Polyimide containing carbazole structure, preparation method thereof and application thereof

A polyimide and polyimide film technology, applied in the field of material science, can solve the problems of improving polymer barrier properties and changing solubility, achieving high glass transition temperature and thermal stability, excellent Barrier properties, effects of various preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

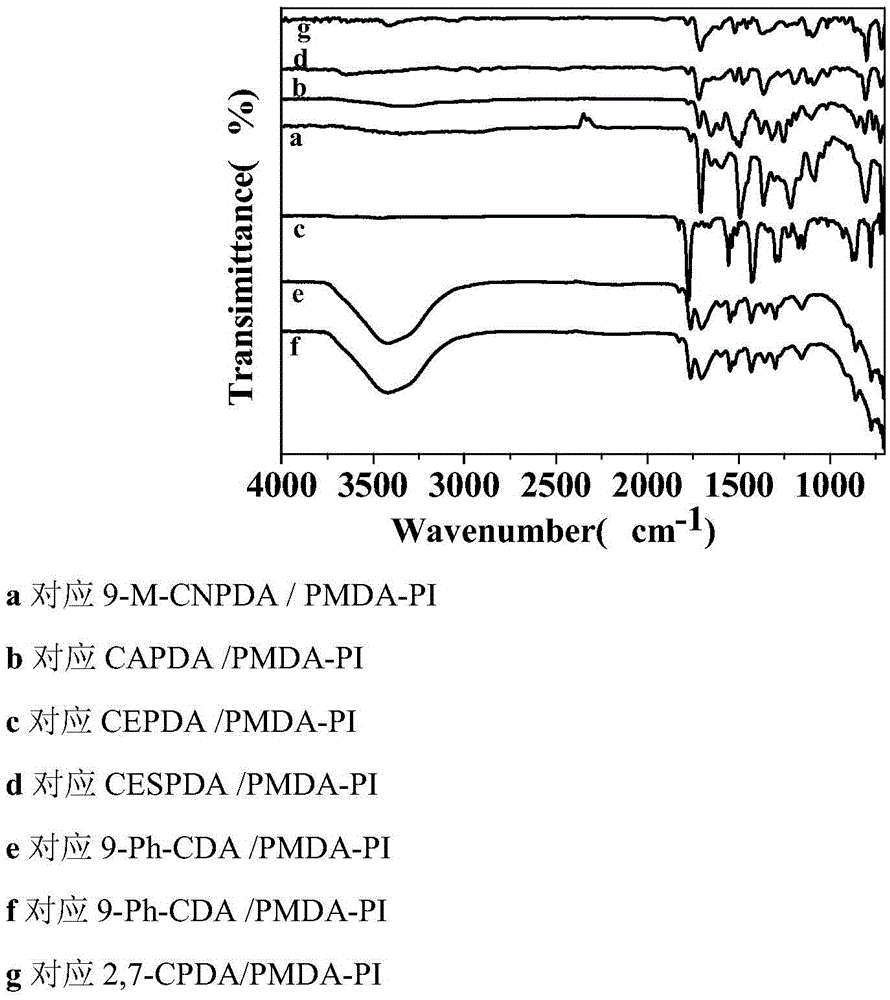

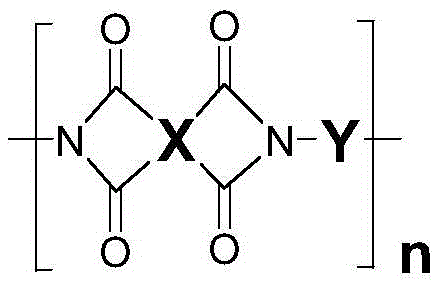

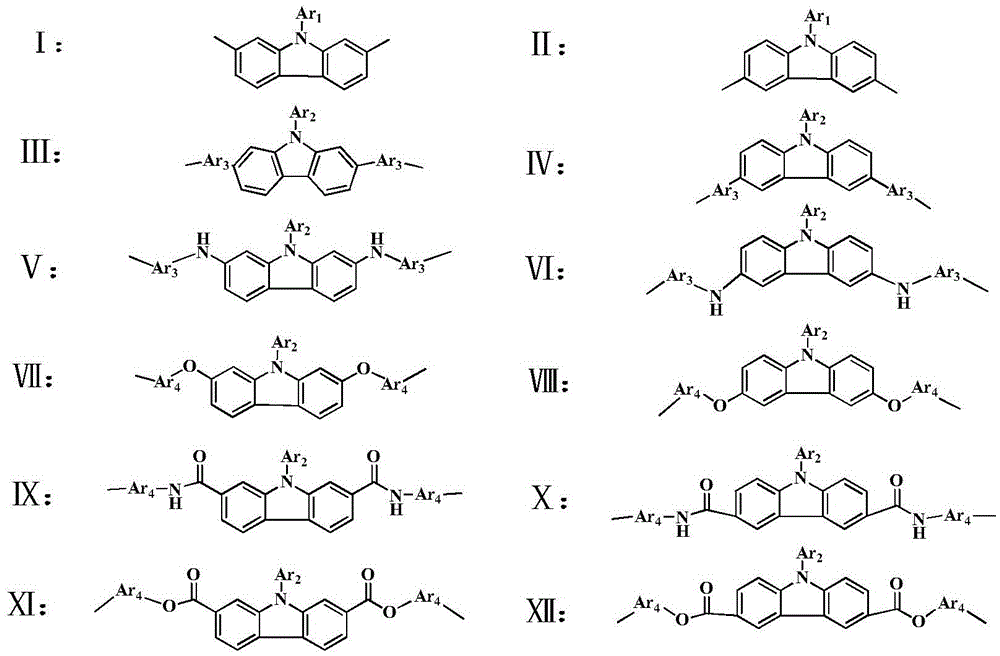

[0042] At room temperature, 3.9348g (0.01mol) N1,N1'-(9-methyl-9H-carbazole-3,6-diyl)bis-(benzene-1,4-diamine)(9-M-CNPDA) and 57.3 g (60.7ml) N,N-dimethylformamide was added to a 100ml three-necked flask, argon was introduced, stirred, and after it was completely dissolved, 2.1812g (0.01mol) 1,2,4,5-Benzenetetracarboxylicanhydride ( 1,2,4,5-Pyromellitic dianhydride, PMDA), continue stirring for 6 hours to obtain a homogeneous transparent and viscous polyamic acid solution. Then scrape and coat the polyamic acid solution on the glass plate after removing air bubbles, then place the glass plate in a vacuum oven and vacuumize. The heating program is as follows: the room temperature is raised to 100°C, and then the temperature is kept constant for 1h→100°C to 200°C. After constant temperature, the whole process is 1h→200°C and the temperature is raised to 300°C. The whole process of constant temperature is 1h~300°C and the temperature is raised to 400°C. The infrared spectrum of ...

Embodiment 2

[0046] At room temperature, mix 4.3548g (0.01mol) N3, N6-bis(4-aminophenyl)-9H-carbazole-3,6-dicarbazole-xamide (CAPDA) and 51.1g (58.4ml) N,N-dimethyl form Add the amide into a 100ml three-necked flask, pass in argon, stir, and after it is completely dissolved, add 2.1812g (0.01mol) of 1,2,4,5-Benzenetetracarboxylicanhydride (1,2,4,5-pyromellitic acid di anhydride, PMDA), and continued stirring for 6h to obtain a homogeneous transparent and viscous polyamic acid solution. Then scrape and coat the polyamic acid solution on the glass plate after removing air bubbles, then place the glass plate in a vacuum oven and vacuumize. The heating program is as follows: the room temperature is raised to 100°C, and then the temperature is kept constant for 1h→100°C to 200°C. After constant temperature, the whole process is 1h→200°C and the temperature is raised to 300°C. The whole process of constant temperature is 1h~300°C and the temperature is raised to 400°C. The infrared spectrum of ...

Embodiment 3

[0050] At room temperature, 3.8148g (0.01mol) 4,4'-((9H-carbazole-3,6-diyl)bis(oxy))dianiline (CEPDA) and 63.9g (67.7ml) N,N-dimethyl Formamide was added to a 100ml three-necked flask, filled with argon, stirred, and after it was completely dissolved, 2.1812g (0.01mol) of 1,2,4,5-Benzenetetracarboxylicanhydride (1,2,4,5-pyromellitic acid Dianhydride, PMDA), continue stirring reaction 6h, obtain homogeneous transparent viscous polyamic acid solution. Then scrape and coat the polyamic acid solution on the glass plate after removing air bubbles, then place the glass plate in a vacuum oven and vacuumize. The heating program is as follows: the room temperature is raised to 100°C, and then the temperature is kept constant for 1h→100°C to 200°C. After constant temperature, the whole process is 1h→200°C and the temperature is raised to 300°C. The whole process of constant temperature is 1h~300°C and the temperature is raised to 400°C. The infrared spectrum of the polyimide film is sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com