Patents

Literature

112results about How to "Good chemical uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

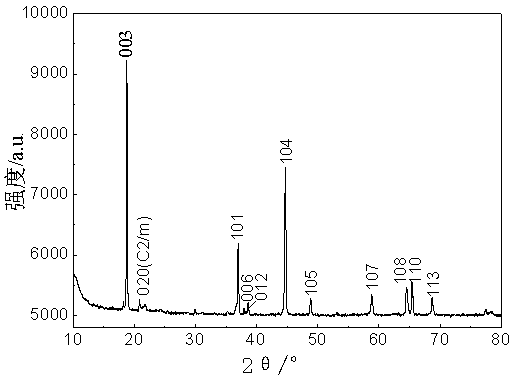

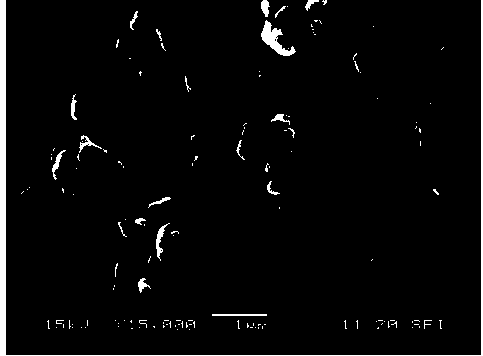

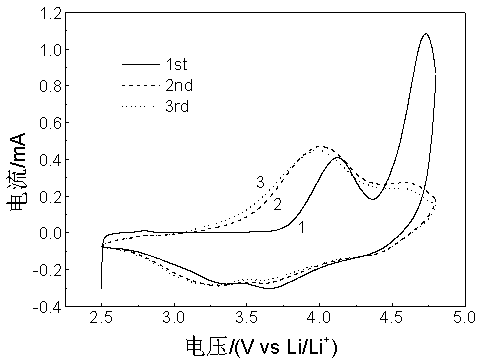

Nanometer perovskite/graphene composite material and preparation method thereof

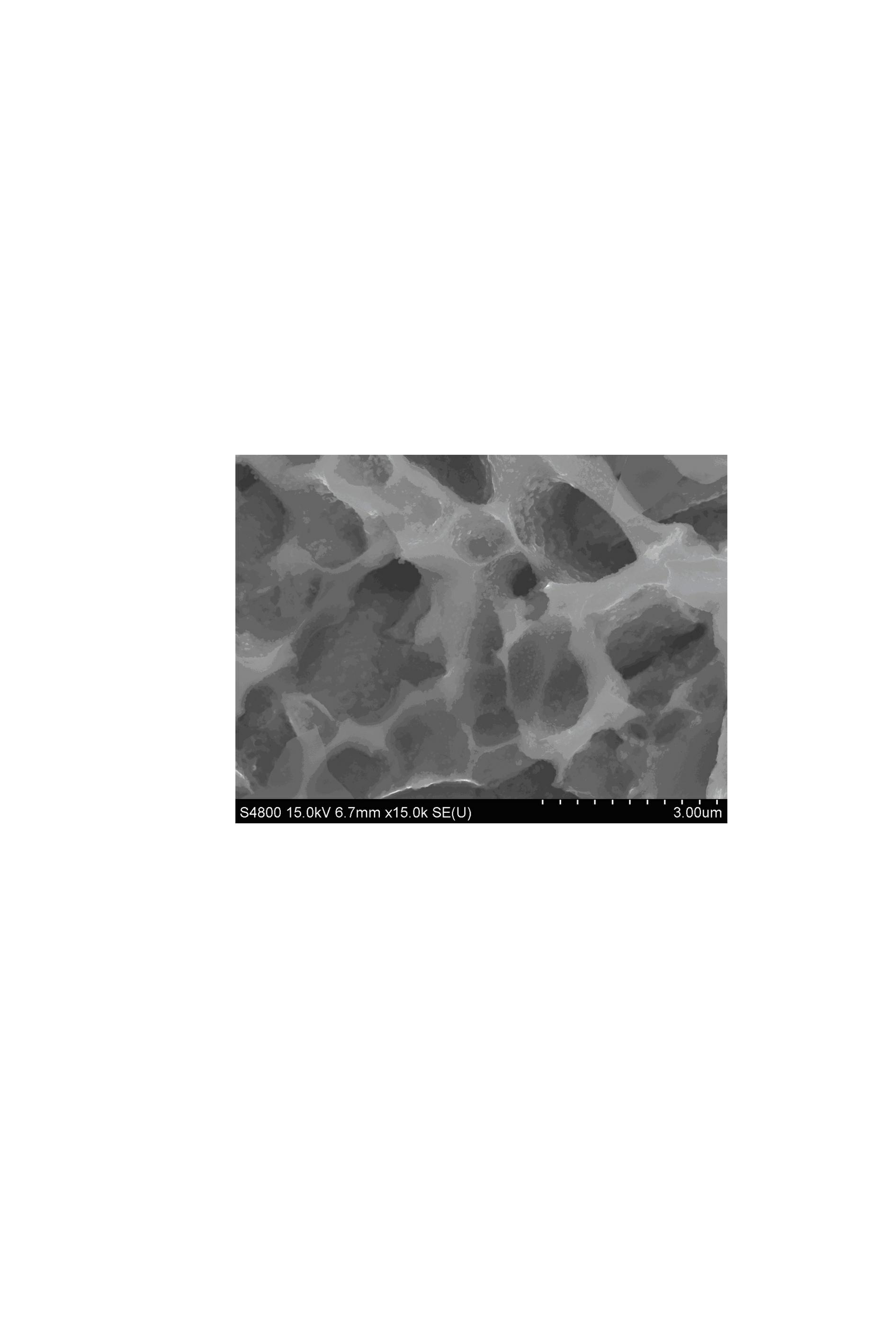

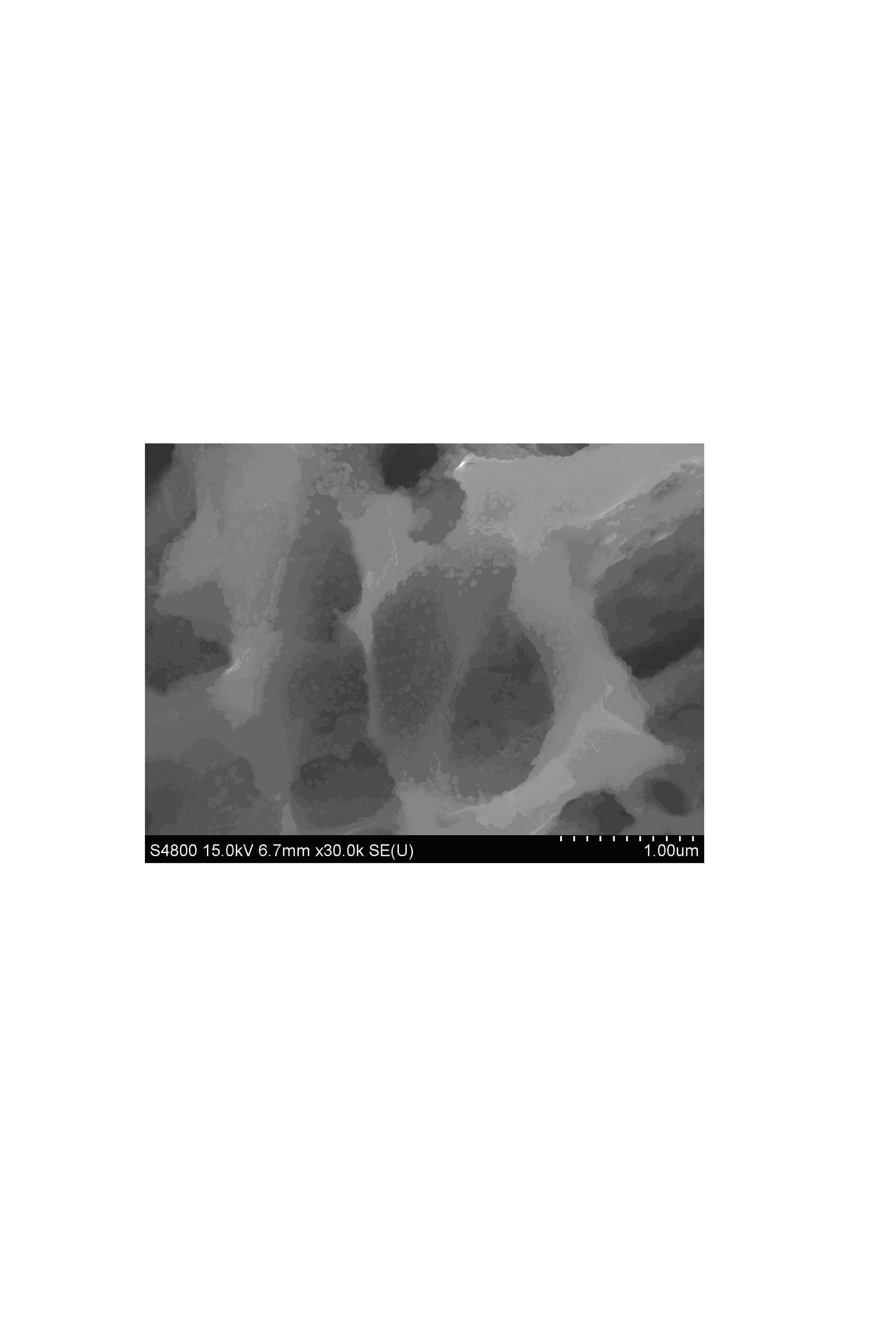

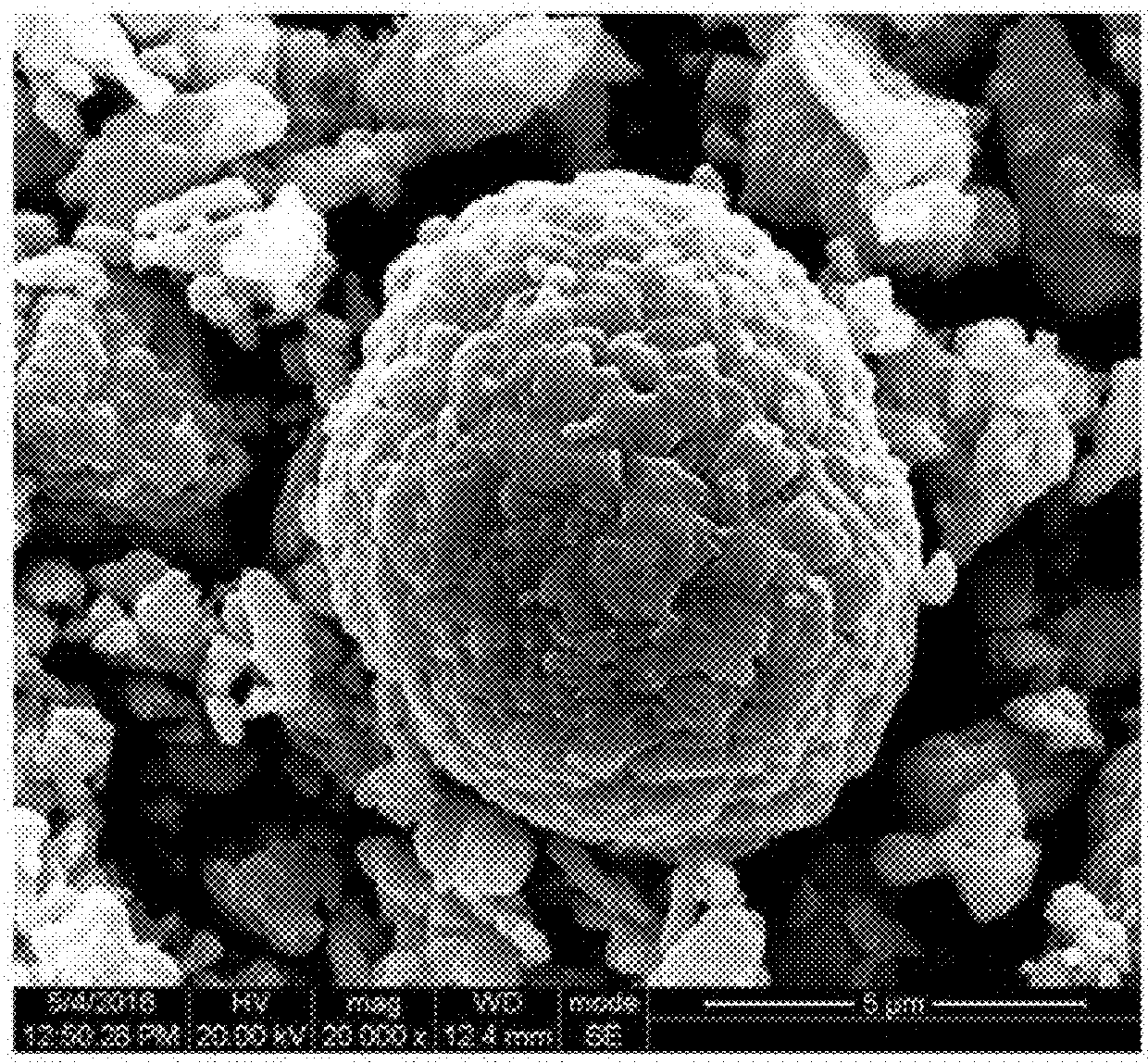

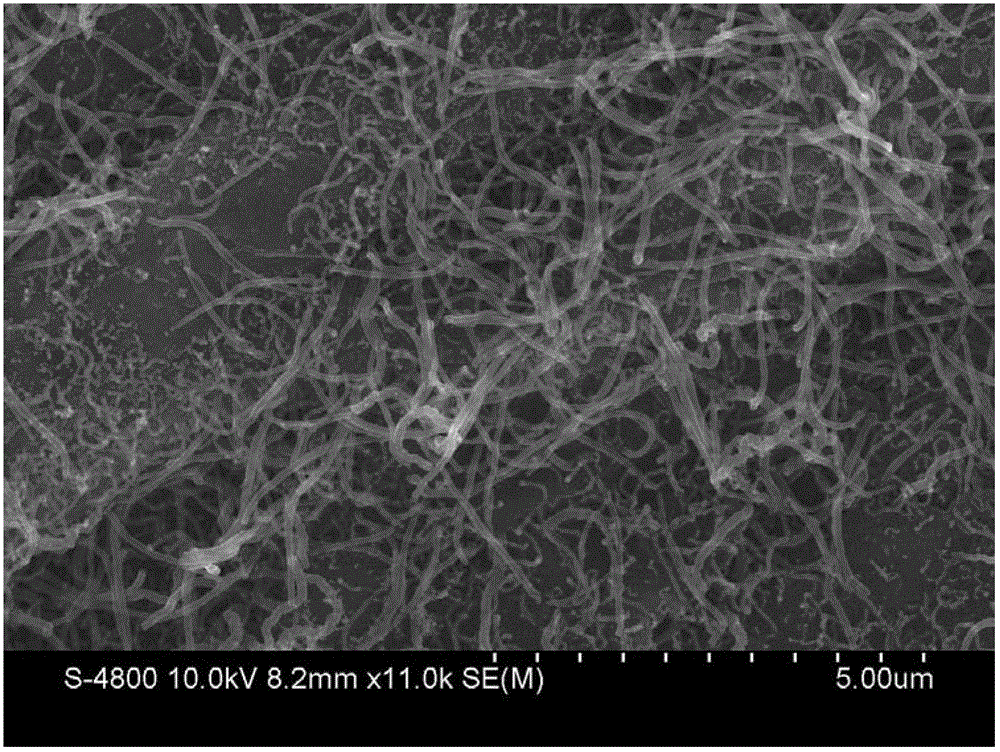

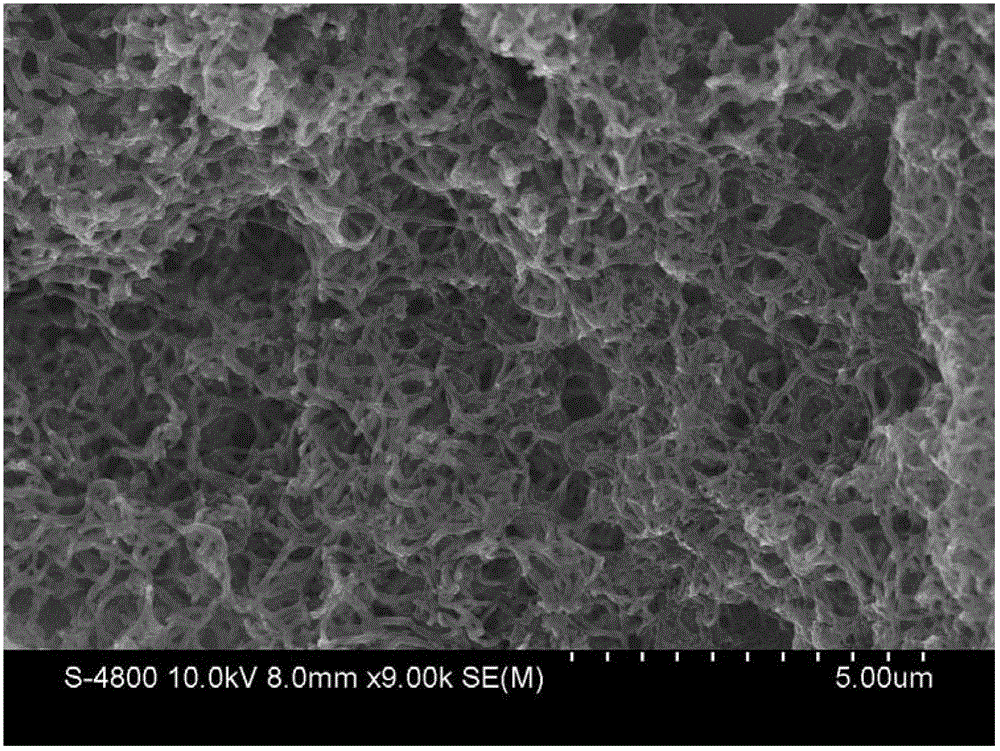

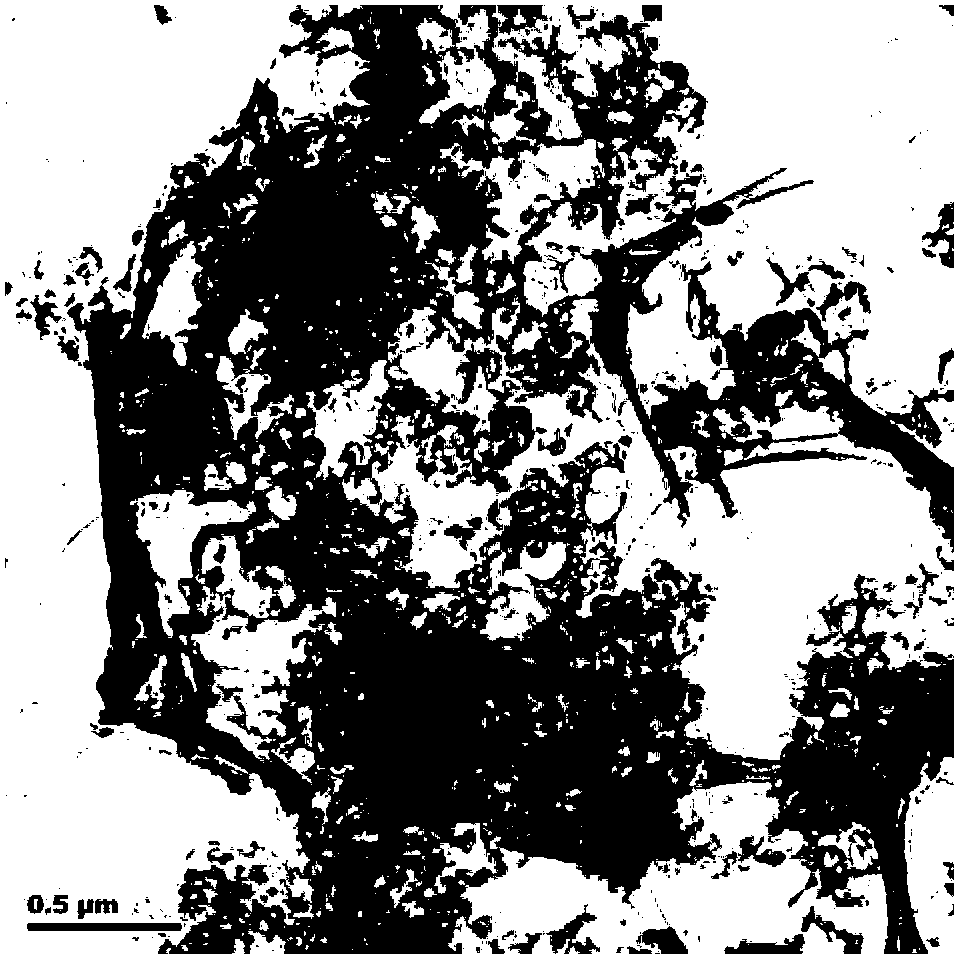

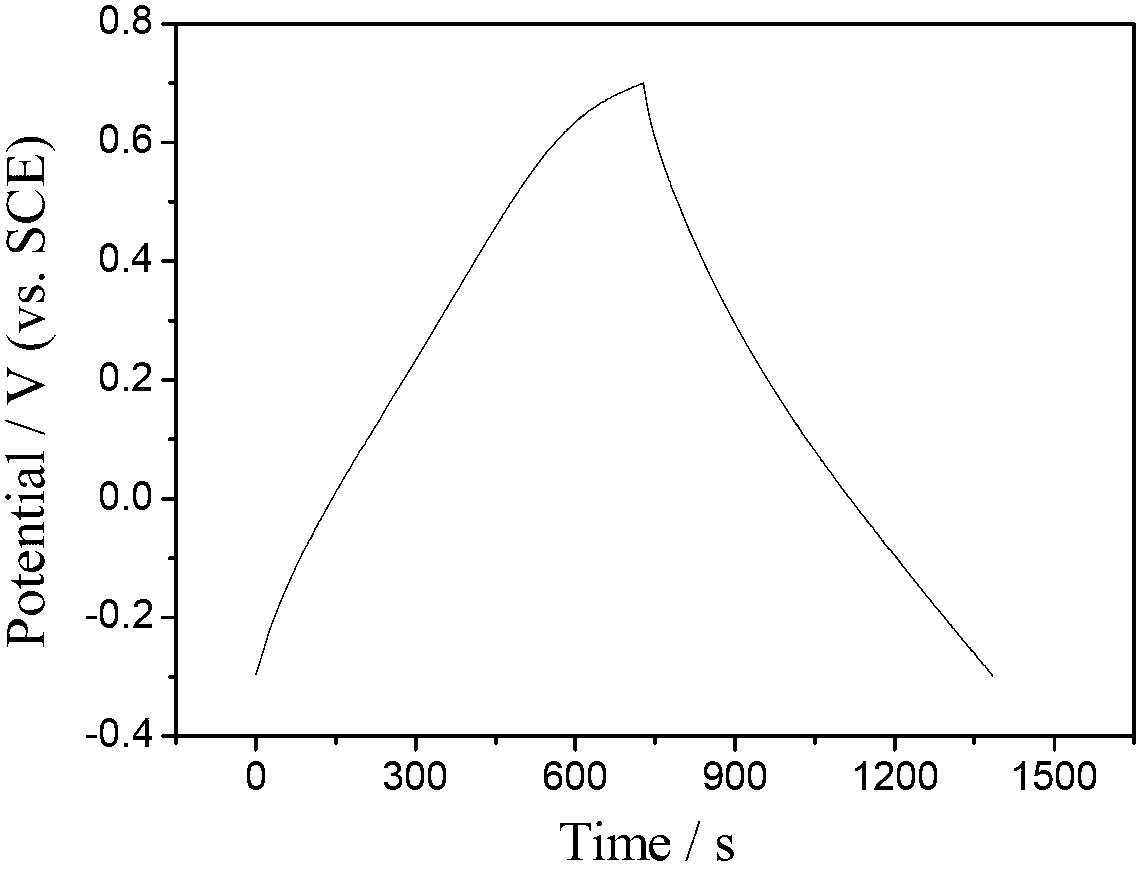

The invention relates to a nanometer perovskite / graphene composite material. The nanometer perovskite / graphene composite material is of a porous structure, the aperture of the nanometer perovskite / graphene composite material is about 0.5-1.5 microns, nanometer perovskite particles are distributed uniformly on a graphene film, and the average crystallite dimension of the composite material is about 10-20nm. A preparation method of the nanometer perovskite / graphene composite material comprises the following steps of: with graphite paper as an anode, a carbon rod as a cathode and concentrated sulfuric acid as an electrolyte, carrying out oxidation peeling to prepare a thin-layer graphene material, and then preparing graphene suspension from the thin-layer graphene material; adding nitrate and citric acid to the graphene suspension to enable the metal nitrate to be hydrolyzed to form sol, polymerizing the sol to form gel, finally drying and baking the gel to obtain the nanometer perovskite / graphene composite material. The preparation method disclosed by the invention has the advantages of simple process and low cost; and the nanometer perovskite / graphene composite material disclosed by the invention has good chemical uniformity; in addition, a reaction process is easy to control, and nanometer perovskite particles are more uniformly distributed on the graphene film and have smaller particle sizes, thus the nanometer perovskite / graphene composite material prepared by the method disclosed by the invention has excellent electro-catalysis performances and is suitable for being taken as an electro-catalysis material of a fuel cell.

Owner:YANSHAN UNIV

High-voltage ternary positive electrode material for lithium-ion battery and preparation method thereof

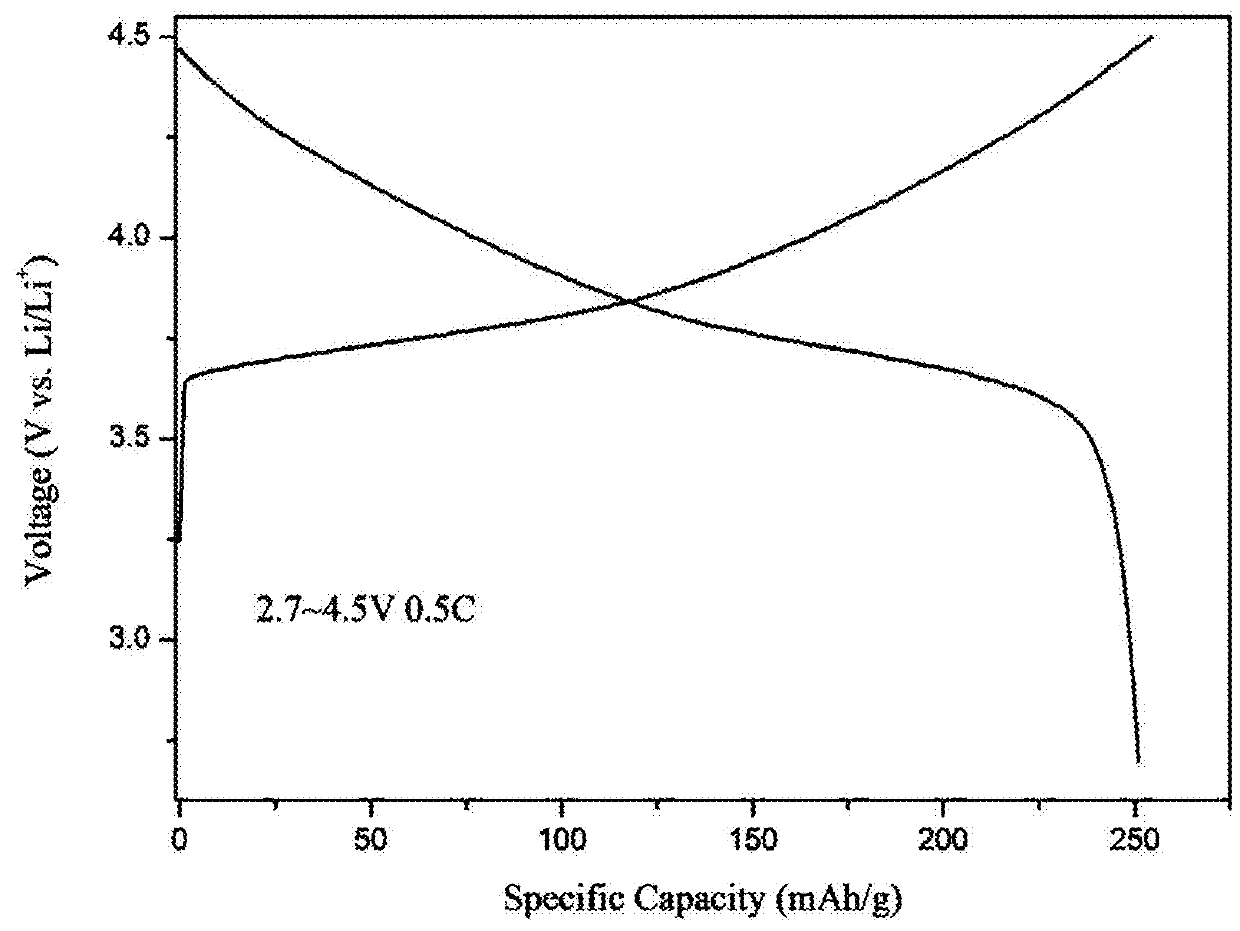

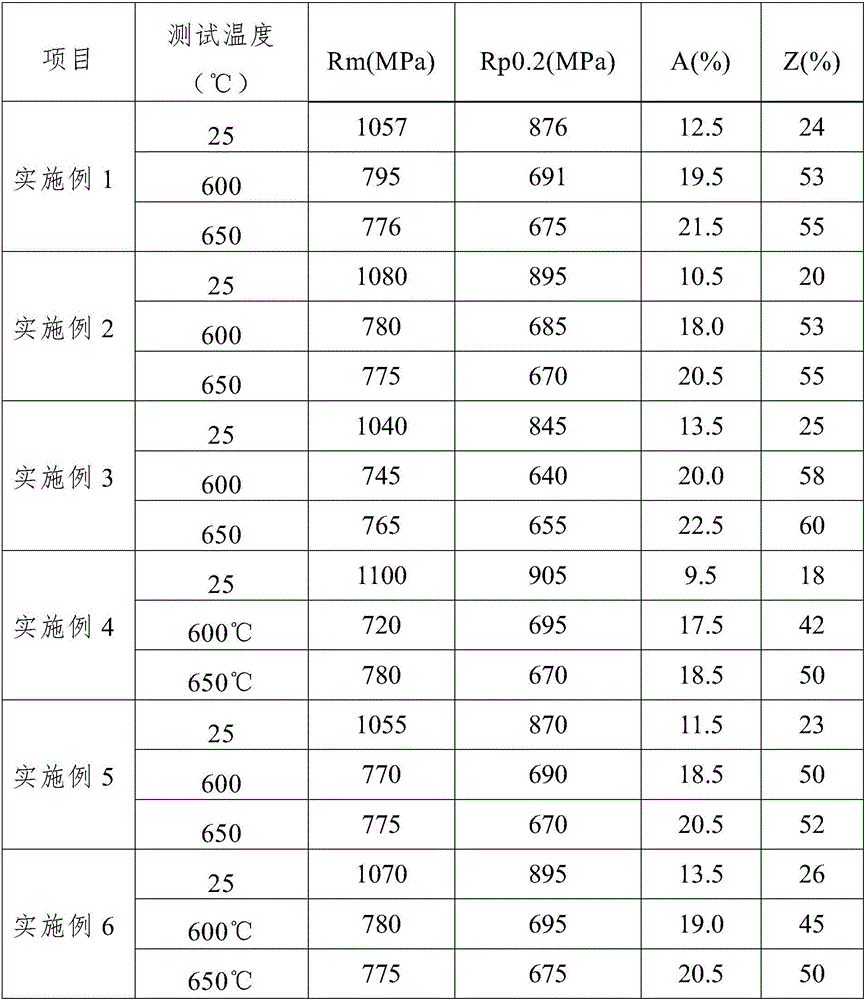

ActiveUS20180183045A1Improve cycle stabilityGood chemical uniformityCell electrodesSecondary cellsAir atmosphereHigh energy

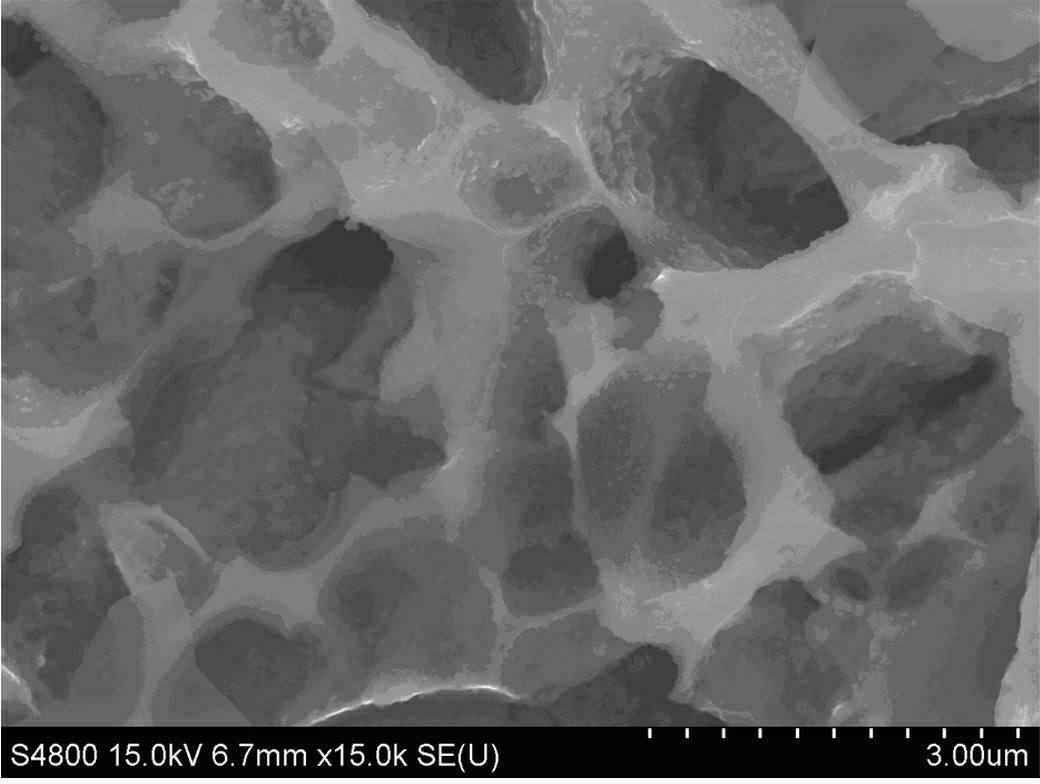

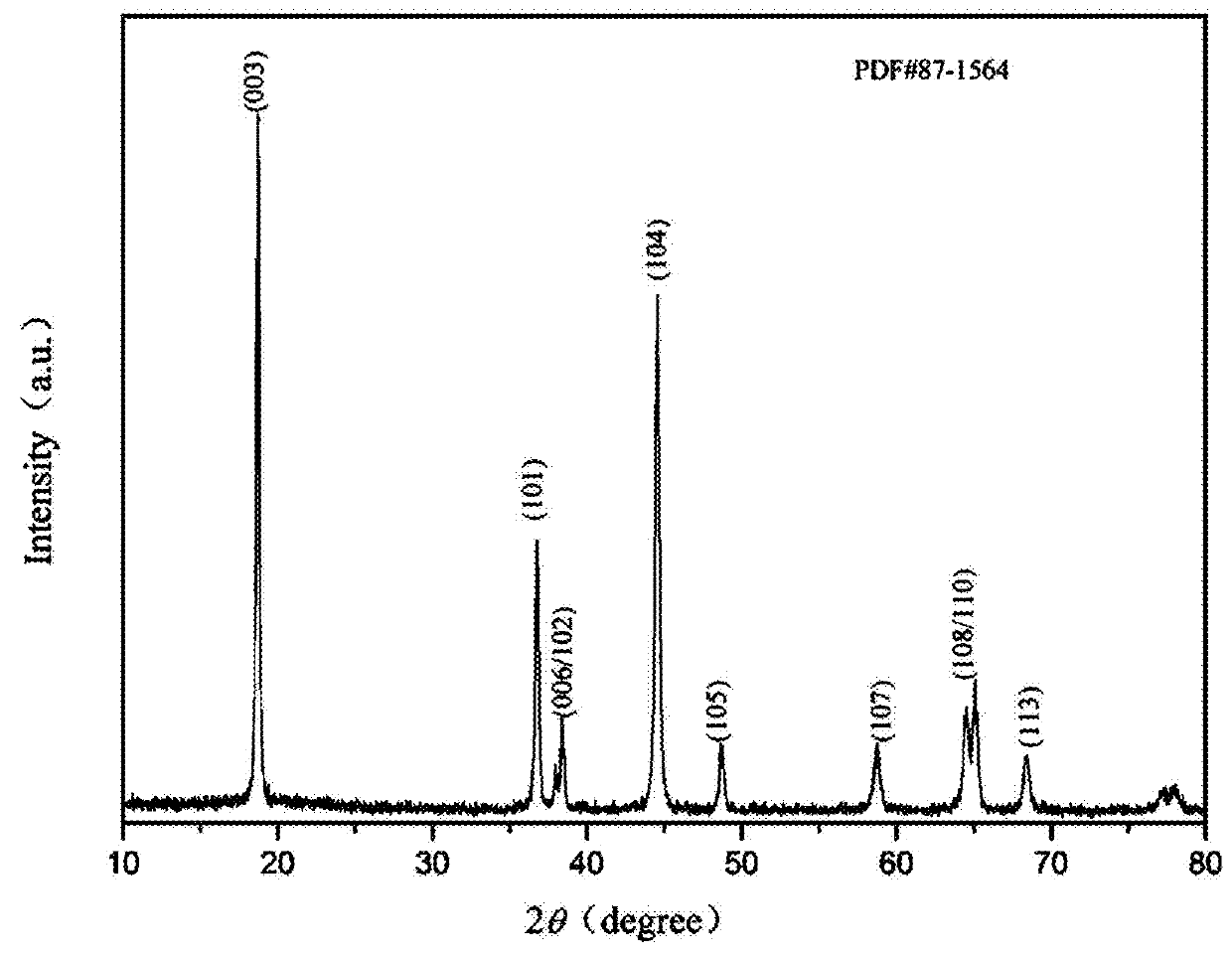

The present invention discloses a high-voltage ternary positive electrode material for lithium-ion battery and preparation method thereof. The chemical formula of the material is LiNi0.6-xMgxCo0.2-yAlyMn0.2-zTizO2-dFd, wherein 0<x,y,z,d≤0.05. The precursor of the positive electrode material is synthesized by gradient co-precipitation method and the positive electrode material is prepared by solid phase method. The content of nickel in the synthesized precursor particles has a gradient distribution from the inside to the outside. The obtained precursor is mixed and grinded evenly with the lithium source and the fluorine source at a certain ratio and put into the tube furnace. The obtained precursor is then pre-sintered in the oxygen-enriched air atmosphere and then heated up to be sintered, to obtain the target product. The positive electrode material for lithium-ion battery prepared by the method is free from impurity phase and has a good crystallinity, which is a high energy density positive electrode material.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

Preparation method of nano hydroxylapatite adsorbent for absorbing heavy metal ions in waste water

InactiveCN102381691ASimple processLow costOther chemical processesPhosphorus compoundsSorbentO-Phosphoric Acid

The invention discloses a preparation method of a nano hydroxylapatite adsorbent for absorbing heavy metal ions in waste water, comprising the following steps of: 1. preparing a precursory solution containing calcium and a precursory solution containing phosphorus: respectively preparing calcium nitrate with the concentration of 0.1-1mol / L and a phosphoric acid solution with the concentration of 0.1-0.5mol / L, and dropwise adding ammonia into the phosphoric acid solution, wherein the pH value is 10-12; 2. dropwise adding the precursory solution containing calcium into the precursory solution containing phosphorus, stirring to obtain a solution with white sediments, controlling the pH value constantly at 10-12; carrying out post-aging for 5-24h to obtain gel; and 3. placing the gel into a drying oven to dry at 55-100 DEG C for 10-24h to obtain xerogel, washing the xerogel by using distilled water 3-5 times, ball-milling for 12-24h, drying at 100 DEG C for 6-10h, calcining at 500-900, and preserving the heat for 2-6h to obtain the nano hydroxylapatite adsorbent. The invention has the characteristics of low cost, simple process and high adsorption efficiency.

Owner:SHENYANG UNIV

Coating method for core-shell novel positive electrode material for lithium ion battery

ActiveCN103474625AIncrease energy densityImprove power densityCell electrodesSodium-ion batterySlurry

The invention discloses a coating method for a core-shell novel positive electrode material for a lithium ion battery. A uniform core-shell structure is formed by effective compounding two materials with electrochemical activity; and an effect for enhancing electrochemical performance of the materials is achieved by improving interface state of the materials and reducing side reactions. The coating method comprises the following steps of dispersing the positive electrode material for the lithium ion battery in deionized water and auxiliarily dispersing in a certain manner to obtain a slurry; dissolving a lithium source, an iron source, a phosphate radical source and a chelating agent in water; stirring for 1 hour at a room temperature to obtain a sol; adding the slurry obtained in the first step in the sol; adjusting a pH; then heating to a temperature of 80 DEG C; keeping the temperature for 1-12 h to form a gel; then drying the gel at a temperature of 100 DEG C; sintering the dry gel obtained by the former step for 1-10 hours at a temperature of 600-900 DEG C under the protection of nitrogen; and cooling to a room temperature naturally, so that the core-shell novel positive electrode material for the lithium ion battery is obtained.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

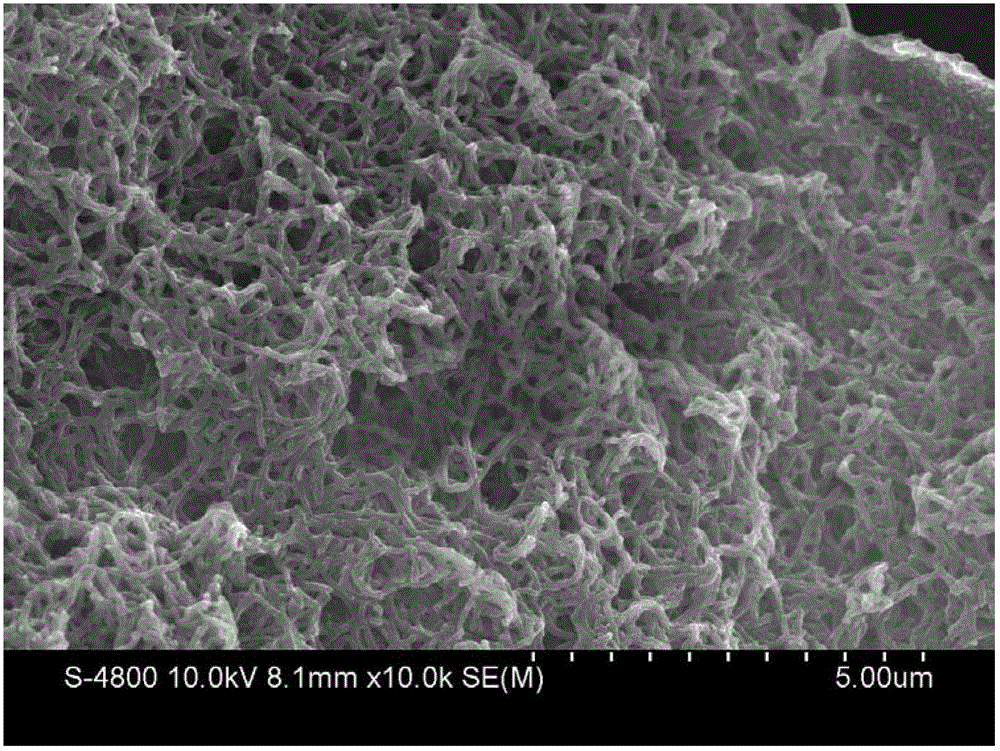

Preparation method for graphene nanosheet/conducting polymer nanowire composite material

InactiveCN102723209AGood electrical propertiesImprove stabilityElectrolytic capacitorsOrthanilic acidNanowire

The invention discloses a preparation method for a graphene nanosheet / conducting polymer nanowire composite material. The preparation method comprises the following steps of: preparing a graphite oxide by utilizing a chemical oxidation method, dispersing the product into de-ionized water, adding an orthanilic acid into the mixed solution according to a proportion, and stirring the mixed solution to make the orthanilic acid fully adsorbed onto a partially reduced graphene oxide nanosheet; adding hydrazine hydrate according to a proportion, stirring the mixed solution, and performing washing, suction-filtration and vacuum drying by using absolute ethanol and the de-ionized water; ultrasonically dispersing the product into the de-ionized water to obtain graphene nanosheet suspension; and uniformly coating the prepared suspension on the surface of the conducting substrate by adopting a spin coating method, performing vacuum drying to form a thin film which is used as a working electrode, placing the working electrode, a counter electrode and a reference electrode into aqueous dispersion containing conducting polymer monomers, and clustering and depositing the monomers on the surface of the graphene nanosheet by using an electrochemical cyclic voltammetry technology. The method is simple, easy, low in reaction temperature, short in time and high in chemical uniformity.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Method for preparing oxidized graphene/conductive polypyrrole nano wire composite material

InactiveCN102800432AIncrease the active siteLower internal resistanceElectrolytic capacitorsCable/conductor manufacturePolypyrroleFiltration

The invention relates to a method for preparing an oxidized graphene / conductive polypyrrole nano wire composite material. The method comprises the following steps of: preparing oxidized graphene by using natural graphite according to a chemical oxidization method, uniformly dispersing the oxidized graphene into deionized water by adopting an ultrasonic method to obtain a stable oxidized graphene suspension; adding hexadecyl trimethyl ammonium bromide with the mole concentration being 0.025 to 0.038 mol / L into the oxidized graphene suspension, uniformly stirring and mixing, adding pyrrole into the suspension, and uniformly mixing and stirring; polymerizing pyrrole monomers on an oxidized graphene nano sheet in situ by taking the hexadecyl trimethyl ammonium bromide as a surface active agent and ammonium persulfate as an oxidant, and performing frequent washing, suction filtration and vacuum drying on a product to finally obtain the oxidized graphene / conductive polypyrrole nano wire composite material. According to the preparation method, the process is simple, and the cost is low; and the product is high in specific capacity and high stability. The method can be applied to fields such as lithium ion batteries, sensors, electronic devices and fuel batteries.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

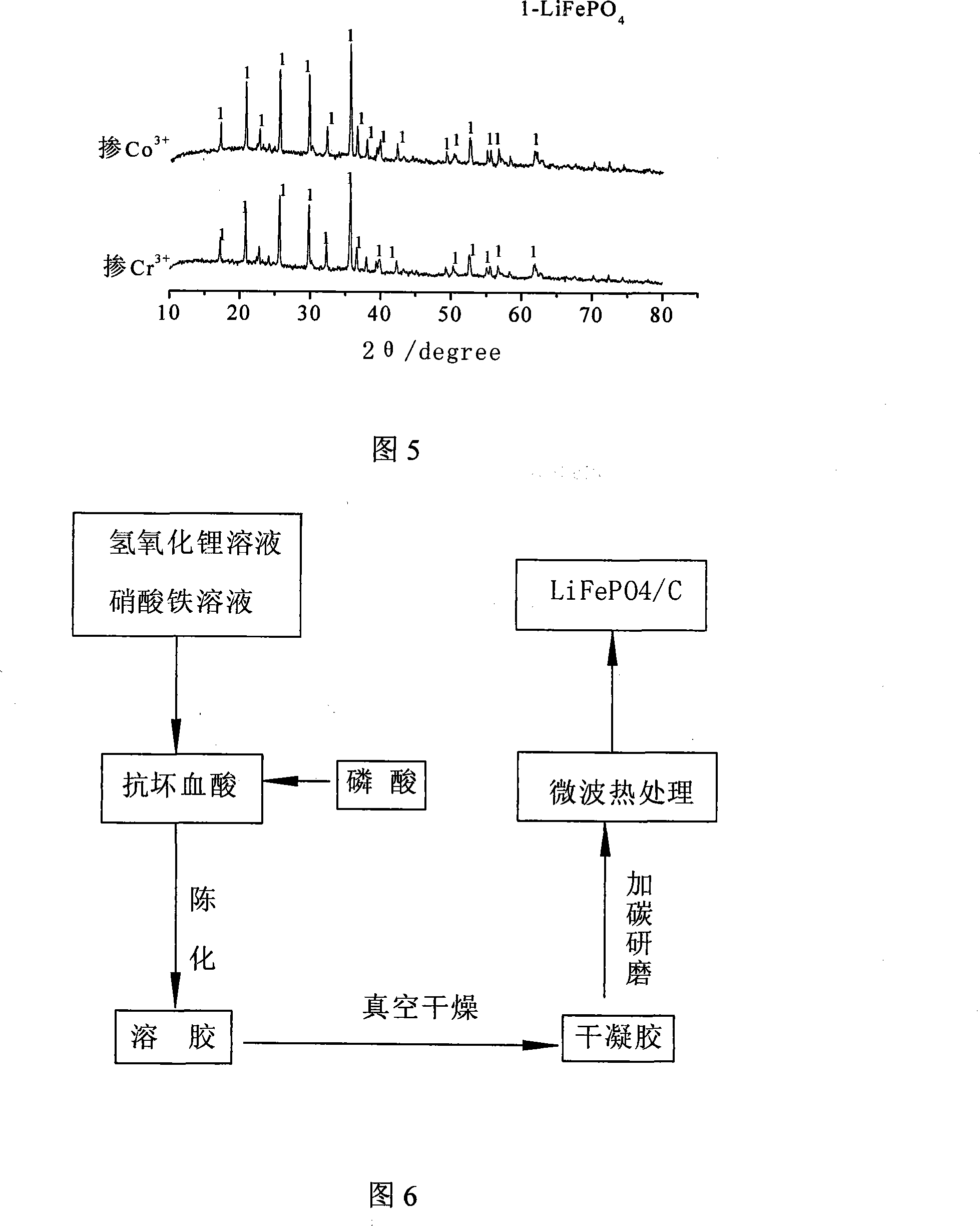

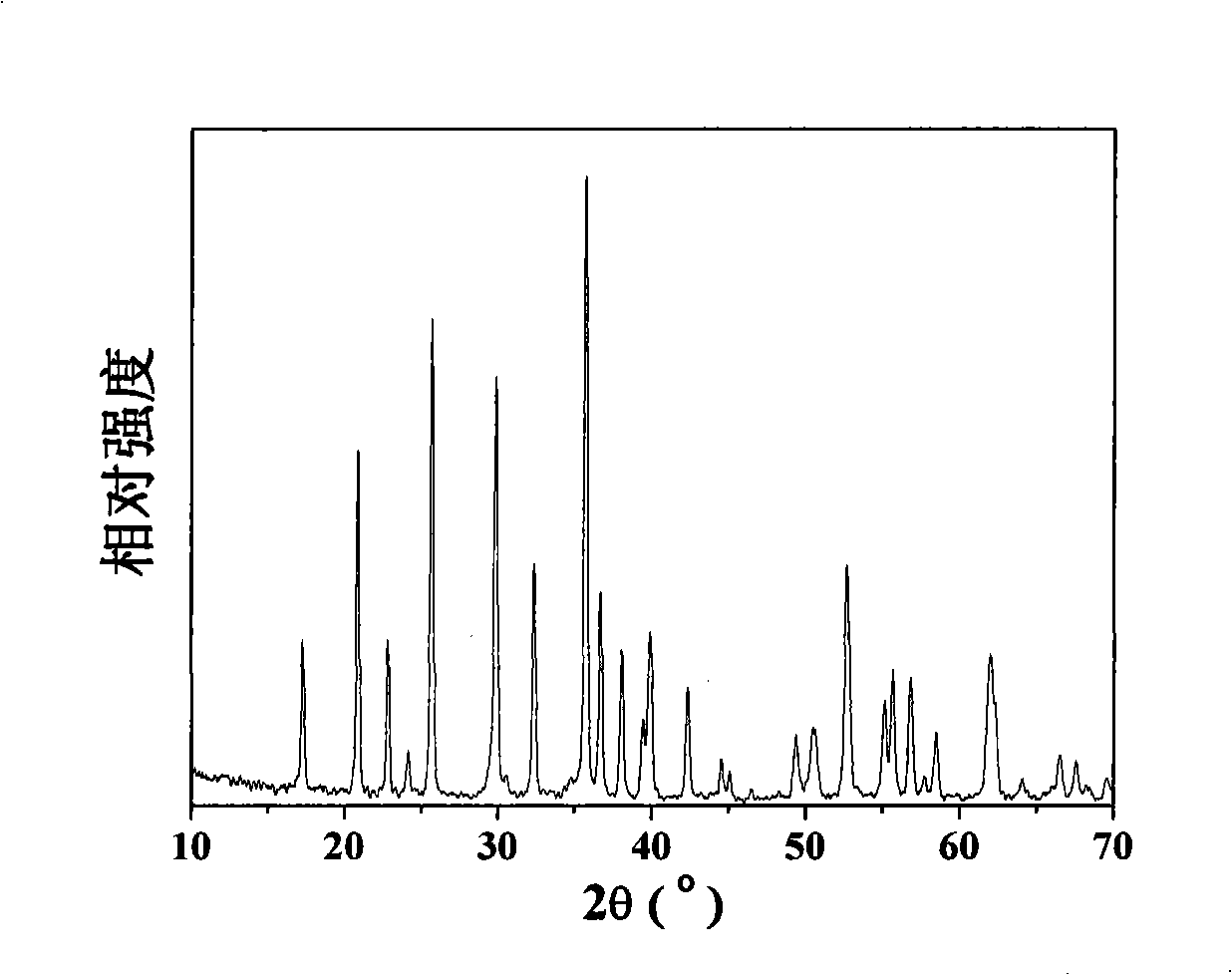

Method for producing high performance lithium ion battery anode material LiFePO4/C

InactiveCN101179124AIncrease the cell volumeIncreased Diffusion ChannelElectrode manufacturing processesPhosphorus compoundsHigh rateCharge discharge

The invention relates to a preparation method for making lithium ion battery cathode materials of LiFePO4 / C by using the reducing agent and inorganic salts of iron source, phosphorus source, lithium source, carbon source and so on as raw materials. Adopt the combining method of sol-gel and microwave treatment and prepare ultrafine particles of LiFePO4 and carbon coat the particles at the same time. On this basis, change the property of LiFePO4 / C by metal doping of Cr3 plus , Co3 plus . By processing with industrial microwave oven of high power, the invention shortens processing time greatly, increases the yield remarkably, reduces material cost and energy loss, simplifies the processes, improves the efficiency of industrial production of lithium ion battery and is convenient for implementation in industry. Take it as cathode materials of lithium ion battery with high-rate discharge. The invention raises conductivity of lithium iron phosphate and at the same time improves charge discharge capacity and cycle numbers by carbon coating and metal element doping.

Owner:江苏君明高新科技有限公司

Lithium iron phosphate anode material for lithium ion battery and modification method

InactiveCN101315981AUniform structureEasy to processElectrode manufacturing processesChemical/physical/physico-chemical processesSolid state reaction methodLithium-ion battery

The invention provides a lithium iron phosphate anode material used for lithium ion batteries; the lithium iron phosphate which is prepared by a water heating method is taken as a precursor which is then uniformly mixed with a conductive matter precursor and metal ion salt, and finally baked in inert gas to obtain the lithium iron phosphate anode material which is coated by the conductive matter and doped by the metal ions. Compared with a pure solid phase reaction method, the method of the invention has small energy dissipation, the chemical uniformity of the synchronized outcome is good, the dimension and the appearance of the outcome are uniform, and the electromechanical performance and the processing performance have good stability and repeatability. Compared with the a pure water heating method, as the coating of the conductive matter, the doping and modifying performance of the metal ions are added during the anaphase, the electric conductivity of the material is greatly improved, and the high magnification electromechanical performance of the material is excellent; wherein, under the 10C discharging magnification, the discharging content of the lithium iron phosphate anode material with the copper ion doped is kept at 107mAh / g. After circulation for 50 times, the discharging content of the material is kept unchangeable basically, which can certify that the material has good circulation performance.

Owner:HEFEI UNIV OF TECH

Method for preparing indium tin oxide powder by aqueous solution method

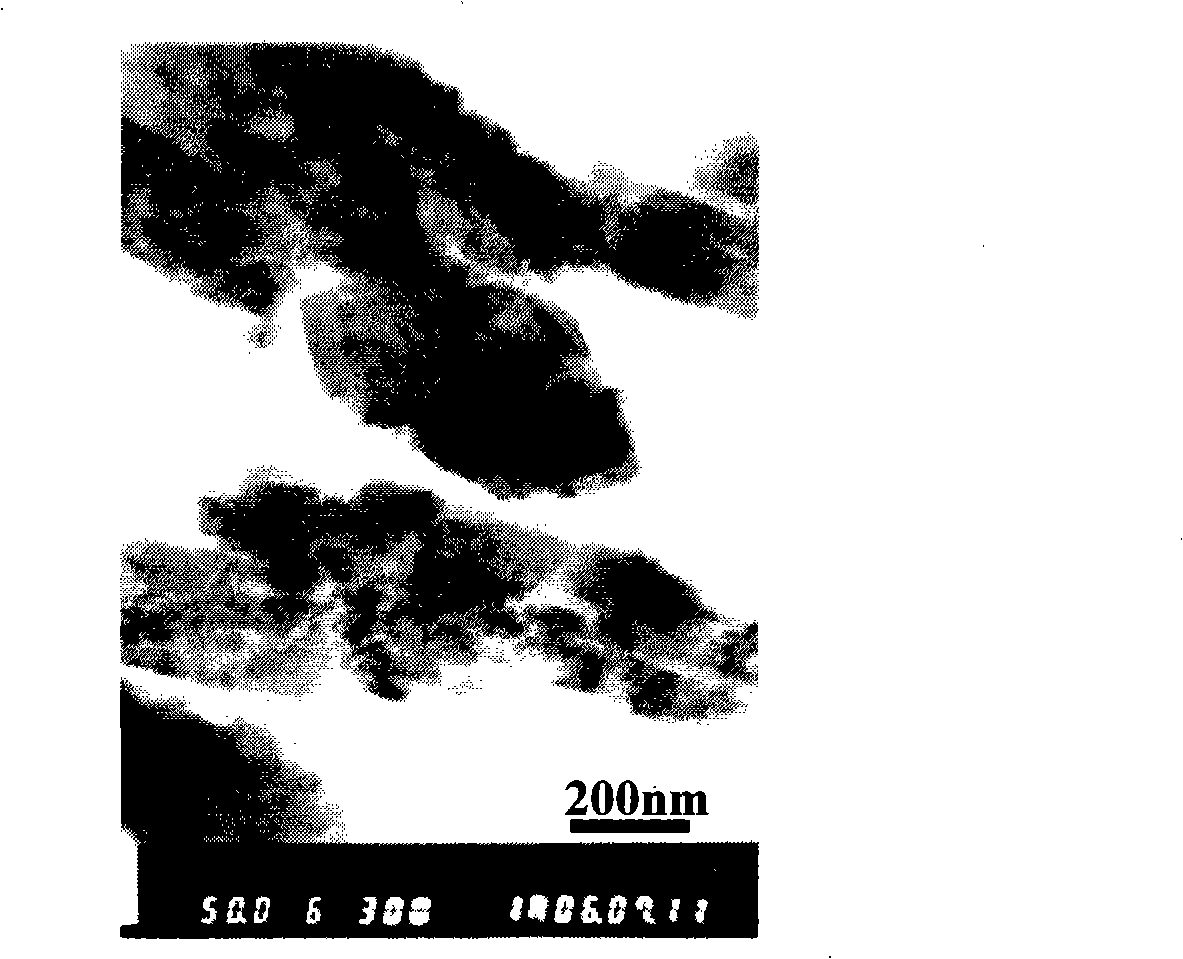

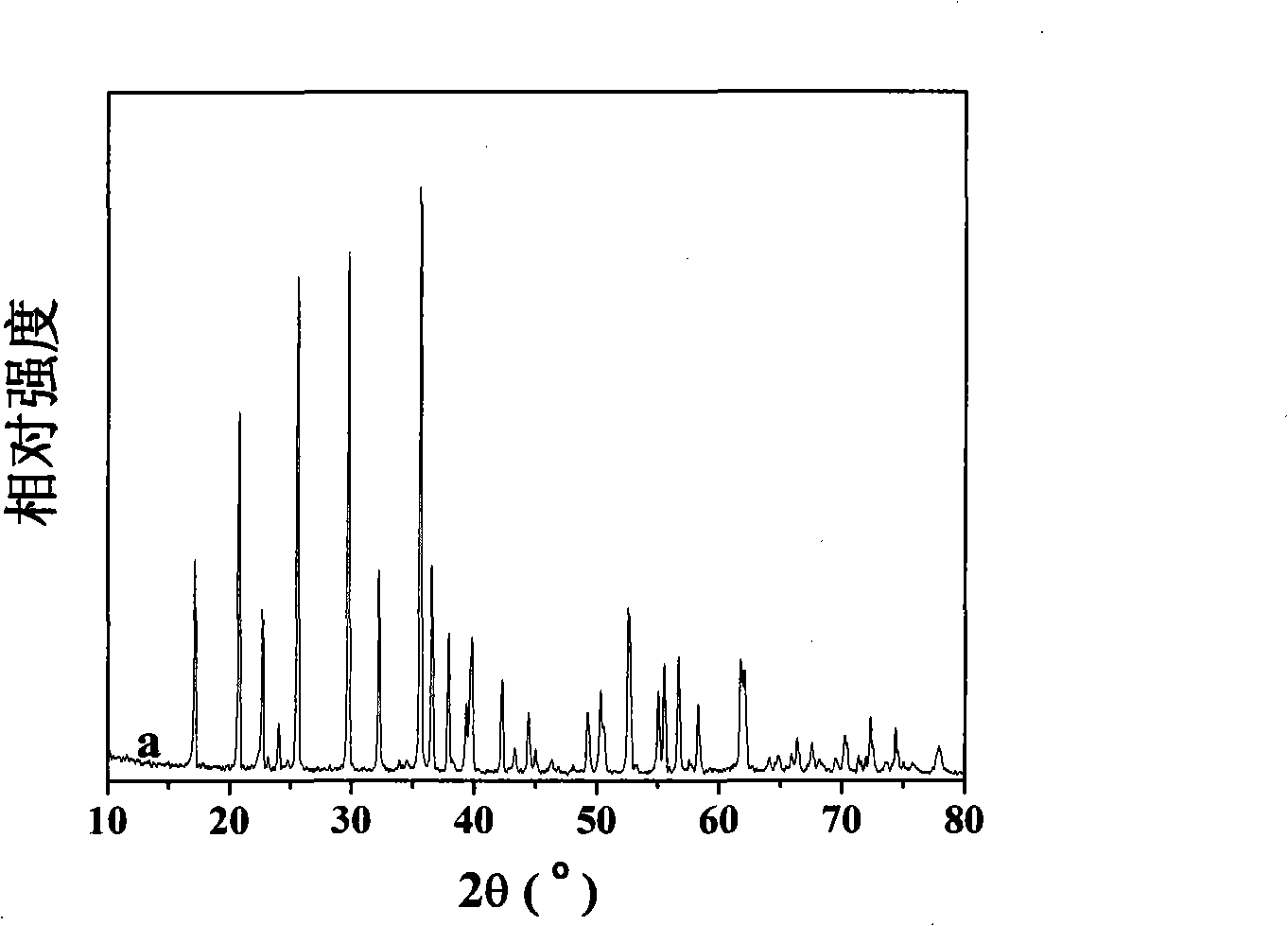

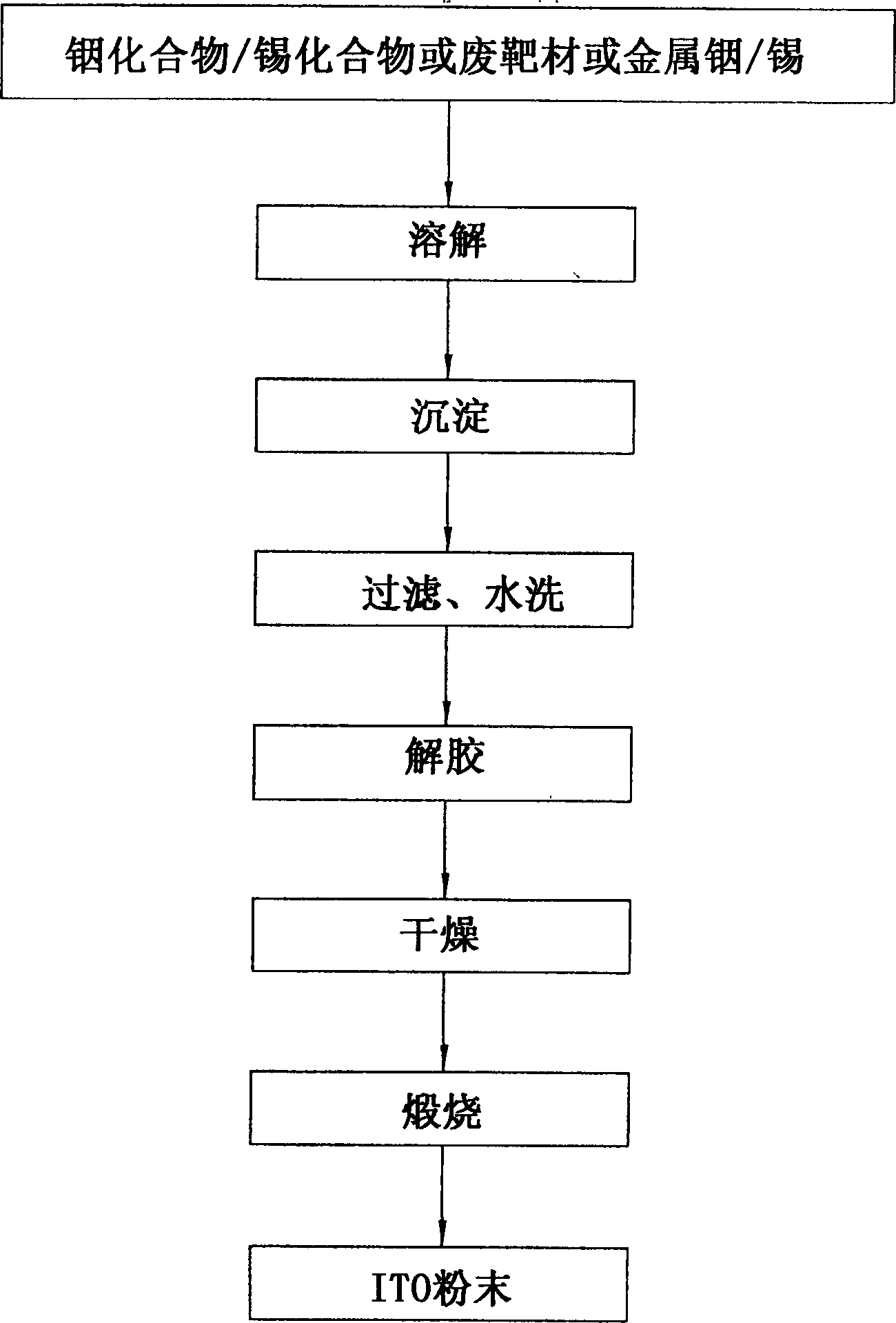

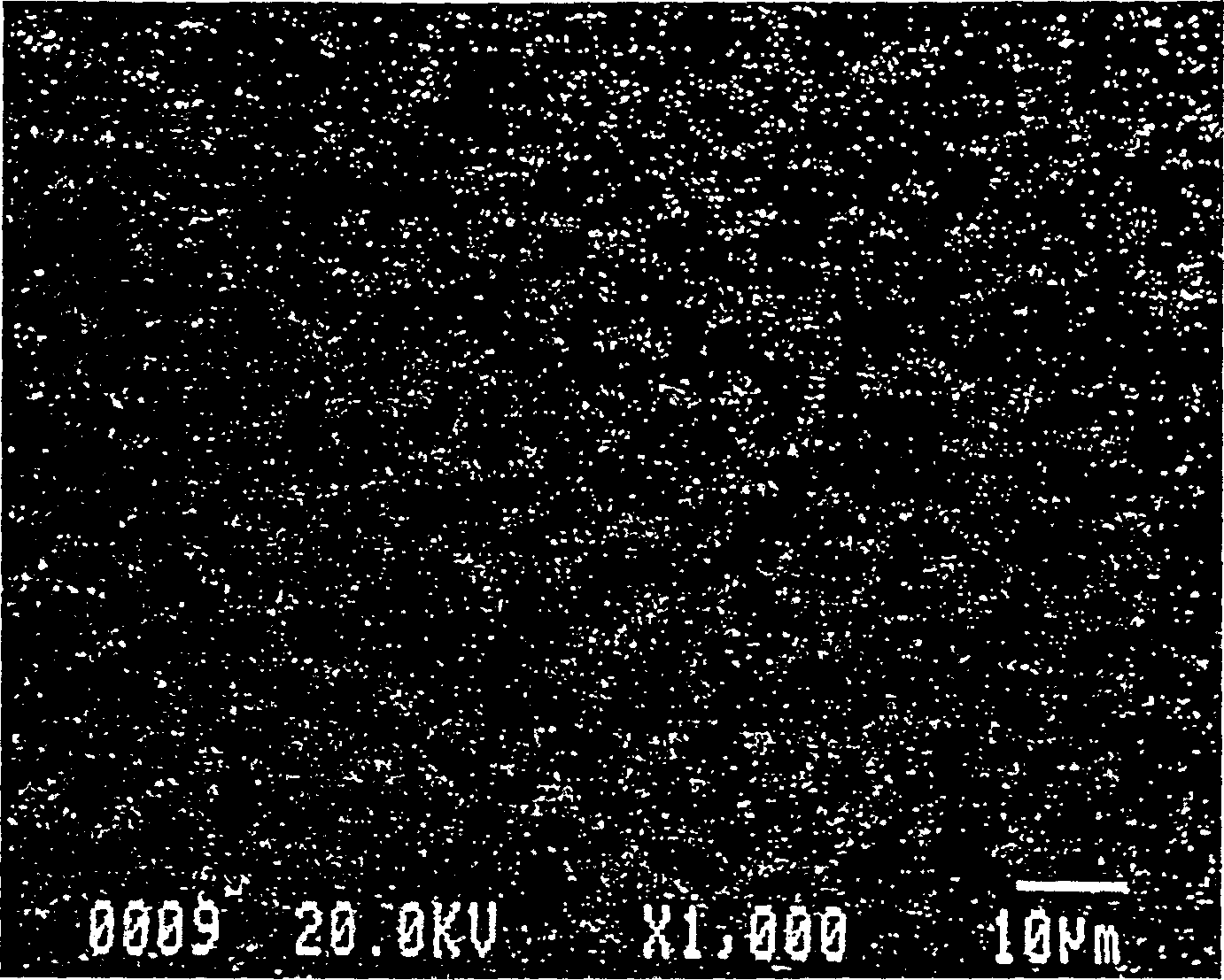

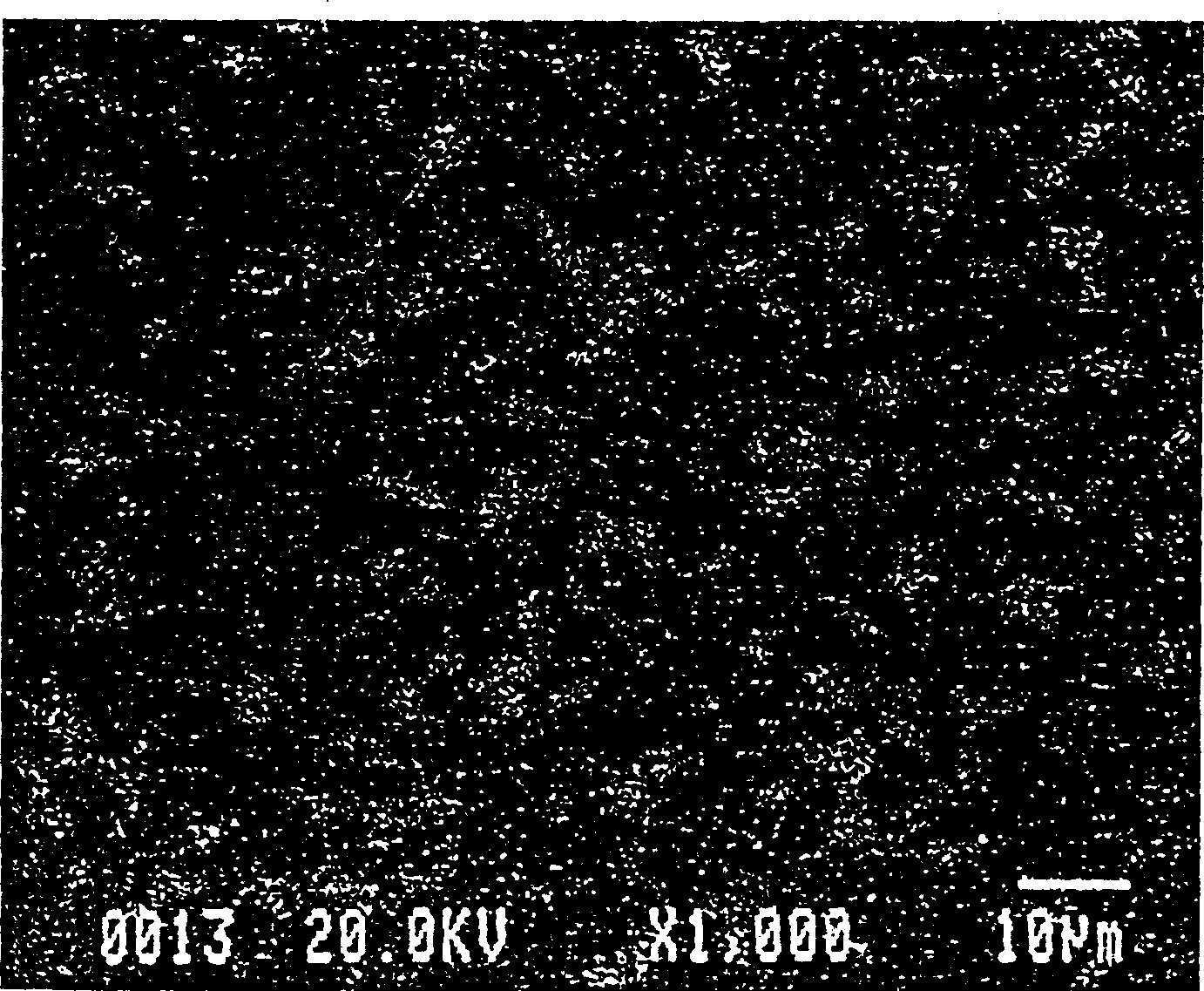

InactiveCN1412117AGood chemical uniformityExtended service lifeGallium/indium/thallium compoundsProcess efficiency improvementIndiumIndium tin oxide

The preparation method of tin indium oxide powder includes the following steps: using water and proper additive to respectively dissolve indium compound and tin compound in water to prepare two clearsolutions; adding proper additive to produce metal hydroxides with a certain proportion; filtering and water washing, and adding proper additive to make dispergation and making specific components ofdifferent metal hydroxides produce the reaction of hydrolysis and condensation, then drying and calcining so as to obtain high-grade nano tin indium oxide powder with high compactness.

Owner:CHENG LOONG CORPORATION

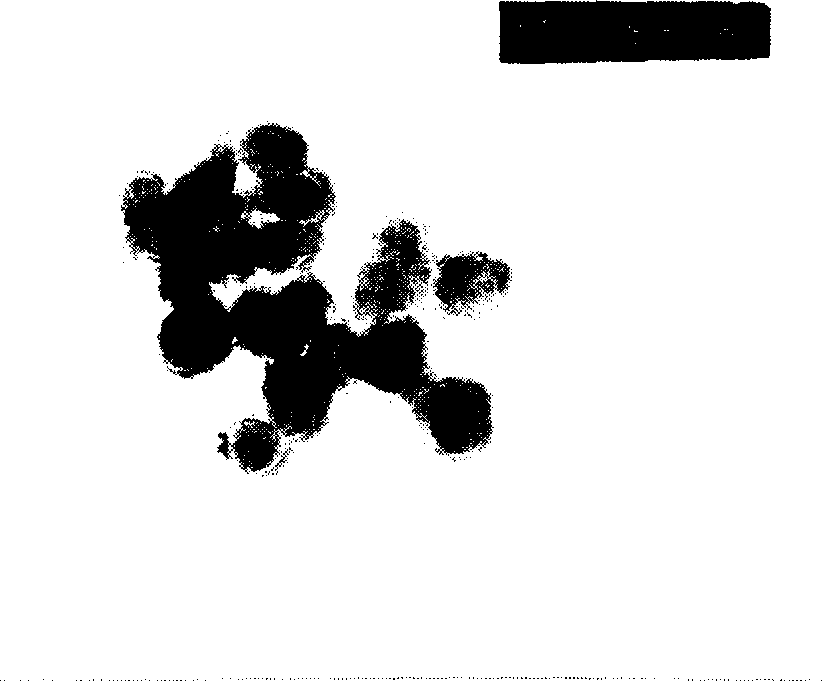

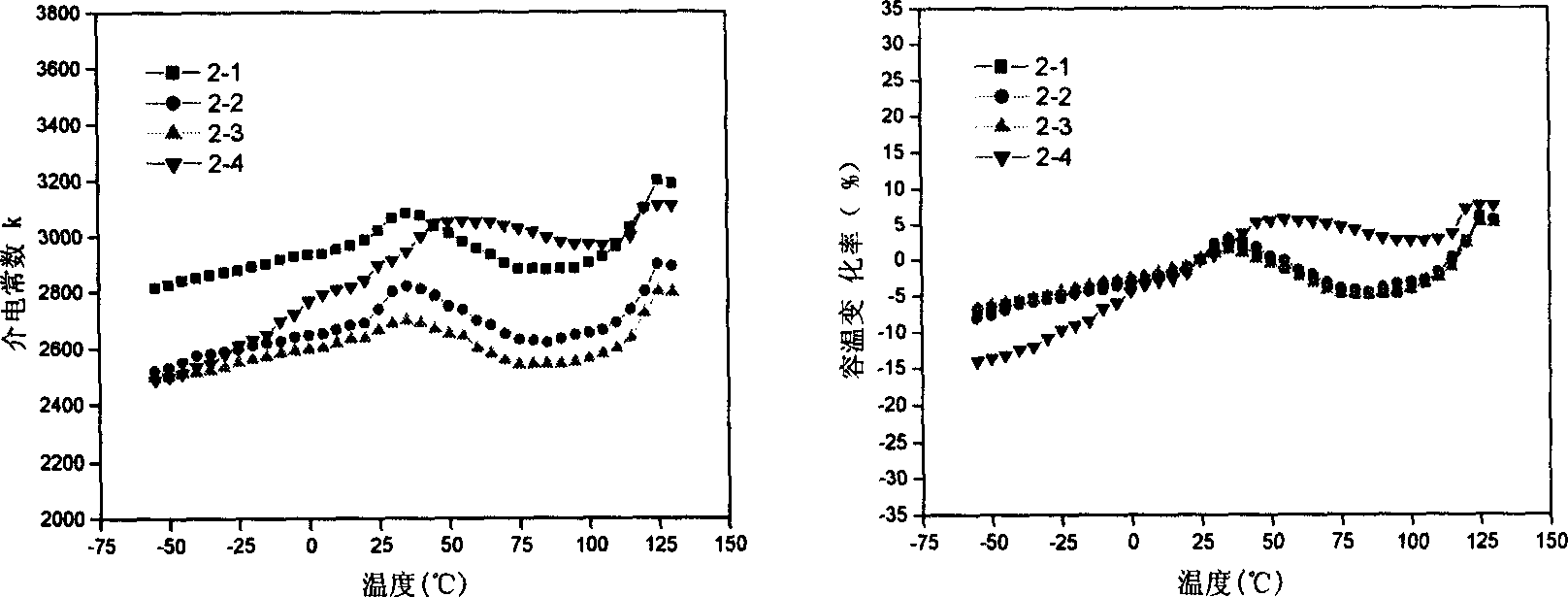

Nanometer ceramic-material doping agent, ceramic capacitor media material and production thereof

InactiveCN1854105APromote lowerMeet miniaturizationFixed capacitor dielectricPiezoelectric/electrostrictive/magnetostrictive devicesDopantCeramic capacitor

A nanometer ceramic material dopant, medium material of ceramic capacitor and their production are disclosed. The formula of the dopant consists of aA.bB.cC.dR2 O3.eSiO2; A contains Na2O; B contains one or multiple of MgO and CaO; C contains one or multiple of MnO2 and Co3O4; R contains one of multiple of Y, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, among them a, b, c, d and e are coefficient, by computing mol%, 0<=a<=10%, 0<=b<=25%, 0<=c<=15%, 20%<=d<=60%, 10%<=e<=50% and b and c can't be zero at same time. Its advantages include large capacity, adjustable material formula, low sintering temperature, less medium loss, high dielectric constant and better reliability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

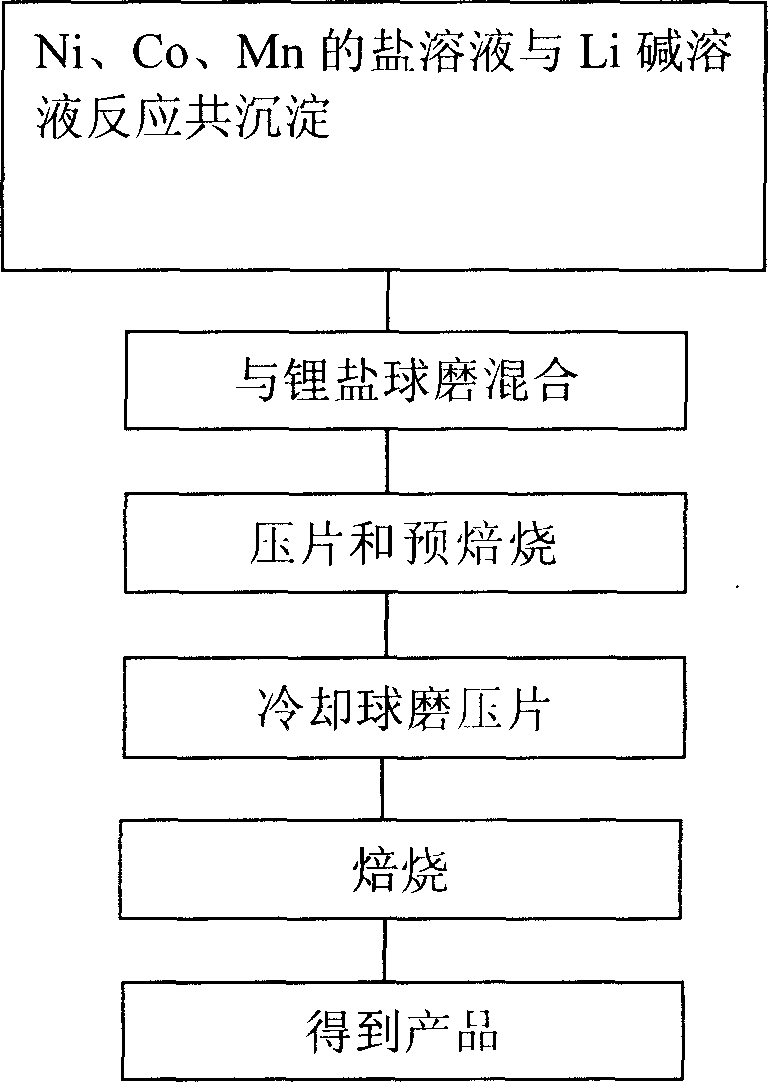

Method for producing anode active material containing lithium, magnesium compound oxide

InactiveCN1741302AStructural Precise TailoringSimple structureElectrode manufacturing processesLithium compoundsMANGANESE ACETATENickel salt

A method for preparing positive electrode multielement active material containing lithium / manganese composite oxide includes directly using lithium hydroxide coprecipitation to prepare M ( OH )2 , mixing it with lithium salt in grinding , forming plate by pressing , prebaking , cooled ball grinding , forming plate by pressing and backing . In the method , applied nickel salt is nickel acetate or nickel nitrate , applied cobalt salt is cobalt acetate or cobalt nitrate, applied manganese salt is manganese nitrate or manganese acetate and applied lithium salt is lithium carbonate or lithium acetate .

Owner:HEBEI UNIV OF TECH

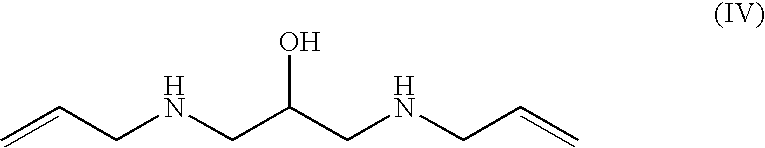

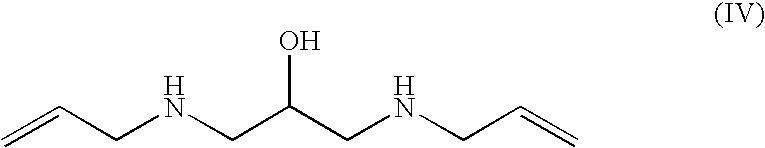

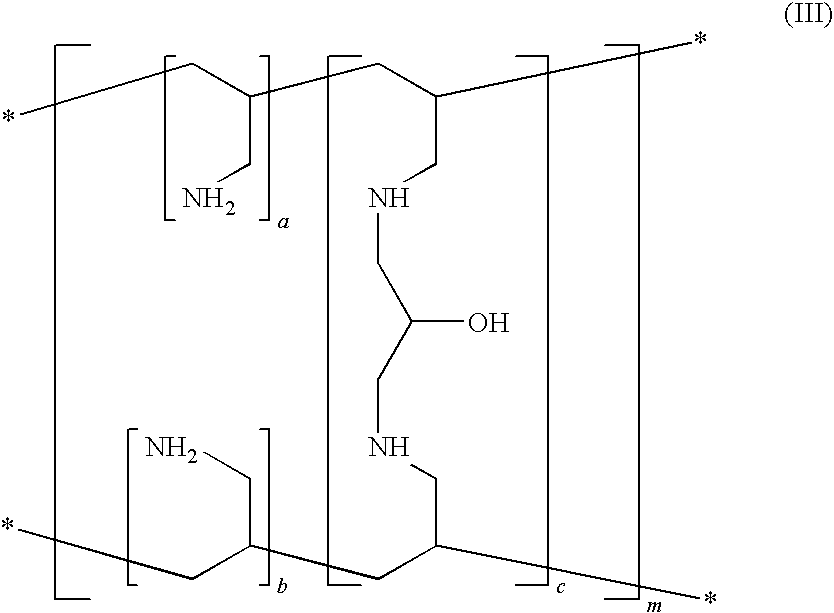

One step process for preparing cross-linked poly(allylamine) polymers

InactiveUS8394416B2Lower energy requirementsGood chemical uniformityOrganic active ingredientsOrganic chemistryCross-linkChemistry

The present invention relates to a novel one step process for preparing cross-linked poly(allylamine) polymers or salts thereof using the novel cross-linking agent of Formula (IV).This invention also relates to the compound of Formula (IV) as well as to a process to obtain it. The cross-linked poly(allylamine) polymers of the invention are useful in medicine as substrate-binding polymers.

Owner:QUIMICA SINTETICA

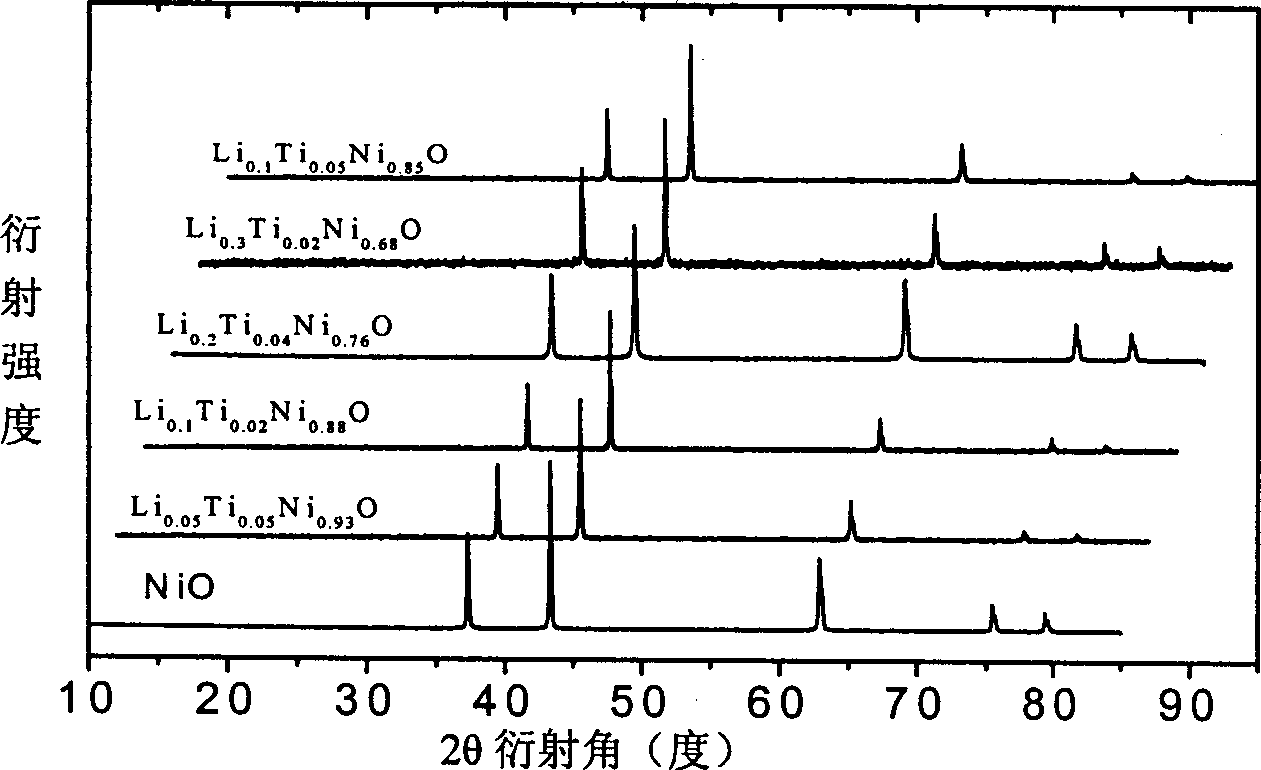

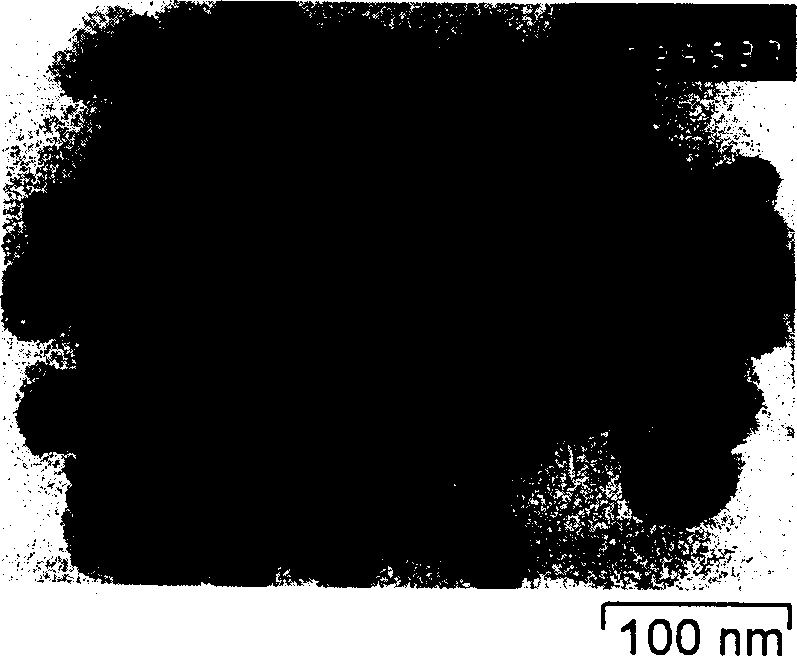

Prepn and application of Li and Ti doped nickel oxide-base ceramic

The Li and Ti doped NiO-base ceramic is prepared through a sol-gel process of preparing Li doped NiO precursor powder and subsequent mixing with TiO2 and sintering. The precursor powder prepared through sol-gel process has msll grain size and homogeneous chemical performance, and is easy to sintered and favorable to raising material performance. Regulating the doped Li and Ti amount can alter thedielectric performance of the ceramic material for different requirement. The ceramic has very high dielectric constant, greater than 10 to the power 4 at 1-10 MHz, and high temperature stability andmay be used in thermoelectric electricity generation, thermoelectric refrigeration, producing high-density capacitor and other fields.

Owner:TSINGHUA UNIV

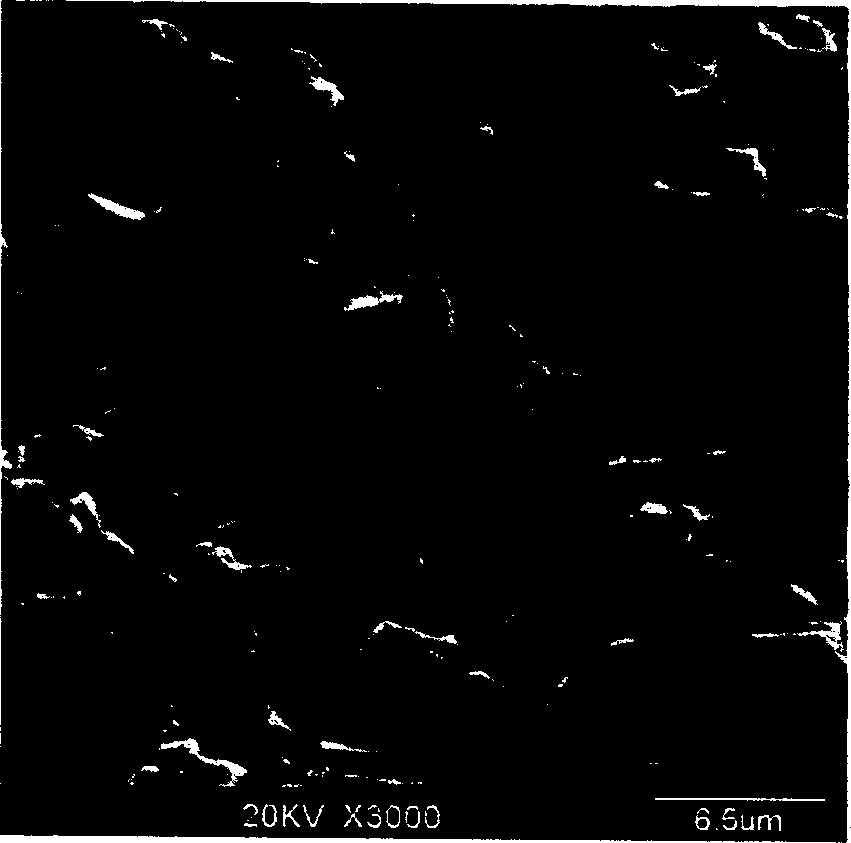

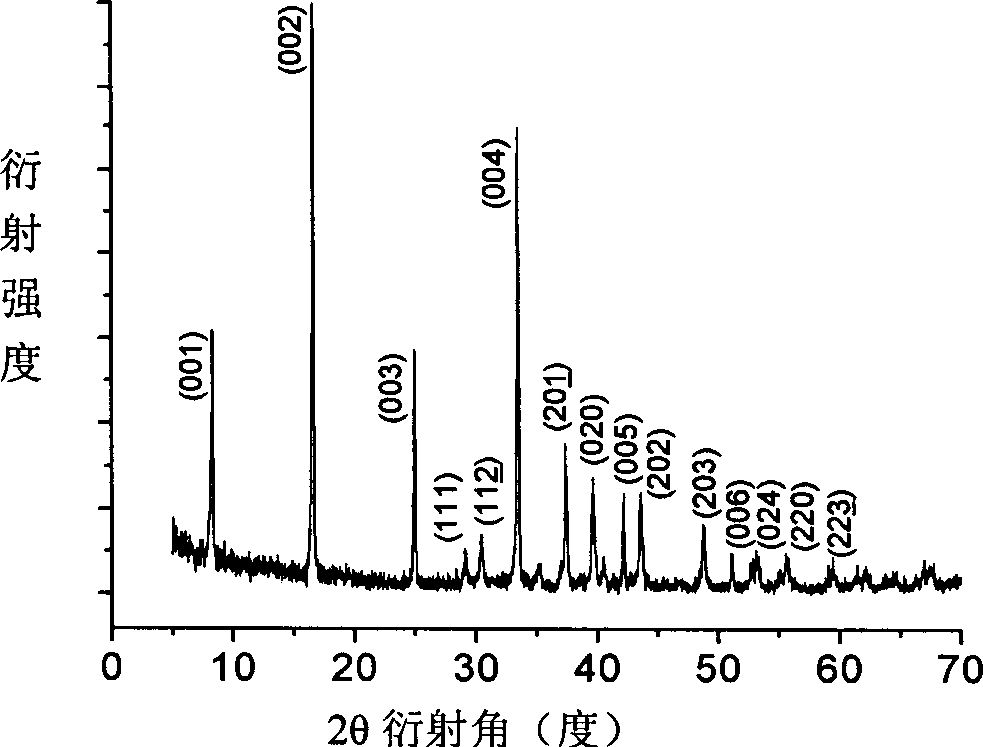

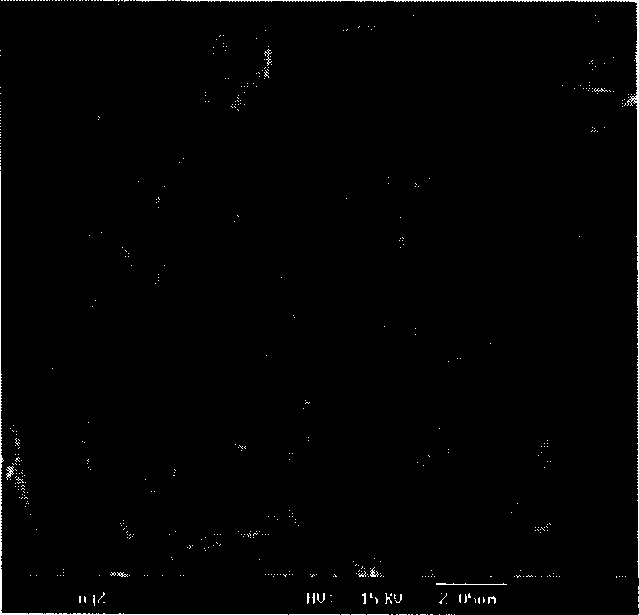

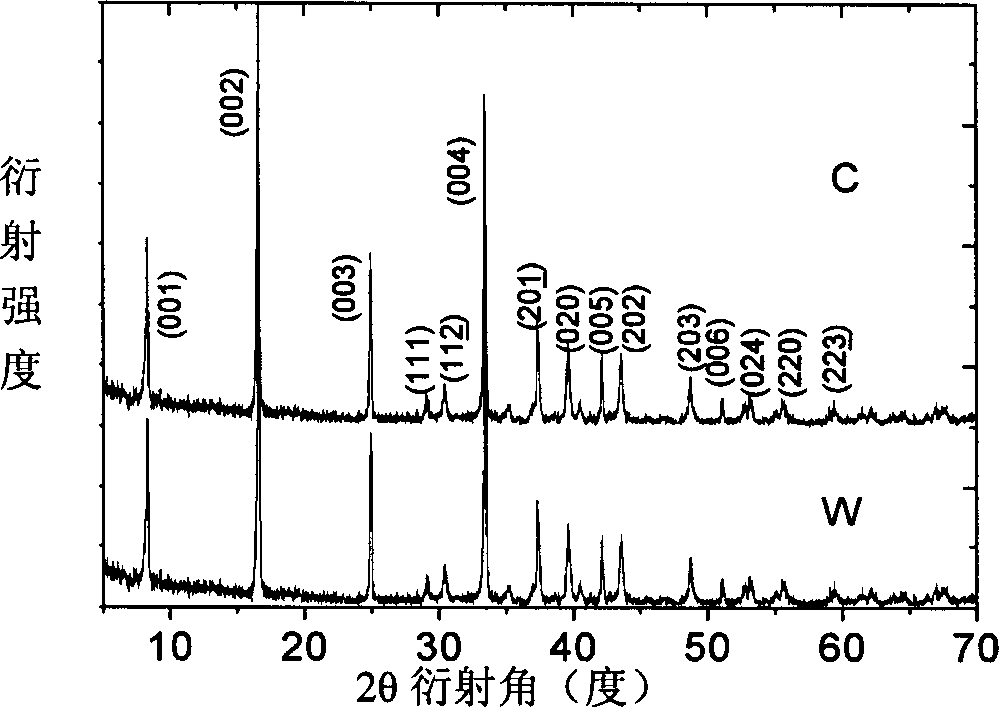

Calcium cobaltate-based oxide thermoelectric material and its prepn.

InactiveCN1389430AEasy to operateLow reaction temperatureSemiconductor/solid-state device manufacturingCobalt compoundsThermoelectric materialsNitrate

The present invention relates to a calcium cobaltate base oxide thermoelectric material and its preparation method. Said invention utilizes sel-gel process, uses inorganic nitrate as raw material, uses citric acid as complexing agent to form sol at 60 deg.C-100 deg.C and form gel at 100 deg.C-130 deg.c, then utilizes presintering process to obtain precursor nano powder, finally utilzies sintering process to obtain block body material. The non-dimensional thermoelectric optimum value ZT of said prepared Ca3Co4O9 base oxide thermoelectric material is about 0.2 (in 1000 K). Said invented product can be used in the field of waste-head utilization and high-temp. power generation.

Owner:TSINGHUA UNIV

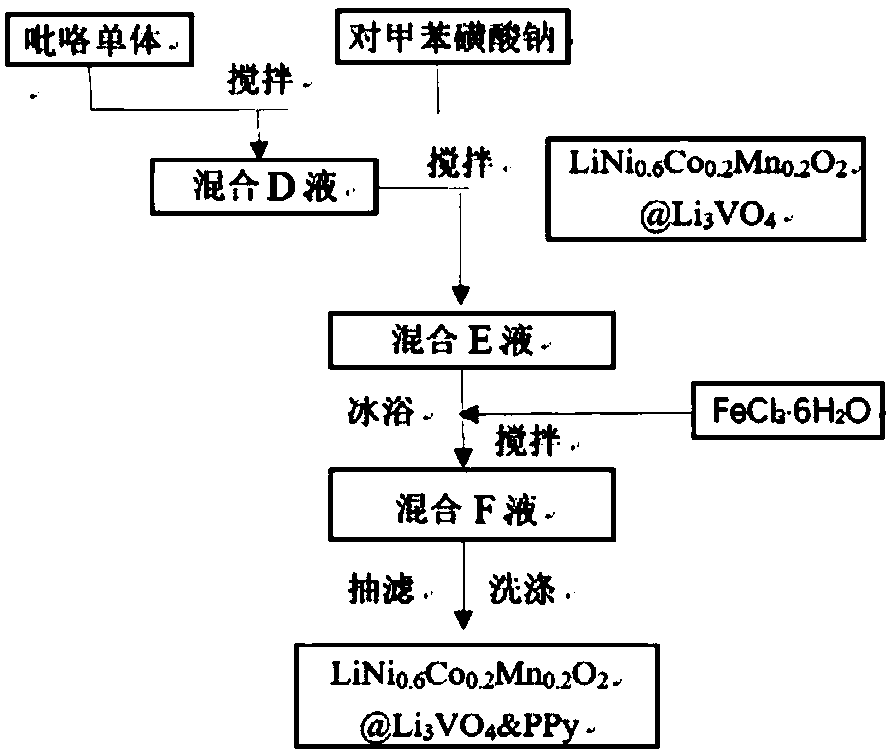

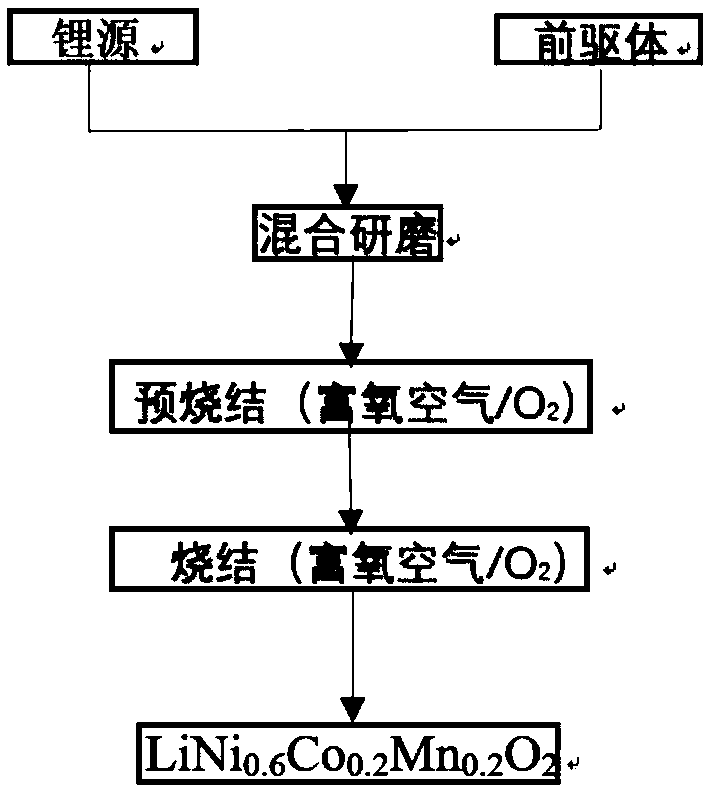

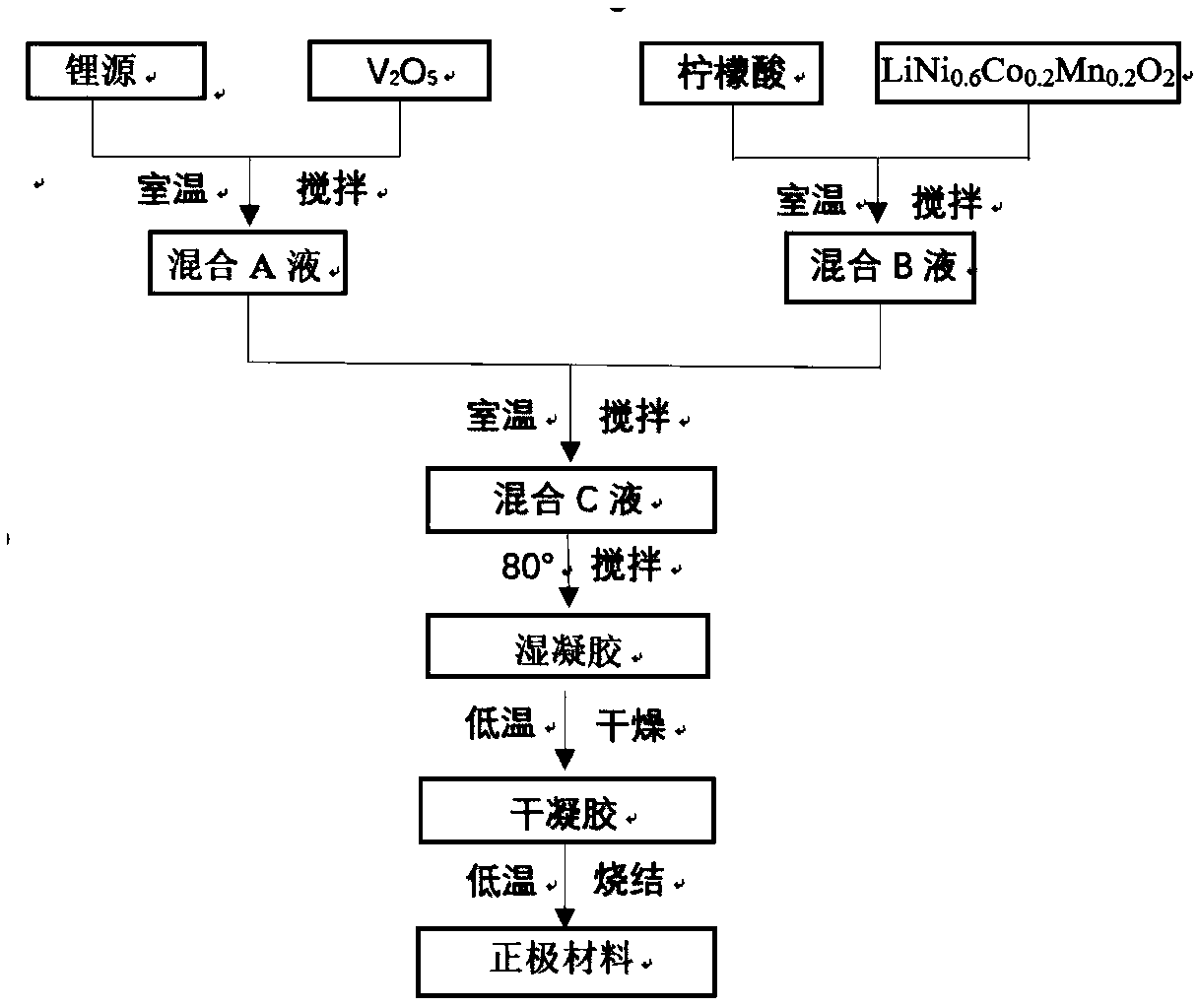

Double-layer coated cathode material LiNi0.6Co0.2Mn0.2O2 for lithium-ion battery and preparation method of double-layer coated cathode material

InactiveCN108807886AImprove ionic conductivityInhibition of erosionCell electrodesSecondary cellsDouble coatingConductive materials

The invention belongs to the technical field of preparation of cathode materials for lithium-ion batteries and specifically provides a double-layer coated cathode material LiNi0.6Co0.2Mn0.2O2 for a lithium-ion battery, wherein the coating amounts of Li3VO4 and PPy are 1 to 5 weight percent; Li3VO4 is a lithium fast ion conductor; by coating Li3VO 4, a protective layer can be provided and the lithium fast ion conductor also can be provided, so that ionic conductivity of the material is enhanced; in addition, lithium ions consumed during the formation of SEI and CEI films are made up and the cycle performance of the material is improved. The PPy is a fast electronic conductive material; by coating PPy, a second protective layer can be provided and the electronic conductivity of the materialcan be improved. Through double-layer coating of Li3VO4 and the PPy, the ionic conductivity is improved and the electrical conductivity is also improved; the cathode material is enabled to have super-high magnification discharge performance and higher discharge specific capacity; besides, double coating layers can more effectively inhibit the erosion effect of HF on the cathode material and enablethe cathode material to have excellent high voltage cycle stability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of loaded cobalt catalyst

ActiveCN106925274AHighlight substantiveEvenly dopedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNanofiberReducing atmosphere

The invention provides a preparation method of a loaded cobalt catalyst, and relates to a cobalt-containing catalyst. The preparation method includes the steps that a spinel-type oxide CoAl2O4 is prepared through a sol-gel method; then, the oxide is loaded on the surface of sepiolite ore nanofiber through an impregnation method, and a CoAl2O4 / sepiolite ore nanofiber composite is obtained; then, the composite is reduced in a reducing atmosphere, and a cobalt / CoAl2O4 / sepiolite ore nanofiber composite, namely, the loaded cobalt catalyst formed by the CoAl2O4 / sepiolite ore nanofiber composite loaded with cobalt is obtained. The defects of an existing loaded cobalt catalyst that the preparation process is complex, the reaction energy consumption is high, and a product is poor in high-temperature stability and prone to agglomeration at a high temperature are overcome.

Owner:HEBEI UNIV OF TECH

Preparation method of silicon carbide/carbon hollow porous microsphere wave-absorbing material

ActiveCN110819302ALow reaction temperatureLow cost of scaleOther chemical processesCarbon compositesActive agent

The invention relates to the technical field of wave-absorbing materials, in particular to a preparation method of a silicon carbide / carbon hollow porous microsphere wave-absorbing material. The invention aims to solve the technical problems of large particle size and easy agglomeration of silicon carbide particles in the silicon carbide / carbon composite material prepared by the existing method. The method includes: mixing deionized water, anhydrous ethanol and ammonia water, adding a surfactant, resorcinol, a silicon source and a formaldehyde solution, stirring the substances uniformly at room temperature, then adding melamine, performing stirring, transferring the mixture into a high-temperature and high-pressure reactor for reaction, and conducting high temperature calcination; and thenperforming mixing with magnesium powder, conducting high temperature calcination in a nitrogen atmosphere, washing off redundant magnesium powder with hydrochloric acid, and carrying out washing anddrying. The silicon carbide / carbon hollow porous microsphere obtained by the method has good chemical homogeneity and large specific surface area, and can effectively avoid agglomeration and sinteringof silicon carbide particles. The material prepared by the method provided by the invention is used for making light and efficient wave-absorbing coatings.

Owner:HARBIN INST OF TECH

Method for preparing ferromagnetic titania cobalt-doped photocatalysis material

InactiveCN101181682ASimple methodGood chemical uniformityMetal/metal-oxides/metal-hydroxide catalystsCobalt oxides/hydroxidesFerromagnetismTitanium oxide

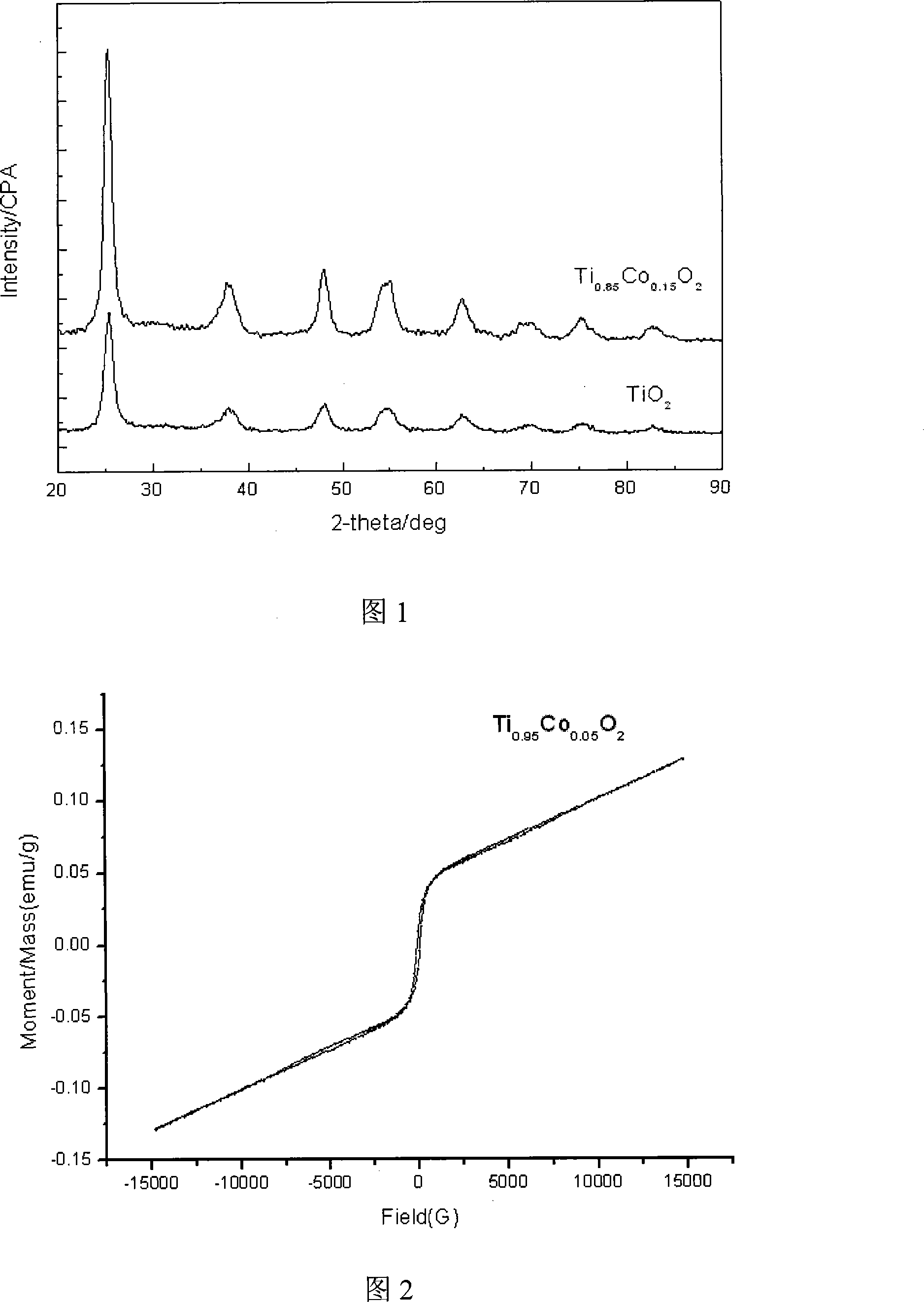

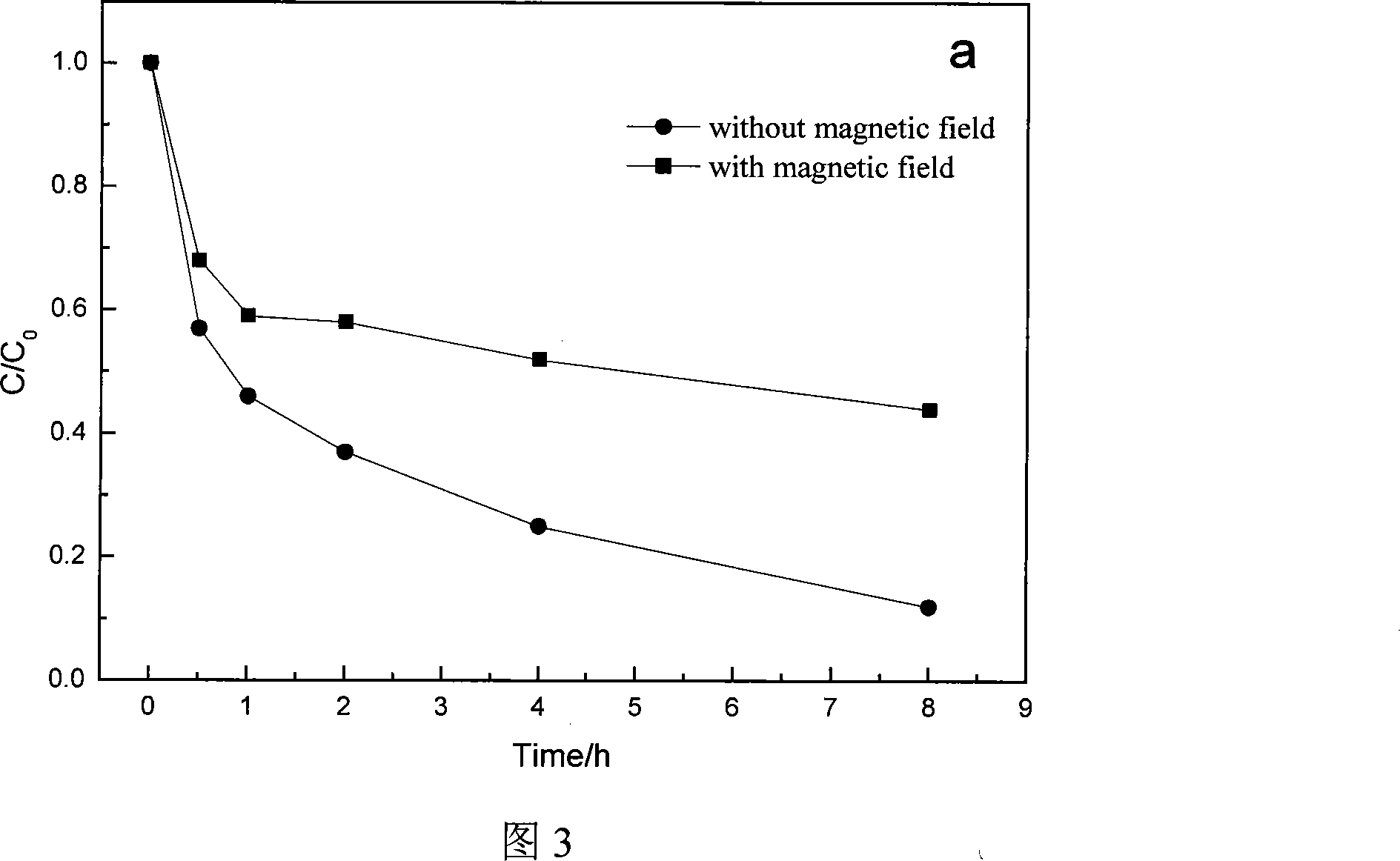

The invention discloses a preparation method of a ferromagnetic titanium oxide-doped cobalt photocatalyst material. A Ti1-xCoxO2 (x=0-15%) photocatalytic material with room temperature ferromagnetism was prepared. The method was as follows: butyl titanate and cobalt acetate were used as precursors and dissolved in a mixed solution of absolute ethanol and acetone, respectively. , prepared into butyl titanate solution and cobalt acetate solution, using nitric acid as a stabilizer, citric acid as a complexing agent, polyethylene glycol 2000 as a dispersant, respectively added to the butyl titanate solution, after fully stirring, the two The solution was mixed, stirred, and left to age to obtain a transparent and uniform sol. The sol is dried and heat-treated to obtain the required ferromagnetic titanium oxide-doped cobalt photocatalytic material. The material is chemically introduced into TiO2 without changing the anatase phase structure, so that it has obvious ferromagnetism at room temperature, and its photocatalytic performance is significantly improved under the action of an external magnetic field.

Owner:ZHEJIANG UNIV

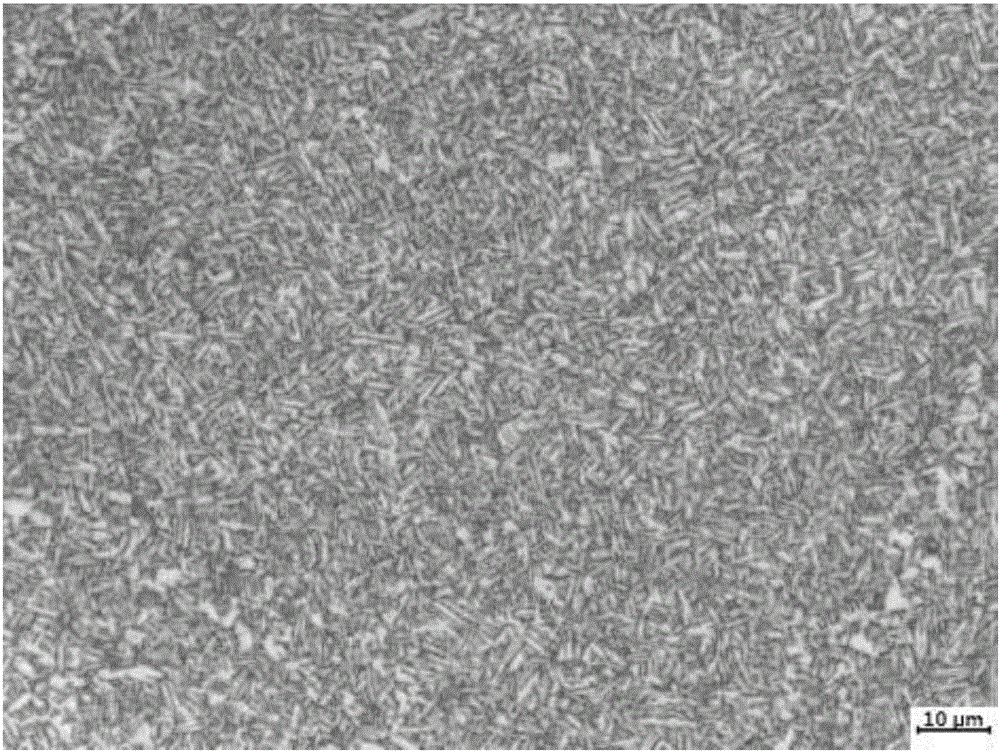

Preparation method of Ti2AlNb alloy material

ActiveCN106319236AImproves ingredient uniformityGood chemical uniformitySelf consumptionHeating time

The invention discloses a preparation method of a Ti2AlNb alloy material. The method comprises the steps of 1, preparing a Ti2AlNb alloy ingot through vacuum self-consumption electric arc melting, kish furnace smelting and vacuum self-consumption electric arc melting; 2, conducting primary homogenization treatment on the Ti2AlNb alloy ingot; and 3, wrapping the Ti2AlNb alloy ingot with asbestos cloth, then conducting heat-preservation heat treatment, and then sequentially conducting cogging forging, improved forging and finished product forging, so that the Ti2AlNb alloy material is finally obtained. The preparation method of the Ti2AlNb alloy material is simple in preparation process and reasonable in process design; an alloy is uniform in structure and stable in performance; the alloy ingot can be effectively refined, purified and homogenized through a smelting method; through the high-quality ingot, smooth implementation of subsequent hot working is guaranteed; by means of homogenization treatment, uniformity of alloy elements can be further improved through element diffusion; and wrapping treatment is conducted with the asbestos cloth, the temperature of the material can be effectively prevented from being lowered in the whole forging process, and large-deformation-amount forging for one heating time is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Mg-doped Li-rich anode material and preparation method for same

InactiveCN103441238AGood cycle performanceGood cycle performance and rate performanceCell electrodesCOBALTOUS ACETATEMagnesium nitrate

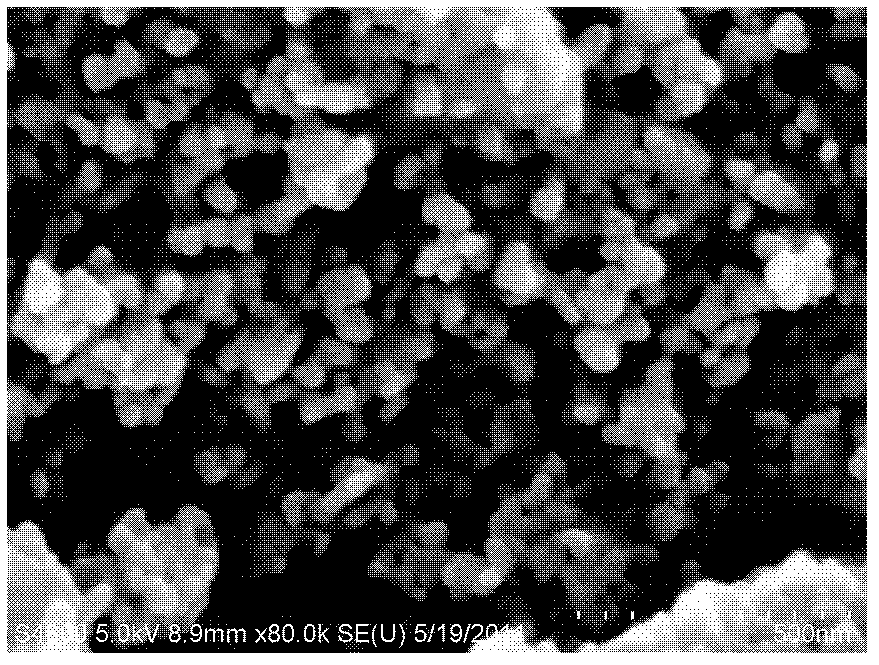

The invention discloses an Mg-doped Li-rich anode material and a preparation method for the same, wherein the molecular formula of the Mg-doped Li-rich anode material is Li(Li0.2Ni0.13Co0.13Mn0.54)0.98Mg0.02O2. The preparation method comprises the following steps of: dissolving lithium acetate, cobaltous acetate, nickel acetate, manganese acetate and magnesium nitrate in deionized water in a molar ratio of Li to Co to Ni to Mn to Mg being 1.196: 0.1274: 0.1274: 0.5292: 0.02 to obtain solution 1; adding citric acid in deionized water to obtain solution 2 in a ratio of the molar weight of the citric acid to the total molar weight of Ni, Co, Mn and Mg being 1: 1; and adding the solution 2 in the solution 1, adjusting the pH value to be 9, stirring at 80 DEG C until a purple gel is formed, sequentially performing drying, ball-milling, segmented calcination and grinding, and thus obtaining the Mg-doped Li-rich anode material which is high in specific discharge capacity, good in circulation performance, and excellent in rate performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

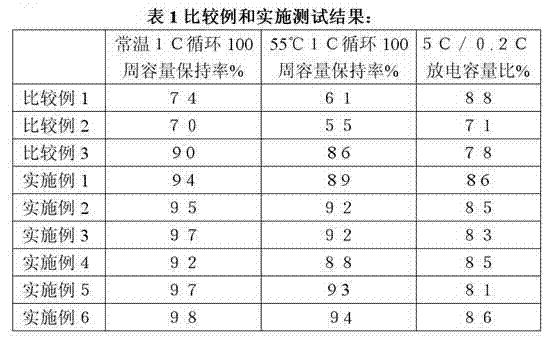

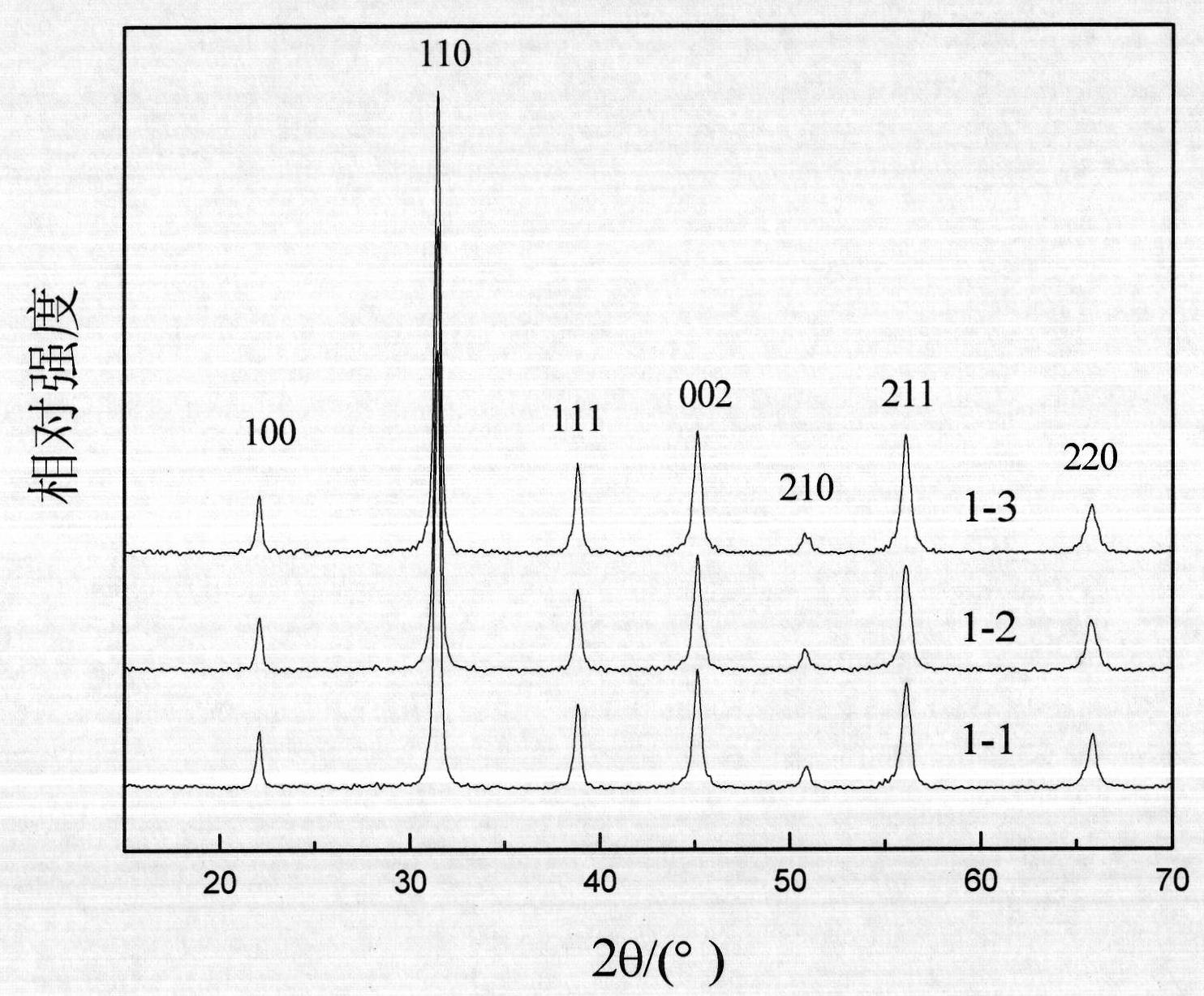

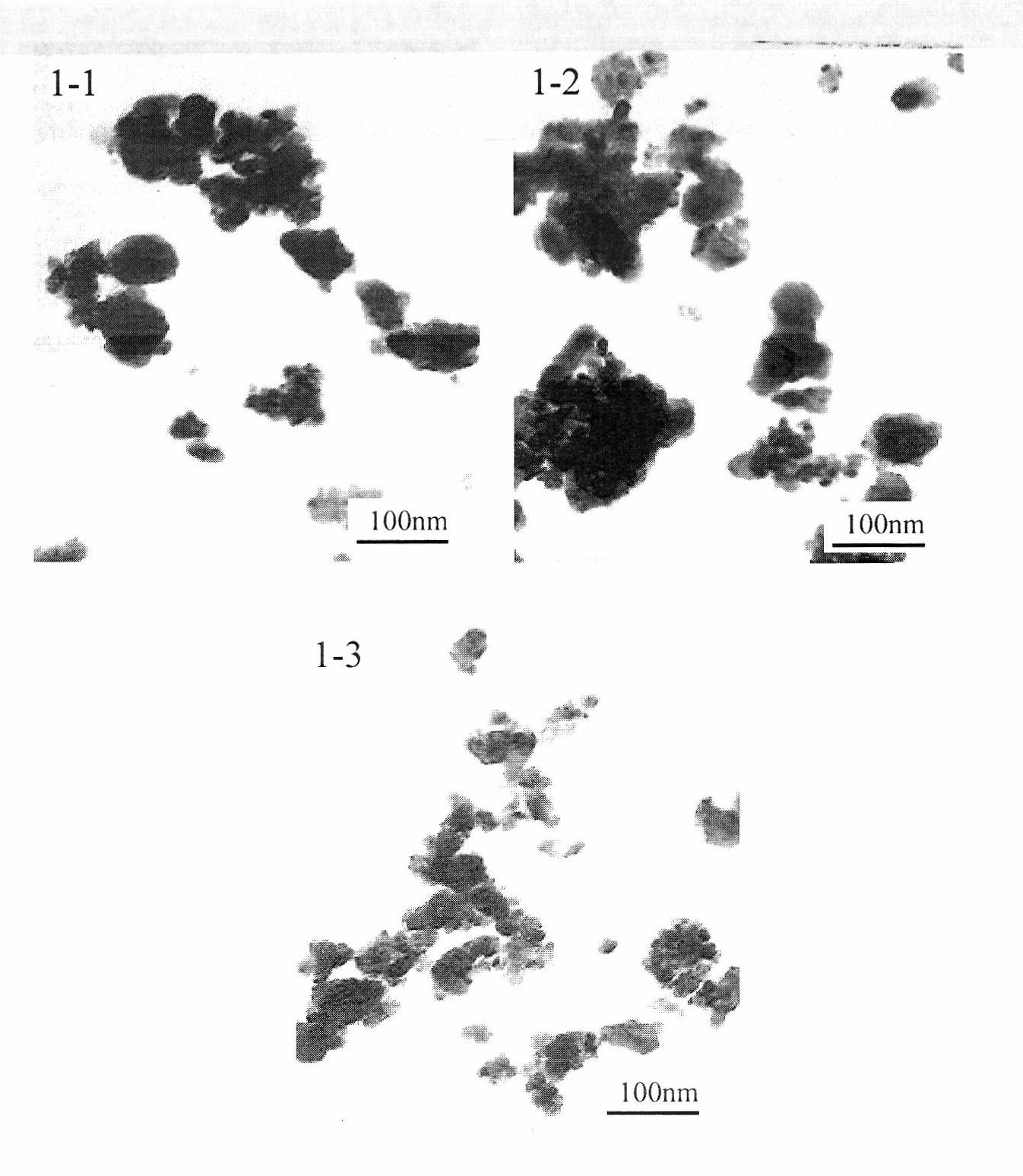

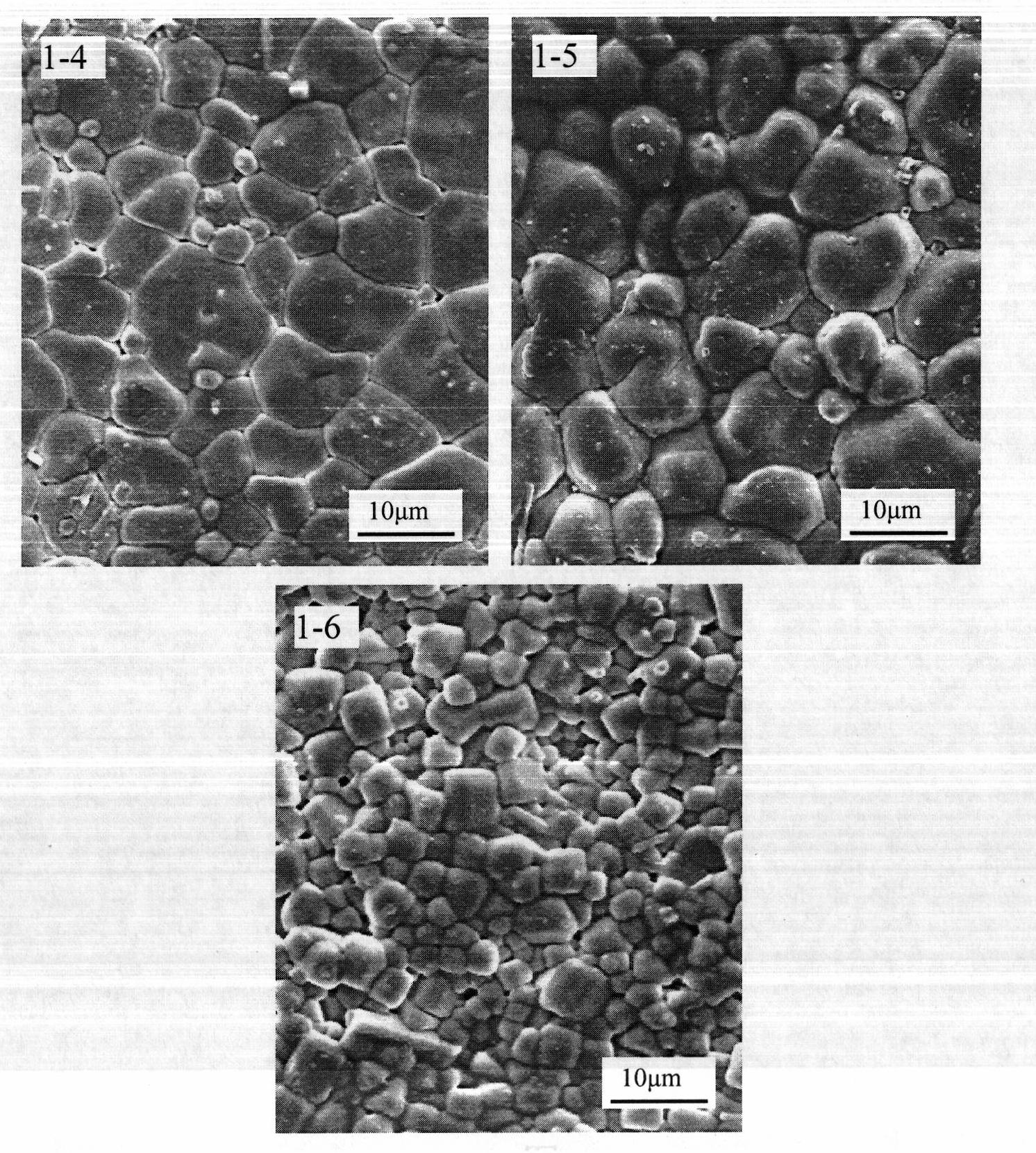

Modified spinel lithium manganate for secondary lithium ion battery and preparation method thereof

InactiveCN102412395AHigh rate characteristicsGood rate characteristicsCell electrodesCarbon coatingCarbon film

The invention is modification of spinel lithium manganate for secondary lithium ion batteries and its preparation method, and is characterized in that the spinel lithium manganate is orderly coated with a silica film and an outer carbon film, which forms a composite material with a spinel lithium manganate-silica-carbon three-layer core-shell structure. The coating is performed by a sol-gel method and a solid phase coating method respectively. The composite material with the three-layer core-shell structure has excellent rate capability, and has a 5C / 0.2C discharge capacity ratio of up to 86%. The normal-temperature and high-temperature cycle performance are greatly improved; the capacity retention rate for 100 cycles of normal-temperature 1C is up to 98%; the capacity retention rate for 100 cycles of 55 DEG C 1C is up to 94%, such as a modified spinel lithium manganate material coated with Li1.04Al0.05Mn1.95O4 body-5 wt% silica coating-5 wt% carbon coating. The problems of unstable cycle performance and poor rate capability of the spinel lithium manganate for secondary lithium ion batteries are effectively solved. The preparation method of the invention is simple and practical, low in cost, and is applicable to large-scale production.

Owner:WUXI LITAI ENERGY TECH

Preparation method of permanent magnetic ferrite material

The invention discloses a preparation method of a permanent magnetic ferrite material. The preparation method comprises the steps of weighing and preparing raw materials depending on mol ratio of a permanent magnetic ferrite main phase MO.nFe2O3, wherein M represents SrCO3, and n represents a mol ratio of Fe2O3 to SrCO3 and ranges from 5.5 to 6.0, and a primary additive added to the raw materials is selected from at least one of SiO2, CaCO3 and Bi2O3; mixing, pre-sintering and grinding the raw materials added with the primary additive, and implementing wet compression molding to obtain the permanent magnetic ferrite material. The preparation method disclosed by the invention, through application of a mixing process and a nano additive, optimizes a micro structure of the permanent magnetic material, thus providing a preparation method of the high-performance sintered permanent magnetic ferrite material which is good in chemical uniformity of mixture, relatively high in density, low in energy consumption and free from addition of rare earth element.

Owner:BGRIMM TECH CO LTD

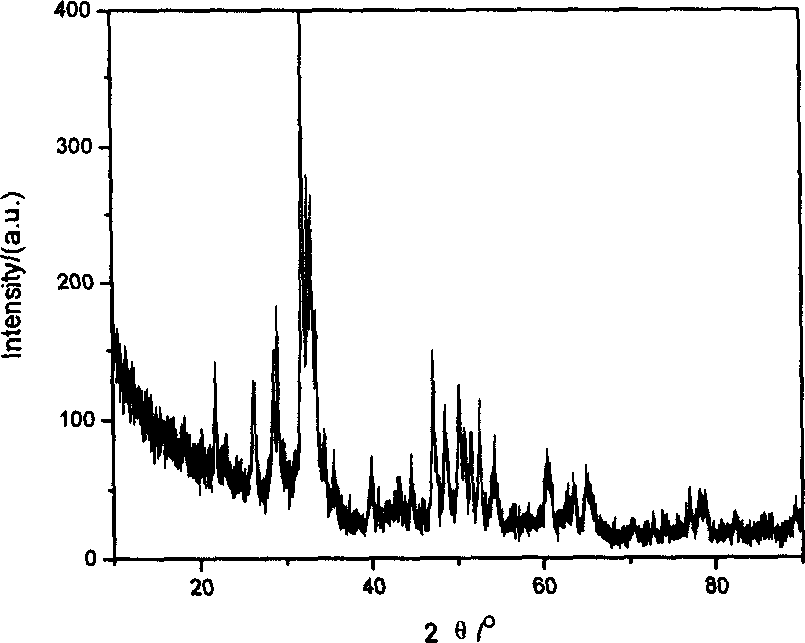

Barium titanate-based Y5V nano-powder and preparation method for ceramic material thereof

The invention discloses barium titanate-based Y5V nano-powder, which is characterized in that: the chemical composition of the powder is represented by a general formula: (Ba1-x-ySrxCay)(Ti1-m-nZrmSnn)O3+A, in which x is more than or equal to 0.01 and less than or equal to 0.05; y is more than or equal to 0.06 and less than or equal to 0.10; m is more than or equal to 0.04 and less than or equal to 0.12; n is more than or equal to 0.01 and less than or equal to 0.06; A may be CeO2, ZnO and SiO2; and dielectric ceramic powder comprises 1 to 4 percent of the A in molar percentage. The powder can be sintered into a barium titanate-based Y5V ceramic material with high dielectric property by sintering at the temperature of between 1,250 and 1,300 DEG C and preserving the heat for 0.5 to 8.0 hours. The preparation method has the advantages of homogeneous components, easy control prescription, and good sintering activity of nano-powder and the powder, and can meet the development requirements on the miniaturization, the base metal and the environmental protection of Y5V ceramic capacitors.

Owner:NORTHWEST UNIV(CN)

Preparation method of nanometer silicate long afterglow luminous material

InactiveCN1948426AGood chemical uniformityControl granularityLuminescent compositionsBoronMaterials science

This invention relates to the preparation of a nanometer silicate long persistence illuminate material, and this invention applies collosol-gelatum technology. Silicate is used as base material, and Eu2+ is used as activating agent, and Dy3+ is assistant activating agent, and boracic compounds is added to improve the performance of afterglow, so the invention is composed by silicate, Eu2+, Dy3+ and boracic compounds. Its molecular formula is Sr2-x-yMgSi2O7: Eux, Dyy, with 0.001 C09K 11 / 59 1 5 1 2006 / 11 / 8 1948426 2007 / 4 / 18 000000000 Tianjin Univ. Tianjin 300072 Ji Huiming Lv Ying Xu Mingxia wangli 12201 The Patent Agency of Tianjin University Qilitai, the City of Tianjin 300072

Owner:TIANJIN UNIV

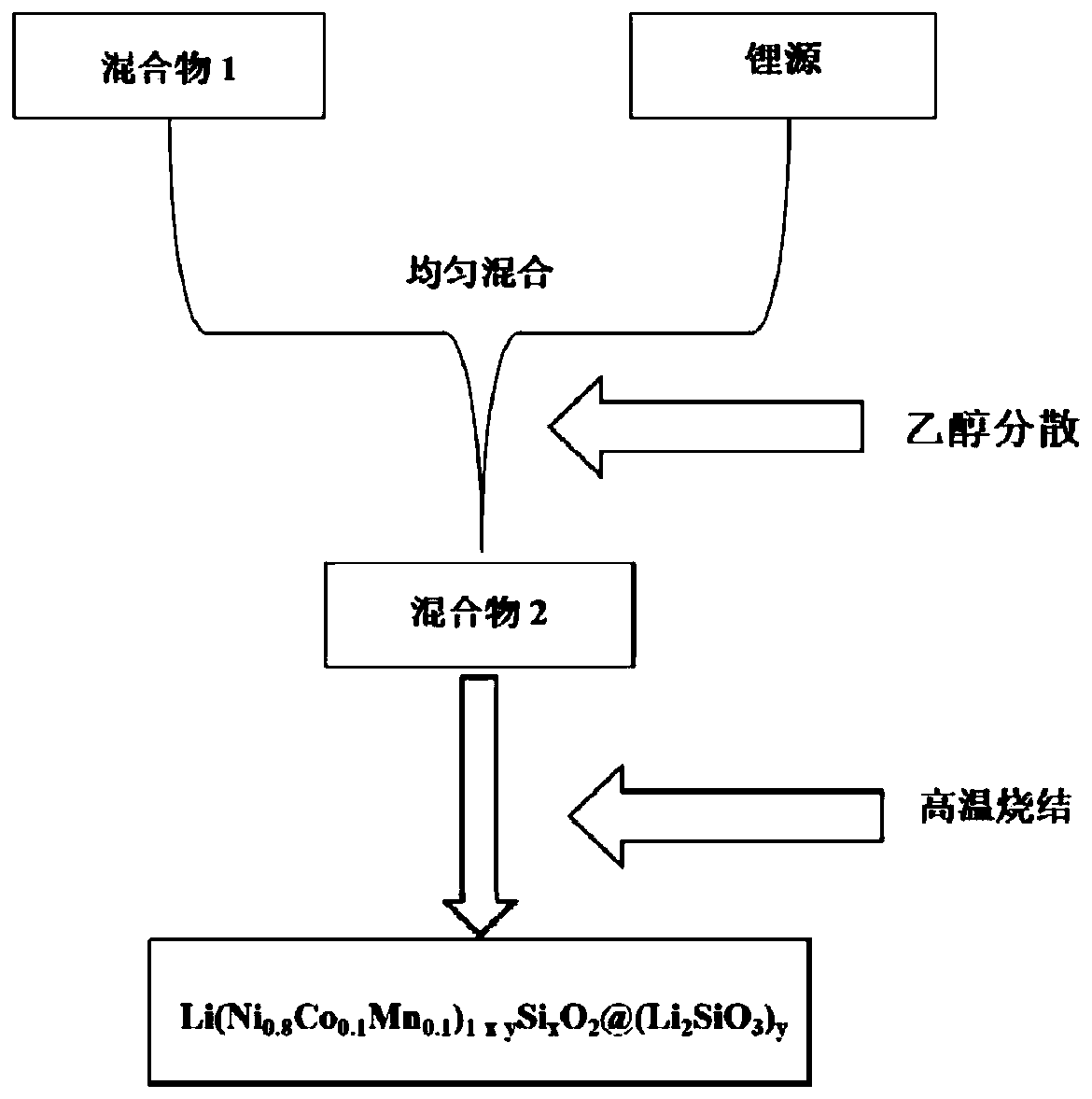

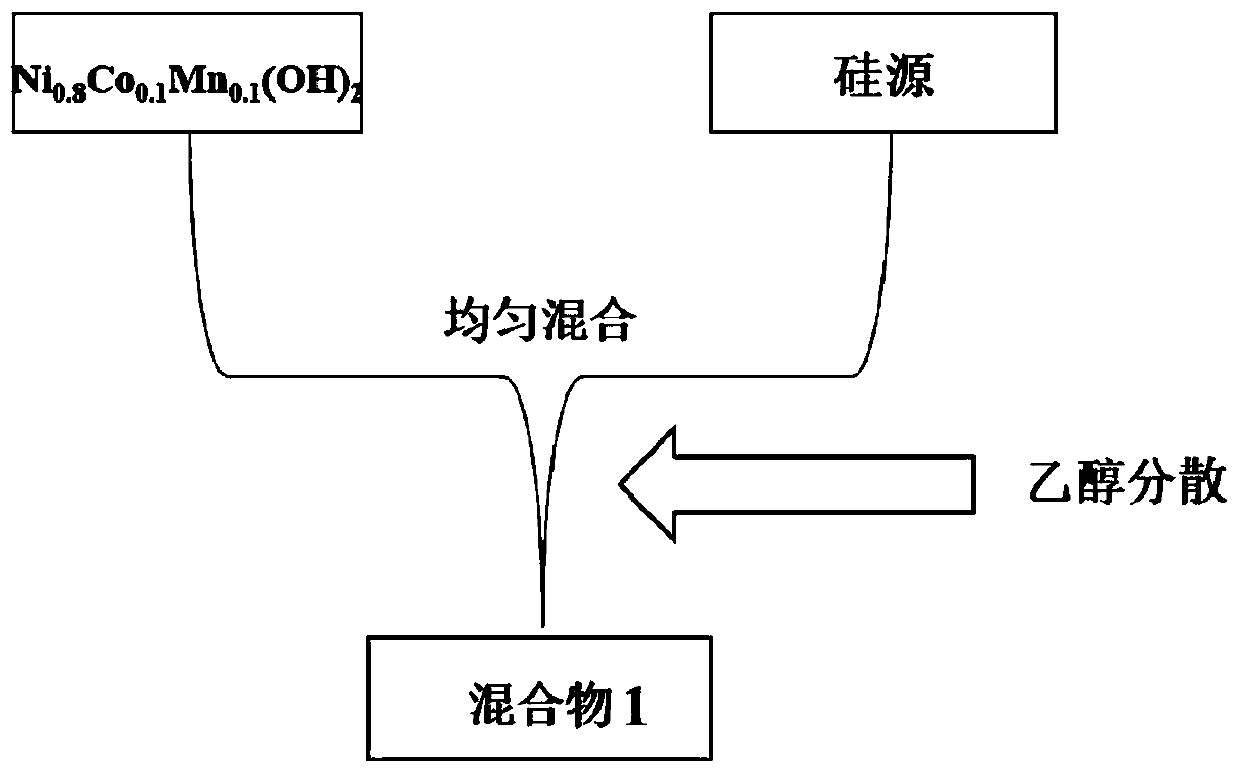

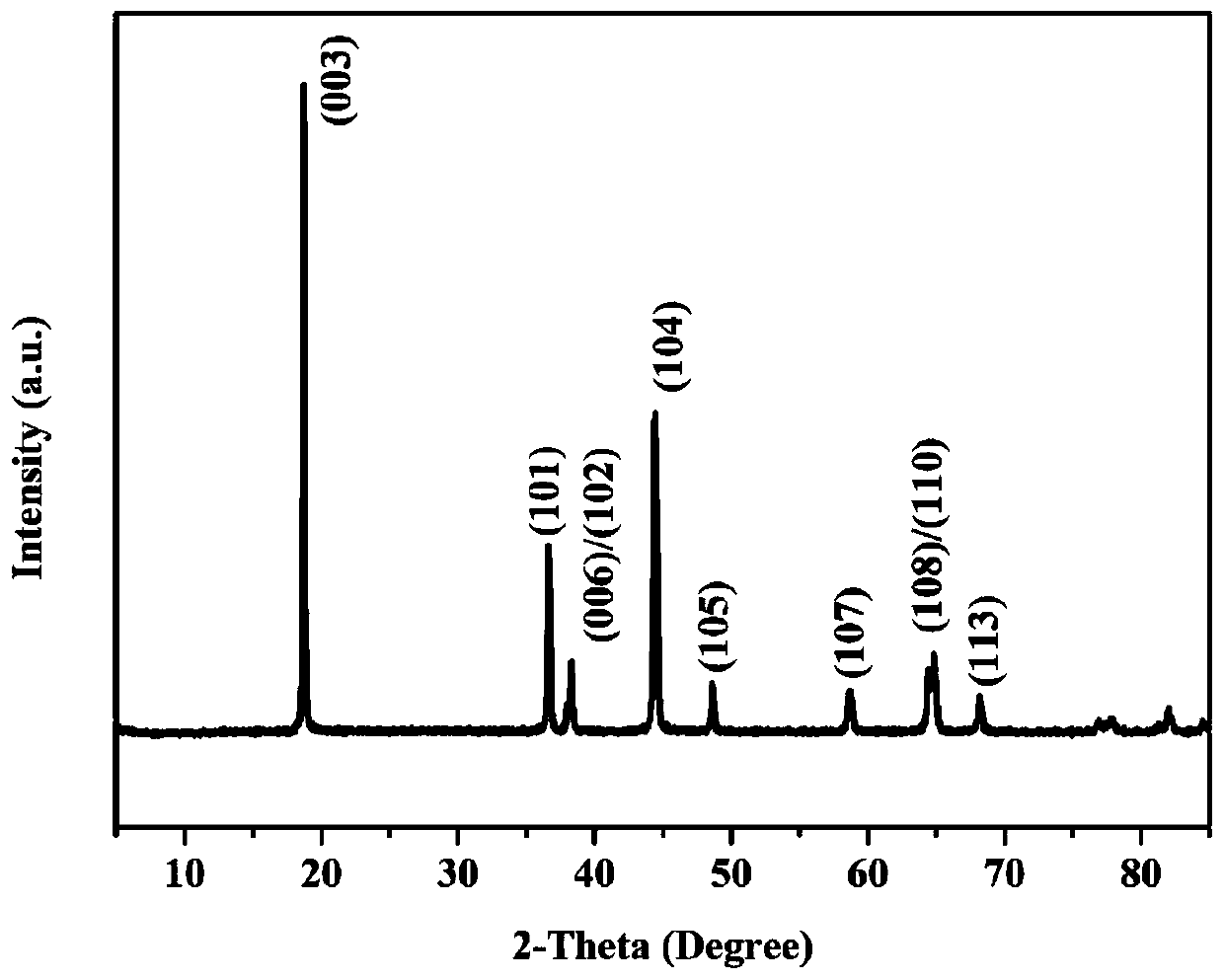

High-potential lithium ion battery NCM ternary anode material and manufacturing method thereof

InactiveCN110534736AIncrease transfer rateStable internal structureCell electrodesSecondary cellsCyclic processHigh rate

The invention belongs to the lithium ion battery field and relates to a lithium ion battery anode material and a manufacturing method thereof. The invention especially relates to a high-potential lithium ion battery NCM ternary anode material and the manufacturing method thereof, which is used for overcoming a defect of poor electrochemical cycle performance of existing lithium ion battery anode material layered high-nickel lithium-nickel-cobalt manganate NCM811 and derivatives. A molecular expression of the anode material is Li (Ni0. 8Co0. 1Mn0. 1) 1-x-ySixO2 @ (Li2SiO3) y, wherein x+y is greater than 0 and is less than or equal to 0.2, and y is much less than x. Li2SiO3 coating modification formed by combining high-valence state Si < 4 + > gradient doping for inhibiting generation of micro-cracks in a circulation process and a surface is adopted. The lithium ion battery anode material has a relatively high specific discharge capacity and excellent cycling stability and a high-rate charge-discharge cycling requirement can be satisfied. Bulk phase doping is performed by adopting a traditional solid phase method, operation is simple, industrial production is easy, a prepared productis high in purity, high in chemical uniformity, high in crystallization quality, fine in product particle, and uniform in distribution, and electrochemical performance is excellent and manufacturingcost is low.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

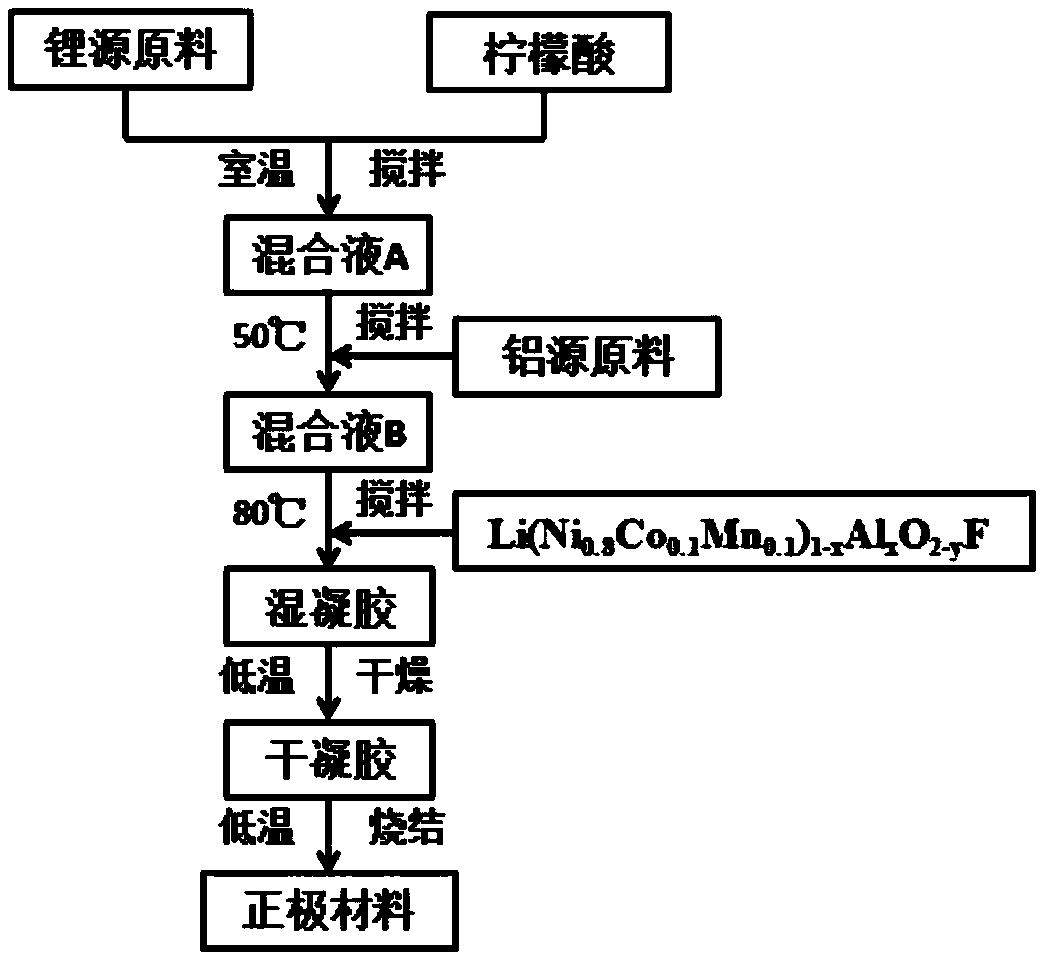

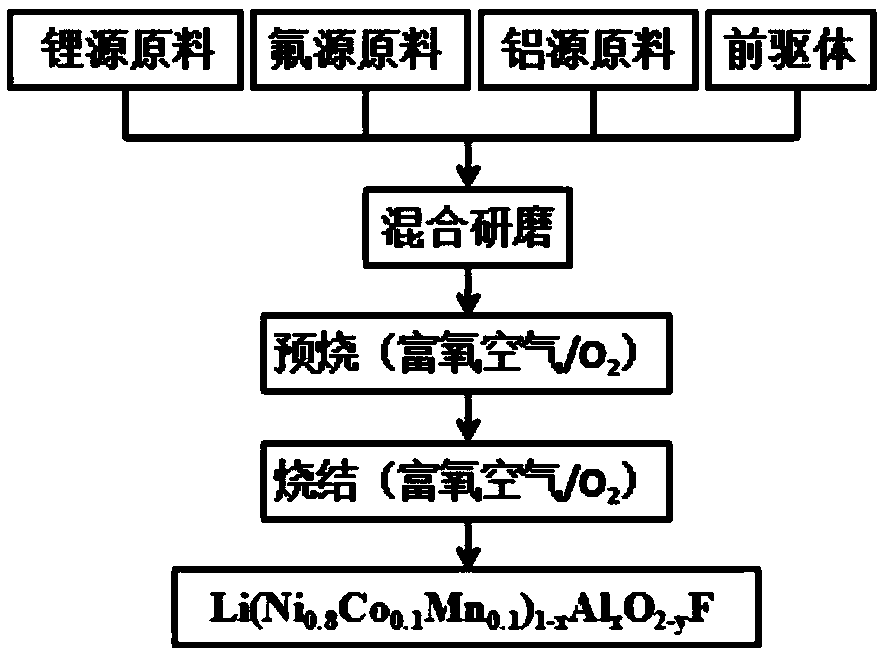

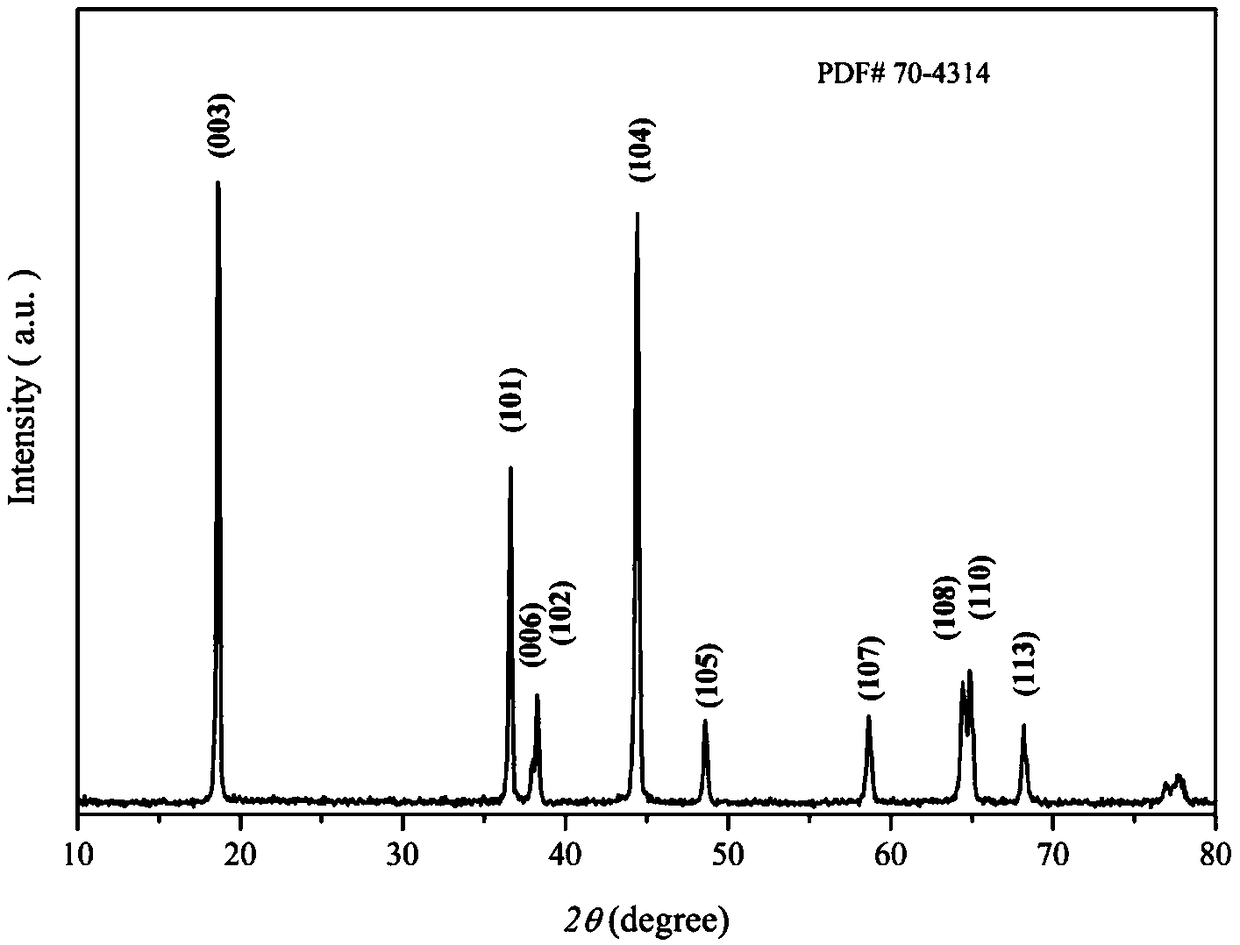

Aluminum and fluorine dual-modified lithium ion battery cathode material and preparation method thereof

InactiveCN108807887AEasy transferStable internal structureCell electrodesSecondary cellsLithium aluminateSide reaction

The invention belongs to the field of lithium ion batteries, and provides a lithium ion battery cathode material Li(Ni0.8Co0.1Mn0.1)1-xAlxO2-yFy@LiAlO2 and a preparation method thereof, wherein x is more than 0, and y is less than or equal to 0.05, and the defects of LiNi0.8Mn0.1Co0.1O2 has poor electrochemical cycle performance and poor safety performance are overcome. Aluminum and fluorine are co-doped in a matrix material, and the trivalent aluminum element not only can stabilize the structure of the material, but also can prevent Ni<2+> from substituting Li<+>, so that the mixing of lithium / nickel cations is reduced, and fluorine can inhibit side reaction between the material and electrolyte; at the same time, the surface of a parent material Li(Ni0.8Co0.1Mn0.1)1-xAlxO2-yFy is coated with an extremely thin lithium fast ion conductor lithium metaaluminate which can enhance the lithium ion transport and reduce the surface alkalinity; the lithium ion battery cathode material can havehigher discharge specific capacity while improving cycling stability, and has a more stable structure compared with LiNi0.8Co0.1Mn0.1O2, the safety and processing performance of the material are improved, and especially at large magnification and high voltage, the safety performance is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing calcium ferroaluminates

The invention relates to a method for preparing calcium ferroaluminates. The method comprises the following steps: proportionally mixing an aluminium nitrate hydrate, a calcium nitrate hydrate, a ferric nitrate hydrate, hexamethylenetetramine, acetylacetone, deionized water and the like uniformly by a sol-gel method, then stirring the mixture at the temperature of 50-70 DEG C to obtain sol, ageing the sol to form gel, carrying out heat treatment on the gel at the temperature of 750-800 DEG C for 2-4 hours and slowly cooling the gel to the room temperature, thus obtaining the calcium ferroaluminates. Compared with the prior art, the method has the following advantages: the preparation process is simple; the reaction process is easy to control; and the product has high uniformity and purityand can be fired at the temperature lower than the temperature in the traditional methods.

Owner:TONGJI UNIV

Nanocrystalline plumbum stannate powder preparation method

The invention relates to a process for preparing nanocrystalline lead stannate, in particular a process for preparing ferro-electrical functional ceramic material, wherein water dissoluble inorganic salt precursor is utilized, the raw material being, PbNO3 (analytical pure), SnCl45H2O (analytical pure), NaOH (analytical pure), HNO3 (analytical pure), and the preparation process comprises the steps of, producing solution A by dissolving PbNO3 and SnCl4-5H2O with mol ratio 1:1 into HNO3 solution, then dissolving NaOH into deionized water to prepare solution B with pH=12, dropping solution an into solution B of equal quantity, maintaining the temperature at 80 deg. C, stirring about 8 hours by magnetic stirrer, maintaining pH=11, thus obtaining lacte colloidal sol, finally heating and dehydrating to obtain the high purity PbSnO3 polycrystalline powder of 10 nm sizes.

Owner:UNIV OF SCI & TECH BEIJING

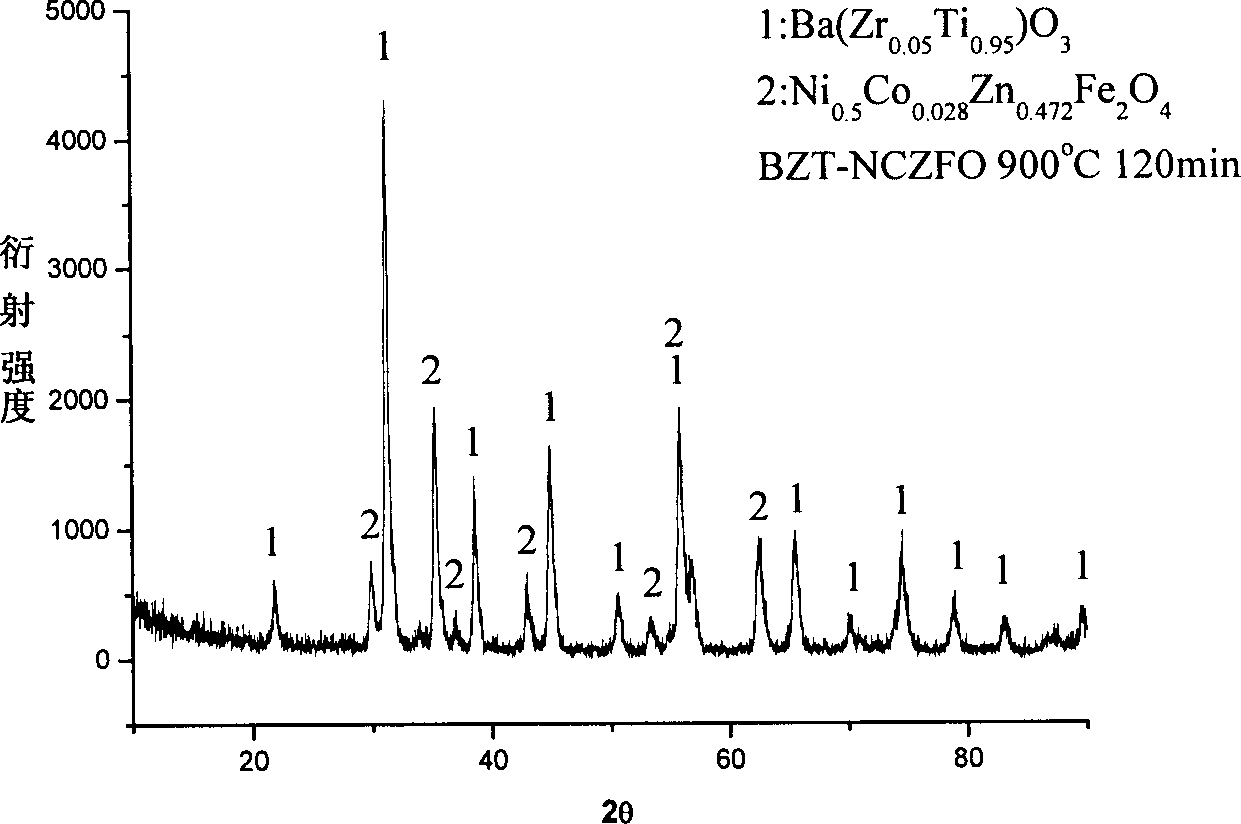

Softening method for producing ferroelectric and ferromagnetic composite material powder by home position

A soft chemical method for in-situ preparing powder with ferroelectric and ferromagnetic composite materials is carried out by adding ferrite metal nitrate and ferroelectric metal nitrate into citric acid solution, heating, stirring, adding into ferroelectric metal alkoxide, adjusting pH value, obtaining homogeneous and stable sol, preparing powder, drying the obtained precursor, baking, burning and heat treating the burnt powder to obtain the final powder. It is cheap and simple, and has better chemical evenness, high purity and fine particles.

Owner:UNIV OF SCI & TECH BEIJING

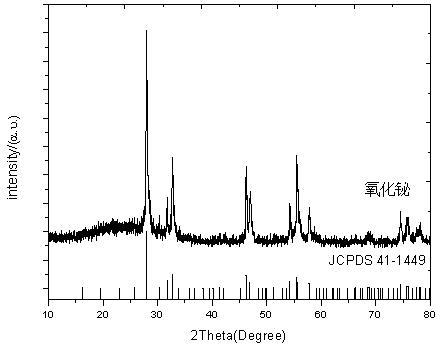

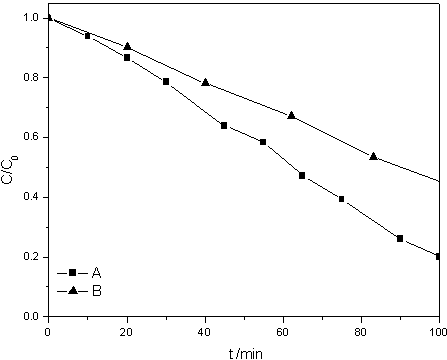

Preparation method and application of spherical nano bismuth oxide photocatalyst

InactiveCN103861580AHigh chemical uniformityFine granularityNanotechnologyMetal/metal-oxides/metal-hydroxide catalystsGluconic acidPhoto catalysis

The invention provides a preparation method and an application of a spherical nano bismuth oxide photocatalyst, and relates to the field of novel catalysts. The preparation method comprises the following steps: dissolving bismuth-containing compounds and gluconic acid sodium in water, and adjusting the pH value to be 10-13 to obtain a mixed solution; putting the mixed solution in a high pressure reaction kettle, sealing, keeping for 18-24 hours at the temperature of 120-180 DEG C, and cooling to the room temperature; centrifuging the solution inside the high pressure reaction kettle, taking out precipitates and roasting after drying so as to obtain the spherical nano bismuth oxide photocatalyst. The invention further provides the spherical nano bismuth oxide photocatalyst prepared by adopting the method and an application of the spherical nano bismuth oxide photocatalyst to decomposition of catalytic organic pollutants. The preparation method is easy and convenient, low in cost and environmentally-friendly, and the productive rate reaches more than 80%. Spherical nano bismuth oxide is in nanoscale, uniform in particle size, relatively high in solar energy utilization rate and relatively high in quantum efficiency, and thus the spherical nano bismuth oxide has the relatively high photocatalytic activity, and can be applied to the decomposition of the catalytic organic pollutants.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com