Patents

Literature

65results about How to "Avoid uneven deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

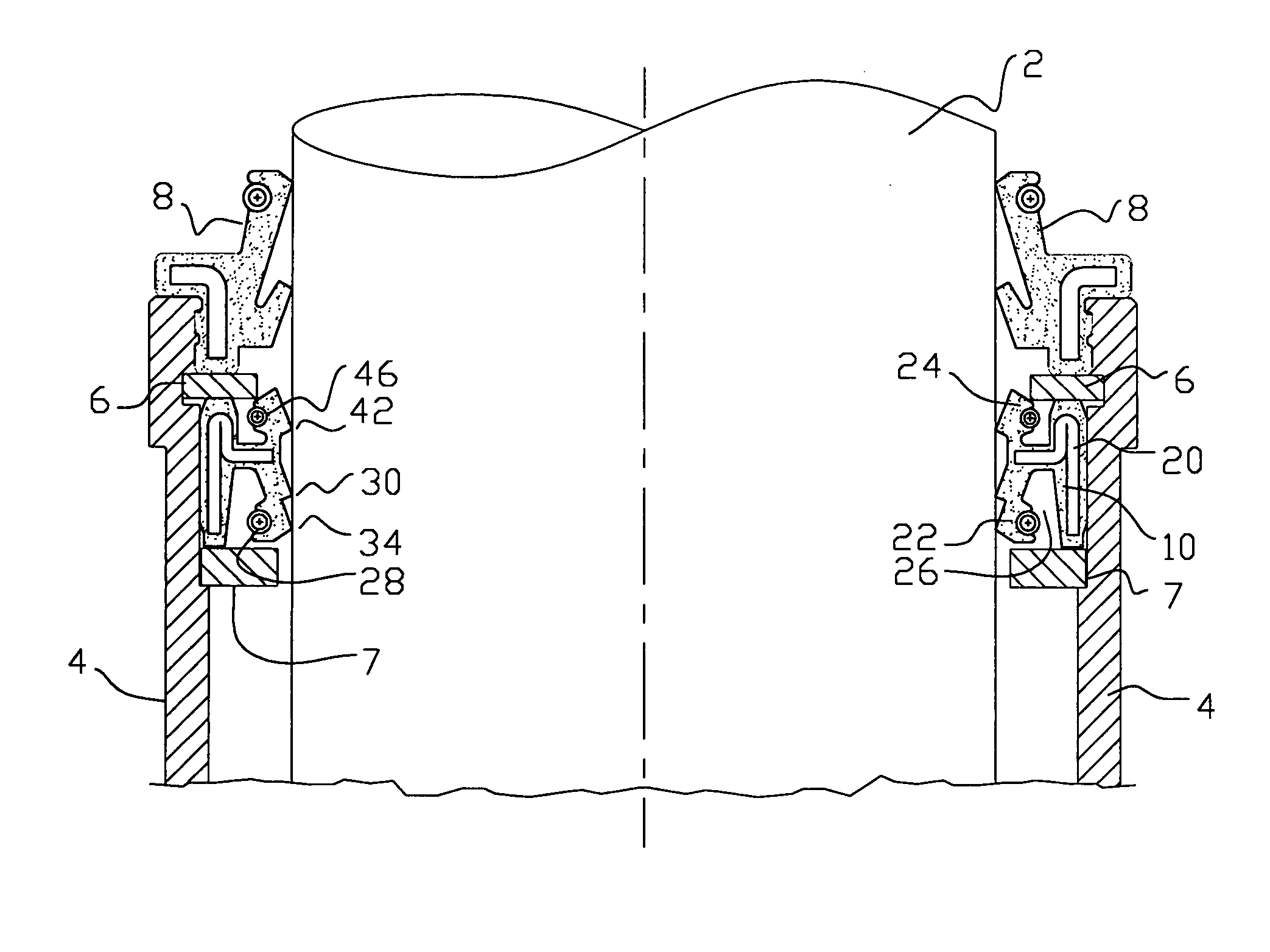

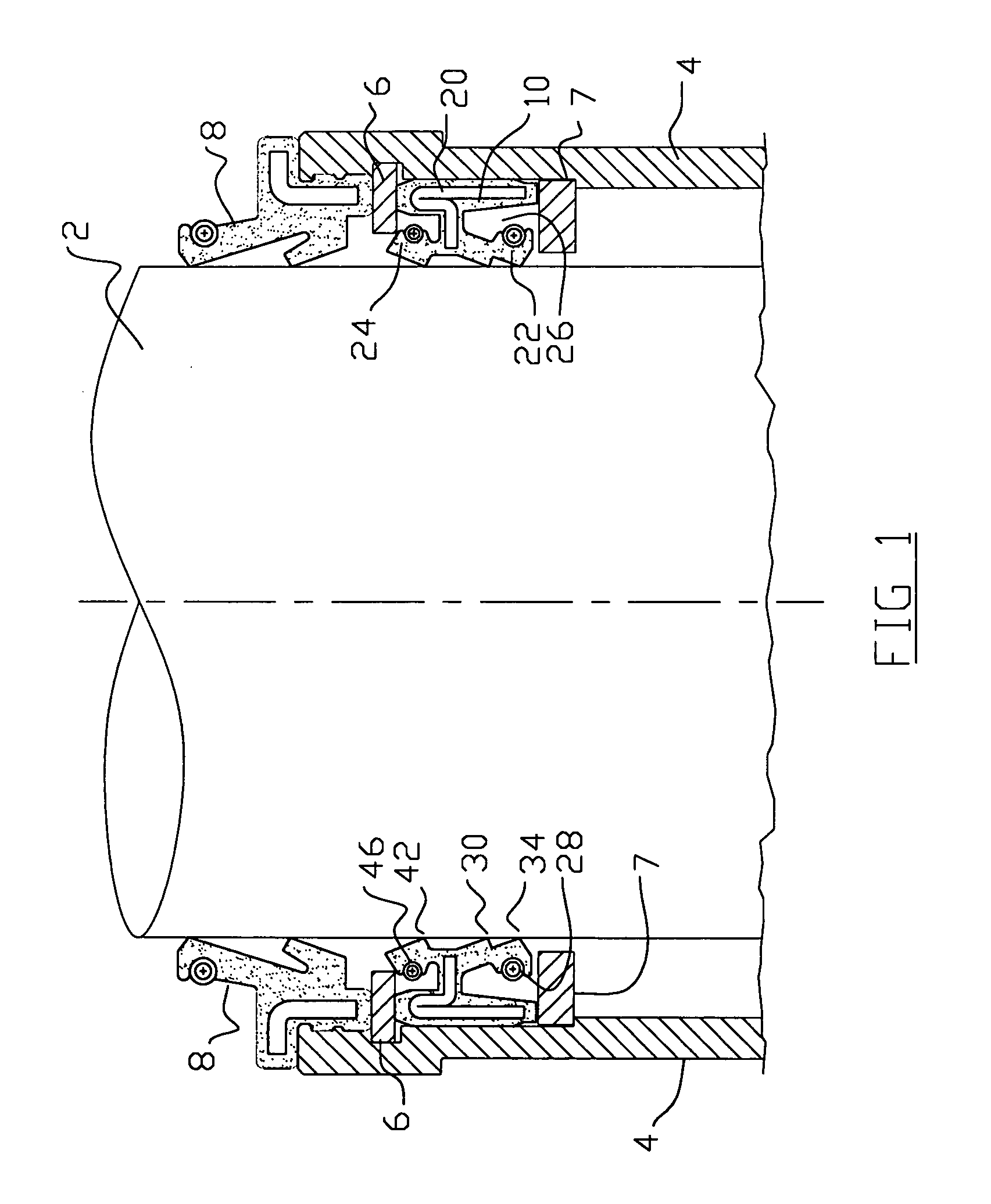

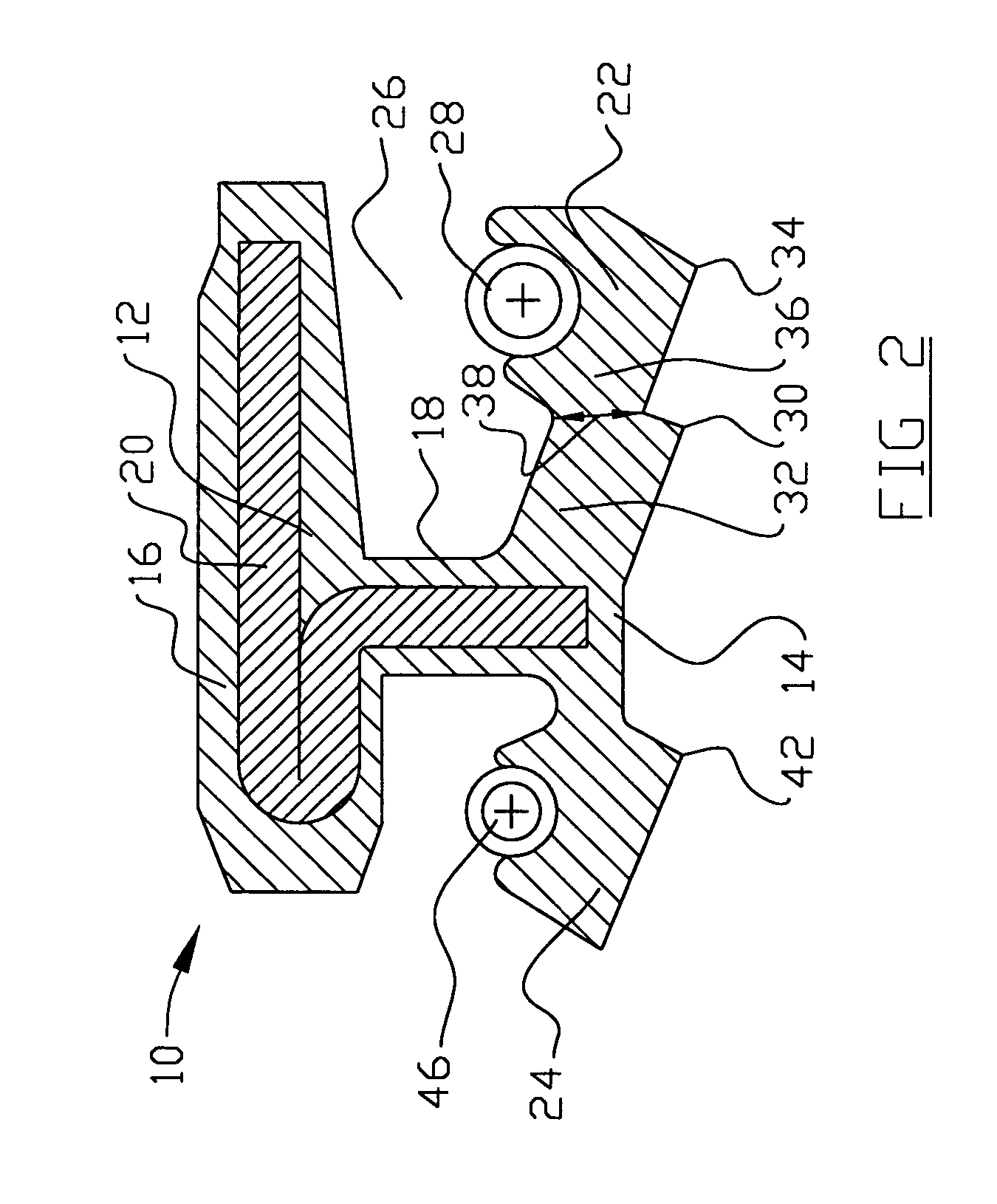

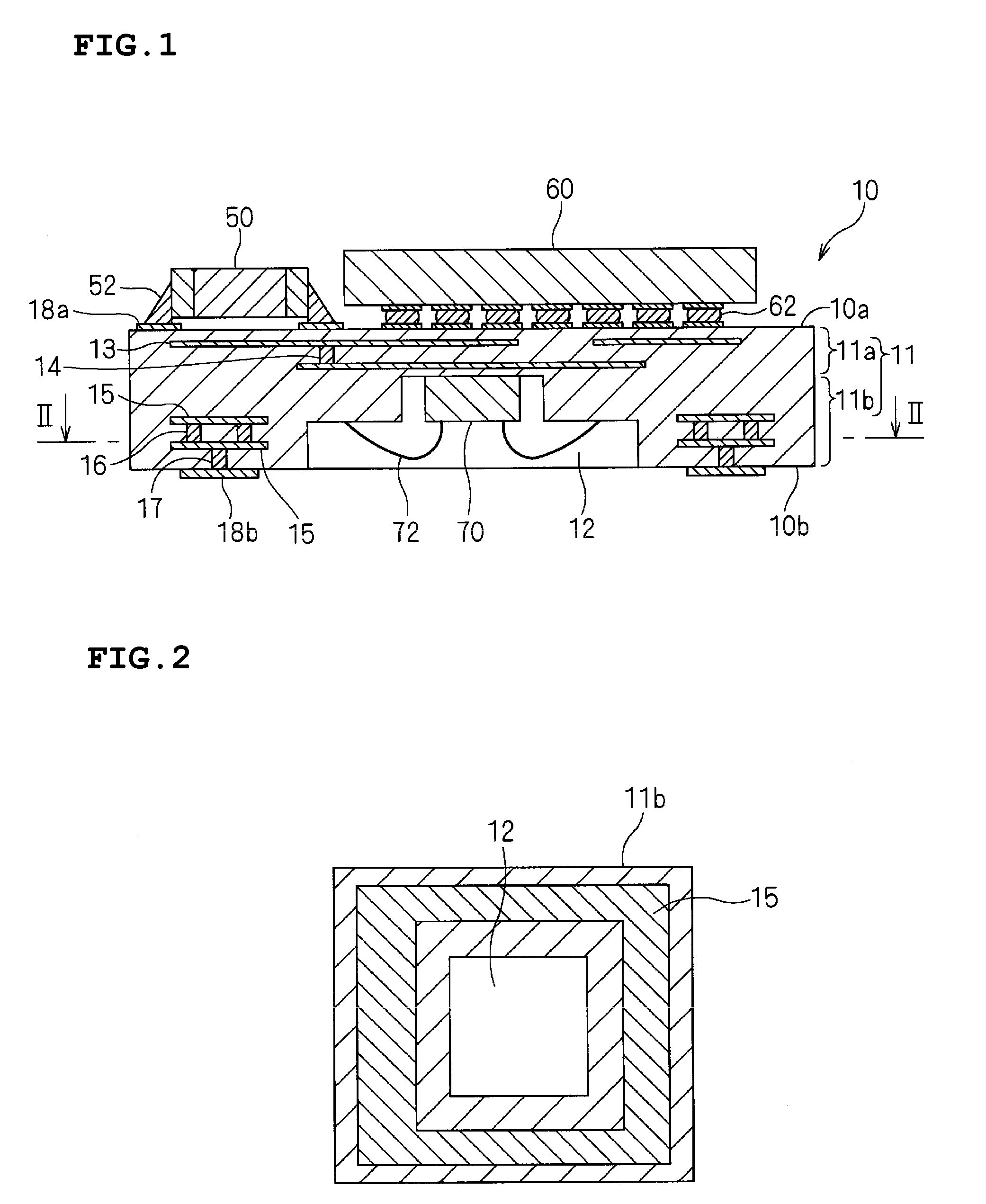

Triple lip fork seal

InactiveUS20060103075A1Separation pointExtended service lifeEngine sealsPiston ringsReciprocating motionLip seal

A triple lip seal for reciprocating members, and especially for an inner cylindrical tube connected to a vehicle wheel and an off-road motorcycle or bicycle. The seal includes an oil side beam generally parallel to the axis of the reciprocating members and having at least two sealing lips for engaging the inner cylindrical tube and wherein the forces applied to the seal are balanced between the two lips to resist flattening of the sealing lips against the shaft and to enhance the service life of the seal. The seal also includes an air side beam having a third sealing lip engaging the inner cylindrical tube.

Owner:CLARK SEALS

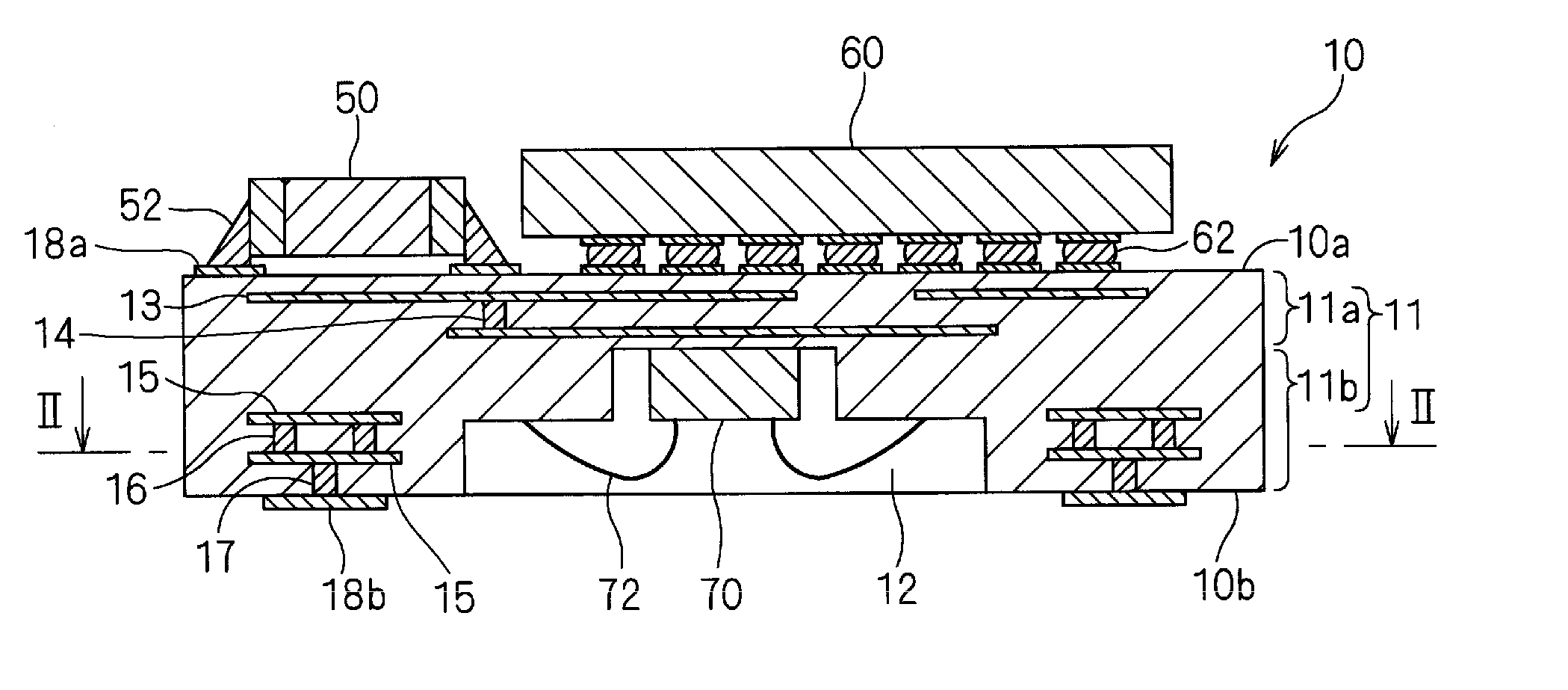

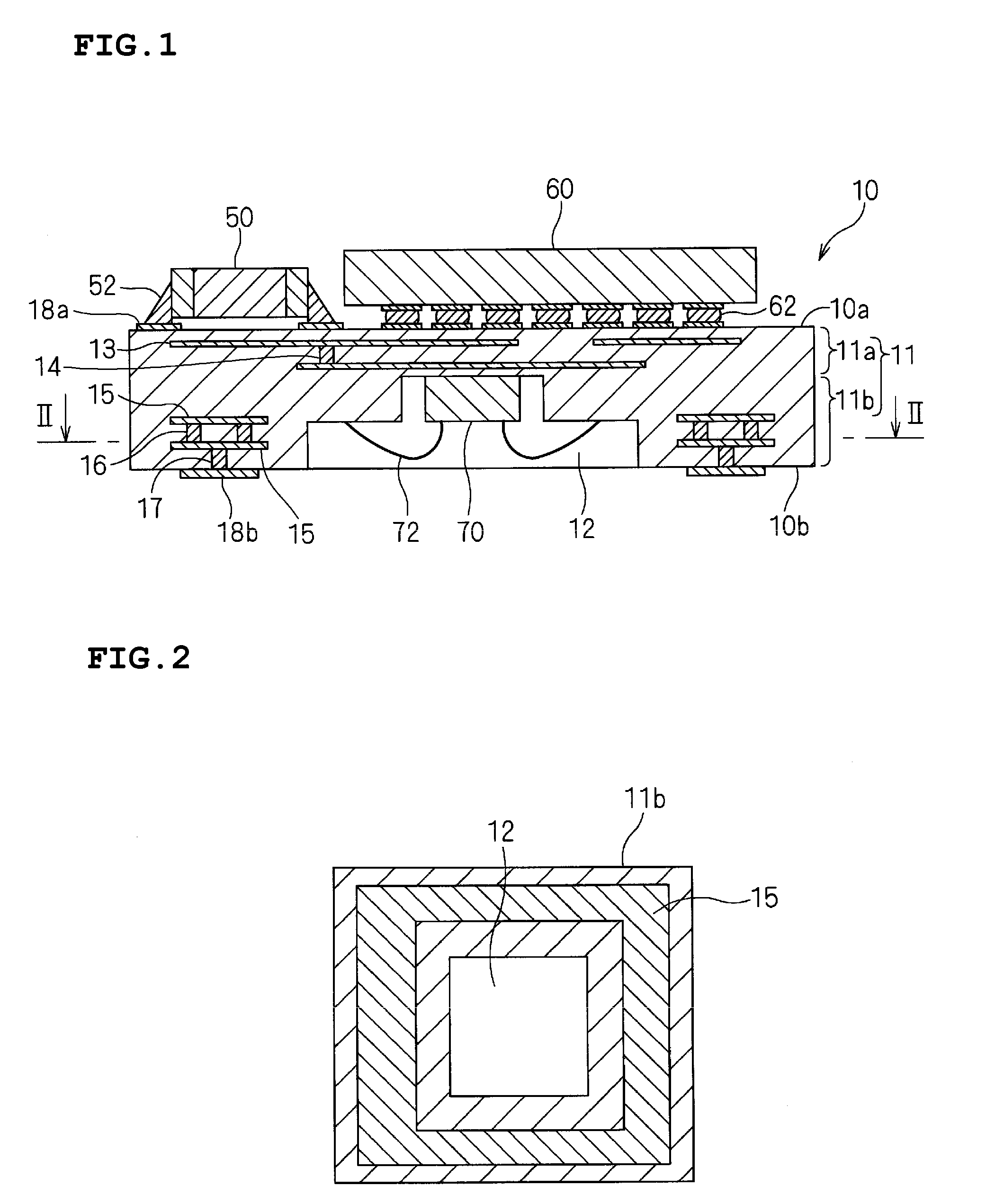

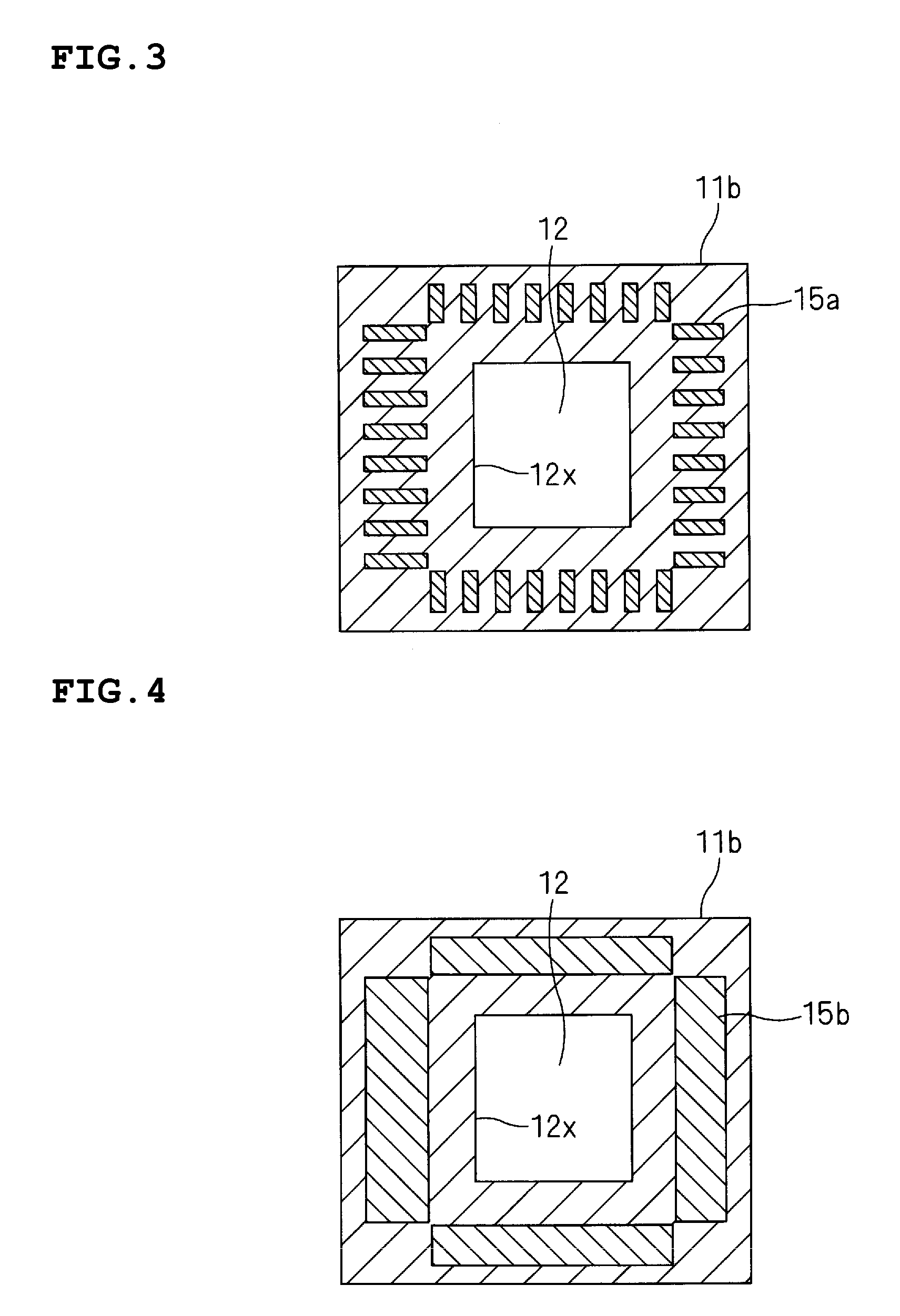

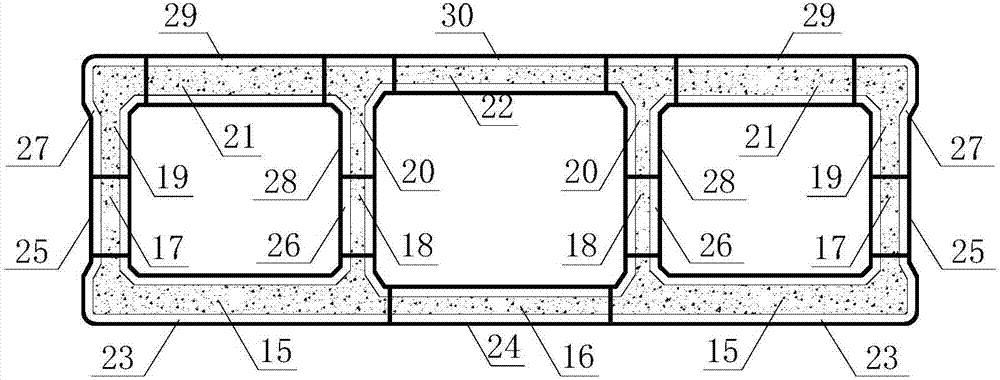

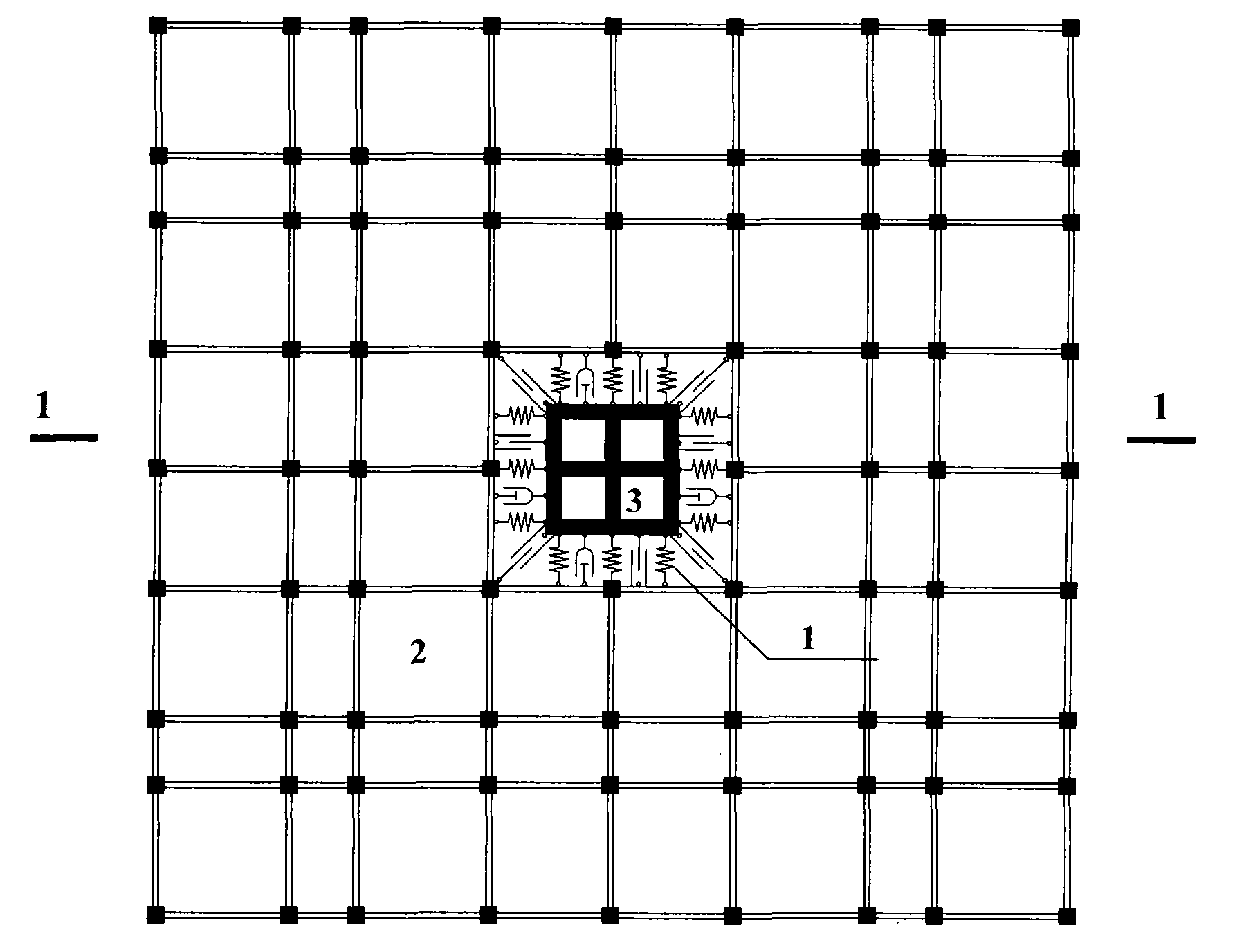

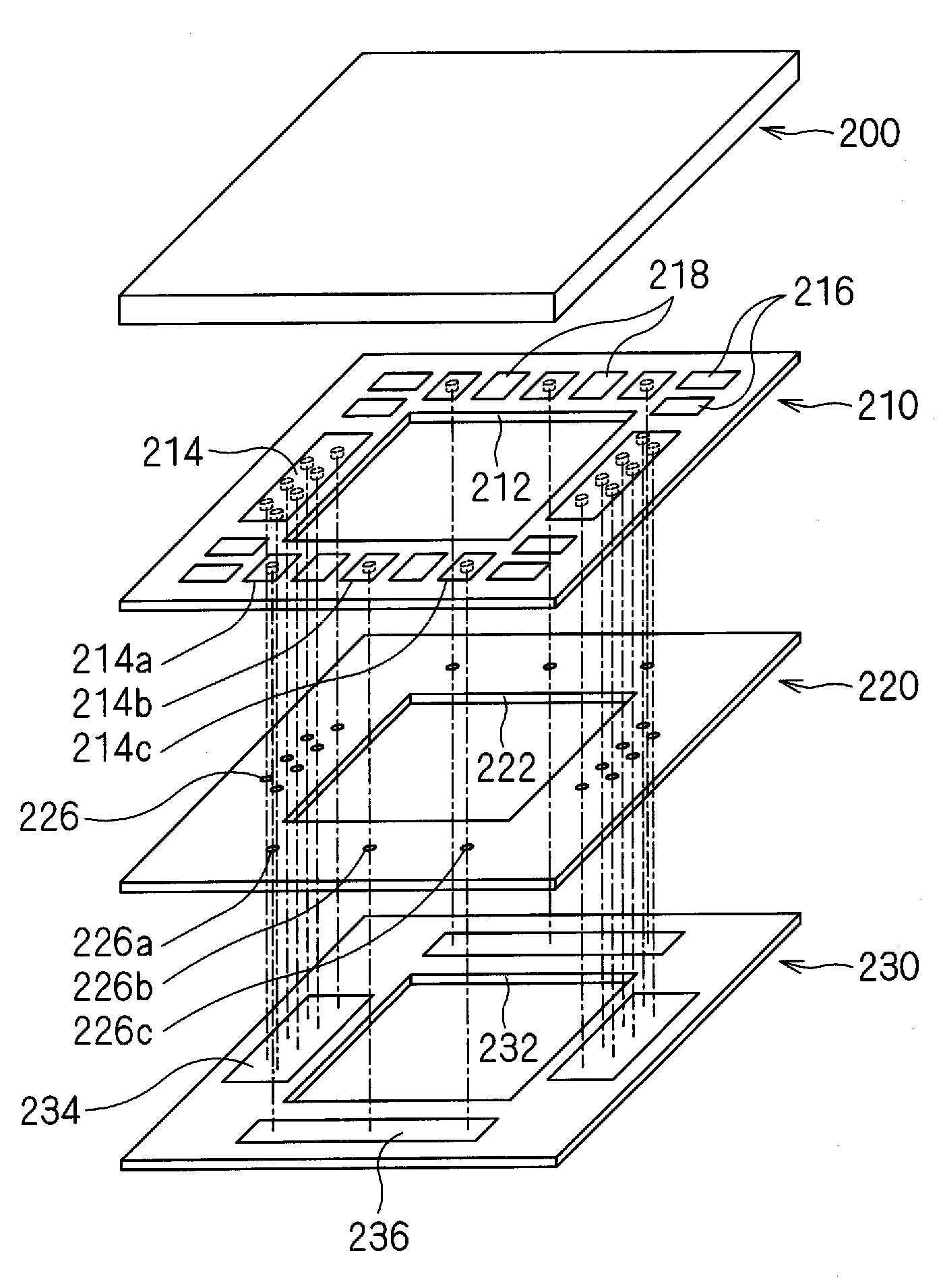

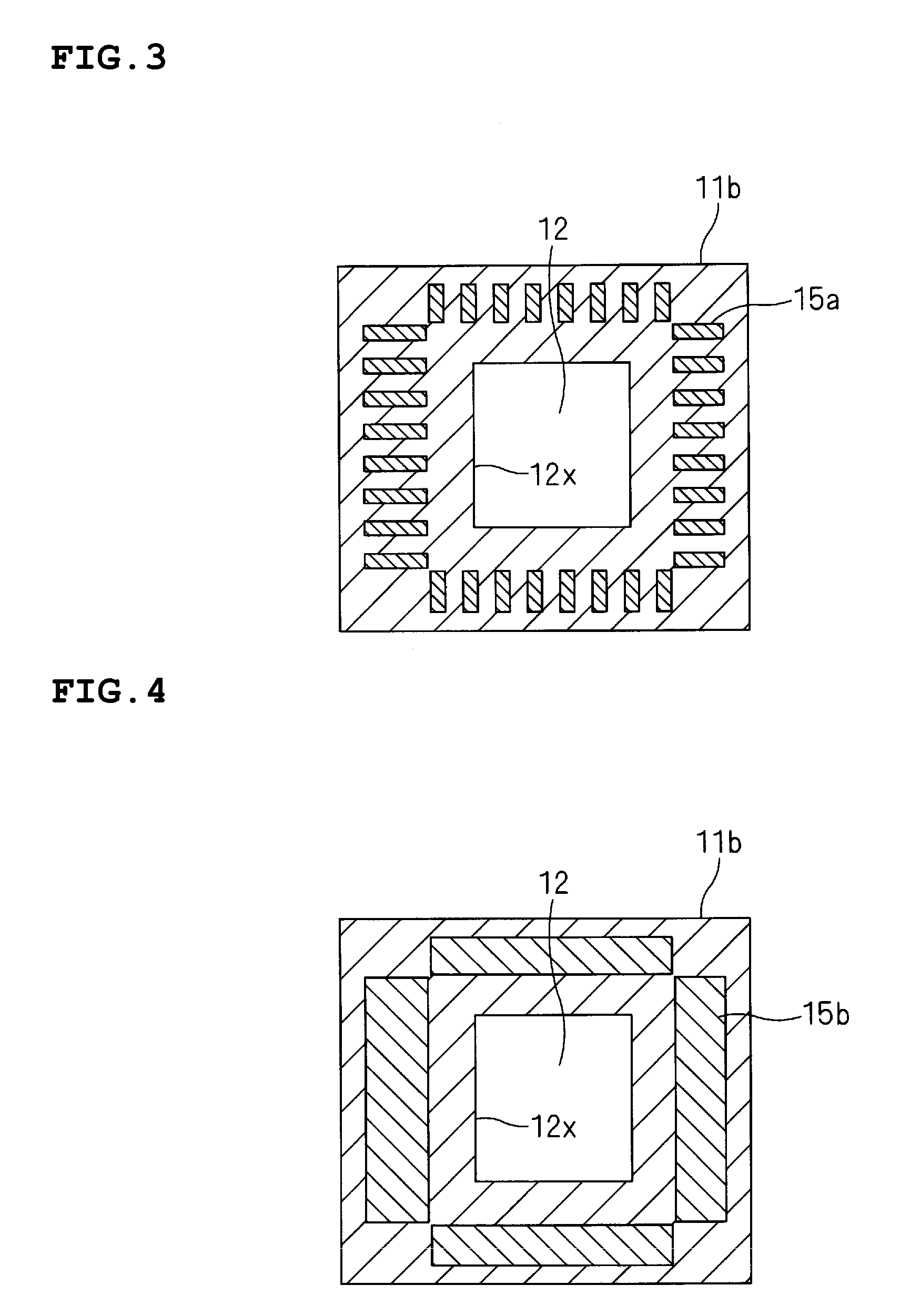

Ceramic multilayer substrate

InactiveUS20070187137A1Avoid uneven deformationSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorMetallurgy

A ceramic multilayer substrate includes a plurality of laminated ceramic layers and at least one conductor pattern and disposed on at least one of the ceramic layers. The ceramic multilayer substrate has a cavity in at least a first main surface. The ceramic multilayer substrate includes a deformation preventing pattern disposed on at least one of the ceramic layers having an opening forming the cavity. The deformation preventing pattern surrounds the entire perimeter of the opening and is made of the same material as the conductor pattern.

Owner:MURATA MFG CO LTD

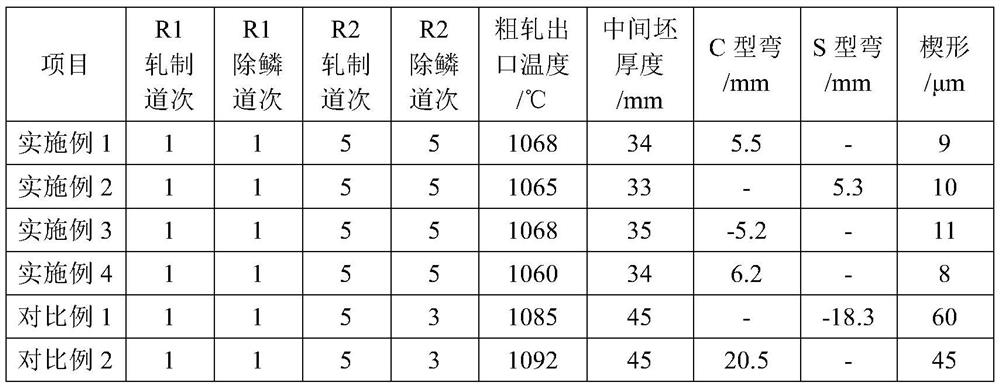

Control method for plate shape of high-strength steel plate

InactiveCN101367091AReduce deformation resistanceImprove plasticityRoll force/gap control deviceTemperature control deviceCooling temperatureSteel plates

The invention provides a method for controlling the shape of a high-strength steel plate. The method comprises the main steps of heating, rolling, cooling after rolling and straightening; and the heating temperature, the rolling pressure, the rolling temperature, the single-pass reduction amount, the rolling speed, the cooling temperature and the like are controlled. The method has simple operation, simplifies production procedure, shortens production cycle, reduces the transportation and transferring of the steel plate in the middle procedure, saves energy consumption, reduces the increase of unscheduled quantity and can achieve good plate shape; and practices prove that the performance of the steel plate is unchanged, meets various standards and has obvious economical benefit.

Owner:WUYANG IRON & STEEL

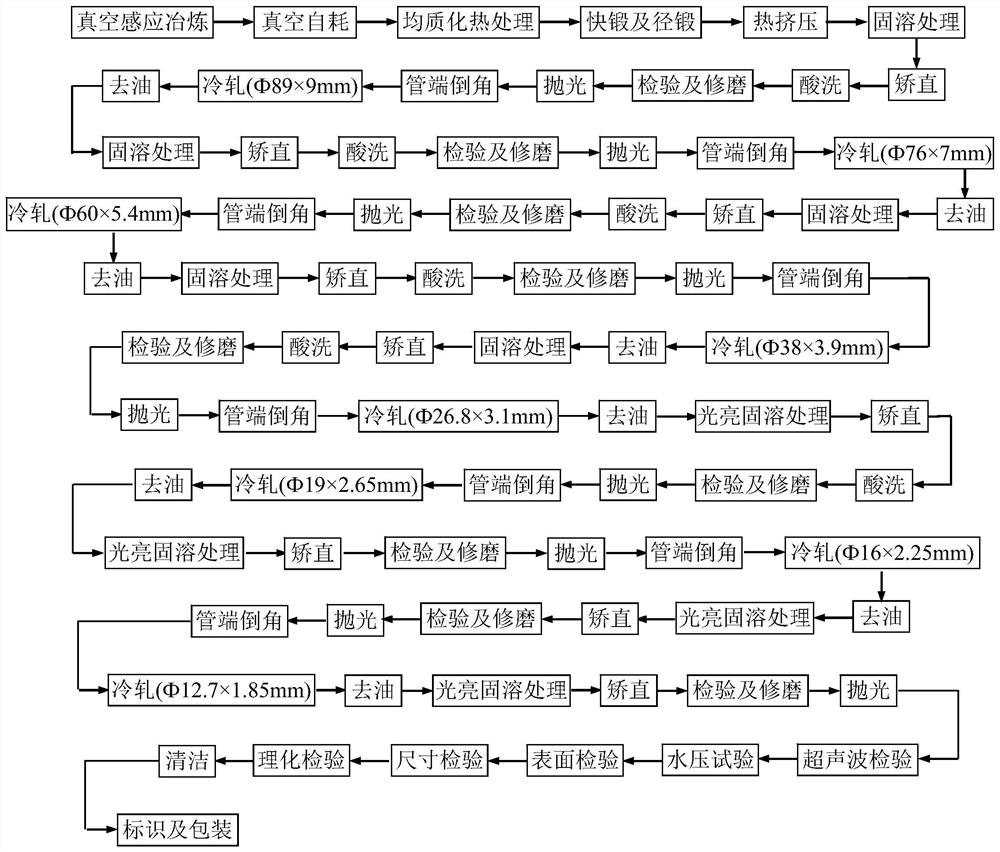

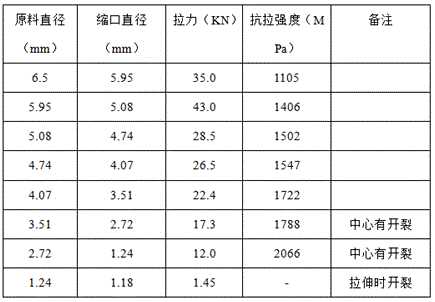

Nickel-chromium-tungsten-series high-temperature alloy seamless tube for 700-DEG C ultra-supercritical boiler and manufacturing method for nickel-chromium-tungsten-series high-temperature alloy seamless tube

The invention relates to a nickel-chromium-tungsten-series high-temperature alloy seamless tube for a 700-DEG C ultra-supercritical boiler. The nickel-chromium-tungsten-series high-temperature alloy seamless tube comprises the following components in percentage by weight: 0.06-0.10% of C, 0.25-0.50% of Si, 0.30-0.50% of Mn, less than or equal to 0.03% of P, less than or equal to 0.010% of S, 22.00%-23.00% of Cr, less than or equal to 1.0% of Co, less than or equal to 0.5% of Al, 1.00-2.00% of Mo, less than or equal to 1.0% of Fe, 13.5-14.5% of W, less than or equal to 0.015% of B, 0.01-0.05% of La and the balance of Ni and trace elements. According to the nickel-chromium-tungsten-series high-temperature alloy seamless tube disclosed by the invention, components are controlled, parameters are limited, and a certain amount of elements such as W, Mo and La is added, and a manufacturing method adopts a vacuum induction and electroslag re-melting smelting process, a hot-extrusion and cold-rolling process, and the like, so that the nickel-chromium-tungsten-series high-temperature alloy seamless tube has very good high-temperature strength and corrosion resistance as well as very good stability of a long-term aged structure and strength, and the structure and the performances completely meet use requirements of a tube for the 700-DEG C ultra-supercritical boiler.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

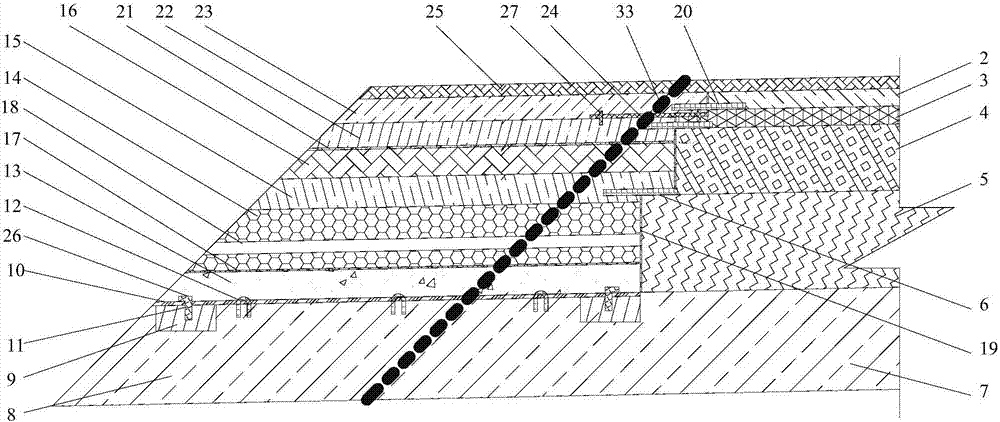

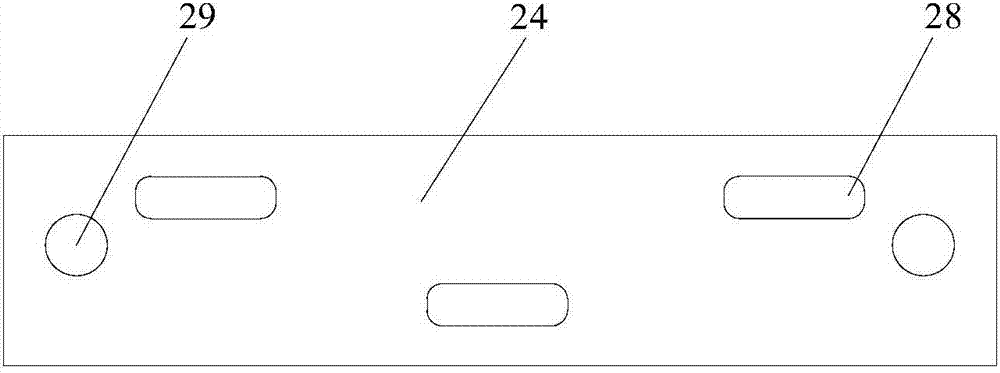

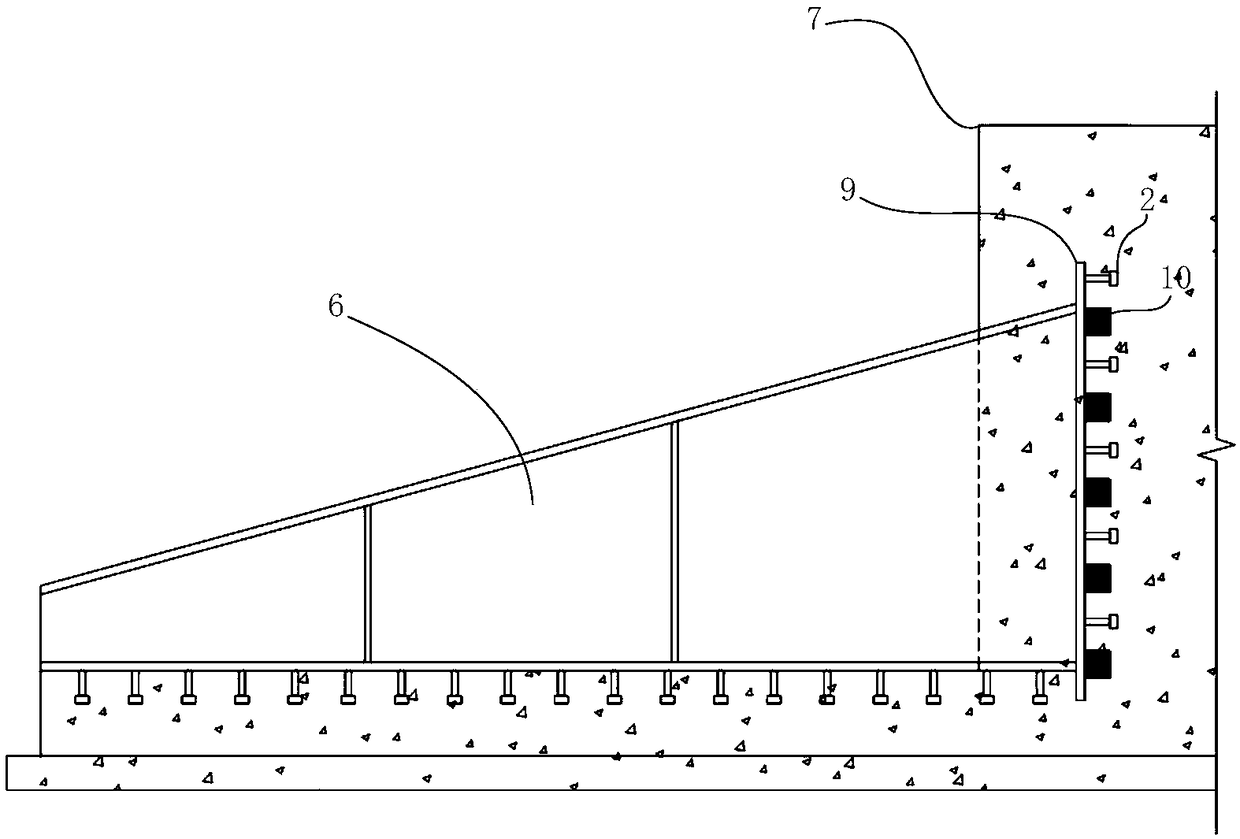

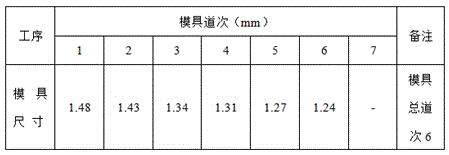

Flexible base layer asphalt pavement splicing and widening construction method

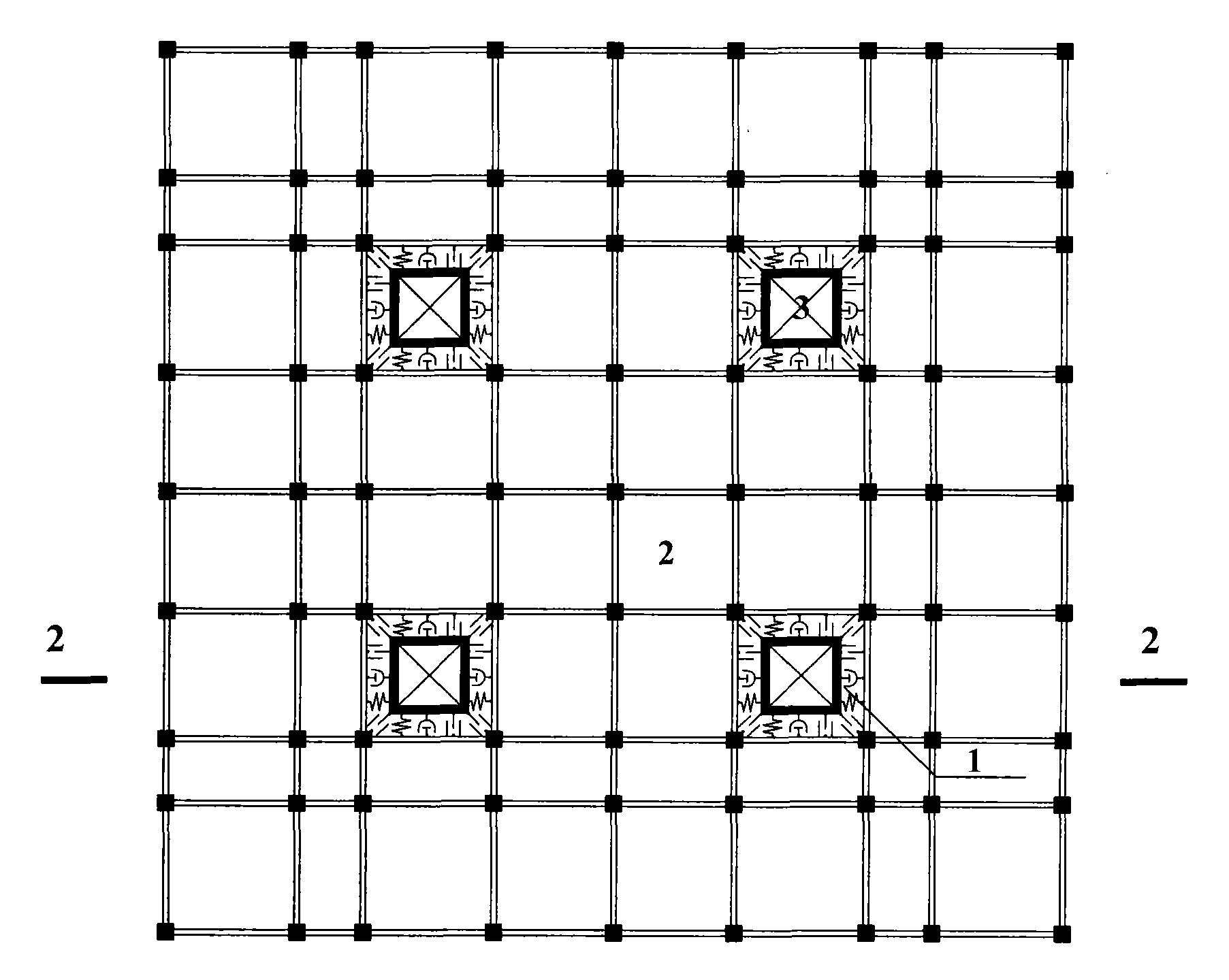

ActiveCN107227667AAvoid uneven deformationGuaranteed carrying capacityPaving reinforcementsIn situ pavingsGlass fiberRoad surface

The invention relates to a flexible base layer asphalt pavement splicing and widening construction method. The construction method is characterized in that old road pavement structure layers are milled and planed, and then connecting steps are arranged at the interfaces of the old road structure layers; then an old road splicing widening connecting joint and the road bed outer edge of a widening pavement are each provided with a road bed solidifying beam, and a steel bar mesh grid is laid on the top surface of each road bed solidifying beam; materials generated after the upper face layer of an old pavement structure and the other structure layers of the old pavement structure are milled are used for new road base layers; in construction, a glass fiber geogrid is laid on the top surface of a two-ash gravel recycling layer, a connecting grid and joint filling slurry are arranged at the connecting joint of a new pavement and an old pavement, and a crack partition plate is laid at a pavement splicing widening connecting joint on the top surface of a lower face layer; and finally, paving construction of pavement upper face layers of the new pavement and the old pavement are conducted simultaneously. The old road building materials can be recycled, the integrality of an asphalt pavement splicing widening structure can be improved, and the solidifying cost of the pavements in the later period can further be reduced.

Owner:SICHUAN JIAOTOU CONSTR ENG CO LTD

Stainless steel seamless steel tube for sulfuric acid waste heat recovery device

ActiveCN103710644AImprove hardenabilityImprove corrosion resistanceUltimate tensile strengthMaterials science

The invention relates to a stainless steel seamless steel tube for a sulfuric acid waste heat recovery device. The stainless steel seamless steel tube comprises the following components: 0.05-0.06 percent of C, 1.5-2.0 percent of Mn, 19.0-22.0 percent of Ni, 24.0-26.0 percent of Cr, 0.45-0.60 percent of Nb, 0.4-0.6 percent of Si, 0.1-0.15 percent of N, less than or equal to 0.2 percent of Cu, less than or equal to 0.015 percent of s, less than or equal to 0.025 percent of p, 0.3-0.5 percent of Mo, 2-4 percent of Al, 0.4-0.6 percent of Ti, 0.0018-00022 percent of v, 0.5-0.8 percent of composite rare earth and the balance of Fe. According to the operations of limiting the components and technological parameters, adding the composite rare earth and performing bright heat treatment on pure nitrogen protective gas, the stainless steel tube has excellent corrosion resistance, low roughness of inner and outer surfaces, high yield strength and high tensile strength.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

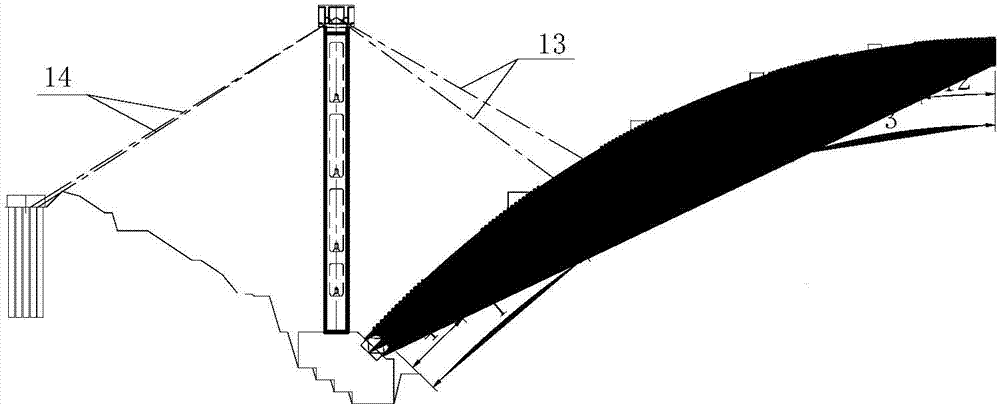

Construction method of outer wrapped concrete obliquely pulling and buckling and ring and section dividing combination method

InactiveCN103572703AMeet pressure requirementsEasy to mix designBridge erection/assemblyFull bridgeTemplate design

The invention discloses a construction method of an outer wrapped concrete obliquely pulling and buckling and ring and section dividing combination method. A whole bridge is divided into six rings of an edge box bottom plate, a lower web, an upper web, an edge box top plate, a middle box bottom plate and a middle box top plate; the semiarch rib of each ring is divided into three working surfaces; each working surface comprises three sections; nine pouring sections exist; three sections are poured for each ring in each time; the sections are poured in three times; before pouring outer wrapped concrete, buckling cables and balance cables are arranged in the arch springing regions, and the cable force is tensioned according to the design requirements. By using the construction method, the construction safety risk in the prior art is effectively reduced, the proportioning of concrete with high grade and the template design are facilitated, the operation is simple, the cost is saved, the construction period is short, and the linear shape and the stress of arch rings can be effectively controlled.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

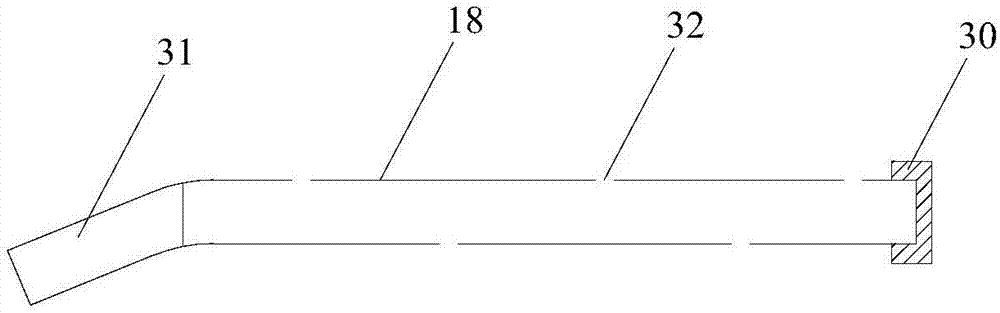

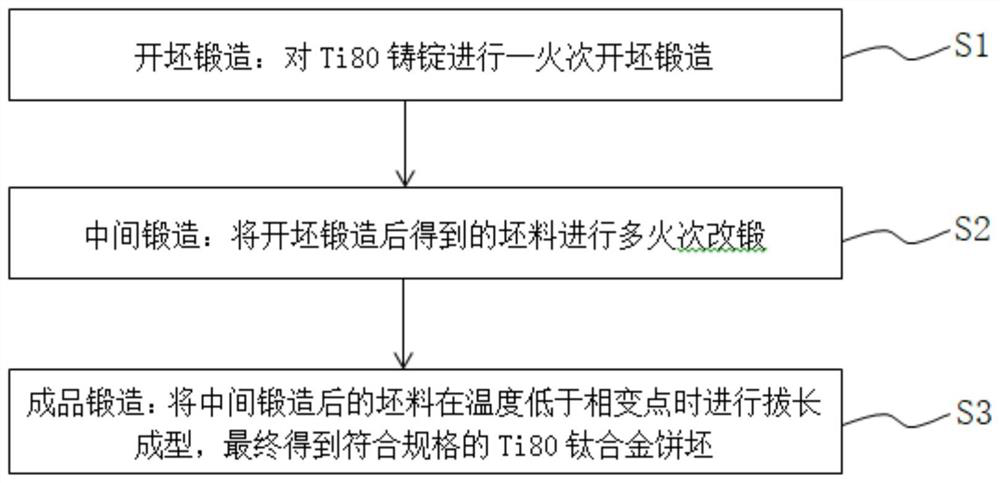

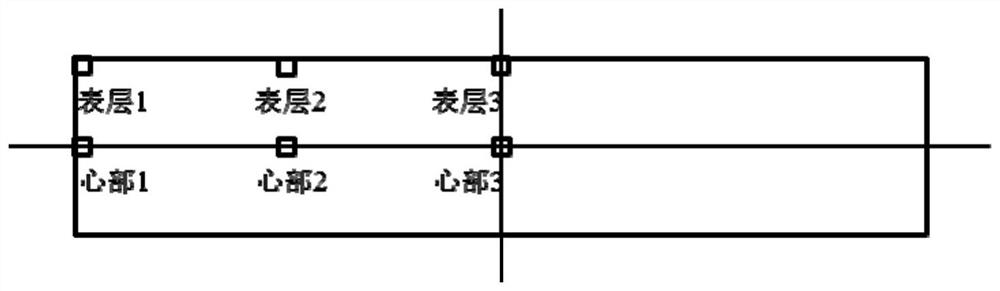

Forging method of super-large-specification Ti80 titanium alloy forging stock

ActiveCN111906225AGuaranteed plastic deformationAvoid uneven deformationHeating/cooling devicesIngotTitanium alloy

A forging method of a super-large-specification Ti80 titanium alloy forging stock comprises the steps that S1, cogging forging is conducted, specifically, a Ti80 cast ingot is subjected to one-heating-number cogging forging, the cogging forging mode is upsetting, and a forged stock is subjected to air cooling; S2, intermediate forging is conducted, specifically, the stock obtained after cogging forging is subjected to multi-heating-number modified forging; and S3, finished product forging is conducted, specifically, drawing-out forming is conducted on the stock obtained after intermediate forging when the temperature is lower than the phase transformation point, air cooling is conducted on the forged stock, and finally the Ti80 titanium alloy forging stock meeting the specification is obtained. According to the forging method of the super-large-specification Ti80 titanium alloy forging stock, the phenomena of end and middle deformation unevenness caused during upsetting of an ingot with the too large height-diameter ratio is avoided, it is guaranteed that as-cast structures in the ingot are fully crushed, homogenized structures are obtained, and the wide application prospect is achieved.

Owner:西部超导材料科技股份有限公司

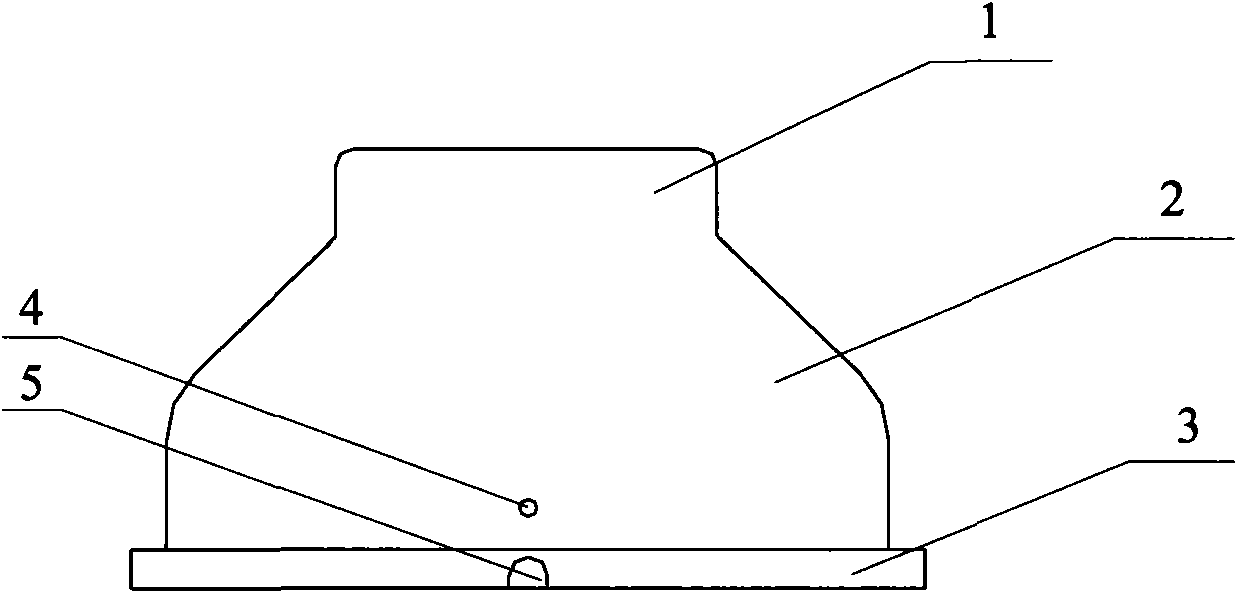

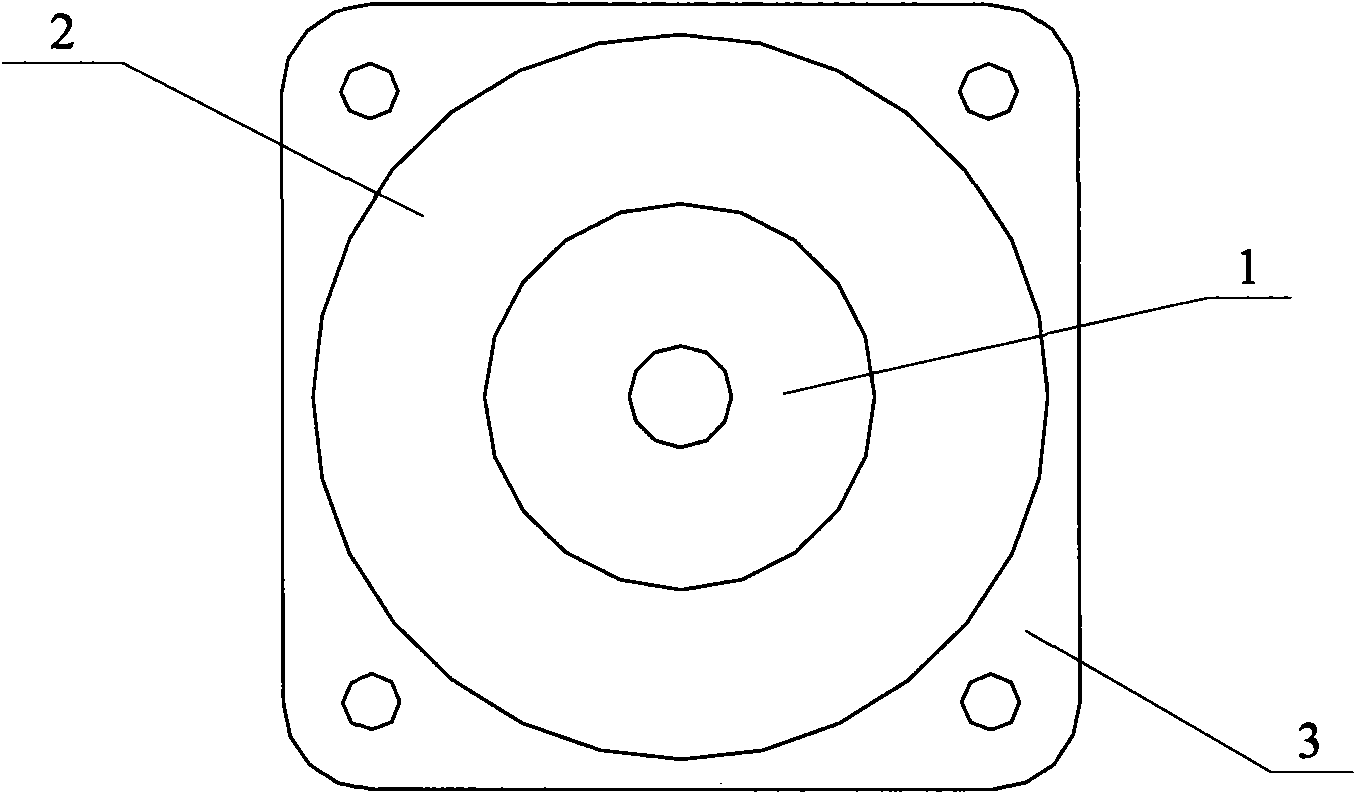

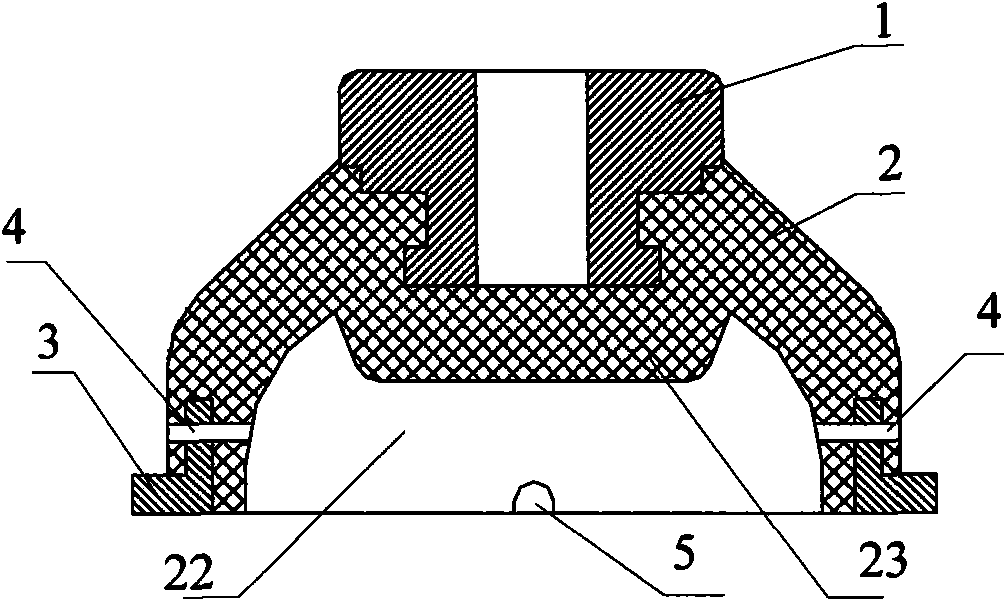

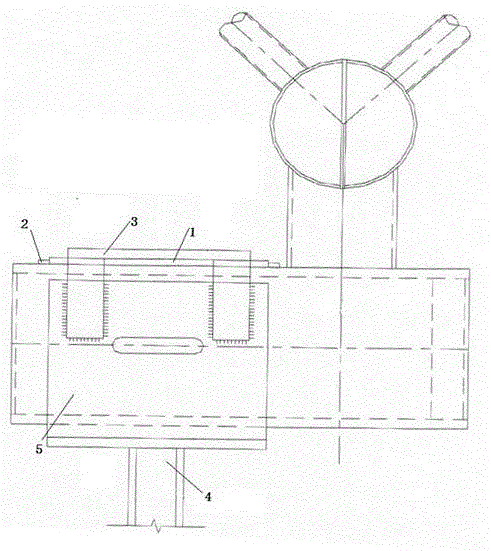

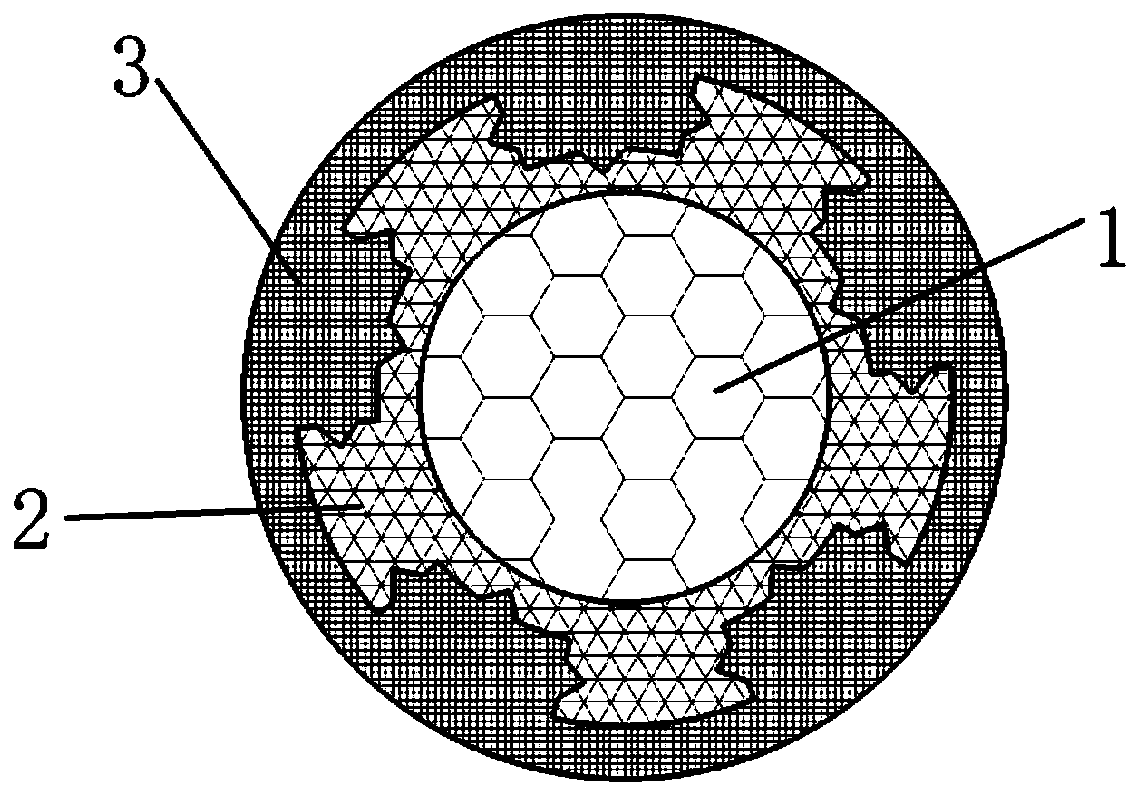

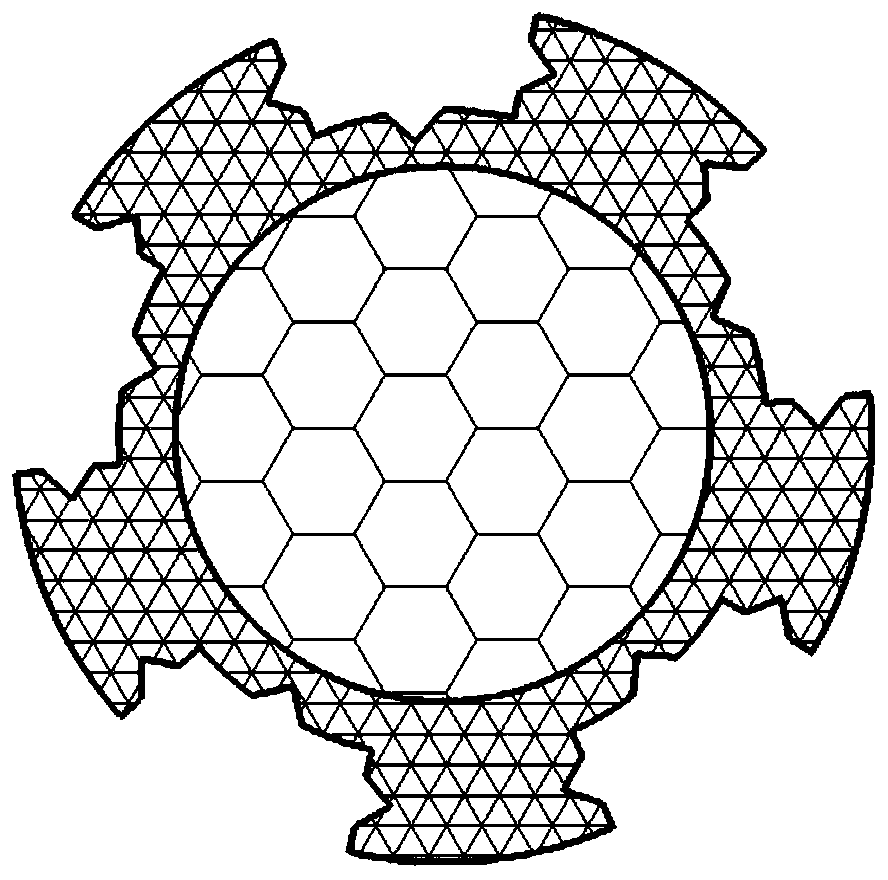

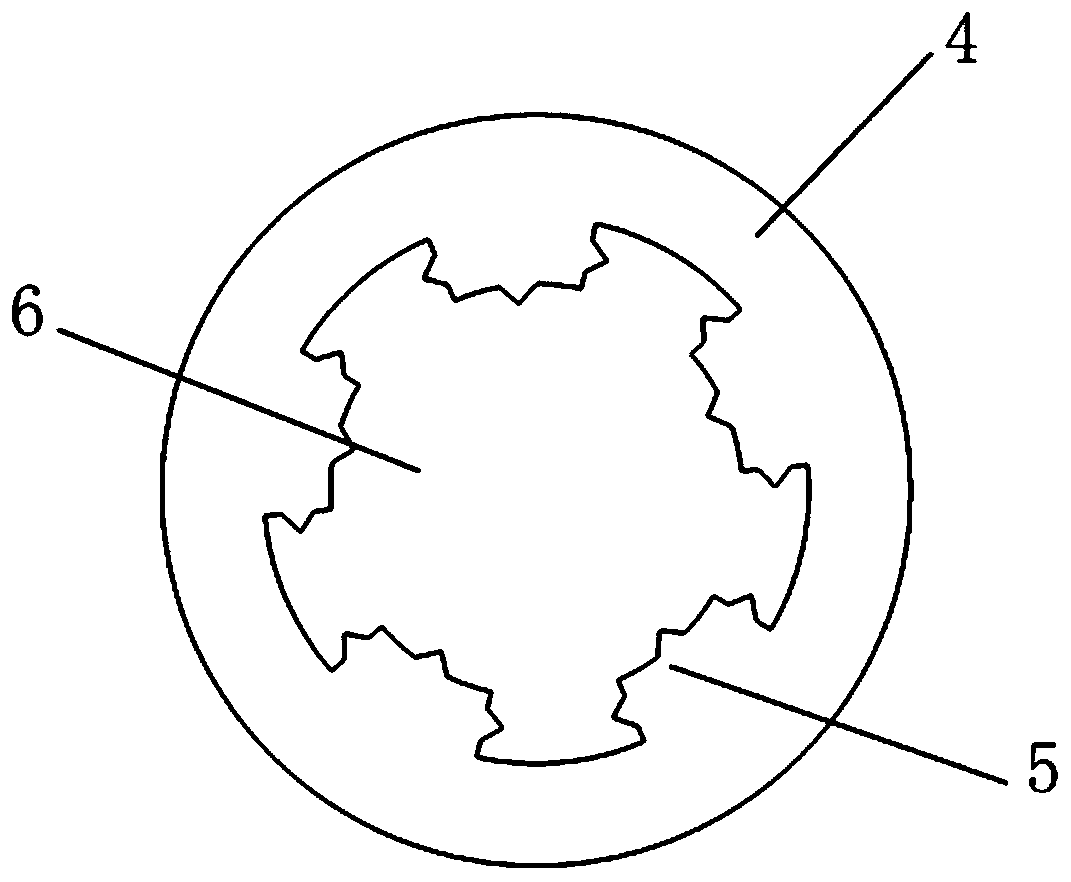

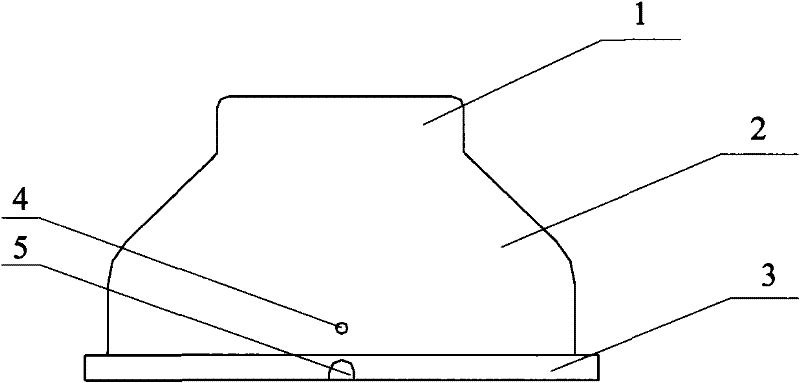

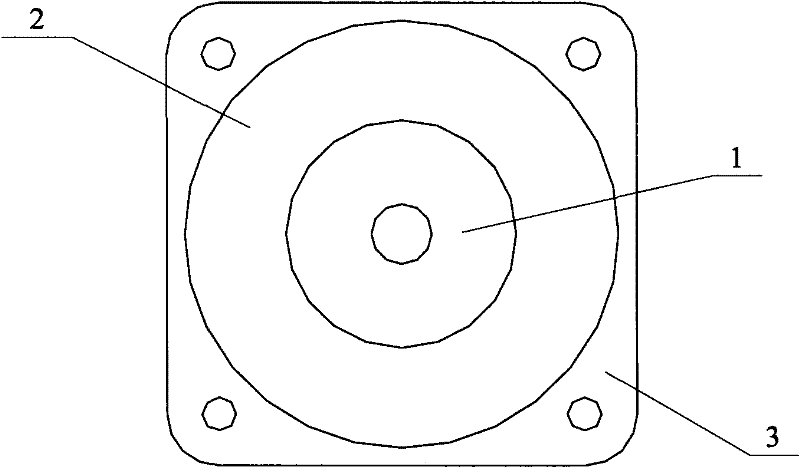

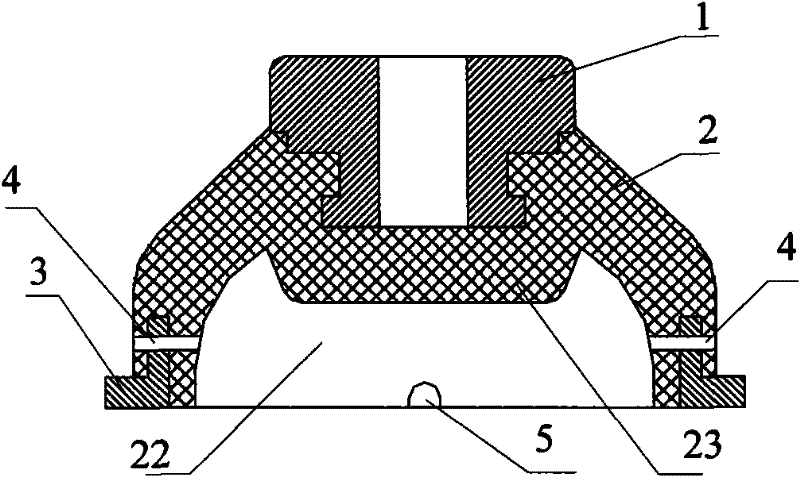

Rubber buffering and vibration isolating elastomer structure

The invention relates to a rubber buffering and vibration isolating elastomer structure which comprises an upper metal part, a rubber part and a lower metal part. An internal cavity structure is adopted by the rubber body of the invention to increase the buffering stroke of the rubber body, and the buffering deformation of the rubber body can reach 100%; and if the space along the axial direction of the elastomer structure is large enough, the buffering deformation can reach about 150%. The design of the cavity structure greatly increases the buffering deformation stroke of the rubber part by 2-4 times of the traditional rubber isolator, thereby greatly improving the buffering effect. The structure of the invention adopts the design of a gas channel; on the one hand, by the design of the gas channel, when the elastomer bears the impact load, because the action time of the load is short, the gas in the cavity is quickly discharged outwards through the gas channel, and the friction action of the gas and the channel increases the damping of the elastomer structure, thereby increasing the buffering effect of the elastomer structure; and on the other hand, by the design of the gas channel, the gas in the cavity can be smoothly discharged under the action of the load to avoid the uneven deformation of the rubber part caused by sealing of the cavity, thereby ensuring the rigidity stability of the elastomer structure in the deformation process.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

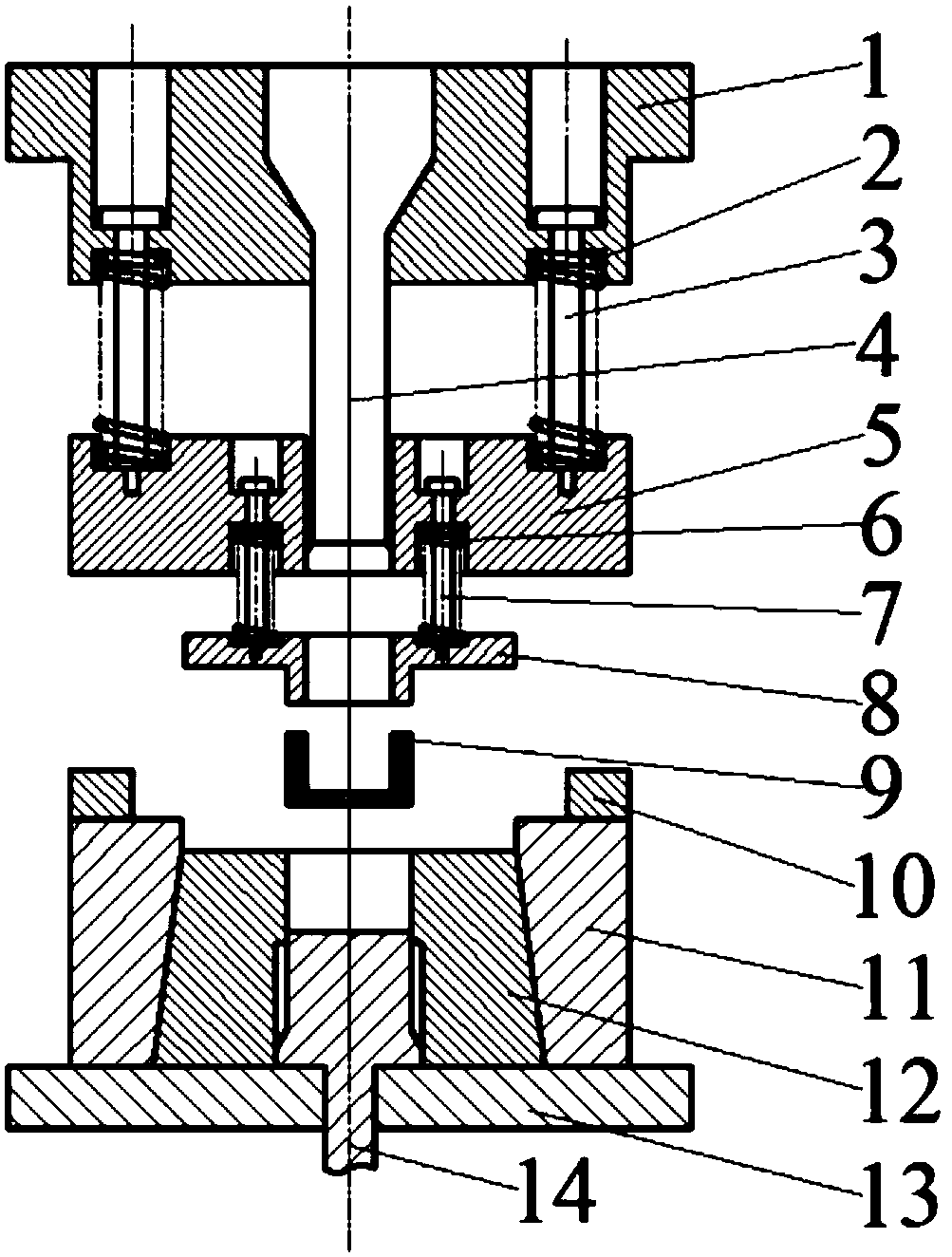

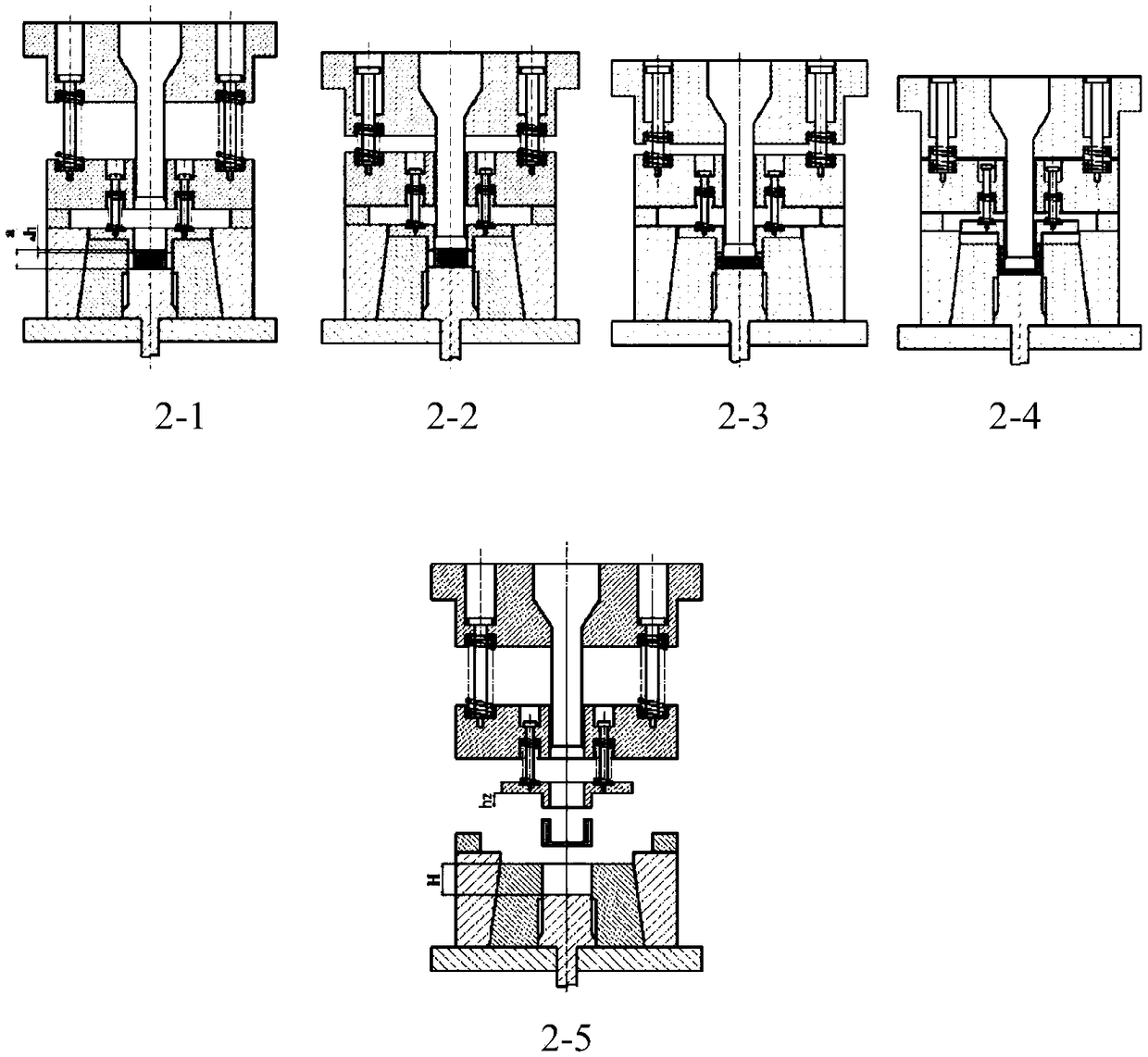

Hot reverse extrusion forming method for titanium alloy cup-shaped part

ActiveCN108838226AIncreased self-directionGuaranteed wall thickness uniformityExtrusion diesEconomic benefitsTitanium alloy

The invention relates to a hot reverse extrusion forming method for a titanium alloy cup-shaped part, and belongs to the technical field of hot reverse extrusion forming technologies. The machining method comprises the steps of placing a heated blank into an extrusion container to be subjected to reverse extrusion one-time forming by utilizing the guide positioning action of a material pressing insert, and the roughing blank making step in the forming process of the cup-shaped part is omitted. The material pressing insert guarantees that lugs of the cup-shaped part are flush through the tension action of a back pressure spring; and meanwhile, because a floating male die is in linkage with the back pressure spring with higher back pressure tension, it is achieved that the cup-shaped part can be demolded smoothly after being formed. With the hot reverse extrusion forming method for the titanium alloy cup-shaped part, the phenomenon that in the traditional reverse extrusion process, because one single unloading spring is overhigh in back pressure, the material of a wall of a cup-shaped part flows inwards sharply to tightly hold a male die, and demolding is difficult to carry out is avoided, and meanwhile the reverse extrusion forming force is reduced, and the requirement on equipment tonnage is lowered; and additionally, because a titanium alloy cup-shaped force piece is formed atone time by adopting reverse extrusion in the preparation process, the step of roughing blank prefabrication in the existing technology is omitted, the production period is shortened, the manufacturing cost is reduced, and the economic benefit is greatly improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Novel nickel-chromium-cobalt-molybdenum high-temperature alloy seamless tube for power station and manufacturing method

PendingCN111636013AAvoid uneven deformationGood surface qualityMetal rolling arrangementsChromiumSmelting process

The invention discloses a novel nickel-chromium-cobalt-molybdenum high-temperature alloy seamless tube for a power station. The novel nickel-chromium-cobalt-molybdenum high-temperature alloy seamlesstube comprises the following components in percentage by weight: 0.03-0.10% of C, less than or equal to 1.0% of Si, less than or equal to 0.70% of Mn, less than or equal to 0.012% of P, less than or equal to 0.008% of S, 20.00-24.00% of Cr, 10.00-15.00% of Co, 0.70-1.50% of Al, 0.20-0.70% of Ti, 8.00-10.00% of Mo, less than or equal to 2.00% of Fe, less than or equal to 0.5% of Cu, 0.001-0.006% ofB, less than or equal to 0.005% of Pb, less than or equal to 0.005% of Sb, less than or equal to 0.001% of Bi, less than or equal to 0.010% of Sn, less than or equal to 0.010% of As and the balance Ni and trace elements, wherein the sum of the components is 100%. According to the nickel-chromium-cobalt-molybdenum high-temperature alloy seamless tube disclosed by the invention, a certain amount ofCo, Mo, B and other elements are added by controlling and limiting the components, a smelting process adopts vacuum induction and vacuum self-consumption, a tube manufacturing process adopts hot extrusion and full cold rolling, and finally solution treatment is performed; and by adopting the way, the alloy seamless tube has good structure stability, mechanical properties and process properties and can meet the using requirements of a heat exchange tube for the novel power station.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

Method for producing improved stainless steel seamless steel pipe

InactiveCN101376135AAvoid crackingImprove straightnessShaping toolsRoll mill control devicesMetallurgySteel tube

The invention relates to a method for producing an improved stainless steel seamless steel pipe, which comprises the steps of heating, piercing, rolling, acid cleaning and straightening a pipe blank, wherein the pipe blank is heated up to 100-200 DEG C before being straightened in the step of straightening; and before entering a straightening machine, the pipe blank is heated up through induction heating coils. The invention further adopts a mild straightening process in the step of straightening, and before entering a straightening machine, the pipe blank is heated up to 100-200 DEG C through the induction heating coils, thereby ensuring that the seamless steel pipe has little possibility in crack rectification and the produced steel pipe has fine straightness and degree of curve being less than 1.5mm / m. In addition, the invention adopts a continuous and equal-diameter hot piercing process and adopts a cold rolling process in the rolling process, thereby effectively preventing pipe materials from being unevenly deformed; and the produced steel pipe has the advantages of small tolerance between the outer diameter and the wall thickness, high accuracy, and better quality and more smooth surface.

Owner:JIANGSU HONGBAO GROUP CO LTD

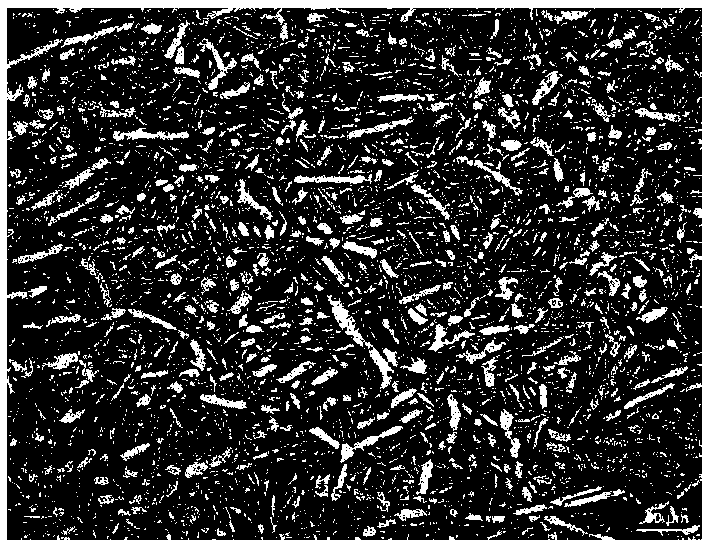

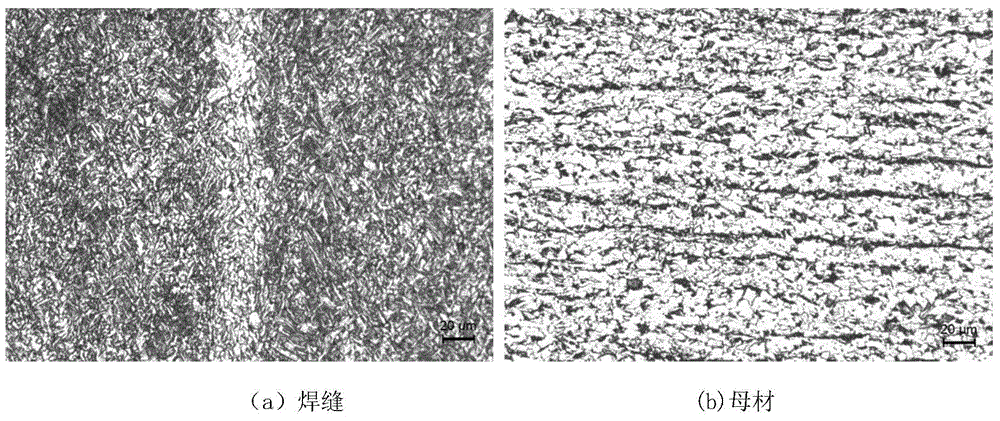

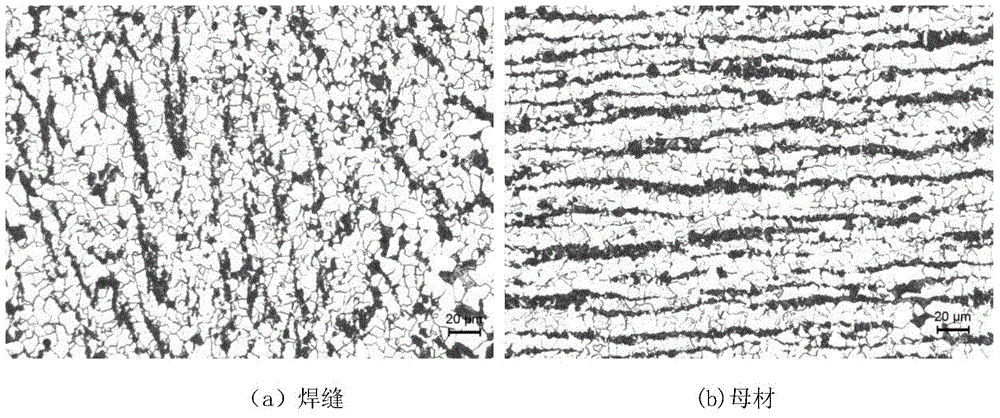

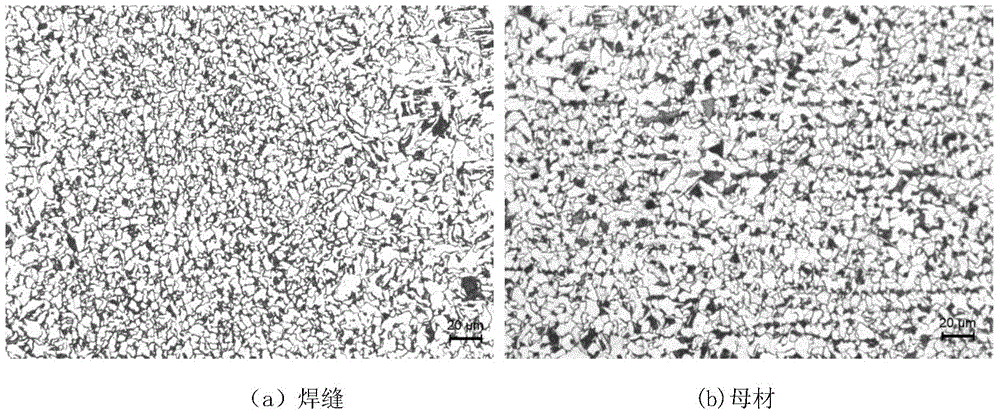

J55-steel-grade SEW expandable casing tube and manufacturing method thereof

The invention discloses a J55-steel-grade SEW expandable casing tube and a manufacturing method thereof. The manufacturing method comprises following steps: (1) quickly heating a HFW welding tube blank through a middle-frequency induction furnace to 960-1020 DEG C; (2) performing multiple-pass full-tube thermal-stretch reducing to the HFW welding tube blank; and (3) rotationally passing the thermal-stretch reduced tube blank at 750-850 DEG C through an on-line-controlled cooling apparatus to quickly cool the tube blank to 250-450 DEG C and finally air-cooling the tube blank to room temperature. In the invention, by means of a one-step method, high-precision thermal moulding and target organism adjustment and control of the tube are achieved, thereby significantly reducing the production costs such as energy consumption. Through HFW welding, full-tube thermal-stretch reduction and on-line-controlled cooling, microstructure differences between welding seams and the base material can be eliminated, thereby achieving uniform organism performance of the full tube (including the base material and the welding seams) and further achieving excellent uniform deformation performance. Meanwhile, a banded structure is eliminated and a double-phase or multi-phase organism which is formed by reasonable combination of soft-phases and hard-phases with a large amount of ferrite and a less amount of bainite or martensite as the main composition, so that the J55-steel-grade SEW expandable casing tube has a high inner diameter expansion rate.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

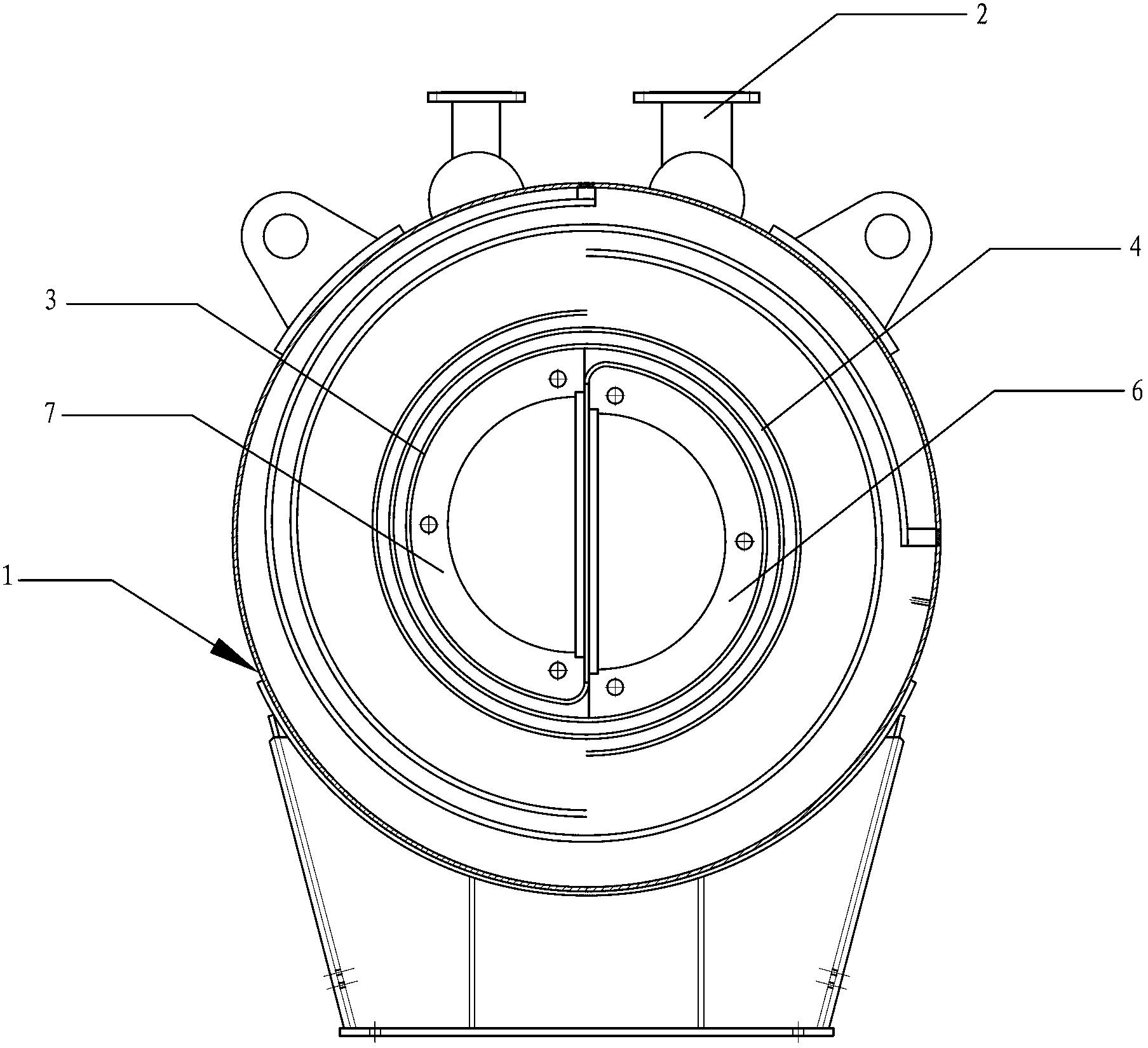

Detachable spiral heat exchanger and manufacturing method thereof

InactiveCN103322839AUniform deformationAvoid deformationHeat exchanger casingsStationary plate conduit assembliesMechanical engineeringIndustrial engineering

The invention discloses a detachable spiral heat exchanger and a manufacturing method thereof. The detachable spiral heat exchanger comprises a shell, two pairs of outlets and inlets, a supporting framework, a first heat exchange plate and a second heat exchange plate, the outlets and the inlets are arranged on the shell, and the first heat exchange plate and the second heat exchange plate are arranged in the shell and are spirally alternately wound by taking the supporting framework as a center. As the supporting framework is firstly arranged and then the first heat exchange plate and the second heat exchange plate are wound by taking the supporting framework as the center, uneven deformation of the first heat exchange plate and the second heat exchange plate can be effectively prevented in winding.

Owner:SUZHOU CITY JINXIANG PRESSURE CONTAINER MFG CO LTD

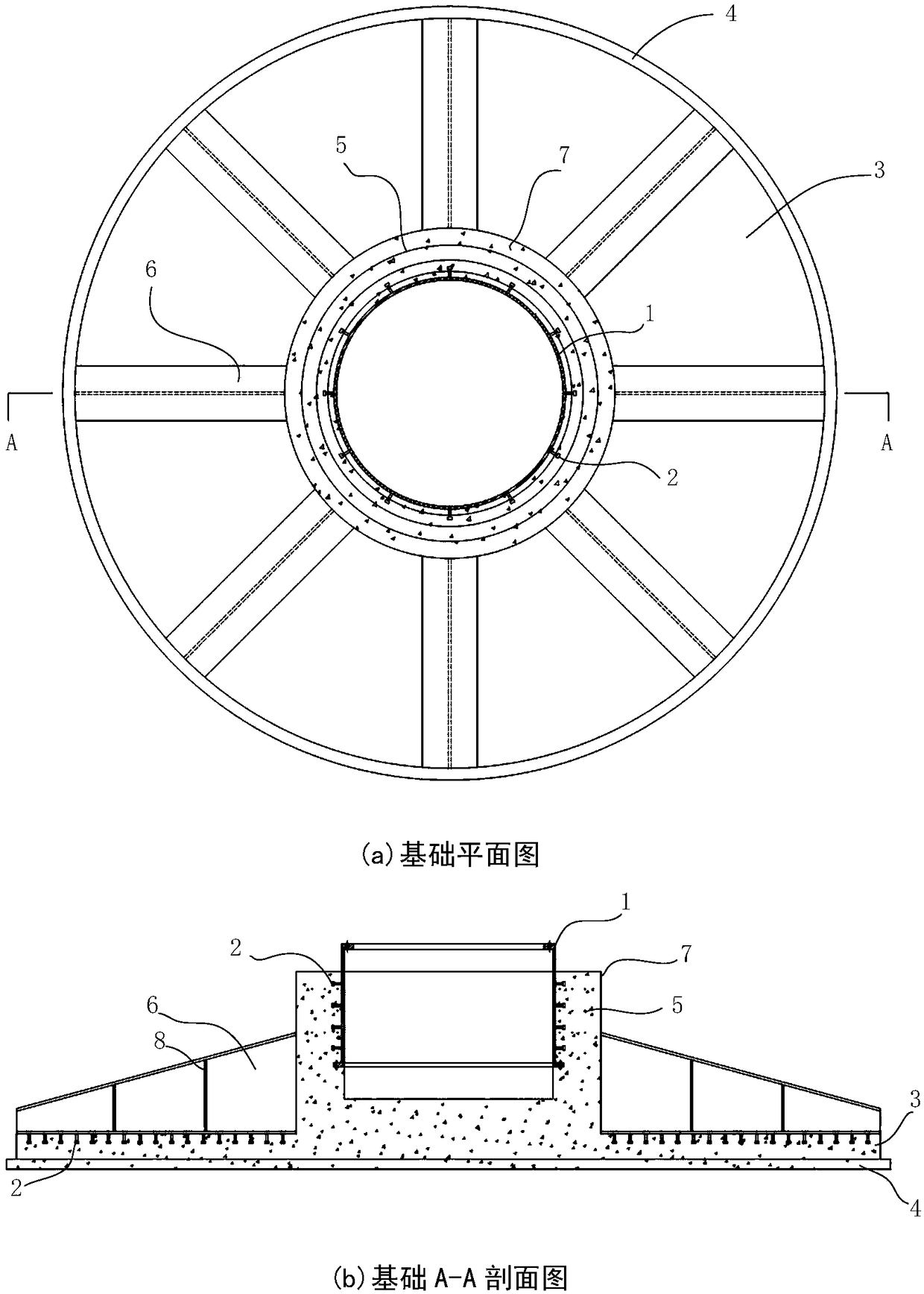

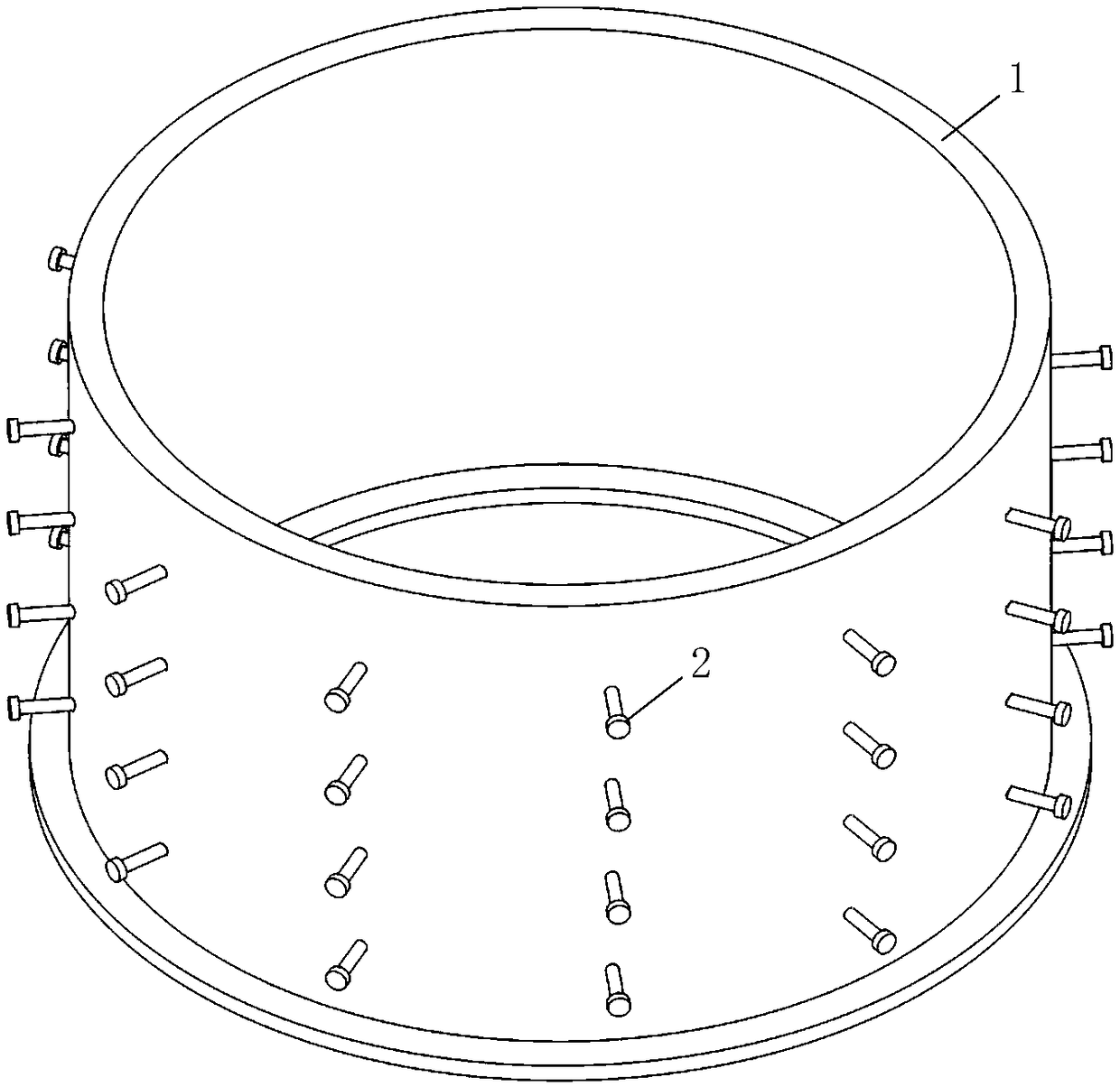

Wind power tower drum foundation ring ribbed beam type foundation based on combined structure

The invention discloses a wind power tower drum foundation ring ribbed beam type foundation based on a combined structure, and relates to the technical field of onshore wind power generation. The system comprises a foundation ring, a circular concrete floor, a variable-cross-section H-shaped steel rib beam, a hollow concrete pillar, a toggle pin and a square steel shear connector. The foundation ring is connected with a wind power tower drum on the upper part, and a perforation reinforcing steel bar required by a traditional basic ring is removed and replaced with the prefabricated welding toggle pin, so that the basic ring and a foundation concrete form effective connection by utilizing favorable shearing resistance and pulling resistance of the toggle pin, and the construction difficultyin reinforcing steel bar perforating on site is remarkably reduced. The variable-cross-section H-shaped steel rib beam is connected with a foundation slab and the pillar through the shear connector so as to form a combined structure stress system, so that the mechanical characteristics of two materials are fully played, and larger internal force produced by the upper load can be resisted. The foundation system can be applied to a circular bearing platform of a circular spread foundation or a pile foundation, and is high in on-site construction efficiency and material-saving so as to have a good engineering application prospect.

Owner:CHONGQING UNIV

Method for producing martensitic stainless steel seamless steel pipe

InactiveCN101376136AAvoid uneven deformationSmall outer diameterShaping toolsRoll mill control devicesMetallurgyMartensitic stainless steel

The invention relates to a method for producing a martensitic stainless steel seamless steel pipe, which comprises the steps of heating, piercing, rolling, acid cleaning and straightening a pipe blank, wherein the step of the piercing is a continuous and equal-diameter hot piercing process, and the step of the rolling is the cold rolling. The invention adopts the continuous and equal-diameter hot piercing process, and adopts a cold rolling process in the rolling process, thereby effectively preventing tube materials from being unevenly deformed; and the produced steel pipe has the advantages of small tolerance between the outer diameter and the wall thickness, high accuracy, and better quality and more smooth surface. In addition, the invention further adopts a mild straightening process in the step of straightening. Therefore, the seamless steel pipe has little possibility in crack rectification and the produced steel pipe has fine straightness and degree of curve being less than 1.5mm / m.

Owner:JIANGSU HONGBAO GROUP CO LTD

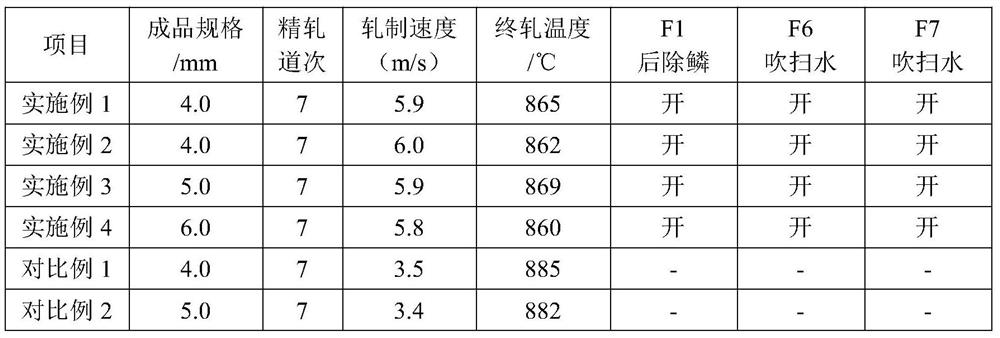

Plate shape control method of high-strength steel for commercial vehicle longitudinal beam

ActiveCN112077152AReduce cooling-heating historySmall footprintTemperature control deviceProfile control deviceShape controlControl mode

Owner:武汉钢铁有限公司

Plate shape control method for steel for hot-rolled high-strength stirring tank body

ActiveCN112108527AReduce cooling-heating historySmall footprintTemperature control deviceRollsProduction lineTemperature control

Owner:武汉钢铁有限公司

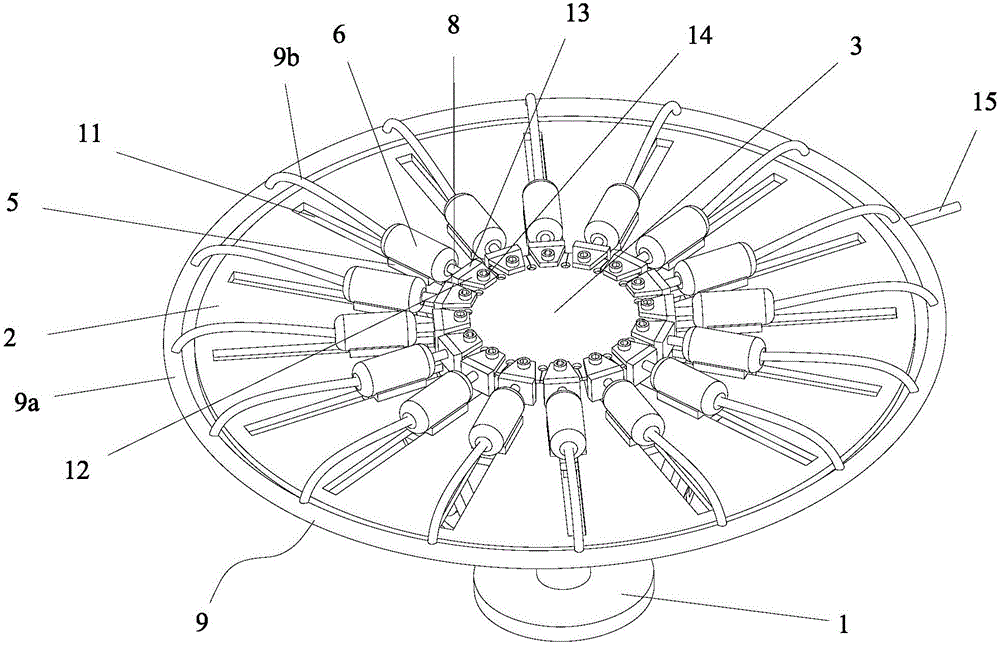

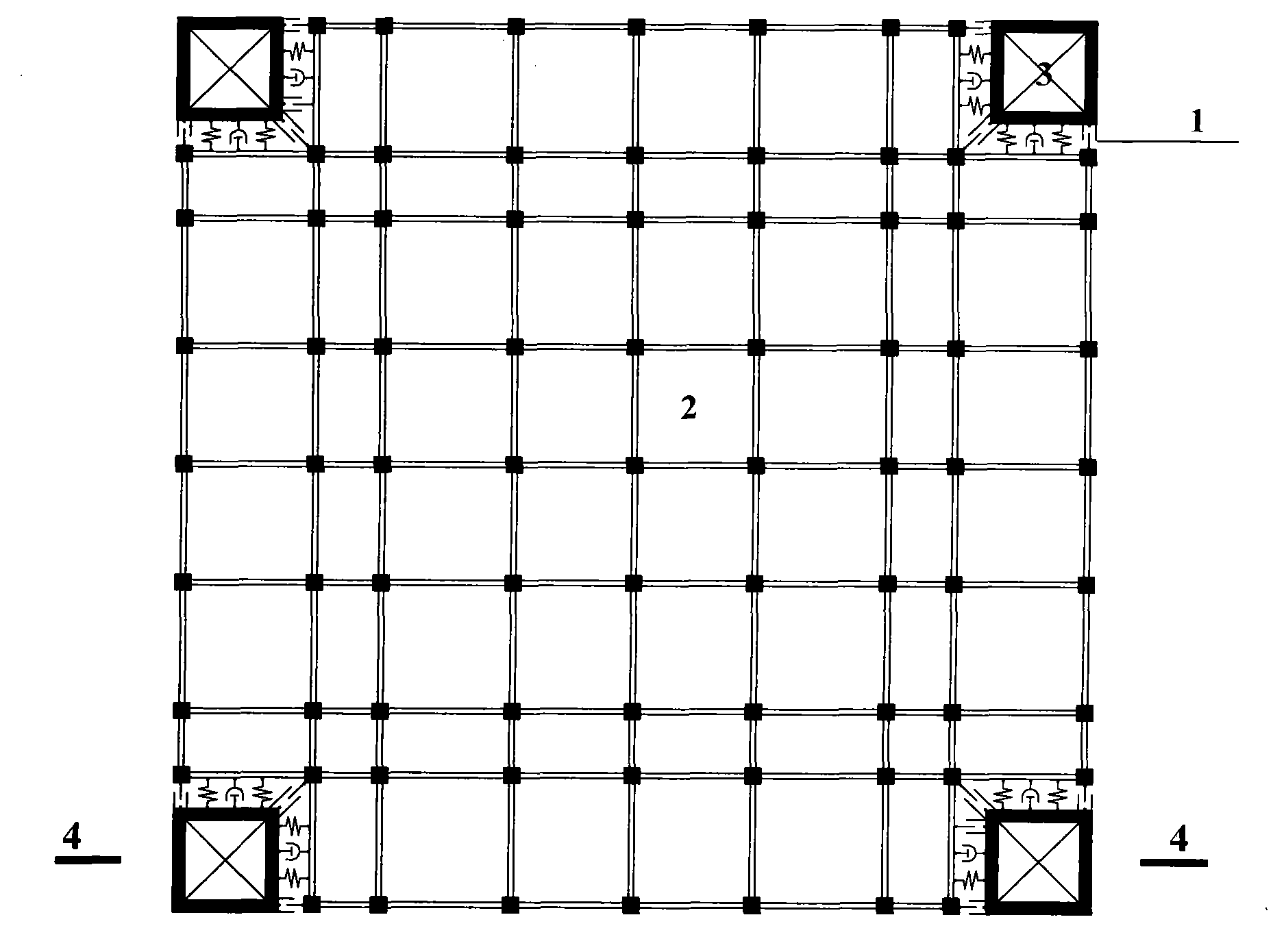

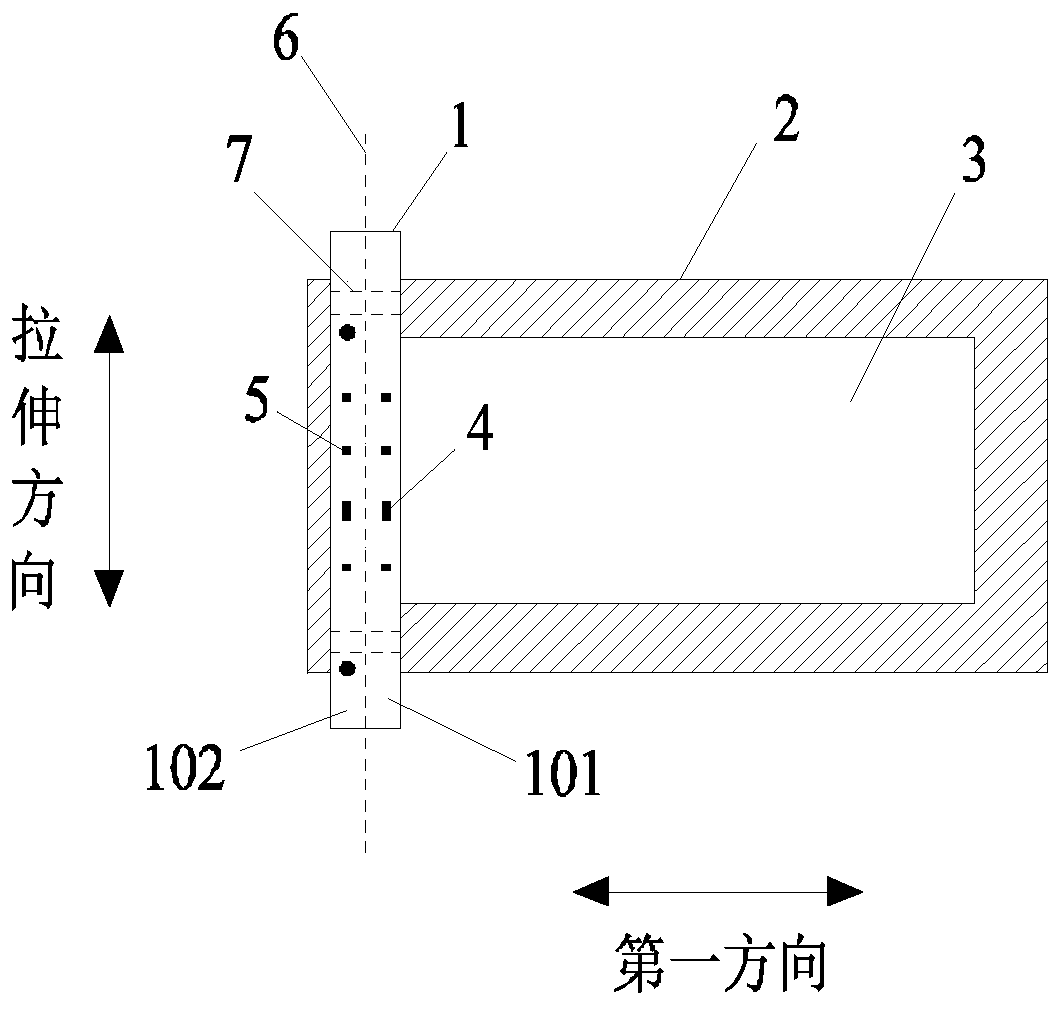

Equal biaxial tensile test device

ActiveCN106525593AAvoid uneven deformationSimple structureMaterial strength using tensile/compressive forcesPhotovoltaic energy generationHydraulic cylinderHydraulic pump

The invention relates to an equal biaxial tensile test device. The device includes a support plate used for placing a test piece, a plurality of connection mechanisms connected with the test piece and a plurality of traction discs connected with the connection mechanisms. Each connection mechanism includes a clamping unit, a driving unit and a traction unit, wherein the clamping unit is used for clamping the test piece, the driving unit is connected with the clamping unit and the two ends of the traction unit are connected with the driving unit and one traction disc respectively. Each driving unit includes a sliding block, a hydraulic cylinder, a piston and a piston rod, wherein the sliding block is slidingly connected with the support plate, the hydraulic cylinder is fixedly arranged on the sliding block and has an inner cavity, the piston is arranged in the hydraulic cylinder, one end of the piston rod is fixedly connected with the piston and the other end of the piston rod is fixedly connected with the clamping unit; the test device further includes a hydraulic pipe, a pipe cavity of the hydraulic pipe is filled with hydraulic oil, each hydraulic cylinder is connected with the hydraulic pipe, and the inner cavity of each hydraulic cylinder is communicated with the pipe cavity of the hydraulic pipe. The device can automatically adjust the uniformity of a force in each drawing direction through the hydraulic pressure, uniform force loading is achieved, and therefore the uneven deformation of the test piece is avoided.

Owner:AUTOMOBILE RES INST OF TSINGHUA UNIV IN SUZHOU XIANGCHENG

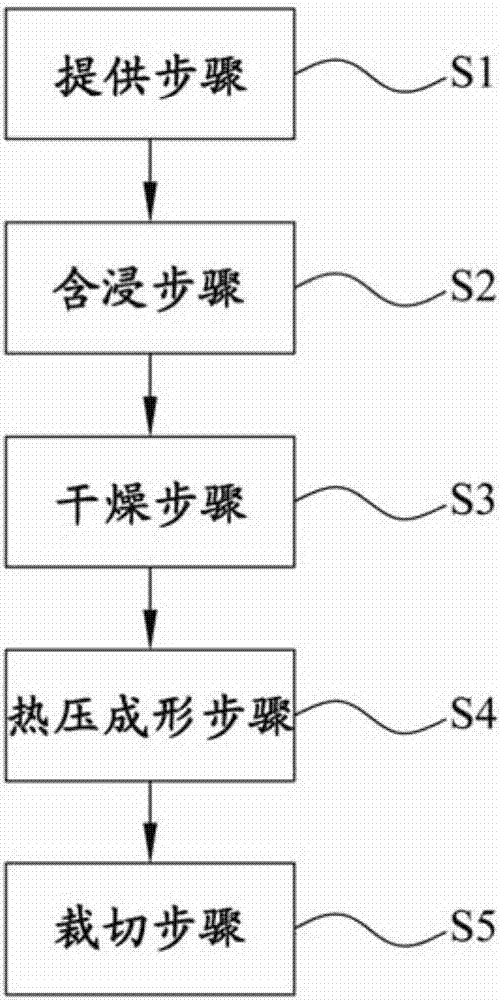

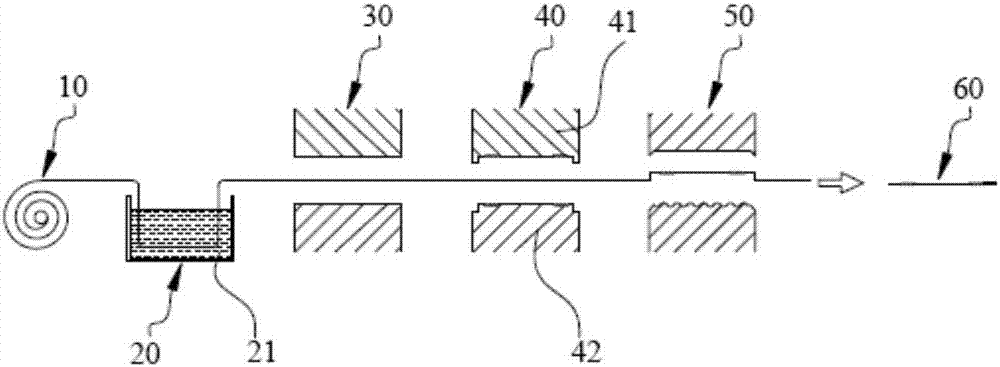

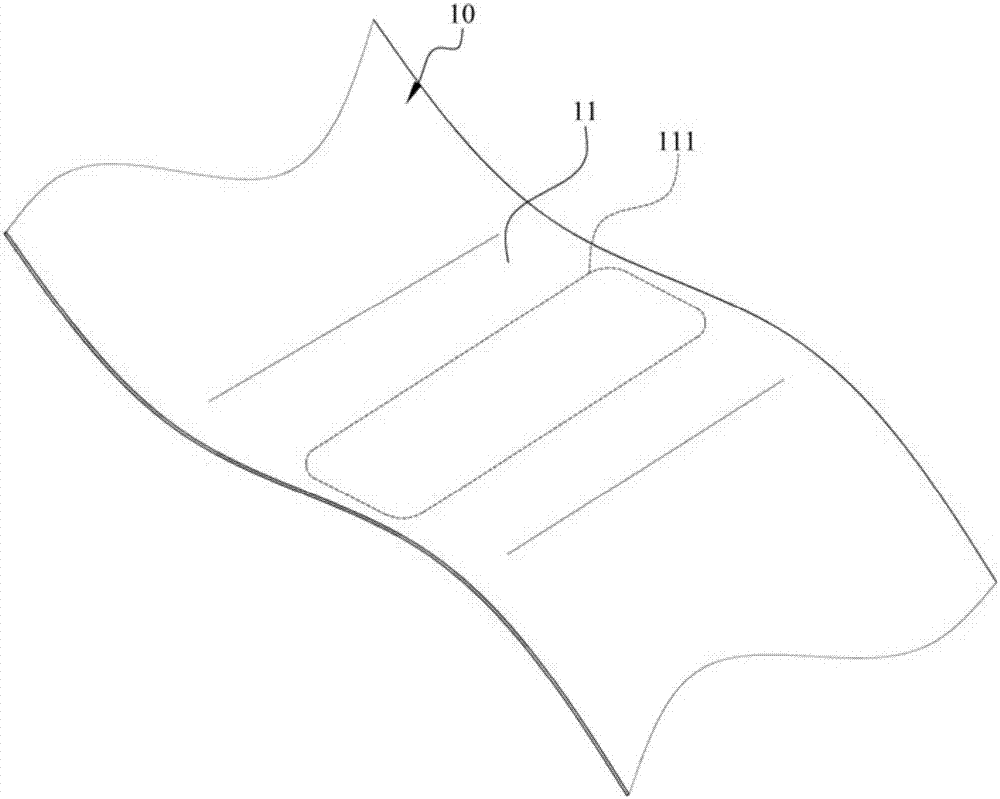

Manufacturing method for preventing damper deformation

InactiveCN107155163AAvoid uneven deformationPrevent elastic deformationElectrical transducersEngineeringHot pressing

The invention relates to a manufacturing method for preventing damper deformation. The manufacturing method comprises a providing step, an impregnating step, a drying step, a hot-pressing formation step and a cutting step, wherein a substrate is provided in the providing step; the substrate is provided with at least one pre-formed damper formation area; furthermore, the providing step is matched with the hot-pressing formation step; the dried substrate is put in a hot-pressing mould; after the substrate is warmed, pressurized and moulded, a brim part is formed on the outer periphery of the damper formation area; due to the brim part, the damper formation area can averagely bear hot-pressing formation shrinkage force; furthermore, the position of the damper formation area is kept same; the problem of unequal deformation of the substrate due to different shrinkage force can be avoided; and finally, a damper is obtained after the cutting step. Thereby, the damper having good quality can be manufactured through the manufacturing method in the invention.

Owner:大原博

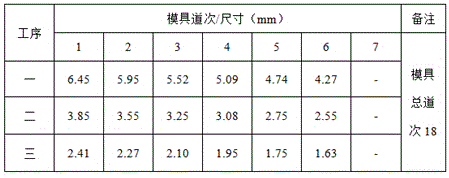

Manufacture process of high-strength welding wires

InactiveCN105983798AGuaranteed smooth productionAvoid crackingDrawing diesFurnace typesWeld lineElectric arc

The invention discloses a manufacture process of high-strength welding wires capable of producing manufacture process of high-strength welding wires with high composite performance. The process comprises following steps: smelting welding wires, performing acid pickling in an off-line manner, pulling and pushing welding wires, plating welding wires with copper and welding welding wires layer by layer. The middle link of the step for pulling and pushing welding wires comprises an annealing process of welding wires. An experiment shows that the annealing process added to the middle link of the step for pulling and pushing welding wires has great advantages. Therefore, the annealing process is selected for production of high-strength welding wires. The high-strength welding wires do not crake during production and smooth production of processes for pulling and pushing welding wires, plating welding wires with copper is ensured. As a result, smooth production of high-strength welding wires is ensured and welding wires produced are featured by being good in cooper plating bonding force and usage performance, stable in arcs and little in weld spatter and attractive in welding line formation.

Owner:KUNSHAN MCC BAOSTEEL WELDING CONSUMABLES

Structural horizontal or vertical and rotatable shock insulation, damping and energy consumption structural system

ActiveCN104278768AAvoid damageHas the ability to absorb shockShock proofingStructural systemEngineering

The invention discloses a structural horizontal or vertical and rotatable shock insulation, damping and energy consumption structural system. A conversion layer or a reinforced layer and a reinforcing member can be arranged above a vertical shock insulation or damping and energy consumption layer, so that vertical non-uniform displacement of an upper shock insulation structure can be reduced. In a rotary shock insulation, damping and energy consumption structural system, each shock insulation, damping and energy consumption support on a rotary shock insulation, damping and energy consumption layer shares an identical integral rotation center, and each shock insulation and damping support can be positioned at the same height but at different inclination angles. In a vertical shock insulation, damping and energy consumption structural system, an oblique vertical shock insulation, damping and energy consumption layer is arranged, and a rubber support can be arranged between oblique sliding surfaces. In a vertical shock insulation, damping and energy consumption structural system, an oblique vertical shock insulation, damping and energy consumption layer is arranged on a large-span spatial structure, the inside of a band-shaped structure or an annular member is enclosed, and a pull rod, a pressure lever and a cable can be arranged for connecting. In a horizontal or vertical shock insulation, damping and energy consumption structural system of a large-span spatial structure, a conversion member is arranged above a vertical shock insulation, damping and energy consumption layer.

Owner:赵世峰

Windproof and horizontal displacement resistant steel column joint of staggered telescopic joint type curtain wall and processing method thereof

ActiveCN104563306AAvoid chippingAddressing design flawsWallsBuilding material handlingStructural deformationJoints types

The invention discloses a windproof and horizontal displacement resistant steel column joint of a staggered telescopic joint type curtain wall and a processing method thereof. The windproof and horizontal displacement resistant steel column joint of the staggered telescopic joint type curtain wall comprises a teflon board, limiting steel plates, a tension resisting steel plate, a windproof column and a quadrate pipe; the telfon board is arranged at the upper part of a horizontal square pipe on a roof; the limiting steel plates are arranged at two ends of the teflon board; the tension resisting steel plate is welded at the upper part of the teflon board; the windproof column is arranged in a telescopic joint staggering area of the curtain wall; the quadrate pipe is horizontally arranged between two joints. According to the windproof and horizontal displacement resistant steel column joint of the staggered telescopic joint type curtain wall, teflon plate through which joints can slide is arranged at the upper part of the horizontal quadrate pipe on the roof, and therefore, the structural deformation of different layers can be removed, and thus the curtain wall system can be prevented from being broken due to non-uniform deformation can be effectively prevented; the joints connected between the windproof column and a roof steel structure are connected through rigid connecting rods; meanwhile, the quadrate pipe is horizontally arranged between the two joints, so that the displacement can be synchronously performed, and as a result, non-uniform deformation can be effectively prevented.

Owner:JIANGSU HUNING STEEL MECHANISM

High-quenching-hardness martensitic stainless steel coil for measuring tool and preparation method thereof

ActiveCN113174532AIncreased level of controlAvoid uneven deformationTemperature control deviceWork heating devicesMartensitic stainless steelManganese

The invention discloses a high-quenching-hardness martensitic stainless steel coil for a measuring tool and a preparation method thereof. The high-quenching-hardness martensitic stainless steel coil is prepared from the following chemical components in percentage by weight: 0.43-0.53% of carbon, less than or equal to 1.0% of silicon, less than or equal to 1.0% of manganese, less than or equal to 0.040% of phosphorus, less than or equal to 0.005% of sulfur, 12.50-14.00% of chromium, less than or equal to 0.30% of nickel, less than or equal to 0.10% of molybdenum, less than or equal to 0.15% of vanadium, less than or equal to 1.0% of nitrogen and the balance iron and inevitable residual elements. The production process comprises the following steps of: (1) smelting; (2) continuous casting; (3) coping; (4) heating; (5) descaling; (6) rough rolling; (7) finish rolling; (8) coiling; (9) annealing; and (10) acid pickling. The HRC hardness of the stainless steel material prepared by the method can reach 57 degrees or above, and the stainless steel material has excellent indexes such as surface smoothness, wear resistance and toughness; and the provided preparation method is short in process flow, low in cost and high in yield.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

A kind of flexible wear-resistant cross embedded rubber cable and preparation method

ActiveCN110444323BImprove flexibilityImprove consistencyRubber insulatorsApparatus for heat treatmentRubber materialEngineering

The invention discloses a flexible wear-resistant cross embedded rubber cable. The flexible wear-resistant cross embedded rubber cable comprises a cable core and rubber wrapping the cable core. The rubber is of a composite structure and is formed by mutually crossing, embedding and combining soft rubber and wear-resistant flexible rubber; the flexible rubber is prepared from the following raw materials in parts by weight: 50-60 parts of natural rubber, 40-50 parts of butadiene styrene rubber, 40-55 parts of VN3 white carbon black, 8-15 parts of softening oil, 4-6 parts of accelerants, 8-10 parts of processing addition agents and 1-2 parts of stabilizers; the wear-resistant flexible rubber is prepared from the following raw materials in parts by weight: 4-6 parts of CPE (chlorinated polyethylene), 40-55 parts of resin powder, 35-40 parts of calcium powder, 12-15 parts of nano argil, 16-20 parts of DOS (dioctyl sebacate), 10-16 parts of chlorinated paraffin, 0.3-0.5 part of stearic acid,0.4-0.6 part of PE wax, 4-6 parts of carbon black and 0.3-0.8 part of a stabilizer. According to the invention, the cable is good in insulativity, high in flexibility and high in abrasion resistanceand corrosion resistance through the two kinds of rubber materials which are embedded into each other.

Owner:MINGPIN CABLE GRP CO LTD

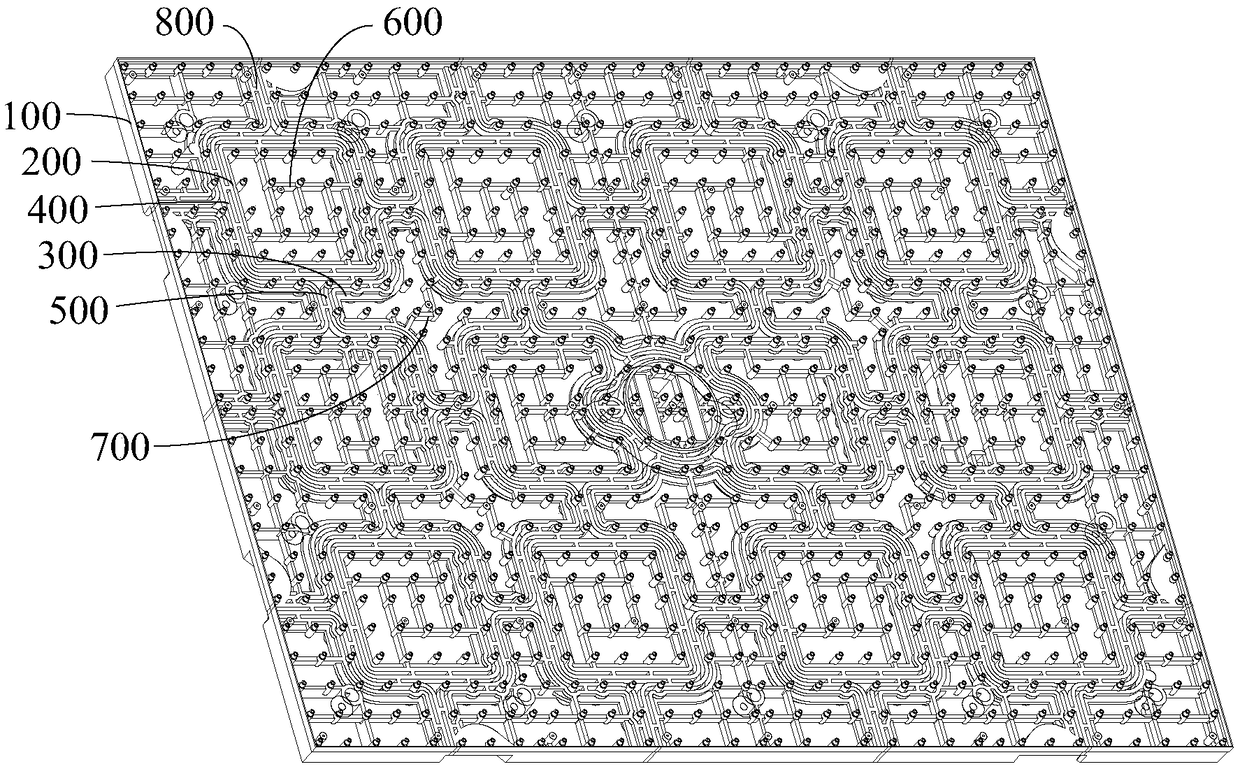

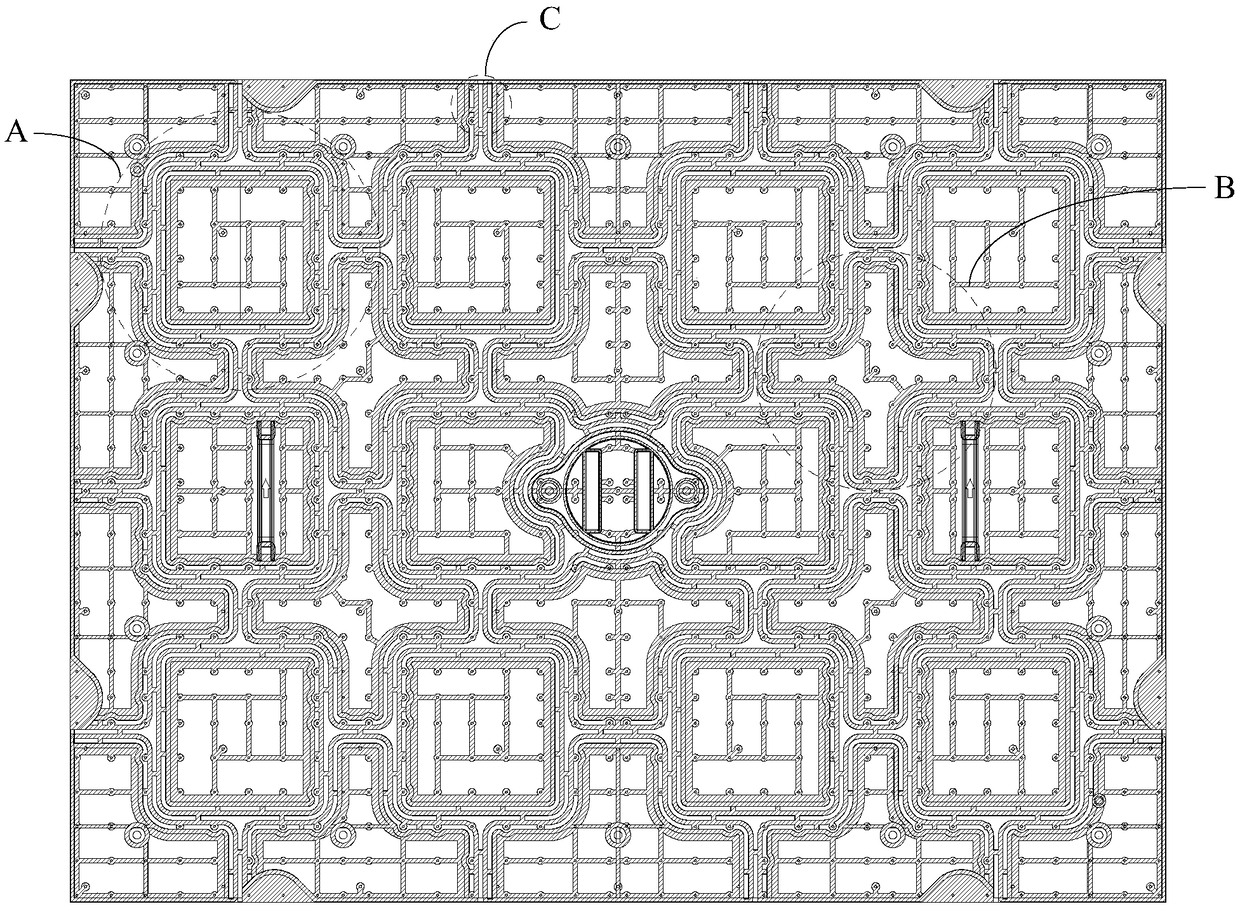

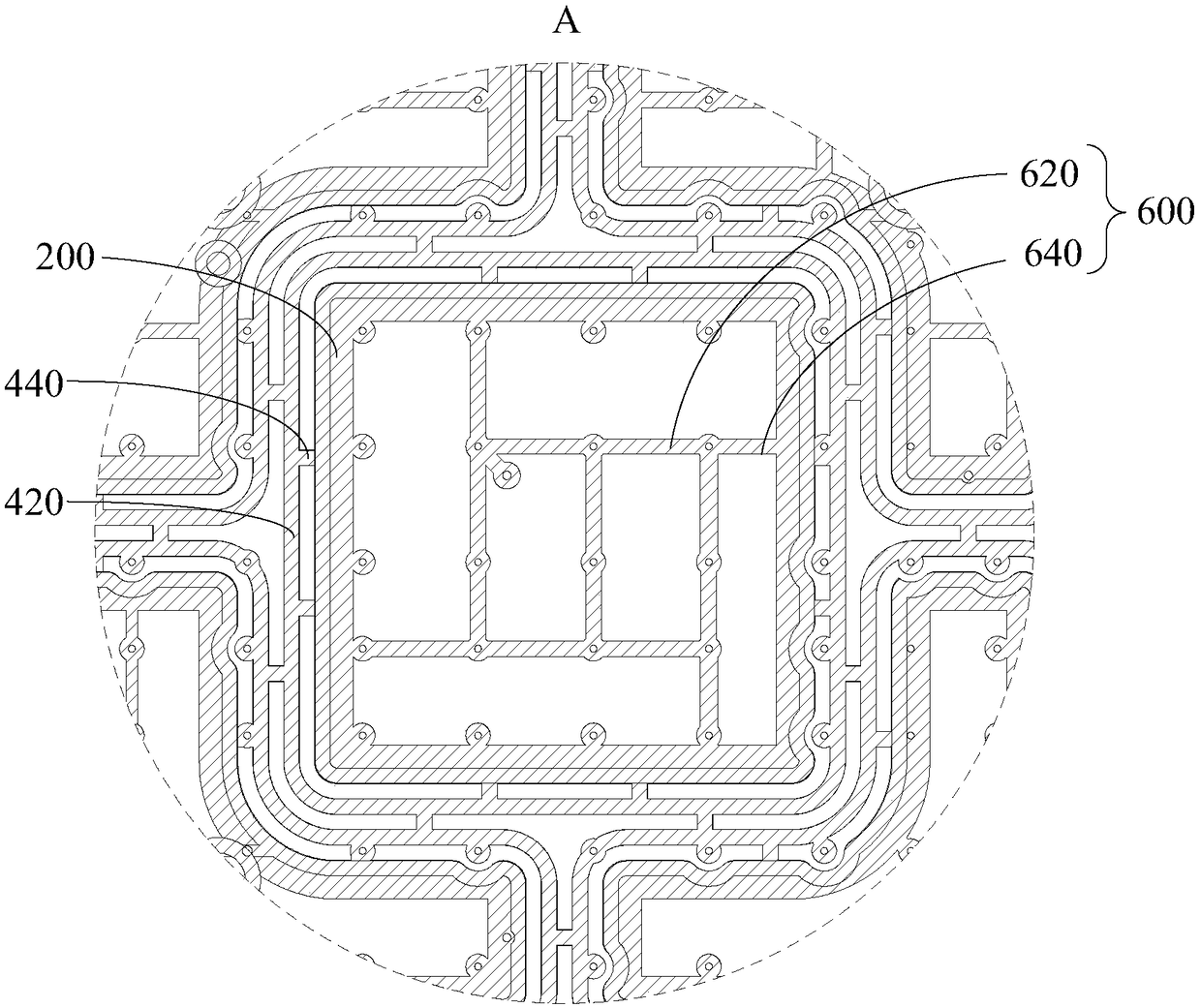

Bottom case of display device

ActiveCN108962019AAvoid uneven deformationGuaranteed DimensionsCasings/cabinets/drawers detailsIdentification meansEngineeringDisplay device

The invention discloses a bottom case of a display device, which comprises an outer edge and a plurality of first rigid structures, a second rigid structure, a first elastic structure and a second elastic structure arranged in the outer edge; the first rigid structures are arranged in rows at intervals; the second rigid structures are arranged in rows and staggered with the first rigid structure;a first elastic structure ring is arranged at the periphery of the first rigid structure and is used for absorbing the deformation amount generated by the expansion and contraction of the first rigidstructure; a second elastic structure ring is arranged at the periphery of the second rigid structure and is used for absorbing the deformation amount generated by the expansion and contraction of thesecond rigid structure. In the technical scheme of the invention, the expansion and contraction amount of the first rigid structure is absorbed by the first elastic structure; the expansion and contraction amount of the second rigid structure is absorbed through the second elastic structure, so that the external dimension of the case is effectively ensured, and the assembly effect of the bottom case and the display module is ensured.

Owner:UNILUMIN GRP

Rubber buffering and vibration isolating elastomer structure

The invention relates to a rubber buffering and vibration isolating elastomer structure which comprises an upper metal part, a rubber part and a lower metal part. An internal cavity structure is adopted by the rubber body of the invention to increase the buffering stroke of the rubber body, and the buffering deformation of the rubber body can reach 100%; and if the space along the axial directionof the elastomer structure is large enough, the buffering deformation can reach about 150%. The design of the cavity structure greatly increases the buffering deformation stroke of the rubber part by2-4 times of the traditional rubber isolator, thereby greatly improving the buffering effect. The structure of the invention adopts the design of a gas channel; on the one hand, by the design of the gas channel, when the elastomer bears the impact load, because the action time of the load is short, the gas in the cavity is quickly discharged outwards through the gas channel, and the friction action of the gas and the channel increases the damping of the elastomer structure, thereby increasing the buffering effect of the elastomer structure; and on the other hand, by the design of the gas channel, the gas in the cavity can be smoothly discharged under the action of the load to avoid the uneven deformation of the rubber part caused by sealing of the cavity, thereby ensuring the rigidity stability of the elastomer structure in the deformation process.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

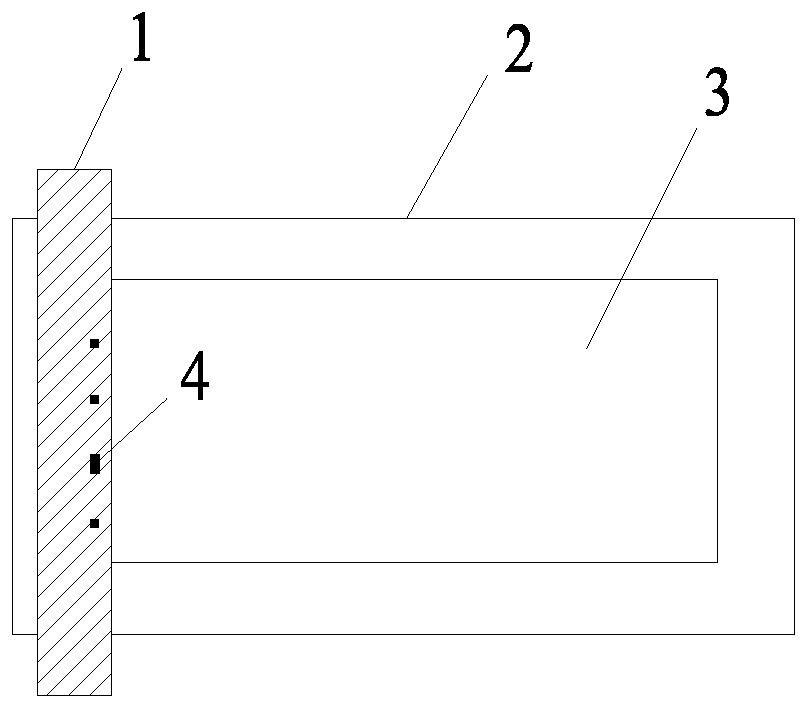

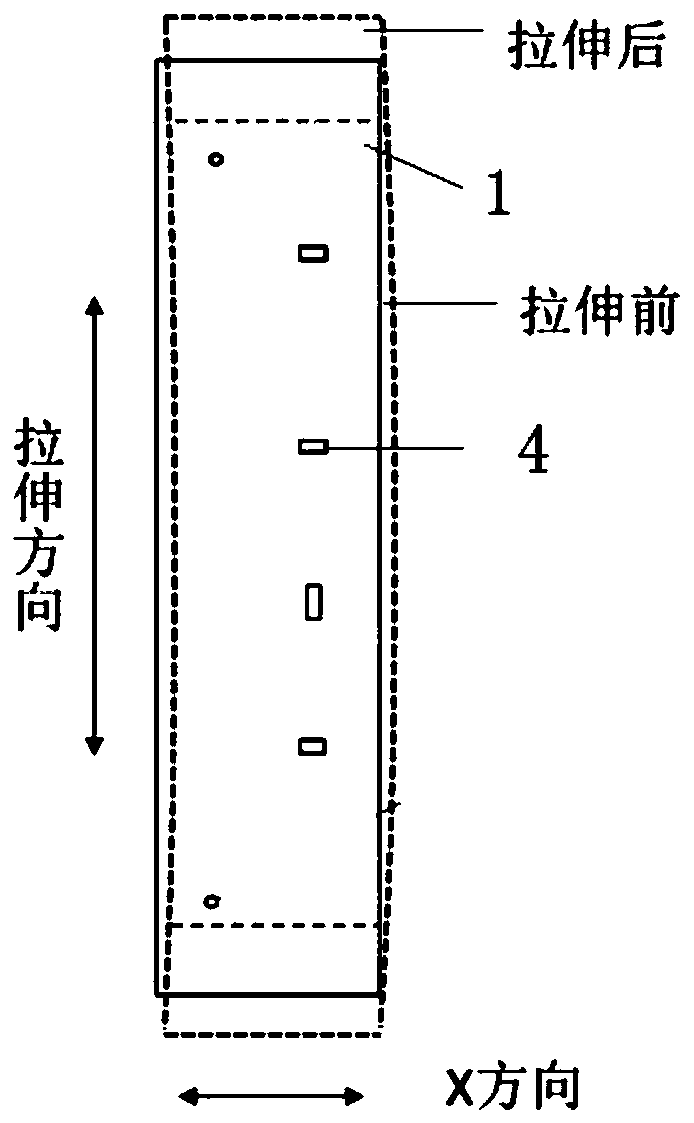

Mask and preparation method thereof

ActiveCN110629159AImprove stabilityImprove deposition accuracyVacuum evaporation coatingSputtering coatingEngineeringEvaporation

The embodiment of the invention provides a mask and a preparation method thereof. The mask comprises a mask body, wherein the mask body is provided with a detection opening, and a balance pattern usedfor balancing stretching stress born by the detection opening, the balance pattern and the detection opening are located on two sides of a center line of the mask body in the first direction length correspondingly, and the first direction is perpendicular to the stretching direction of the mask body. After the mask is stretched, the deformation is uniform, the alignment precision stability of themask can be improved, and the evaporation deviation caused by the poor alignment precision of the mask in the evaporation process is avoided.

Owner:BOE TECH GRP CO LTD +1

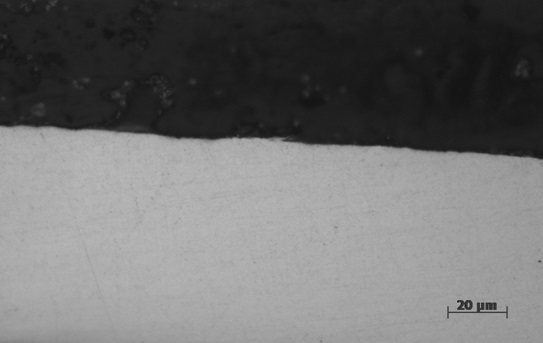

Preparation method of Haynes 214 alloy strip foil

ActiveCN114703434AAvoid uneven deformationNo crackIncreasing energy efficiencyFurnace typesSolution treatmentSand blasting

The invention belongs to the field of metal material processing, and particularly relates to a preparation method of Haynes 214 alloy strip foil, which comprises the following specific process flows: smelting, cogging and forging, hot rolling, solution treatment, acid pickling, sand blasting, repeated cold rolling, annealing and solution treatment of a finished product. The cogging forging heating temperature is 1030-1150 DEG C, and the total deformation is 35%-60%; the heating temperature of hot rolling is 1150-1250 DEG C, and the total deformation is 85-95%; the solution treatment comprises the following steps: preserving heat at 1100-1180 DEG C for 30-60 minutes, cooling with water, pickling the surface, and blasting sand; the rolling speed in cold rolling is 4-30 m / min, and the cold rolling deformation between two times of annealing is 30%-60%; the intermediate annealing temperature ranges from 1050 DEG C to 1150 DEG C; and the solution treatment of the finished product comprises the following steps: preserving heat at 1065-1120 DEG C for 10-60 minutes, cooling by adopting 99.999% high-purity argon after the heat preservation is finished, keeping the heat preservation temperature to 200 DEG C and the cooling rate greater than 180 DEG C / min, and then correcting the plate shape. The strip foil prepared through the method has the advantages of being high in size precision, smooth in surface, good in uniformity and consistency and the like, and higher use requirements can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ceramic multilayer substrate

InactiveUS7745734B2Avoid uneven deformationSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorMetallurgy

A ceramic multilayer substrate includes a plurality of laminated ceramic layers and at least one conductor pattern and disposed on at least one of the ceramic layers. The ceramic multilayer substrate has a cavity in at least a first main surface. The ceramic multilayer substrate includes a deformation preventing pattern disposed on at least one of the ceramic layers having an opening forming the cavity. The deformation preventing pattern surrounds the entire perimeter of the opening and is made of the same material as the conductor pattern.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com