Prepn and application of Li and Ti doped nickel oxide-base ceramic

A nickel oxide-based, co-doped technology, applied in ceramics, inorganic insulators, etc., can solve the problems of unstable dielectric constant of ferroelectric materials, poor material uniformity, unfavorable environmental protection requirements, etc., and achieve good temperature stability and short time. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

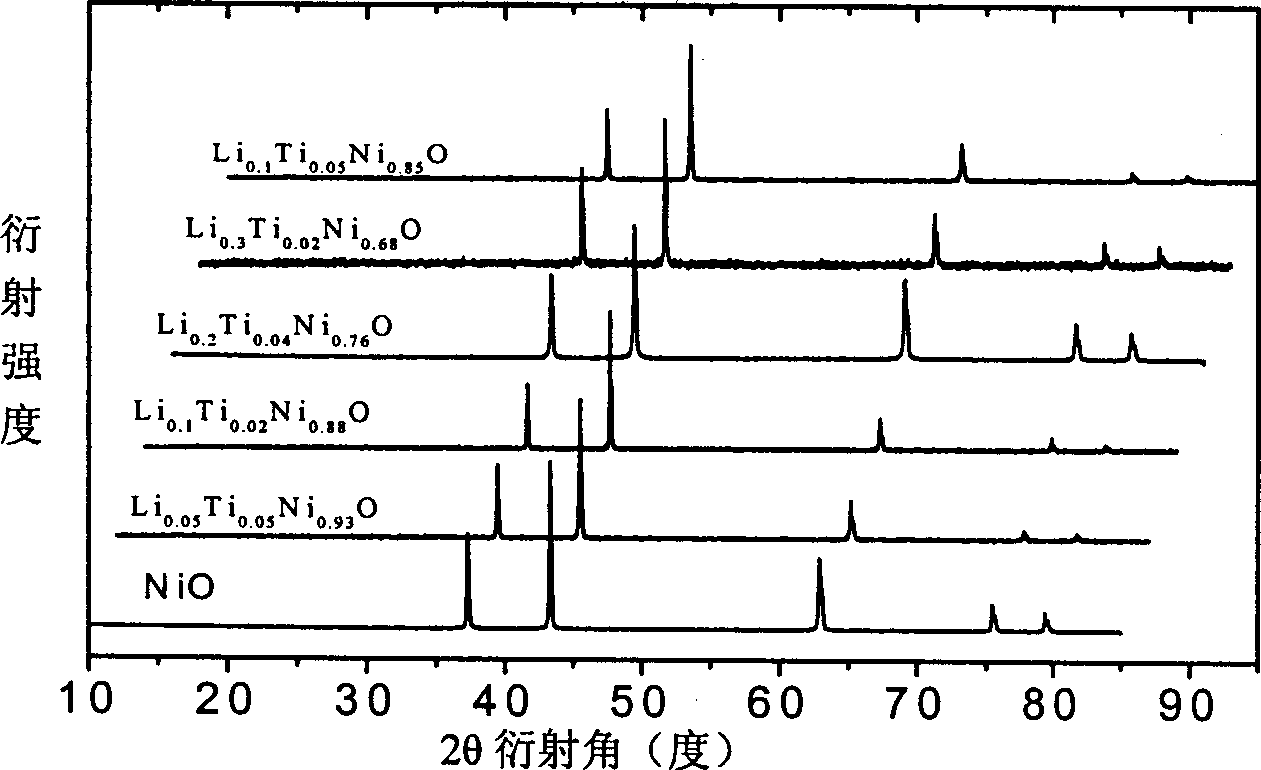

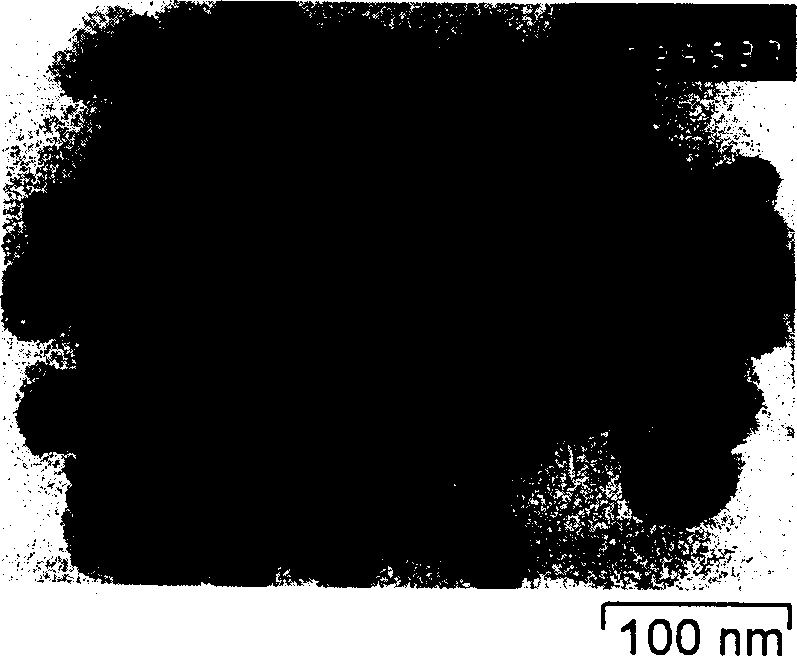

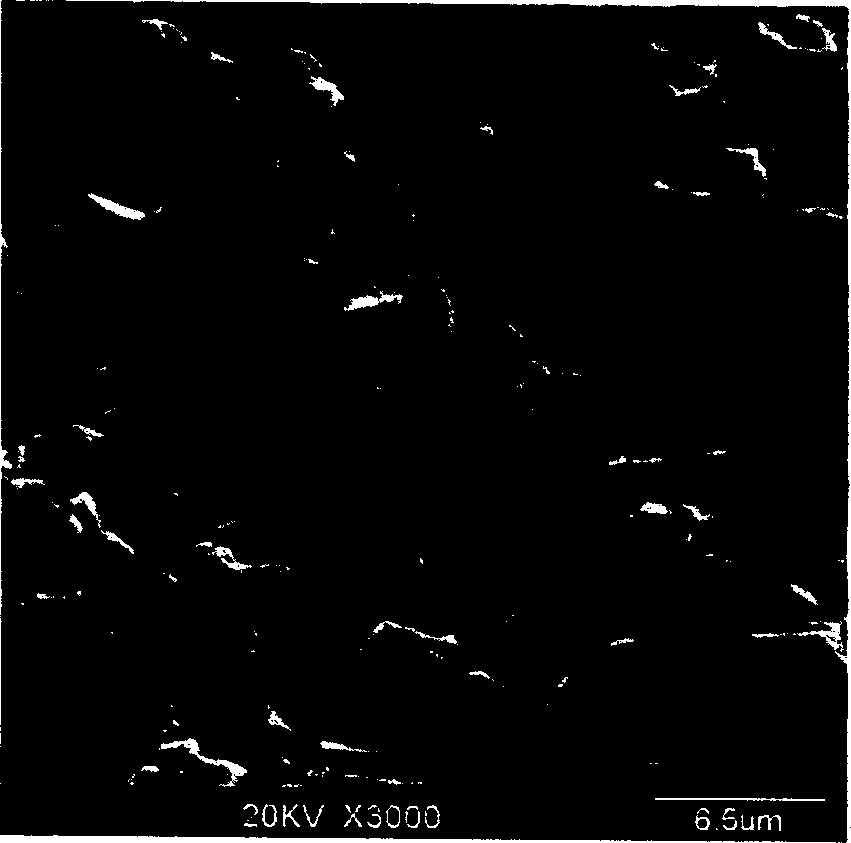

[0037] Ni(NO 3 ) 2 (0.093mol) and LiNO 3 (0.005mol) was dissolved in 250ml deionized water, stirred to obtain a transparent solution, 0.121mol citric acid was dissolved in the above solution, and stirred at 70°C for about 3 hours to obtain a viscous sol, which was put into an oven and dried at 110°C for about 12 Hours, a dry gel was obtained, ground, and pre-calcined at 400°C for 2 hours to obtain a black Li-Ni-O precursor powder. The powder and TiO 2 (0.002mol) powder mixing, ball milling, drying, dry pressing at 4Mpa, sintering at 1300°C for 4 hours to obtain bulk Li 0.05 Ti 0.02 Ni0.93 oCeramic materials. At room temperature, the relative permittivity ε = 12190 (10000Hz). For material characterization and properties see figure 1 , image 3 , Figure 10 and Figure 11 ; The precursor is a spherical particle with a size of about 30 nm (see figure 2 ).

Embodiment 2

[0039] Ni(NO 3 ) 2 (0.088mol) and LiNO 3 (0.01mol) was dissolved in 250ml deionized water, stirred to obtain a transparent solution, 0.176mol citric acid was dissolved in the above solution, stirred at 80°C for about 3 hours to obtain a viscous sol, put the sol in an oven, and dry at 130°C for about 12 Hours, to obtain a dry gel, ground, 600 ° C pre-calcination for 1 hour, to obtain black Li-Ni-O precursor powder. The powder and TiO 2 (0.002mol) powder mixing, ball milling, drying, dry pressing at 5 MPa, and sintering at about 1100 °C for 8 hours to obtain bulk Li 0.1 Ti 0.02 Ni 0.88 oCeramic materials. At room temperature, the relative permittivity ε = 52280 (10000Hz). For material characterization and properties see figure 1 , Figure 4 and Figure 12 .

Embodiment 3

[0041] Ni(NO 3 ) 2 (0.076mol) and LiNO 3 (0.02mol) was dissolved in 250ml deionized water, stirred to obtain a transparent solution, 0.128mol citric acid was dissolved in the above solution, and stirred at 70°C for about 3 hours to obtain a viscous sol, which was put into an oven and dried at 120°C for about 12 hours, a dry gel was obtained, ground, and pre-calcined at 450° C. for 1 hour to obtain a black precursor powder. The powder and TiO 2 (0.004mol) powder mixing, ball milling, drying, dry pressing at 5 MPa, and sintering at about 1280 °C for 6 hours to obtain bulk Li 0.2 Ti 0.04 Ni 0.76 oCeramic materials. At room temperature, relative permittivity ε = 200850 (10000Hz). For material characterization and properties see figure 1 , Figure 5 and Figure 13 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com