Preparation method of nano hydroxylapatite adsorbent for absorbing heavy metal ions in waste water

A technology of nano-hydroxyapatite and heavy metal ions, which is applied in the fields of non-metal elements, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the limitations of the wide application of hydroxyapatite, complex artificial synthesis, complex preparation process, etc. problems, achieve the effect of improving chemical uniformity, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

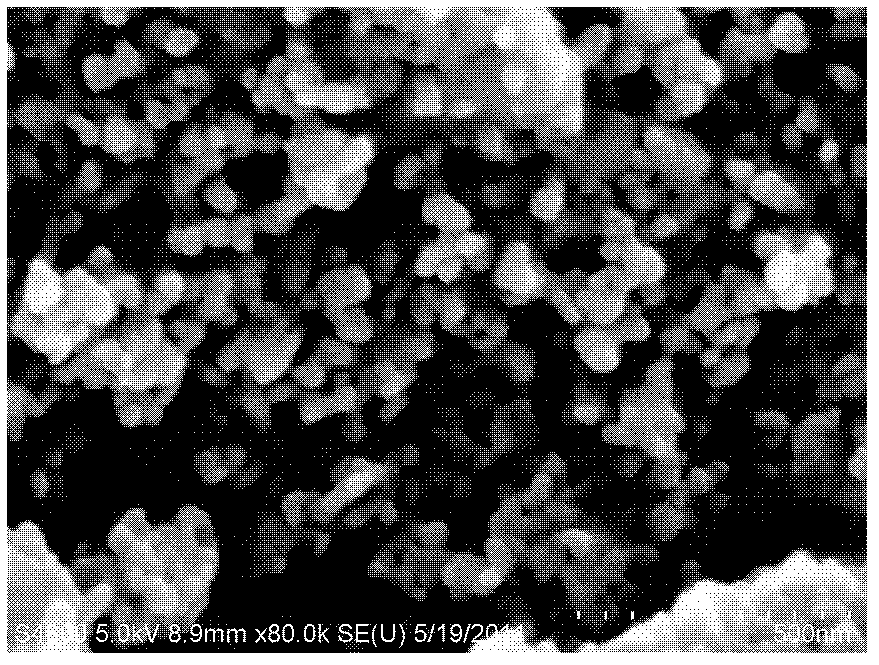

Image

Examples

Embodiment 1

[0015] A preparation method of nano-hydroxyapatite adsorbent for the adsorption of heavy metal ions in wastewater is as follows:

[0016] 1. Preparation of calcium and phosphorus precursor solutions: prepare 0.1 mol / liter of calcium nitrate (Ca(NO 3 ) 2 ) with 0.3 mol / L phosphoric acid (H 3 PO 4 ) aqueous solution; after the calcium nitrate and phosphoric acid solutions are stirred uniformly, ammonia water (NH 4 OH) was added dropwise to the phosphoric acid solution, and the pH value was adjusted to 10 to obtain a precursor solution containing calcium and phosphorus.

[0017] 2. Gelation process: According to the molar ratio of calcium and phosphorus of 1.5:1, the calcium-containing precursor solution is added dropwise to the phosphorus-containing precursor solution while stirring continuously to obtain a white precipitate solution, and ammonia water is continuously added during the reaction to make The pH value of the white precipitate solution is kept constant at 10; aft...

Embodiment 2

[0021] A preparation method of nano-hydroxyapatite adsorbent for the adsorption of heavy metal ions in wastewater is as follows:

[0022] 1. Preparation of calcium and phosphorus precursor solutions: prepare 0.5 mol / liter of calcium nitrate (Ca(NO 3 ) 2 ) with 0.25 mol / L phosphoric acid (H 3 PO 4 ) aqueous solution; after the calcium nitrate and phosphoric acid solutions are stirred uniformly, ammonia water (NH 4 OH) was added dropwise to the phosphoric acid solution, and the pH value was adjusted to 11 to obtain a precursor solution containing calcium and phosphorus.

[0023] 2. Gelation process: According to the molar ratio of calcium and phosphorus of 1.67:1, the calcium-containing precursor solution is added dropwise to the phosphorus-containing precursor solution, while stirring continuously, to obtain a white precipitate solution, and ammonia water is continuously added during the reaction. The pH value of the white precipitate solution is kept constant at 11; after ...

Embodiment 3

[0027] A preparation method of nano-hydroxyapatite adsorbent for the adsorption of heavy metal ions in wastewater is as follows:

[0028] 1. Preparation of calcium and phosphorus precursor solutions: prepare 0.75 mol / liter of calcium nitrate (Ca(NO 3 ) 2 ) with 0.4 mol / L phosphoric acid (H 3 PO 4 ) aqueous solution; after the calcium nitrate and phosphoric acid solutions are stirred uniformly, ammonia water (NH 4 OH) was added dropwise to the phosphoric acid solution, and the pH value was adjusted to 12 to obtain a precursor solution containing calcium and phosphorus.

[0029] 2. Gelation process: According to the molar ratio of calcium and phosphorus of 1.75:1, the calcium-containing precursor solution is added dropwise to the phosphorus-containing precursor solution while stirring continuously to obtain a white precipitate solution, and ammonia water is continuously added during the reaction to make The pH value of the white precipitate solution is kept constant at 12; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com