Thermal-shock-resistant ultrahigh-temperature ceramic and preparation method thereof

A technology of ultra-high temperature ceramics and thermal shock resistance, applied in the field of ultra-high temperature ceramics, to achieve the effect of simple process, low shear modulus and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

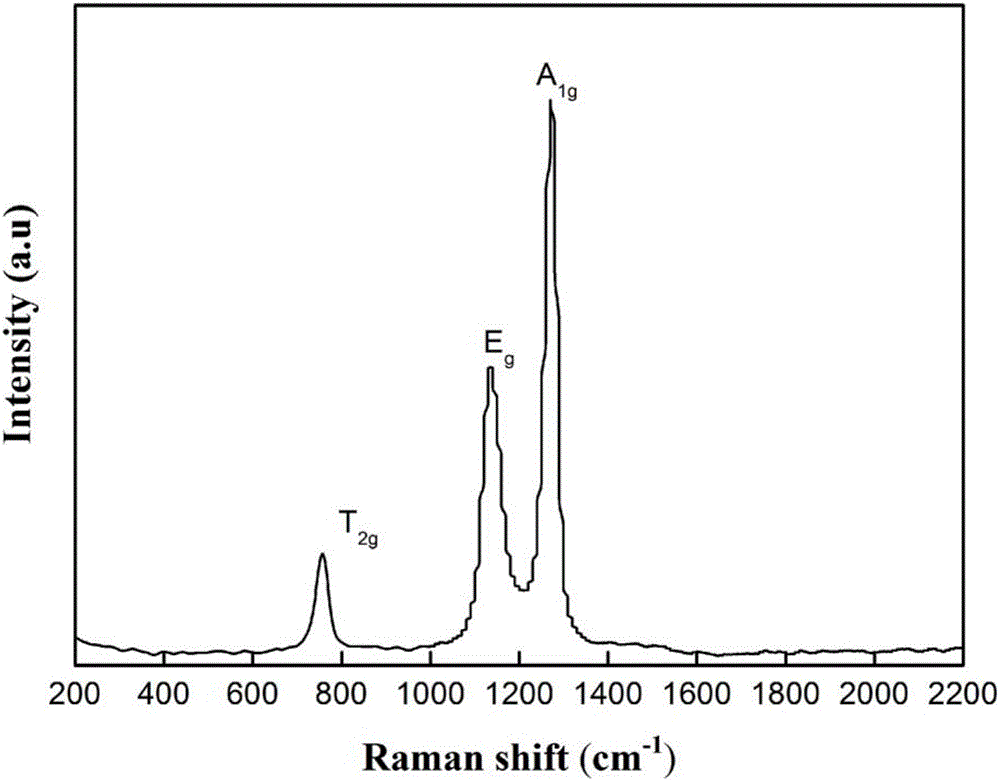

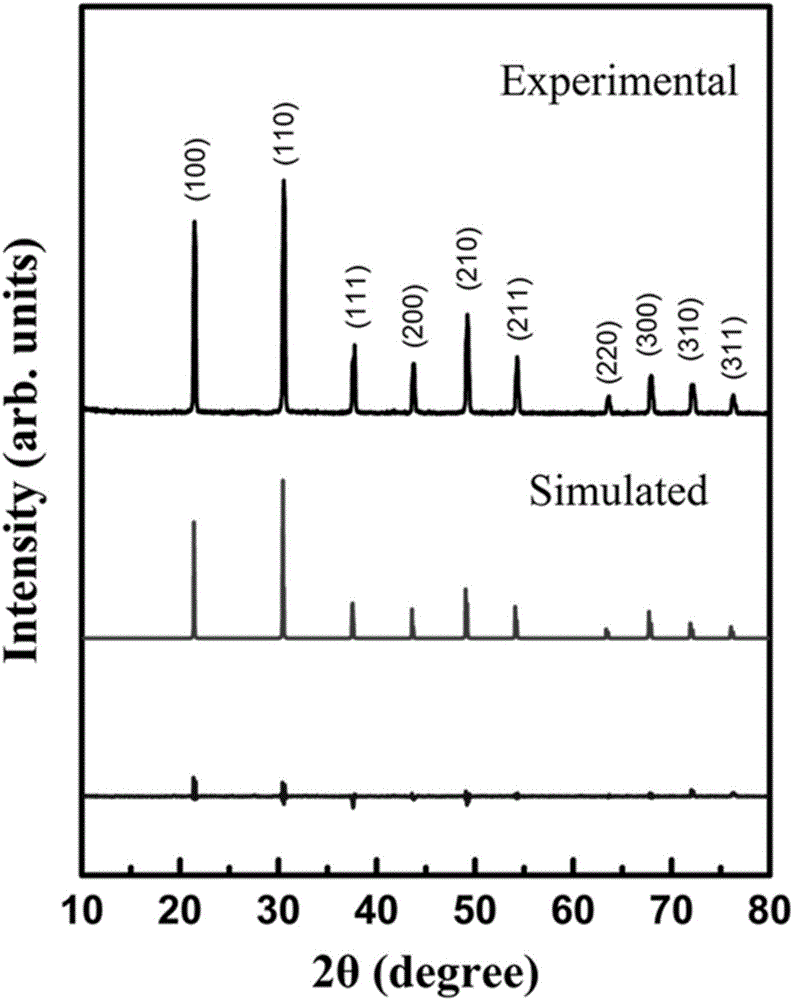

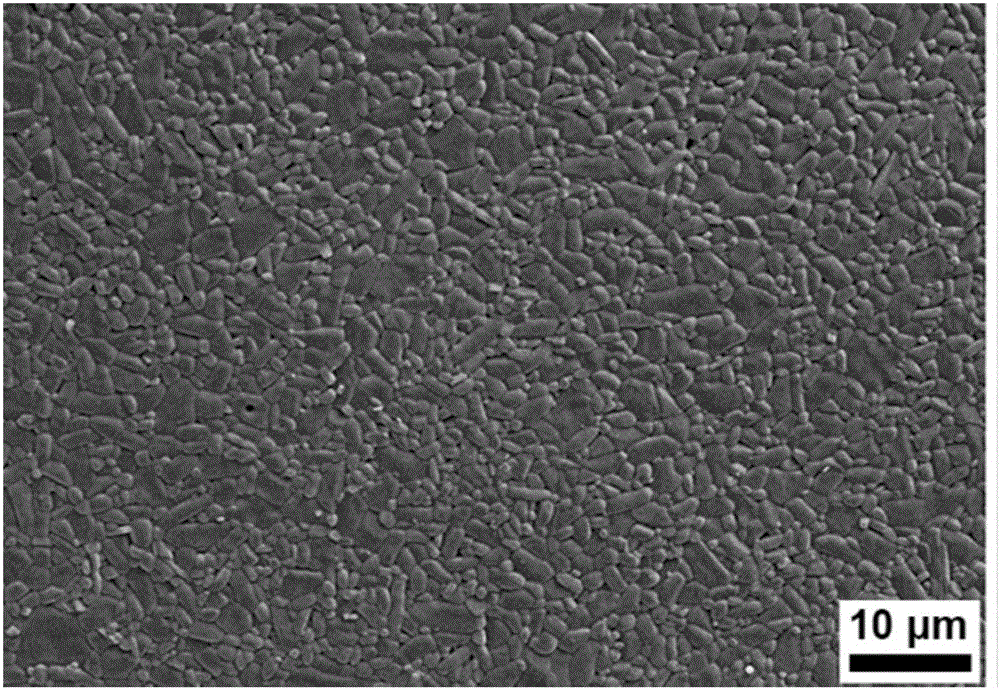

[0062] Will Yb 2 o 3Weigh the B raw material powder according to the molar ratio of Yb:B=1:6.2, add absolute ethanol, and mix with a drum mixer for 12 hours at a speed of 120 rpm, and vacuum the uniformly mixed raw materials at 25°C Dry for 48 hours to get Yb 2 o 3 Mix powder with B; Yb 2 o 3 Put the powder mixed with B into a high-temperature carbon tube furnace and heat it to 1680°C at a heating rate of 10°C / min for 1 hour to obtain YbB 6 Ultra-high temperature ceramic powder, its Raman spectrum is as follows figure 1 shown. Will YbB 6 The ultra-high temperature ceramic powder was ball-milled with WC balls at a speed of 300 rpm for 10 hours in absolute ethanol medium, and dried under vacuum at 30°C for 24 hours. The dried YbB 6 Put the ultra-high temperature ceramic powder into a graphite mold with a diameter of 50 mm, and dry-press 5 times under a cyclic loading pressure of 10 MPa, and hold the pressure for 2 minutes each time to obtain YbB 6 Ultra-high temperature...

Embodiment 2

[0064] Will Yb 2 o 3 and B 4 C The raw material powder is weighed according to the molar ratio of Yb:B=1:6.3, adding absolute ethanol, mixing with a drum mixer for 15 hours at a speed of 100 rpm, and vacuum-drying the uniformly mixed raw materials at a temperature of 28°C 30 hours to get Yb 2 o 3 and B 4 C mixed powder; Yb 2 o 3 and B 4 C mixed powder was put into a high-temperature carbon tube furnace and heated to 1600°C at a heating rate of 8°C / min for 2 hours to obtain YbB 6 Ultra-high temperature ceramic powder. Will YbB 6 The ultra-high temperature ceramic powder was milled with WC balls at a speed of 350 rpm in an anhydrous ethanol medium for 8 hours, and dried under vacuum at 28°C for 30 hours, and the dried YbB 6 Put the ultra-high temperature ceramic powder into a graphite mold with a diameter of 50 mm, and dry-press 8 times under a cyclic loading pressure of 10 MPa, and hold the pressure for 1 minute each time to obtain YbB 6 Ultra-high temperature cerami...

Embodiment 3

[0066] Will Yb 2 o 3 and B 4 C The raw material powder is weighed according to the molar ratio of Yb:B=1:6.5, adding absolute ethanol, mixing with a drum mixer for 24 hours at a speed of 100 rpm, and vacuum-drying the uniformly mixed raw materials at a temperature of 30°C 36 hours to get Yb 2 o 3 and B 4 C mixed powder; Yb 2 o 3 and B 4 C mixed powder was put into a high-temperature carbon tube furnace and heated to 1500°C at a heating rate of 15°C / min for 4 hours to obtain YbB 6 Ultra-high temperature ceramic powder. Will YbB 6 The ultra-high temperature ceramic powder was milled with WC balls in absolute ethanol medium at a speed of 400 rpm for 6 hours, and dried under vacuum at 25°C for 48 hours, and the dried YbB 6 Put the ultra-high temperature ceramic powder into a graphite mold with a diameter of 50 mm, and dry-press 3 times under a cyclic loading pressure of 15 MPa, and hold the pressure for 3 minutes each time to obtain YbB 6 Ultra-high temperature ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com