Novel tungsten-nickel-cobalt material and preparation method thereof

A new type of tungsten-nickel technology, applied in the field of new tungsten-nickel-cobalt materials and their preparation, can solve the problems of limited corrosion resistance and poor mechanical properties of tungsten-nickel-cobalt series materials, so as to improve efficiency, avoid material oxidation problems, reduce Effect of subsequent sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

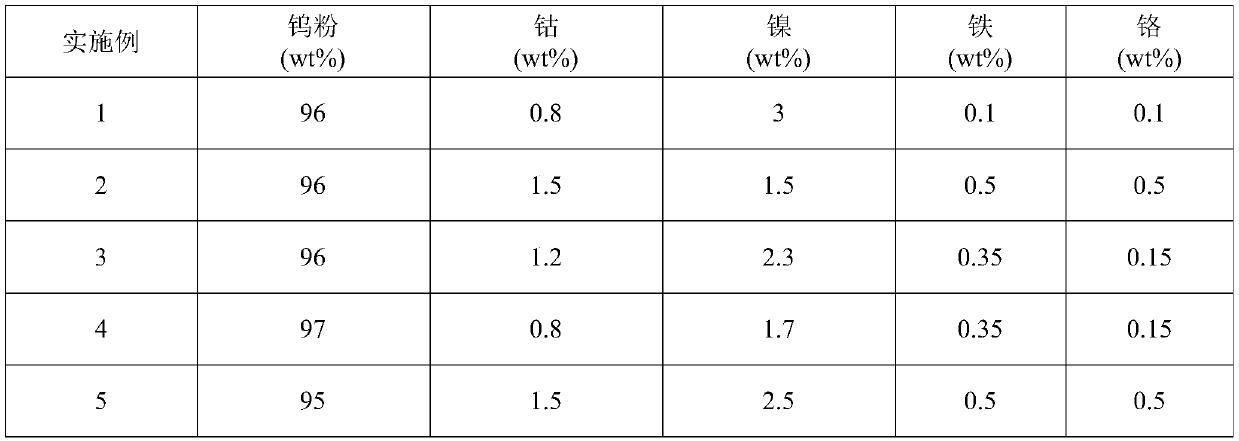

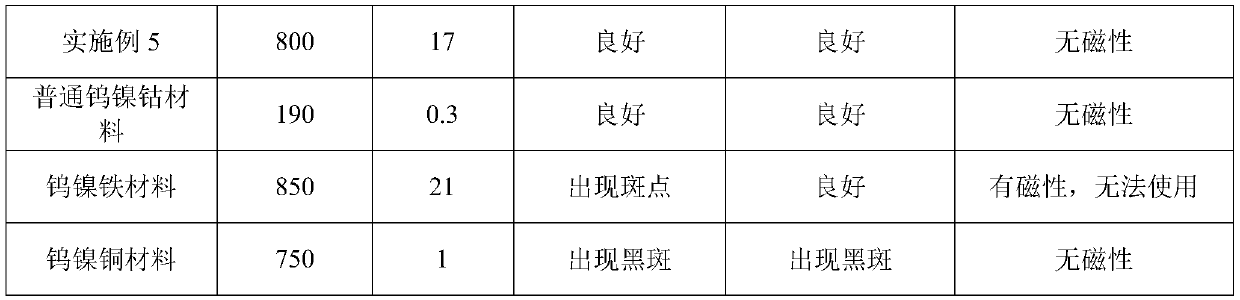

Embodiment 1~5

[0041] A novel tungsten-nickel-cobalt material, the novel tungsten-nickel-cobalt material is prepared by the following process:

[0042] 1) Batching: weighing the raw materials according to the proportion;

[0043] 2) Wet milling: 30 kg of raw materials weighed, 60 kg of stainless steel balls and 6 kg of ethanol were mixed and placed in a 40L ball mill for milling for 6 hours at a speed of 40 r / min. After milling, the milling medium was separated and removed to obtain a mixture;

[0044] 3) Drying: place the mixture at 70°C and vacuum degree -0.06MPa for 2 hours in vacuum;

[0045] 4) Glue blending and drying: use PVA forming agent to blend the dried mixture under the condition of heating to 90°C, and continue to dry at 90°C after the stirring and blending is completed;

[0046] 5) Granulation: After the drying is completed, wipe the sieve on the sieve to granulate. After the granulation is completed, dry and pass through 80 mesh, 100 mesh and 120 mesh sieves for use;

[004...

Embodiment 6~10

[0071] A novel tungsten-nickel-cobalt material, the novel tungsten-nickel-cobalt material is prepared by the following process:

[0072] 1) batching: according to the proportioning described in embodiment 3, raw material is weighed batching;

[0073] 2) Wet milling: Mix the weighed raw materials, stainless steel balls and absolute ethanol and place them in a ball mill for ball milling. After ball milling, the ball milling medium is separated and removed to obtain the mixture;

[0074] 3) drying: carry out vacuum drying to mixture;

[0075] 4) Adhesive drying: use PVA molding agent to carry out adhesive drying treatment on the dried mixture under heating conditions;

[0076] 5) Granulation: After the drying is completed, wipe the sieve on the sieve to granulate. After the granulation is completed, dry and classify and sieve for later use;

[0077] 6) Molding: According to the size requirements of the product, the mold is used for compression molding to obtain the embryo;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com