Self-spreading metallurgical process of preparing LaB6 powder

A self-propagating, metallurgical technology, applied in the field of boride powder material preparation, can solve the problems of difficult process control, complex process, high production cost, avoid the existence of borates, low process condition requirements, and reduce raw material costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

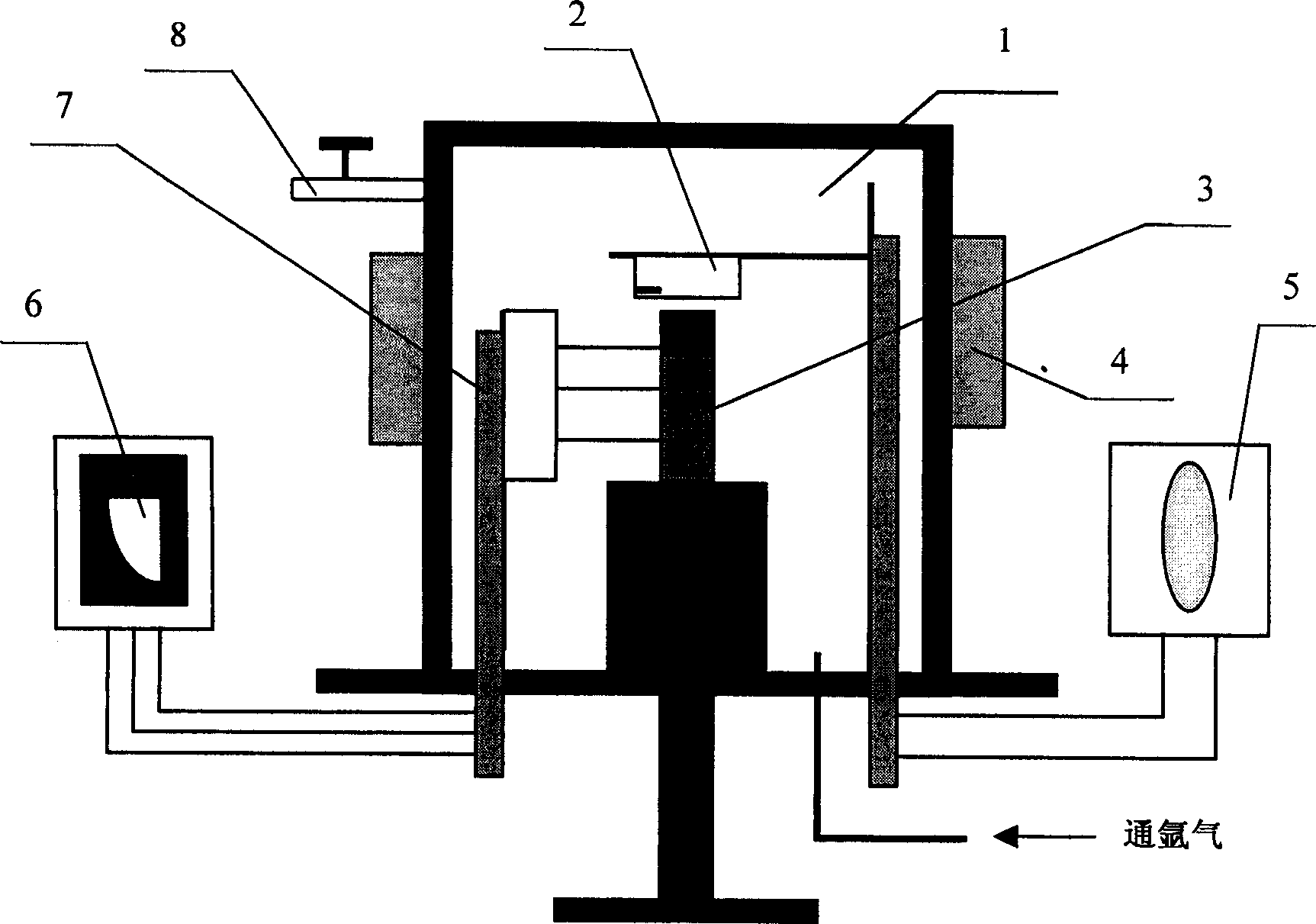

Image

Examples

Embodiment 1

[0025] Take La 2 o 3 , B 2 o 3 , Mg powder by mass ratio La 2 o 3 :B 2 o 3 : Mg is the ratio batching of 100: 128: 160, namely magnesium powder is excessive 3%, raw material is mixed uniformly with mortar, and then the mixed raw material is pressed into cylindrical block, and the pressure of sample pressing is 10MPa, and the pressed The blank sample is placed in a self-propagating reaction furnace, and the blank sample is heated at a constant temperature in an air atmosphere. The furnace temperature is controlled at 700°C until the self-propagating reaction is initiated, then the heating is stopped, and the reaction product is collected after natural cooling to room temperature; Dilute sulfuric acid is used as the leaching agent, and the theoretical excess of acid is 20%. The combustion product is directly leached at room temperature without being crushed. The leaching time is 30h, filtered, and the filtered product is washed with deionized water circulation. Then use 5...

Embodiment 2

[0027] Take La 2 o 3 , B 2 o 3 , Mg powder, by mass ratio La 2 o 3 :B 2 o 3 : Mg is the ratio batching of 100: 140: 170, namely magnesium powder is excessive 10%, the raw material is mixed uniformly with a mortar, then the mixed raw material is pressed into a cylindrical block, the pressure of the sample is 20MPa, and the pressed The blank sample is placed in a self-propagating reaction furnace, and the blank sample is heated at a constant temperature in an air atmosphere. The furnace temperature is controlled at 750°C until the self-propagating reaction is initiated, then the heating is stopped, and the reaction product is collected after natural cooling to room temperature; Dilute sulfuric acid is used as the leaching agent, the theoretical excess of acid is 20%, the combustion product is directly leached at room temperature without crushing, the leaching time is 40h, filtered, and the filtered product is washed with deionized water circulation. Then use 5% hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com