Soft soil foundation combined pile net structure

A soft soil foundation and combined pile technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of huge investment in bored pile engineering, poor pile quality, and inclined deformation, so as to enhance the overall effect of the plane and ensure the bearing capacity. Ability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

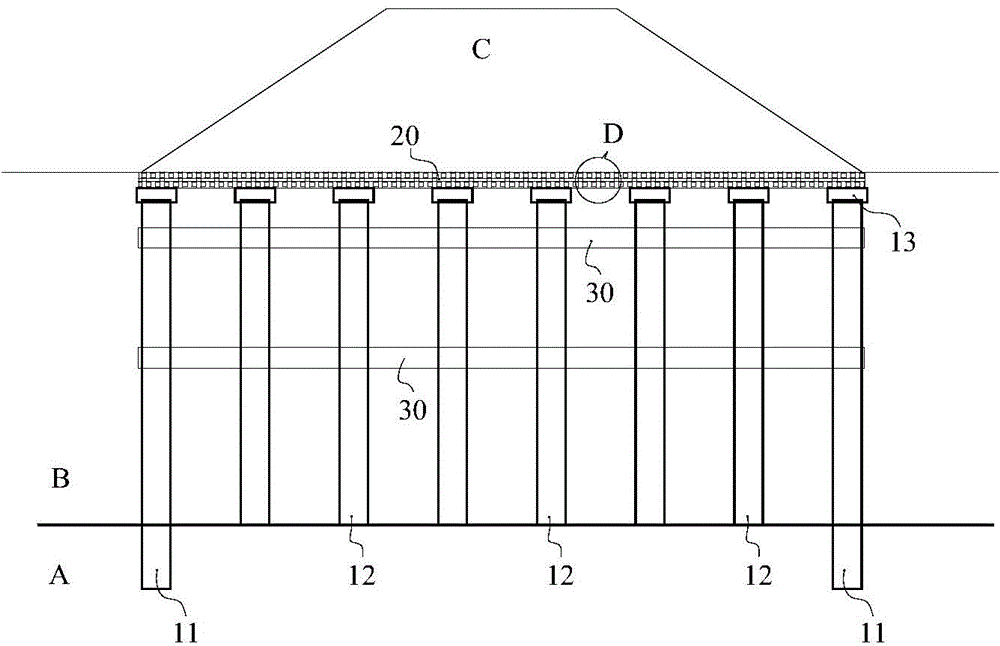

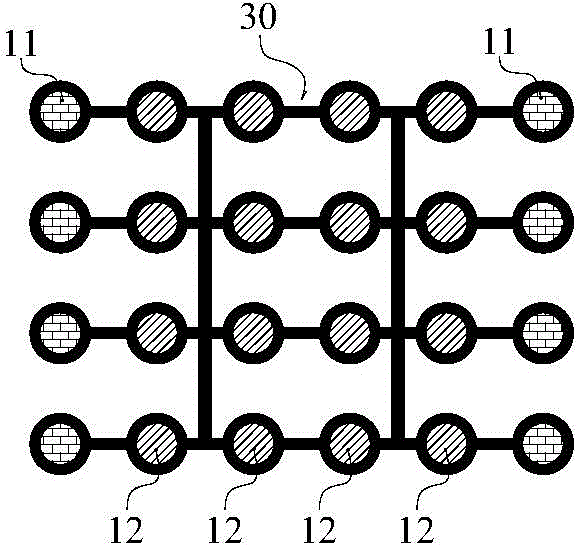

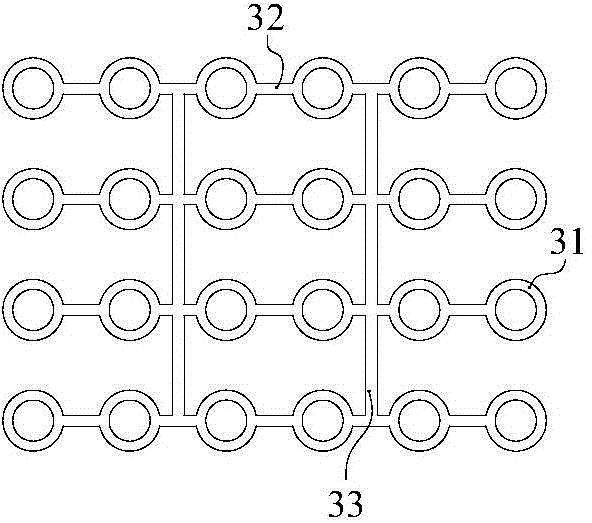

[0014] refer to figure 1 and figure 2 , the soft soil foundation composite pile network structure includes: bored cast-in-situ piles 12, which are arranged at intervals around the boundary of the filling body C, and the bottom of the piles enters a certain depth in the underlying bedrock layer A of the soft soil layer B. When the width of the filling body C is large , the bored piles 12 can be arranged in multiple rows; the press-in piles 12 are arranged at intervals in the soft soil layer B within the scope of the bored piles 11, and the bottom is pressed into the top surface of the bedrock layer A; the pile cap 13 is arranged on Bored cast-in-place piles 11 and tops of pressed-in piles 12 are integrated with them; guiding and fixed frame lattice 30 is located in soft soil layer B, forming lateral constraints on each bored piles 12 and pressed-in pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com