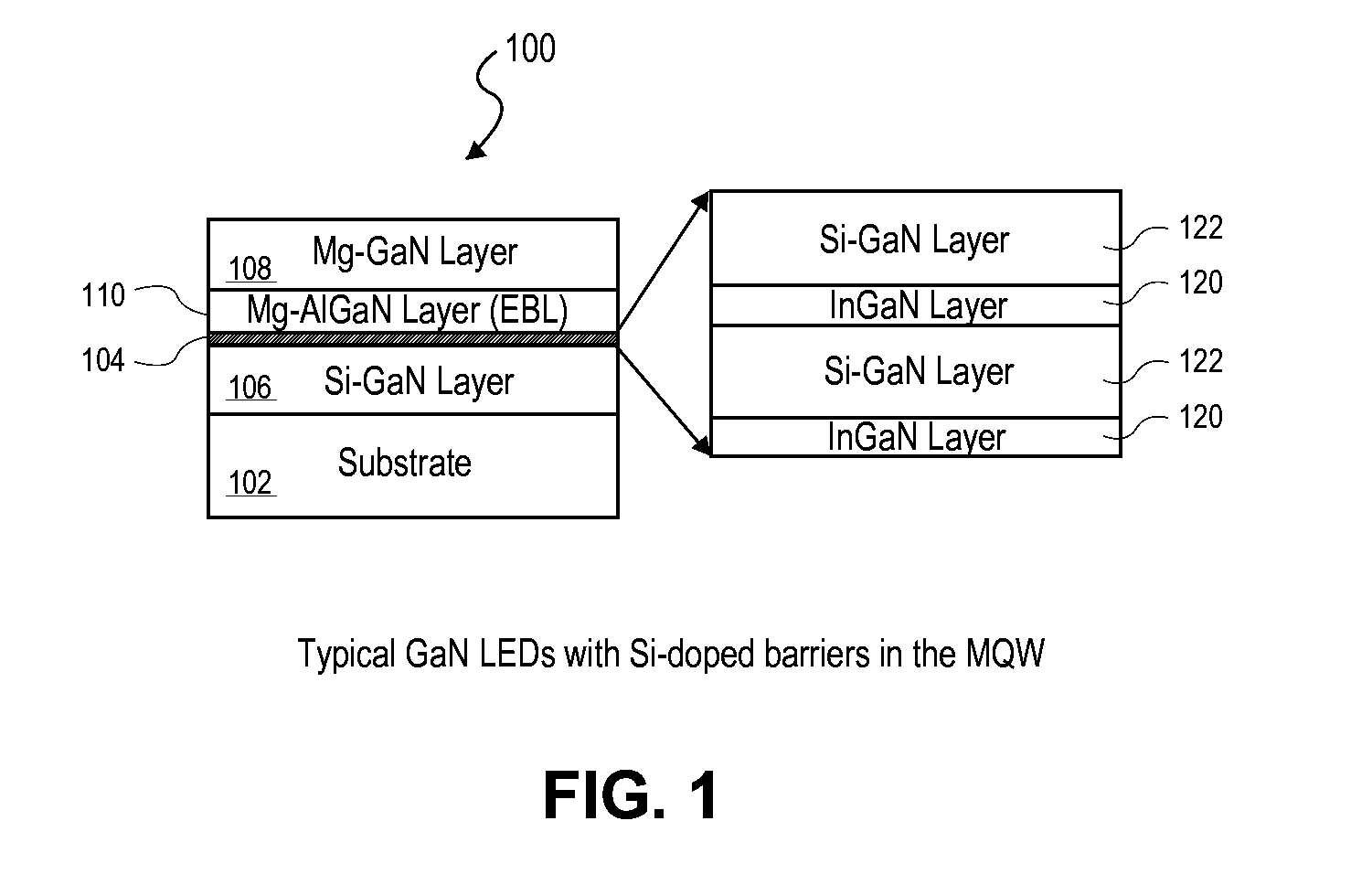

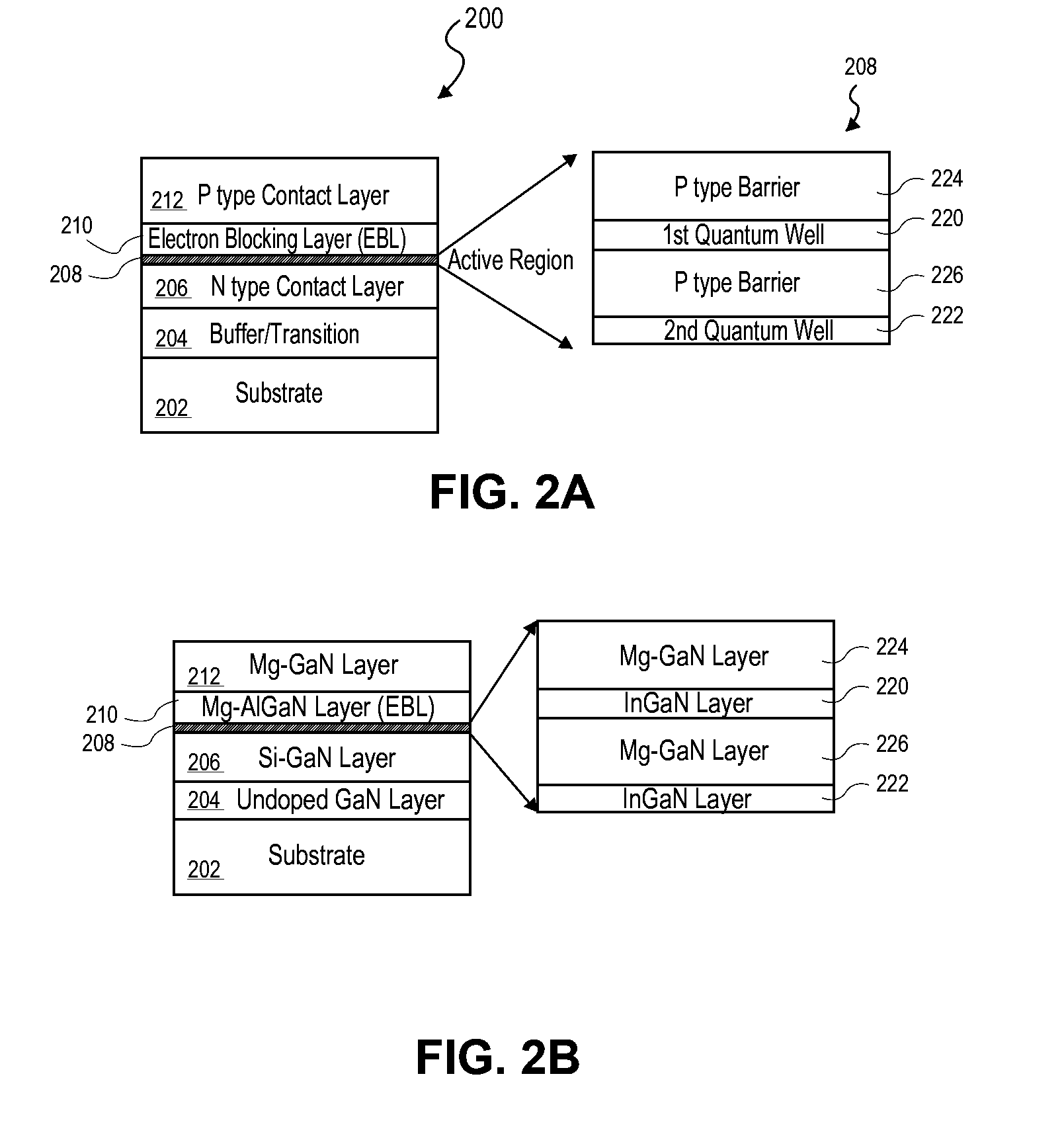

Light emitting diode with enhanced quantum efficiency and method of fabrication

InactiveUS20120235116A1Low costIncrease varietyPolycrystalline material growthConductive materialIndiumAlloy

One embodiment of a quantum well structure comprises an active region including active layers that comprise quantum wells and barrier layers wherein some or all of the active layers are p type doped. P type doping some or all of the active layers improves the quantum efficiency of III-V compound semiconductor light emitting diodes by locating the position of the P-N junction in the active region of the device thereby enabling the dominant radiative recombination to occur within the active region. In one embodiment, the quantum well structure is fabricated in a cluster tool having a hydride vapor phase epitaxial (HVPE) deposition chamber with a eutectic source alloy. In one embodiment, the indium gallium nitride (InGaN) layer and the magnesium doped gallium nitride (Mg—GaN) or magnesium doped aluminum gallium nitride (Mg—AlGaN) layer are grown in separate chambers by a cluster tool to avoid indium and magnesium cross contamination. Doping of group III-nitrides by hydride vapor phase epitaxy using group III-metal eutectics is also described. In one embodiment, a source is provided for HVPE deposition of a p-type or an n-type group III-nitride epitaxial film, the source including a liquid phase mechanical (eutectic) mixture with a group III species. In one embodiment, a method is provided for performing HVPE deposition of a p-type or an n-type group III-nitride epitaxial film, the method including using a liquid phase mechanical (eutectic) mixture with a group III species.

Owner:APPLIED MATERIALS INC

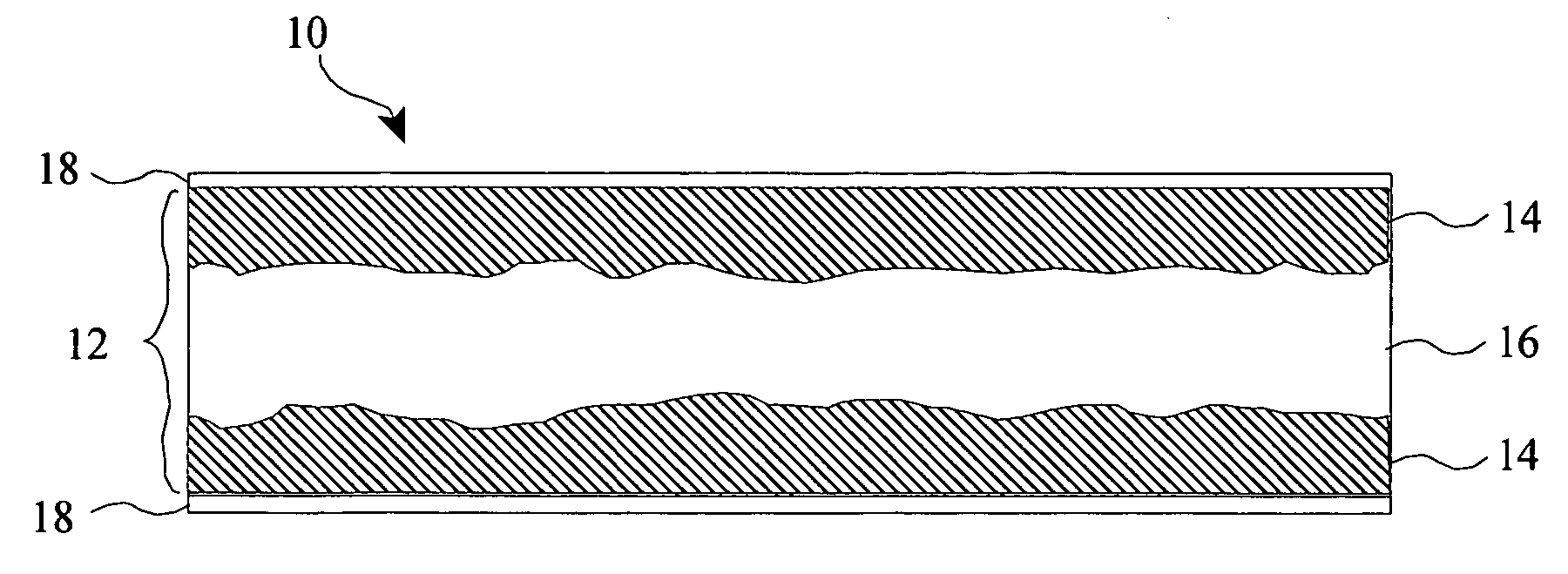

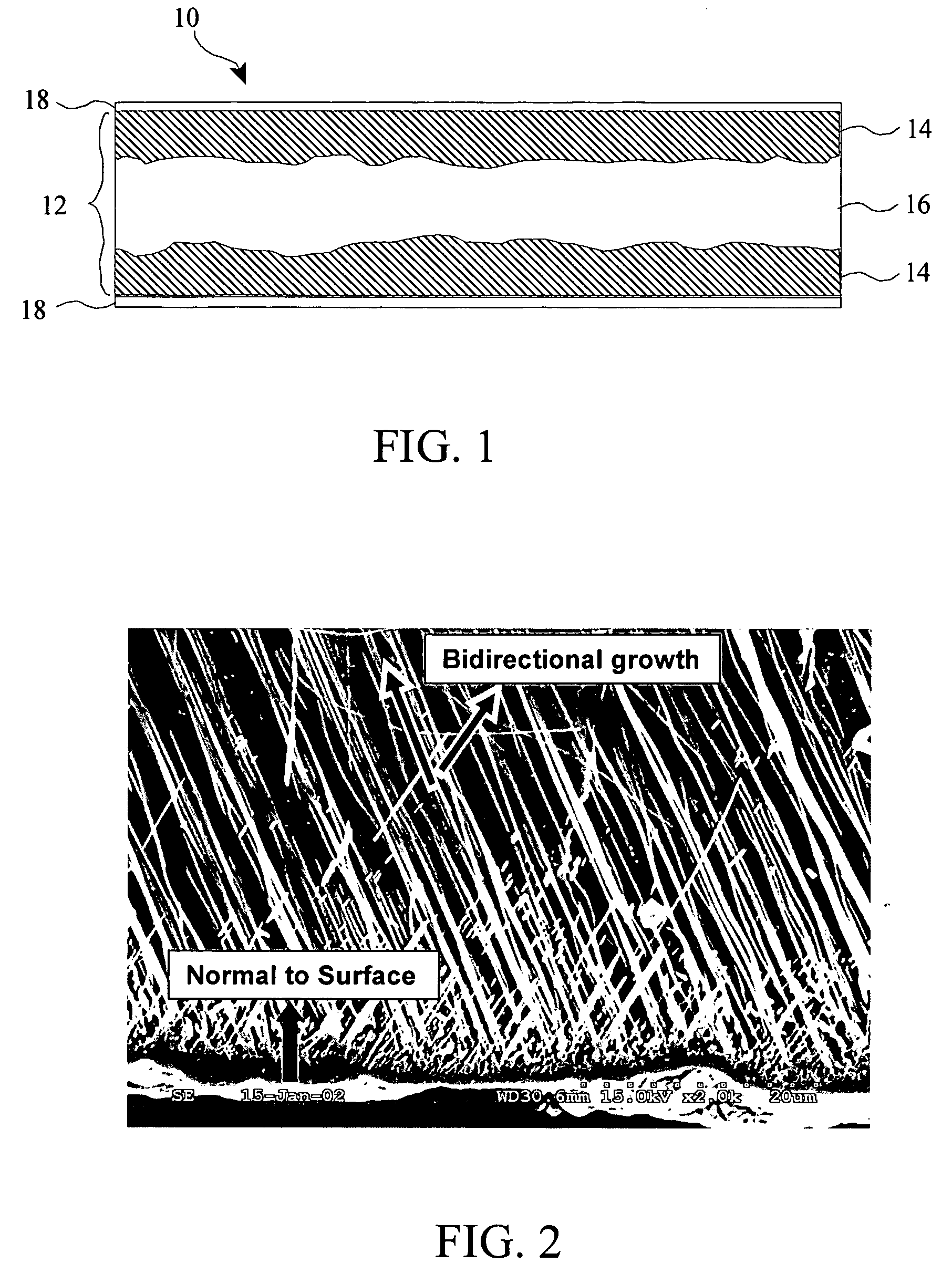

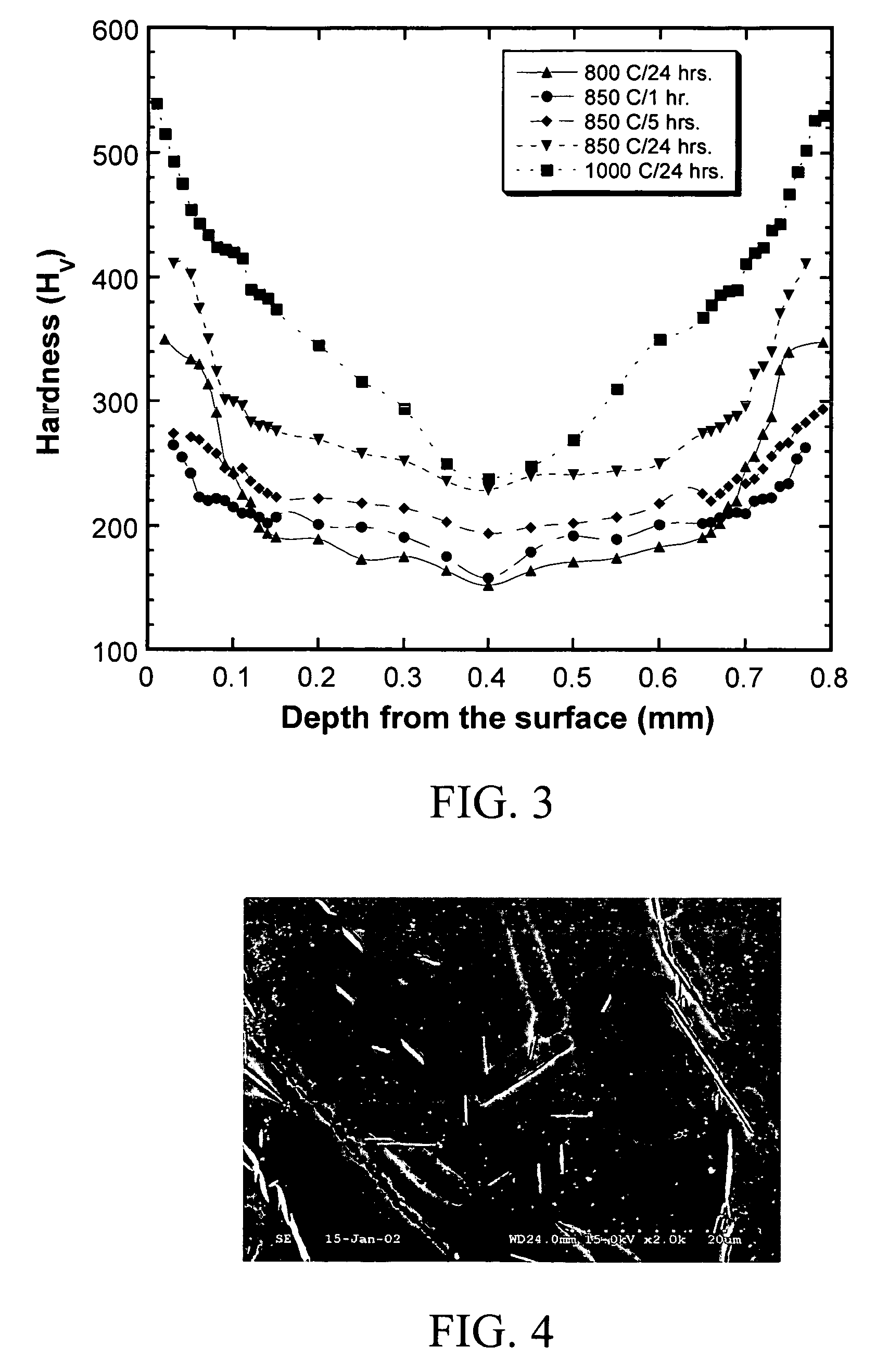

Titanium boride coatings on titanium surfaces and associated methods

InactiveUS20050208213A1High wear and corrosion and oxidation resistanceResistance to galling and seizureLiquid surface applicatorsSolid state diffusion coatingParticulatesSolid particle

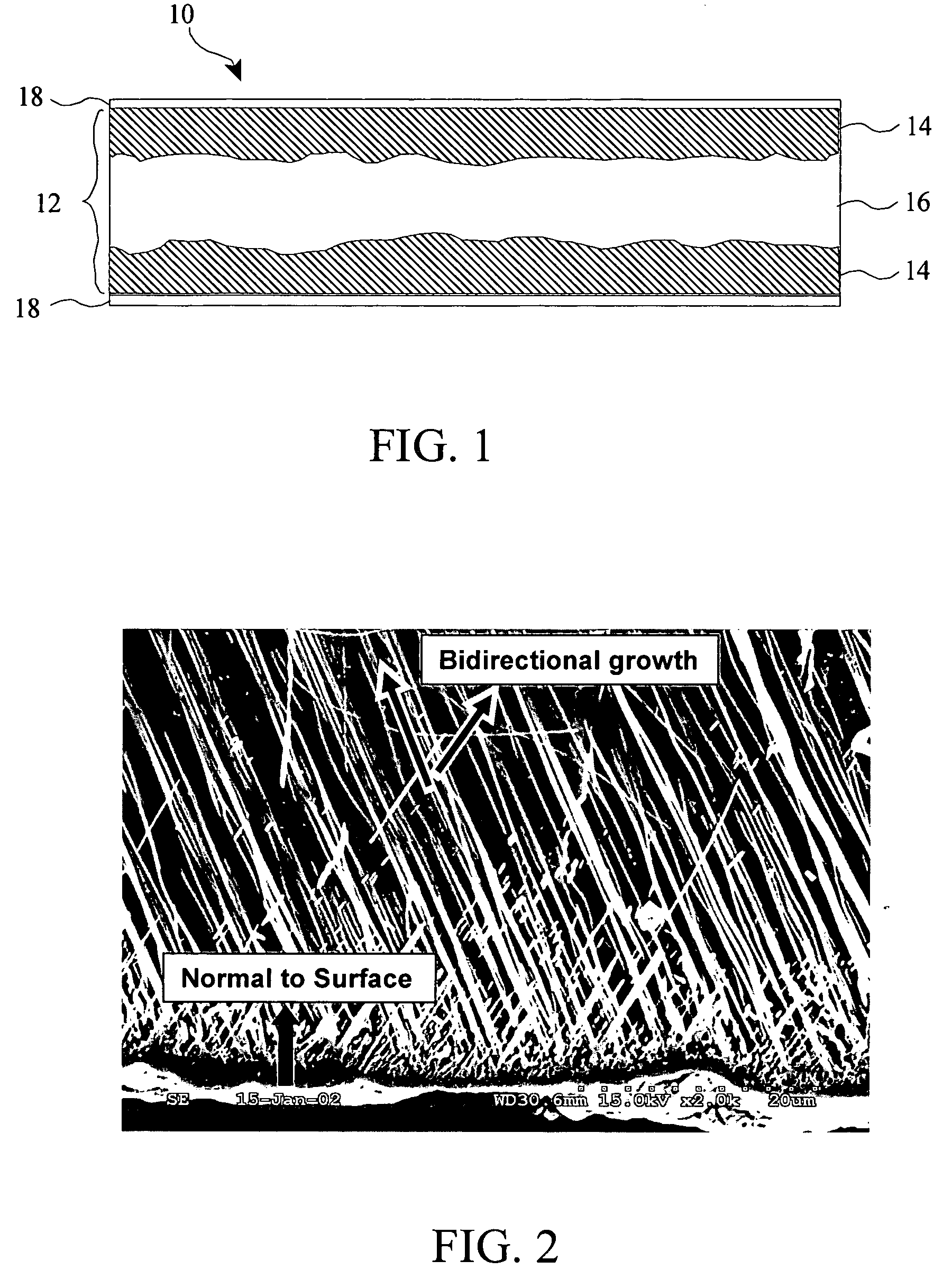

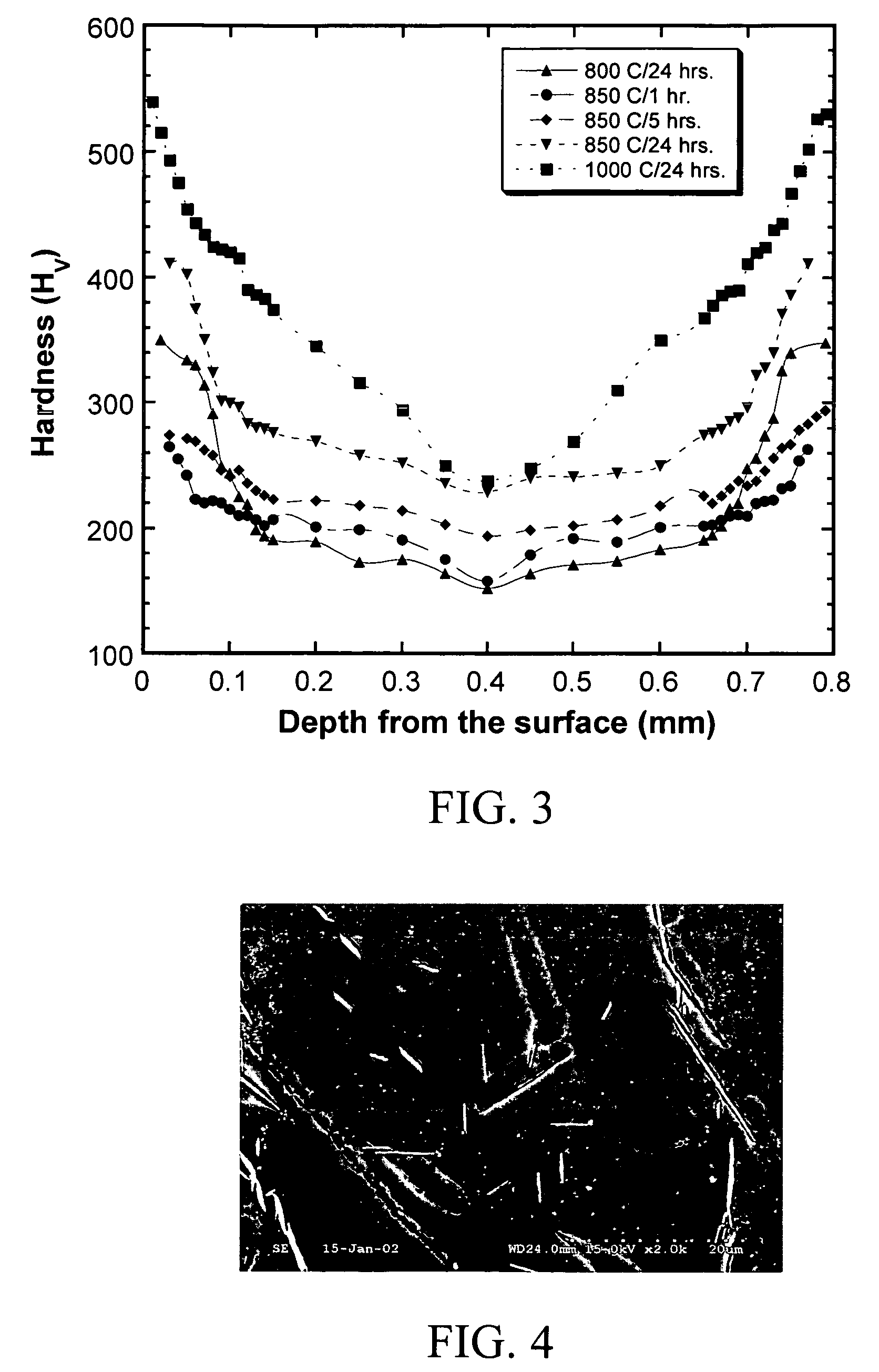

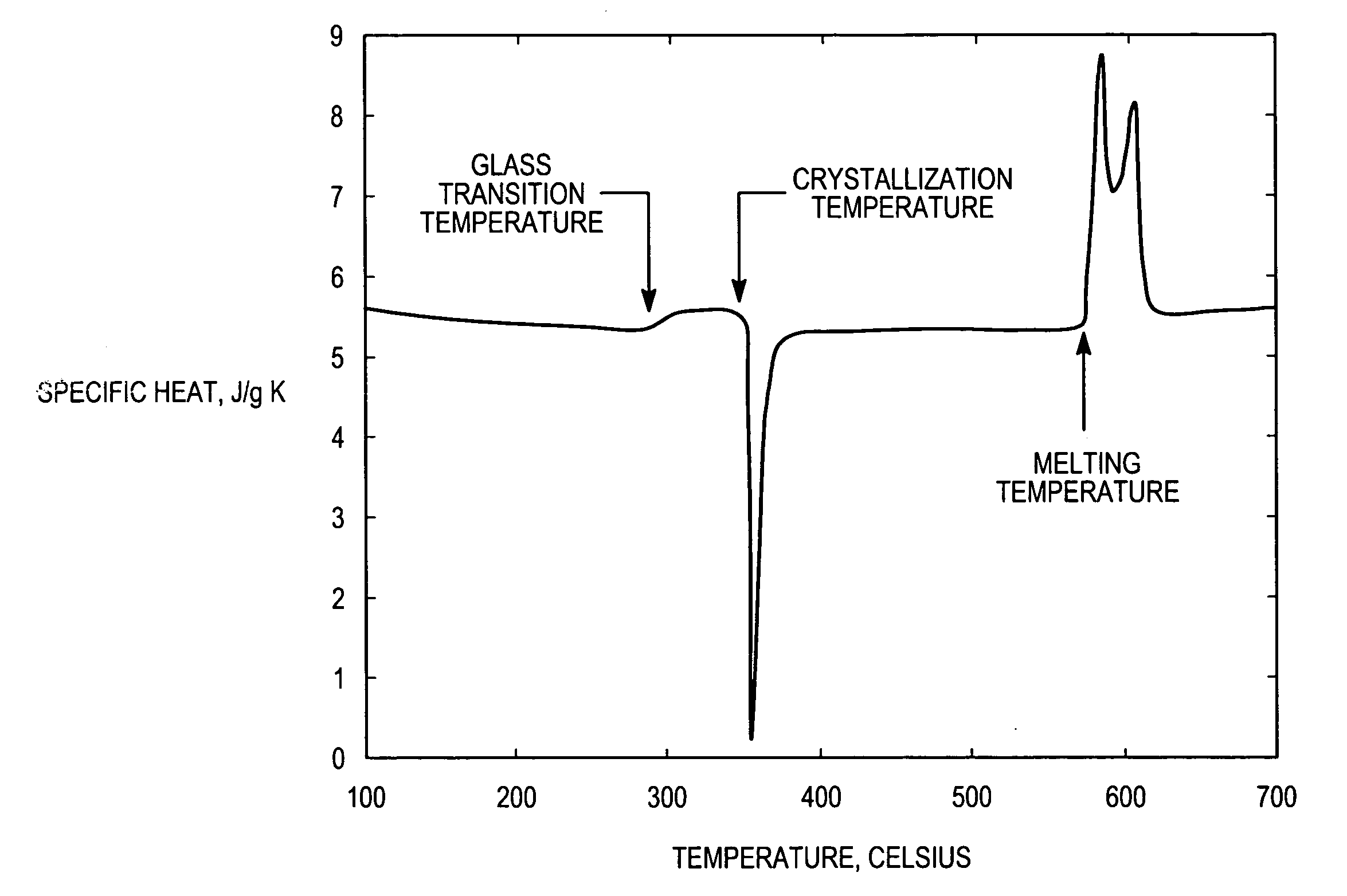

A borided titanium article can include a titanium mass having titanium monoboride whiskers infiltrating inward from a surface of the titanium mass to form an integral surface hardened region. The titanium mass can be almost any titanium based metal or alloy such as high purity titanium, commercial grade titanium, α-titanium alloy, α+β titanium alloy, β-titanium alloy, titanium composite, and combinations thereof. Borided titanium articles can be formed by methods which include providing a titanium mass, contacting a surface of the titanium mass with a boron source medium, and heating the titanium mass and boron source medium to a temperature from about 700° C. to about 1600° C. The boron source medium can include a boron source and an activator selected to provide growth of titanium monoboride whiskers. The boron source medium can be provided as a solid particulate mixture, liquid mixture, or as a gaseous mixture. During heating, boron from the boron source infiltrates into the titanium mass and forms titanium monoboride whiskers which improve the surface hardness, wear resistance, oxidation resistance, and corrosion resistance of the treated surface. The titanium monoboride whiskers can be controlled to have the desired dimensions, depending on the application requirements. Boriding titanium surfaces using these methods, provides a relatively inexpensive and effective process for improving the surface properties of titanium which are then useful in a wide variety of applications.

Owner:UNIV OF UTAH RES FOUND

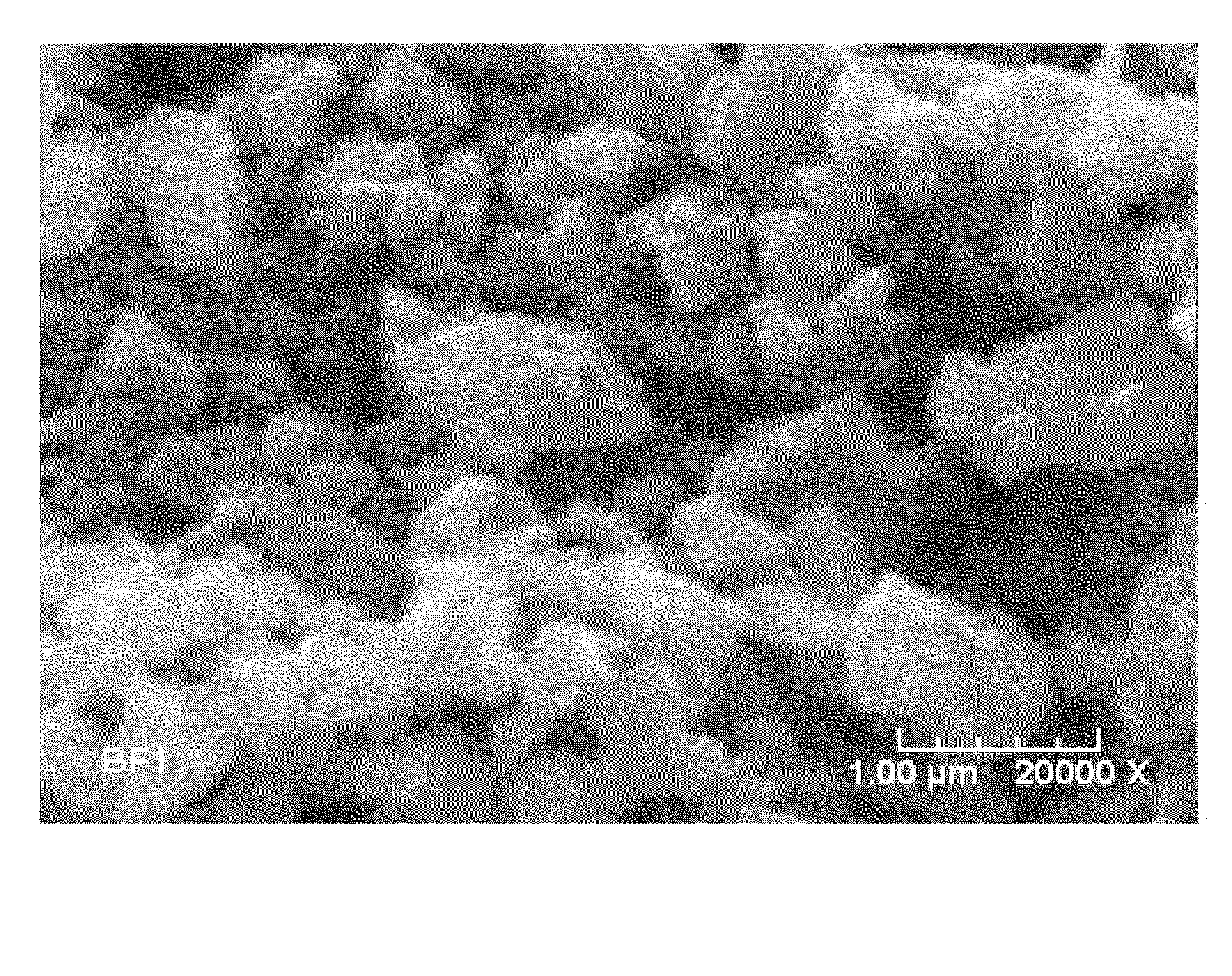

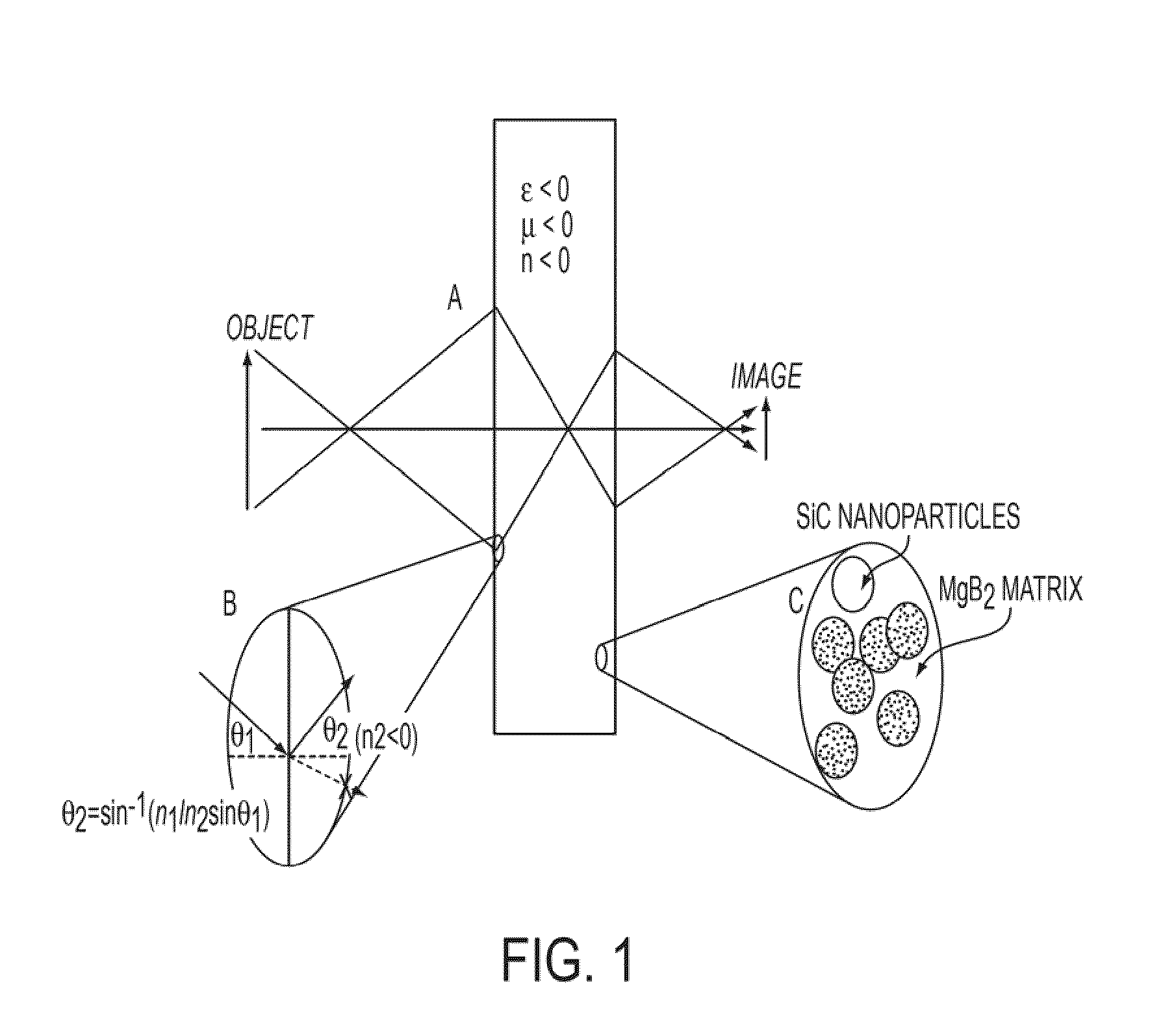

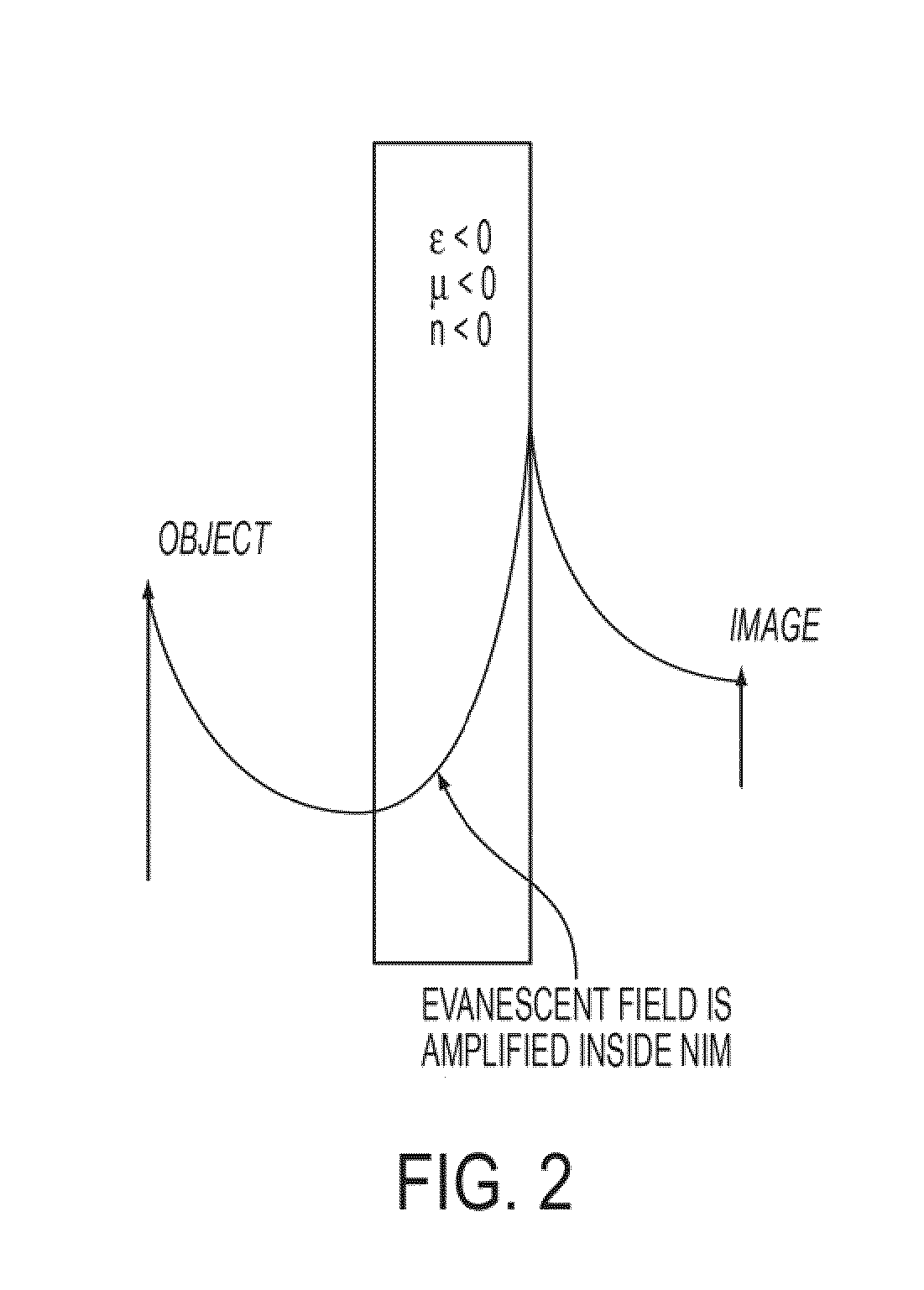

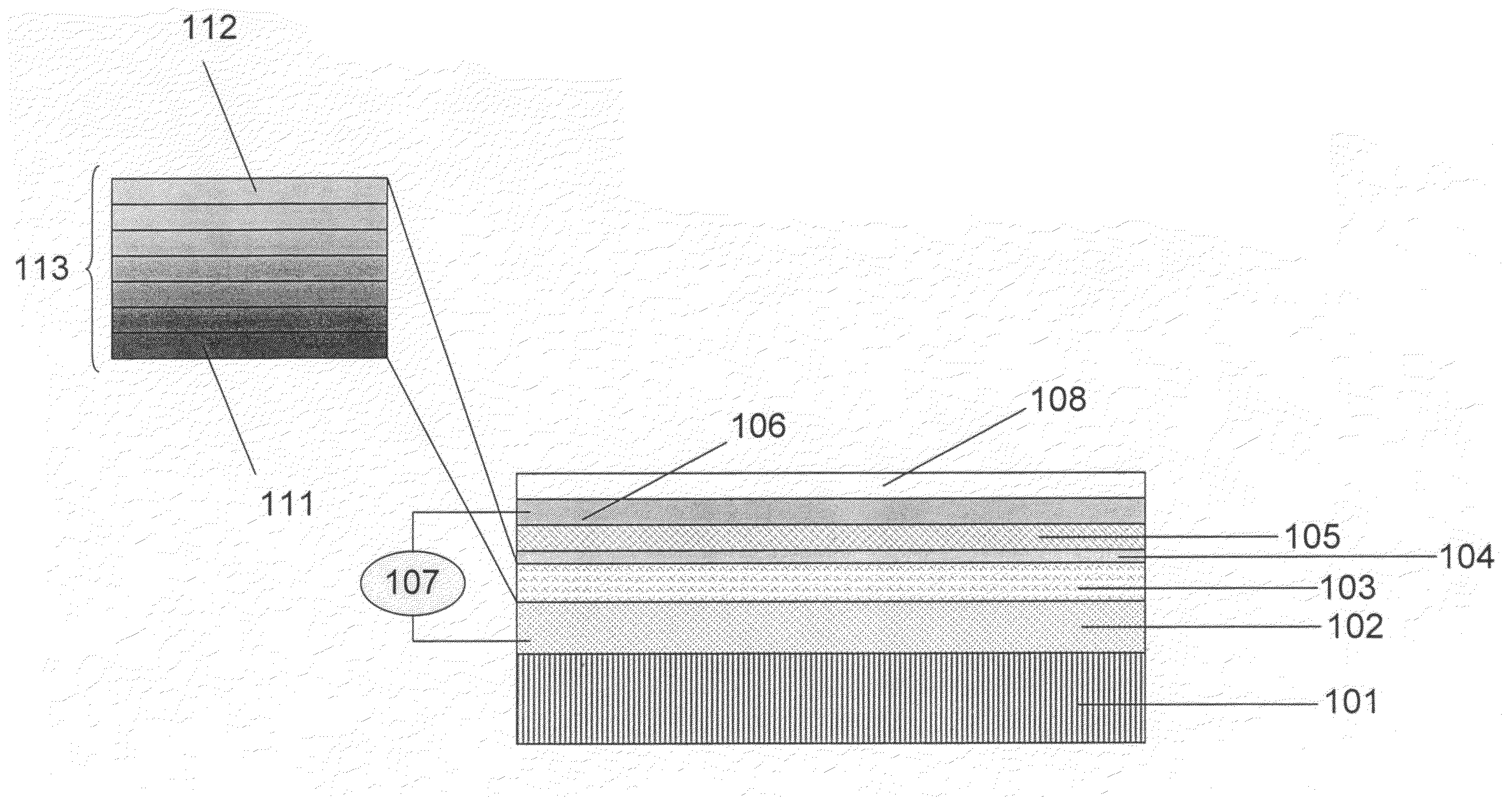

Negative refractive index materials and methods for making same

InactiveUS20100157437A1Reduce the temperatureDiffusing elementsOptical filtersOptical frequenciesRefractive index

Embodiments of the invention described herein include metamaterials that exhibit negative permittivity and negative permeability at optical frequencies, methods for preparing such materials, and devices prepared from same.

Owner:TRITON SYST INC

Composition and method of preparing nanoscale thin film photovoltaic materials

InactiveUS20080190483A1Reduce harmImprove uniformityFinal product manufactureMetal boridesSolar absorberIndium

A photo-absorbing layer for use in an electronic device; the layer including metal alloy nanoparticles copper, indium and / or gallium made preferably from a vapor condensation process or other suitable process, the layer also including elemental selenium and / or sulfur heated at temperatures sufficient to permit reaction between the nanoparticles and the selenium and / or sulfur to form a substantially fused layer. The reaction may result in the formation of a chalcopyrite material. The layer has been shown to be an efficient solar energy absorber for use in photovoltaic cells.

Owner:BRICOLEUR PARTNERS LP

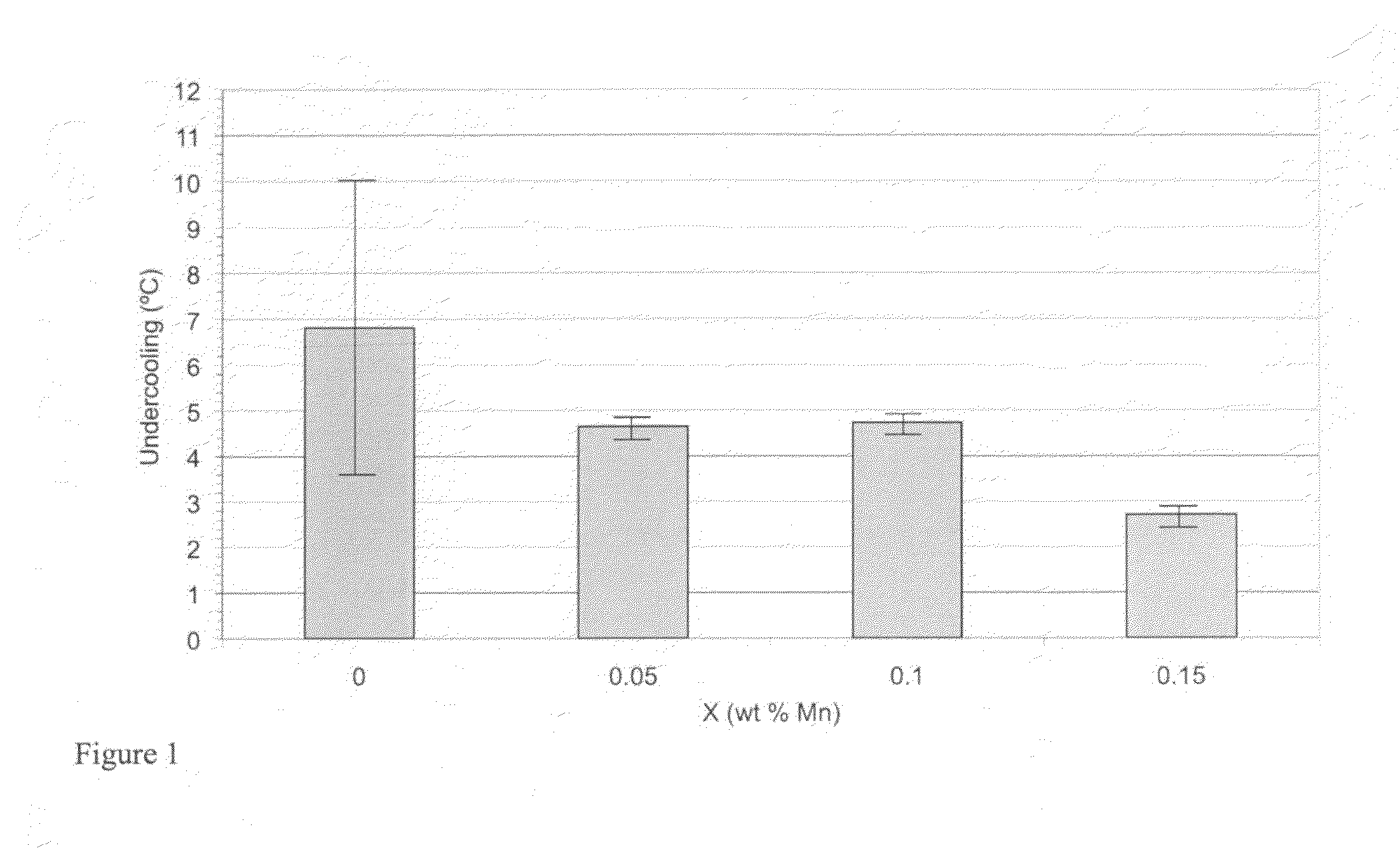

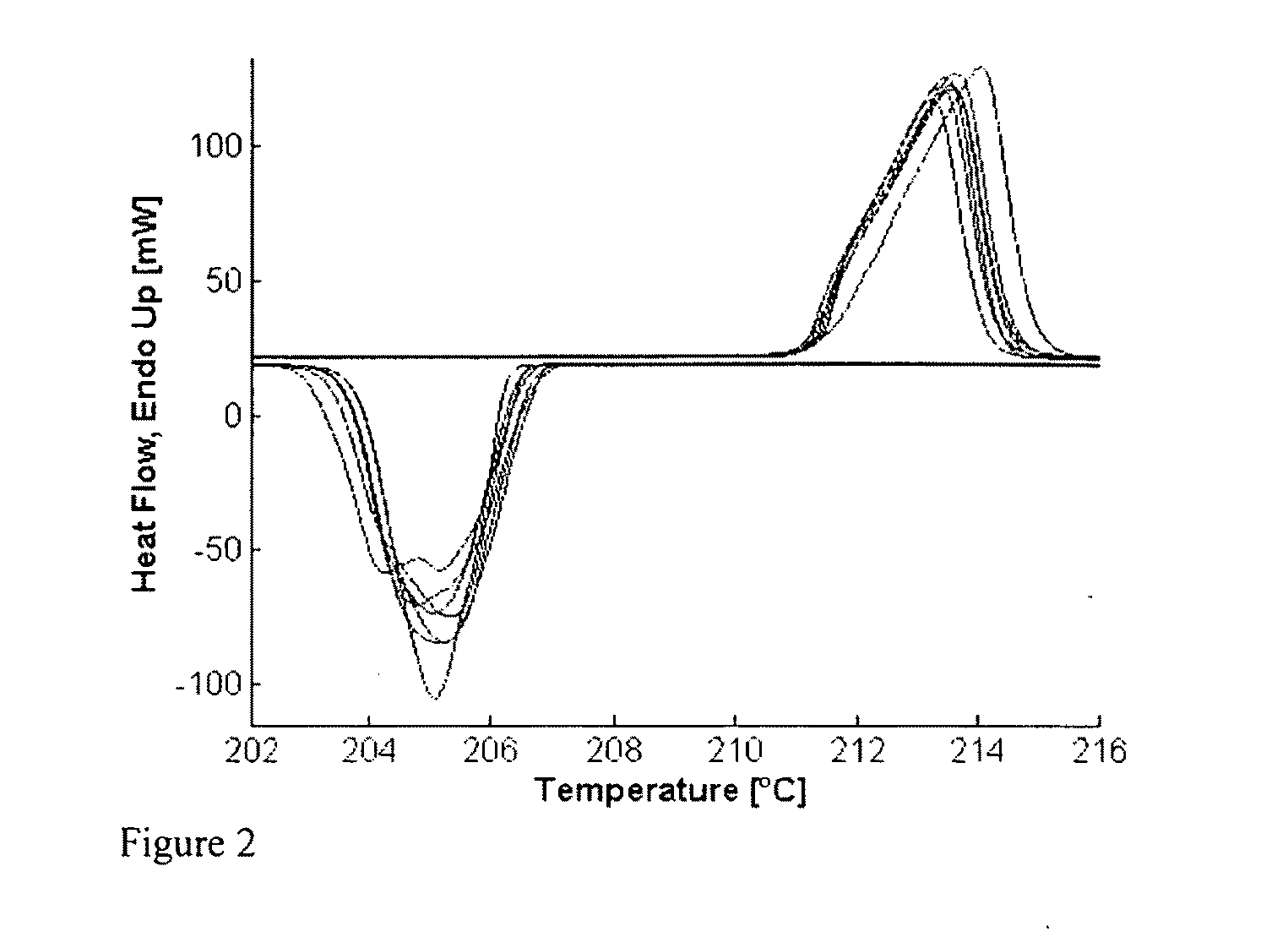

Pb-Free Sn-Ag-Cu-Mn Solder

InactiveUS20100203353A1Improve wettabilityLow melting pointCooking-vessel materialsMetal boridesSolder ballSolder paste

A solder alloy comprises Sn, Ag, Cu, and Mn and has a melting temperature of about 211 degrees C. A solder joint and solder process embody the solder alloy as well as solder balls and solder paste made therefrom to provide a solidified joint that includes three different intermetallic phases and a Sn metal phase. An exemplary Sn—Ag—Cu—Mn alloy consists essentially of about 3 to about 4 weight % Ag, about 0.80 to about 1.0 weight % Cu, and about 0.05 to about 0.15 weight % Mn, and balance consisting essentially of Sn.

Owner:IOWA STATE UNIV RES FOUND

Self-spreading metallurgical process of preparing LaB6 powder

The self-spreading metallurgical process of preparing LaB6 powder adopts La2O3, B2O3 and Mg in the mass ratio of 100 to 115-140 to 160-170 as material, and includes the steps of: mixing material and pressing into block; setting inside self-spreading reaction furnace and detonating directly or in constant temperature mode to initiate self-spreading reaction; cooling naturally after reaction to obtain primary product; lixiviating with dilute as lixiviating agent at room temperature, reinforced lixiviating of the filtered extract of the foregoing step with hydrochloric acid as lixiviating agent, filtering, washing and stoving to obtain LaB6 powder. The present invention has low material cost, low power consumption, simple operation and relaxed technological conditions. The product obtained through self-spreading produce producing process has high purity, small granularity, high activity and other advantages.

Owner:NORTHEASTERN UNIV

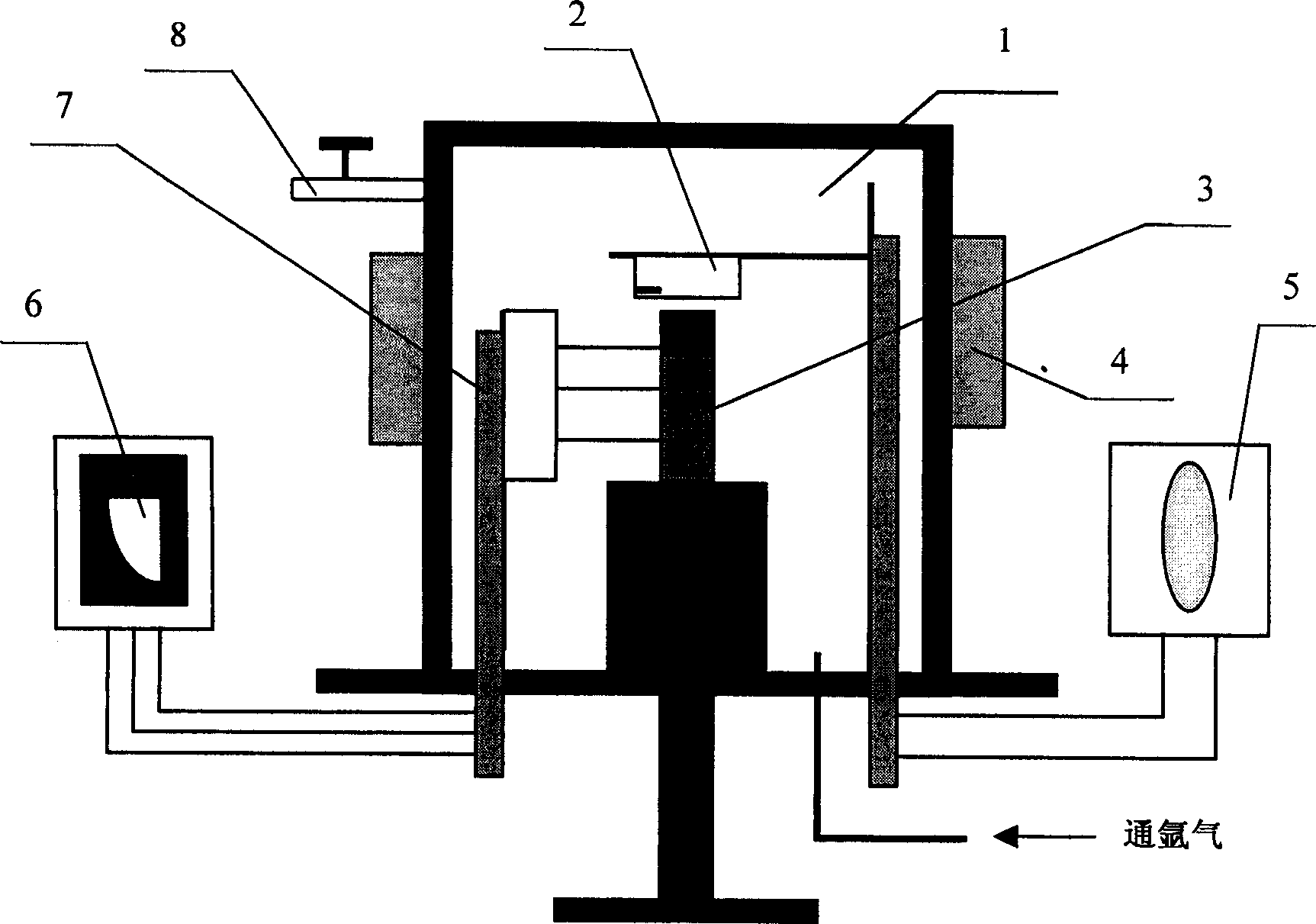

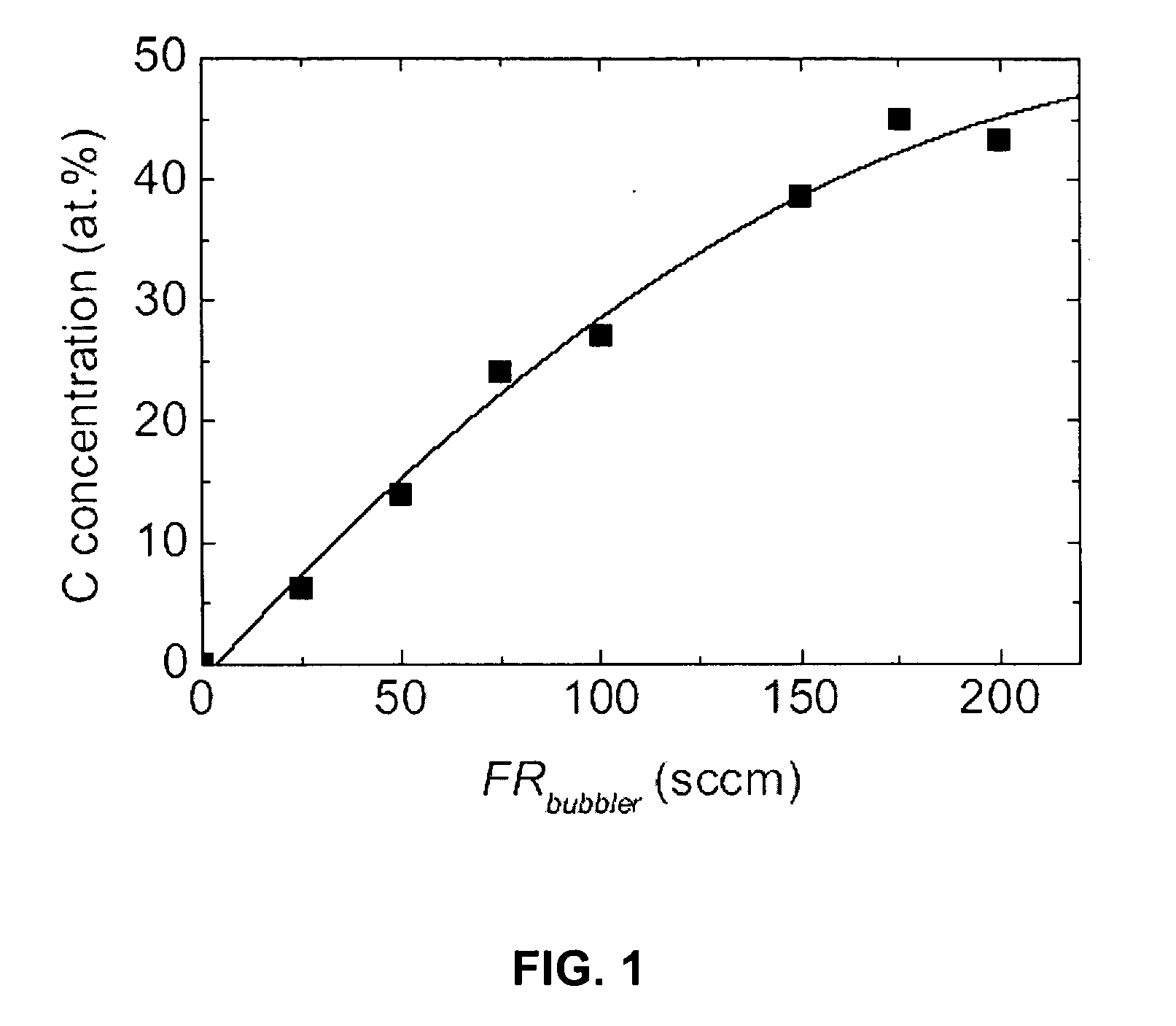

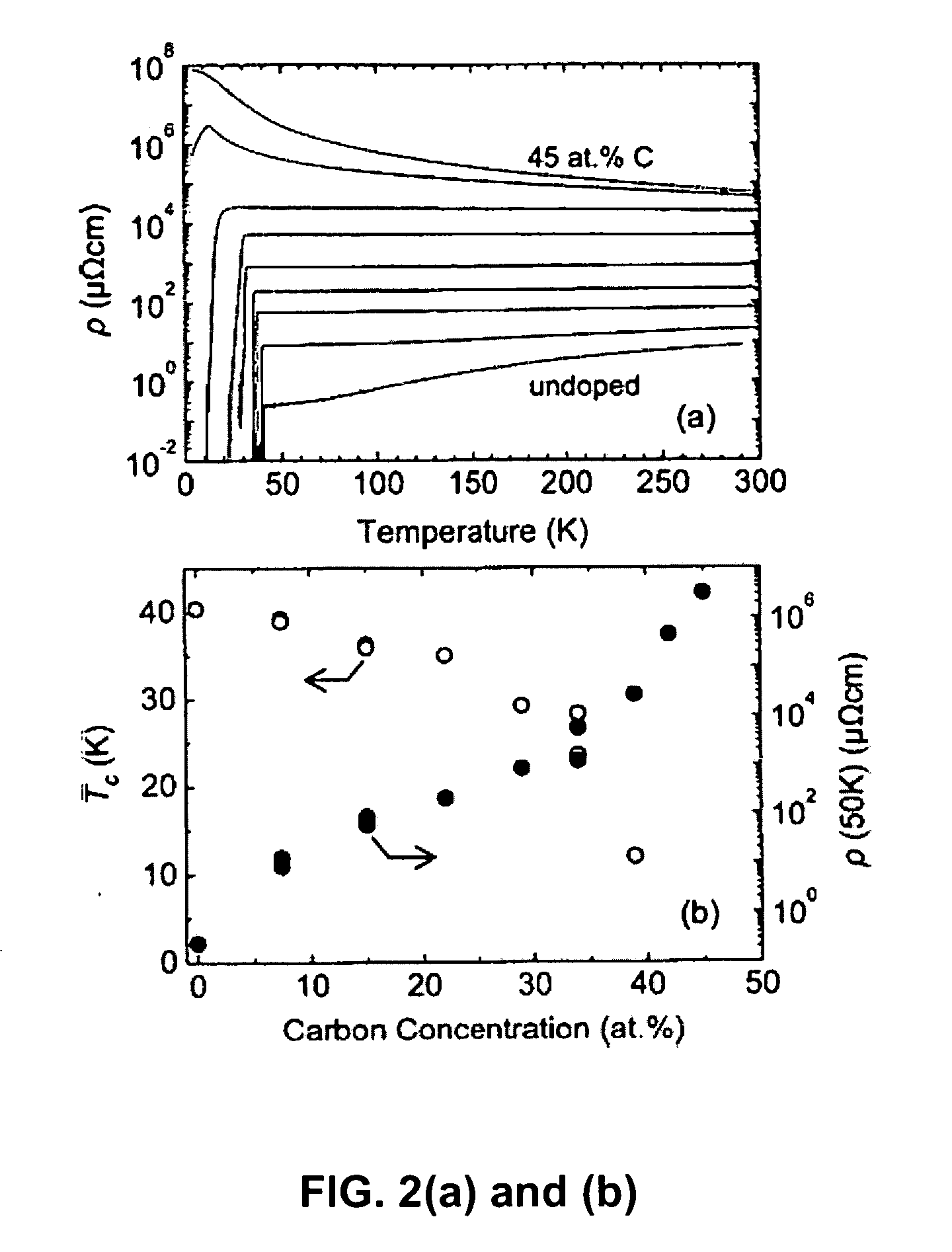

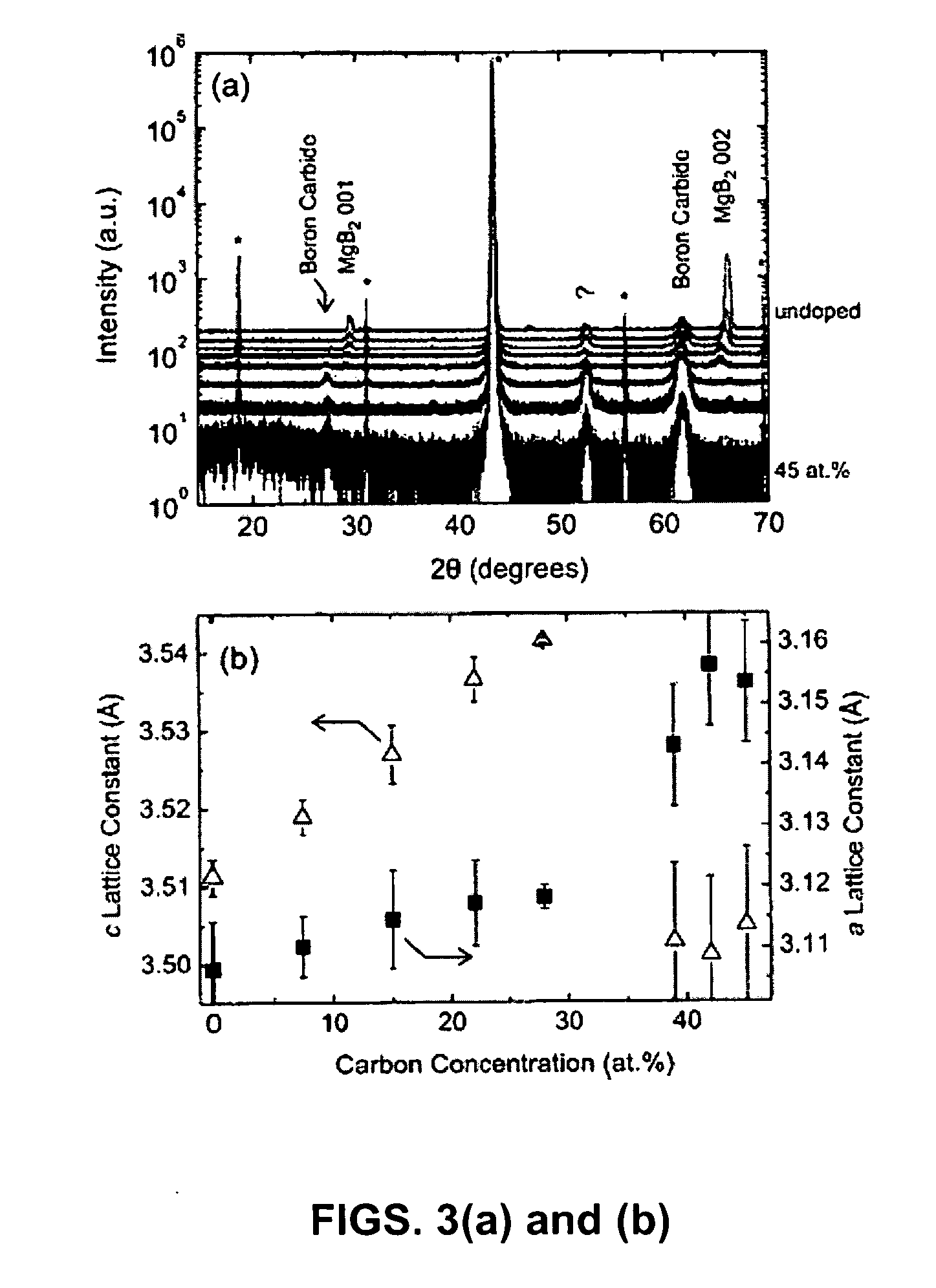

Method for producing doped, alloyed, and mixed-phase magnesium boride films

Conducting and superconducting doped, magnesium boride materials are formed by a process which combines physical vapor deposition with chemical vapor deposition by physically generating magnesium vapor in a deposition chamber and introducing a boron containing precursor and a dopant into the chamber which combines with the magnesium vapor to form the material. Embodiments include forming carbon-doped magnesium diboride film and powder with hybrid physical-chemical vapor deposition (HPCVD) by adding a carbon-containing metalorganic magnesium precursor, bis(methylcyclopentadienyl)magnesium, with a hydrogen carrier gas together with a borane precursor in a chamber having a source of magnesium vapor.

Owner:PENN STATE RES FOUND

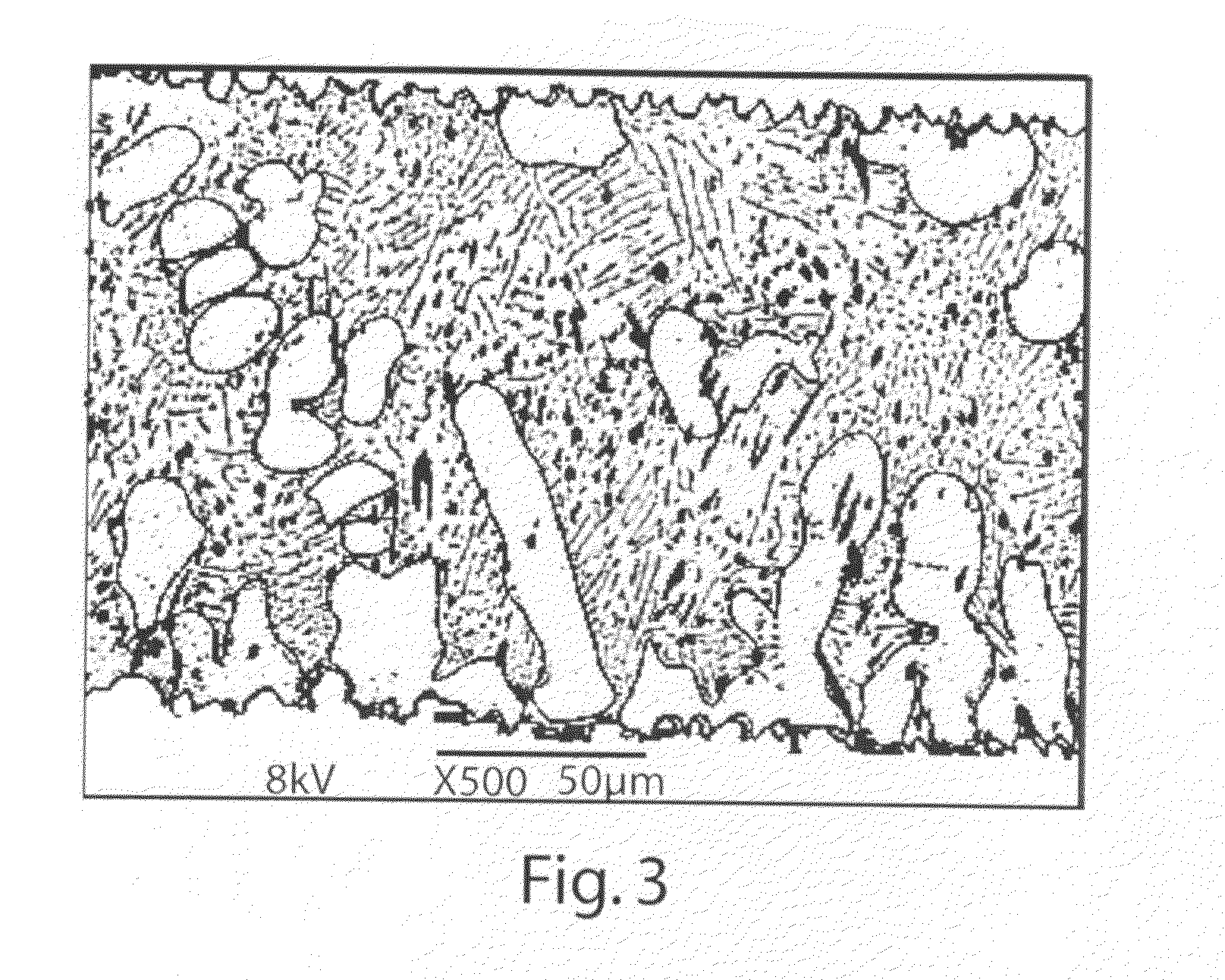

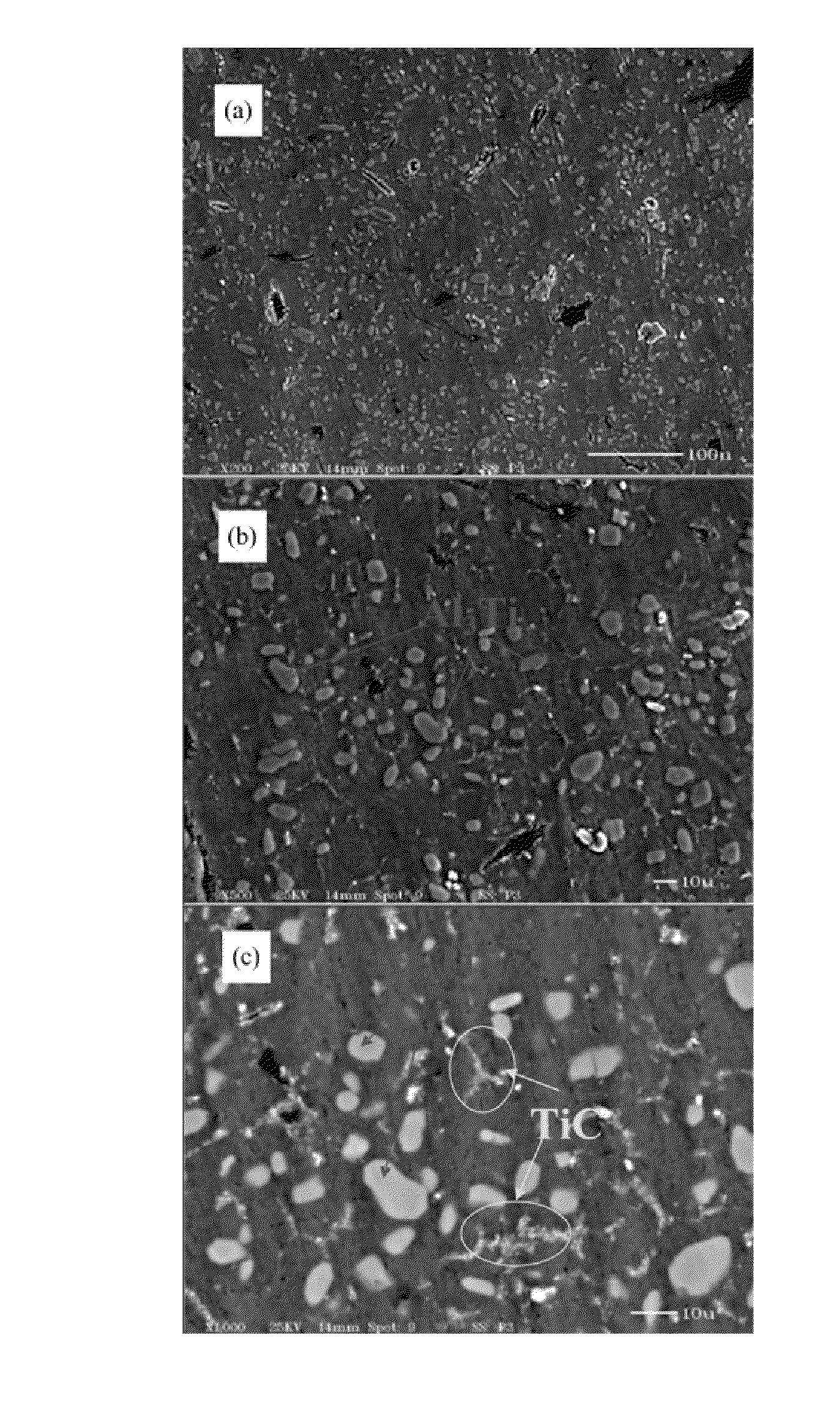

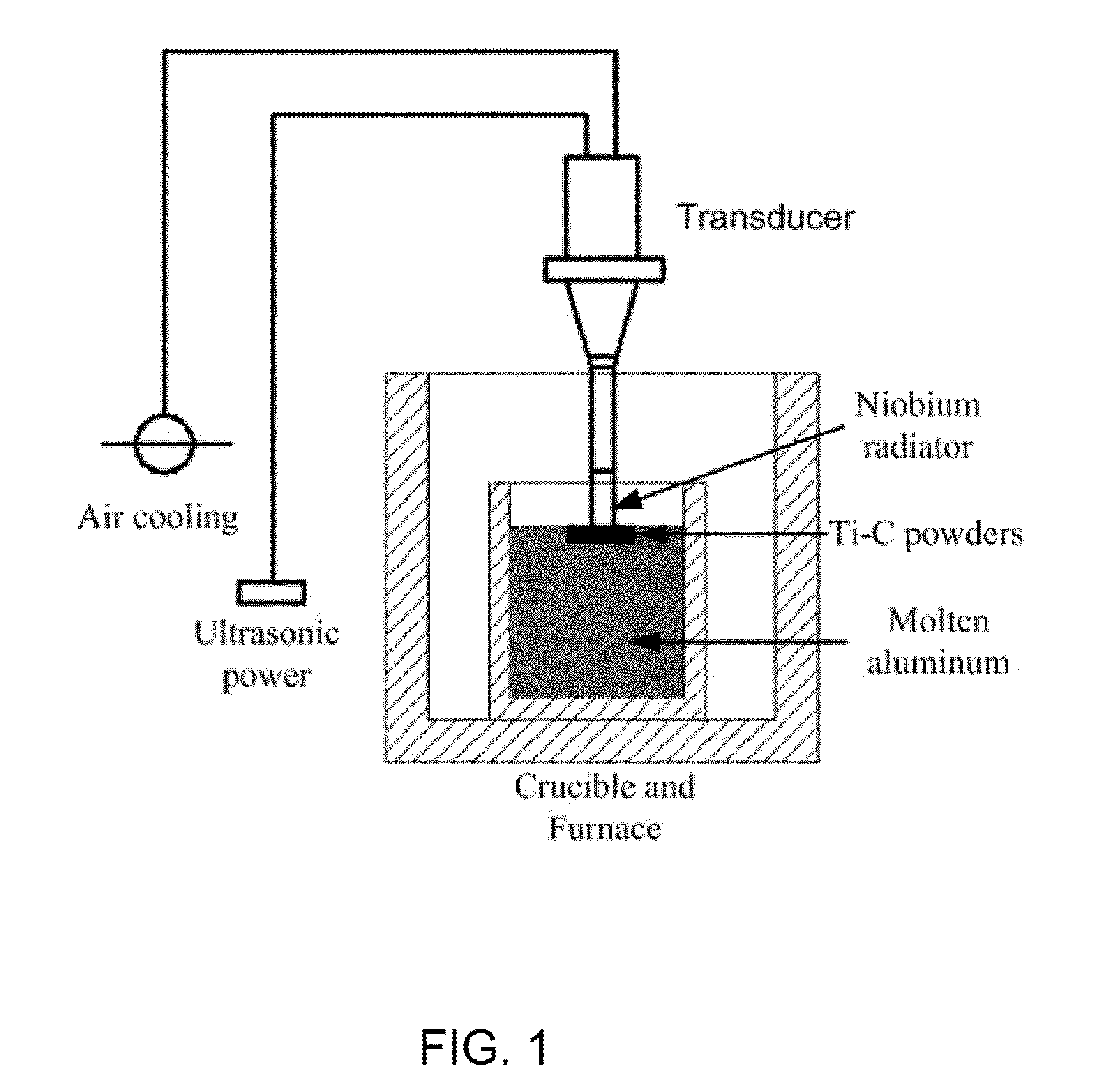

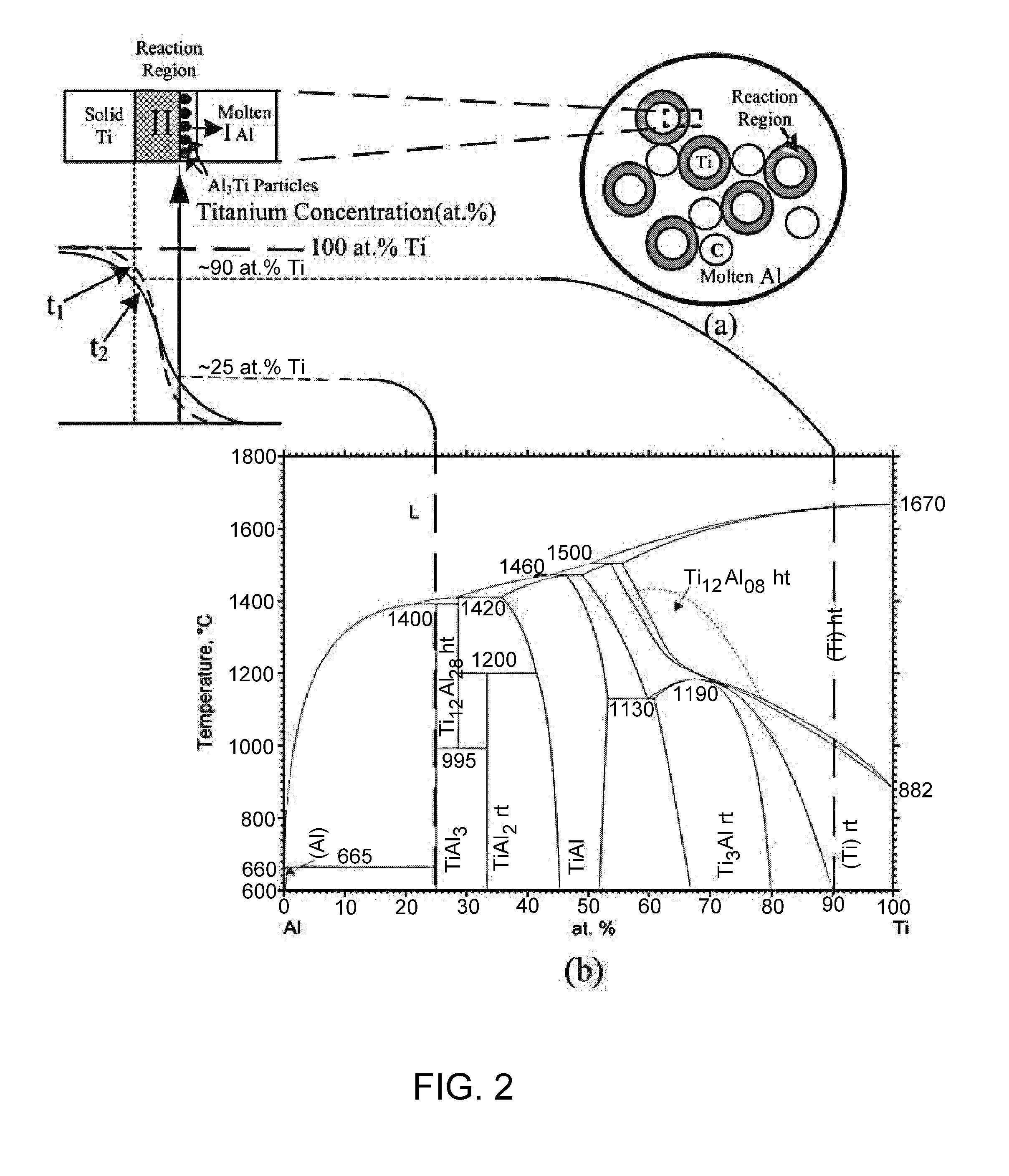

Method of producing particulate-reinforced composites and composites produced thereby

A process for producing particle-reinforced composite materials through utilization of an in situ reaction to produce a uniform dispersion of a fine particulate reinforcement phase. The process includes forming a melt of a first material, and then introducing particles of a second material into the melt and subjecting the melt to high-intensity acoustic vibration. A chemical reaction initiates between the first and second materials to produce reaction products in the melt. The reaction products comprise a solid particulate phase, and the high-intensity acoustic vibration fragments and / or separates the reaction products into solid particles that are dispersed in the melt and are smaller than the particles of the second material. Also encompassed are particle-reinforced composite materials produced by such a process.

Owner:PURDUE RES FOUND

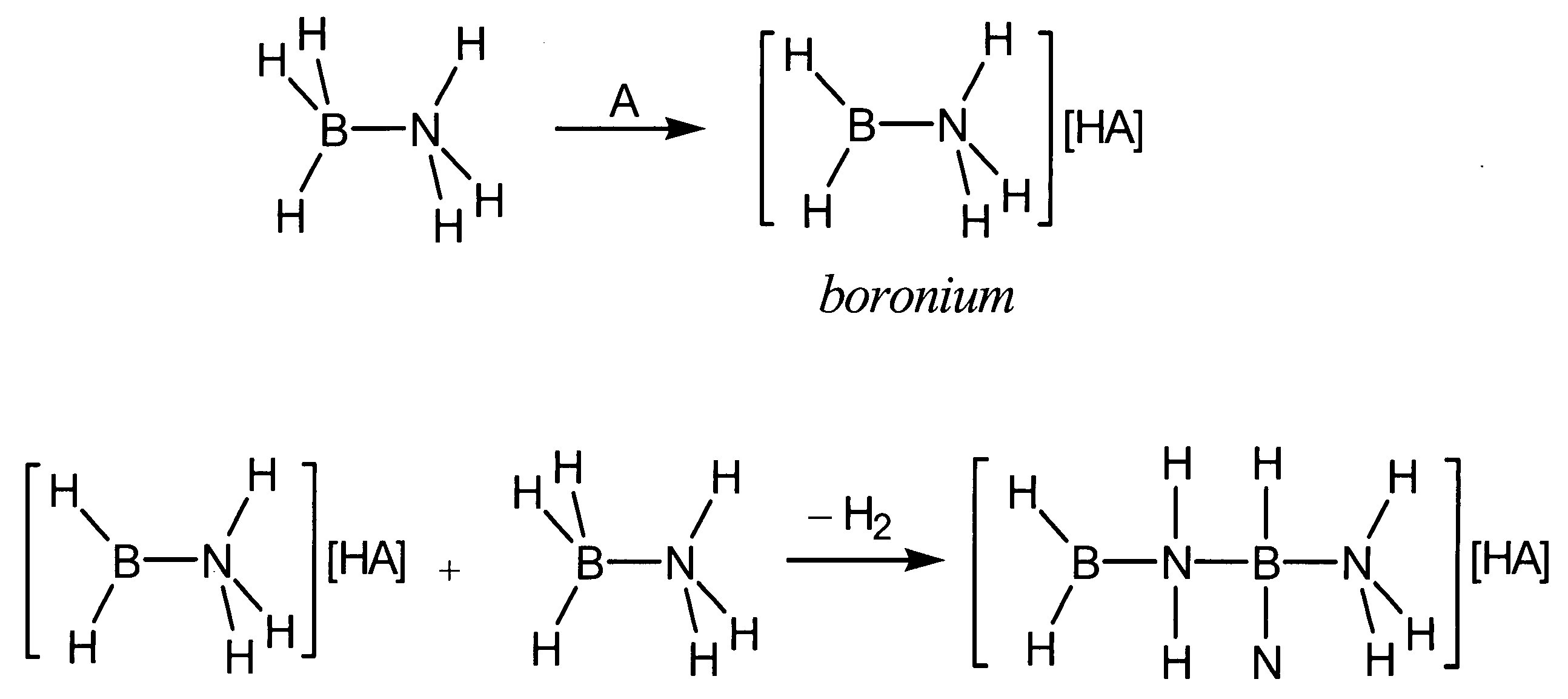

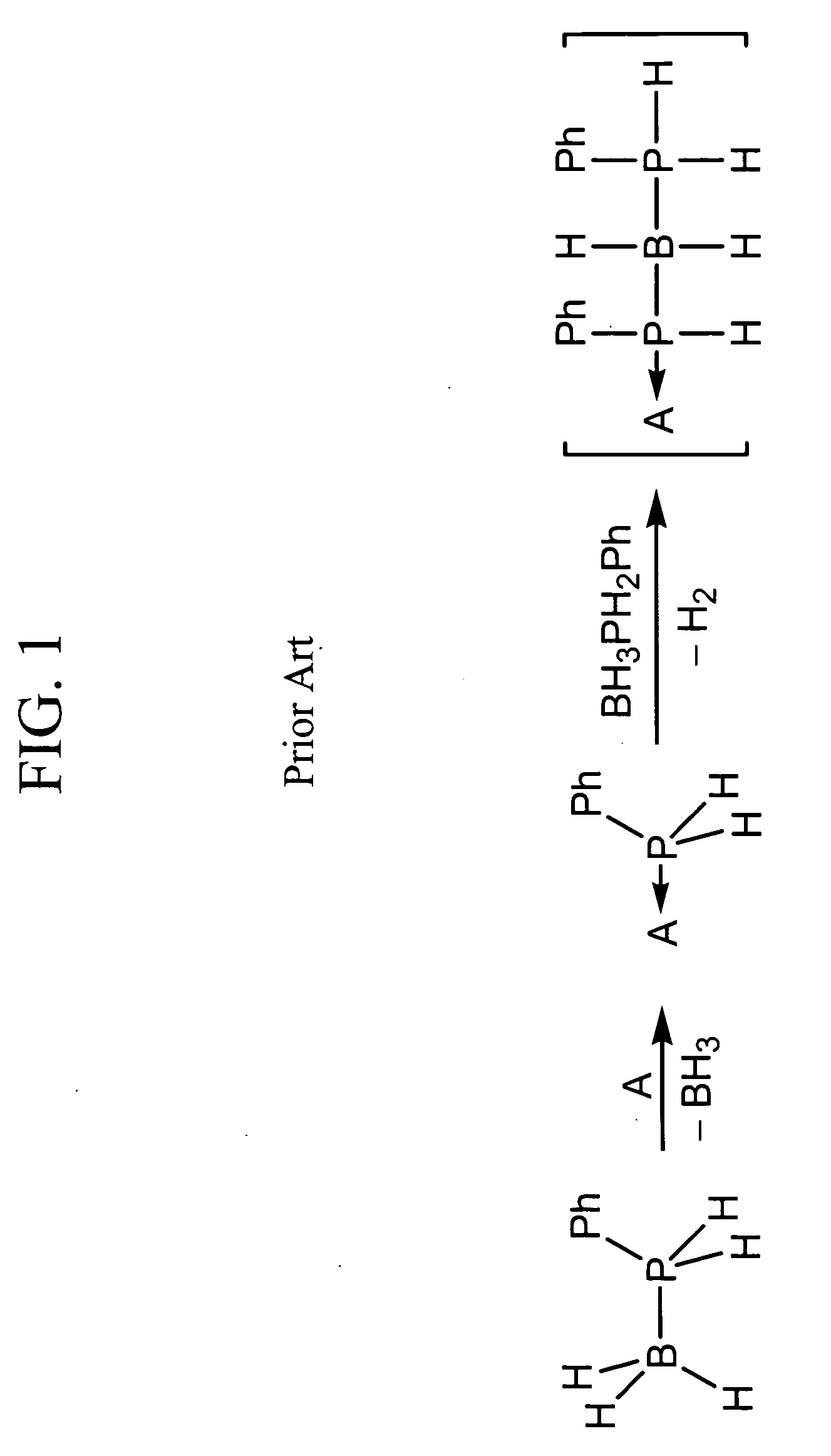

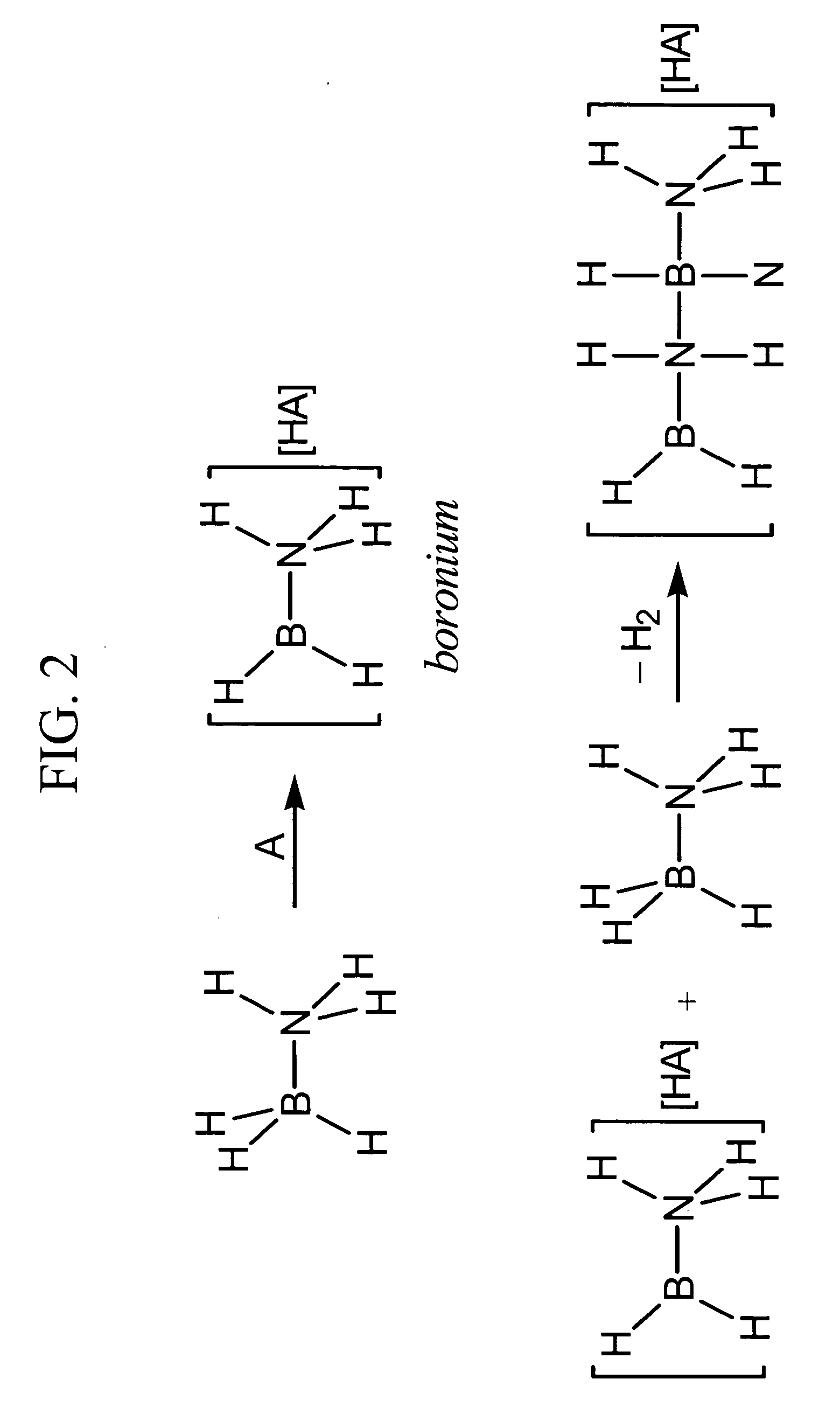

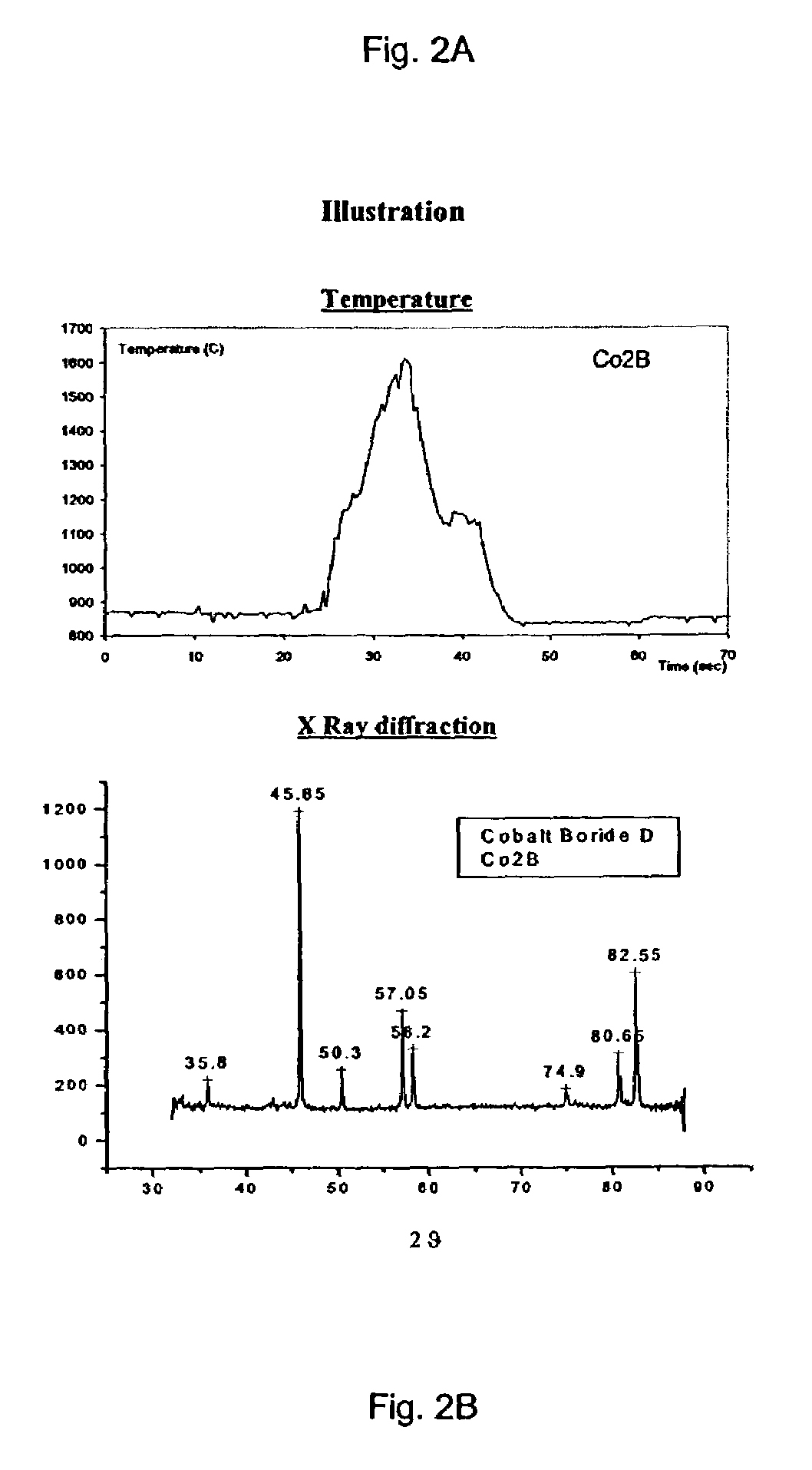

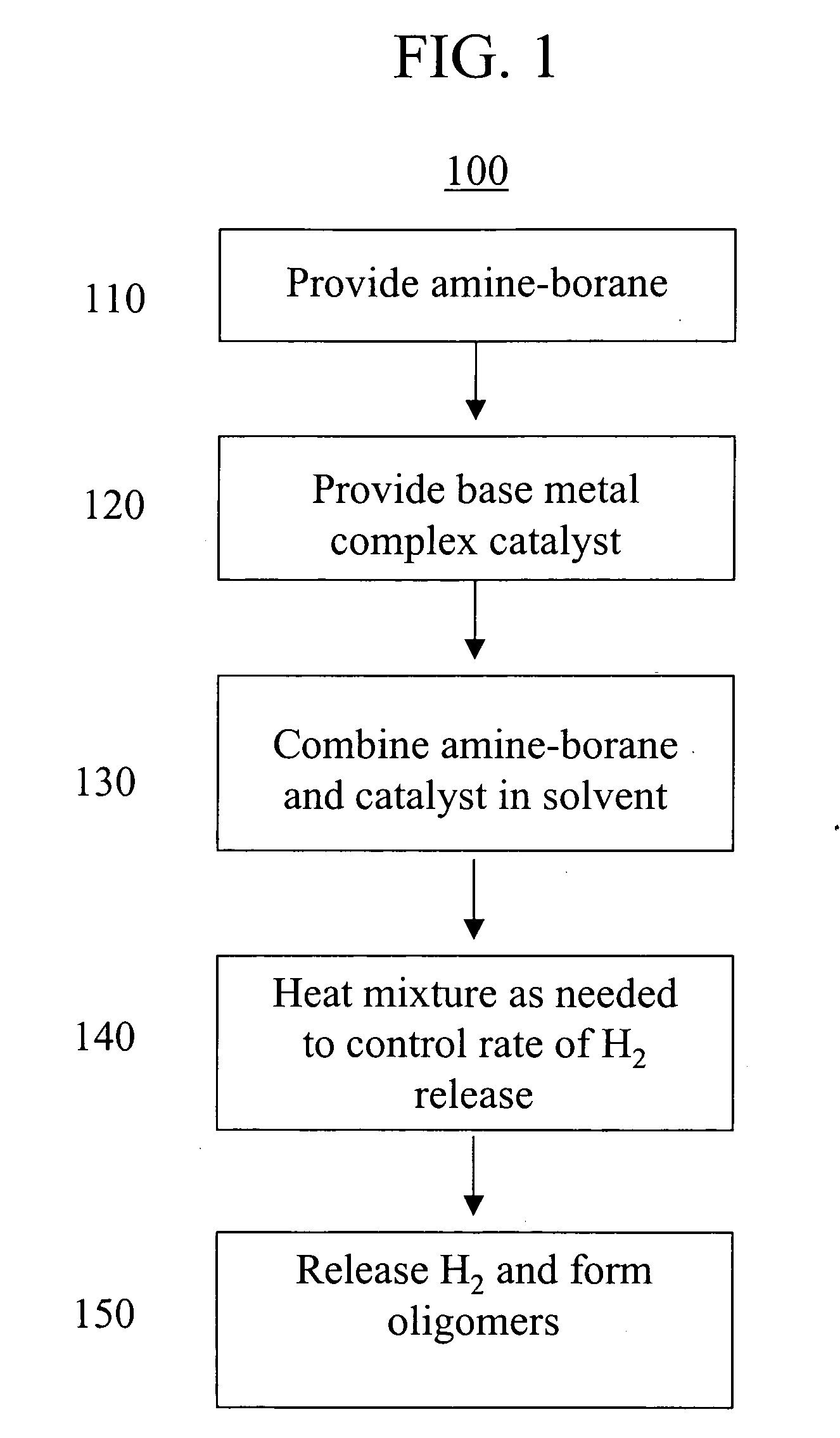

Acid-catalyzed dehydrogenation of amine-boranes

InactiveUS20060292068A1Regenerative fuel cellsCarburetting by solid carbonaceous material pyrolysisHydrogenAcid catalyzed

A method of dehydrogenating an amine-borane using an acid-catalyzed reaction. The method generates hydrogen and produces a solid polymeric [R1R2B—NR3R4]n product. The method of dehydrogenating amine-boranes may be used to generate H2 for portable power sources.

Owner:LOS ALAMOS NATIONAL SECURITY

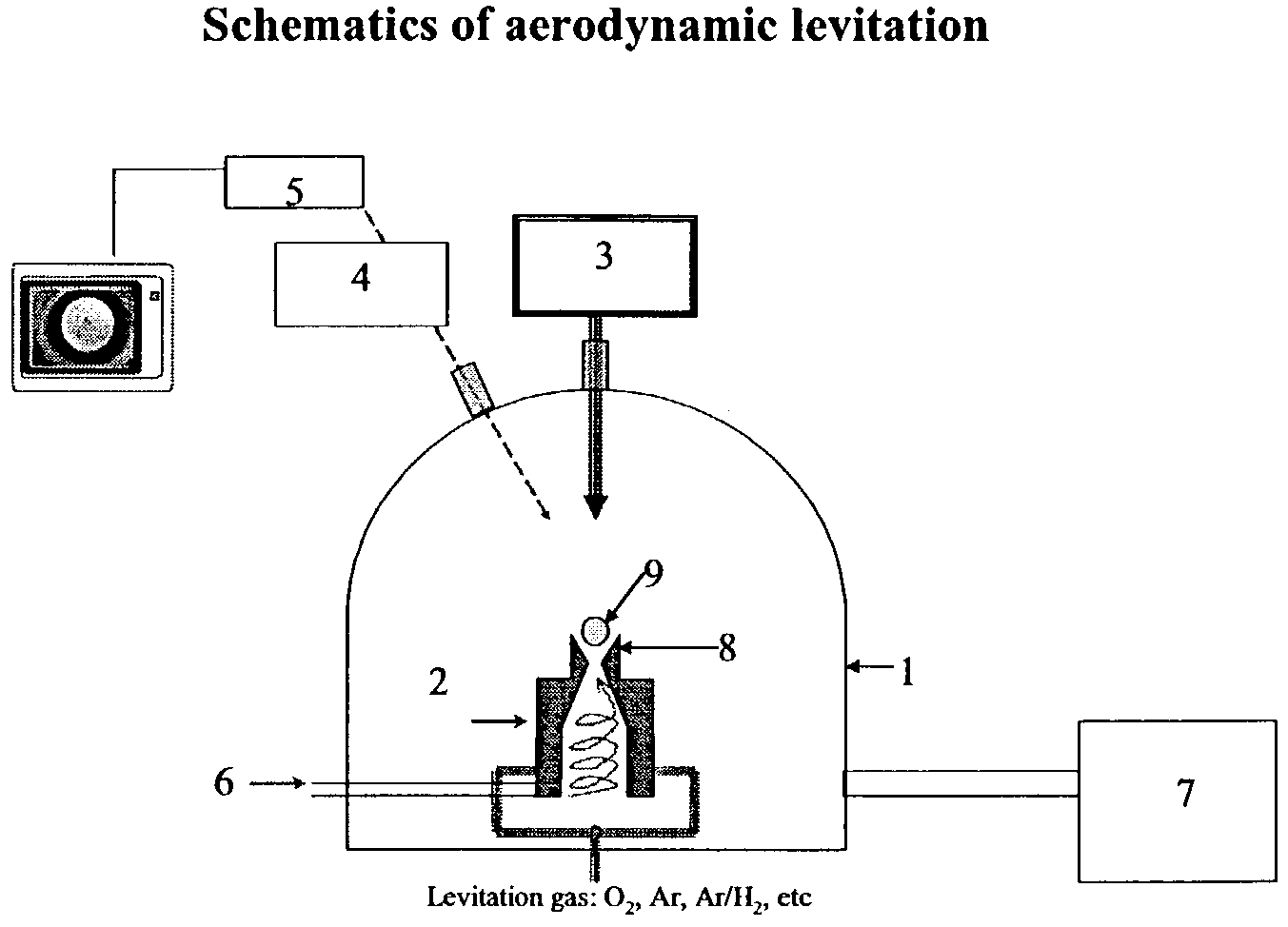

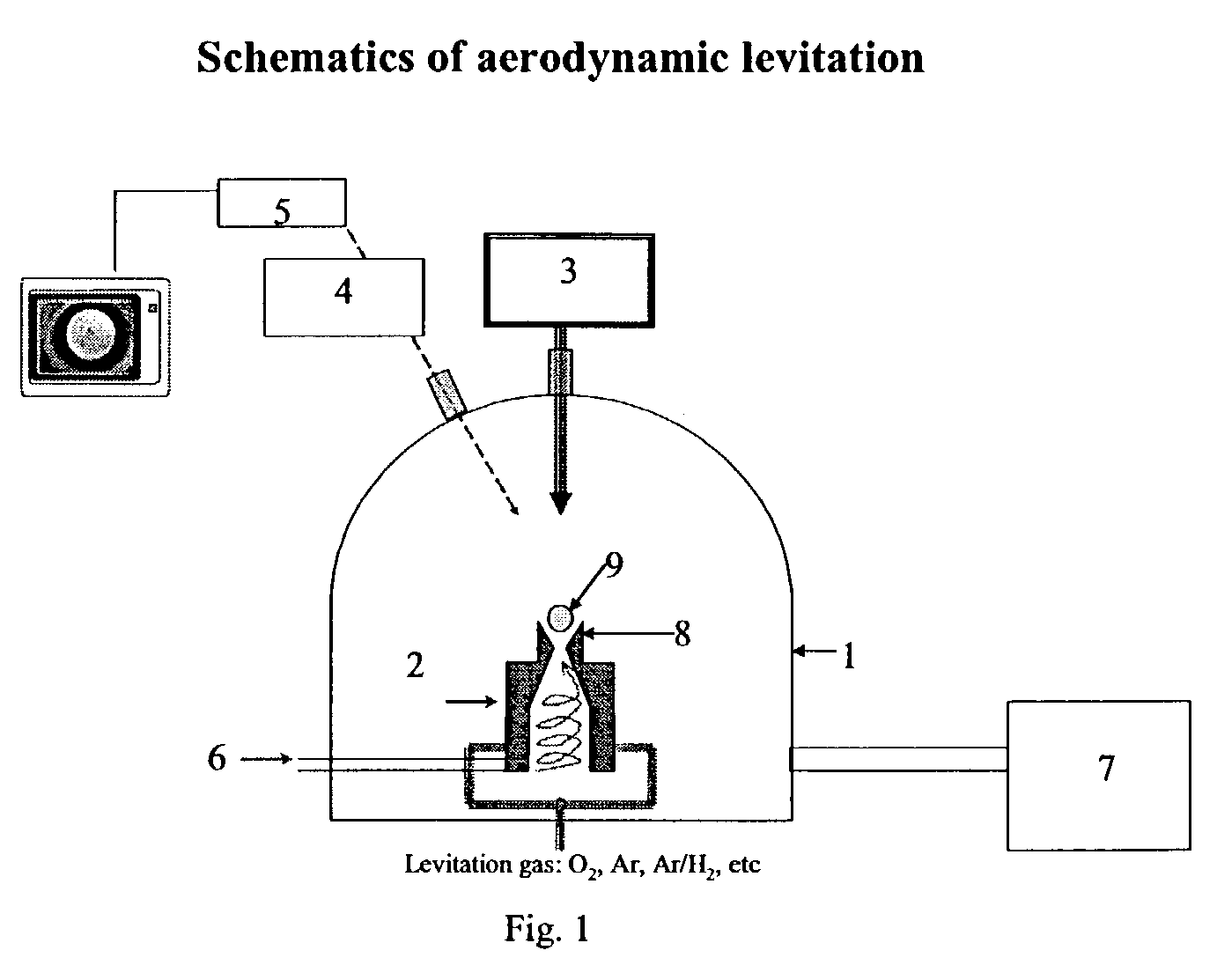

Method for synthesizing extremely high-temperature melting materials

The invention relates to a method of synthesizing high-temperature melting materials. More specifically the invention relates to a containerless method of synthesizing very high temperature melting materials such as borides, carbides and transition-metal, lanthanide and actinide oxides, using an Aerodynamic Levitator and a laser. The object of the invention is to provide a method for synthesizing extremely high-temperature melting materials that are otherwise difficult to produce, without the use of containers, allowing the manipulation of the phase (amorphous / crystalline / metastable) and permitting changes of the environment such as different gaseous compositions.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Base metal dehydrogenation of amine-boranes

A method of dehydrogenating an amine-borane having the formula R1H2N—BH2R2 using base metal catalyst. The method generates hydrogen and produces at least one of a [R1HN—BHR2]m oligomer and a [R1N—BR2]n oligomer. The method of dehydrogenating amine-boranes may be used to generate H2 for portable power sources, such as, but not limited to, fuel cells.

Owner:LOS ALAMOS NATIONAL SECURITY

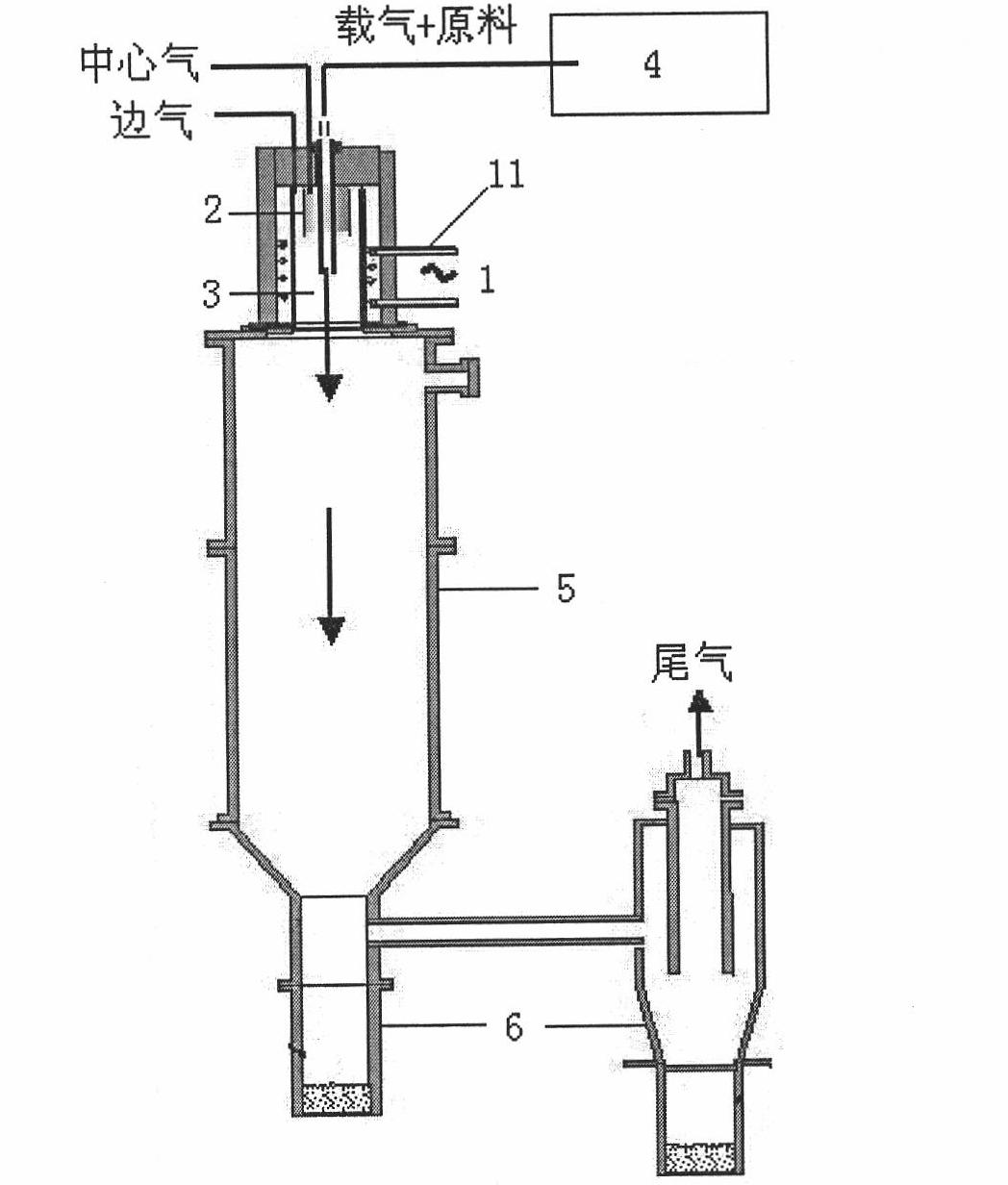

Method for preparing high-purity superfine zirconium boride powder by high-frequency plasma

The invention relates to a method for preparing a high-purity superfine zirconium boride powder by high-frequency plasma. A superhigh temperature heat source provided by a high-frequency plasma arc provides enough high temperature and energy for synthetic reaction; the electrodeless heating characteristic of the high-frequency plasma guarantees the high-purity quality of the product; particles freely deposit and grow in an airflow to obtain superfine particles with good dispersibility; and a reactor is designed to achieve a purpose of regulating product particle size. The zirconium boride powder prepared by the method provided by the invention has the advantages of high purity, good dispersibility and nano-scale size and is suitable for preparing high-temperature ceramic and compound material. The high-frequency plasma technology has a short flow and is suitable for large-scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Biodegradable iron-containing compositions, methods of preparing and applications therefor

The invention relates to biodegradable iron alloy-containing compositions for use in preparing medical devices. In addition, biodegradable crystalline and amorphous compositions of the invention exhibit properties that make them suitable for use as medical devices for implantation into a body of a patient. The compositions include elemental iron and one or more elements selected from manganese, magnesium, zirconium, zinc and calcium. The compositions can be prepared using a high energy milling technique. The resulting compositions and the devices formed therefrom are useful in various surgical procedures, such as but not limited to orthopedic, craniofacial and cardiovascular.

Owner:UNIVERSITY OF PITTSBURGH

Synthesis method of nano hexaboride

InactiveCN1923686AReduce manufacturing costLow reaction temperatureMetal boridesSynthesis methodsRare earth

The invention discloses a synthesizing method of nanometer hexaboride (RB6), which comprises the following steps: adopting chloride of random one or two combinations of 57-71 rare earth metal elements, metal Y, alkaline earth Ba, Sr and Ca as raw material; making NaBH4 or KBH4 as reducer; reacting under low-temperature condition at 500-600 deg.c; washing; filtering; drying to obtain high-purity RB6 nanometer crystal powder.

Owner:HANGZHOU DIANZI UNIV

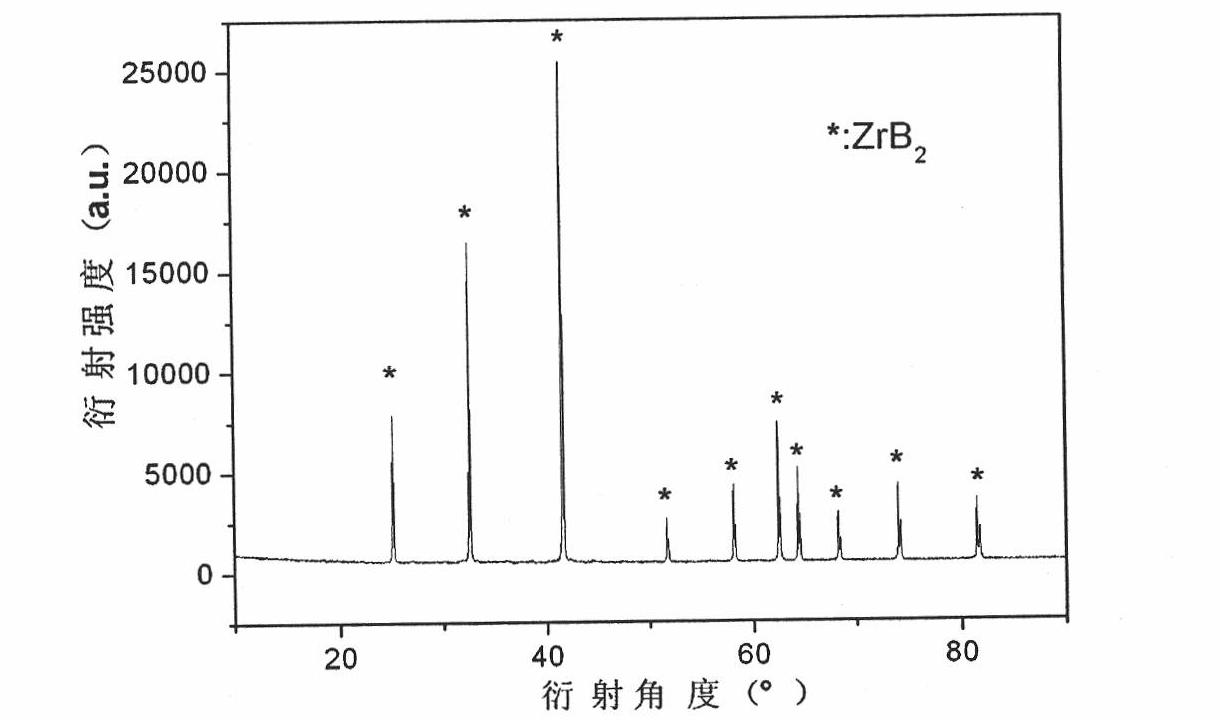

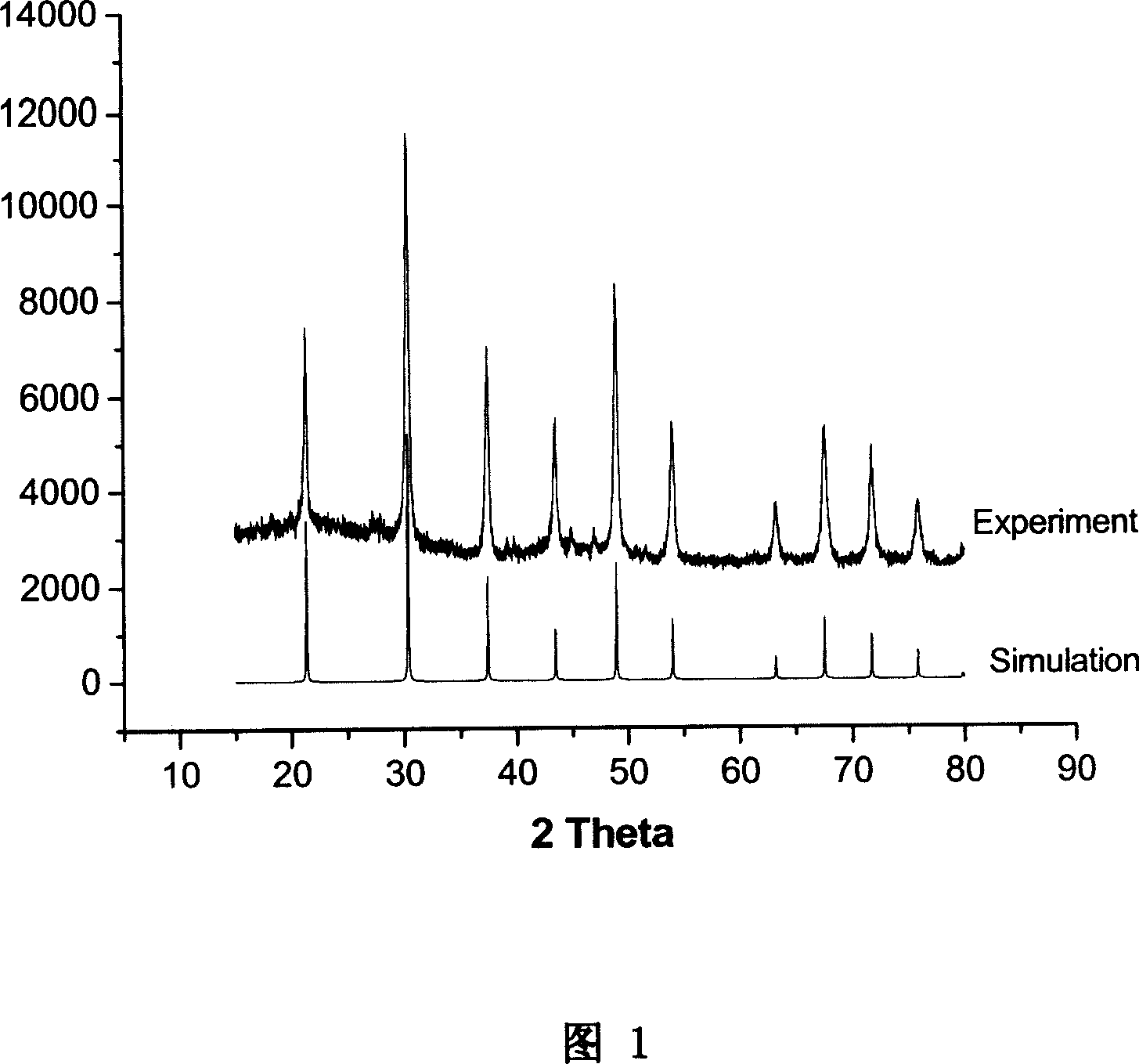

High purity ultra fine zirconium biboride powder and its preparation method

The present invention relates to a high-purity ultrafine zirconium diboride powder material and its preparation method. It is characterized by that the described powder material contains zirconium oxychloride, boron carbide powder and active carbon powder, their mole ratio is ZrOcl2:B4C:C=1:0.4-0.8:1.4-1.8. Its preparation method includes the following steps: firstly, mixing boron carbide powder, active carbon powder and water according to mixing ratio, regulating pH value to obtain mixed suspension; dissolving zirconium oxychloride in deionized water to obtain the zirconium oxychloride solution; mixing the above-mentioned suspension and zirconium oxychloride solution, adding ammonia water, making the zirconium oxychloride be fully hydrolyzed and precipitated; making suspension undergo the processes of solid-liquor separation, waster-washing, removing NH4+ and Cl-, drying and sieving; then placing the powder material into a vacuum furnace to make reaction synthesis, its synthesis temperature is 1500-1600 deg.C, heat-insulating for 0.5-4 h; grinding powder and sieving so as to obtain the invented powder material.

Owner:칭다오정왕철강수통제주식유한회사

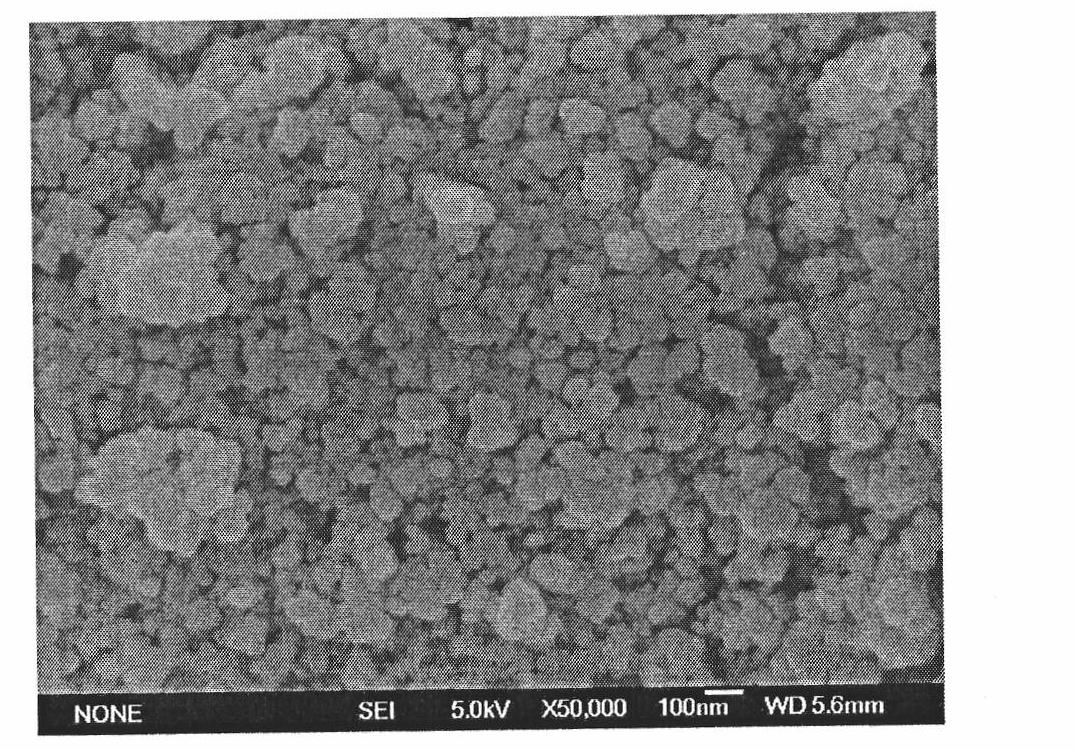

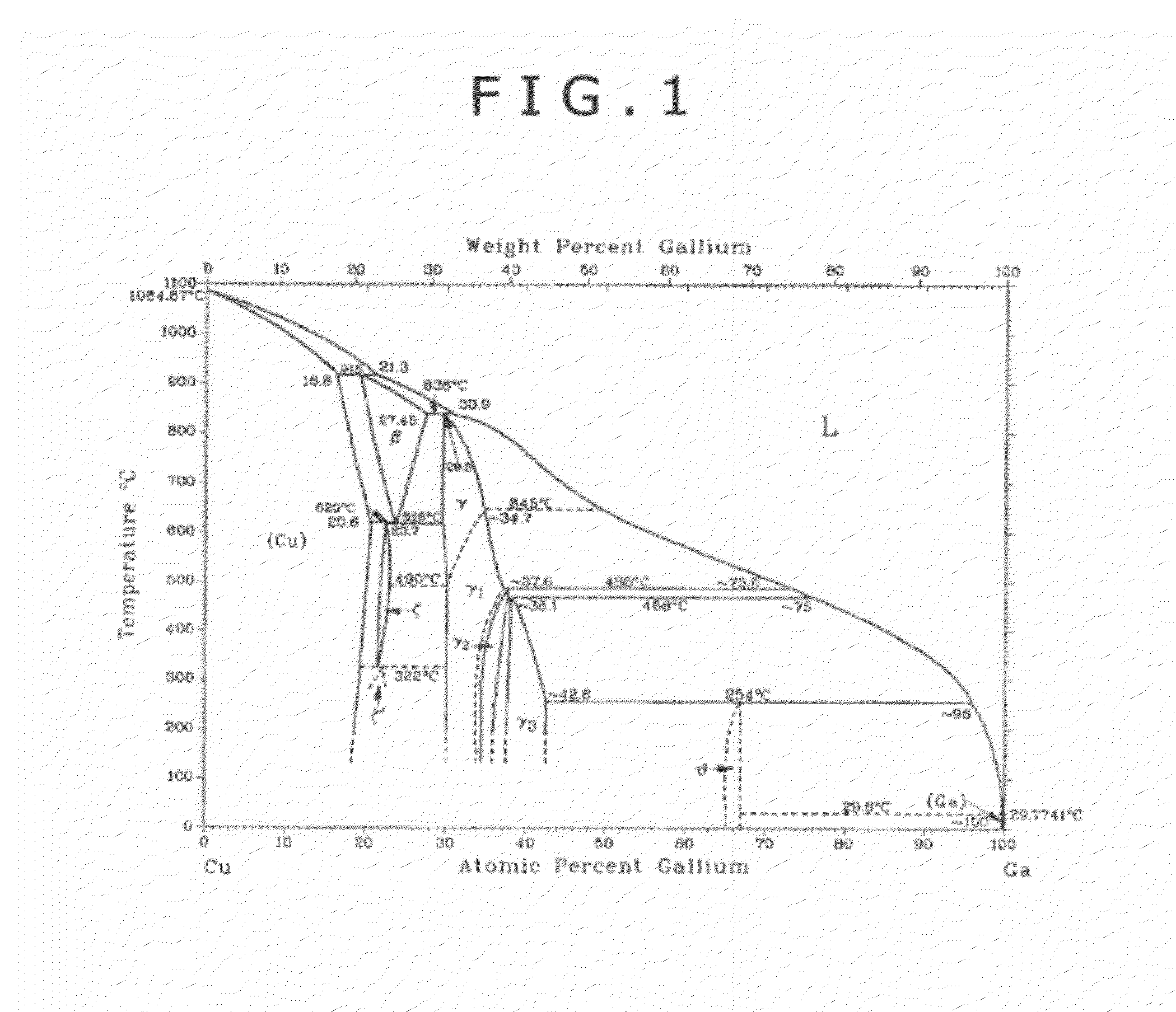

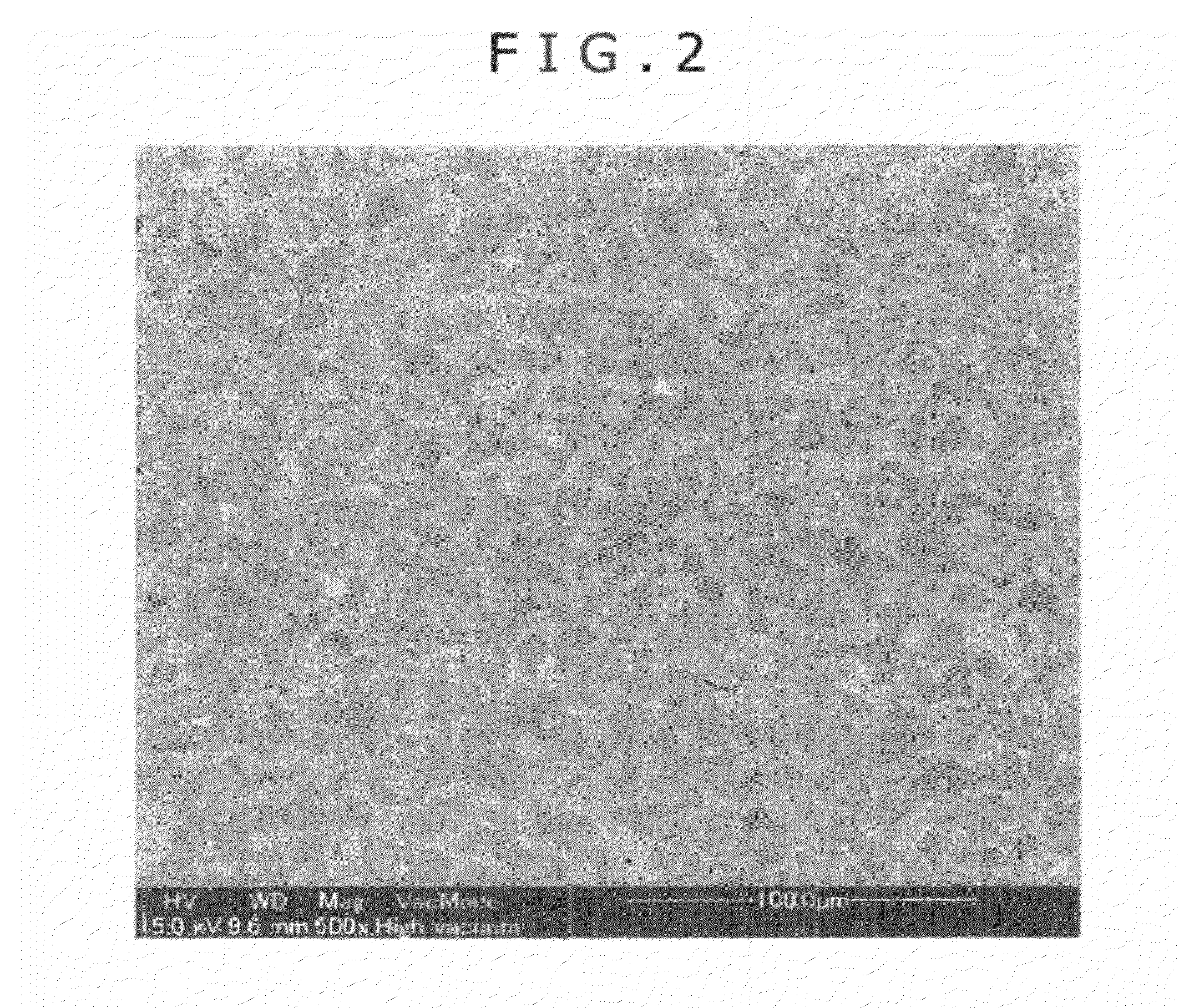

Cu-ga alloy sputtering target and manufacturing method thereof

Disclosed is a Cu—Ga alloy sputtering target which enables the formation of a Cu—Ga sputtering film having excellent uniformity in film component composition (film uniformity), enables the reduction of occurrence of arcing during sputtering, has high strength, and rarely undergoes cracking during sputtering. Specifically disclosed is a Cu—Ga alloy sputtering target which comprises a Cu-based alloy containing Ga, has an average crystal particle diameter of 10 μm or less, and has a porosity of 0.1% or less.

Owner:KOBELCO RES INST

Use of nanoparticles in film formation and as solder

InactiveUS20070044295A1Lower melting temperatureMaintain structureMaterial nanotechnologyWave amplification devicesMulti materialSemiconductor materials

Nanoparticle compositions for use as solder, and methods for joining two or more material surfaces using nanoparticle solder compositions are described. Due to their small size, nanoparticles of a particular material have a lower melting temperature than the same material in bulk, thereby providing a homogenous bond between two or more materials when the nanoparticle solder is solidified. A gas species, such as hydrogen, can be introduced to further lower the melting temperature of the nanoparticles. The nanoparticles can also be used to form films on low melting point, substrates, including flexible substrates. The nanoparticles for use in the present invention can comprise any material, including semiconductor materials, metals, or insulator materials, and are less than about 20 nm in diameter, although larger sizes can also be used.

Owner:NANOSYS INC

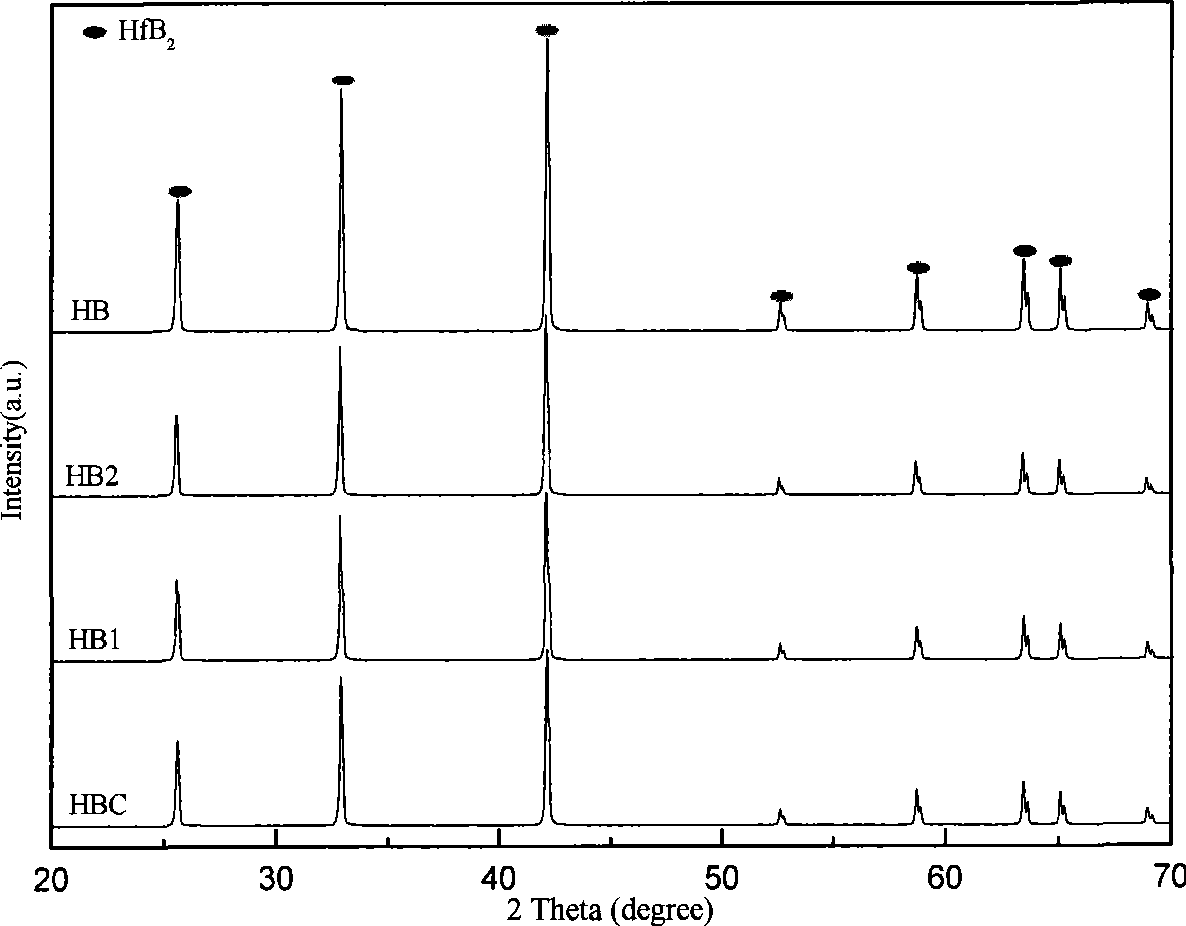

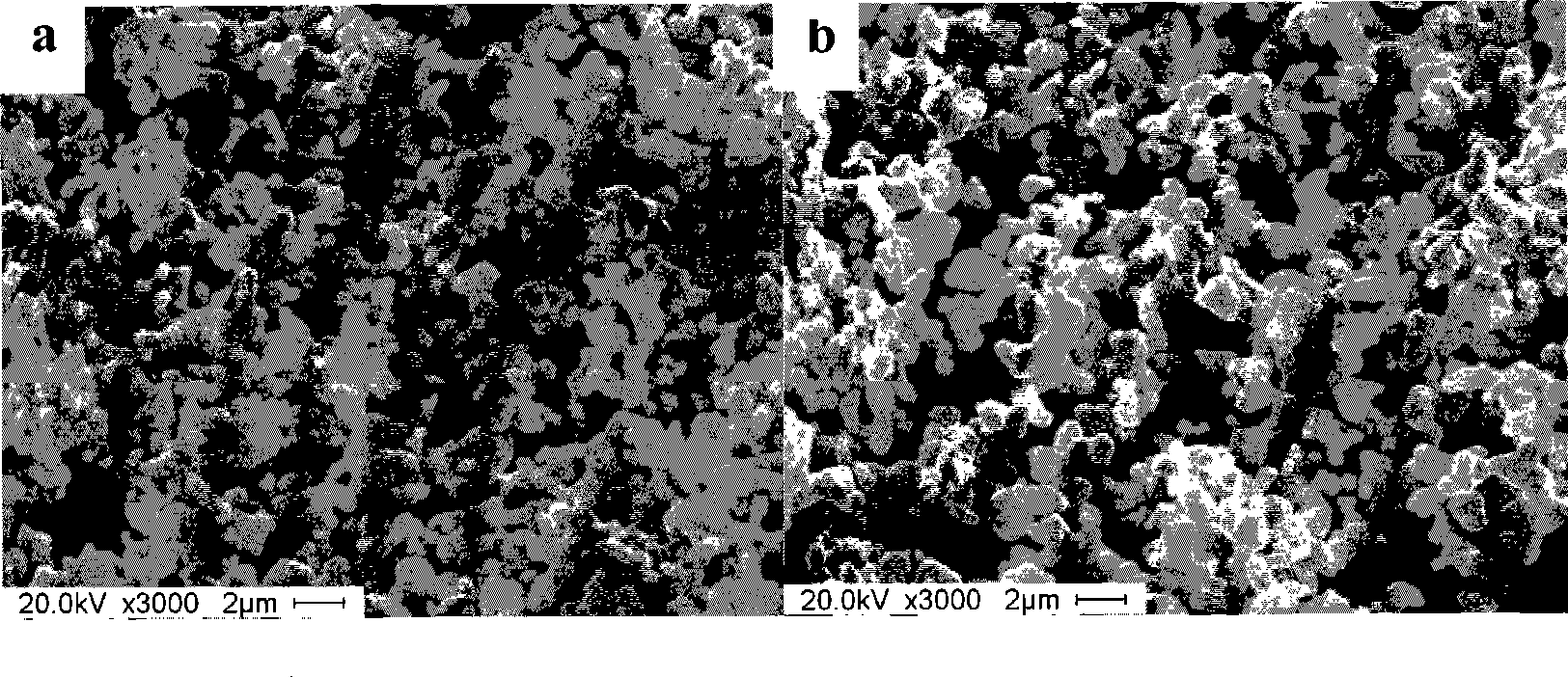

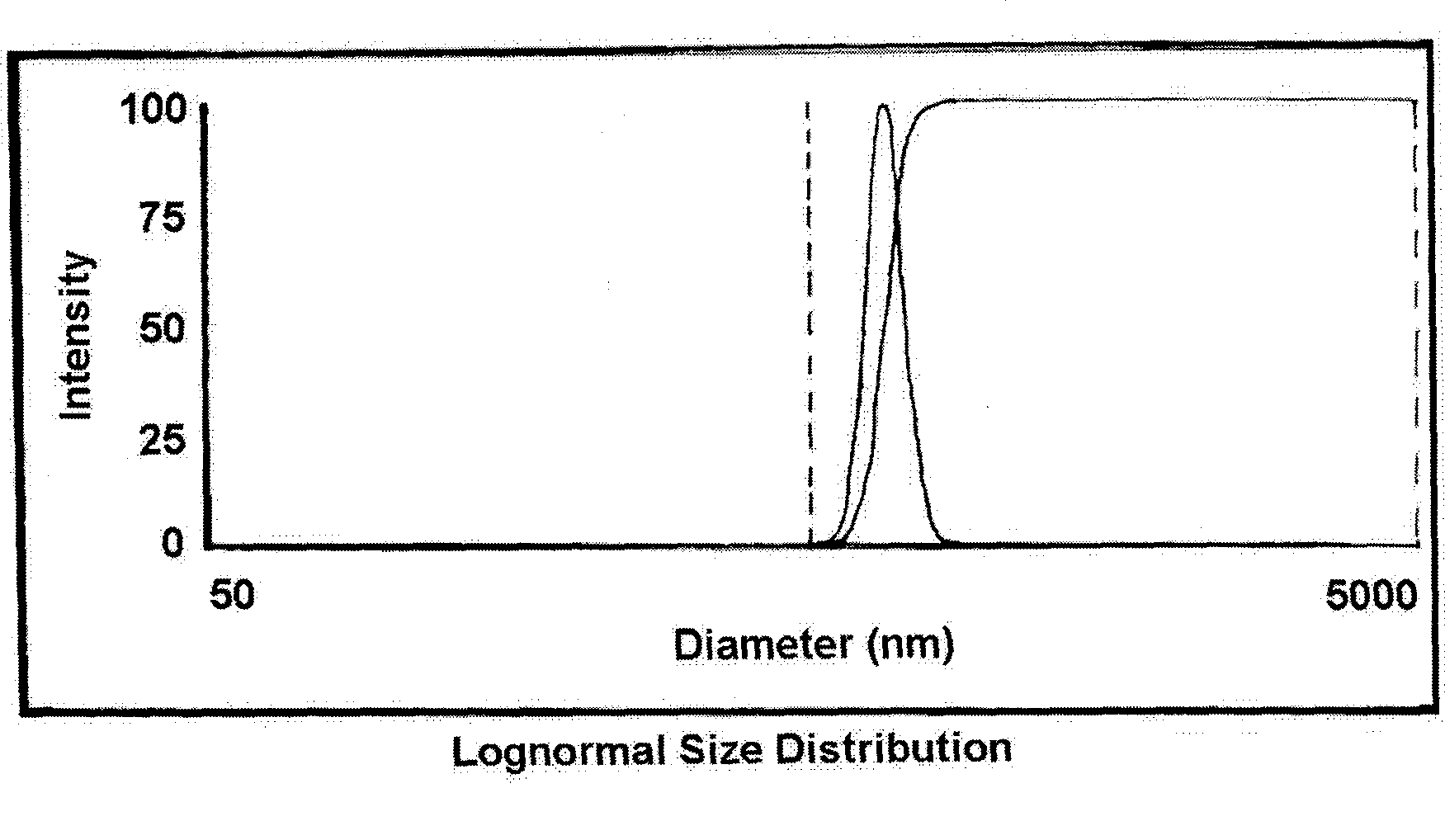

Synthesis of high-purity hafnium boride powder

The invention relates to hafnium boride powder with advantages of high purity, good dispersibility, small grain size and narrow distribution range, and a process for synthesizing the powder. The invention is characterized in that the process adopts hafnium oxide, boron carbide, graphite and amorphous boron as raw materials and is based on carbothermic / borothermic reduction reaction, wherein, in the carbothermic reduction, the mass ratio of HfO 2, B4C and C ranges from (1-5 / 4):(5 / 7-6 / 7):(0-3 / 2); and in the borothermic reduction, the mass ratio of HfO2 and B is 1:(10 / 3-4). Through adjusting the proportion of the raw materials, controlling the synthesizing process, adopting relatively cheap HfO2 raw material, the invention can synthesize the HfB2 powder with oxygen content less than 0.2wt% under the conditions that the temperature is 1500-1600 DEG C, an Ar atmosphere is adopted, or the vacuum degree is smaller than 1 Pa. SEM and laser grading analysis show that the distribution range of powder grain diameter is narrow (the polydispersity coefficient is 0.005), and the average grain diameter is around 1Mum. All of the parameters are superior to the ordinary commercial HfB2 powder, the preparation process and the required equipment are simple, the cost is low and the yield is high.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

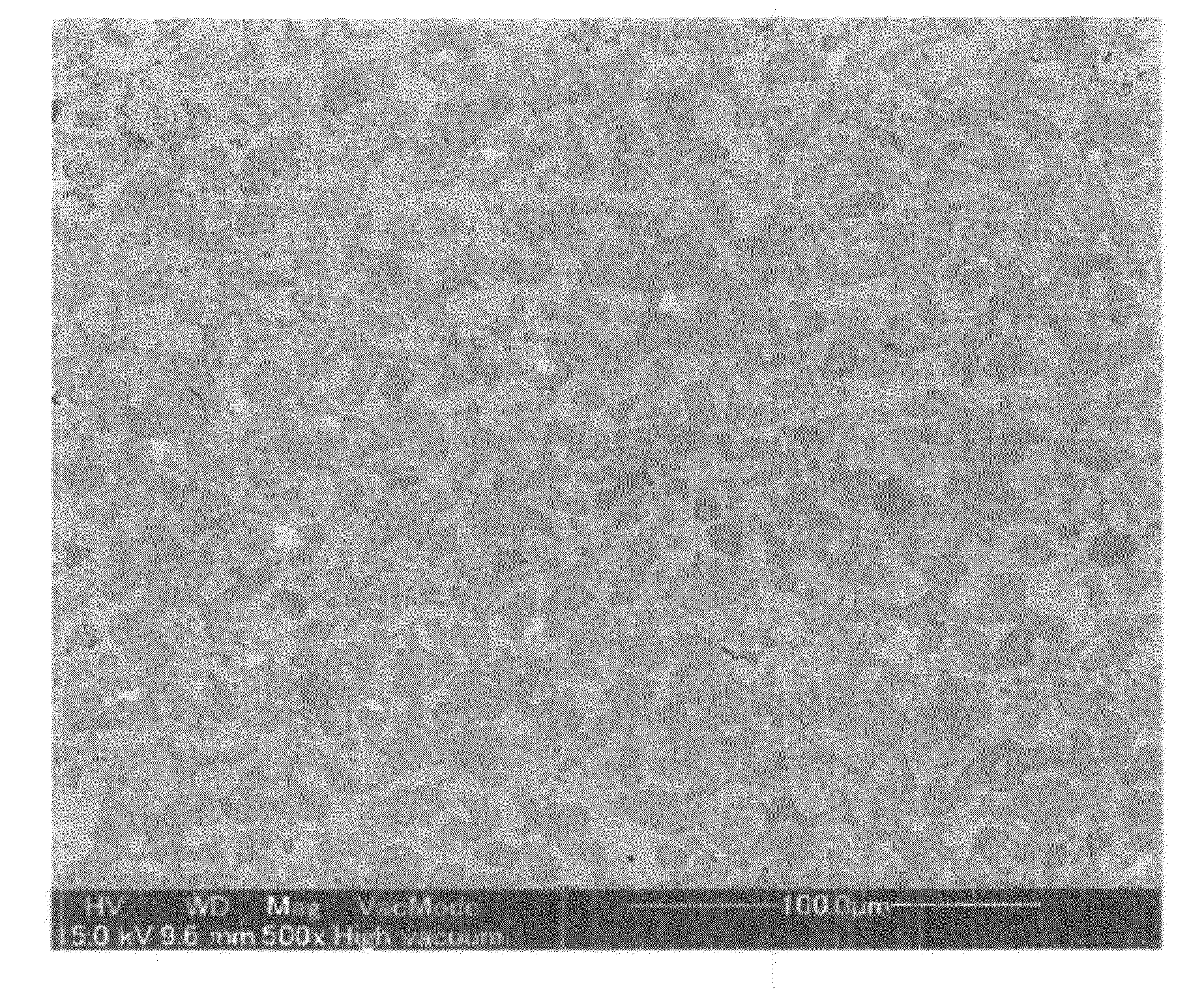

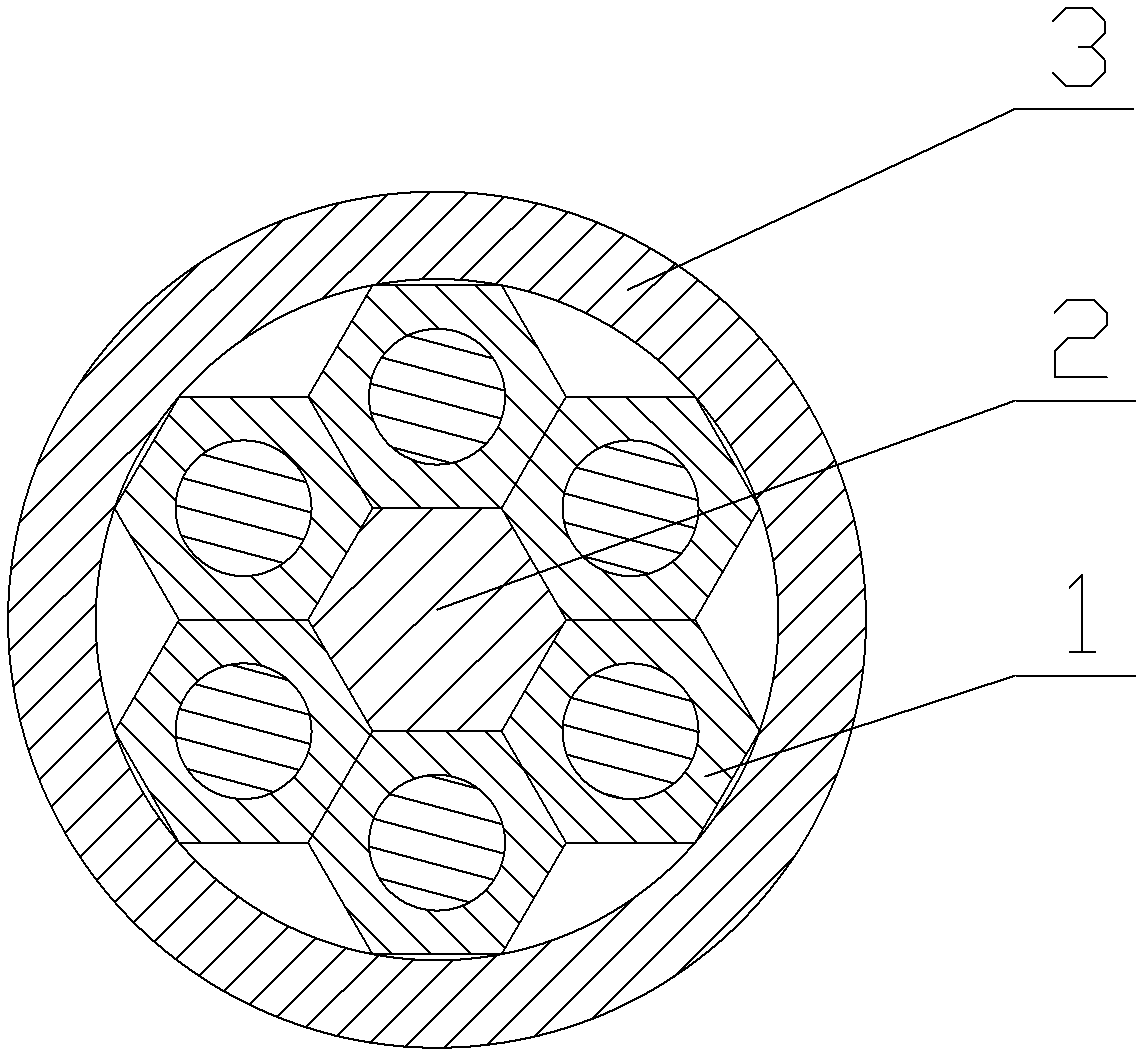

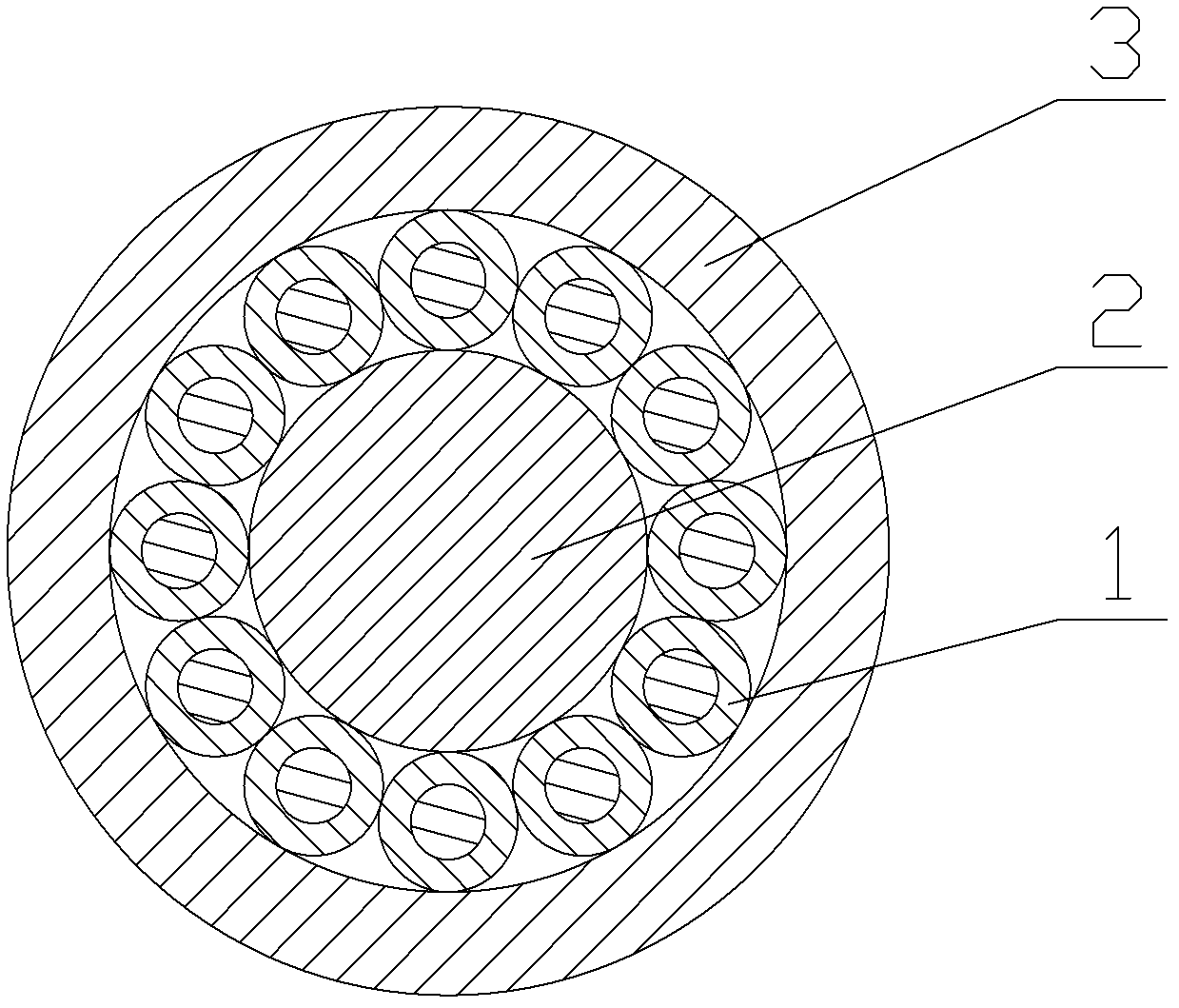

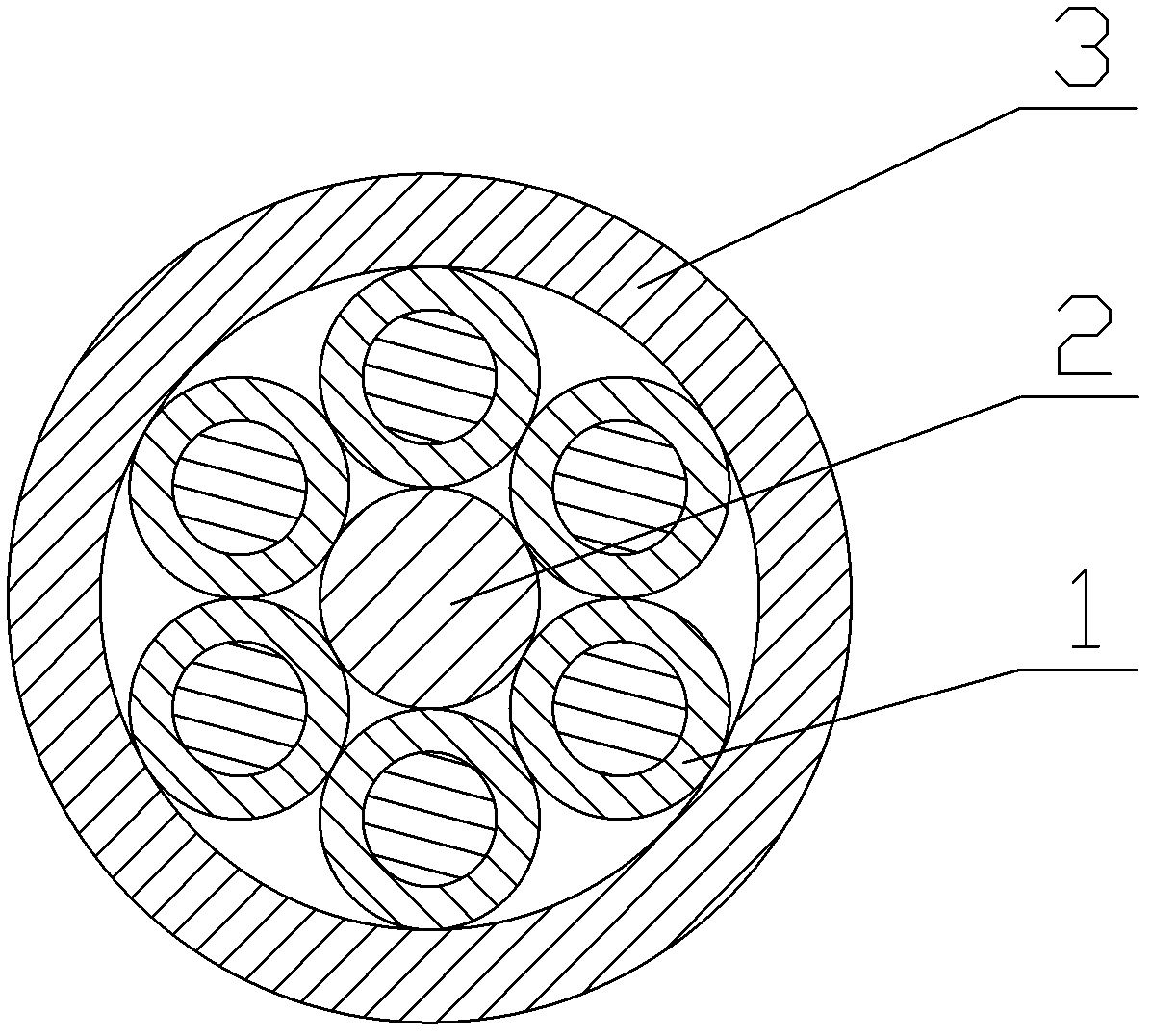

A kind of preparation method of multi-core mgb2 superconducting wire/tape

ActiveCN102280198AIncrease the critical current densityHigh densitySuperconductors/hyperconductorsMetal boridesElectrical conductorNiobium

The invention discloses a preparation method for a multi-core MgB2 superconducting wire / band. The method comprises the following steps of: 1, preparing precursor powder; 2, feeding the precursor powder into a Nb / Cu composite metal tube to obtain a tubing complex; 3, performing rotary swaging and drawing treatment, and thus obtaining single-core wires; 4, placing a copper-niobium composite rod anda plurality of single-core wires into an anaerobic copper tube for secondary assembly to obtain a secondary composite rod, performing the rotary swaging and drawing treatment, and thus obtaining multi-core wires; and 5 sintering in vacuum, and thus obtaining the multi-core MgB2 superconducting wire; or rolling into multi-core bands, then sintering in vacuum, and thus obtaining the multi-core MgB2superconducting band. By the preparation method, powder is subjected to high-temperature heat treatment, so that the condition that high-activity carbon which is decomposed from SiC can better replace boron can be ensured, and the improvement on the critical current density of the wire / band in a magnetic field is better facilitated. Due to the adoption of a center copper-niobium composite bar enhanced conductor structure, the improvement on the density of the MgB2 superconducting wire is facilitated, the connectivity of MgB2 crystal grains is enhanced, and the critical current density of the wire / band is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

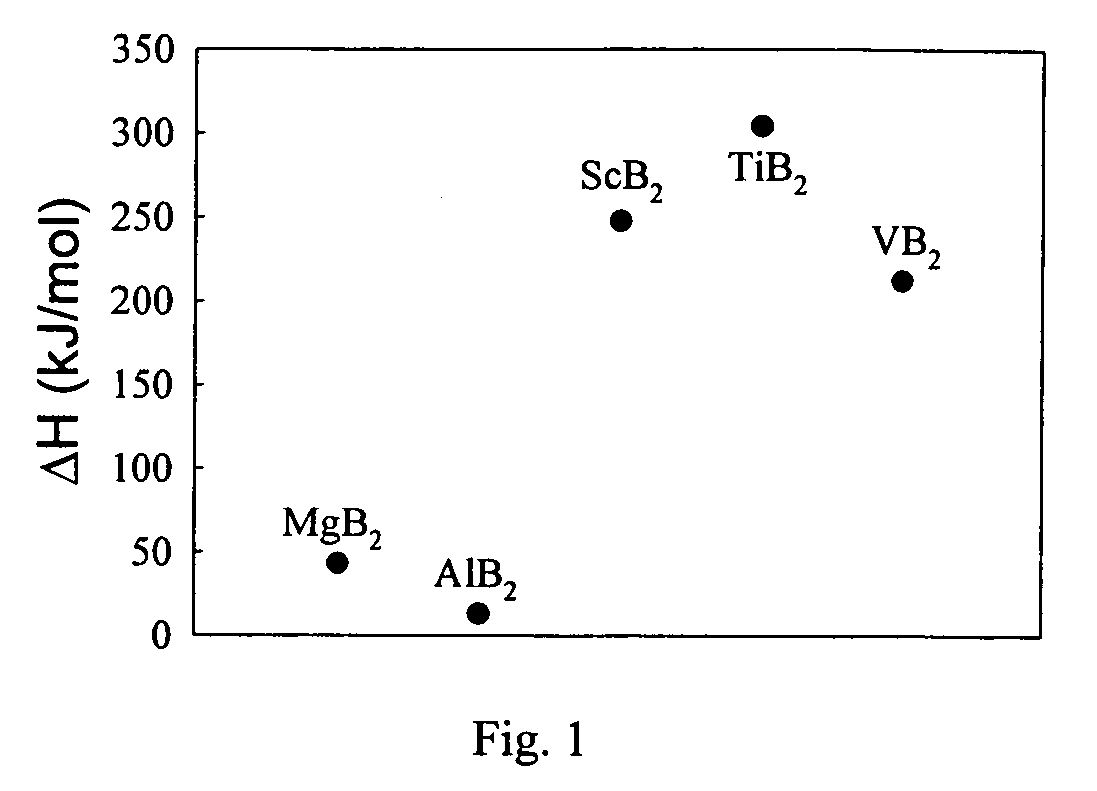

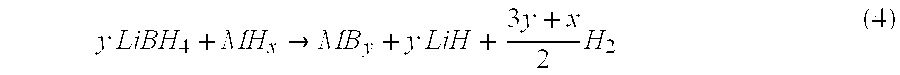

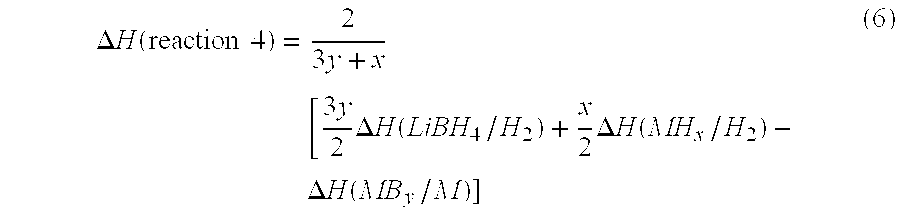

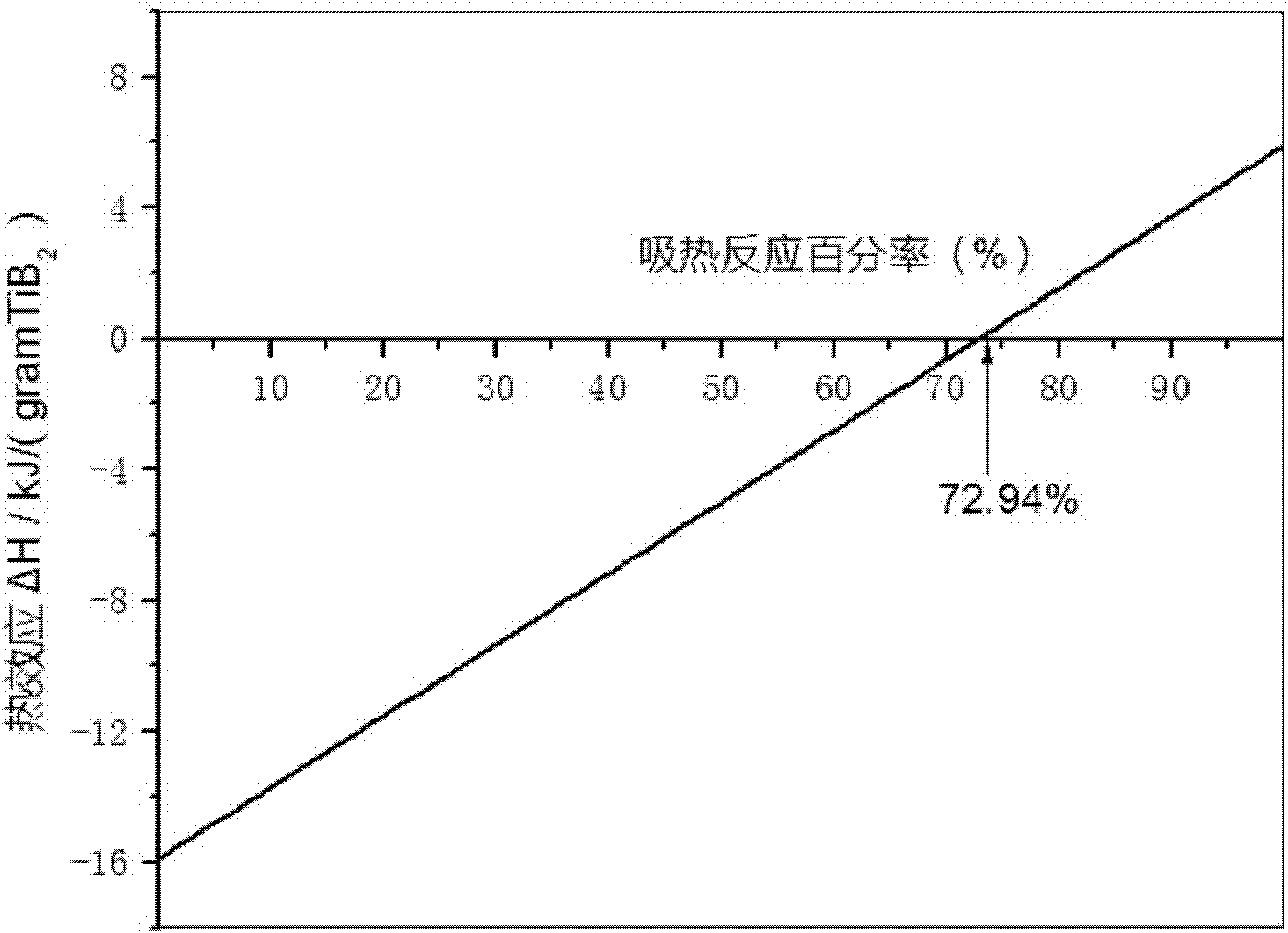

High density hydrogen storage material

InactiveUS20060292065A1Improve storage densityEasily reversibleAlkali/alkaline-earth/beryllium/magnesium hydridesReactant parameters controlHigh densityMaterials science

A hydrogen storage material. The hydrogen storage material is a combination of LiBH4 with MHx, wherein greater than about 50% of M comprises Al.

Owner:UOP LLC +1

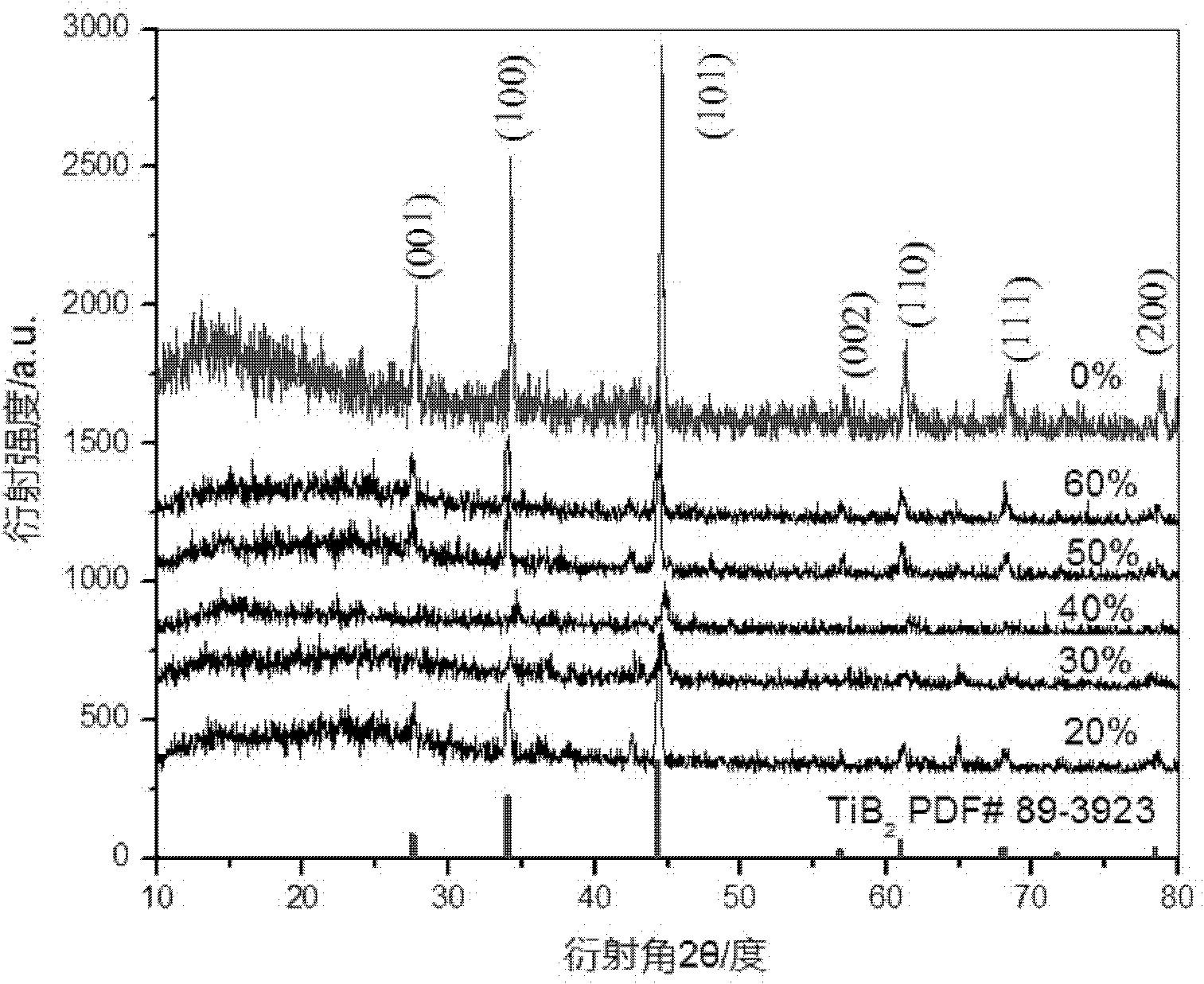

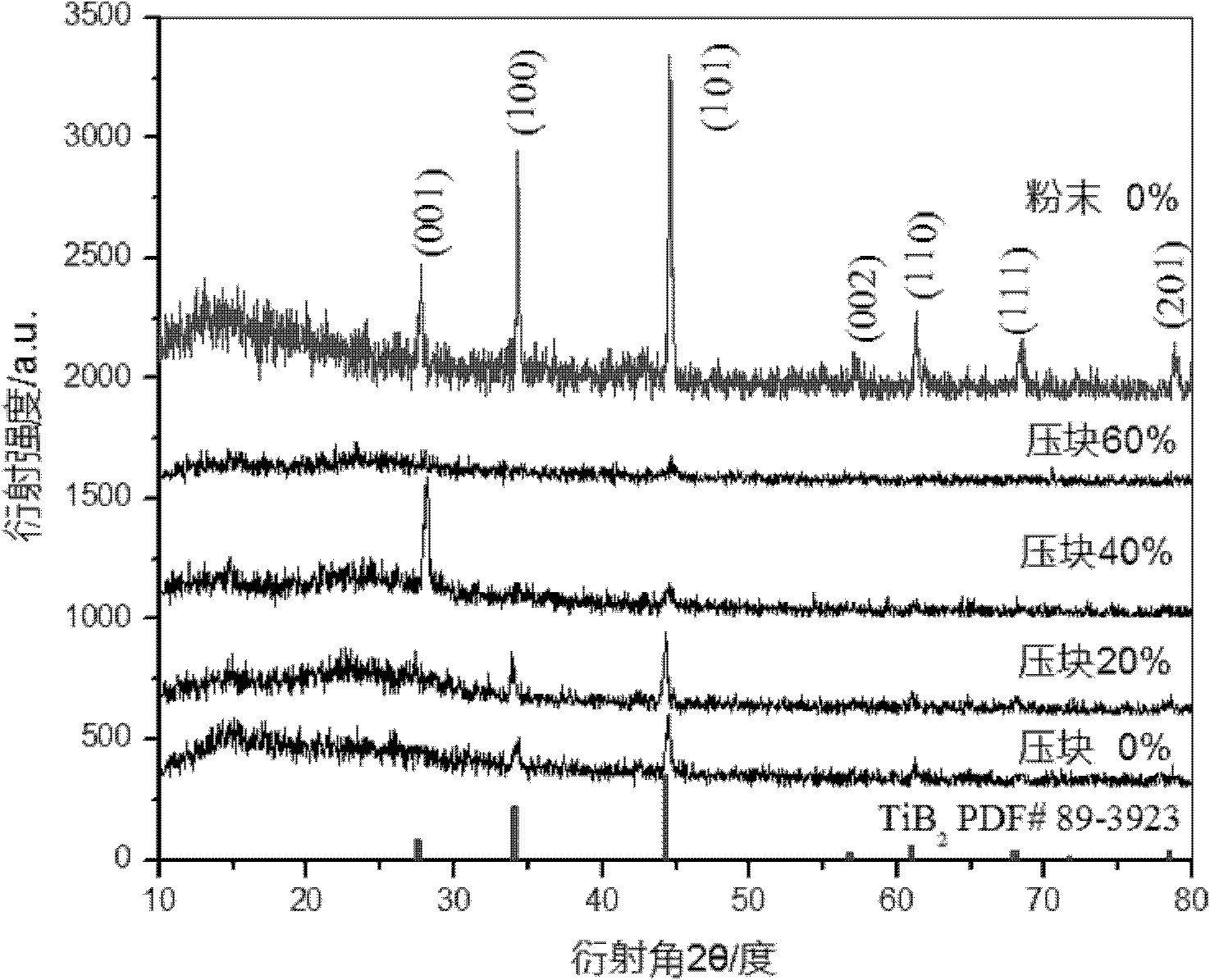

Method for preparing nano titanium diboride polycrystalline powder

InactiveCN101891215AReduce manufacturing costAvoid grain growthNanostructure manufactureMetal boridesReaction temperatureSide reaction

The invention relates to a method for preparing nano titanium diboride polycrystalline powder, which comprises the following steps of: mixing raw materials B2O3, TiO2, Mg and KBH4 uniformly, directly performing self-propagating reaction or performing self-propagating reaction after briquetting on the obtained mixed raw materials, and separating and purifying the self-propagating reaction product to obtain the nano titanium diboride polycrystalline powder. The method has the advantages that: (1) the method controls the heat effect of the reaction system, can save energy, reduce the self-propagating reaction temperature and inhibit side reaction and byproduct impurities, and greatly improves the purity of the product; (2) a large amount of gas formed in the reaction process inhibits product grain growth and sintering agglomeration and realizes grain size control of the nano TiB2; and (3) the method has simple reaction process and technique, is easy to control and suitable for industrial production, reduces the preparation cost for preparing the nano titanium diboride polycrystalline powder, and has great utility value.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

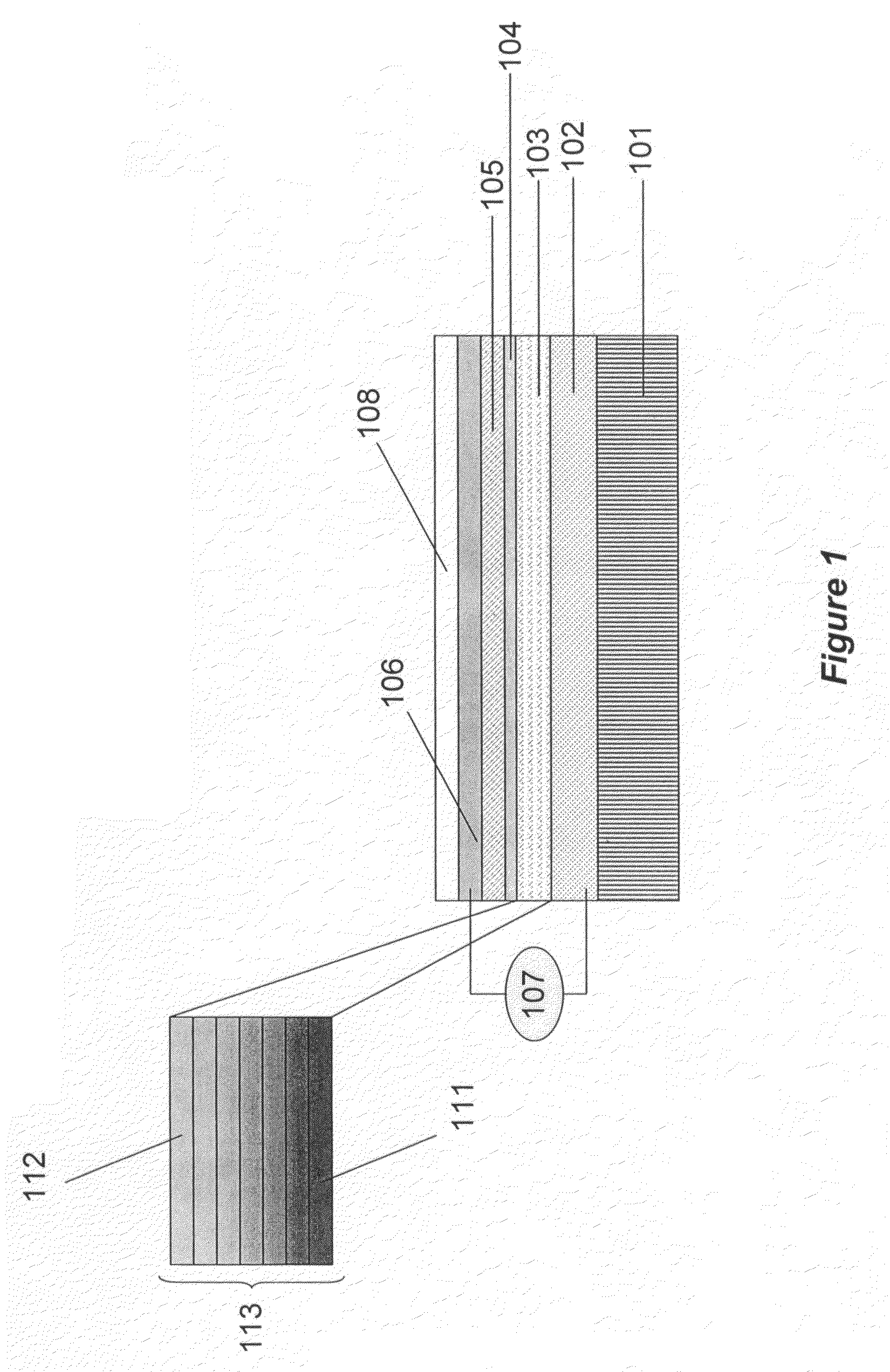

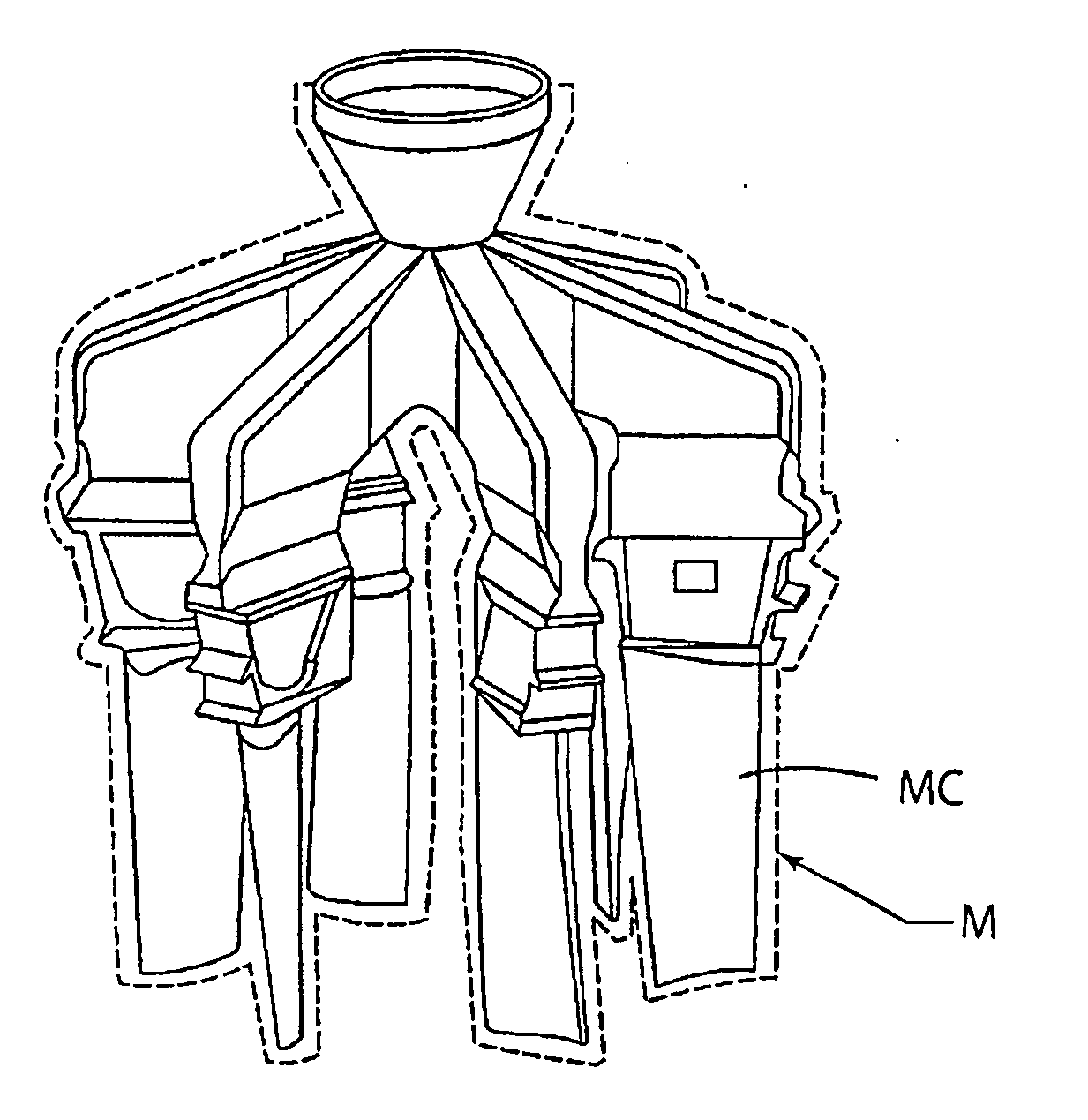

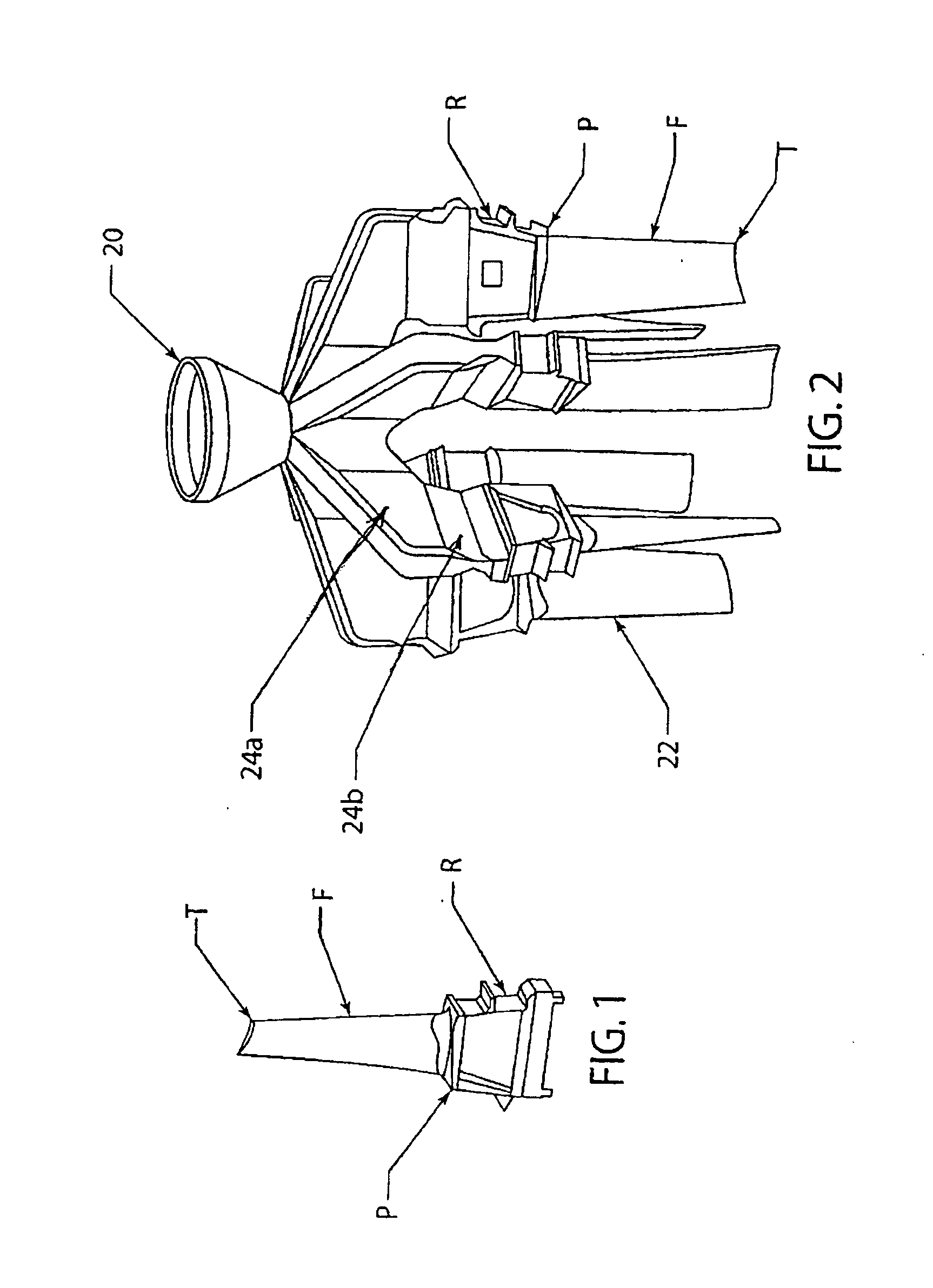

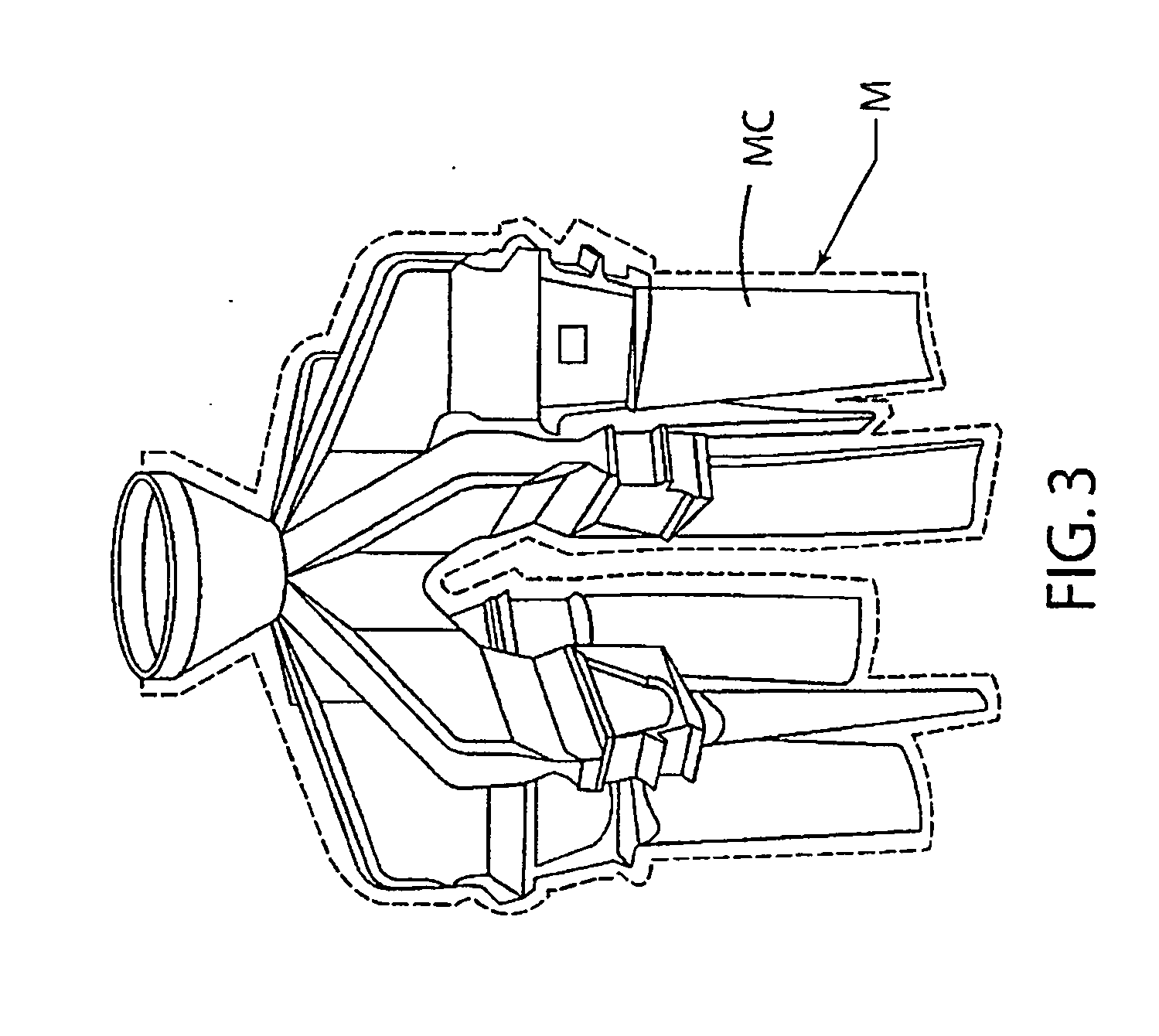

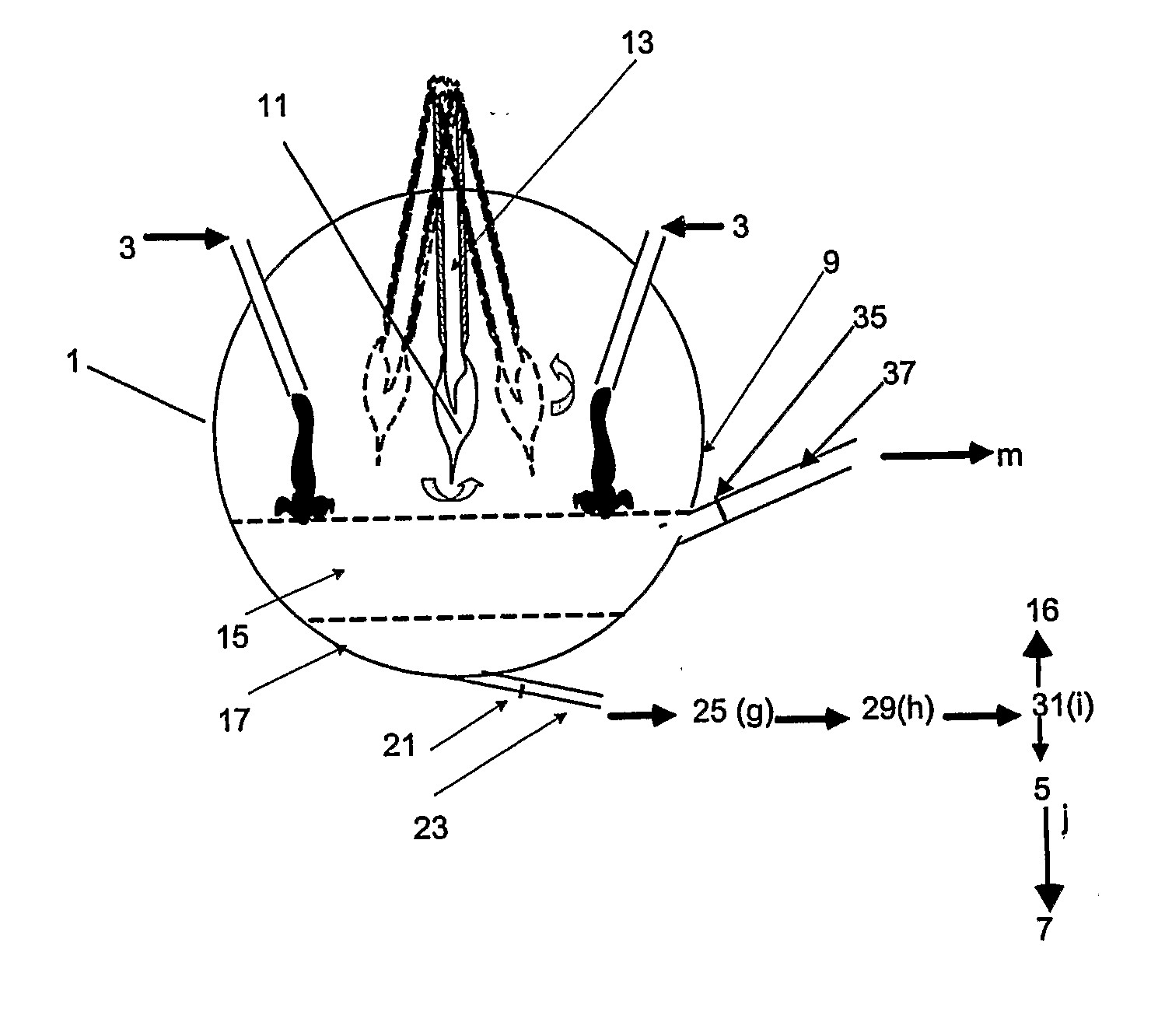

Casting method, apparatus, and product

ActiveUS20140127032A1Facilitate heat extractionLow thermal expansionPropellersPump componentsActive coolingHeating furnace

A casting method and apparatus are provided for casting a near-net shape article, such as for example a gas turbine engine blade or vane having a variable cross-section along its length. A molten metallic melt is provided in a heated mold having an article-shaped mold cavity with a shape corresponding to that of the article to be cast. The melt-containing mold and mold heating furnace are relatively moved to withdraw the melt-containing mold from the furnace through an active cooling zone where cooling gas is directed against the exterior of the mold to actively extract heat. At least one of the mold withdrawal rate, the cooling gas mass flow rate, and mold temperature are adjusted at the active cooling zone as the melt-containing mold is withdrawn through the active cooling zone to produce an equiaxed grain microstructure along at least a part of the length of the article.

Owner:HOWMET CORPORATION

Plasma method and apparatus for recovery of precious metals

ActiveUS20110274580A1Quantity minimizationMaximise palladium (Pd) recovery ratePig casting plantsMetal boridesSlagCompound (substance)

The present invention relates to a method, and apparatus for the recovery of precious metals. Accordingly, it provides a continuous process for obtaining a precious metal composition from a feedstock material, the process comprising the steps of: (i) heating a feedstock material in a plasma furnace to form an upper slag layer and a lower molten metal layer; (ii) removing the slag layer; (iii) removing the molten metal layer; (iv) allowing the removed molten metal layer to solidify; (v) fragmenting the solidified metal layer to form fragments; and (vi) recovering a precious metal composition from the fragments; wherein the feedstock material comprises a precious metal containing material and a collector metal, said collector metal being a metal or an alloy that is capable of forming a solid solution, an alloy or an intermetallic compound with one or more precious metals. This allows for high recovery yields of precious metals. The apparatus comprises a plasma furnace, a casting table enabling continuous casting of the molten metal pool to form a solidified sheet, a fragmentation device and a separation unit for recovering precious-metal-rich alloy from the sheet fragments.

Owner:TETRONICS INT

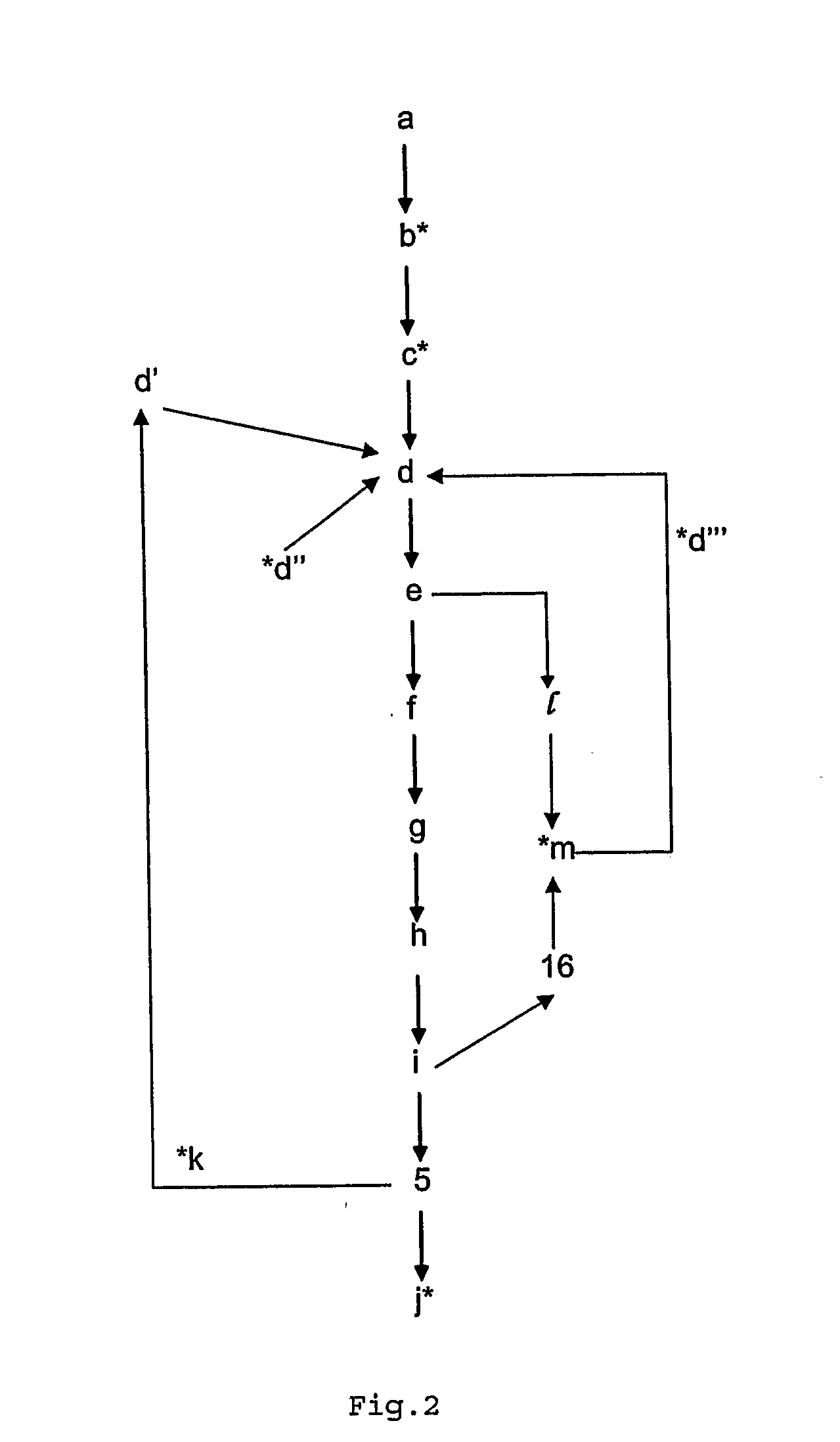

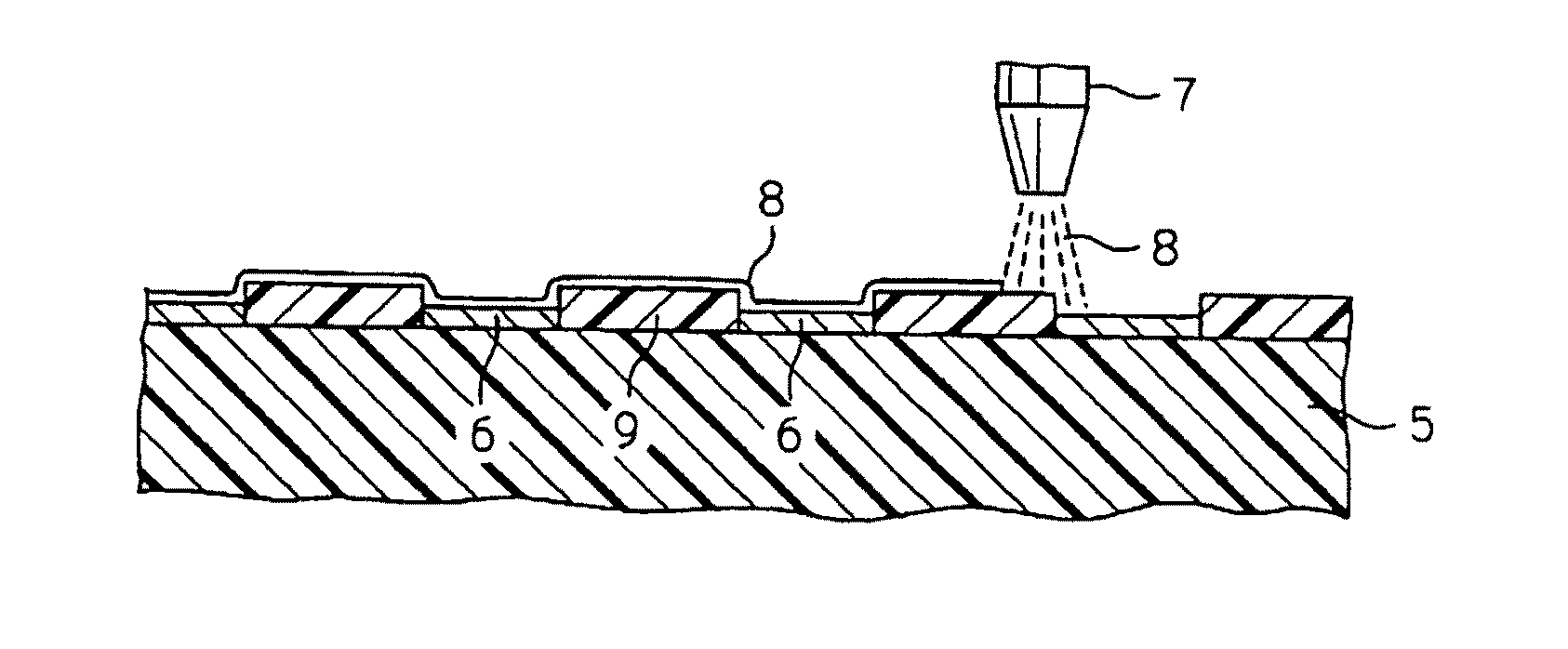

Solder bump formation on a circuit board using a transfer sheet

ActiveUS20110297433A1Efficiently formedSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingSolder pasteSolid phases

A method of forming solder bumps on electrodes of a circuit board without producing bridging using a solder transfer sheet which does not require alignment includes superposing a circuit board and a solder transfer sheet having a solder layer adhered to at least one side of a supporting substrate, performing heating under pressure to a temperature lower than the solidus temperature of the solder to selectively perform solid phase diffusion bonding of the solder layer to electrodes, and peeling the transfer sheet from the circuit board. The solder layer is in the form of a continuous solder coating or in the form of a monoparticle layer of solder particles which are adhered to the supporting substrate by an adhesive layer.

Owner:SENJU METAL IND CO LTD

Hafnium silicide target for gate oxide film formation and its production method

The present invention relates to a hafnium silicide target for forming a gate oxide film composed of HfSi0.05-0.37. Obtained is a hafnium silicide target superior in workability and embrittlement resistance, and suitable for forming a HfSiO film and HfSiON film that may be used as a high dielectric gate insulation film in substitute for a SiO2 film, and the manufacturing method thereof.

Owner:JX NIPPON MINING & METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com