Plate shape control method of high-strength steel for commercial vehicle longitudinal beam

A shape control, high-strength steel technology, applied in contour control, temperature control and other directions, can solve the problems of increasing equipment investment and high production costs, and achieve the effect of reducing energy consumption, saving investment, and reducing plant floor space

Active Publication Date: 2020-12-15

武汉钢铁有限公司

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Chinese patent document CN101670372A discloses a method for eliminating shape defects of hot-rolled high-strength steel plates. The process route of temper rolling + bell annealing + roller straightening has achieved good results, but this pro

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

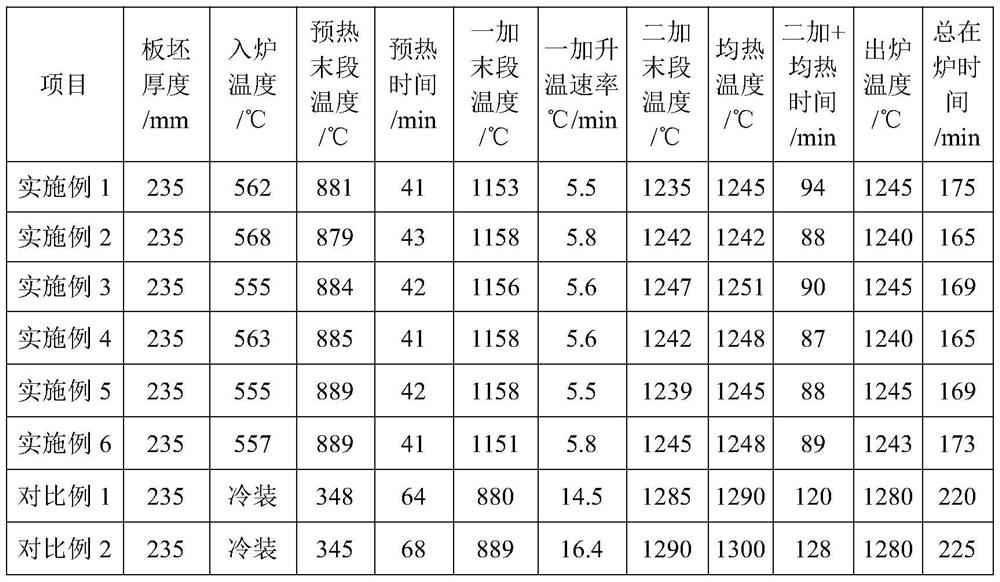

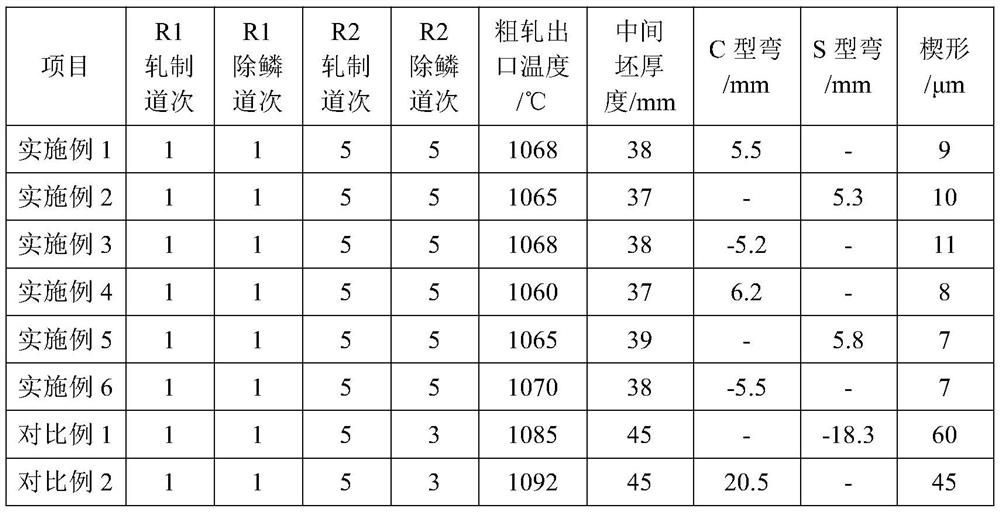

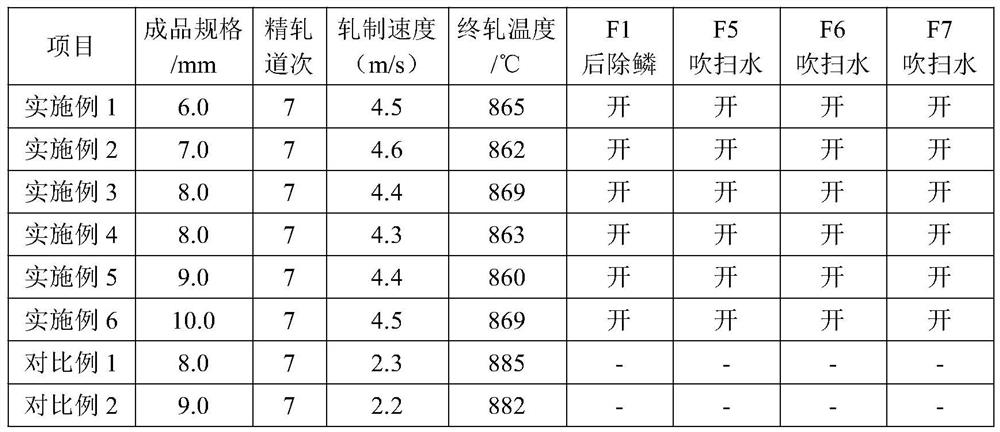

The invention discloses a plate shape control method of high-strength steel for a longitudinal beam of a commercial vehicle. The plate shape control method comprises the following steps that: 1) a hotblank is charged into a furnace; 2) the plate blank is heated; (3) rough rolling is conducted, specifically, a 1+5 rolling mode is adopted, bending amount of a C-shaped bend or an S-shaped bend in the last pass is controlled within +/-10mm, wedge shape control range is controlled within +/-20[mu]m, and rough rolling finishing temperature is controlled within 1040-1080 DEG C; (4) finish rolling isconducted, specifically, outlets of F1-F4 racks adopt large convexity value control, F5-F7 racks adopt an equal-proportion convexity control mode, and convexity control range of a finished product is0-20[mu]m; 5) layer cooling is conducted, specifically, a front-section ultrafast cooling and rear-section air cooling mode is adopted; 6) slow cooling is conducted, specifically, preheating is conducted in advance in a heat preservation wall, and a steel coil is hoisted into the heat preservation wall for slow cooling; and 7) straightening and flattening are conducted. According to the plate shape control method of the high-strength steel for the longitudinal beam of the commercial vehicle, the high-strength steel for the longitudinal beam of the commercial vehicle prepared is good in apparent plate shape, has no potential plate shape risk, and completely meets the high-standard requirement of a rolling forming process of the high-strength steel for the longitudinal beam of the commercial vehicle on the plate shape.

Description

technical field [0001] The invention relates to a method for controlling the shape of a hot-rolled steel strip, in particular to a method for controlling the shape of a high-strength steel for a commercial vehicle longitudinal beam. Background technique [0002] The lightweight of commercial vehicles is one of the important measures to reduce smog and emissions in the automotive field, which has attracted widespread attention from the whole society. Especially with the release and implementation of GB1589-2016 "External Dimensions, Axle Load and Mass Limits of Automobiles, Trailers and Automobile Trains", people's requirements for high-strength and thinning automotive steel are becoming more and more urgent. [0003] Automobile longitudinal beams are the main load-bearing parts of commercial vehicles, carrying almost all the weight of the goods. Therefore, the quality of steel for automobile longitudinal beams directly affects the driving safety and service life of the vehic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B37/28B21B37/30B21B37/44B21B37/74C21D8/02

CPCB21B37/30B21B37/44B21B37/74B21B37/28C21D8/0205C21D8/0226C21D8/0263

Inventor 王立新尹云洋张鹏武赵江涛魏兵梁文陶文哲王世森刘冬张扬

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com