Plate shape control method for steel for hot-rolled high-strength stirring tank body

A technology of plate shape control and stirring tank, which is applied in temperature control, roll speed control, metal rolling, etc., can solve the problems of limited production equipment capacity, difficult welding and forming, and high equipment cost, so as to promote microstructure and grain Homogenization, reduction of plant floor area, reduction of heating process effect

Active Publication Date: 2020-12-22

武汉钢铁有限公司

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its disadvantage is that there is no measure to control the shape of the steel plate, and because the strength of the steel plate is too high, it is difficult to weld and form, and the production equipment capacity of the auto

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Convexity | aaaaa | aaaaa |

Login to View More

Abstract

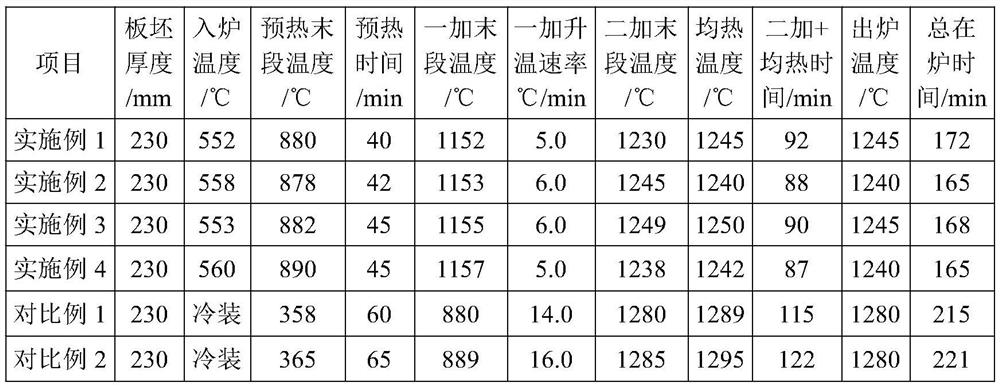

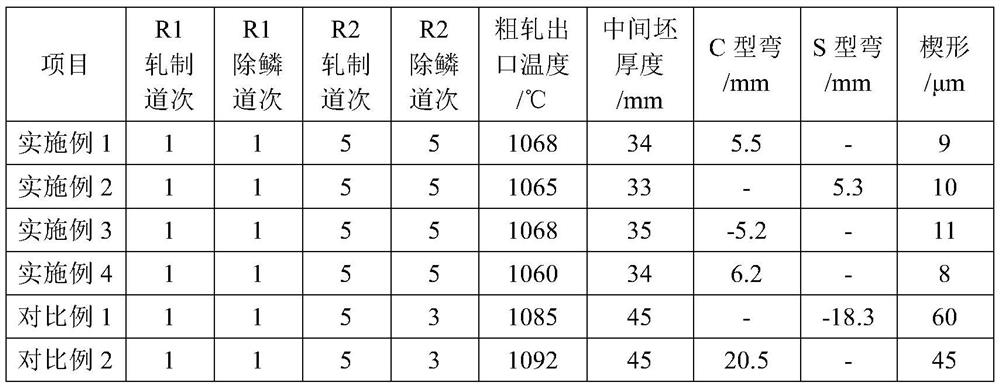

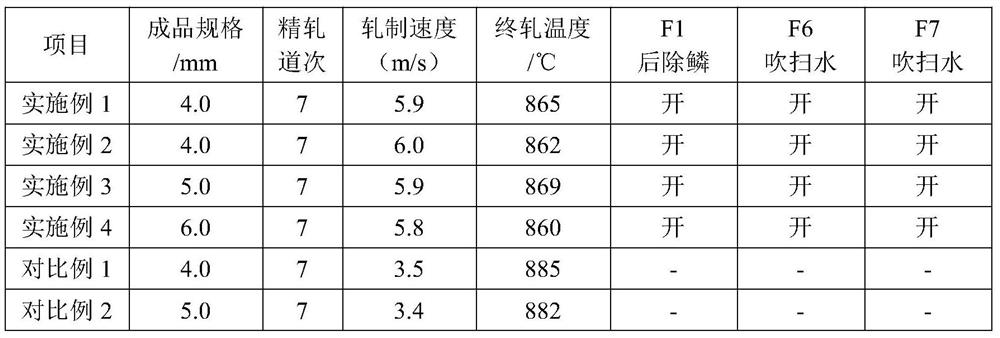

The invention discloses a plate shape control method for steel for a hot-rolled high-strength stirring tank body. The plate shape control method comprises the following steps that (1) hot blanks are charged; (2) plate blanks are heated; (3) rough rolling is conducted, specifically, a 1+5 rolling mode is adopted, the bending amount of C-shaped bending or S-shaped bending of the last pass is controlled within +/-10mm, the wedge-shaped control range is within +/-20[mu]m, and the rough rolling ending temperature is controlled to be 1040-1080 DEG C; (4) finish rolling is conducted, specifically, large convexity value control is adopted for outlets of F1-F4 racks, an equal proportion convexity control mode is adopted for F5-F7 racks, and the finished product convexity control range is 0-30[mu]m;(5) layer cooling is conducted, specifically, a front-section ultra-fast cooling and rear-section air cooling mode is adopted; (6) slow cooling is conducted, specifically, preheating is conducted ina heat preservation wall in advance, and steel coils are discharged from a production line and hoisted into the heat preservation wall for slow cooling; and (7) straightening and flattening are conducted. The steel for the hot-rolled stirring tank body is prepared according to the plate shape control method, the apparent plate shape of a material is good, the warping amount during discharging cutting is less than or equal to 5mm, and the requirements of the welding process of an automobile concrete stirring tank body for the plate shape are completely met.

Description

technical field [0001] The invention relates to a method for controlling the shape of a hot-rolled steel strip, in particular to a method for controlling the shape of a hot-rolled high-strength stirring tank steel. Background technique [0002] The mixing device of the automobile concrete mixing tank is composed of a tank body and a mixer. It is one of the main components of the concrete mixer truck and the core component for the function of the concrete mixer truck. The steel plate is required to have good wear resistance, cold formability and weldability. With the development trend of automobile lightweight and the need for weight reduction and energy saving, from the perspective of reducing the weight of the body and reducing the weld seam, the hot-rolled steel strip for the tank body of the mixing tank is developing to a high-strength, thin specification, and ultra-wide specification, such as ( 4.0~6.0)*(1650~1900) mm specification, tensile strength (480~620) hot-rolled...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B45/00B21B37/74B21B37/46B21B45/02B21B15/00

CPCB21B45/004B21B37/74B21B37/46B21B45/0233B21B15/00B21B2015/0057B21B2015/0071B21B2267/18Y02P70/10

Inventor 王立新尹云洋袁金梁文徐峰刘斌习天辉刘冬张扬陶文哲

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com