Windproof and horizontal displacement resistant steel column joint of staggered telescopic joint type curtain wall and processing method thereof

A technology of expansion joints and wind-resistant columns, applied in the direction of walls, building components, buildings, etc., to prevent uneven deformation, avoid safety accidents, and solve design defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

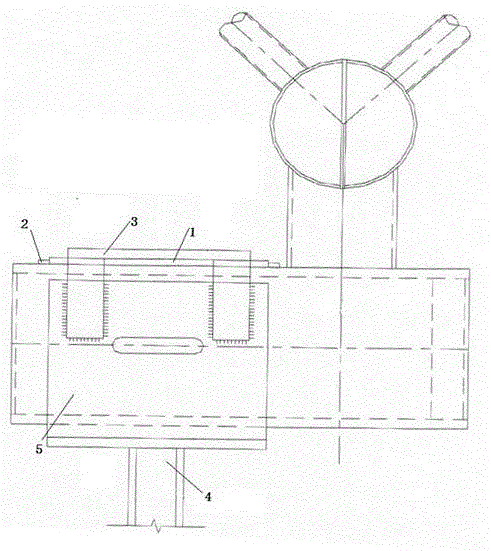

[0031] Such as figure 1 A staggered expansion joint curtain wall anti-wind and horizontal displacement steel column node is shown: it is characterized in that it includes: polytetrafluoroethylene plate 1, limit steel plate 2, tensile steel plate 3, wind-resistant column 4, and square tube 5.

[0032] The relationship between the above components is as follows:

[0033] The polytetrafluoroethylene plate 1 is arranged on the top of the horizontal square tube of the roof, the limiting steel plate 2 is arranged at the two ends of the polytetrafluoroethylene plate 1, and the tensile steel plate 3 is welded to the top of the polytetrafluoroethylene plate 1 In the upper part, the wind-resistant column 4 is made of steel and is located in the staggered section of the expansion joints of the curtain wall. The nodes connected between the wind-resistant column 4 and the roof steel structure are connected by rigid connecting rods. The tube 5 is horizontally arranged between the two nodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com