Conductive plastic, preparation method thereof and shell

A conductive plastic and shell technology, applied in the field of conductive materials, can solve the problems of difficult resin matrix compatibility, easy agglomeration, and large carbon nanotubes, and achieve the effects of fine grain size, low cost, and improved powder activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

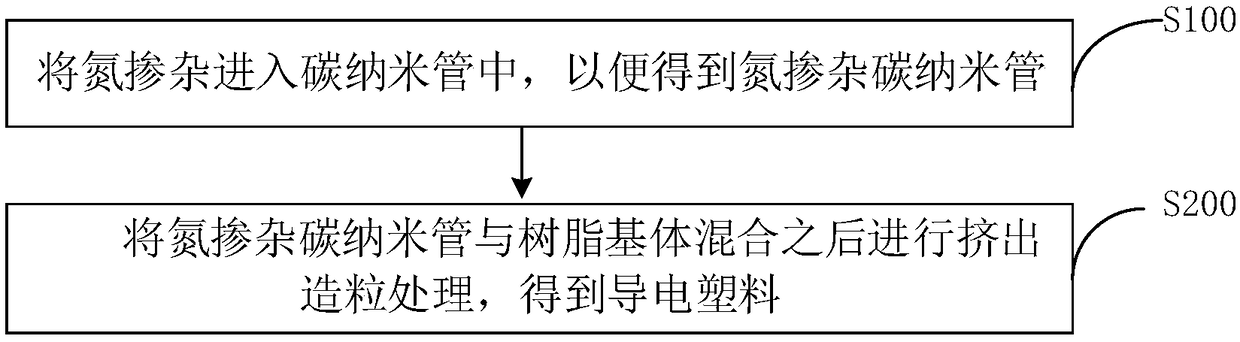

Method used

Image

Examples

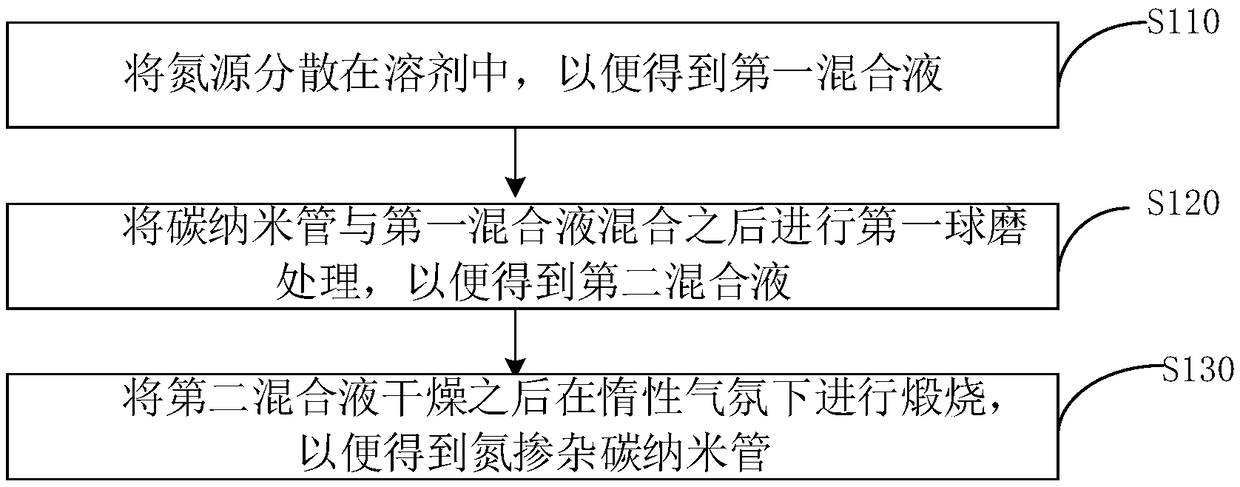

Embodiment 1

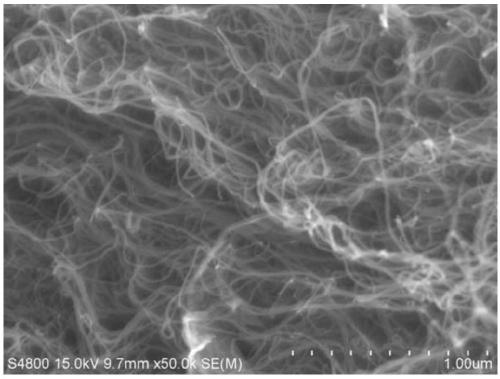

[0067] Add 2.6 g of melamine and 100 g of formaldehyde in a beaker, ultrasonically disperse for 30 min, then add 6.0 g of multi-wall wound carbon nanotubes that have been pre-milled (ball milling speed 400 rpm, time 4 h), stir well and pour into a high energy ball mill to continue high energy Ball mill (ball milling speed: 400rpm) for 24h, and then dry. The dried mixture was placed in a tube furnace under N 2 Carry out calcination at 600° C. for 1 h under the atmosphere, wash the product after natural cooling with 2 mol / L hydrochloric acid solution once, wash twice with deionized water, suction filter and dry to obtain nitrogen-doped carbon nanotubes. Nitrogen-doped carbon nanotubes and high-impact polystyrene resin particles are configured and mixed (wherein, based on the total mass of nitrogen-doped carbon nanotubes and high-impact polystyrene resin particles, the content of nitrogen-doped carbon nanotubes 3wt%), then the mixture is sent into parallel twin-screw extrusion g...

Embodiment 2

[0069] Add 3.72g of urea and 160g of formaldehyde in the beaker, ultrasonically disperse for 40min, then add 8.6g of pre-milled (ball milling speed 400rpm, time 4h) multi-wall winding carbon nanotubes, stir well and pour into the high energy ball mill to continue high energy Ball milled for 24h (ball milling speed is 400rpm) and then dried. The dried mixture was placed in a tube furnace under N 2 Carry out calcination at 700°C for 2 hours under the atmosphere, wash the product after natural cooling with 2mol / L hydrochloric acid solution once, wash twice with deionized water, suction filter and dry to obtain nitrogen-doped carbon nanotubes. Nitrogen-doped carbon nanotubes and high-impact polystyrene resin particles are configured and mixed (wherein, based on the total mass of nitrogen-doped carbon nanotubes and high-impact polystyrene resin particles, the content of nitrogen-doped carbon nanotubes 3wt%), then the mixture is sent into parallel twin-screw extrusion granulator fo...

Embodiment 3

[0071] Add 3.72g of urea and 160g of formaldehyde in the beaker, ultrasonically disperse for 40min, then add 8.6g of pre-milled (ball milling speed 400rpm, time 4h) multi-wall winding carbon nanotubes, stir well and pour into the high energy ball mill to continue high energy Ball milled for 24h (ball milling speed is 400rpm) and then dried. The dried mixture was placed in a tube furnace under N 2 Carry out calcination at 700°C for 2 hours under the atmosphere, wash the product after natural cooling with 2mol / L hydrochloric acid solution once, wash twice with deionized water, suction filter and dry to obtain nitrogen-doped carbon nanotubes. Nitrogen-doped carbon nanotubes are mixed with MAPE (maleic anhydride grafted polyethylene) resin particles (wherein, based on the total mass of nitrogen-doped carbon nanotubes and MAPE resin particles, the content of nitrogen-doped carbon nanotubes is 5wt% ), then the mixture is sent to a parallel twin-screw extrusion granulator for extrus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com