Small high-low temperature tester

A high and low temperature test, high and low temperature test chamber technology, applied in the direction of laboratory appliances, heating or cooling equipment, shell or chamber, etc., can solve the problem of complex structure of high and low temperature test chamber, difficulty in meeting humidity test, complicated operation process, etc. problems, to achieve the effect of convenient structural design and layout, simple structure, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the embodiments.

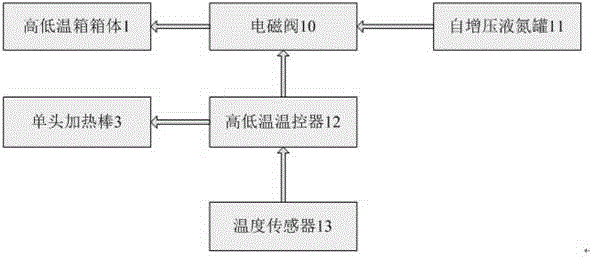

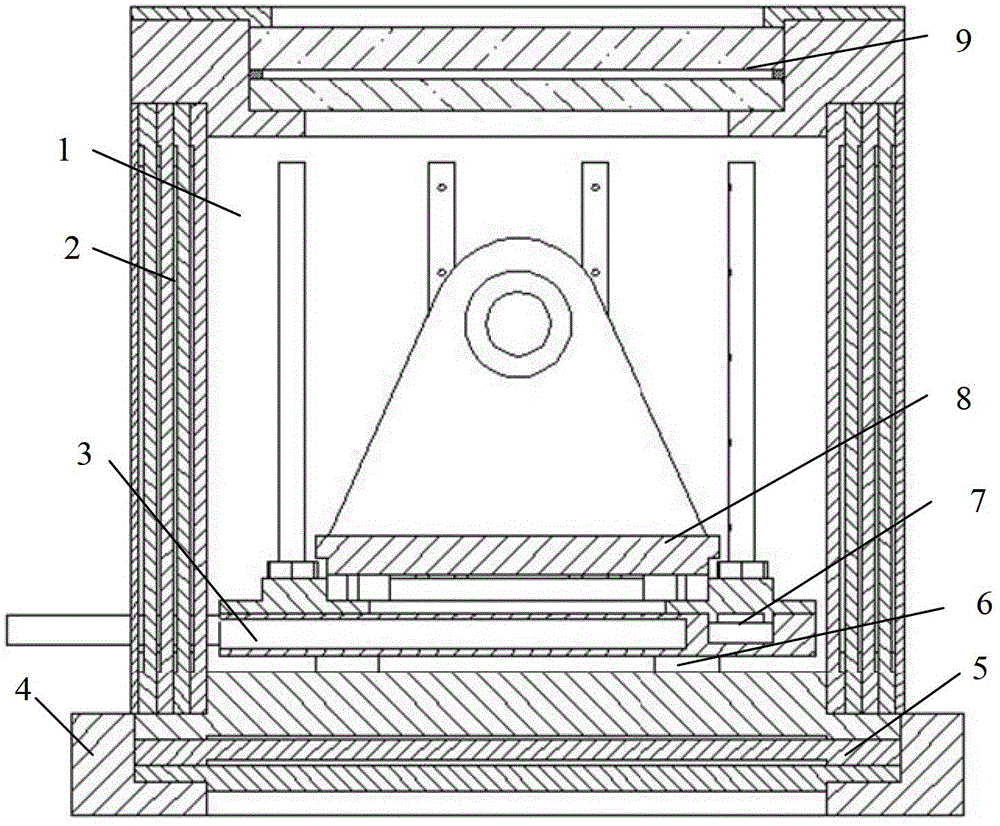

[0021] Referring to the accompanying drawings, the high and low temperature test chamber includes a high and low temperature test chamber body 1, a temperature sensor 13, a single-head heating rod 3, a solenoid valve 10, a self-pressurized liquid nitrogen tank 11 and a high and low temperature thermostat 12. The high and low temperature test box body 1 includes a side insulation board 2 , a bottom insulation board 5 , a tempered glass cover 9 , a base 4 , a cooling and heating system stand 7 and a test piece mounting bracket 8 .

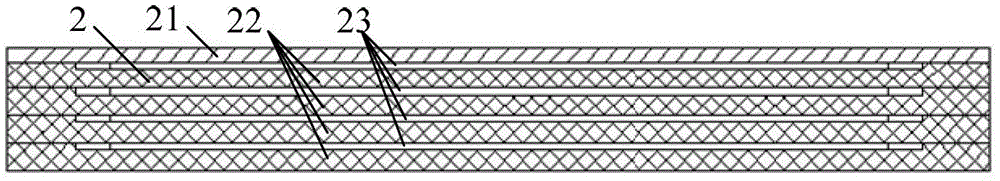

[0022] The side insulation board 2 is composed of four layers of epoxy boards 22 and one layer of stainless steel boards 21 stacked and fixed. A thin layer of air layer 23 is formed between the epoxy boards 22 and between the epoxy board 22 and the stainless steel board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com