Patents

Literature

52results about How to "High powder activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

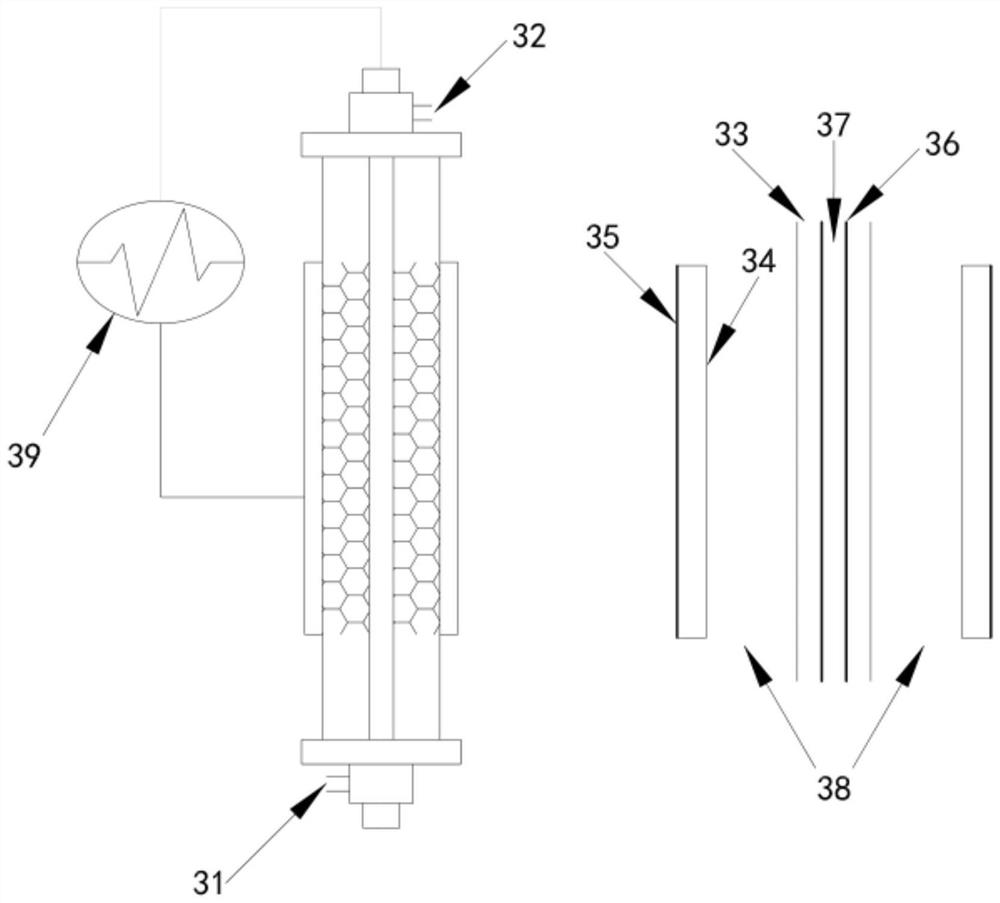

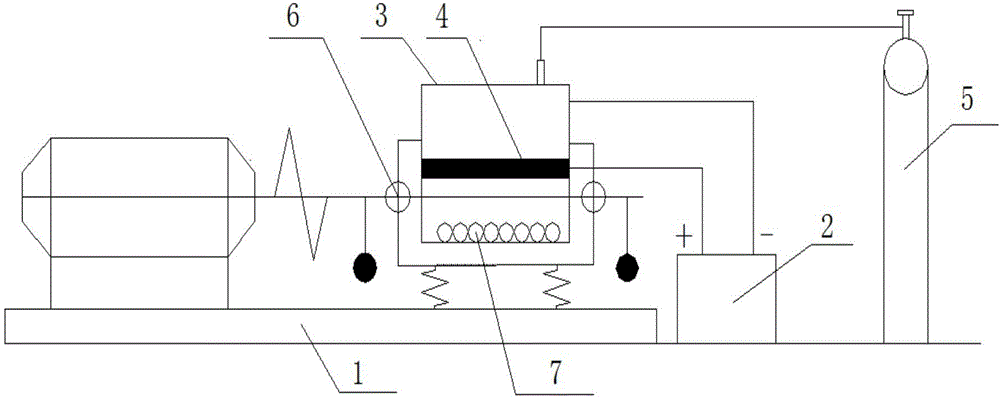

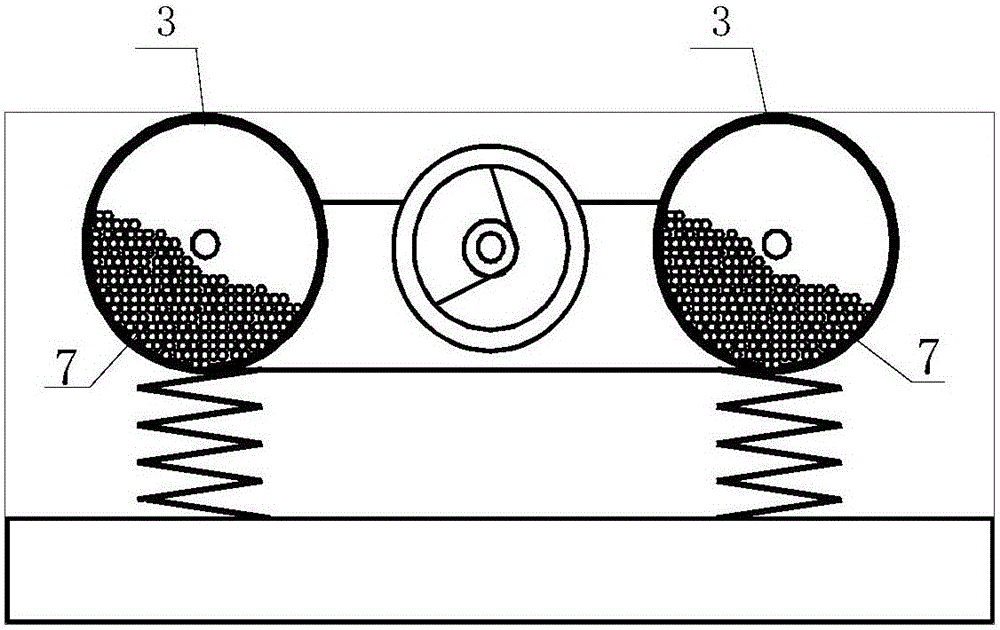

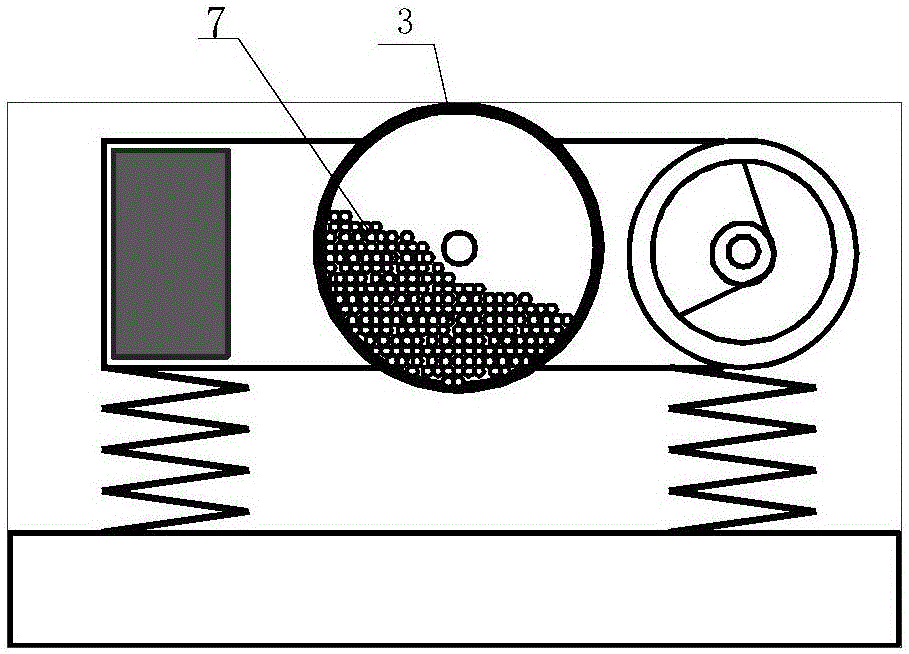

Application method of cold field plasma discharge assisted high energy ball milled powder and plasma assisted high energy ball milling device

The invention provides an application method of cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the cold field plasma discharge assisted high energy ball milling method. The method comprises the following steps: utilizing dielectric barrier discharge to generate plasmas, introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball-milling tank, on one hand, requiring a solid insulating medium on the outer layer of the electrode bar to simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, requiring the high-speed vibrating ball milling device to uniformly process the powder. The method is based on the ordinary ball milling technology; the processing efficiency and the effect of the ball mill can be greatly improved by the following steps: under a non-heat-balance discharge condition of the pressure that the discharge space pressure is set to be about 102-106 Pa, introducing the discharge plasmas to input another effective energy to the processed powder, promoting the powder to be processed to be subjected to combined action of the mechanical stress effect and the heat effect of the external electric field, and further accelerating refining of the powder and promoting the alloying progress.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of superfine low-sodium alpha-alumina powder with high activity

The invention discloses a preparation method of superfine low-sodium alpha-alumina powder with high activity. Industrial aluminum hydroxide is taken as a raw material; alkali is removed and adsorbed by adding an acid; a compound mineralizer is added to calcine; the superfine low-sodium alpha-alumina powder with high activity, of which the mean grain size D50 is 0.2-1.0micron, is obtained by combining dry ball milling with wet ball milling; the sodium content is 0.01%-0.05%; and the content of the alpha phase is 97%-99%. The problems that the alpha-alumina is high in sodium content, uneven in grain size, poor in sintering activity and the like are solved, special requirements of high-performance ceramic, grinding and polishing materials and the like are met, and the method has the advantages of being simple in process, environmentally friendly, low in cost and the like, and is suitable for large-scale production.

Owner:广西朗琨科技有限公司

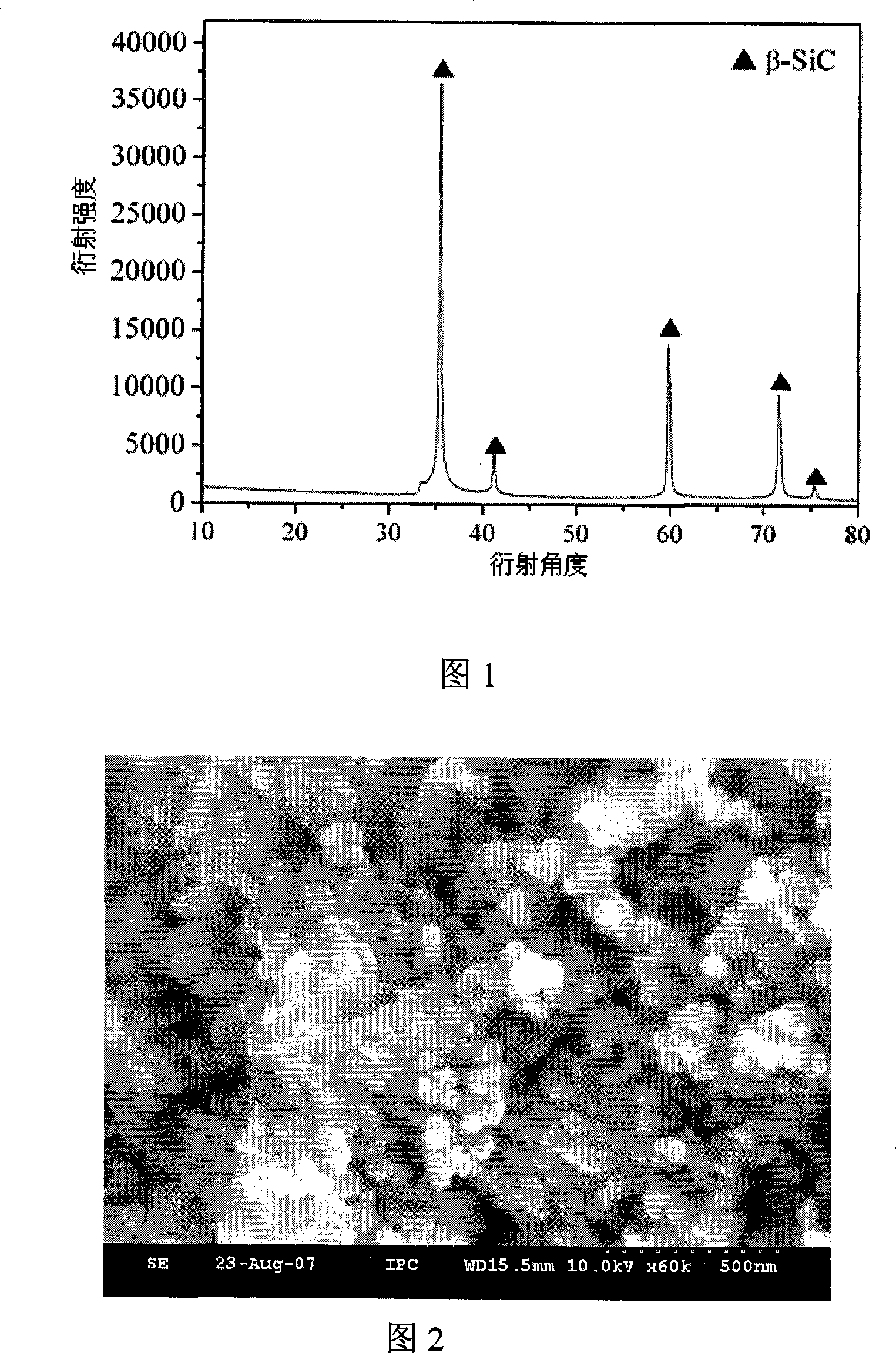

Method for synthesizing homogeneous nano silicon carbide powder by burning

The invention pertains to a preparation technique field of inorganic nano material, in particular to a combustion synthesis method of heterogeneous nano silicon carbide powder. Silicon powder, carbon powder, silicon nitride or silicon carbide additive, and polytetrafluoroethene are adopted as materials, and made into reaction materials according to a certain proportion, and ground and mixed, then held in a praphite crucible, and put into a sealed high pressure reaction synthesis equipment; the reaction equipment is vacuumized and filled with nitrogen to a proper pressure, and the combustion synthesis reaction is triggered by partial electrothermal ignition or partial high frequency induction heating; after the completion of the reaction, the products are collected and treated, and the heterogeneous nano silicon carbide powder with an average crystal particle size less than 100nm can be obtained. The invention realizes the target of preparing high quality nano silicon carbide powder through combustion synthesis technique with low cost, and has the advantages of simple and convenient technique, energy conservative synthesis process, cleanness and pollution free, etc.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

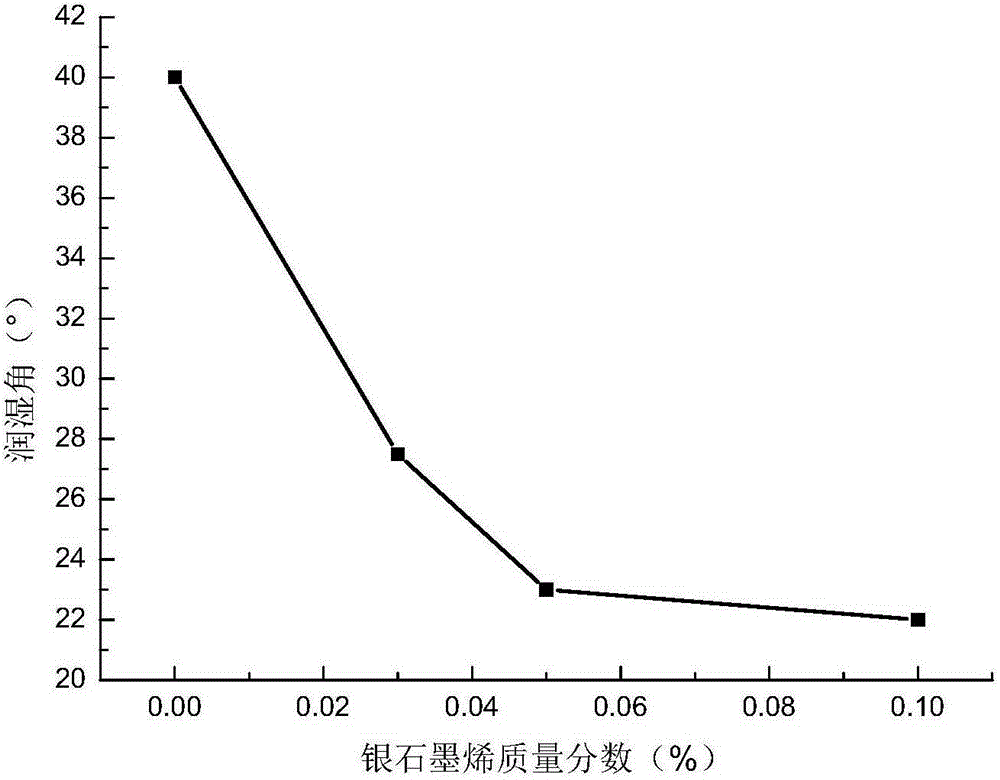

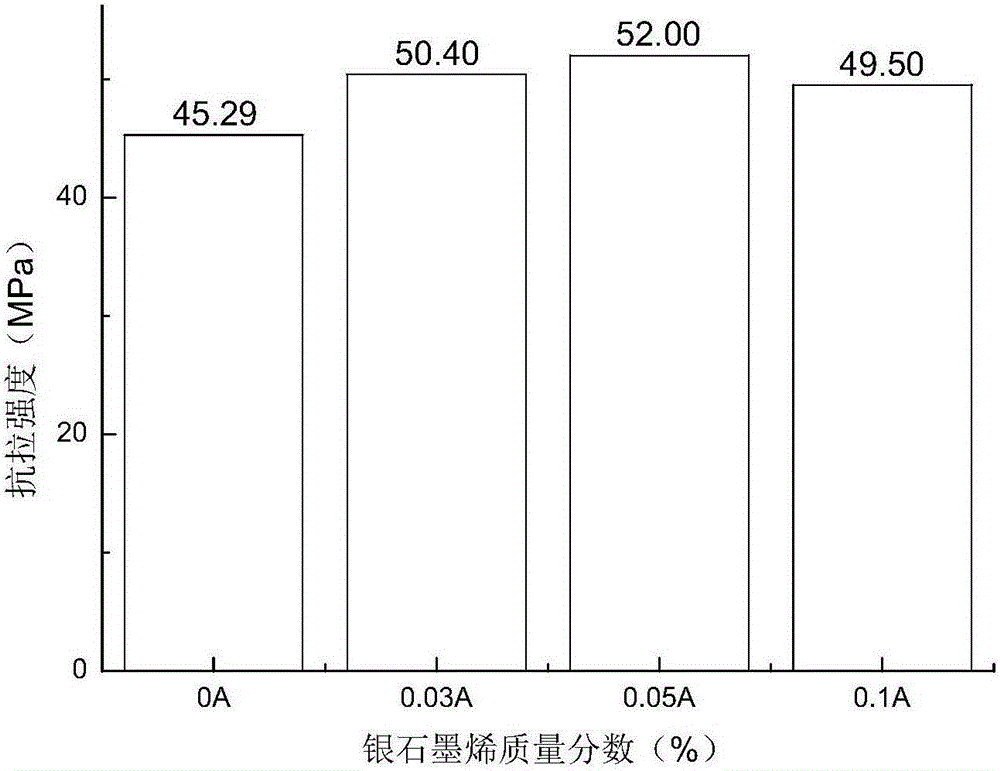

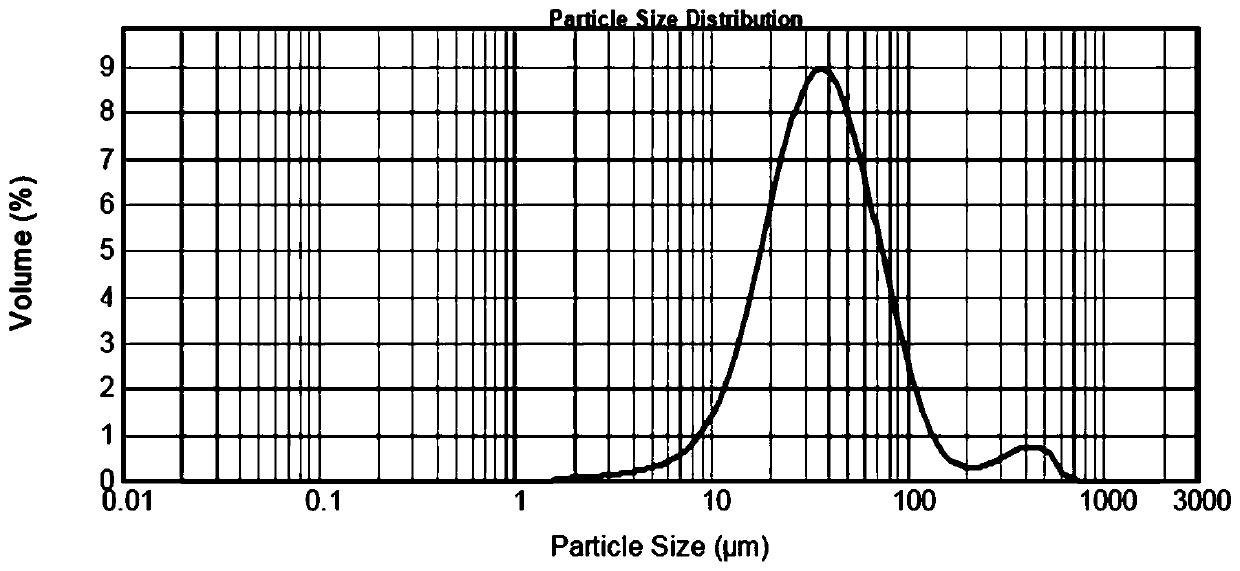

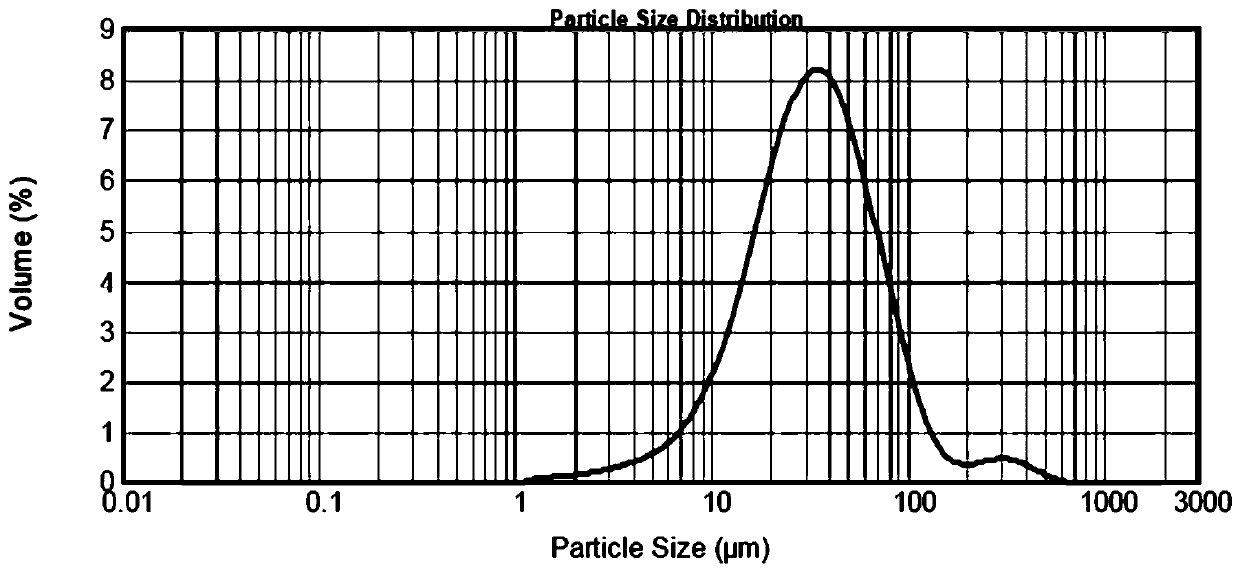

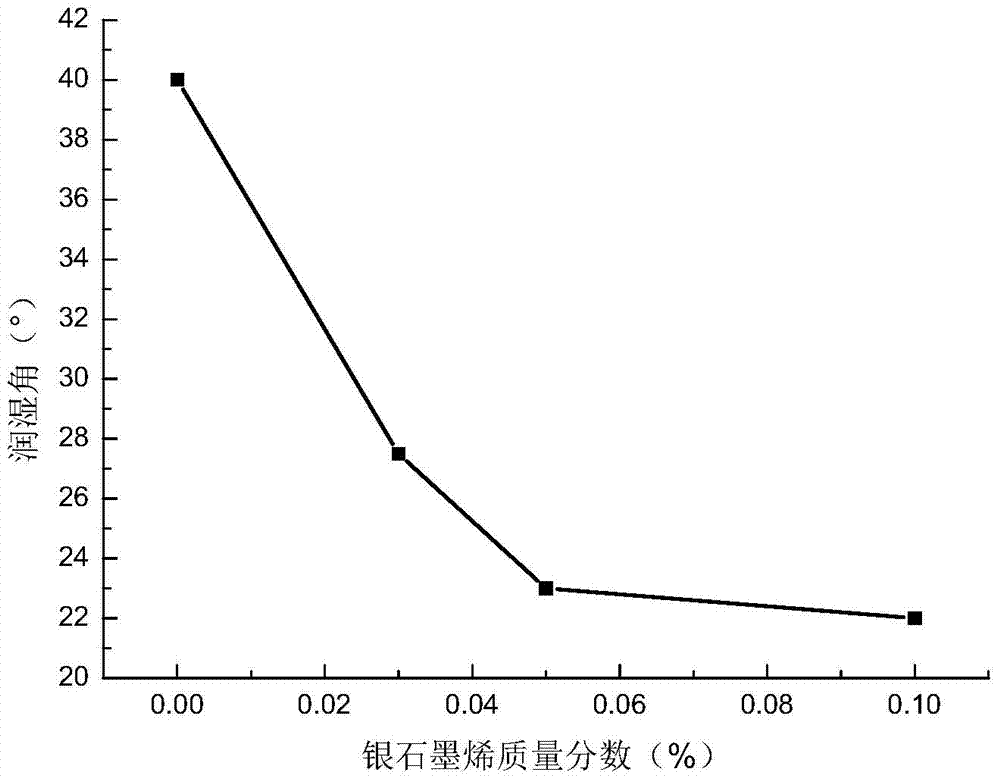

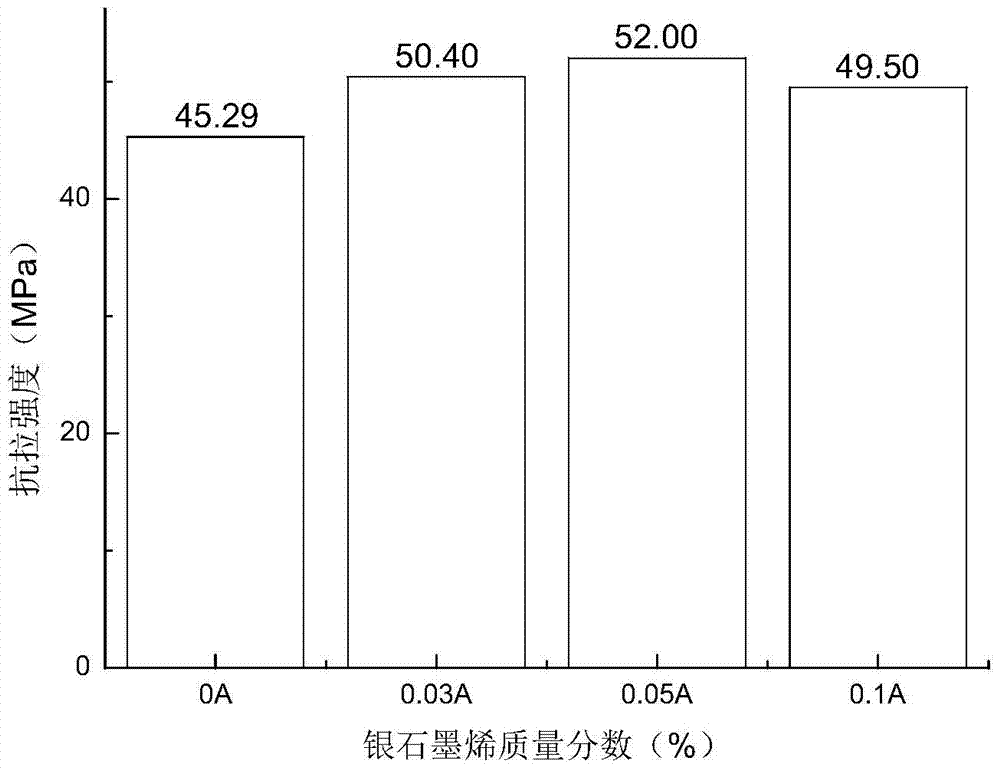

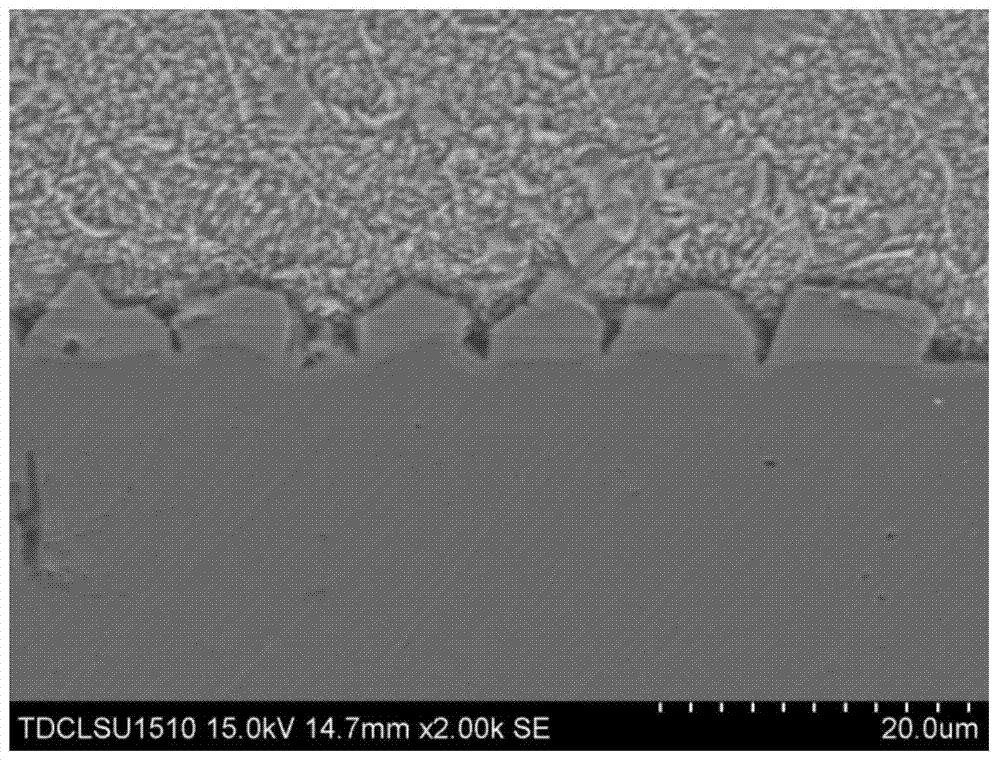

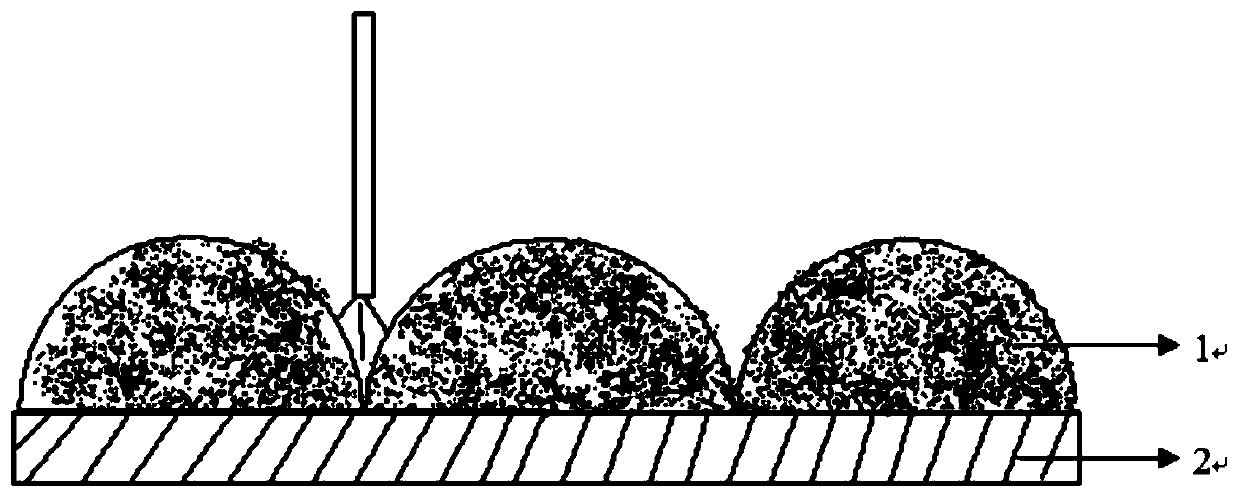

Preparation method of tin-based silver graphene lead-free composite solder

InactiveCN105171277AImprove distribution uniformityUniform compositionTransportation and packagingWelding/cutting media/materialsSolder matrixRoom temperature

The invention discloses a preparation method of tin-based silver graphene lead-free composite solder. The method comprises the steps that a certain amount of graphene and lauryl sodium sulfate are mixed, then a certain amount of dimethylformamide is added, ultrasonic treatment is performed for 2 h, a certain amount of silver nitrate is added into a mixed solution, ultrasonic treatment is performed continuously, and finally a self-made silver graphene nanosheets are obtained; and required solder matrix powder is weighed according to different graphene mass fractions and poured into a ball milling tank for ball milling for 5 h, the powder is placed into a stainless steel mold after being dried and placed under a hydraulic machine to be pressed and molded at the pressure of 500 Mpa, and then a cylinder obtained through cold pressing is placed into a high-vacuum tubular resistance furnace for vacuum sintering for 2 h at the temperature of 175 DEG C and placed under the hydraulic machine after being cooled to the room temperature to obtain a cylinder through impact extrusion. According to the preparation method, Ag-particle-modified graphene is selected as a strengthening material so as to improve load transmitting between the nano-silver-modified graphene and a Sn matrix, and therefore the better strengthening effect is achieved.

Owner:TIANJIN UNIV

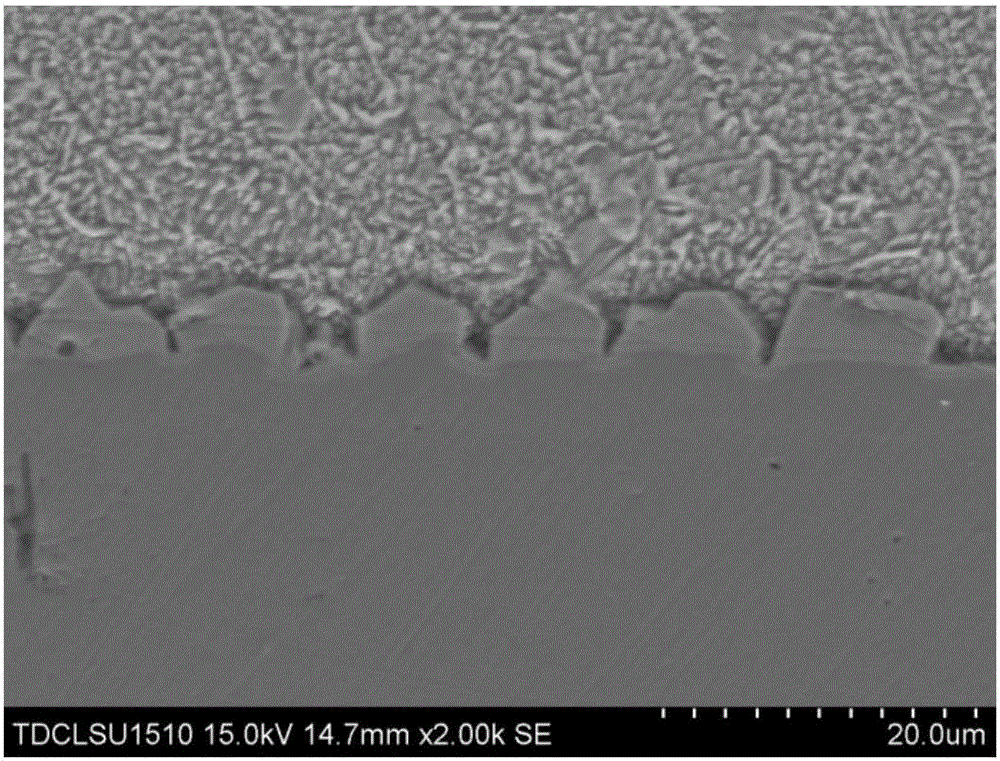

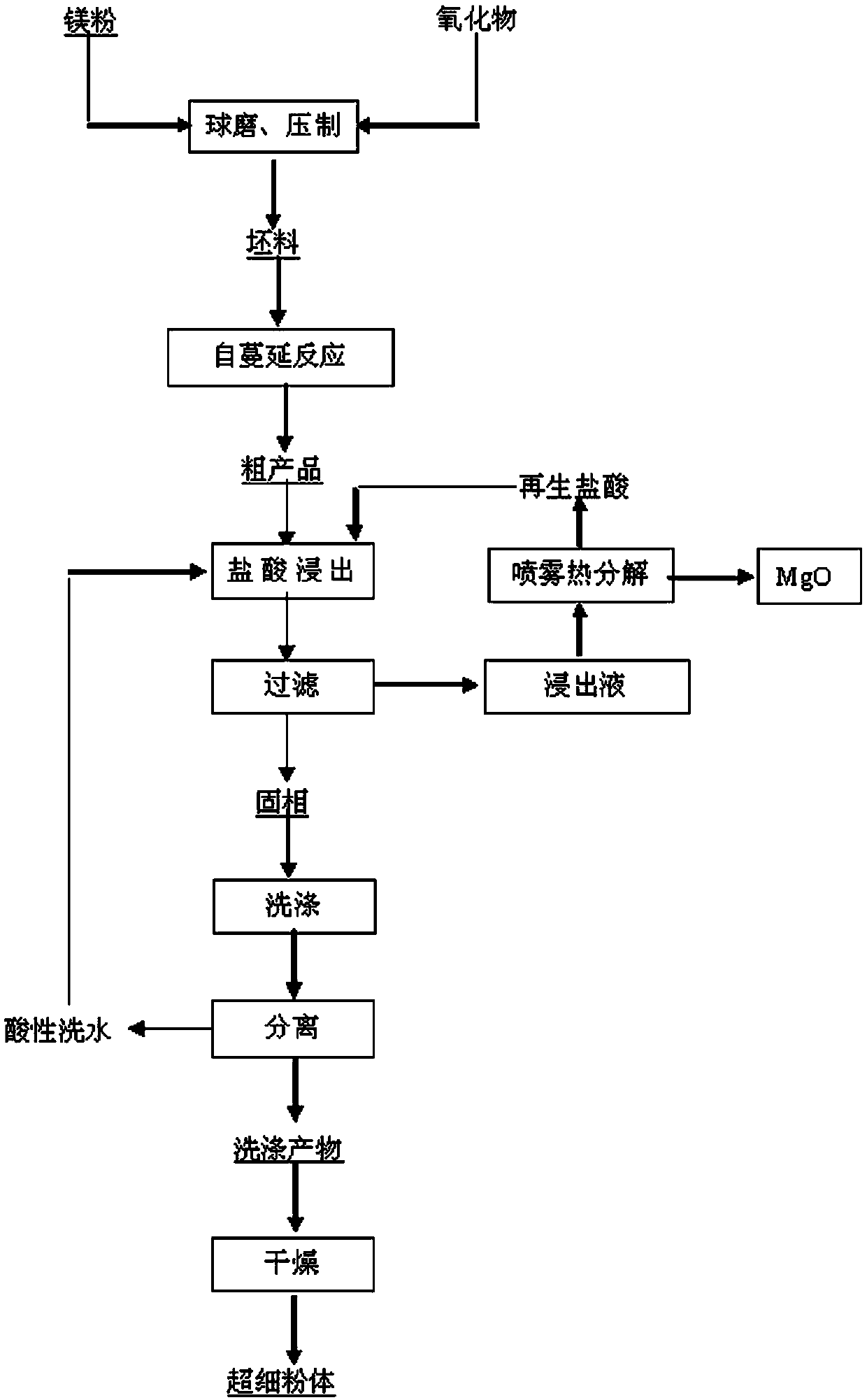

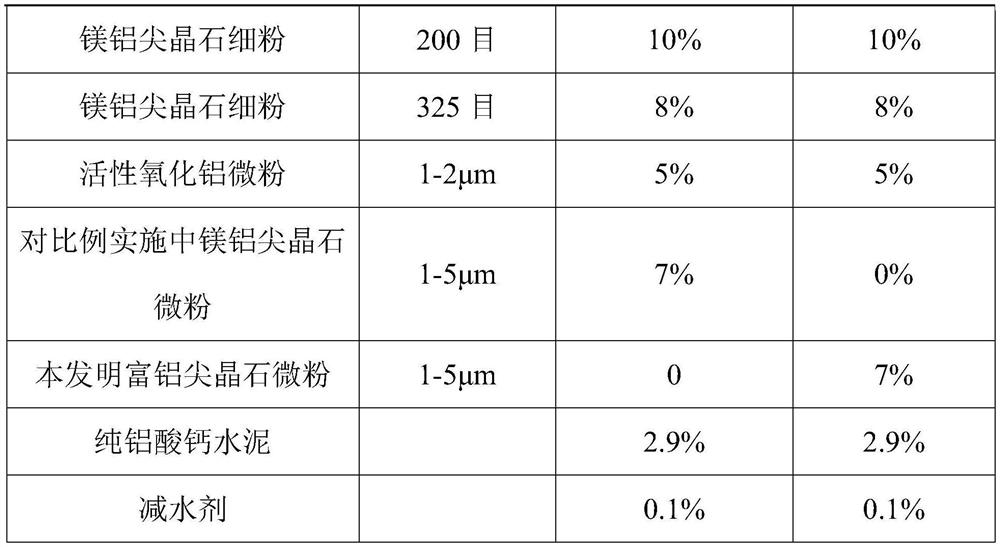

Cleaner production method for preparing superfine powder through self-propagating metallurgy method

ActiveCN103466648ALow raw material costReduce energy consumptionMaterial nanotechnologyBoron/boridesHydrogen chlorideCleaner production

A cleaner production method for preparing superfine powder through a self-propagating metallurgy method is carried out according to the following steps: (1) mixing and conducting ball-milling on the powdery oxide and magnesium powder, then compacting into a blank, putting the blank into a self-propagating reaction furnace to cause a self-propagating reaction, and naturally cooling to the room temperature to obtain a coarse product; (2) using hydrochloric acid to leach and separate magnesium oxide in the coarse product after breaking, and filtering to obtain a solid phase and a leaching agent; (3) washing and drying the solid phase and making the solid phase into ultrafine powder; (4) processing the leaching agent through a spray-pyrolysis mode to obtain a nanoscale magnesium oxide and pyrolysis tail gas, wherein the hydrogen chloride in the pyrolysis tail gas is absorbed to form hydrochloric acid and is circularly used back in the leaching process. The cleaner production method producing the ultrafine powder through the self-propagating metallurgy mode has the characteristics of low material cost, low energy consumption, simple operation, low requirement on process conditions and the like, and the product is high in purity, small in particle size and high in powder activity.

Owner:NORTHEASTERN UNIV

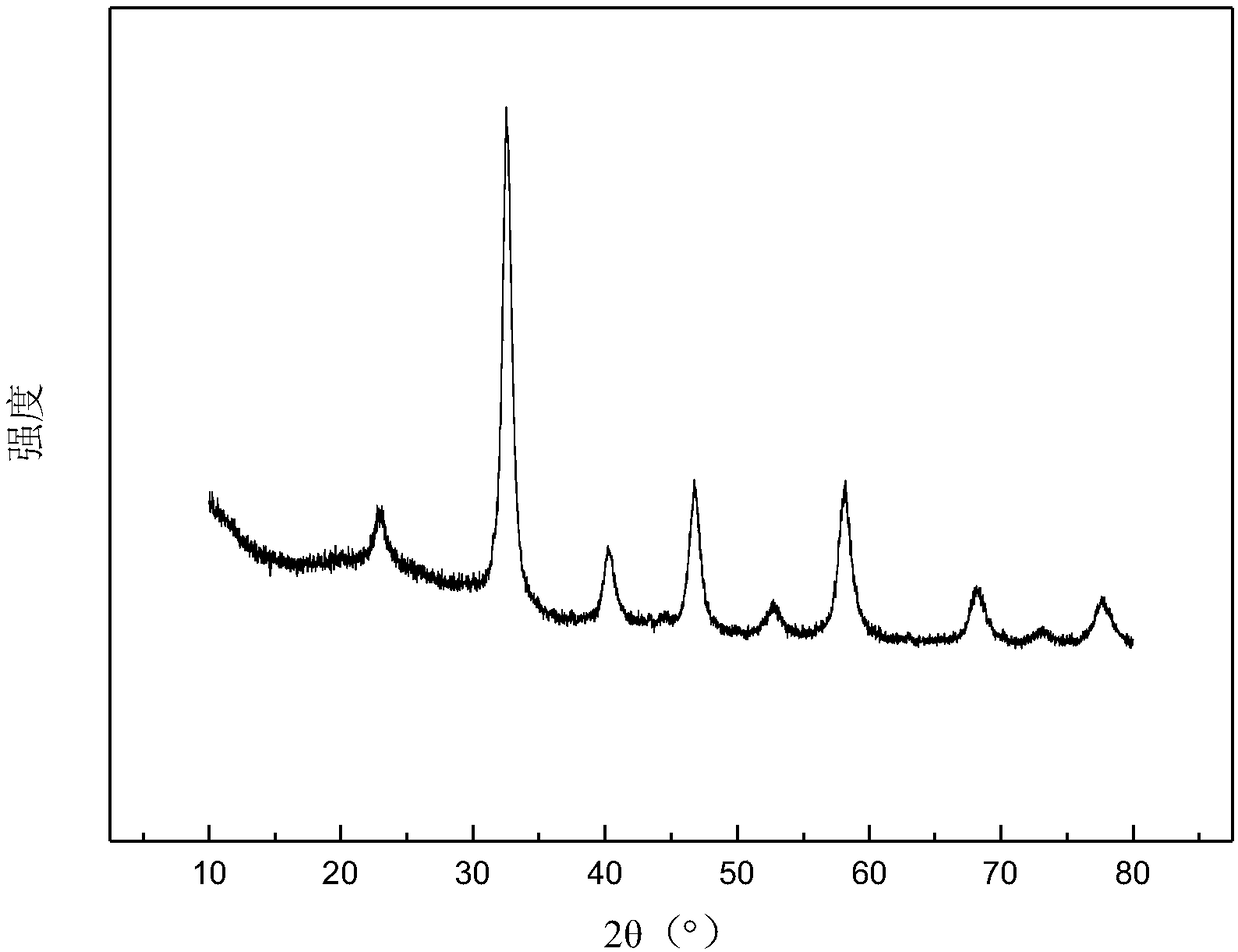

Rare earth hafnate high-entropy ceramic powder through low-temperature synthesis and preparation method

The invention relates to rare earth hafnate high-entropy ceramic powder through low-temperature synthesis and a preparation method, wherein the chemical formula of the rare earth hafnate high-entropyceramic powder is (5RE0.2)2Hf2O7, and rare earth elements RE are La, Ce, Nd, Pr, Sm and Eu. The preparation method specifically comprises the following steps: by taking hafnium tetrachloride (HfCl4) and hydrated rare earth nitrate (RE(NO3)3.xH2O) as raw materials and selecting urea as a combustion agent, mixing the components in a solution, combusting in an air atmosphere at a low temperature to generate fluffy powder, and carrying out high-temperature carbon removal treatment to obtain high-purity (5RE0.2)2Hf2O7 powder. Compared with high-energy ball milling, spray pyrolysis, coprecipitationand other oxide high-entropy ceramic synthesis methods, the method has the advantages of low synthesis temperature, simple operation, high preparation speed and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Anti-ferroelectric ceramic material with high energy storage density and preparation method thereof

The invention provides an anti-ferroelectric ceramic material with high energy storage density and a preparation method thereof. The chemical general formula of the anti-ferroelectric ceramic materialis Pb0.97La0.02[(Zr0.375Sn0.625)1-xTix]O3+a SiO2, wherein x is greater than or equal to 0.1 and less than or equal to 0.15, a is the molar percentage of SiO2 to Pb0.97La0.02[(Zr0.375Sn0.625)1-xTix]O3, and a is greater than or equal to 3% and less than or equal to 5%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

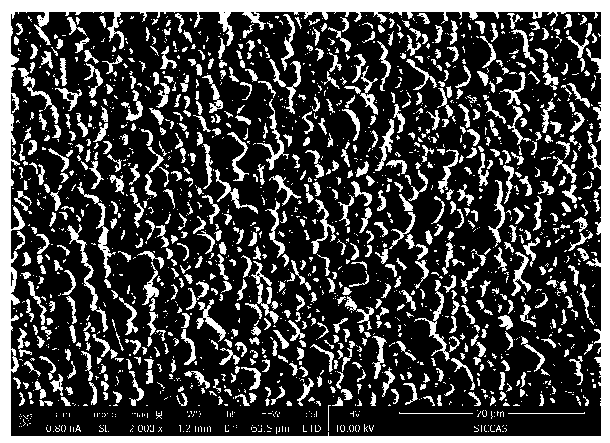

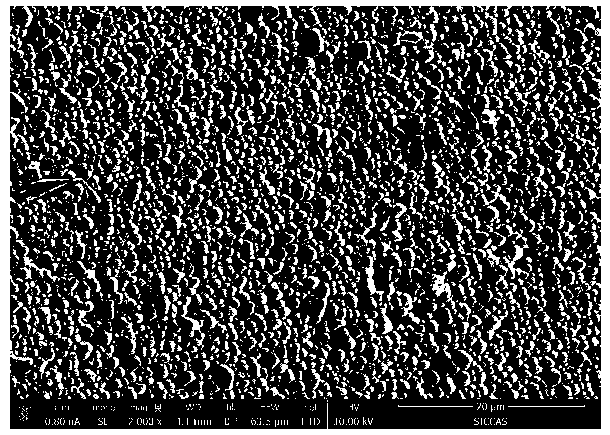

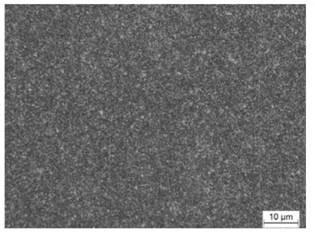

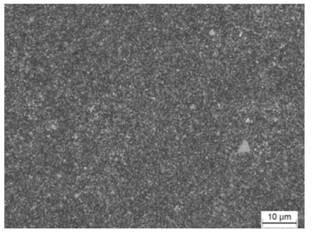

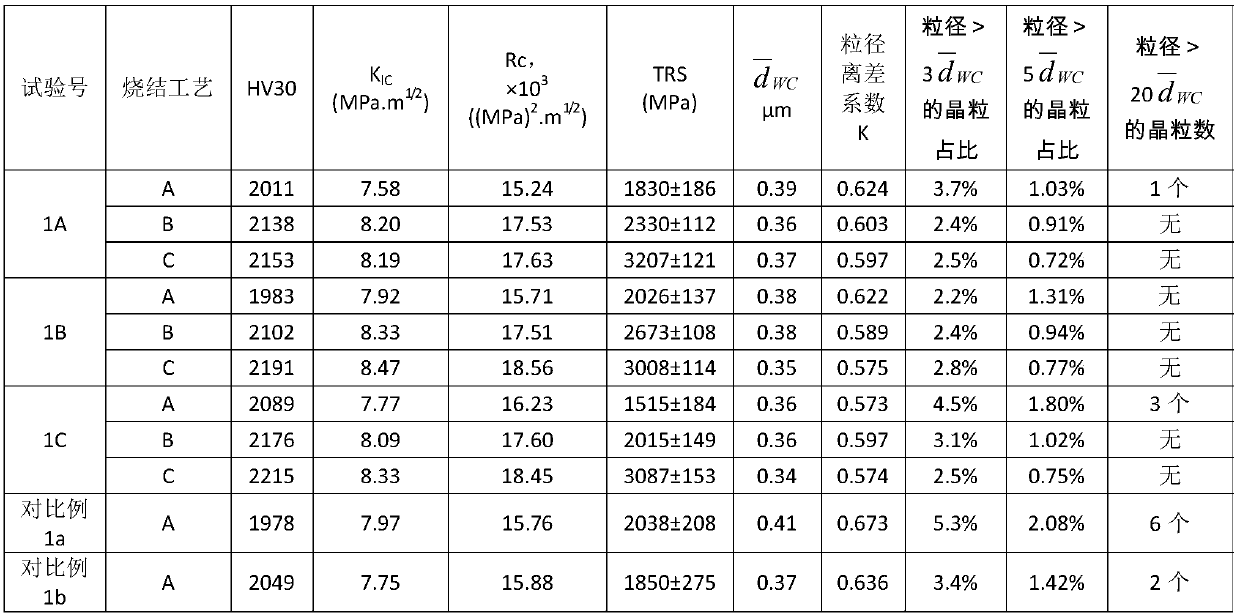

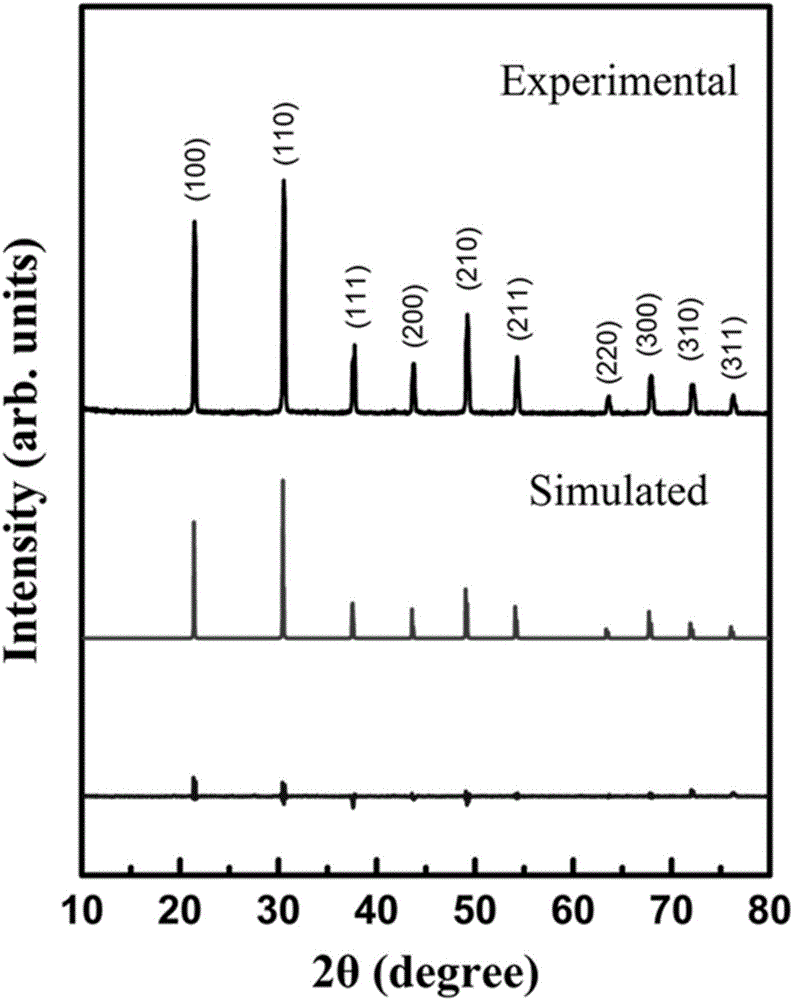

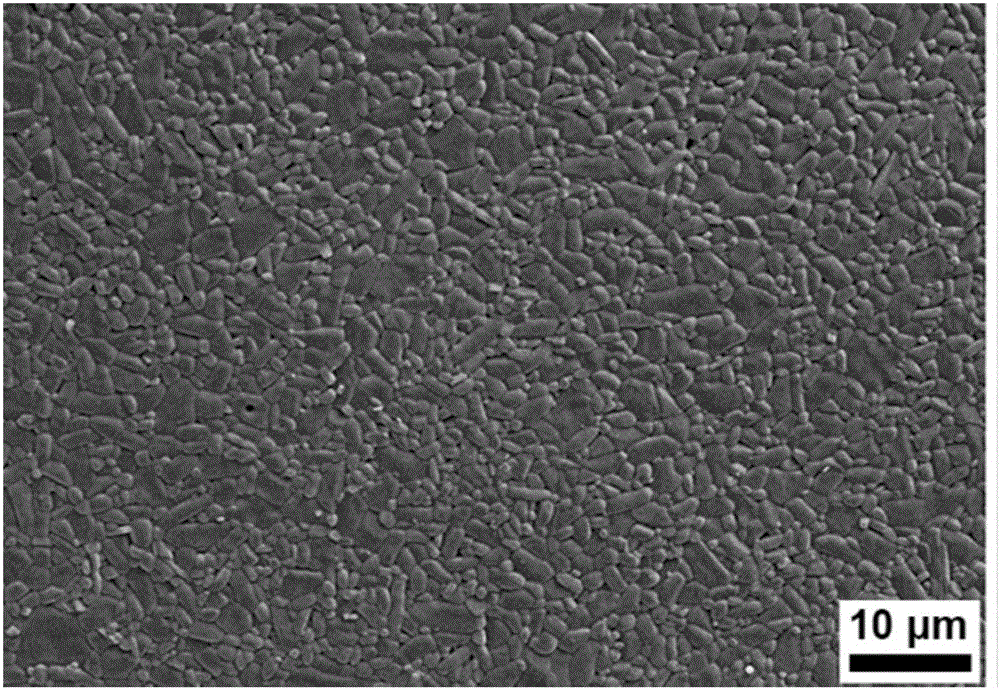

Ultra-fine grain hard alloy and preparing method thereof

The invention relates to an ultra-fine grain hard alloy which comprises WC, a binding phase and a grain growth inhibitor. The weight percentage content of the WC is 83%-96%, the average grain size is(0.2-0.6) micron, the WC grain size deviation coefficient K is larger than or equal to 0.54 and smaller than or equal to 0.61, the grain number percentage of the WC with the grain size larger than 3 times and smaller than 5 times is smaller than or equal to 5%, and the grain number percentage of the WC with the grain size larger than 5 times is smaller than or equal to 1.1%; and the binding phaseis Co, the content of Co in percentage by weight is 3%-15%, and the grain growth inhibitor comprises Cr3C2, VC, TiC and / or Ti (C, N). The invention further relates to a preparation method of the superfine hard alloy. An end mill or a drill bit manufactured by adopting the ultrafine grain hard alloy has excellent use performance in high-speed or high-efficiency cutting machining of difficult-to-machine materials such as stainless steel, a titanium alloy, PCBs, acrylic, glass fibers, hardwood, resin and CFRP.

Owner:ZIGONG CEMENTED CARBIDE CORP

Method of preparing samarium iron nitrogen permanent amgnet material using mechanical alloying

Owner:UNIV OF SCI & TECH BEIJING

Alumina-based insulator and low-temperature sintering method thereof

InactiveCN106495675AUniform particle sizeImprove controllabilityNanotechnologyAluminium oxides/hydroxidesNano al2o3Young's modulus

The invention discloses an alumina-based insulator and a low-temperature sintering method thereof. The sintering temperature of the alumina-based insulator is lower than 1100 DEG C, the volume resistivity is not lower than 5*10<13> ohm cm, the dielectric strength is not lower than 500 kV / cm, the heat conductivity is not less than 30 W / m K, the bending strength is not lower than 400 Mpa, the Young's modulus is not lower than 300 Gpa, and the fracture toughness is not lower than 10 Mpa. The alumina-based insulator is prepared through the following steps: preparing nano alumina powder through a specific sol-gel technology and then adding various functional agents and sintering aids for high-pressure low-temperature sintering. According to the alumina-based insulator disclosed by the invention, the preparation temperature is low, the mechanical performance and the electric performance are excellent, the economical performance is good, the structure is dense, and the alumina-based insulator is suitable for large-scale industrial production.

Owner:郑平珍

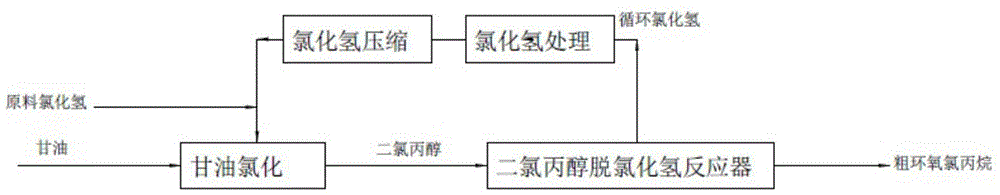

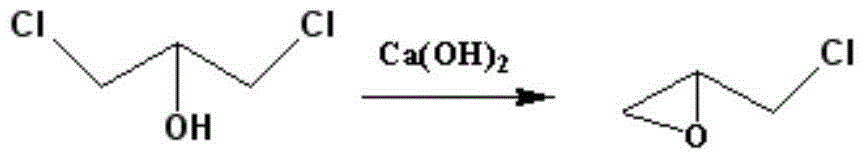

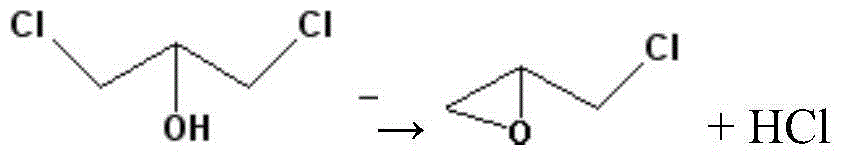

Method for removing gas phase hydrogen chloride from dichloropropanol to produce epichlorohydrin

InactiveCN104059031AHigh activityImprove stabilityChlorine/hydrogen-chlorideOrganic chemistryFluidized bedGas phase

The invention relates to a method for removing gas phase hydrogen chloride from dichloropropanol to produce epichlorohydrin. The method comprises the steps of: 1. filling a tubular reactor or a fixed bed reactor or a fluidized bed reactor with an atom mixed alkaline catalyst; 2. sending dichloropropanol produced by glycerol chlorination in last process into the tubular reactor or the fixed bed reactor or the fluidized bed reactor to undergo reaction; 3. directly removing the gas phase hydrogen chloride generated in step 2 reaction to obtain crude epichlorohydrin; 4. performing purification treatment on the gas phase hydrogen chloride removed in step 3, then conducting compression to a pressure of more than 0.2MPaG and subjecting the compressed hydrogen chloride to cyclic utilization in the procedure of production of dichloropropanol by the last process of glycerol chlorination.

Owner:CHINA TIANCHEN ENG +1

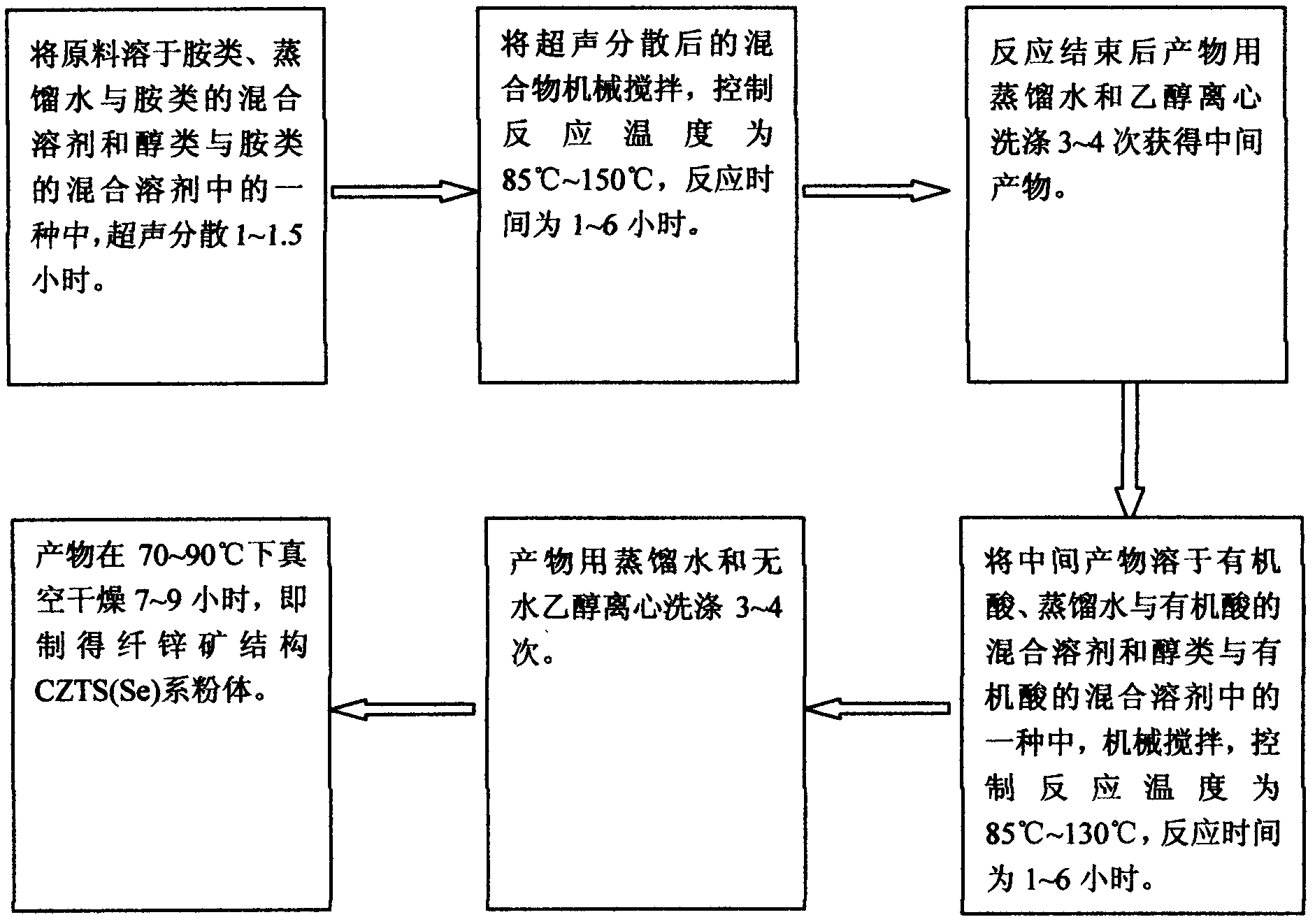

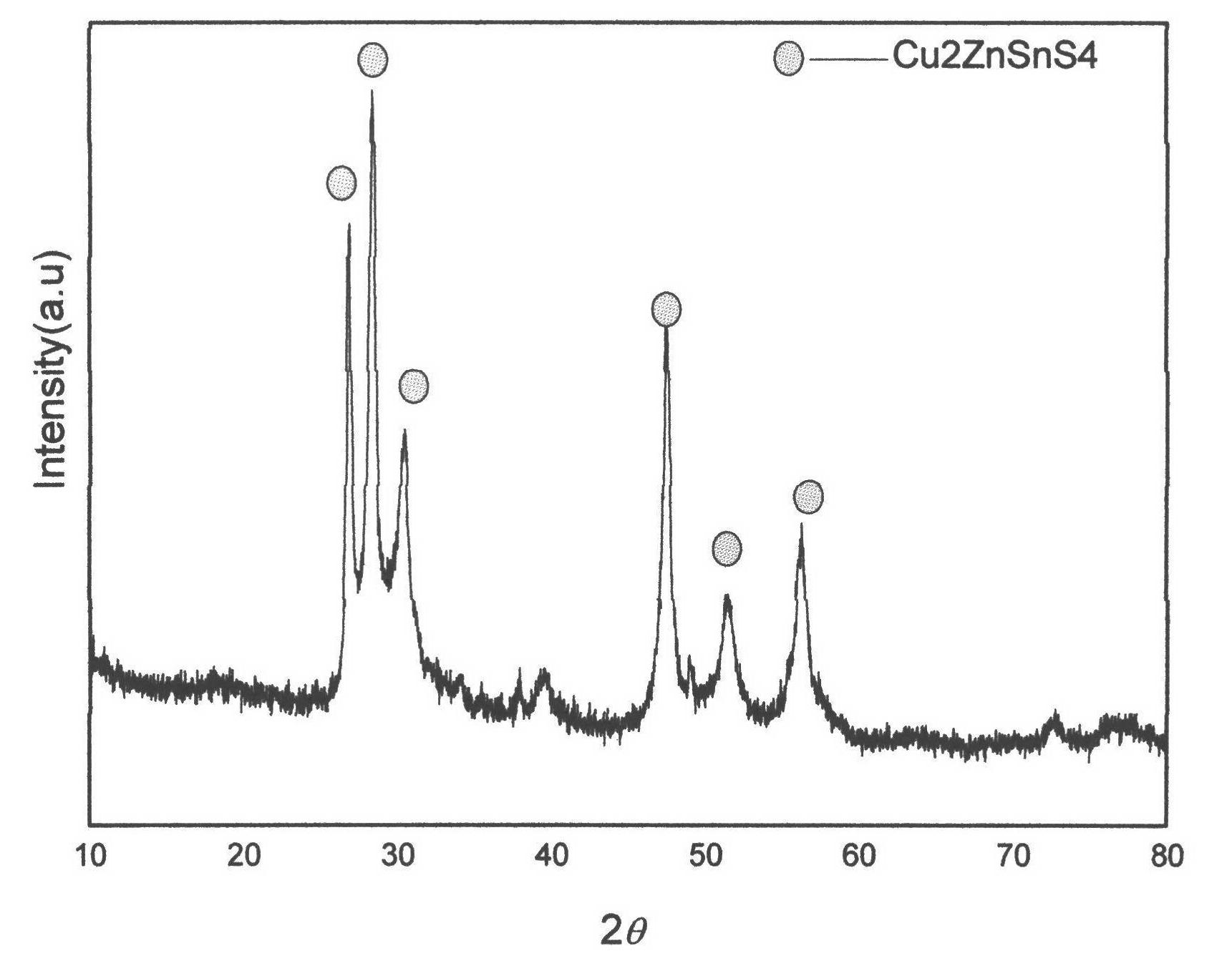

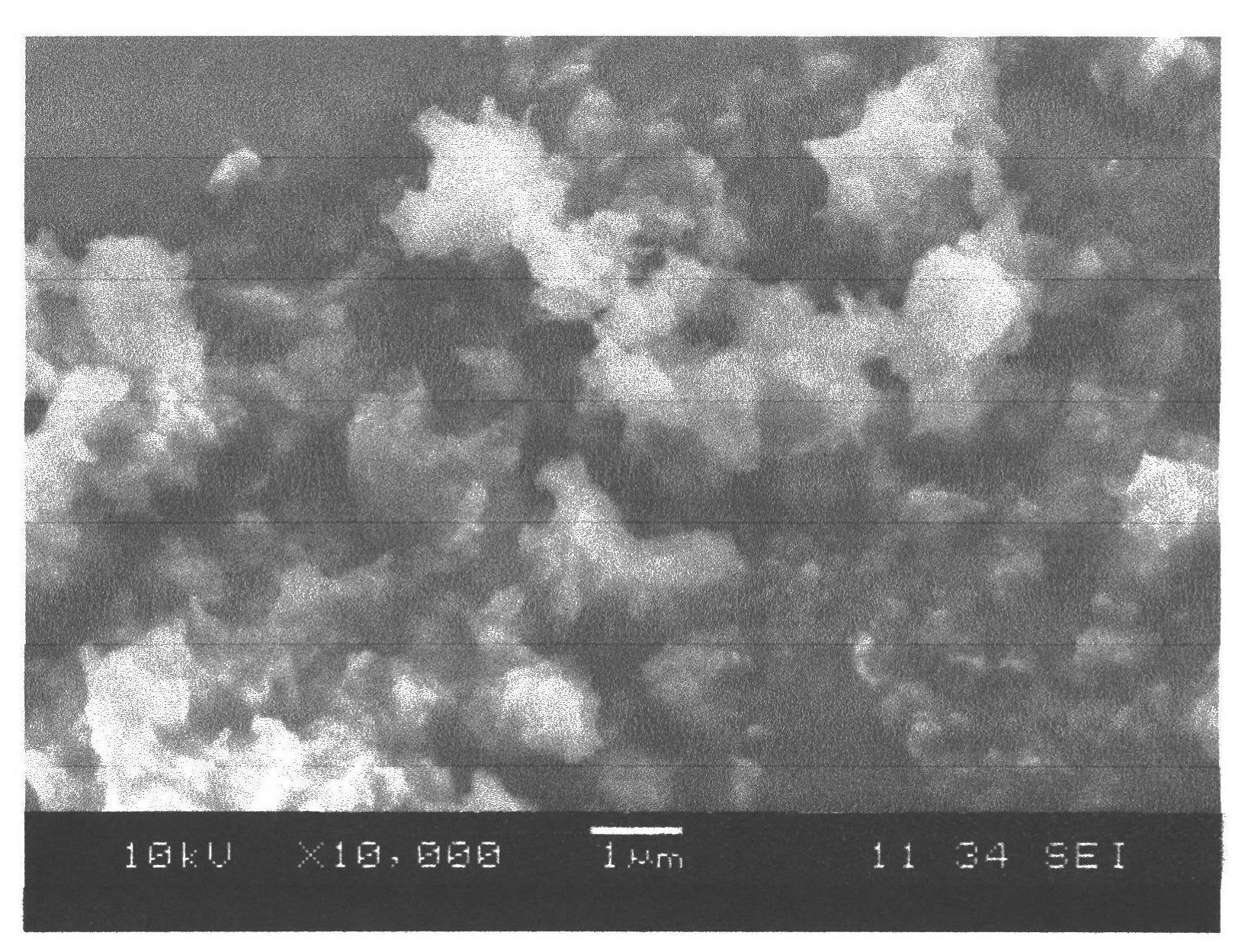

Preparation method of wurtzite structure CZTS (Se) system powder

InactiveCN102627315AHigh powder activitySynthesis speedTin compoundsSelenium/tellurium compundsOrganic acidAlcohol

The invention discloses a preparation method of wurtzite structure CZTS (Se) system powder. The method comprises the steps of allowing elemental Cu powder, Zn powder, Sn powder and S (Se) powder to dissolve in an amine, a mixed solvent of distilled water and an amine or a mixed solvent of an amine and an alcohol, carrying out dispersing through ultrasonic, carrying out heating to a rated temperature, reacting for a rated time to obtain a corresponding intermediate product, allowing the intermediate product to dissolvean organic acid, a mixed solvent of an organic acid and distilled water or a mixed solvent of an alcohol andan organic acid, heating to a rated temperature, reacting for a rated time, and carrying out centrifugal vacuum drying to obtain wurtzite structure CZTS (Se) system powder. The method provided by the invention has the advantages of high activity of synthesized powder, rapid synthesis, simple required equipment pure productand so on, and can flexibly control the entire reaction preparation process so as to form specific structure and specific phase.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

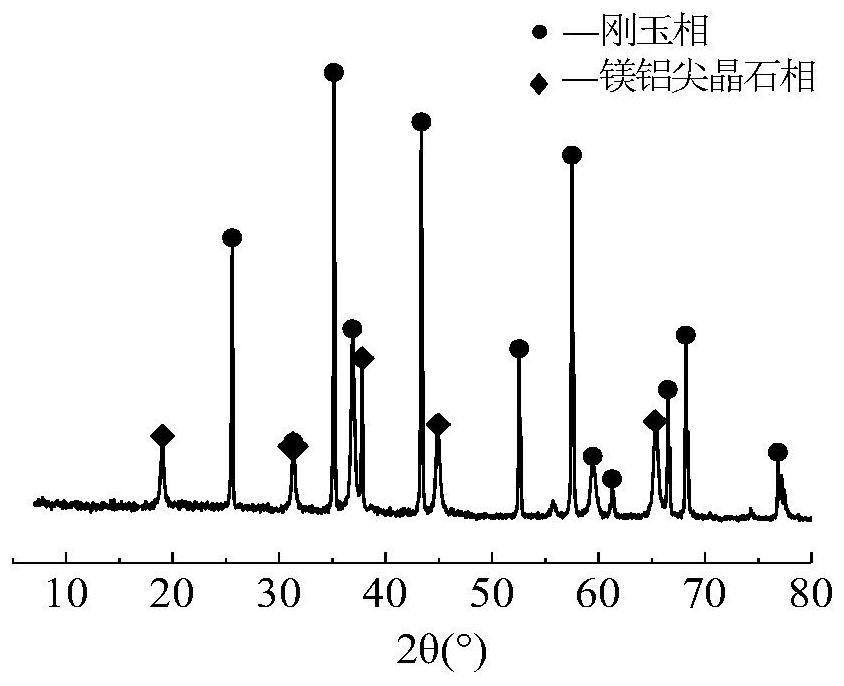

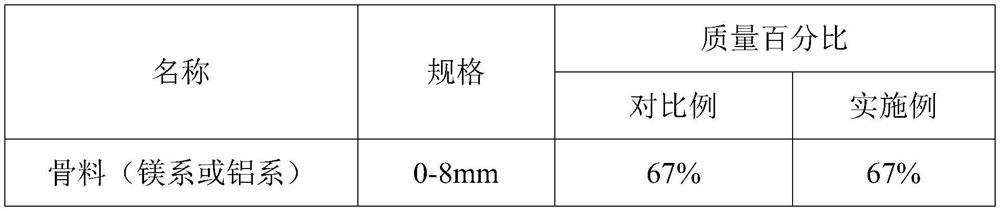

Method for synthesizing aluminum-rich spinel through low-temperature solid-phase reaction

The invention belongs to the field of refractory materials, and particularly relates to a method for synthesizing aluminum-rich spinel through a low-temperature solid-phase reaction. The method specifically comprises the following steps: firstly, mixing 80-90 parts by weight of an aluminum oxide raw material, 10-20 parts by weight of a magnesium oxide raw material, 0.5-2 part by weight of magnesium aluminate spinel micro powder and 0.5-3 part by weight of an additive, and co-grinding the materials until the particle size of the raw materials is in a range of 5-20 microns; transferring the co-ground powder into a high-temperature kiln, heating to 1000-1500 DEG C, and calcining; and finally, keeping for 3-12 hours at the calcining temperature, and implementing naturally cooling or quickly air-cooling to room temperature to obtain the aluminum-rich spinel. A low-temperature synthesis process is adopted, the aluminum-rich spinel synthesized through low-temperature calcination is fine in grain and high in lattice defect degree, and meanwhile the prepared aluminum-rich spinel powder is high in activity. The prepared aluminum-rich spinel does not contain beta aluminum oxide or impurity phases such as free magnesium oxide, and the content of aluminum oxide in the aluminum-rich spinel reaches 80-90%. When the prepared aluminum-rich spinel powder is used in a corundum spinel castable, the aluminum-rich spinel powder has the advantages of high sintering strength and strong slag penetration resistance.

Owner:湖北斯曼新材料股份有限公司

Method for preparing B4C nano-powder through in-situ combustion synthesis

InactiveCN106976883AHigh purityHigh activityCarbon compoundsChemical industryHigh energyBiological activation

The invention discloses a method for preparing B4C nano-powder through in-situ combustion synthesis, and belongs to the technical field of powdering in a powder metallurgy process. The method comprises the steps of mixing boron oxide and magnesium powder at a molar ratio, feeding into a high-energy ball mill for mechanical activation treatment; mixing with carbon nano-powder evenly at a molar ratio, putting into a mold, pressing into a block blank at 10-60MPa and then putting into a self-propagating reactor for triggering self-propagating reaction; immersing the product into diluted hydrochloric acid and carrying out intensified leaching in a closed reaction kettle; and finally carrying out spray pyrolysis to obtain a high-purity boron carbide nano-powder product. The high-purity and high-activity nano B4C powder is prepared through the method. The method is low in raw material cost, low in energy consumption, simple in operation, and low in requirement for technological conditions and instruments and equipment; and a foundation is laid for industrial production. By adopting high-energy ball milling activation, the disadvantages of a traditional magnesium heat reduction method are improved; and by adopting a self-propagating powder technology, the product has the advantages of high purity, controllable particle size distribution and high powder activity.

Owner:NORTHEASTERN UNIV

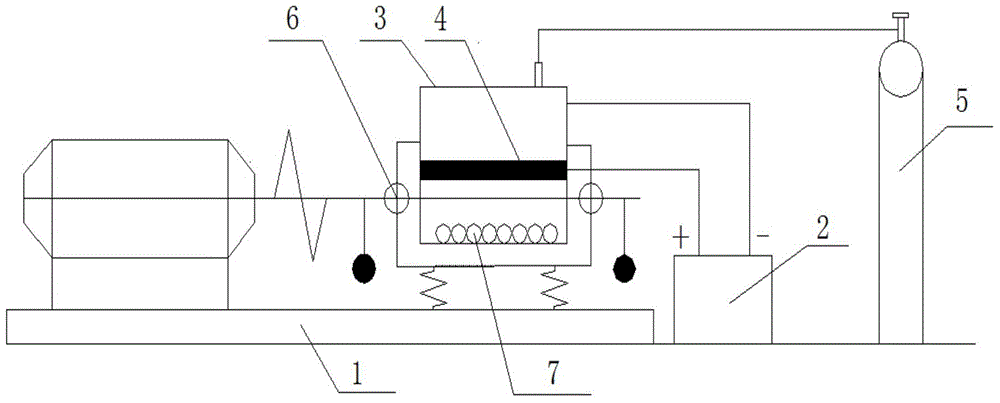

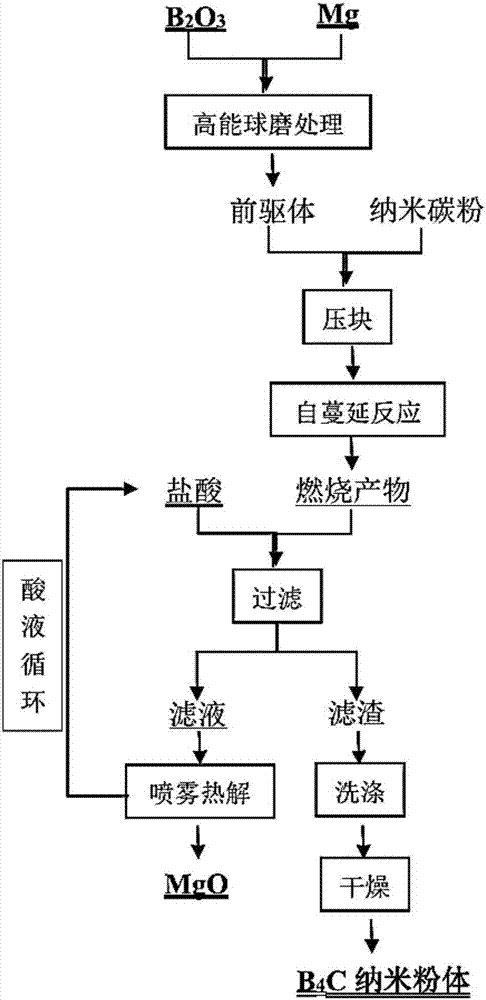

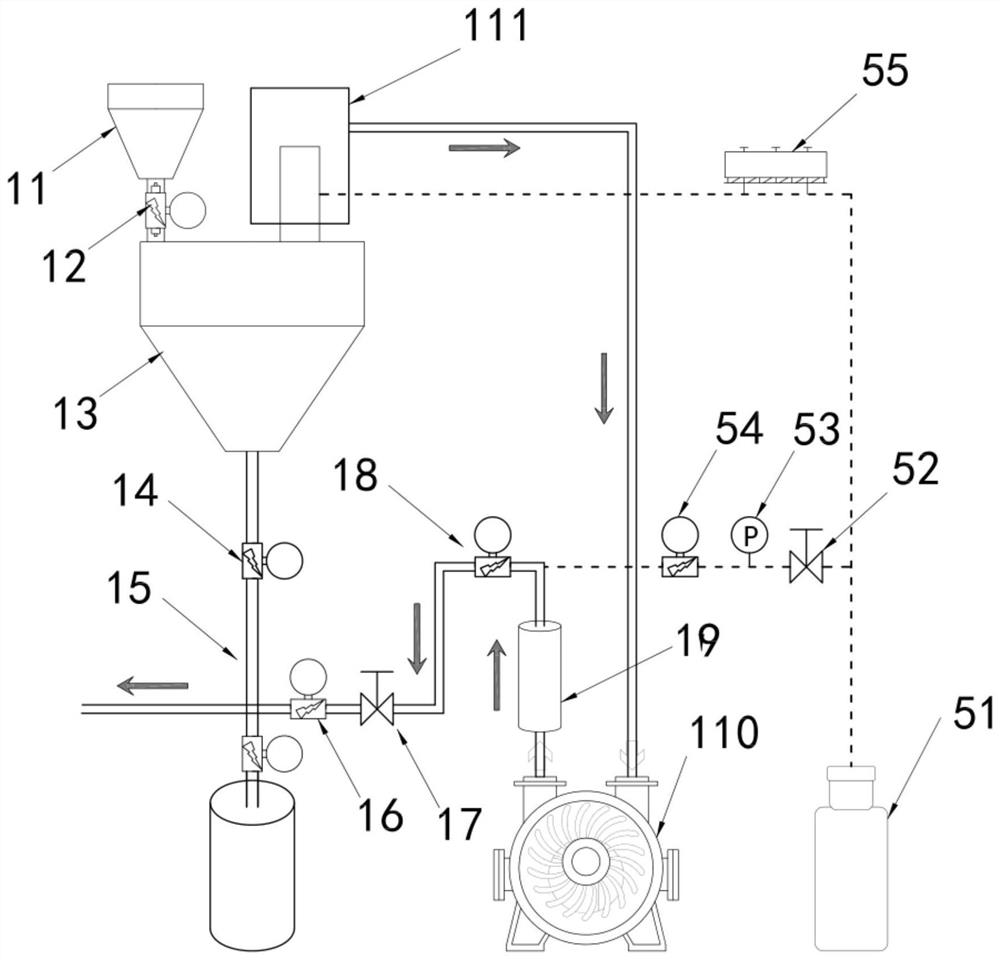

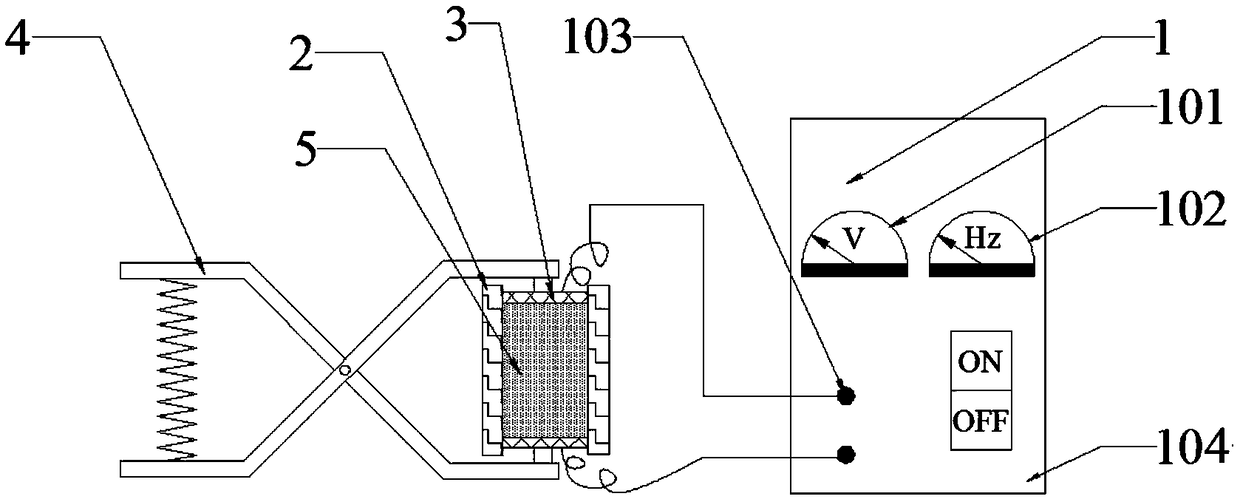

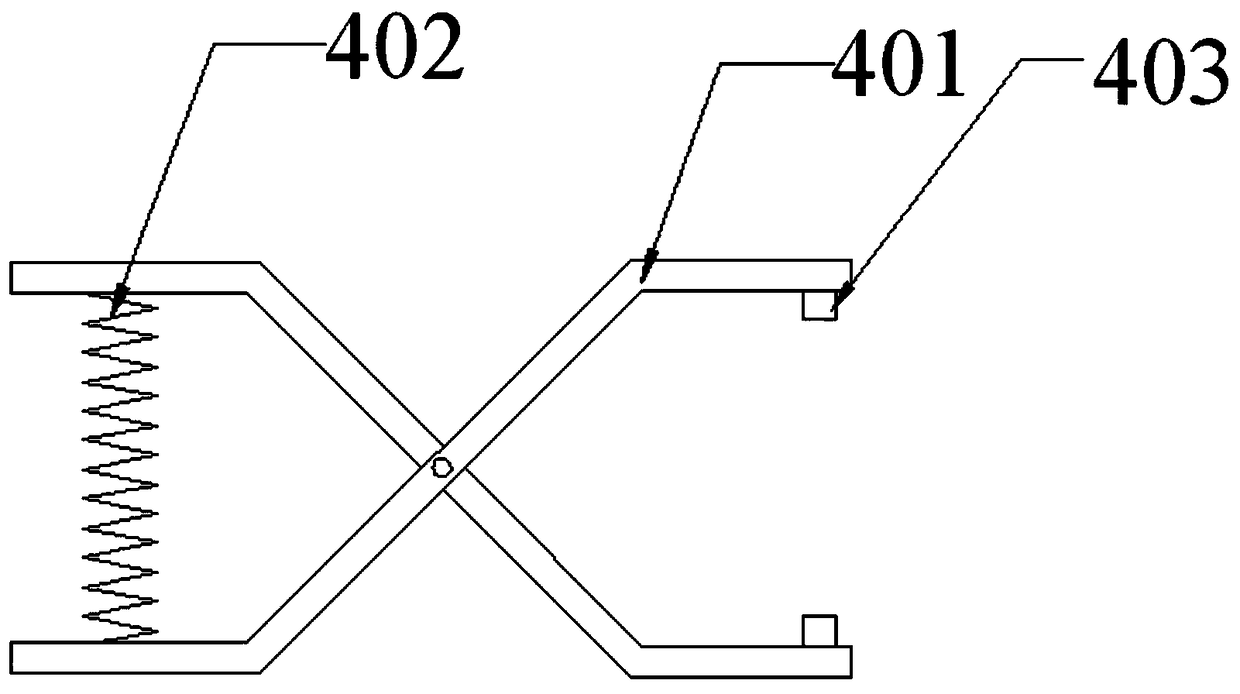

Continuous low-temperature plasma powder treatment and ball milling production device and method thereof

PendingCN112452507AHigh energyIncrease the areaGraphiteTungsten oxides/hydroxidesLow temperature plasmaBall mill

The invention discloses a continuous low-temperature plasma powder treatment and ball milling production device and a method thereof. The device comprises a powder circulating conveying pipeline system, a ball mill, a low-temperature plasma discharge pipeline, a vacuum discharge system and a controllable atmosphere system. According to the device, the powder to be treated is circularly conveyed ina pipeline under controllable air pressure and circulation speed by utilizing the powder circulating conveying system, and in the process, on one hand, the ball mill is introduced in the powder pipeline conveying process to perform ball milling refining or alloying on material powder; and on the other hand, a dielectric barrier discharge structure is introduced into part of the powder conveying pipeline to perform plasma discharge treatment on the ball-milled powder flowing in the pipeline. On the basis of a common powder circulating conveying technology, near-normal-pressure discharge plasmas in the pipeline cooperate with mechanical ball milling to jointly treat powder. The device can also be used for carrying out surface cyclic modification treatment on conventional metal, macromolecule or oxide powder.

Owner:SOUTH CHINA UNIV OF TECH

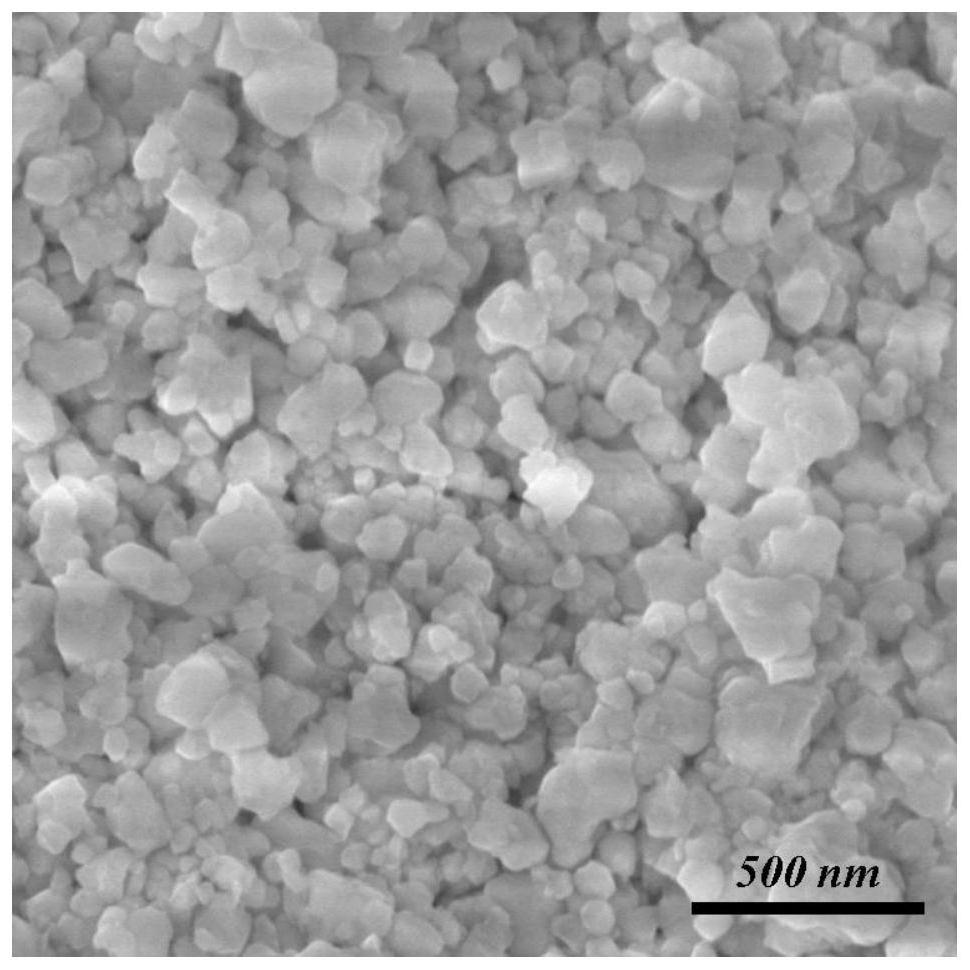

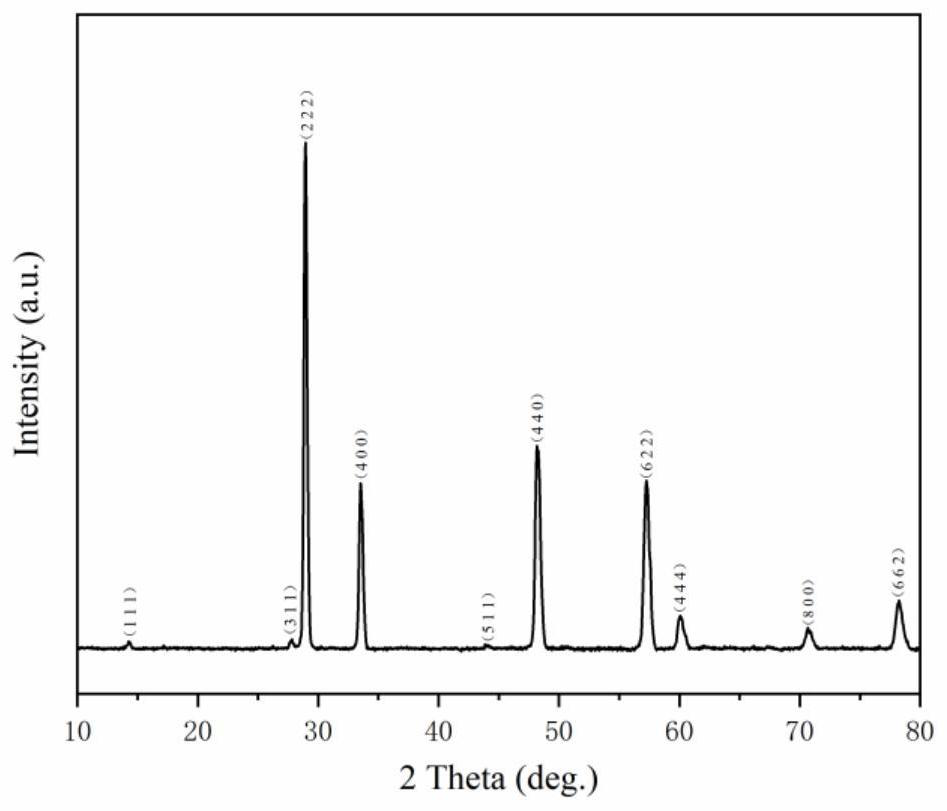

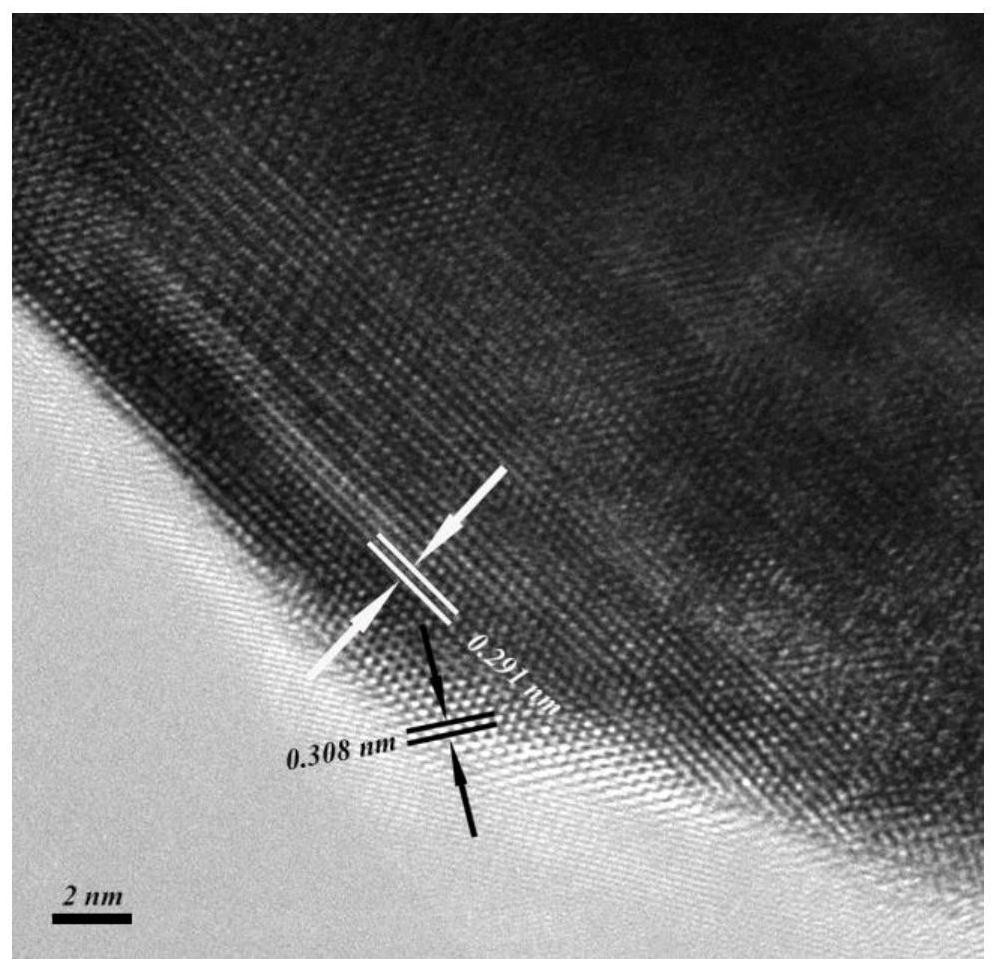

Composite zirconia powder for solid oxide fuel cell and preparation method of composite zirconia powder

ActiveCN107473737AHigh powder activityReduce energy consumptionFinal product manufactureFuel cellsComposite oxideBatch production

The invention discloses composite zirconia powder for a solid oxide fuel cell and a preparation method of composite zirconia powder. The method comprises the following steps: adding a composite oxide additive and a PEG dispersing agent into a zirconium oxychloride aqueous solution, and performing precipitation, aging, filtration, washing and the like, wherein the composite oxide additive consists of Al2O3, TiO2, CeO2, Bi2O3 and Li2O; each component of the composite oxide additive accounts for 0.2 to 5 weight percent of the total system; a solid oxide fuel cell electrolyte piece which is prepared from the composite zirconia powder prepared by the method has the conductivity of 0.37 s / cm at 800 DEG C and the bending strength Kf of greater than 580 MPa; the application of serving as a high-performance electrolyte material in the solid oxide fuel cell can be met, and moreover, the preparation method disclosed by the invention has the characteristics of few aggregates, small particle sizes, uniform particle size distribution, high powder activity, safety and convenience in operation and the like, and is suitable for industrial batch production.

Owner:SANXIANG ADVANCED MATERIALS

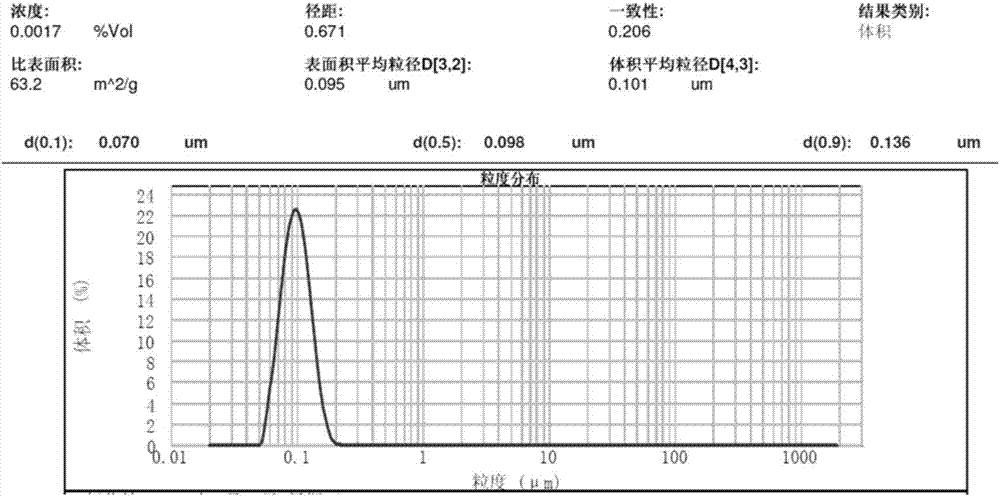

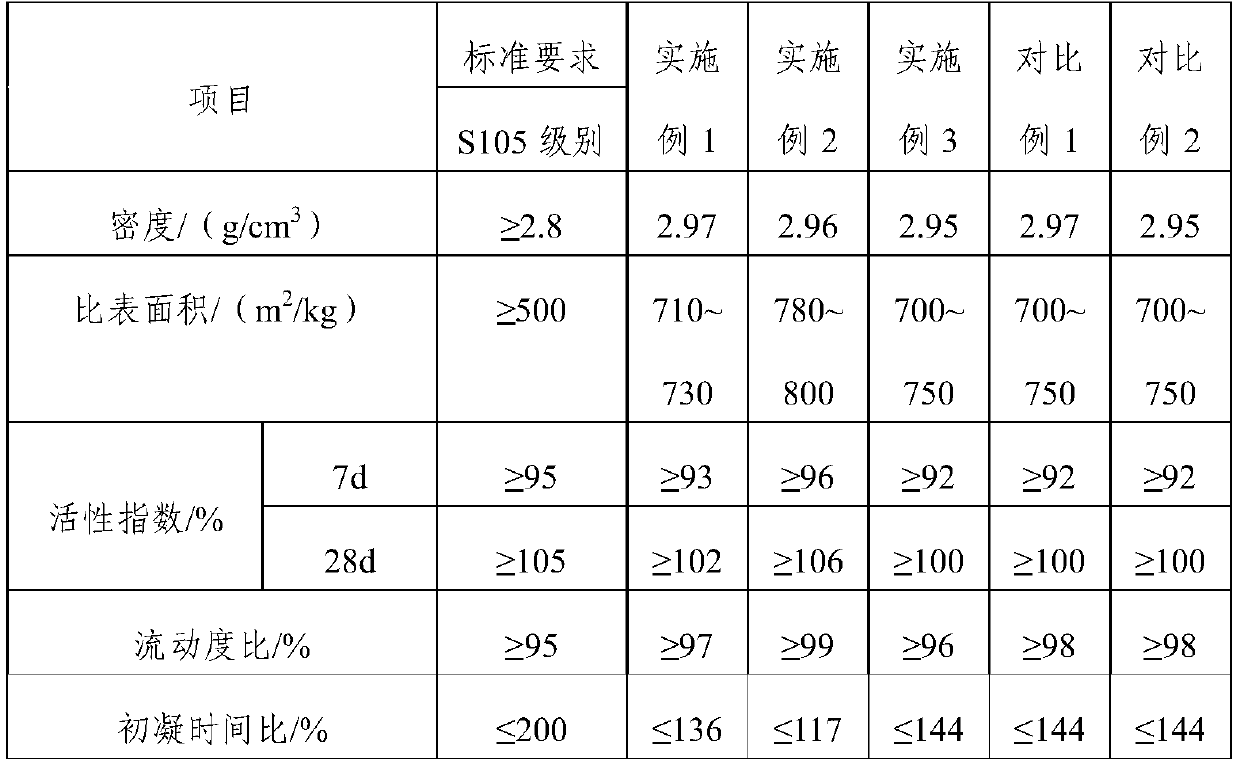

Vanadium-titanium slag ultrafine powder admixture and preparation method thereof

ActiveCN110606675AImprove grinding efficiencyHigh powder activityCement productionTitanium slagResource utilization

The invention relates to a vanadium-titanium slag ultrafine powder admixture and a preparation method thereof. The preparation method comprises the following steps: carrying out pre-grinding, gradingseparation, ultrafine grinding and re-separation on vanadium-titanium slag particles; wherein the specific surface area of the powder after the grading separation is 400-500 m<2> / kg; wherein the specific surface area of the resorted discharged powder is 700-800 m<2> / kg. According to the efficient preparation method of the vanadium-titanium slag superfine powder admixture, superfine powder with a high specific surface area is obtained, the hydration activity of vanadium-titanium slag is greatly improved, the contribution to cement strength is greater, the grinding efficiency is high, and efficient resource utilization of vanadium-titanium slag in cement and concrete is achieved.

Owner:中建材科创新技术研究院(山东)有限公司

Method for preparing porous material by physicochemical treatment

ActiveCN103316634AImprove performanceImprove compactnessOther chemical processesMolecular sieveMicrowave

The invention relates to a method for preparing a porous material by physicochemical treatment. The method comprises the following steps of: mixing a base subjected to high-temperature activation and metal solid salt to obtain a mixture; carrying out the physicochemical treatment on the mixture; and then, washing, dehydrating, drying and / or baking a product to obtain the porous material, wherein the base is zeolite, a molecular sieve, active aluminum oxide, active carbon or a metal compound porous material containing organic functional groups; the metal solid salt is nitrate, acetate or chloride containing metal cations; the physicochemical treatment comprises the step of carrying out microwave heating treatment or mechanical mixing treatment on the mixture. The porous material prepared by the preparation method disclosed by the invention has good application prospects in the fields of separation, purification, storage and the like of gas.

Owner:王朝晖

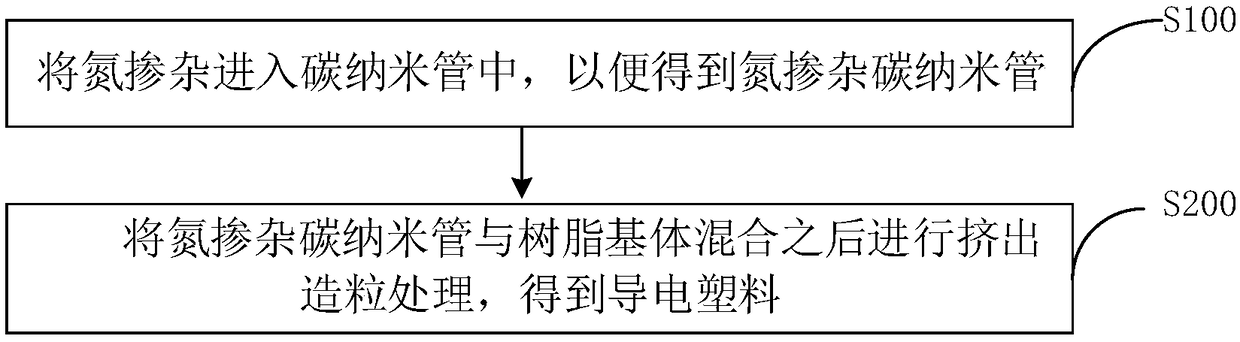

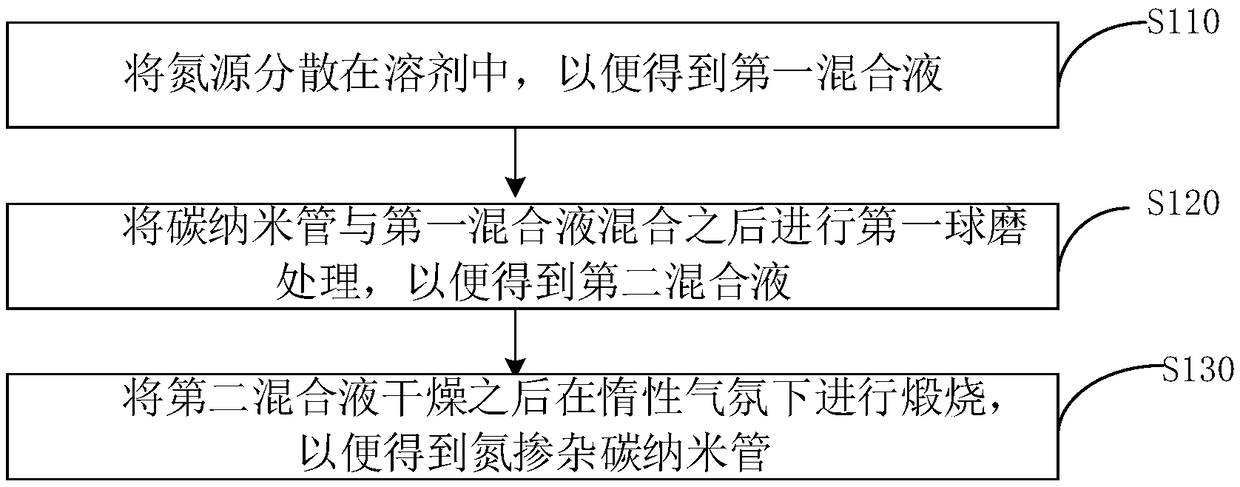

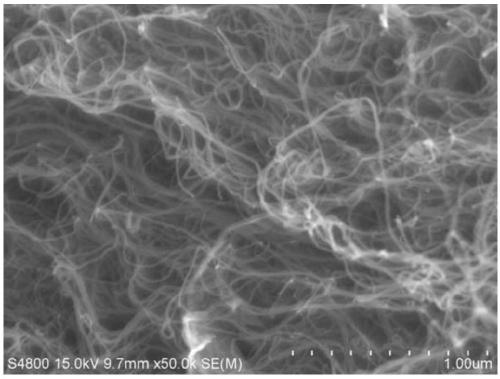

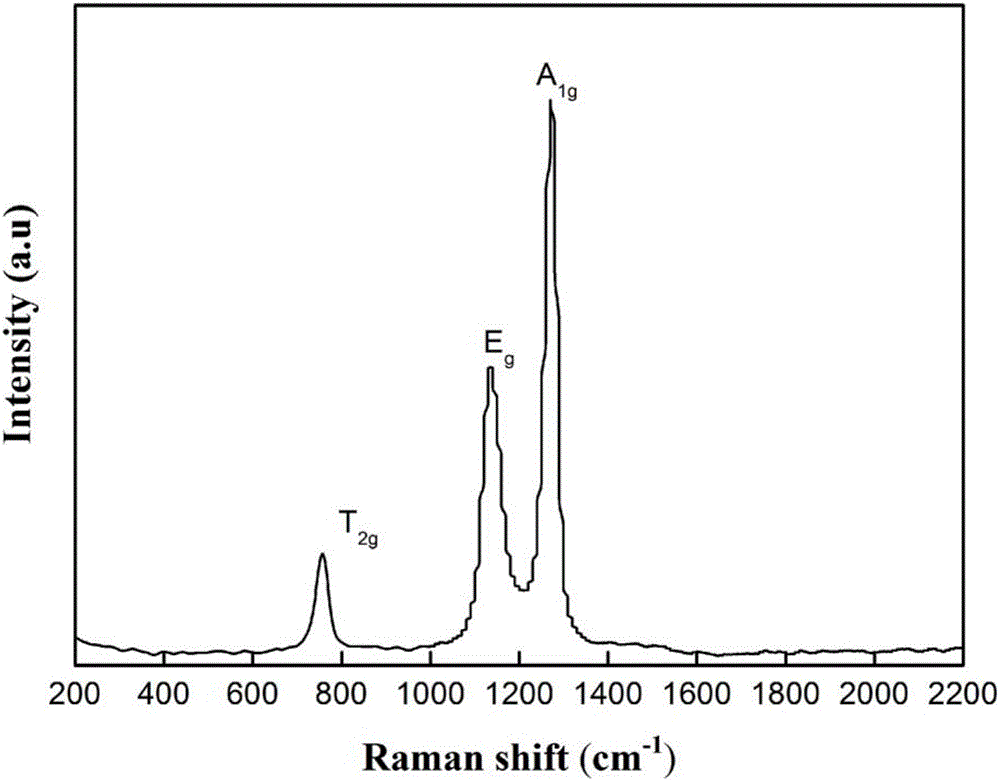

Conductive plastic, preparation method thereof and shell

The invention provides conductive plastic, a preparation method thereof and a shell. The conductive plastic is prepared from a resin substrate and nitrogen-doped carbon nanotubes, wherein the nitrogen-doped carbon nanotubes are dispersed in the resin substrate. As found by the inventor, the conductive plastic is simple in structure, and is easy to implement. The nitrogen-doped carbon nanotubes areuniformly dispersed in the resin substrate, so that a good conductive network is formed in the conductive plastic, and the conductive plastic has high conducting performance. Moreover, the bonding force between the nitrogen-doped carbon nanotubes and the resin substrate is high, so that the conductive plastic has a stable structure and long service life.

Owner:内蒙古信敏惠纳米科技有限公司

Preparation method of graphene modified zirconium oxide powder for oxygen sensor

ActiveCN109592711AImprove conductivityImprove mechanical propertiesMaterial analysis by electric/magnetic meansGrapheneThioureaPolyethylene glycol

The invention discloses a preparation method of graphene modified zirconium oxide powder for an oxygen sensor and belongs to he technical field of production methods of oxygen sensors. The preparationmethod comprises the following specific steps: preparing a zirconium oxychloride water solution; dissolving Y2O3 into the zirconium oxychloride water solution; adding a PEG (Polyethylene Glycol) dispersant and graphene oxide; adding thiourea and adding ammonia water; hydrolyzing at 70 DEG C for 12h to obtain slurry; adding the slurry into a mineralizing agent and carrying out hydrothermal reaction; filtering and washing slurry subjected to the hydrothermal reaction; drying and calcining, and crushing through a vibration mill until the granularity is smaller than 200 meshes; adding a triethanolamine dispersant and grinding by adopting a sand mill; and spraying and drying to obtain the graphene modified zirconium oxide powder. The preparation method disclosed by the invention has the characteristics of low energy consumption, small agglomeration, small grain diameter, uniform granularity distribution, high powder activity and the like and is suitable for industrial batch production. Thegraphene modified zirconium oxide powder prepared by the method can be used for manufacturing a high-end oxygen sensor and a product has high electrical conductivity and good mechanical performance.

Owner:SANXIANG ADVANCED MATERIALS

Thermal-shock-resistant ultrahigh-temperature ceramic and preparation method thereof

The invention relates to thermal-shock-resistant YbB6 ultrahigh-temperature ceramic and a preparation method thereof and belongs to the field of ultrahigh-temperature ceramic. The thermal-shock-resistant YbB6 ultrahigh-temperature ceramic has the advantages of high purity, high compactness, high strength, low elastic modulus, low shear modulus and high thermal shock resistance. The preparation method includes: utilizing high-temperature reaction to synthesize and prepare YbB6 ultrahigh-temperature ceramic powder; performing ball milling and high-temperature hot press sintering to prepare a compact YbB6 ultrahigh-temperature ceramic material. The method particularly includes: using Yb2O3 and B4C (or Yb2O3 and B) powder as raw materials, mixing according to different proportions, and obtaining high-purity YbB6 ultrahigh-temperature ceramic powder through high-temperature reaction of 1500-1750 DEG C; subjecting the YbB6 ultrahigh-temperature ceramic powder to mechanical ball milling, dry press forming and high-temperature hot press sintering at 1850-2000 DEG C to obtain compact YbB6 ultrahigh-temperature ceramic having high purity, high compactness, high strength, low elastic modulus, low shear modulus and high thermal shock resistance. The preparation method of the YbB6 ultrahigh-temperature ceramic is simple in process and needless of adding of forming auxiliary and second sintering auxiliary.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Preparation method for nuclear grade concentrated 10B zirconium diboride powder and target

The invention discloses a preparation method for nuclear grade concentrated 10B zirconium diboride powder and a target and mainly solves the problem that in the ZrB2 powder preparation process in the prior art, the raw material concentrated 10B BC4 is expensive, great in boron loss rate and great in hot-pressing and sintering difficulty for manufacturing the target. The preparation method comprises: (1) by taking nuclear grade hafnium-free zirconyl nitrate as a zirconium source and concentrated 10B-enriching boric acid as a boron source, preparing a gel by using a sol-gel method, and heating, drying and grinding the gel into powder to prepare a precusor; and (2) by adopting argon as a protective atmosphere, and synthesizing the precusor at a high pressure by using a carbon heat reduction method to obtain the 10B-enriching zirconium diboride ultrafine powder, wherein the elemental abundance of 10B in the boric acid in the step (1) is 30-70%. The invention further discloses a method for preparing nuclear grade ZrB2 target by using the concentrated 10B zirconium diboride powder. The method disclosed by the invention has the advantages of being low in cost of raw materials, effectively reducing the boron loss rate and being simple in process and suitable for preparing the nuclear grade ZrB2 target and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A kind of preparation method of superfine high-activity low-sodium α-alumina powder

The invention discloses a preparation method of superfine low-sodium alpha-alumina powder with high activity. Industrial aluminum hydroxide is taken as a raw material; alkali is removed and adsorbed by adding an acid; a compound mineralizer is added to calcine; the superfine low-sodium alpha-alumina powder with high activity, of which the mean grain size D50 is 0.2-1.0micron, is obtained by combining dry ball milling with wet ball milling; the sodium content is 0.01%-0.05%; and the content of the alpha phase is 97%-99%. The problems that the alpha-alumina is high in sodium content, uneven in grain size, poor in sintering activity and the like are solved, special requirements of high-performance ceramic, grinding and polishing materials and the like are met, and the method has the advantages of being simple in process, environmentally friendly, low in cost and the like, and is suitable for large-scale production.

Owner:广西朗琨科技有限公司

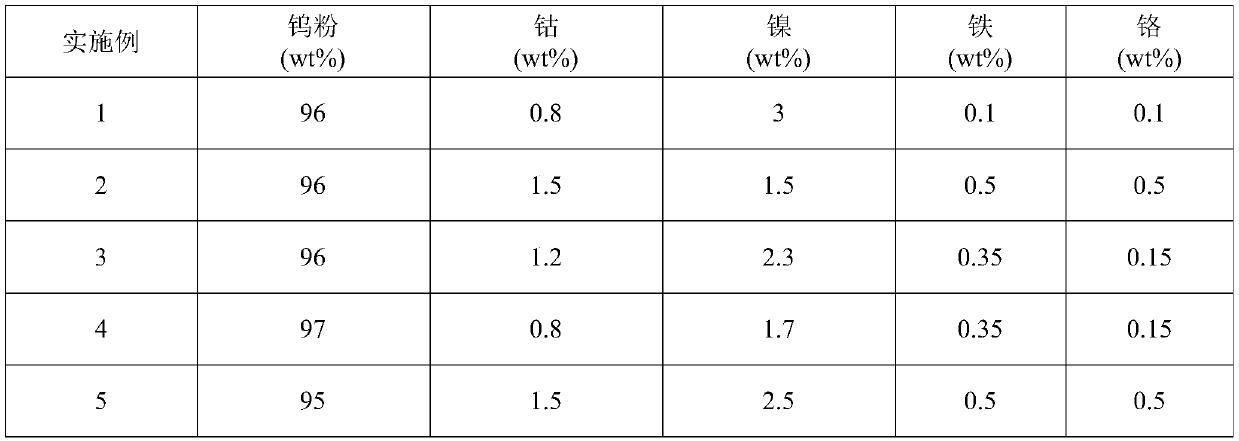

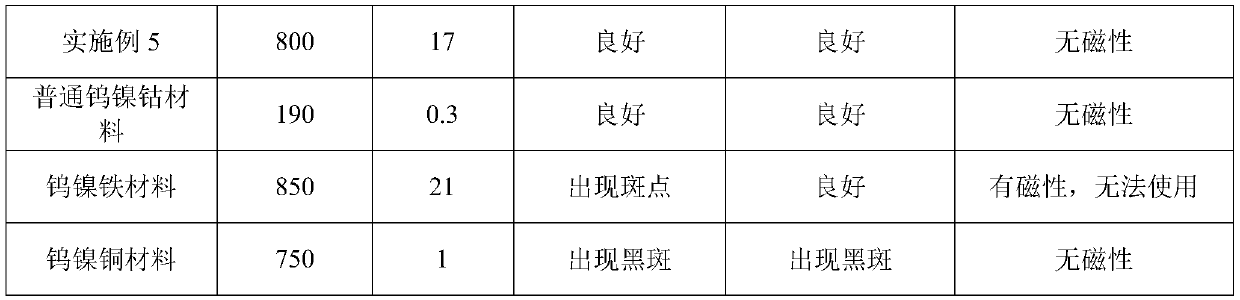

Novel tungsten-nickel-cobalt material and preparation method thereof

The invention relates to the field of alloy materials, in particular to a novel tungsten-nickel-cobalt material and a preparation method thereof. The novel tungsten-nickel-cobalt material is preparedfrom the following raw materials in percentage by weight: 95-97% of tungsten powder, 0.8-1.5% of cobalt, 1.5-3.0% of nickel, 0.1-0.5% of iron and 0-0.5% of chromium. The preparation method includes the steps of blending, wet grinding, drying, glue mixing and drying, granulating, molding, and glue discharging and sintering. The prepared novel tungsten-nickel-cobalt material has extremely high strength and toughness, and is far better than existing tungsten-nickel-cobalt materials; good high-temperature and high humidity resistance and salt mist corrosion resistance are achieved, and generationof magnetism can be avoided; compared with traditional processes, the preparation method has the characteristics of higher preparation efficiency and better preparation effect; and use of an electroplating process is avoided, and more environmental protection is achieved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Nano ceramic-aluminum composite powder and preparation method and device thereof

The invention provides nano ceramic-aluminum composite powder and a preparation method and device thereof. The nano ceramic-aluminum composite powder is prepared from following components by volume including 1-10 parts of aluminum alloy powder and 90-99 parts of ceramic nano particles, wherein the aluminum alloy powder is pure aluminum or 6061 aluminum alloy or 2024 aluminum alloy or 7075 aluminum alloy, the ceramic nano particles are silicon carbide or aluminum oxide or boron nitride or titanium diboride with the grain diameter of 1-50 nm, and the product is obtained after drying, ball-milling and passivating are completed. The product is high in added value, the raw materials are cheap, the preparation method is efficient, the equipment is simple, the grain diameter and the structure of the final product can be adjusted and controlled by adjusting and controlling the ball-milling time and the proportions of the raw materials, and industrial large-scale production is facilitated.

Owner:WUHAN NANRUI ELECTRIC POWER ENG TECH EQUIP +4

A kind of preparation method of tin-based silver graphene lead-free composite solder

InactiveCN105171277BImprove distribution uniformityUniform compositionTransportation and packagingWelding/cutting media/materialsRoom temperatureComposite solder

The invention discloses a preparation method of tin-based silver graphene lead-free composite solder, which comprises mixing a certain amount of graphene with sodium lauryl sulfate, then adding a certain amount of dimethylformamide, and ultrasonically treating it for 2 hour, then add a certain amount of silver nitrate to the mixed solution, continue ultrasonic treatment, and finally get homemade silver graphene nanosheets; weigh the required solder matrix powder according to different silver graphene mass fractions, pour it into a ball mill jar and mill for 5 hours , put the powder into a stainless steel mold after drying, put it under a hydraulic press and press it at a pressure of 500Mpa, then put the cold-pressed cylinder into a high-vacuum tubular resistance furnace for vacuum sintering at 175°C for 2 hours, and cool to room temperature After that, it is punched into a cylinder under the hydraulic press. The present invention selects the graphene modified by Ag particles as the reinforcement material to improve the load transfer between the graphene modified by nano-silver and the Sn matrix, so as to achieve a better strengthening effect.

Owner:TIANJIN UNIV

A kind of cermet alloy powder block for overlay welding

ActiveCN109112381BImprove craftsmanshipEasy to use and flexibleTransportation and packagingWelding/cutting media/materialsBorideCrack resistance

The invention provides a ternary boride cermet Mo for overlay welding 2 FeB 2 The alloy powder block is composed of the following raw materials in parts by weight: 20-38 parts of ferroboron, 32-50 parts of molybdenum powder, 7-24 parts of iron powder, 2-4 parts of nanometer titanium carbide powder, and 2-4 parts of yttrium oxide powder. Using iron boron, molybdenum powder and iron powder as raw materials to synthesize Mo by metallurgical reaction 2 FeB 2 When adding an appropriate amount of nano-titanium carbide powder, in the welding metallurgy process, because the melting point of nano-titanium carbide powder is as high as 3140 ° C, it can be used as dispersed Mo in liquid metal 2 FeB 2 Non-spontaneous nucleation core, so that the formed ternary boride Mo 2 FeB 2 Dispersed distribution, so the surfacing metal has excellent high temperature hardness, wear resistance, good toughness and crack resistance. The steps are simple, the operation is convenient and the practicability is strong.

Owner:SHANDONG UNIV

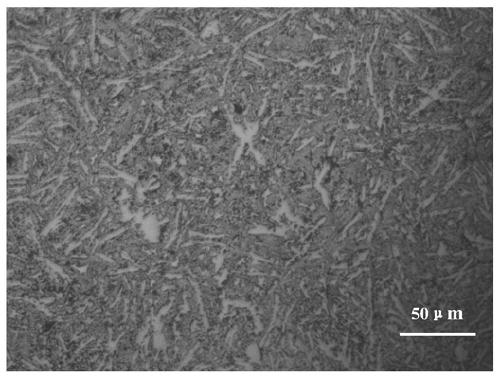

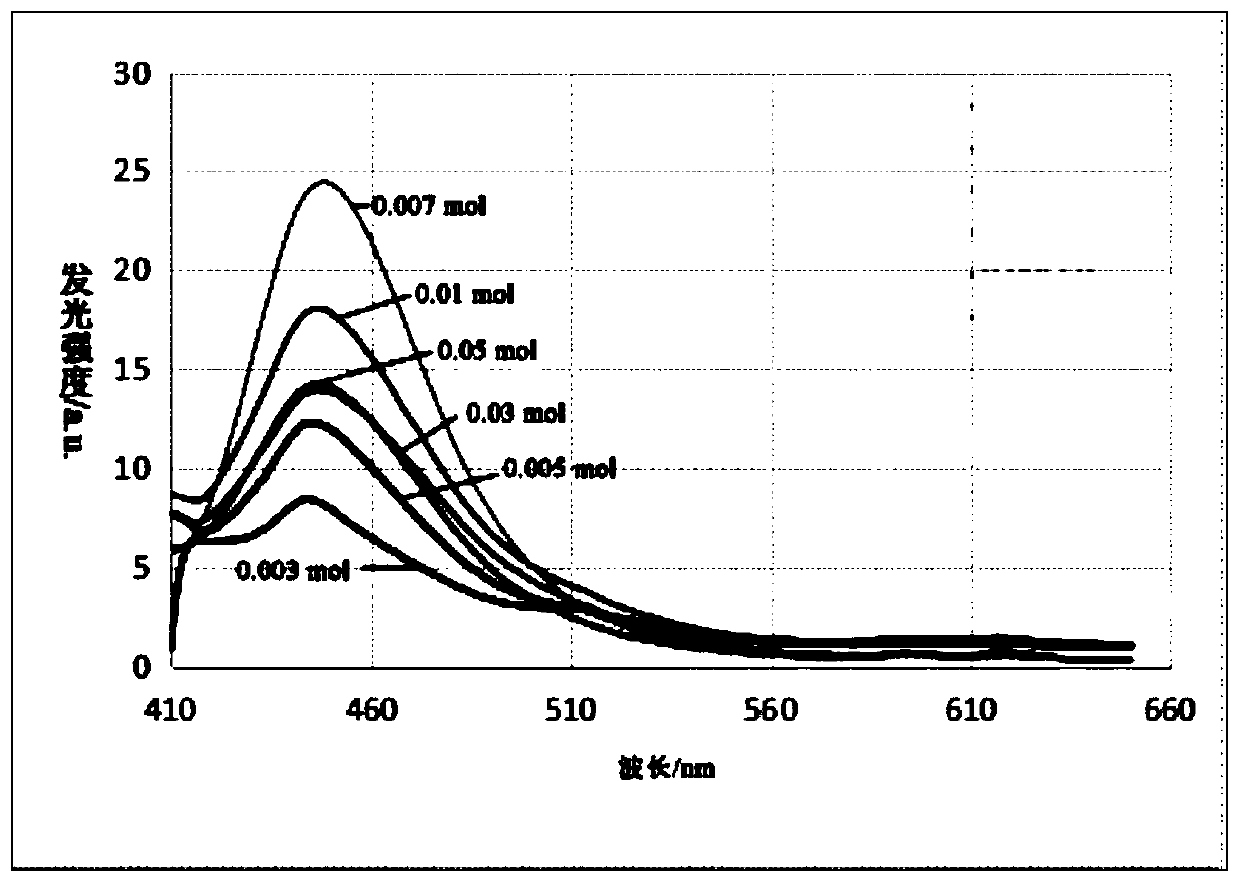

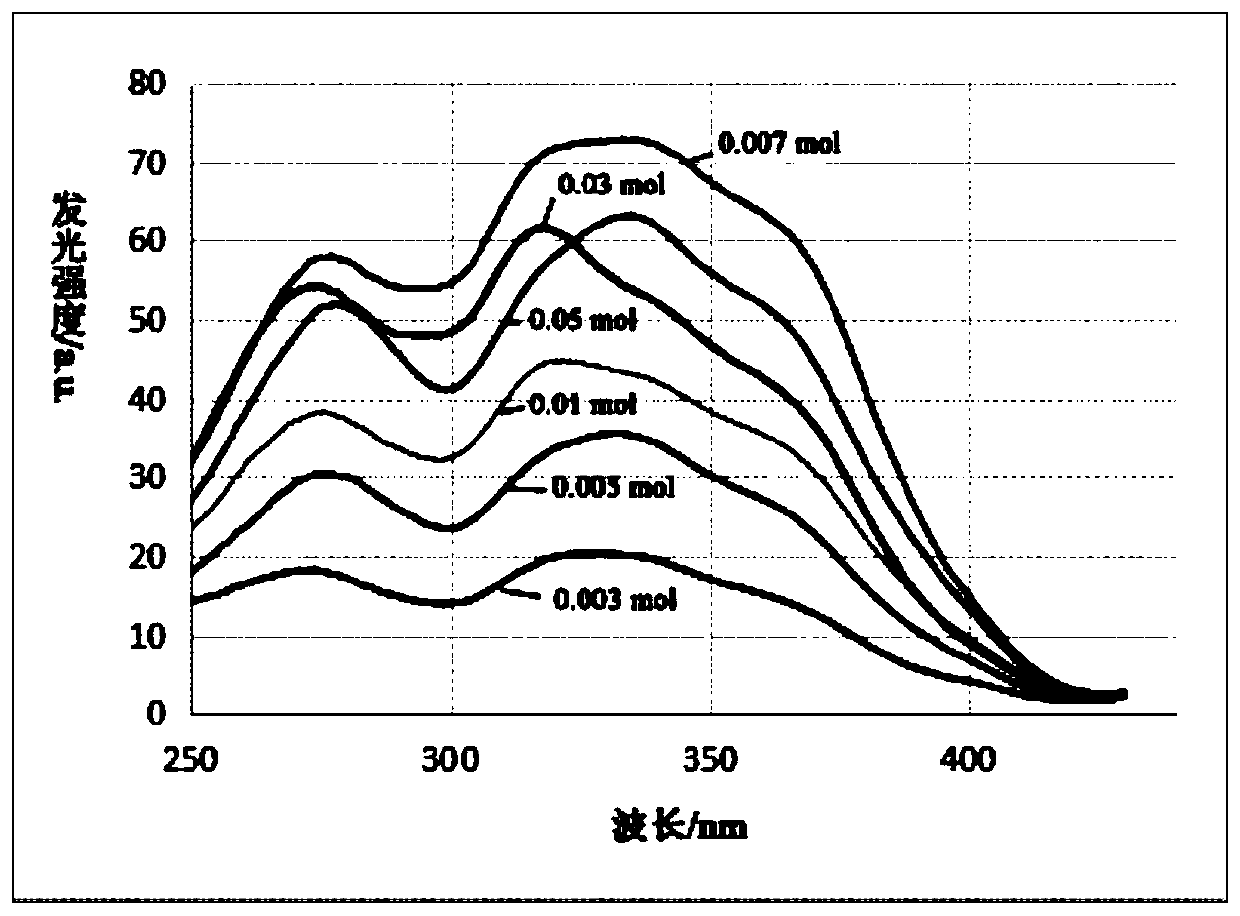

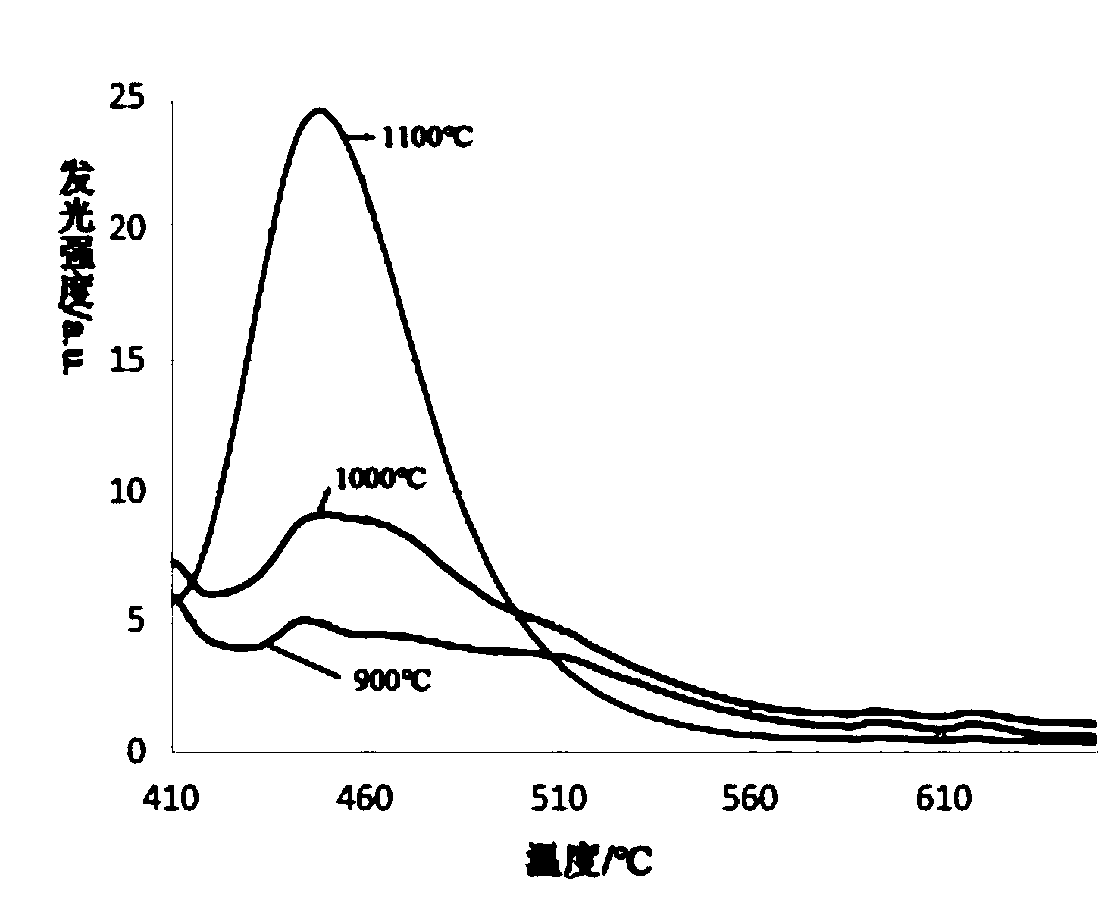

Blue phosphor as well as preparation method and application thereof

PendingCN110330967AWell mixedHigh powder activityLuminescent compositionsSemiconductor devicesChemistrySol-gel

The invention relates to a blue phosphor as well as a preparation method and application thereof, and belongs to the technical field of phosphors for light-emitting diodes (LEDs) in the fields of illumination and display. According to the preparation method, Eu<2+> is used as an activator to prepare SrAl2SiO6:nEu<2+>(n=0.006-0.008) blue phosphor by a sol-gel method. By adopting the preparation method provided by the invention, the raw materials can be uniformly mixed, and the powder activity is high, thereby greatly reducing the sintering temperature in a later stage, saving energy, and facilitating the reaction; a formed sample is good in purity, and can be matched with an ultraviolet type and / or a near ultraviolet type LED chip; the preparation process is simple, and the production process is easy to operate.

Owner:WUYI UNIV

Cold field plasma discharge assisted high energy ball milling powder device

The invention provides an application method of cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the cold field plasma discharge assisted high energy ball milling method. The method comprises the following steps: utilizing dielectric barrier discharge to generate plasmas, introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball-milling tank, on one hand, requiring a solid insulating medium on the outer layer of the electrode bar to simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, requiring the high-speed vibrating ball milling device to uniformly process the powder. The method is based on the ordinary ball milling technology; the processing efficiency and the effect of the ball mill can be greatly improved by the following steps: under a non-heat-balance discharge condition of the pressure that the discharge space pressure is set to be about 102-106 Pa, introducing the discharge plasmas to input another effective energy to the processed powder, promoting the powder to be processed to be subjected to combined action of the mechanical stress effect and the heat effect of the external electric field, and further accelerating refining of the powder and promoting the alloying progress.

Owner:SOUTH CHINA UNIV OF TECH

A kind of electric pulse preparation method of dissolution type perovskite

ActiveCN107555493BGood chemical uniformityLow reaction temperatureCell electrodesNickel compoundsFuel cellsElectrical impulse

The invention discloses an electric pulse preparation method for dissolved perovskite. The method comprises the following steps: preparing ABO3 perovskite type oxide powder by using a sol-gel method,putting the perovskite type oxide powder into a treatment ceramic casing, connecting two ends of the treatment ceramic casing with pulse electrodes, and performing electric pulse treatment on the ABO3perovskite type oxide powder prepared in the step (1), thereby obtaining a dissolved perovskite oxide, wherein the pulse voltage is 400-700V, the pulse frequency is 1-5Hz, and the pulse treatment time is 30-300 seconds. The method has the advantages that the method is simple, the dissolved perovskite can be prepared safely and efficiently, and the electrochemical properties of the dissolved perovskite as a solid oxide fuel battery anode material are improved.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com