Patents

Literature

41results about How to "Avoid irregular deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing a container containing a content fluid, a method for placing an inside of a container under a positive pressure, a filled container, a blow molding method, and a blow molding device

ActiveUS20150076105A1Without compromising productivityInhibitory contentLarge containersSolid materialBlow moldingInternal pressure

Owner:DISCMA

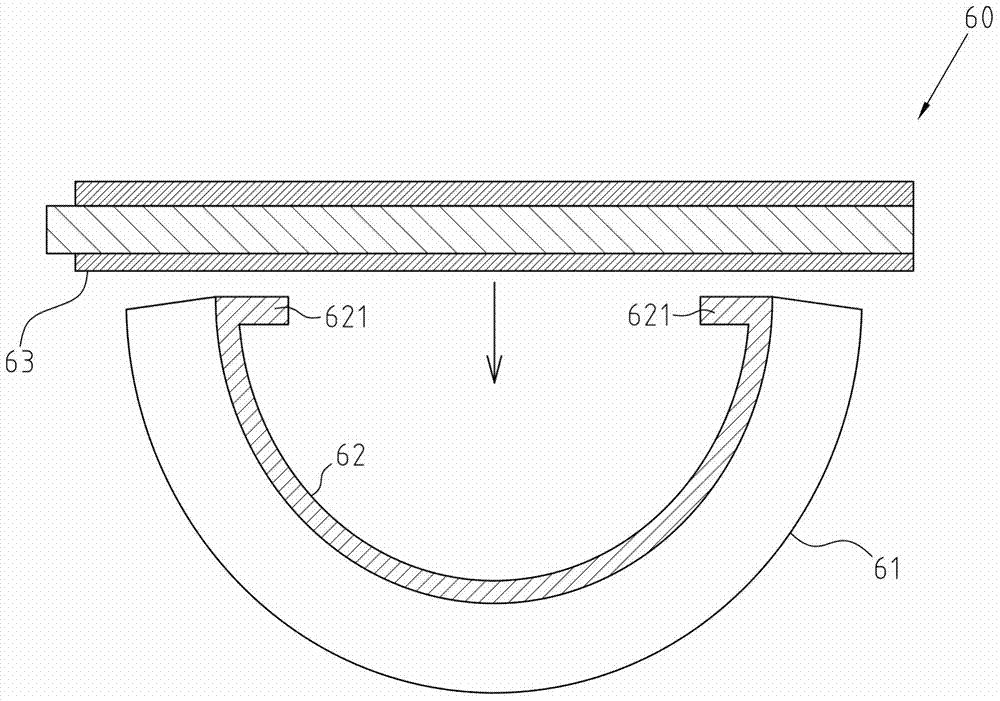

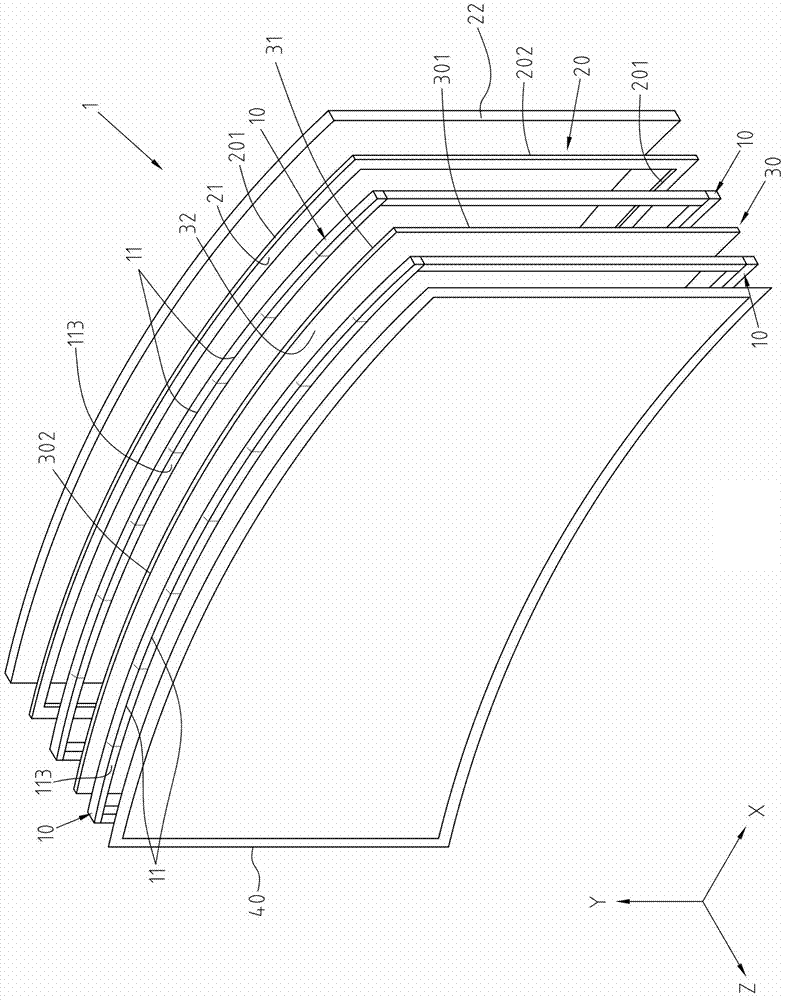

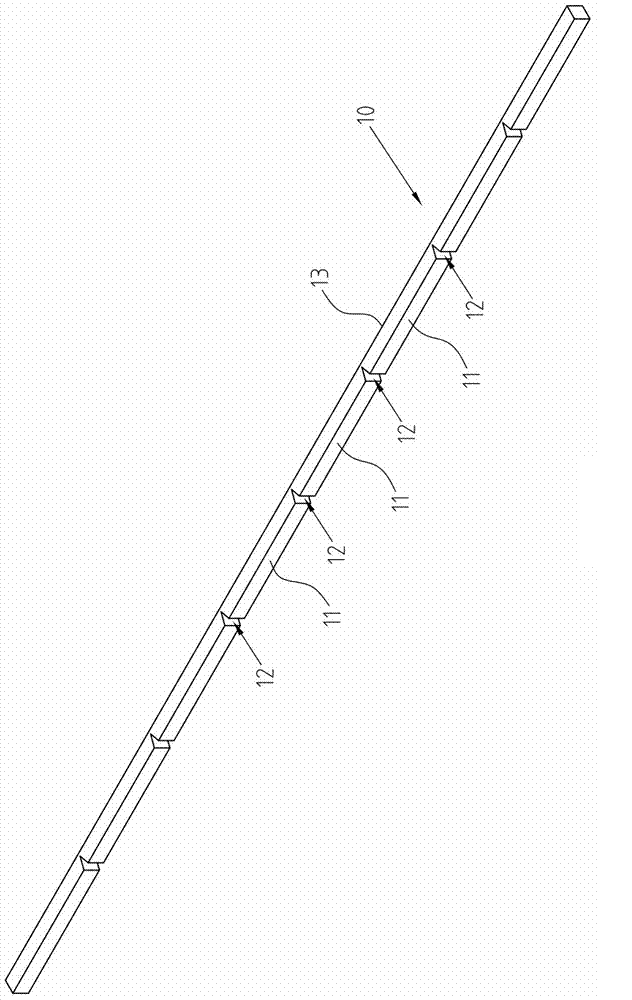

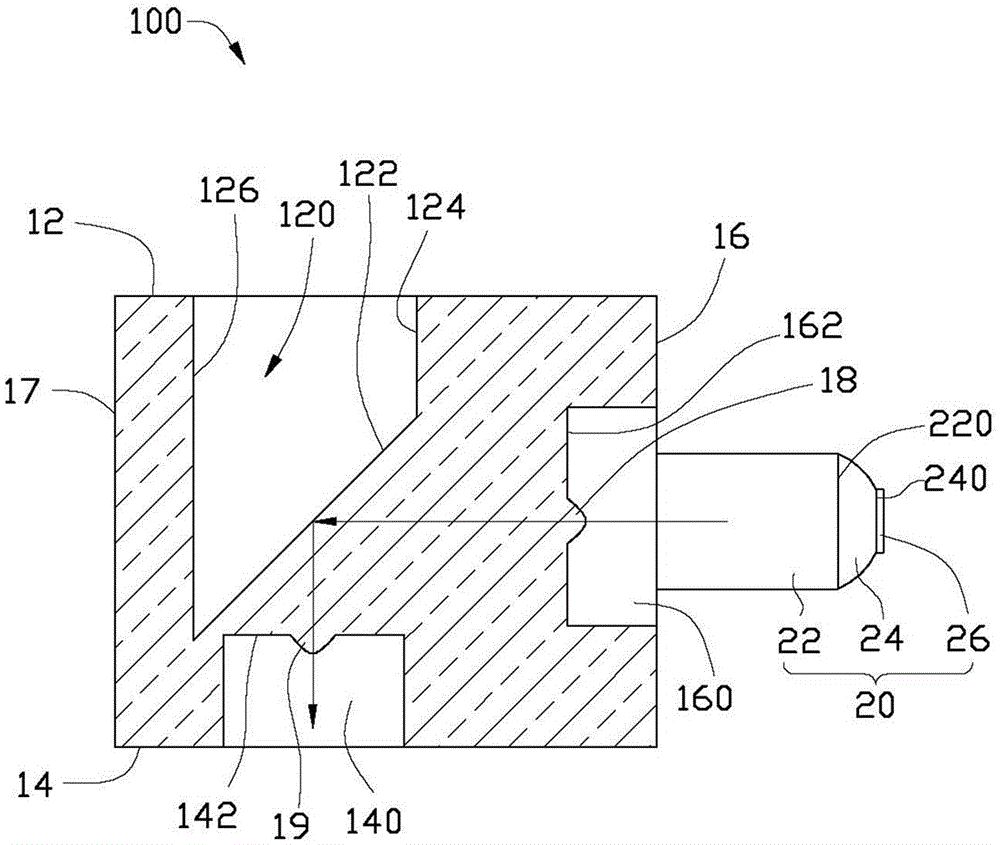

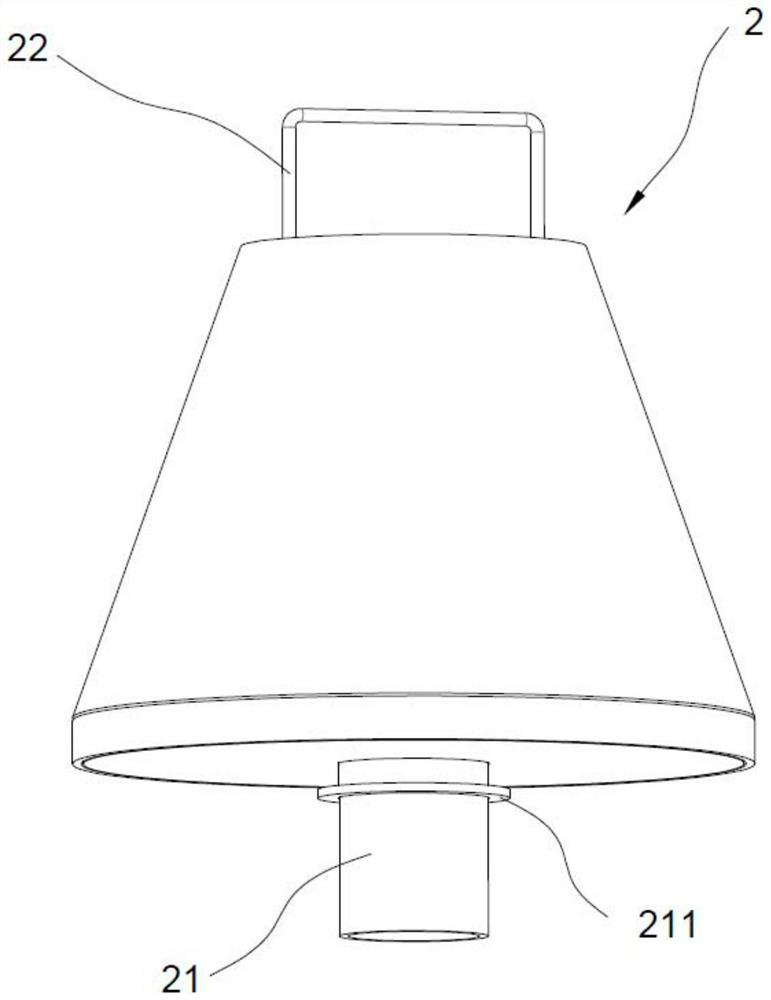

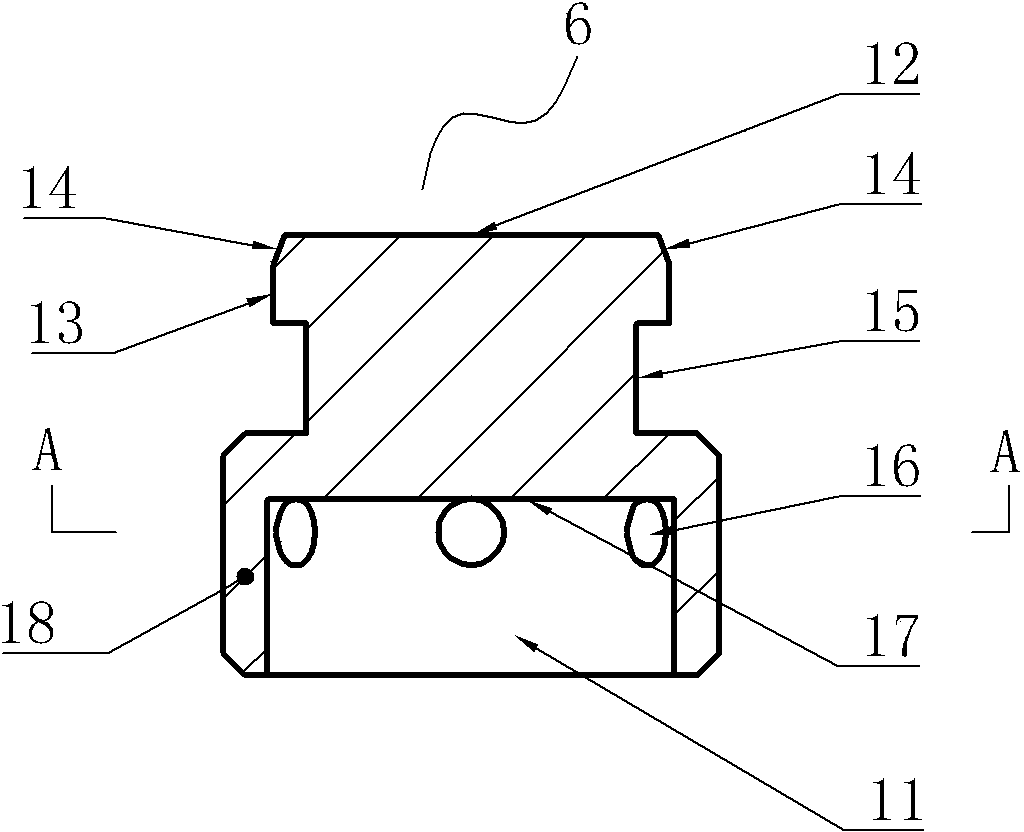

A display device

ActiveCN104238160AHigh strengthAvoid irregular deformationNon-linear opticsIdentification meansSurface displayDisplay device

The invention provides a display device comprising a plurality of buffer strips, a rubber frame and a curved surface display panel. Each buffer strip comprises a body and a plurality of protruding lugs; the protruding lugs are arranged on one side of the body and are arranged at intervals; each protruding lug comprises a top surface and an interval is arranged between each two adjacent protruding lugs. The rubber frame is provided with a concave curved surface. The curved surface display panel is provided with an inner curved surface and an outer curved surface. The inner curved surface is convex, and the inner curved surface is correspondingly arranged at the concave curved surface of the rubber frame. The buffer strips are respectively attached to the two edges of the inner curved surface along the curved contour of the inner curved surface, and the sum of the arc lengths of the top surface of the above protruding lugs is less than the arc length, opposite to the side of the protruding lugs, of the body.

Owner:AU OPTRONICS CORP

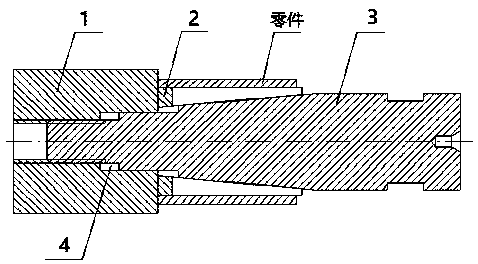

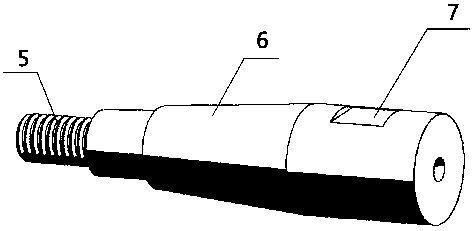

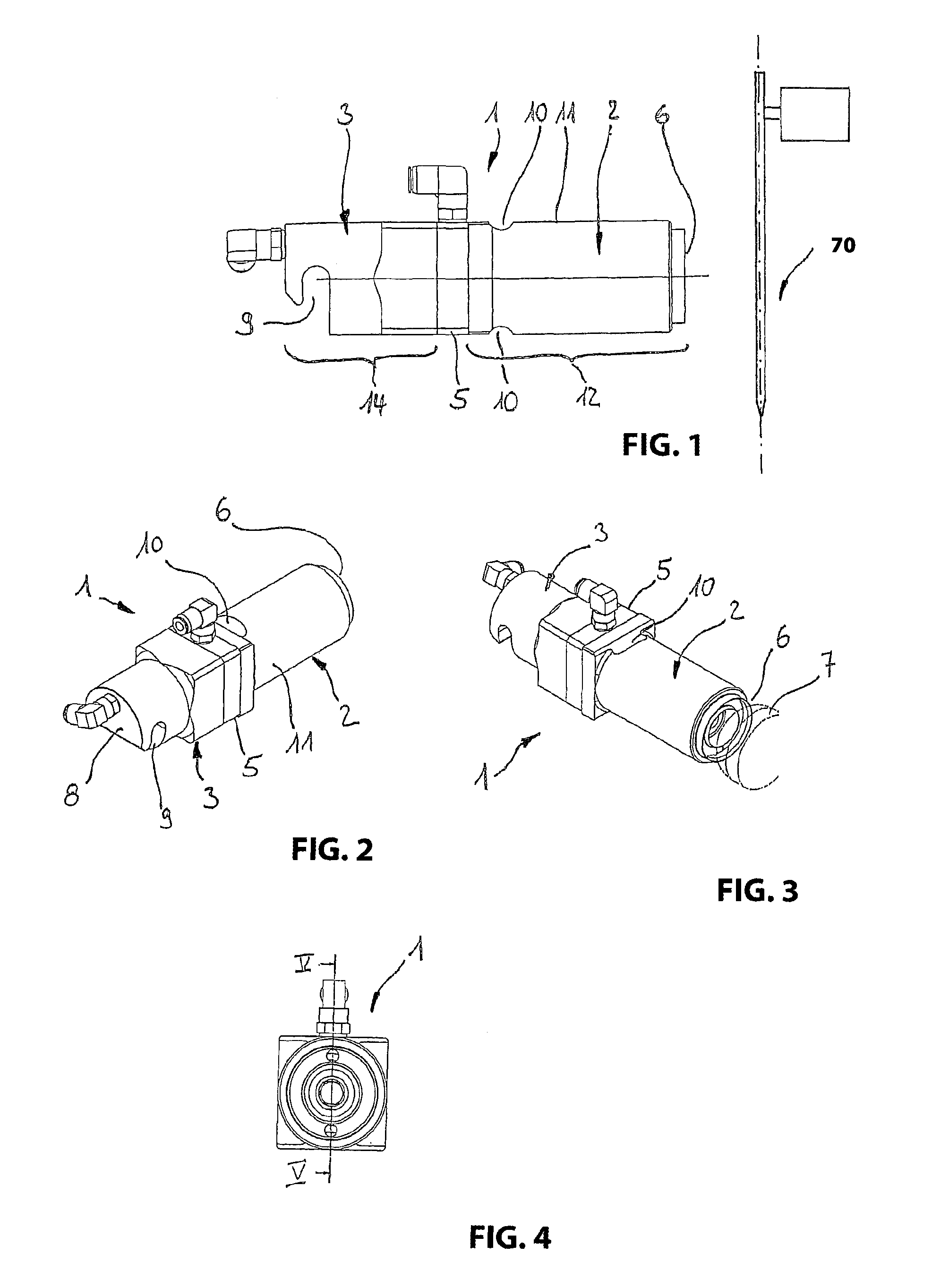

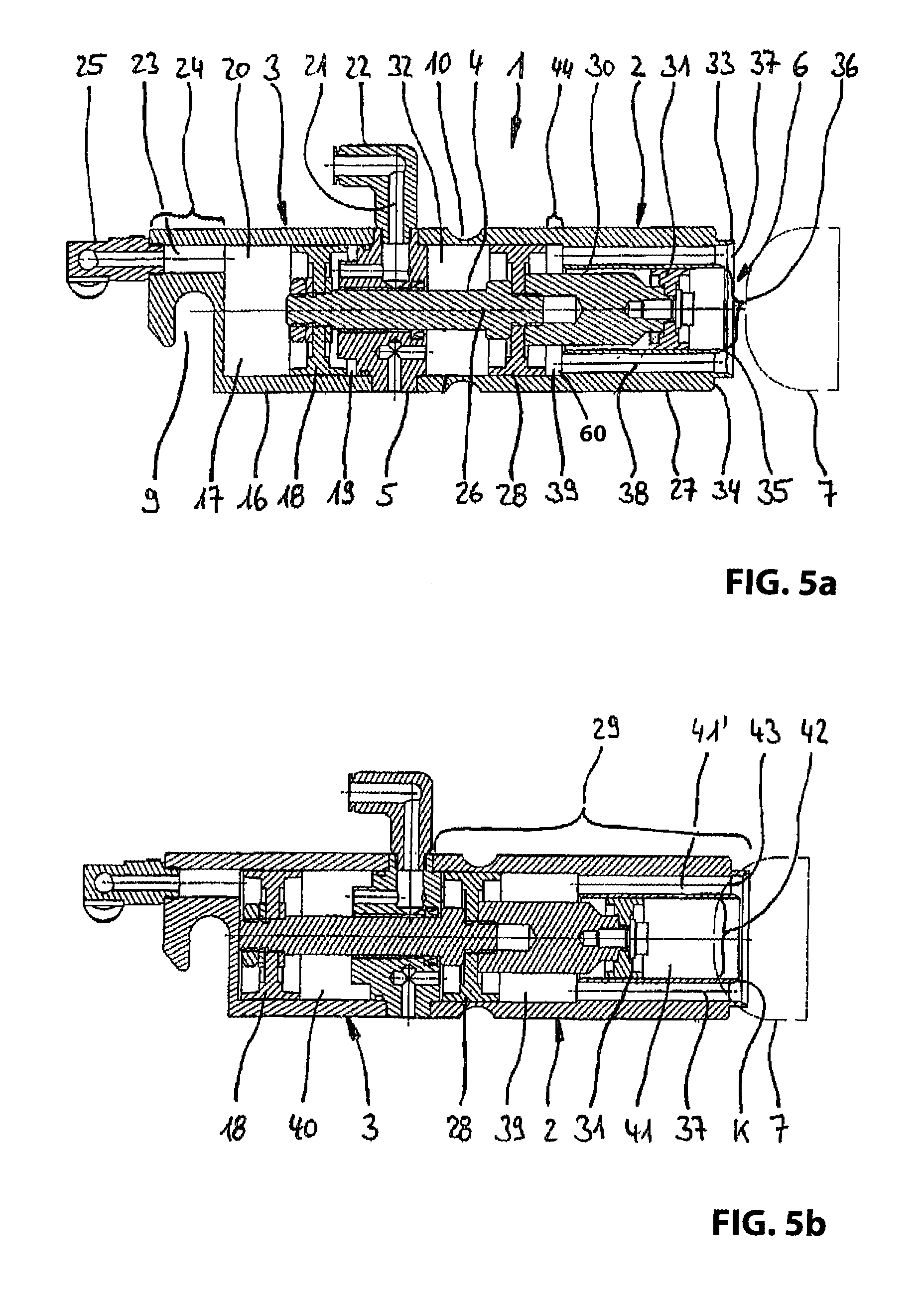

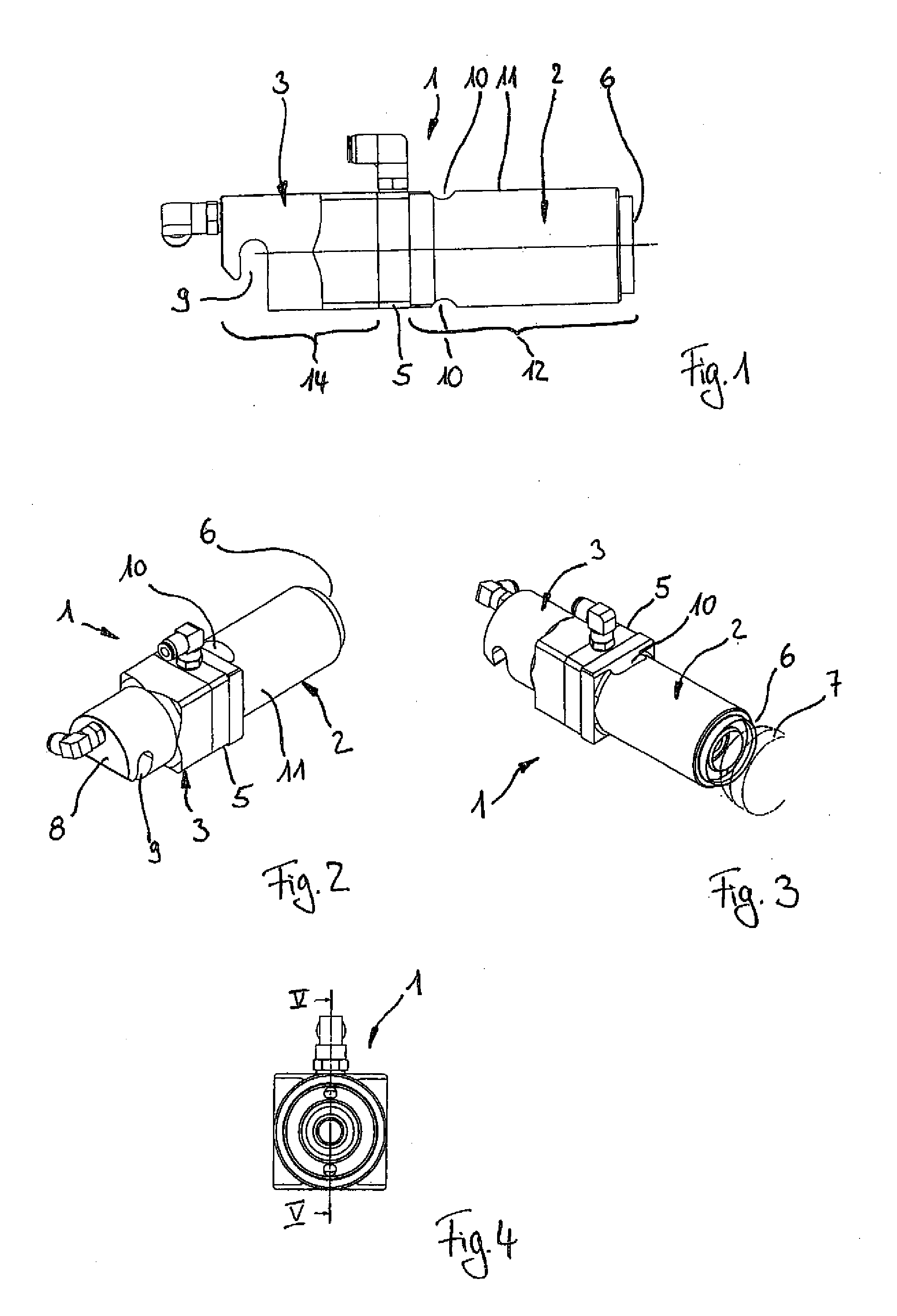

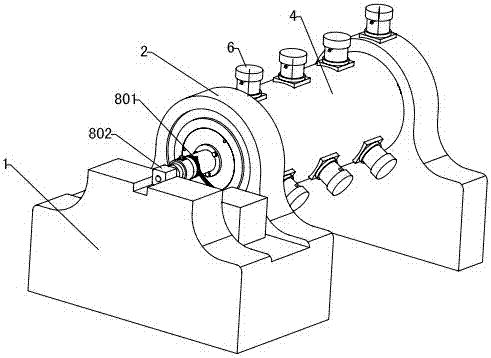

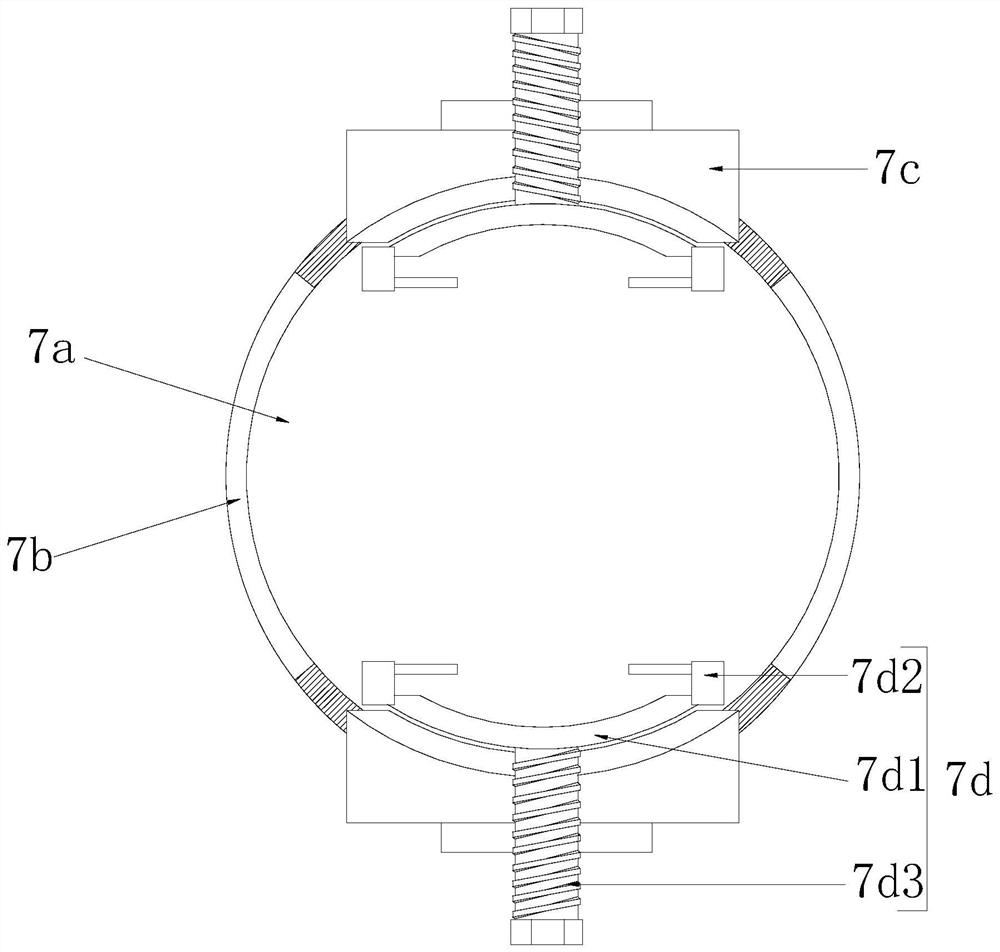

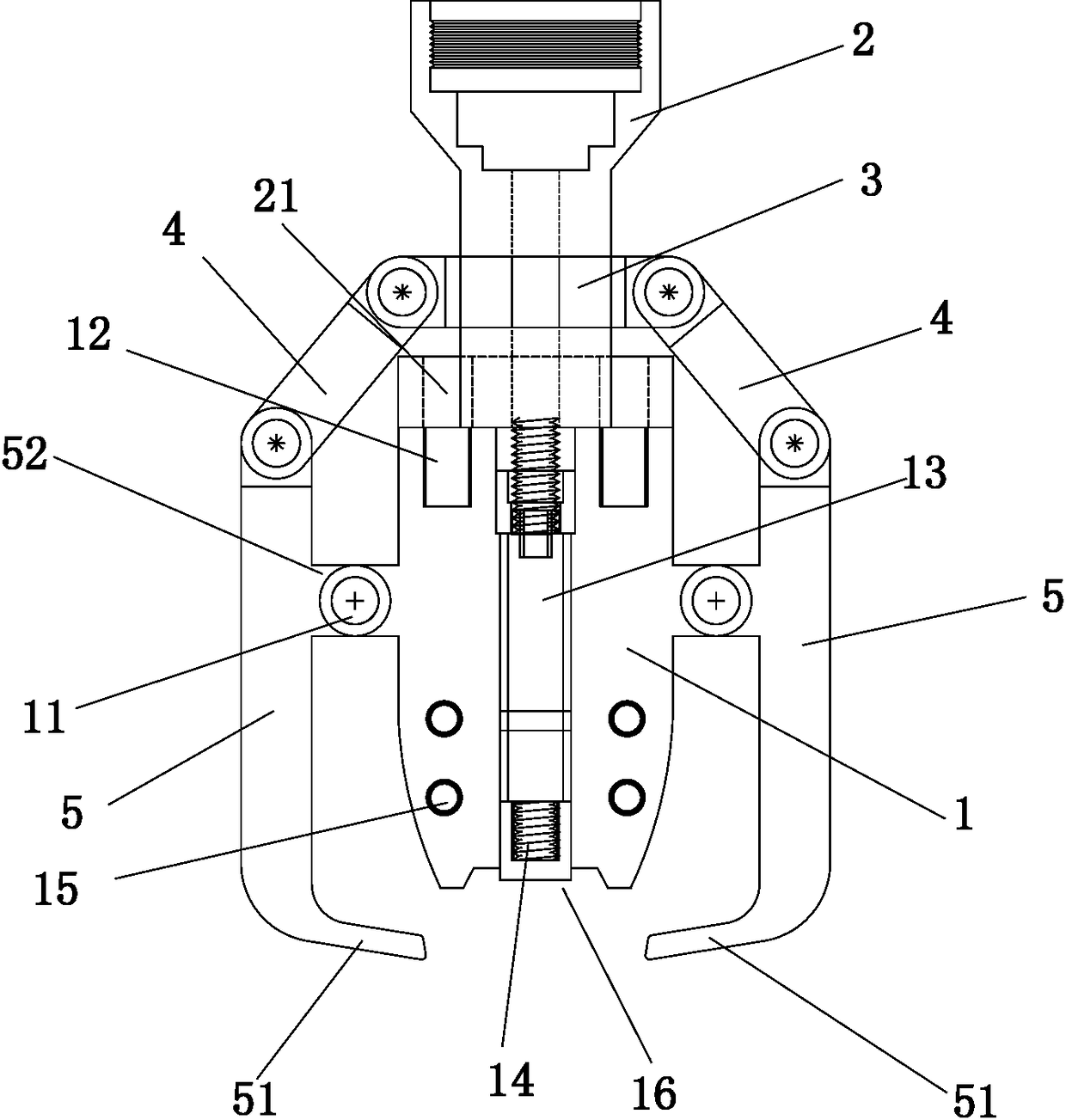

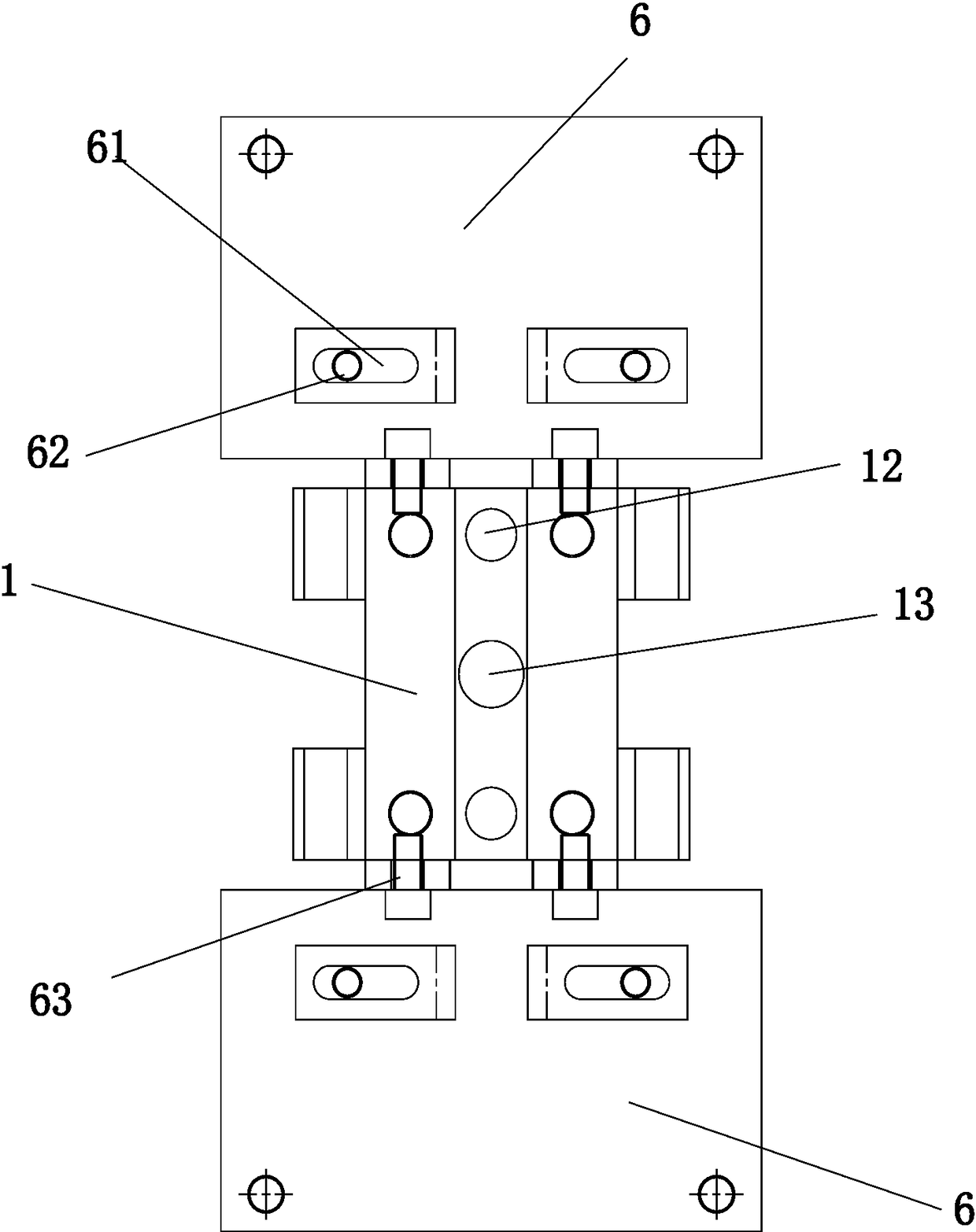

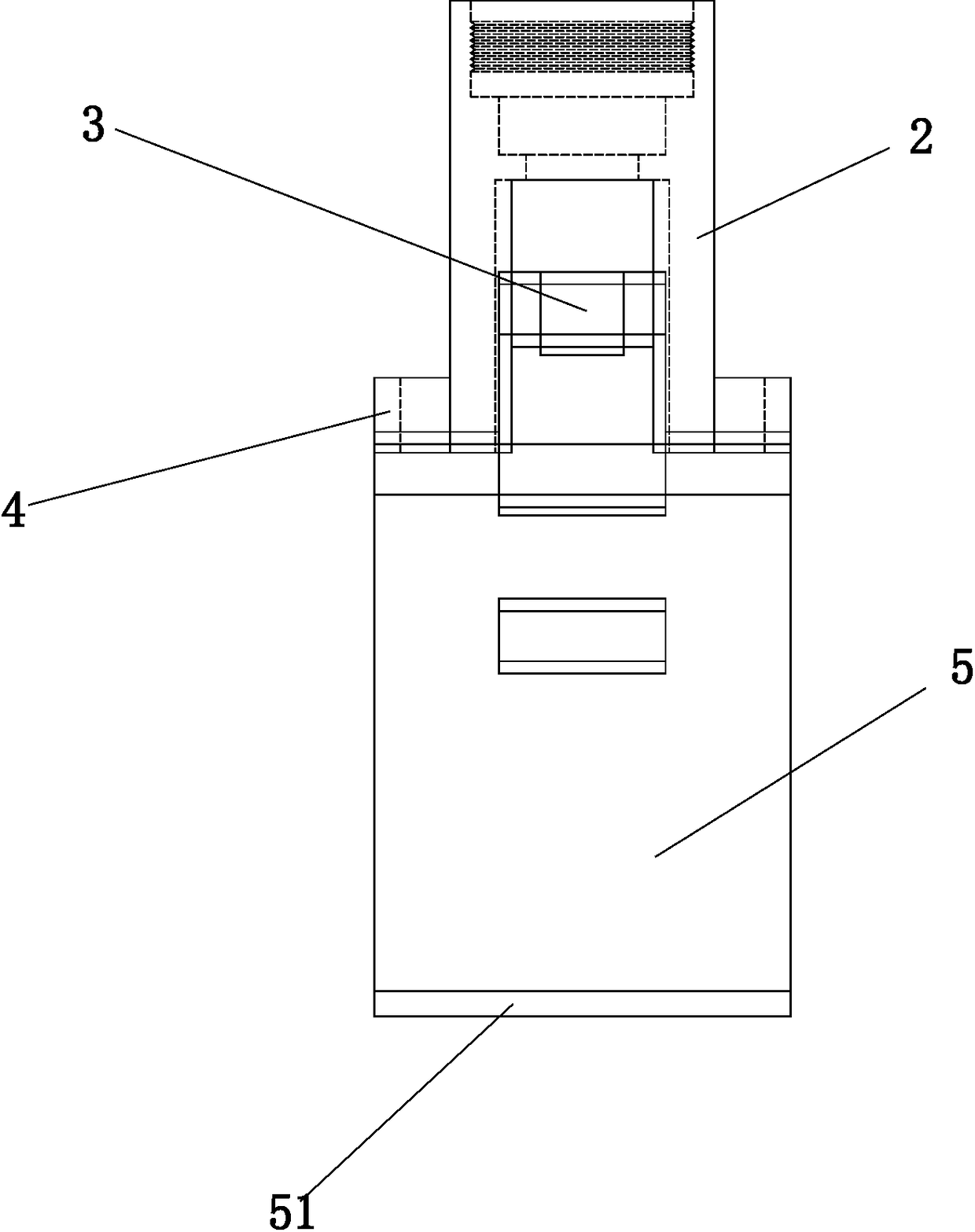

Thin-wall rotary type component cylindrical lathe cutting clamping method and device

The invention discloses a thin-wall rotary type component cylindrical lathe cutting clamping method and device. According to the method, an inner hole of a thin-wall rotary type component is tightened, and the purpose of clamping the thin-wall rotary type component is achieved; the clamping device used in the method comprises a base, an elastic hollow shaft and a top rod with a threaded conical surface, wherein a guide hole is formed in the center of the base; the guide hole is in threaded connection with the top rod of the threaded conical surface; the elastic hollow shaft is arranged at theperiphery of the top rod with the threaded conical surface. The device is relatively simple in structure, convenient in clamping operation and reliable in clamping mode, the situation that the thin-wall rotary type component is deformed or scraped in cylindrical latch cutting operation is avoided. Not only is the processing precision improved, but also the processing rejection rate is reduced, andthe processing cost is reduced.

Owner:GUIZHOU HONGLIN MACHINERY

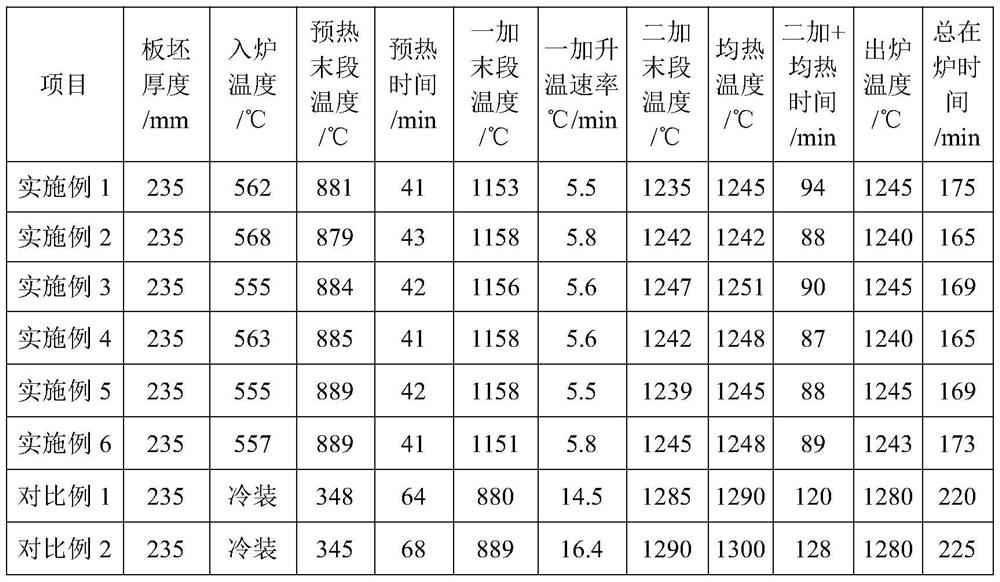

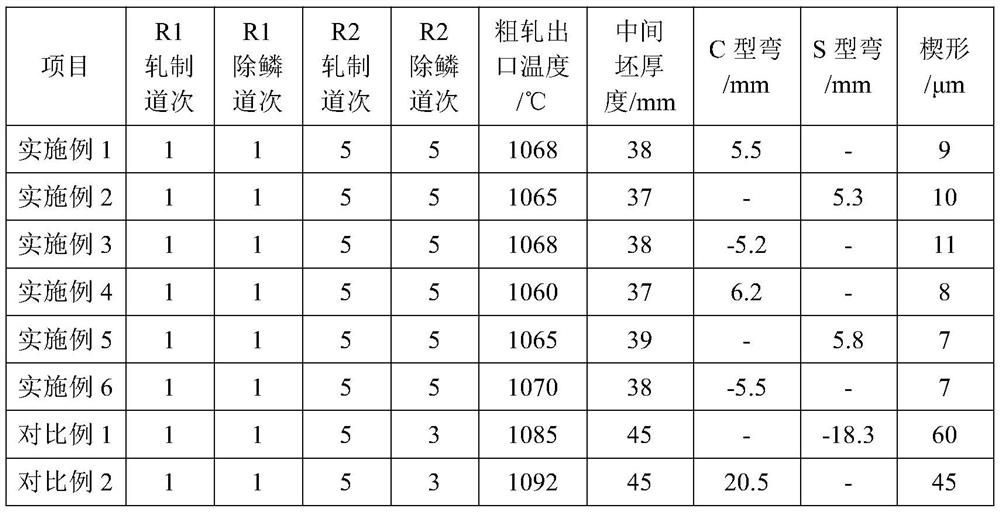

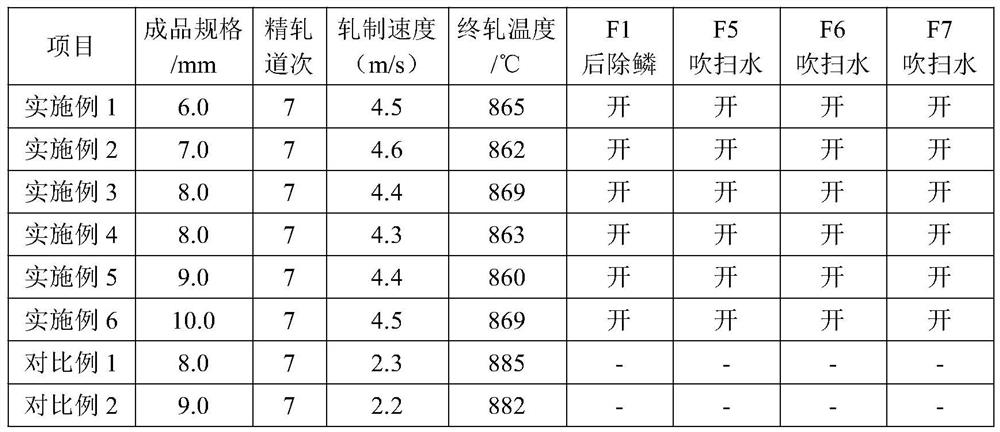

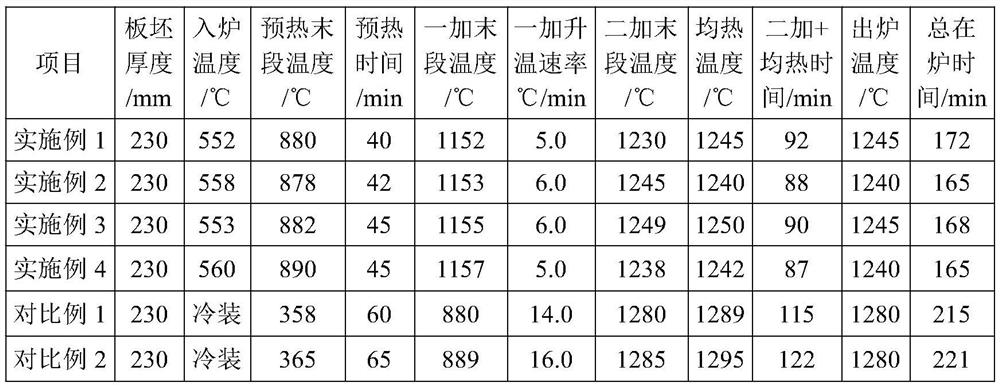

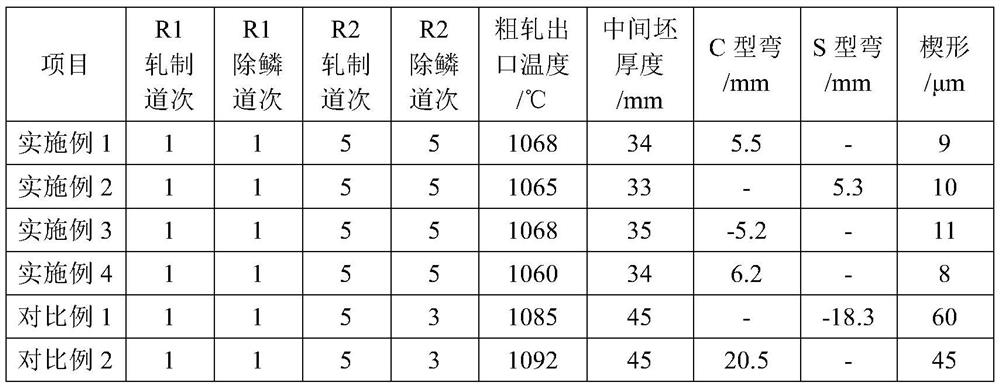

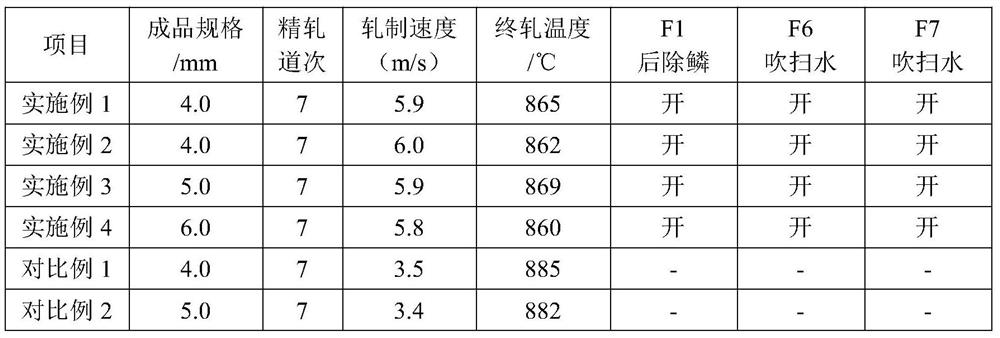

Plate shape control method of high-strength steel for commercial vehicle longitudinal beam

ActiveCN112077152AReduce cooling-heating historySmall footprintTemperature control deviceProfile control deviceShape controlControl mode

Owner:武汉钢铁有限公司

Plate shape control method for steel for hot-rolled high-strength stirring tank body

ActiveCN112108527AReduce cooling-heating historySmall footprintTemperature control deviceRollsProduction lineTemperature control

Owner:武汉钢铁有限公司

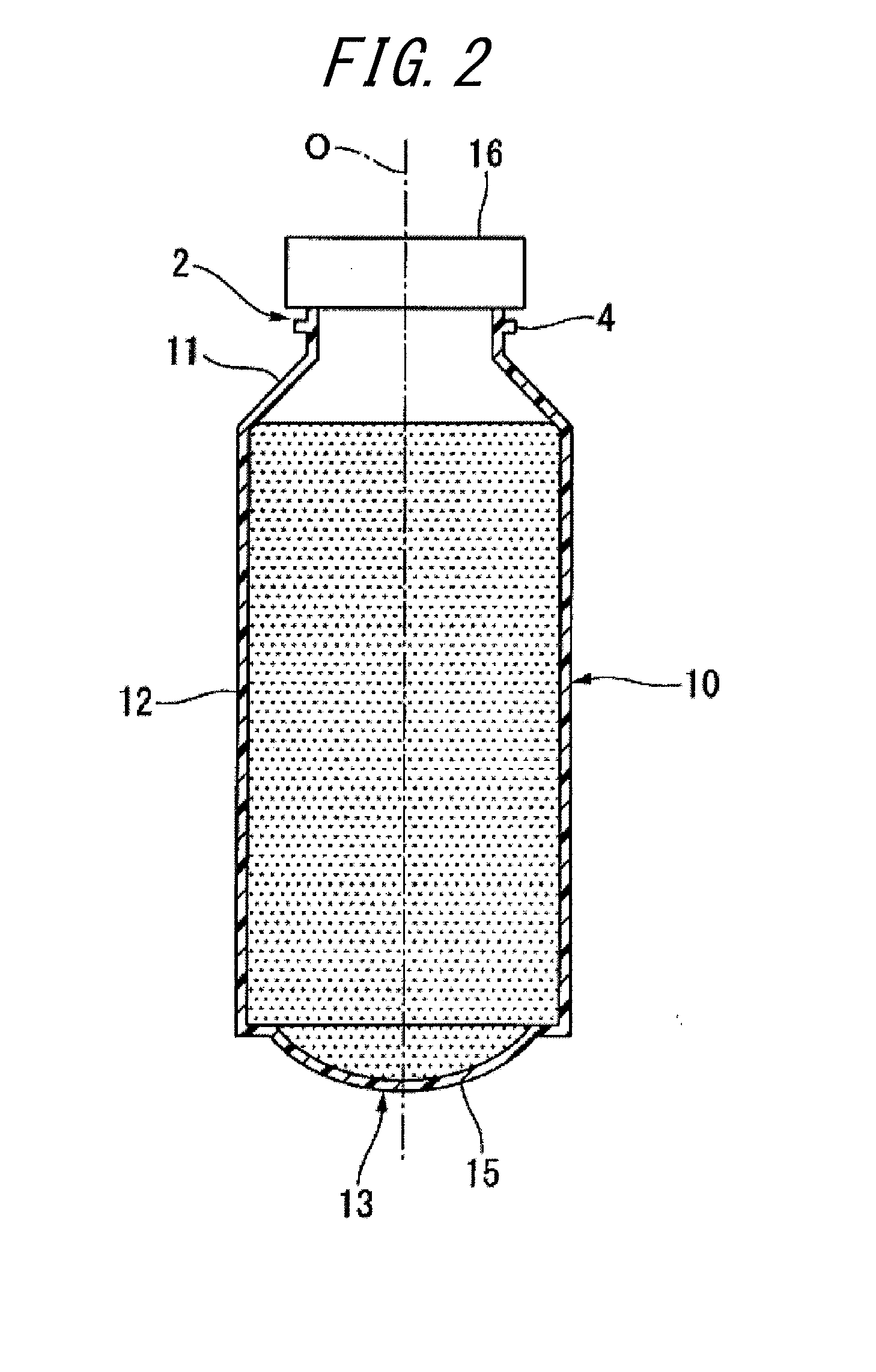

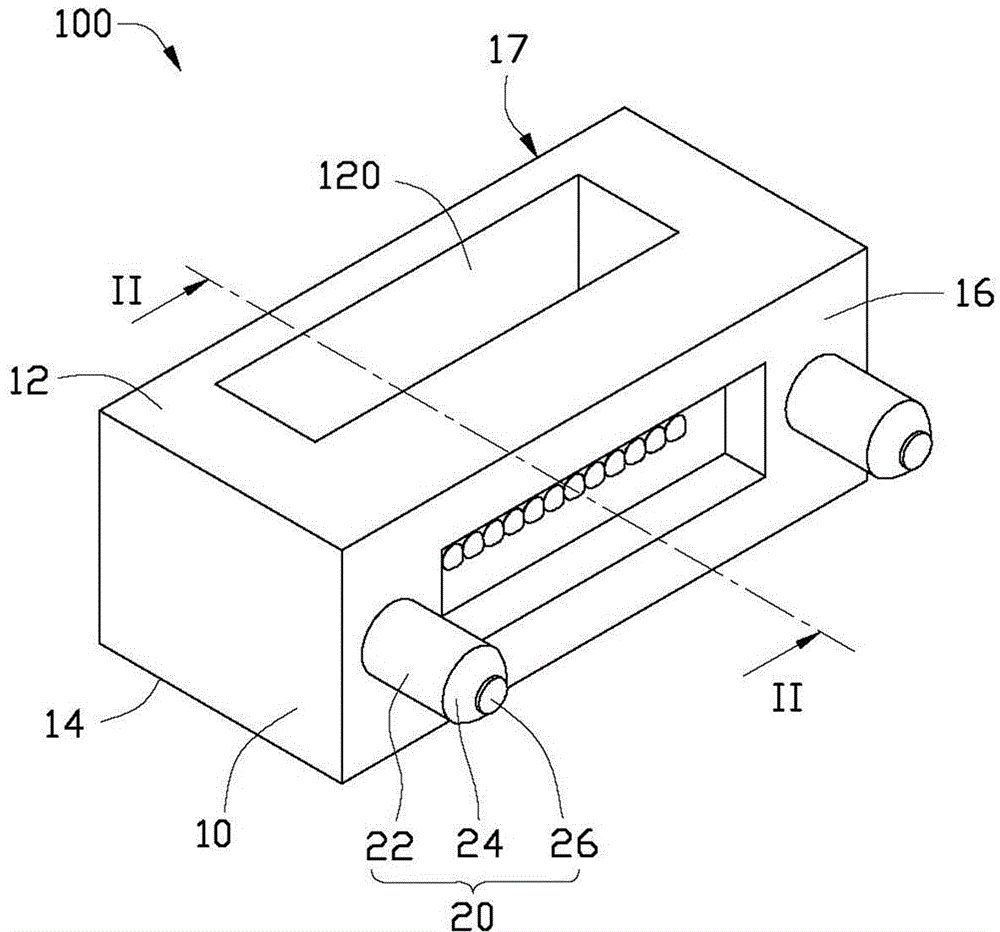

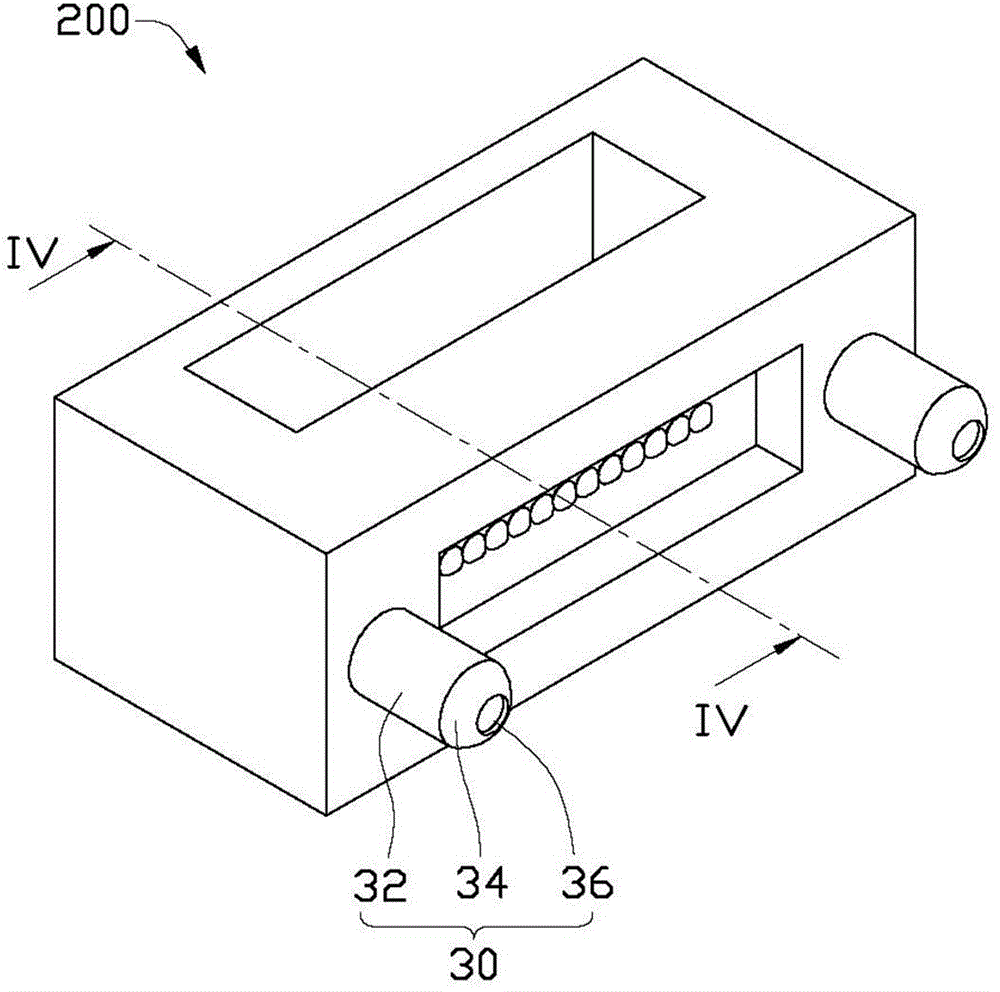

Optical coupling lens

InactiveCN104570234AImprove manufacturing yieldAvoid irregular deformationCoupling light guidesOptical surfaceOptical coupling

The invention relates to an optical coupling lens. The optical coupling lens comprises a coupling body and two plug pins, wherein the coupling body comprises a front surface, a back surface, a first optical surface, a second optical surface, a reflecting surface, a plurality of first converging parts and a plurality of second converging parts, wherein the front surface and the back surface are parallel to each other and are back to each other; the first optical surface is sunken from the front surface towards the back surface; the second optical surface is perpendicular to the first optical surface; the reflecting surface is inclined relative to the first optical surface and the second optical surface; the first converging parts and the second converging parts are respectively positioned on the first optical surface and the second optical surface. The first converging parts are positioned between the two plug pins and are in one-to-one correspondence with the second converging parts. Each plug pin comprises a cylindrical body part, a boss part which extends from the end surface of the body part, and a buffer part. The boss part is of a bowl-shaped structure and comprises a top surface which is far away from the body part; the diameter of the boss part is gradually reduced in the direction from the end surface to the top surface. The buffer part is arranged on the top surface so as to buffer the methane gas which is concentrated at the top surface when the optical coupling lens is formed.

Owner:武汉冠宇世纪科技技术有限公司

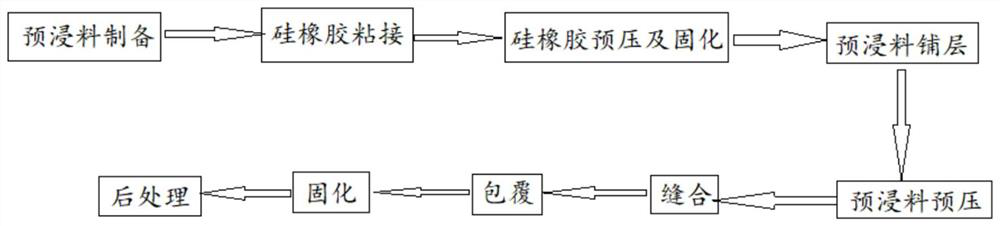

Forming method for improving ablation and controlling deformation of special-shaped structure product

PendingCN112677513AAvoid irregular deformationMaintain heat resistanceDomestic articlesCoatingsFlight vehicleMetallic materials

The invention discloses a forming method for improving ablation and controlling deformation of a special-shaped structure product. The forming method comprises the following steps that by using a prepreg formed by dipping 2.5D woven fabric in flexible phenolic resin as a thermal protection layer, laying of a heat-proof layer is completed layer by layer, a silicon rubber layer is added between a special-shaped structure metal shell and the heat-proof layer, finally pressurizing, curing and forming are conducted, and a special-shaped structure product coated with the heat-proof layer is obtained. According to the forming method for improving the ablation and the controlling deformation of the special-shaped structure product, the linear expansion coefficient difference between an internal metal material and an external surface composite material of the special-shaped structure product is reduced, the bonding quality is improved, surface composite material loss is avoided, the heat-proof performance of the special-shaped product can be kept, the normal working time of an aircraft is prolonged, and the maintenance cost is reduced.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Method for cutting a loaf-shaped food using a cutting machine

InactiveUS9132563B2Simple processAvoid irregular deformationGang saw millsMetal working apparatusEngineeringContact element

Owner:REIFENHAEUSER UWE

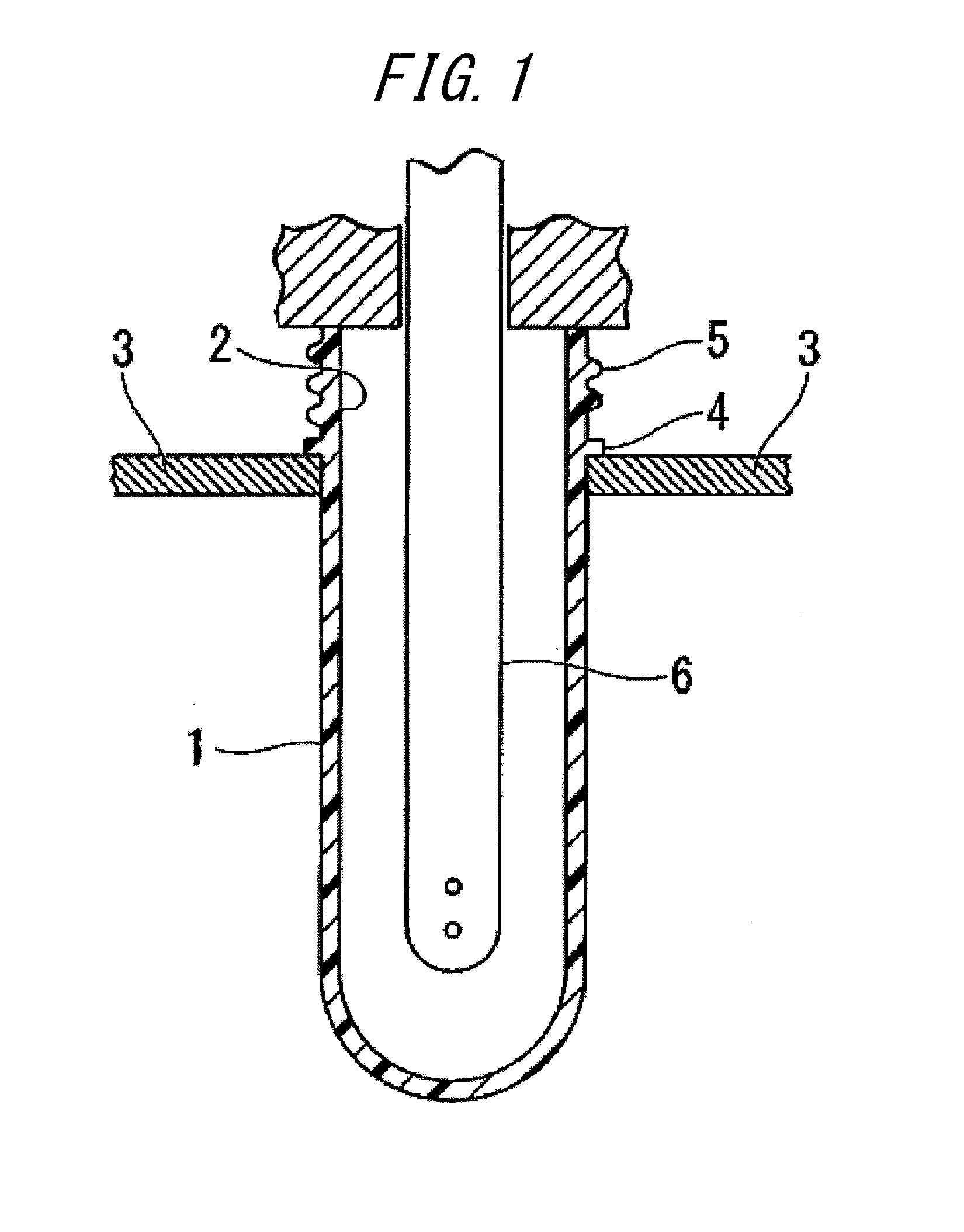

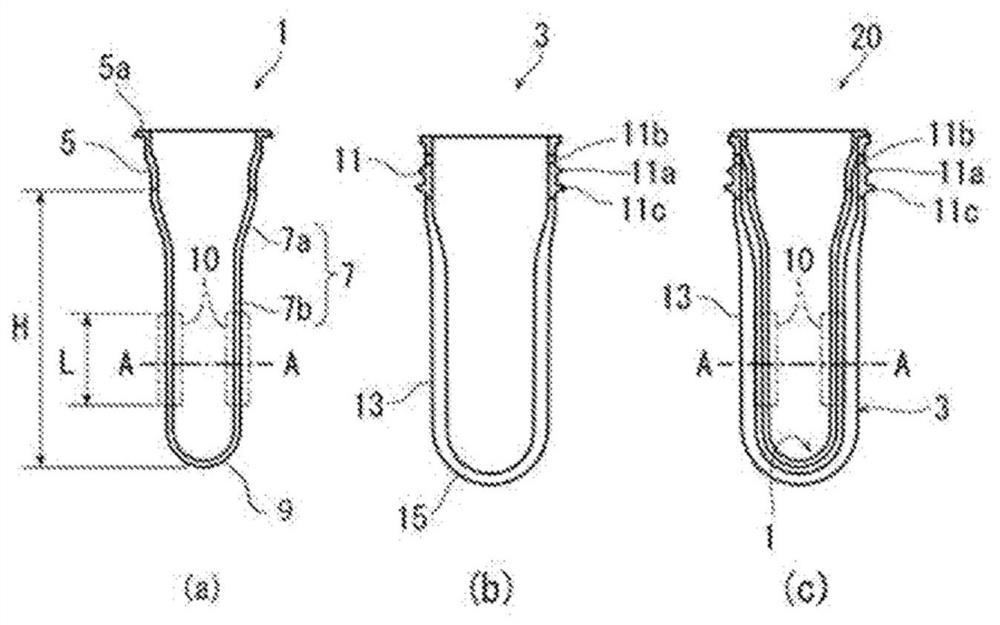

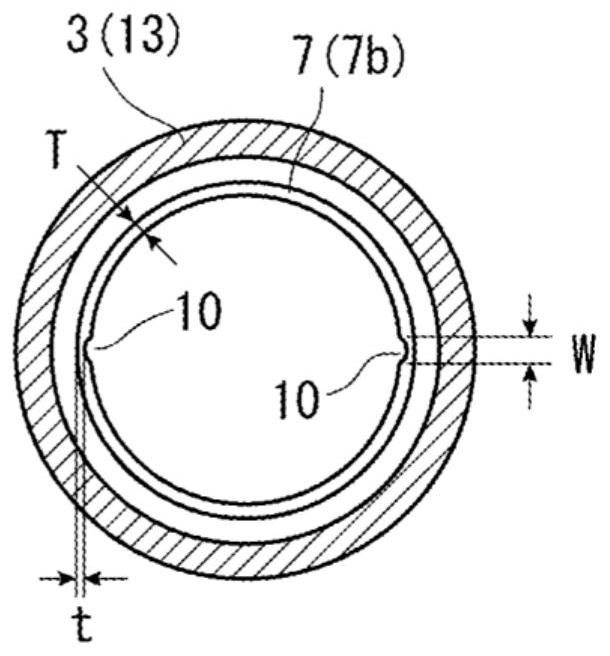

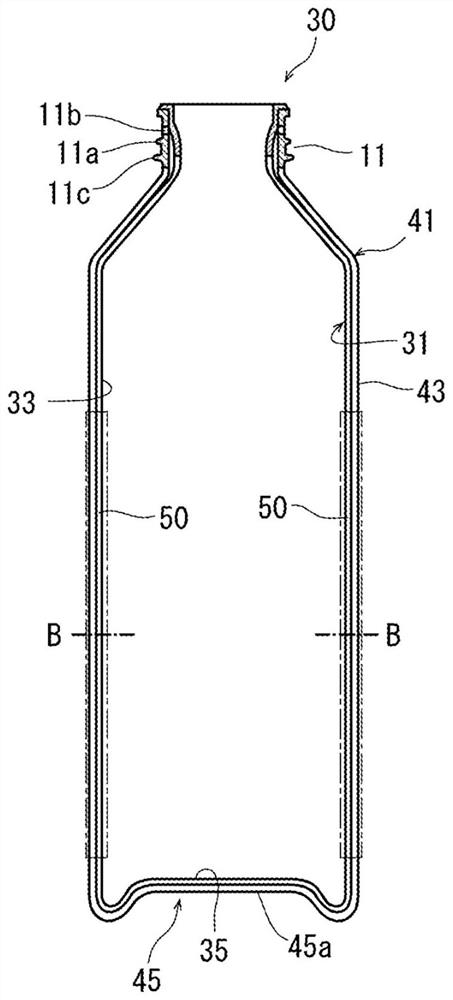

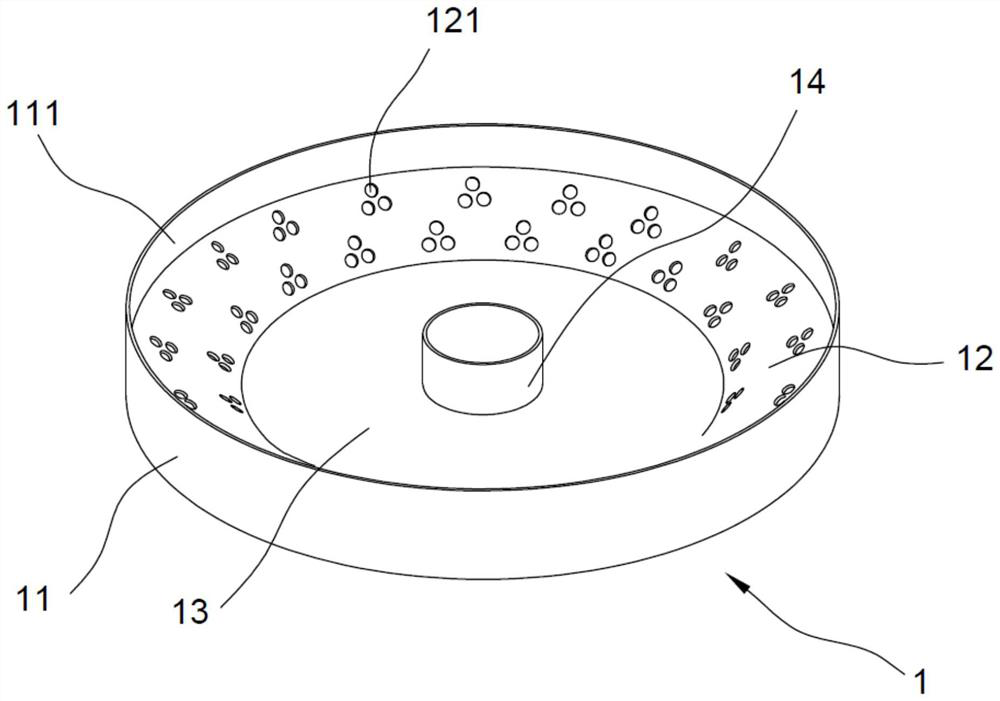

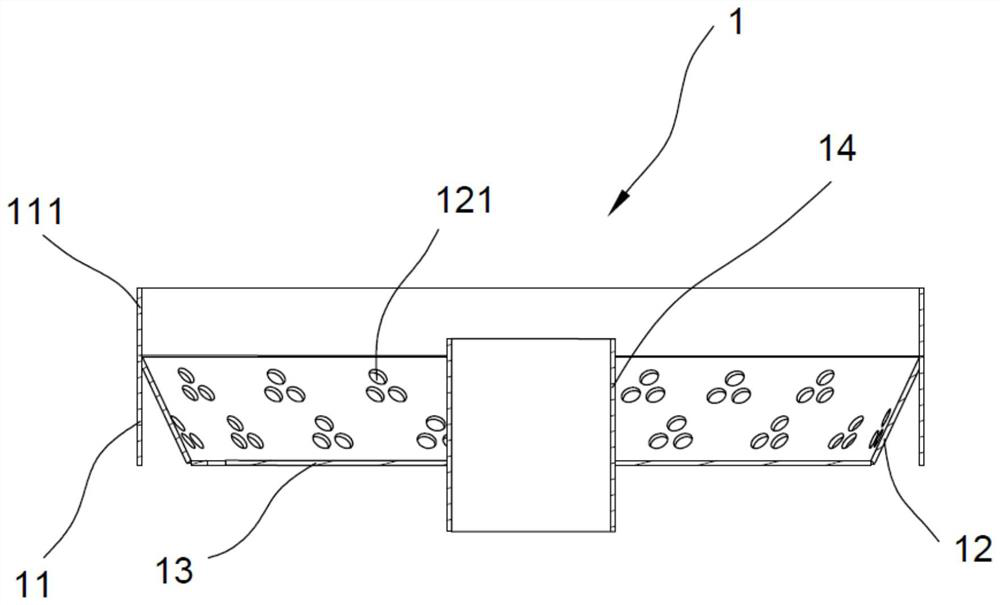

Dual-structure container with inner bag container having excellent regular contractility

The present invention provides a dual-structure container in which contractility of an inner bag container is regulated and which effectively solves the problem that ejection of a content liquid becomes difficult as the content liquid is ejected. The present invention provides a dual-structure container which comprises an inner bag container 31 and an outer container 41 and which is obtained by simultaneous stretch blow molding according to a stack preform method using an inner bag container preform 1 and an outer container preform 3, the dual-structure container being characterized in that abarrel part 33 of the inner bag container 31 has contractility-regulating thin parts 50 extending in a band shape in an axial direction at a plurality of locations at intervals in a circumferential direction.

Owner:TOYO SEIKAN GRP HLDG LTD

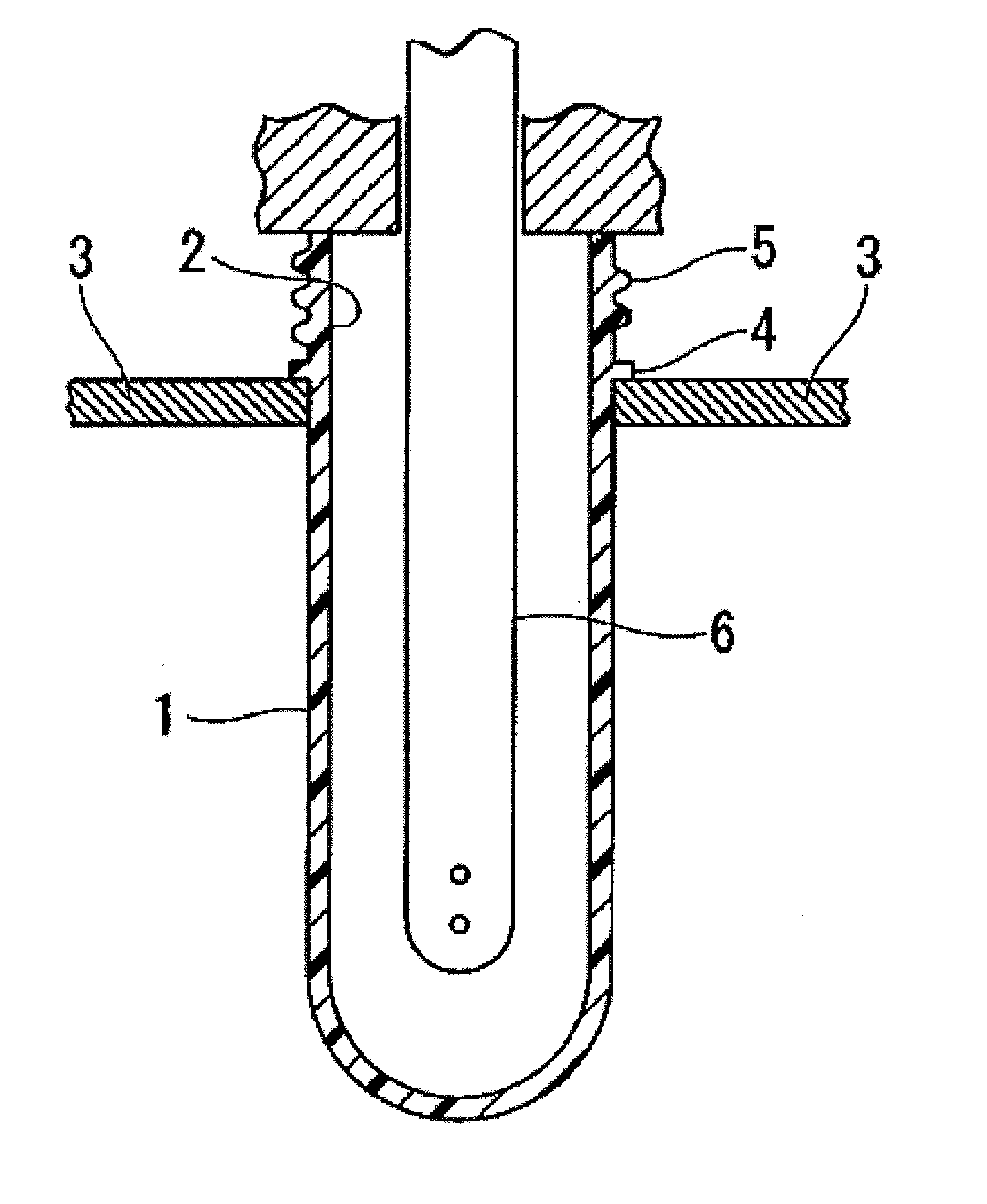

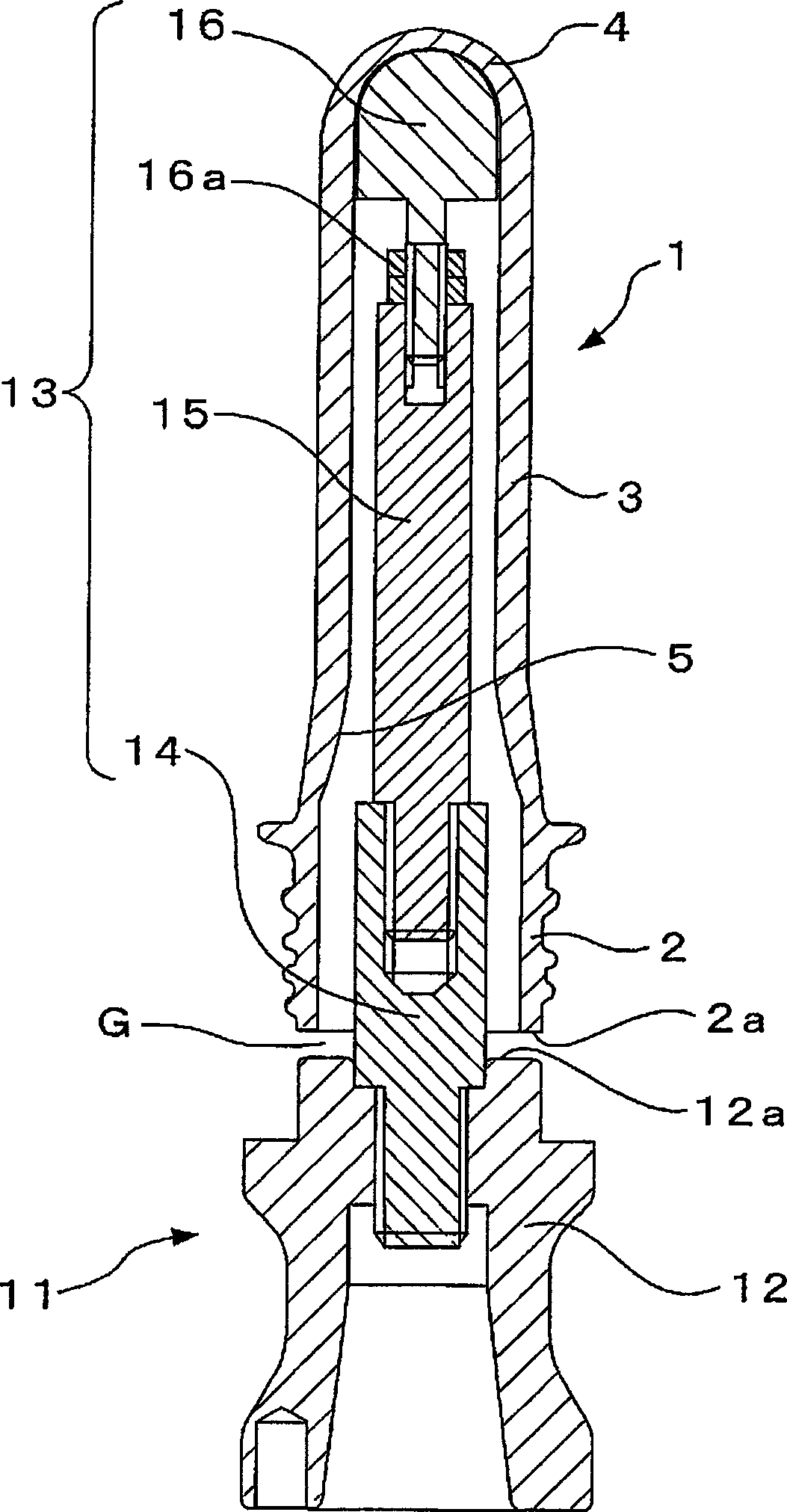

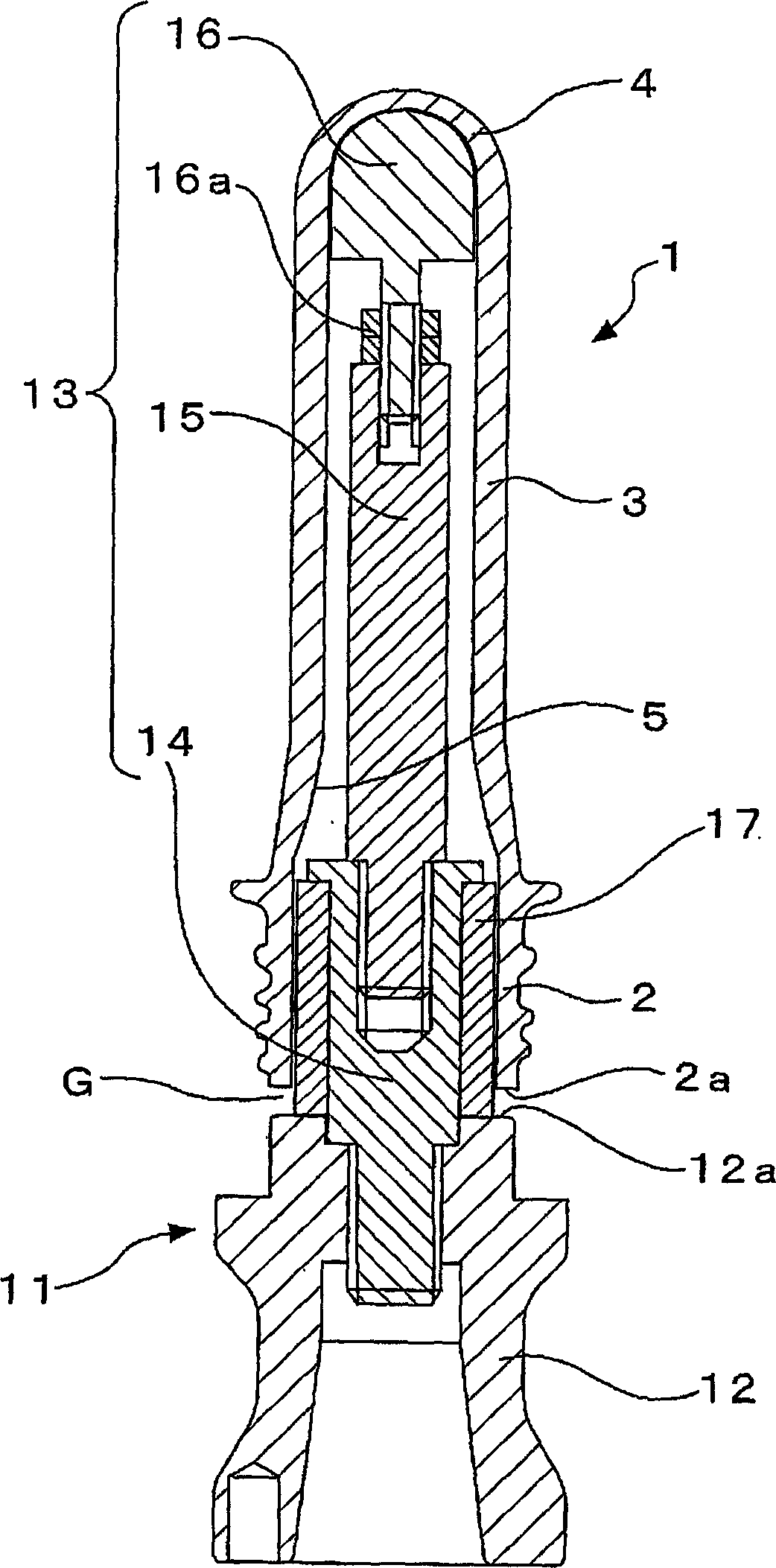

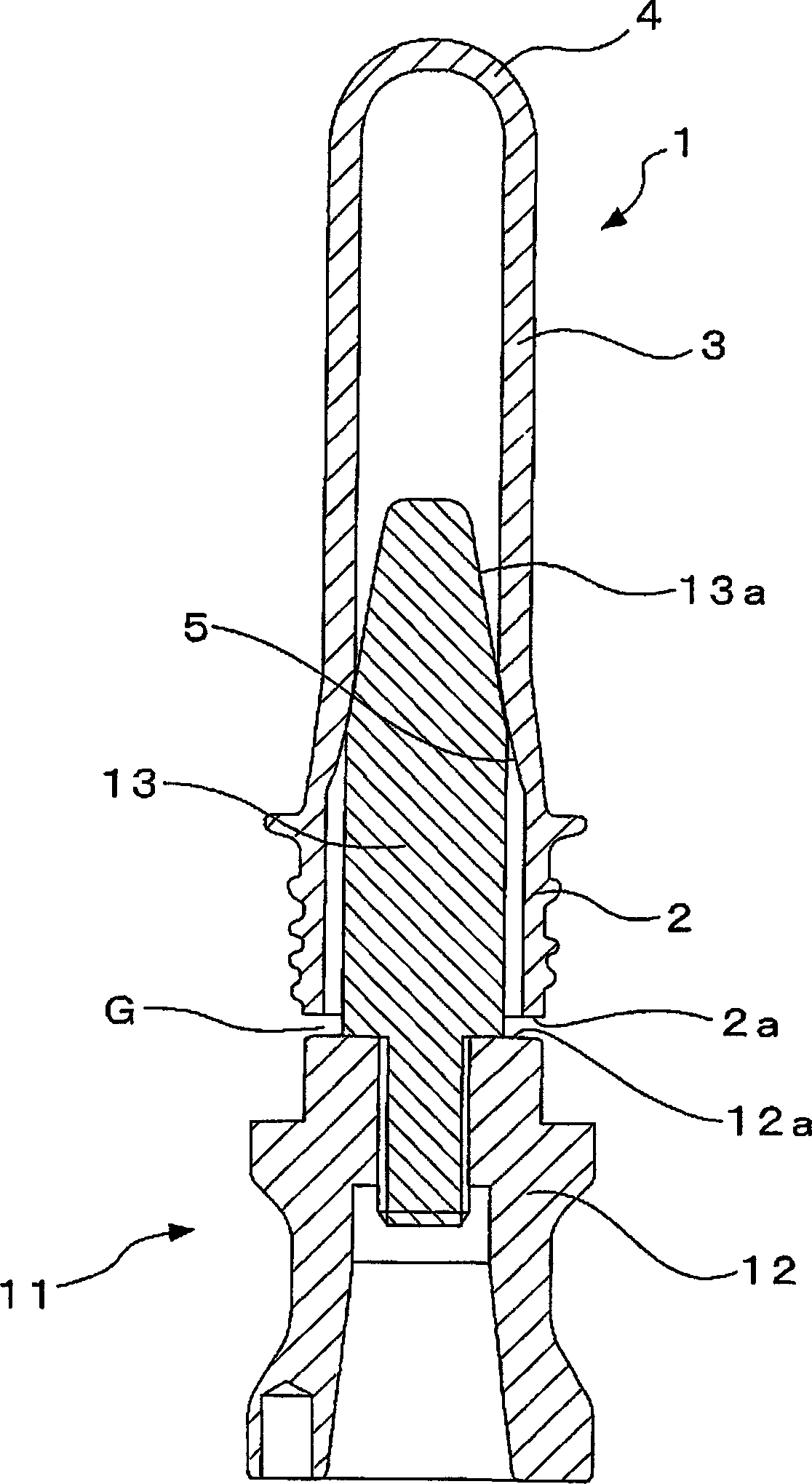

Method of thermal crystallization treatment for cylindrical mouthpart of preform

InactiveCN1839028AAvoid irregular deformationAvoid deformationHollow articlesThermal crystallizationHigh dimensional

A method of thermal crystallization treatment by means of an inverted conveyance type jig, by which a cylindrical mouthpart of preform with high dimensional accuracy can be obtained; a process of thermal crystallization treatment for a cylindrical mouthpart, conducted in high productivity; and a process of biaxially stretching blow molding. There is provided a method of while mounting a preform of synthetic resin for biaxially stretching blow molding on an inverted conveyance type jig, conducting thermal crystallization treatment of a cylindrical mouthpart thereof, wherein the thermal crystallization treatment is carried out while having, fitted on the jig, a preform with a gap provided under the top plane of the cylindrical mouthpart of the preform.

Owner:YOSHINO KOGYOSHO CO LTD

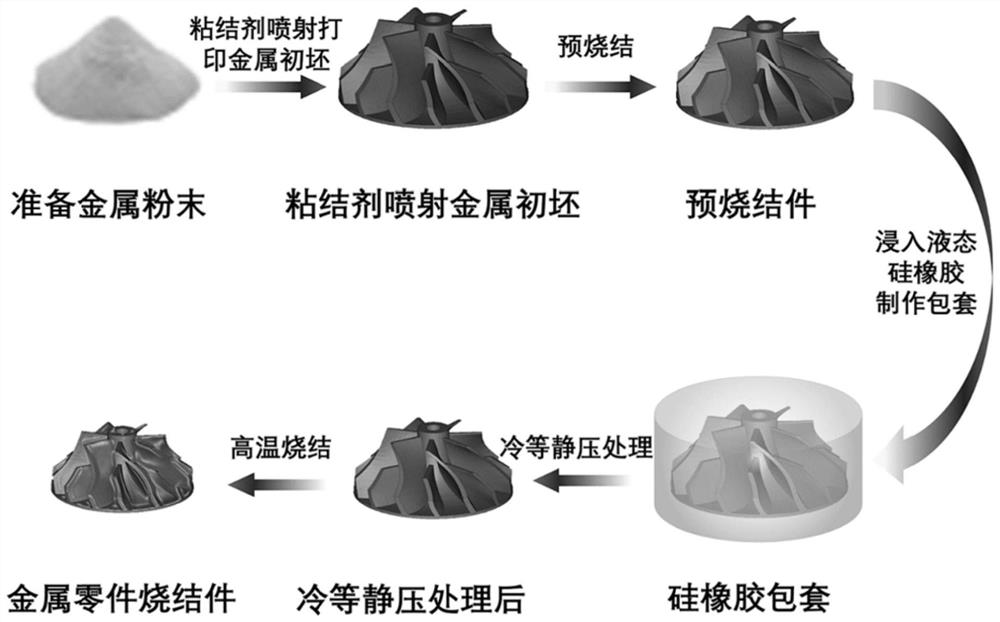

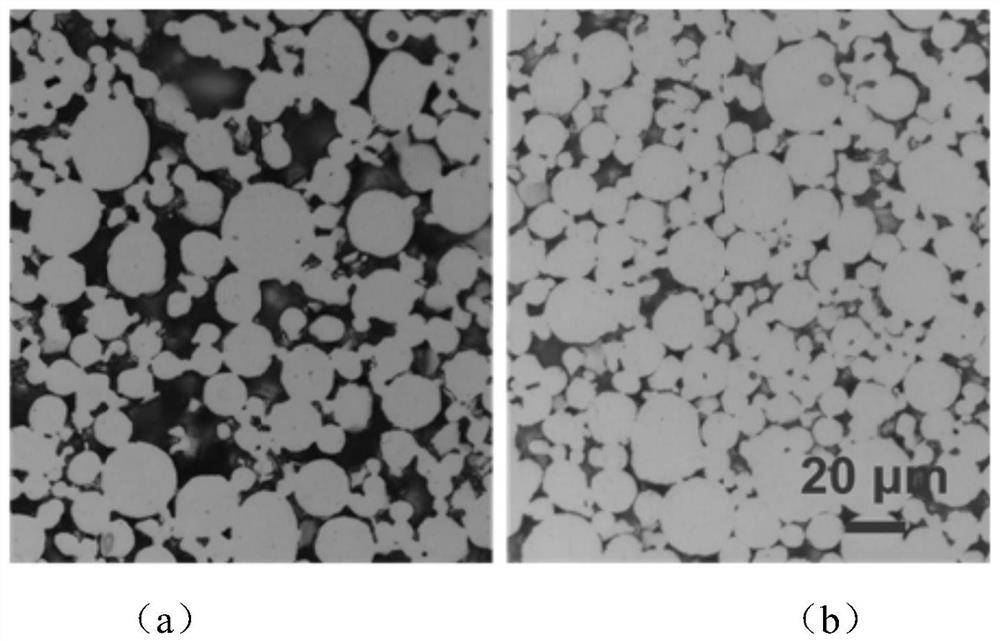

Metal part and near-net forming method thereof

PendingCN113909490AHigh densityImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencySilicon rubberMetal powder

The invention belongs to the related technical field of additive manufacturing, and discloses a metal part and a near-net forming method thereof. The near-net forming method comprises the following steps: (1) using metal powder and a binder as raw materials, adopting a binder spraying technology for jet printing to form a metal initial blank, and degreasing and pre-sintering the metal initial blank; and (2) coating the obtained pre-sintered part with silicone rubber to form a sheath; and then, conducting cold isostatic pressing treatment and sintering densification in sequence, and then obtaining the metal part. According to the method, densification can be achieved at the low temperature, the problems of low sintering density, large shrinkage rate, non-uniformity and difficulty in size control in the process of spraying the binder to the metal part are solved, the probability of size pores can be reduced, the uniformity of a microstructure is improved, rapid mold-free manufacturing of the high-performance metal part is achieved, and the cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

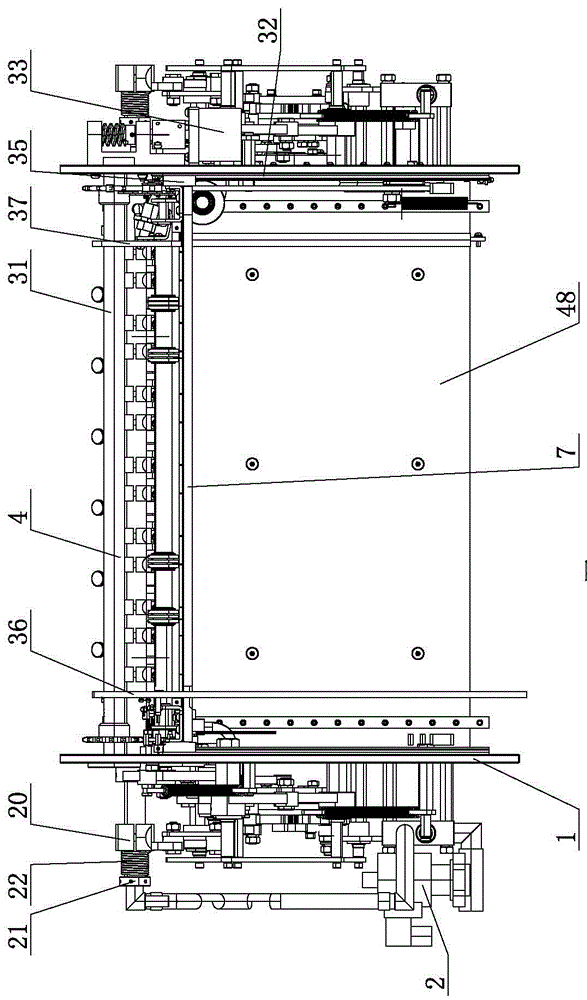

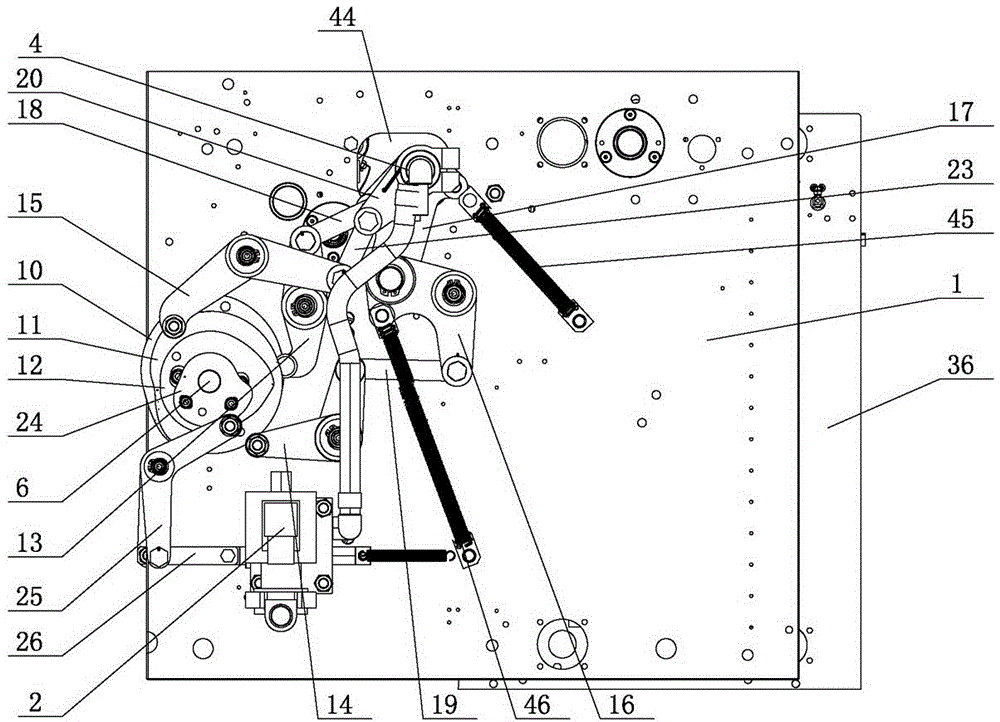

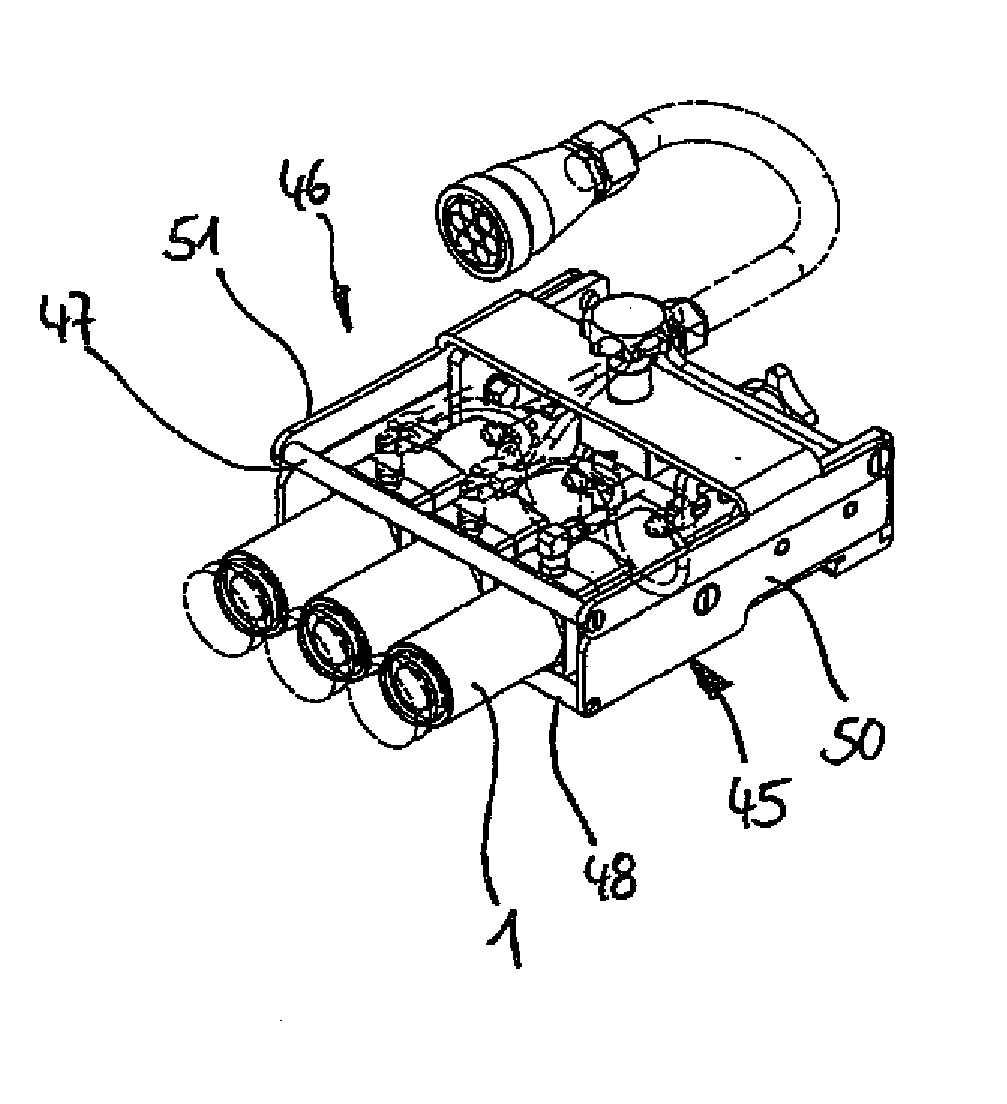

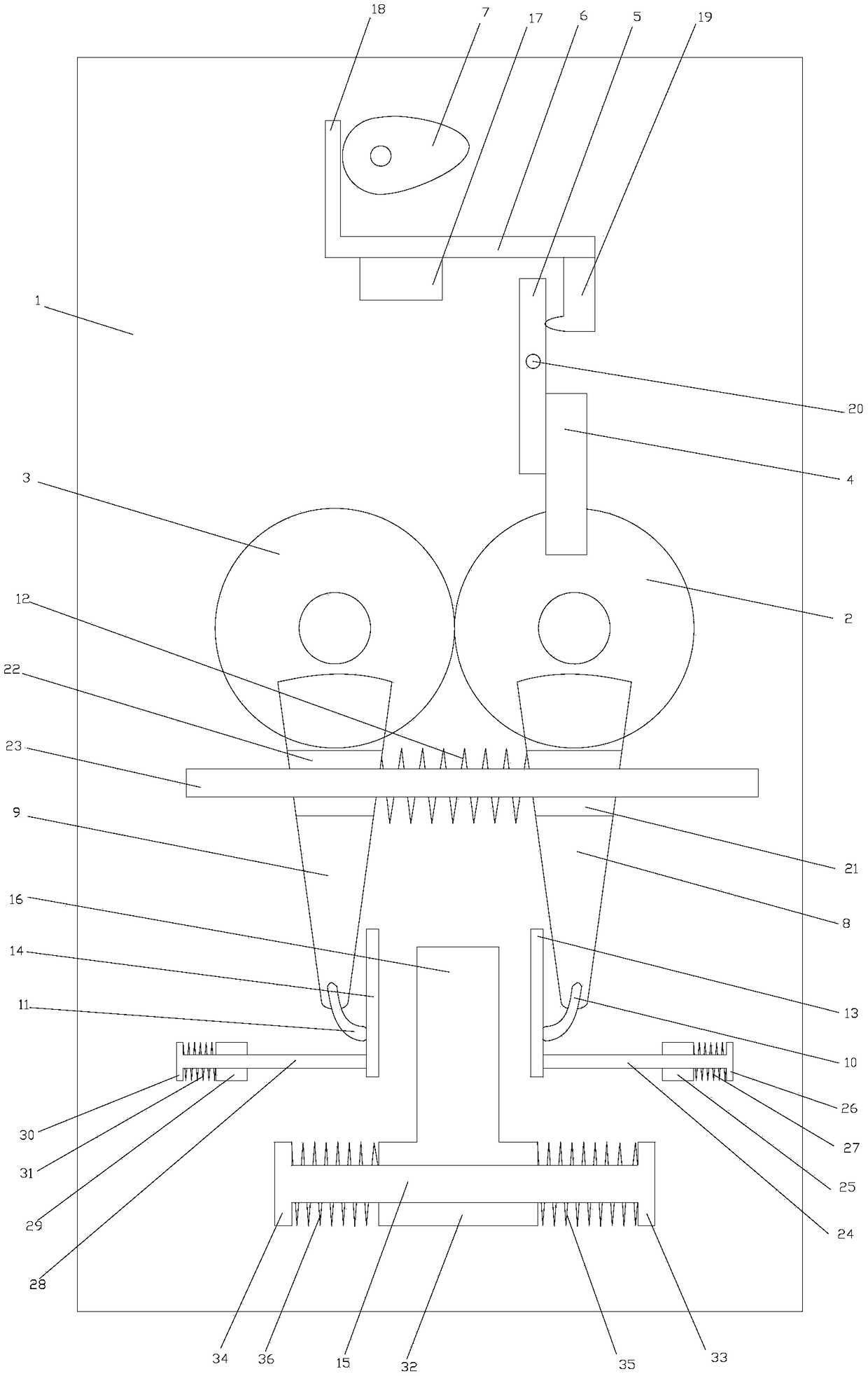

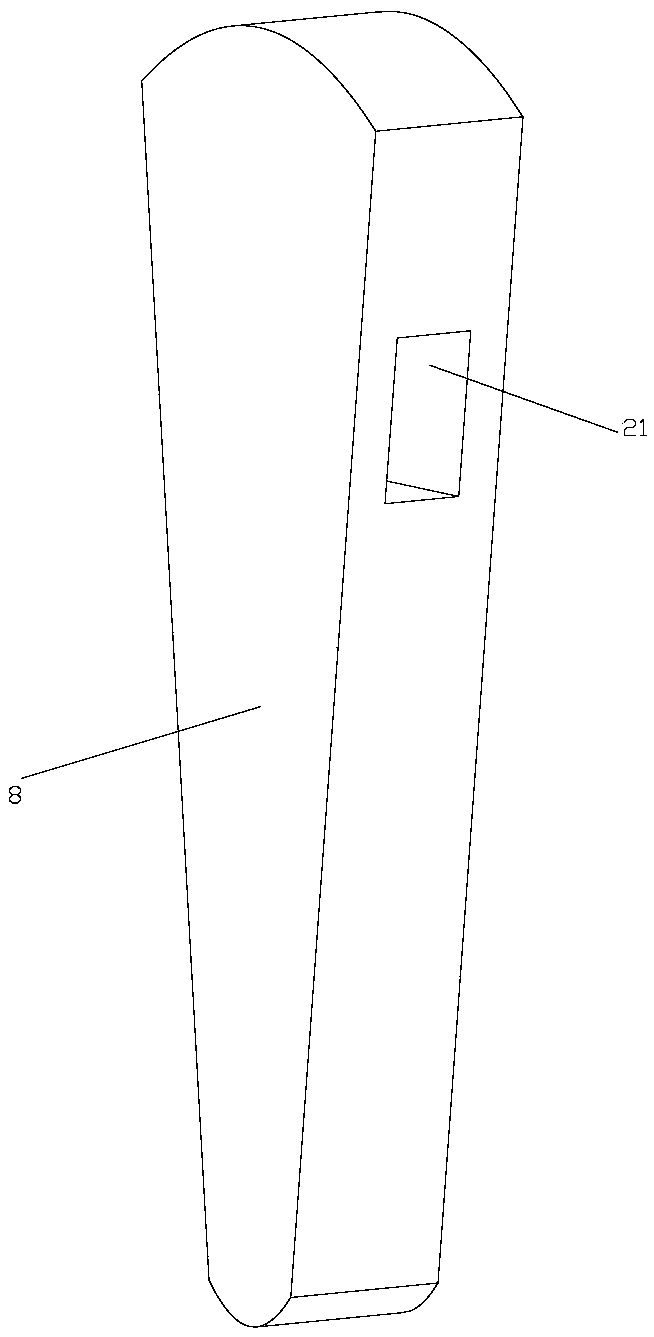

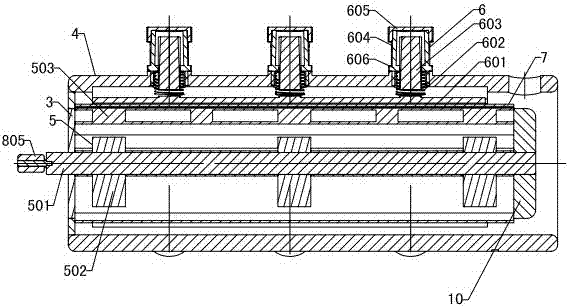

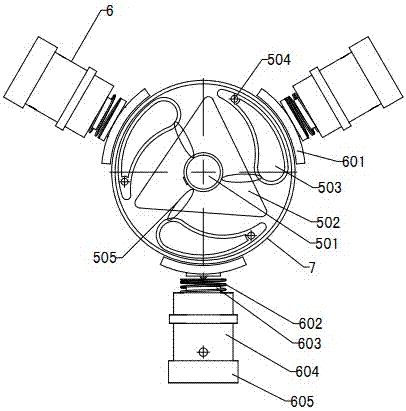

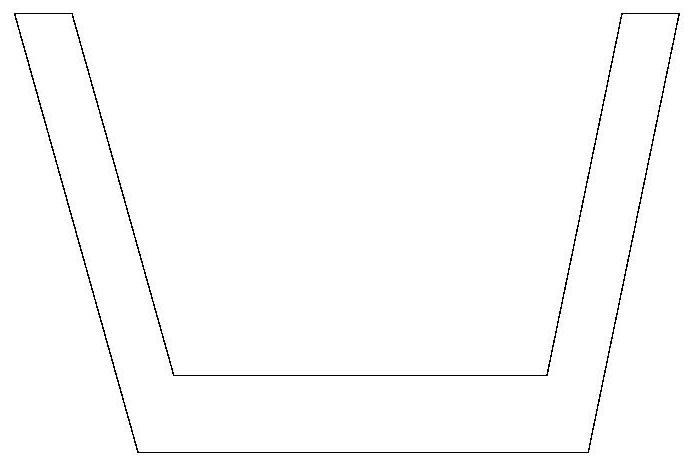

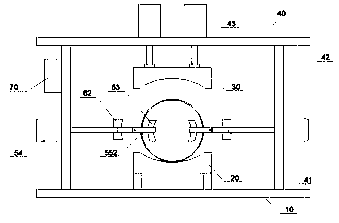

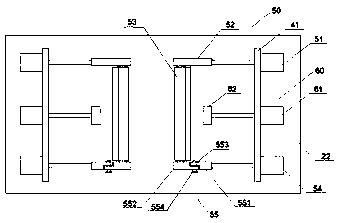

Air suction inverted twisting type single-sheet feeding device

The invention discloses an air suction inverted twisting type single-sheet feeding device. The air suction inverted twisting type single-sheet feeding device comprises a sheet feeding table, and the sheet feeding table comprises a rack, a lifting mechanism and a sheet feeding plate; the rack of the sheet feeding table comprises a vertical plate in the middle and side supporting plates arranged at the left and right ends; the lifting mechanism is mounted at the back of the vertical plate; the sheet feeding plate is mounted on the lifting mechanism; a suction nozzle air guide tube and a cam driving shaft are horizontally mounted between the two side supporting plates; at least two suction nozzles which communicate with the suction nozzle air guide tube are sequentially mounted on the suction nozzle air guide tube in the length direction; the suction nozzle air guide tube is above the sheet feeding plate; the cam driving shaft is in front of the vertical plate; and a moving groove is formed in each of the two side supporting plates, so that the suction nozzle air guide tube can drive the suction nozzles to cross to the position in front of the vertical plate. According to the air suction inverted twisting type single-sheet feeding device, a scattered sheet baffle plate is vertical and rod-like, the rigidity and strength can be fully guaranteed, the front ends of sheets on the sheet feeding table are horizontal and consistent, wavy concave and convex parts are avoided, and the front ends of the sheets are synchronously bent according to the amount of elastic deformation and bow tension of the sheets.

Owner:潍坊天达机械有限公司

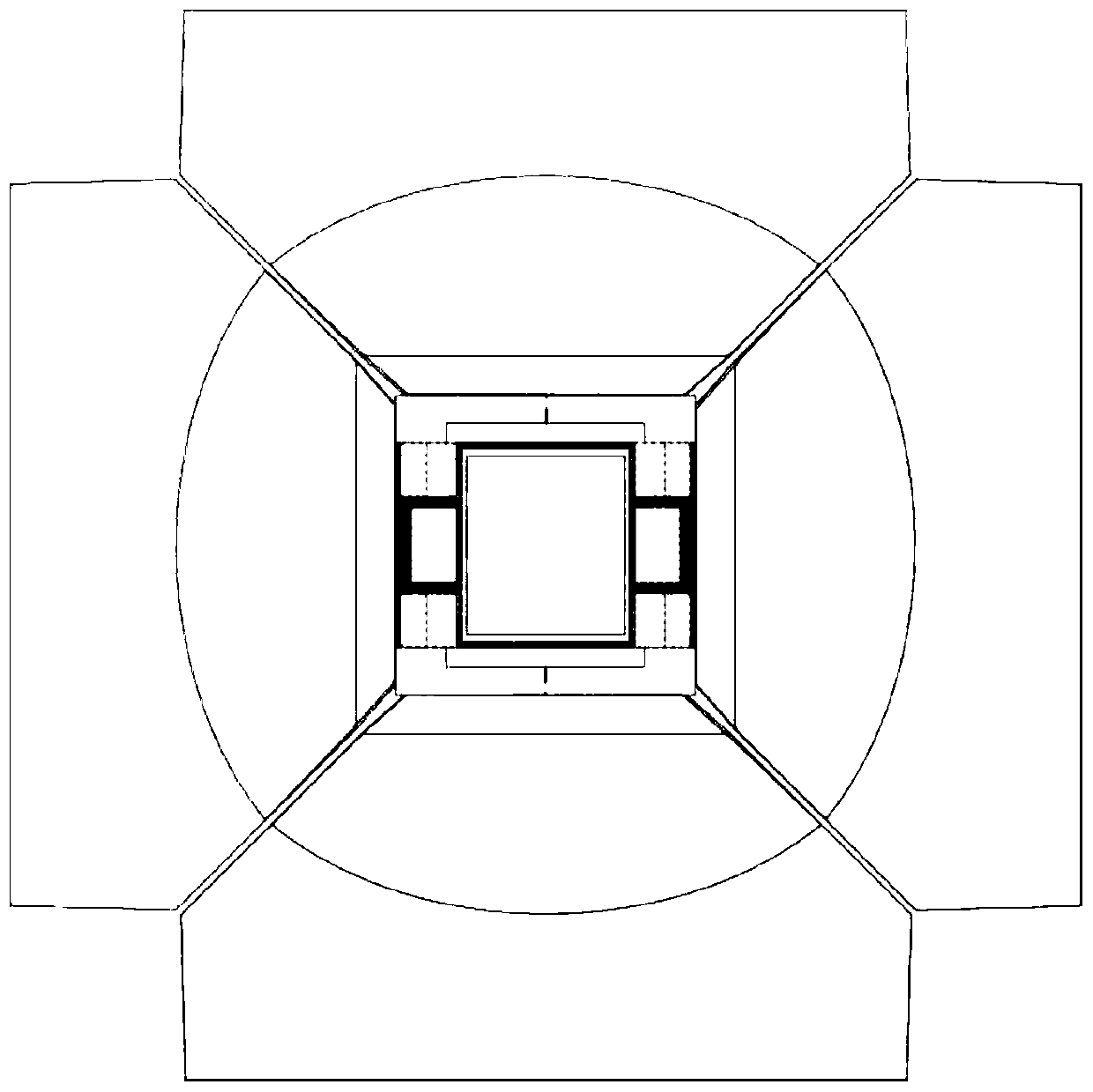

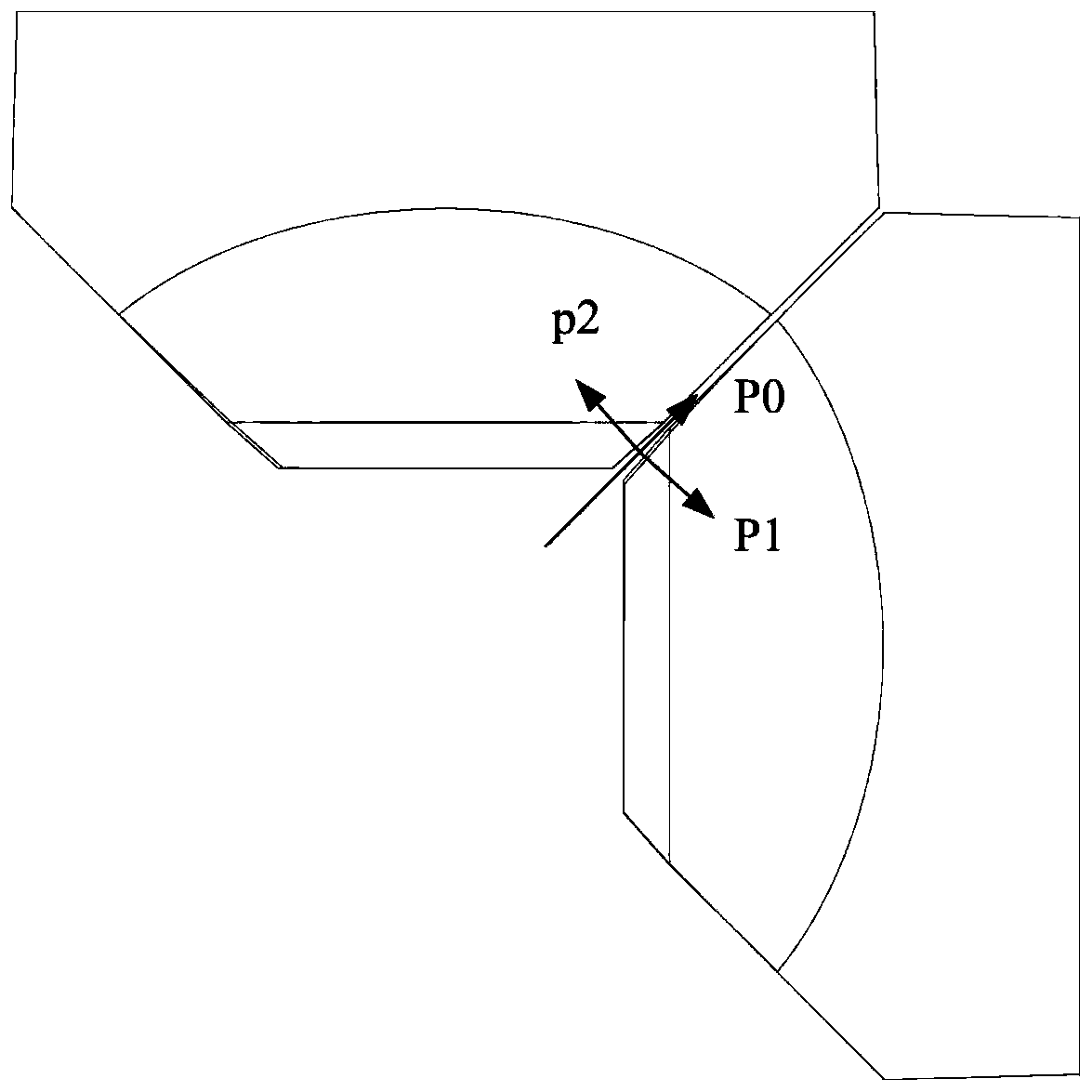

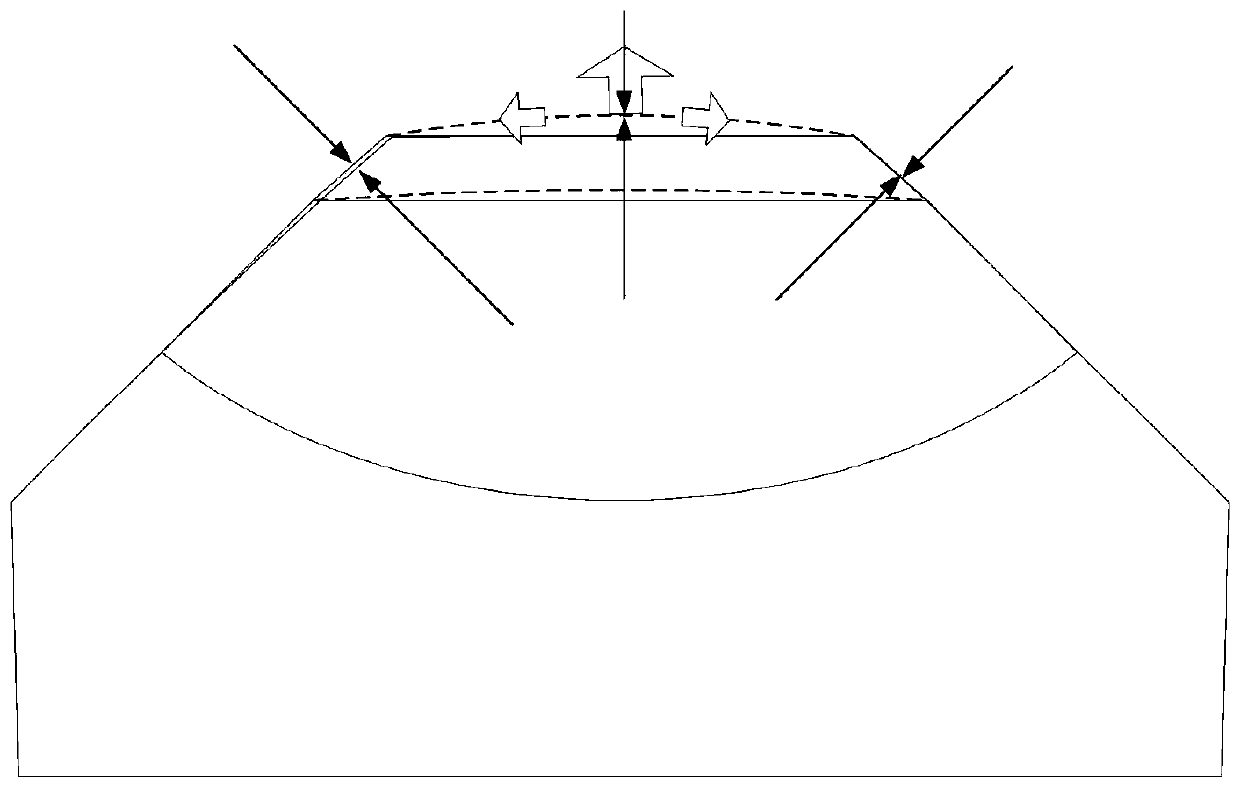

Operation and sealing method of large cubic press based on two-sided jacking mode

ActiveCN111203153AImproves pressure uniformityIncrease the proportionEngine sealsUltra-high pressure processesMechanical engineeringOil pressure

The invention relates to an operation and sealing method of a large cubic press based on a two-sided jacking mode. The top surfaces of four transverse non-heating hammers of the cubic press are designed into rectangles and are first fitted to form a square cavity during operation, and the oil ways of oil cylinders corresponding to two vertical heating hammers are separated from those of the otherfour oil cylinders and independently controlled; square columns with proper heights are designed at the top ends of the two heating hammers, the pressurizing process is realized by pushing the squarecolumns in the square cavity, and an inner sealing form is adopted between the heating hammers and the cavity; and inner sealing edges with proper widths and angles are designed on the four sides of the square columns. According to the invention, a traditional pressurizing mode is changed, the four non-heating hammers form a square cavity in advance under proper pressure, the pressure of the non-heating hammers is gradually increased and is matched with the pressure of the heating hammers while the heating hammers are pushed forwards, the utilization rate of oil pressure is increased, and theproblem that the pressure of a top hammer plane and the pressure of the sealing edges are uneven due to volume shrinkage in the diamond synthesis process is solved.

Owner:CHANGZHOU UNIV

Method for cutting a loaf-shaped food and cutting machine

ActiveUS20100050833A1Avoid irregular deformationSimple processGang saw millsMetal working apparatusContact elementContact line

In a method for cutting a loaf-shaped food, a loaf of the food is advanced toward a cutting device by means of a feed apparatus and the loaf is cut into slices, strips or cubes by means of said cutting device such that the loaf is fixed during the feed movement by means of a vacuum gripper that is advanced together with the loaf and a negative pressure is generated within an interior of a contact element of the vacuum gripper and acts upon a fixing region of the surface of the loaf in a suction region of the contact element; in order to avoid the risk of defects due to a vacuum loss and a loss of the fixing force, it is proposed that the suction region is divided into at least two separate partial suction regions and the interior of the contact element is accordingly divided into at least two partial interiors, wherein the partial suction regions respectively adjoin one another, are separated from by a contact line and form separate partial fixing regions.

Owner:REIFENHAEUSER UWE

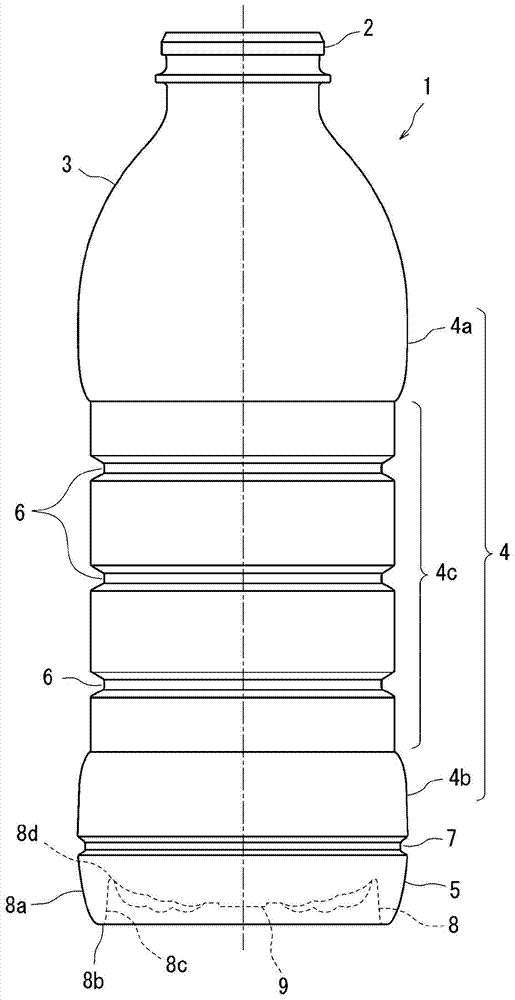

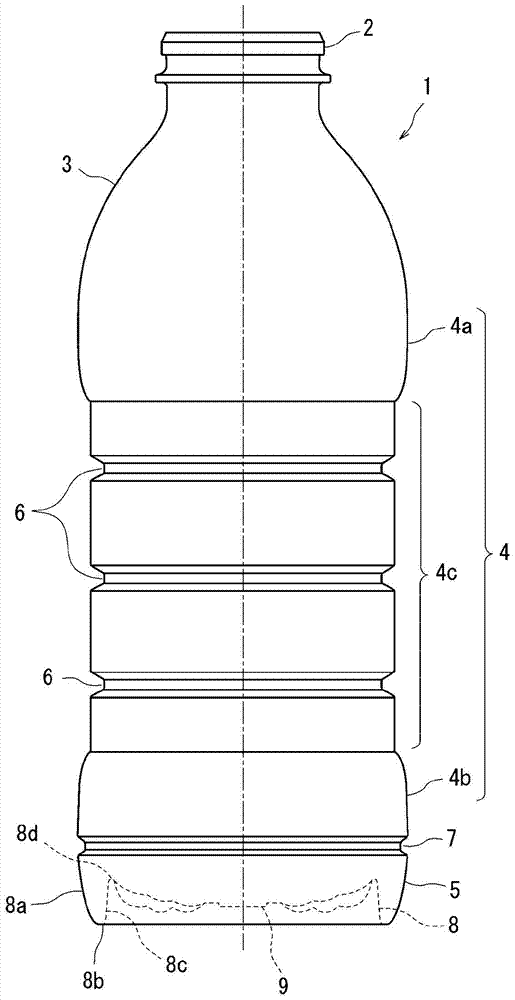

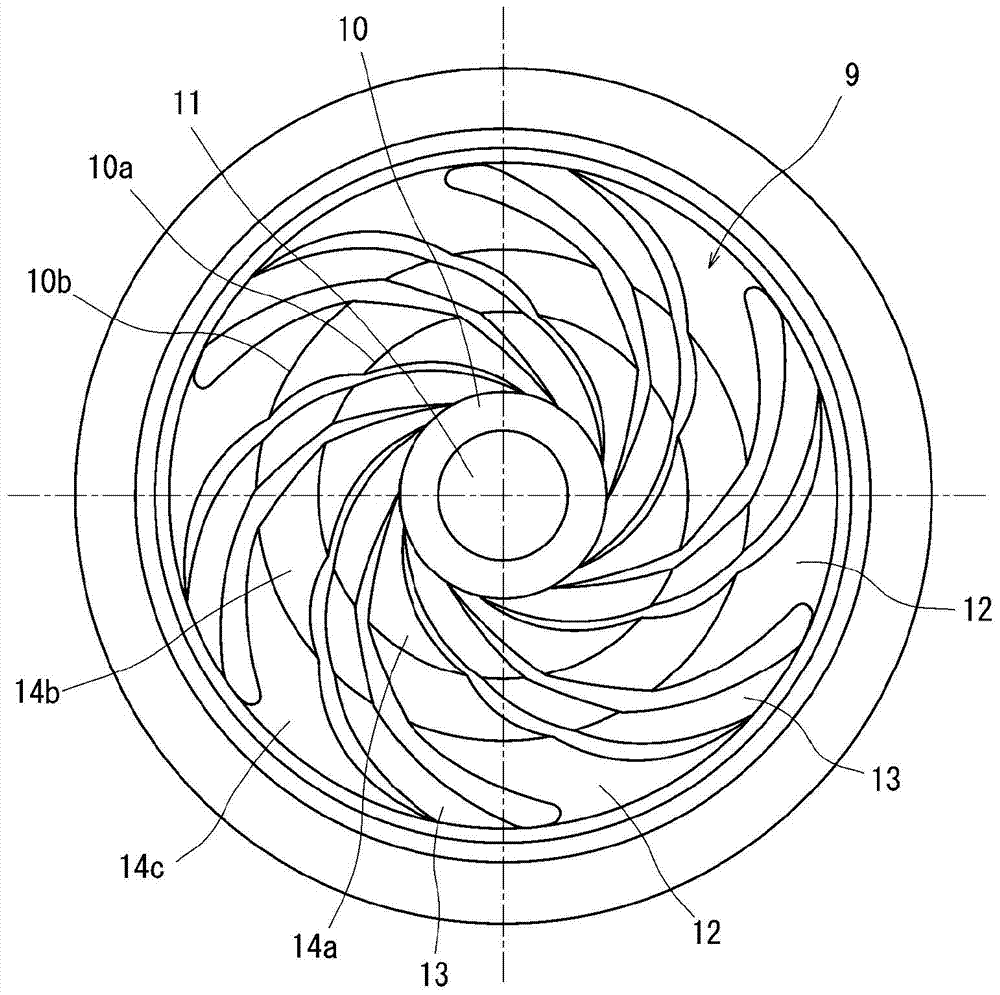

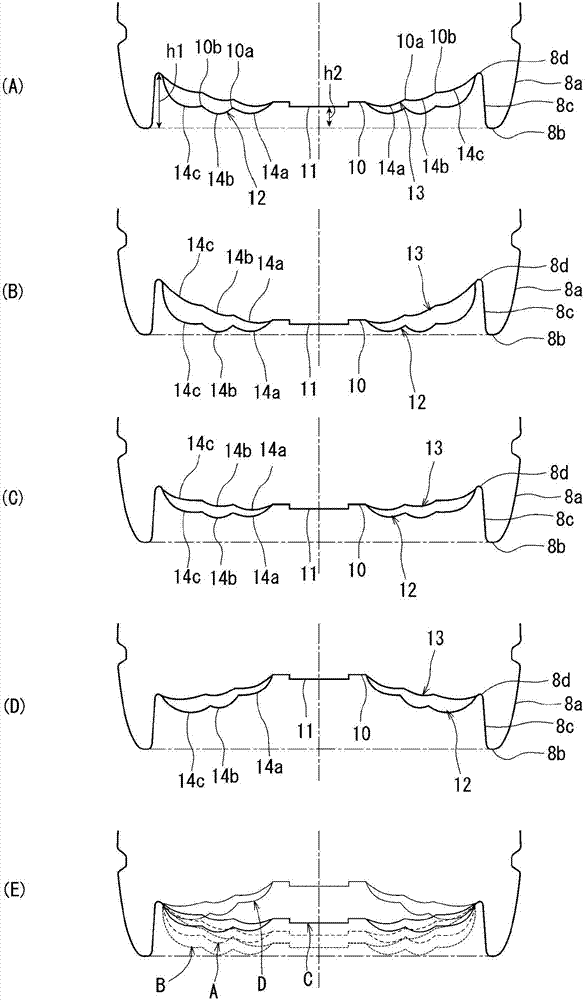

Container consisting of synthetic resin

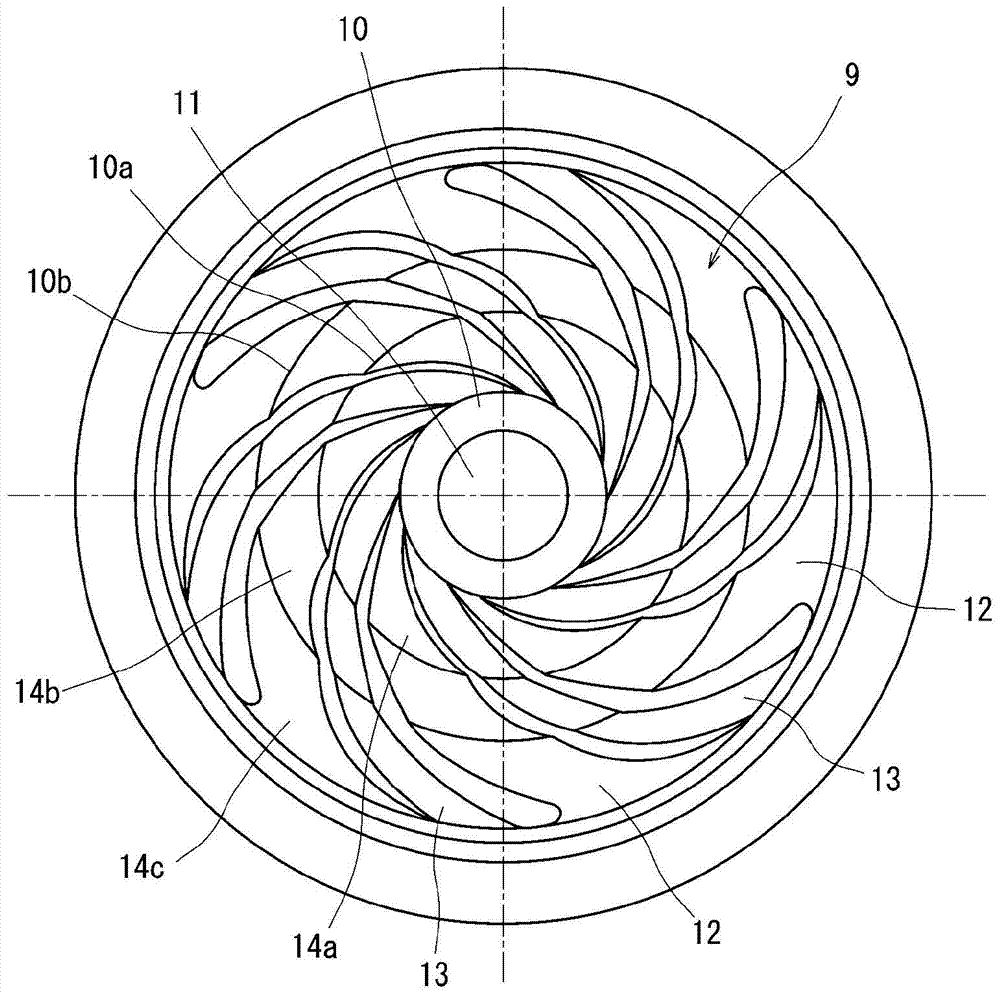

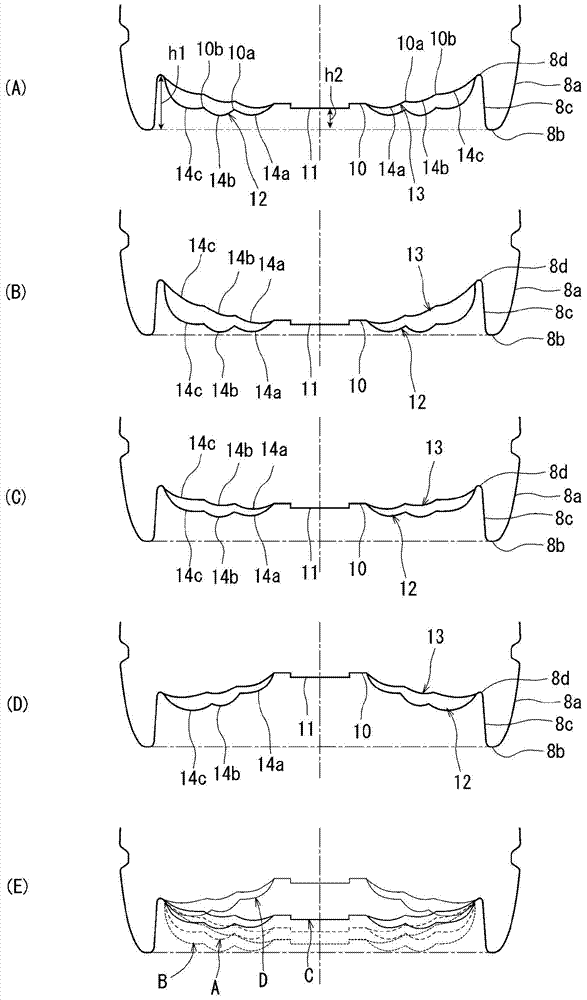

The present invention relates to a container consisting of a synthetic resin, the container having a bottom structure configured so that the deformation of the bottom due to a change in pressure within the container is uniform and gradual and so that the bottom structure has pressure reduction absorbing performance capable of reliably accommodating a large change in pressure within the container. A container consisting of a synthetic resin has, formed at the bottom thereof: an annular leg comprising an outer peripheral wall which continues from the barrel, a ground contact section, and an inner peripheral wall; and a raised bottom located on the inside of the inner wall surface of the leg at a position above the ground contact section. The container consisting of a synthetic resin is characterized in that the raised bottom protrudes further downward than the base of the inner peripheral wall of the leg, in that the raised bottom has spiral arc-shaped protrusions extending from the outer edge of the center section of the raised bottom toward the outer peripheral side, and in that arc-shaped recesses are formed between adjacent arc-shaped protrusions.

Owner:TOYO SEIKAN GRP HLDG LTD

Powder distributor for placing target material green body, positioning piece and sintering method of rotating target material

PendingCN113375463AAvoid irregular deformationAvoid crackingFurnace typesStatic frictionFriction force

The invention relates to a powder distributor for placing a target material green body, a positioning piece and a sintering method of a rotary target material. A powder pile with a slope at the top is piled on a load bearing plate by using auxiliary sliding powder, and then the rotary target material green body is placed on the slope of the powder pile. During sintering, the target green body shrinks to drive alumina powder pile to move inwards in the radial direction relative to the load bearing plate, so that the horizontal static friction force between the rotating target green body and the load bearing plate is converted into sliding friction force, and sliding effect after the auxiliary sliding powder forms the powder pile is superior to the sliding effect of paving one layer in the prior art; the friction resistance between the target material and the load bearing plate can be better reduced, friction resistance generated when the target material green body shrinks is reduced, and irregular deformation and cracking of the target material caused by the friction resistance are prevented.

Owner:广州市尤特新材料有限公司

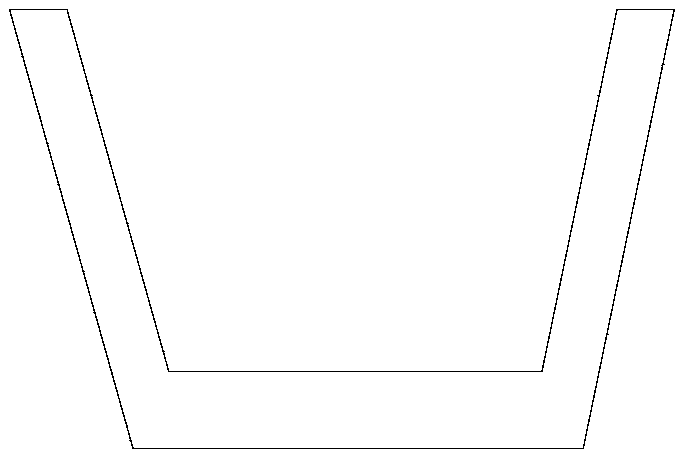

Automatic U-shaped part truing device

ActiveCN108856373AHigh precisionAvoid irregular deformationMetal-working feeding devicesPositioning devicesSlide plateCam

The invention discloses an automatic U-shaped part truing device. The device comprises a workbench. A first gear and a second gear engaged with the first gear are rotationally connected to the workbench. A plectrum is arranged on the first gear. A transmission plate is rotationally connected to the workbench. The workbench is in sliding connection with a sliding plate used for pulling the transmission plate to rotate. The lower end of the transmission plate abuts against the plectrum tightly. A cam used for driving the sliding plate to slide is arranged on the workbench. A first oscillating bar and a second oscillating bar are arranged on the first gear and the second gear correspondingly. A first pressure claw and a second pressure claw are arranged at the lower ends of the first oscillating bar and the second oscillating bar correspondingly, and a reset pressure spring is arranged between the first oscillating bar and the second oscillating bar. A first limit plate used for abuttingagainst the first pressure claw tightly and a second limit plate used for abutting against the second pressure claw tightly are connected to the workbench in a sliding mode. The first limit plate andthe second limit plate are located in a gap between the first pressure claw and the second pressure claw. The automatic U-shaped part truing device can be used for improving the precision of U-shapedparts.

Owner:姚奇圣

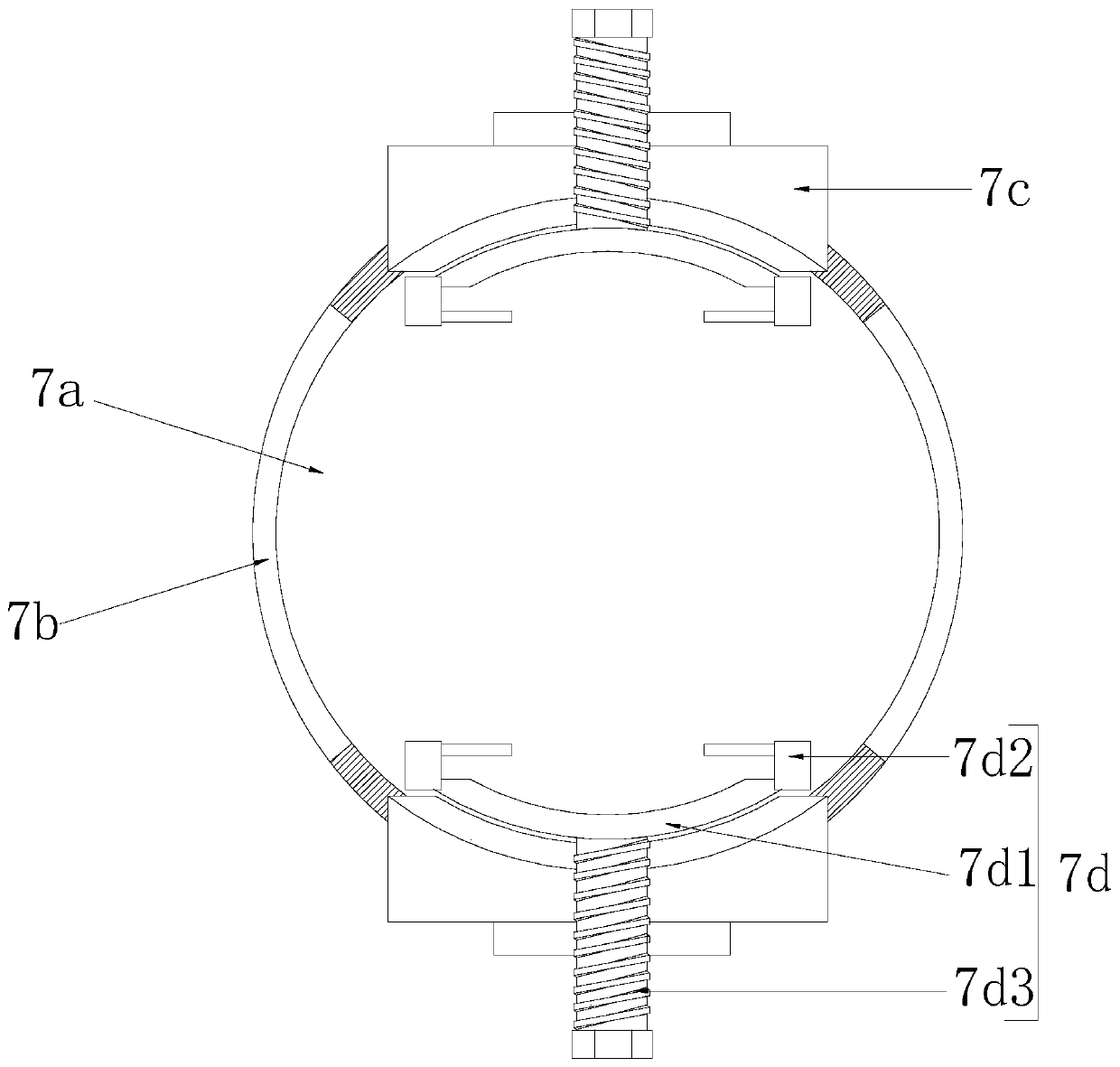

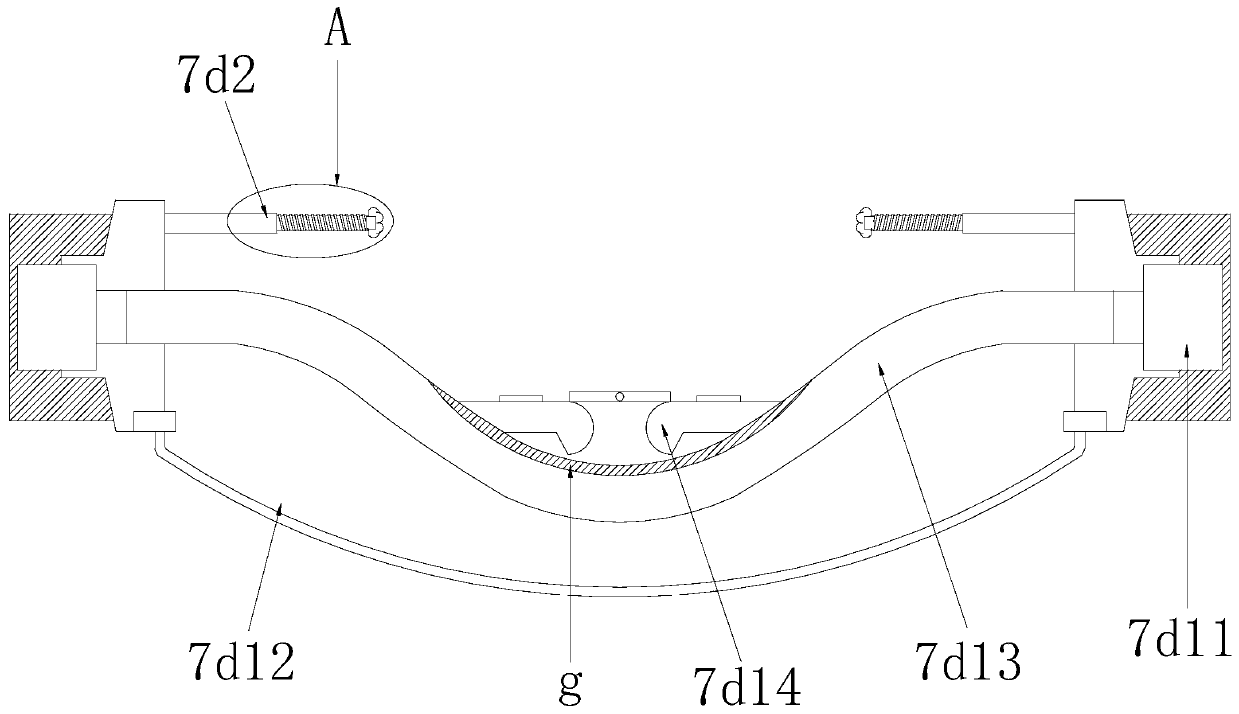

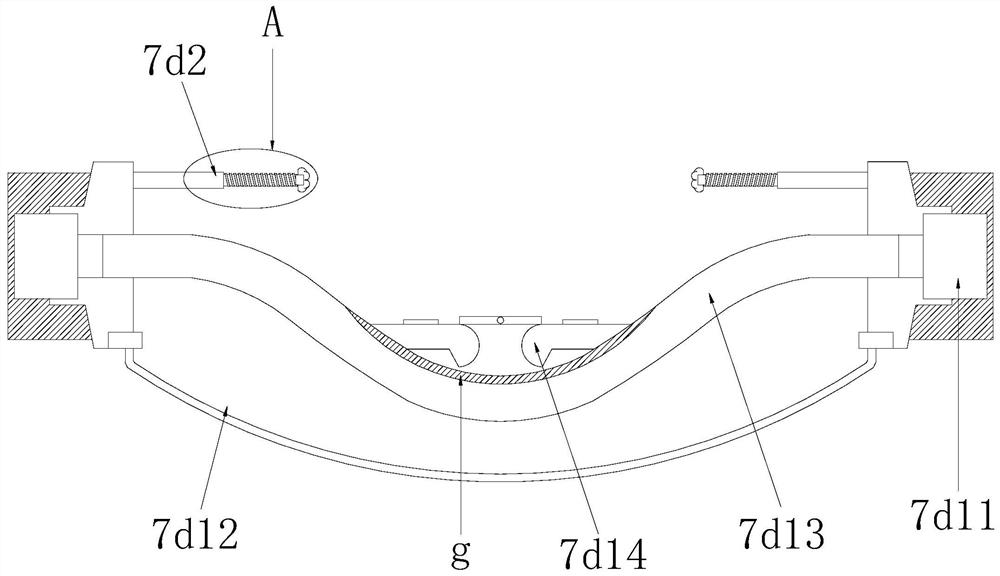

A pvc-o pipe radial stretching device and its processing method

Owner:SHANDONG UNIV OF TECH

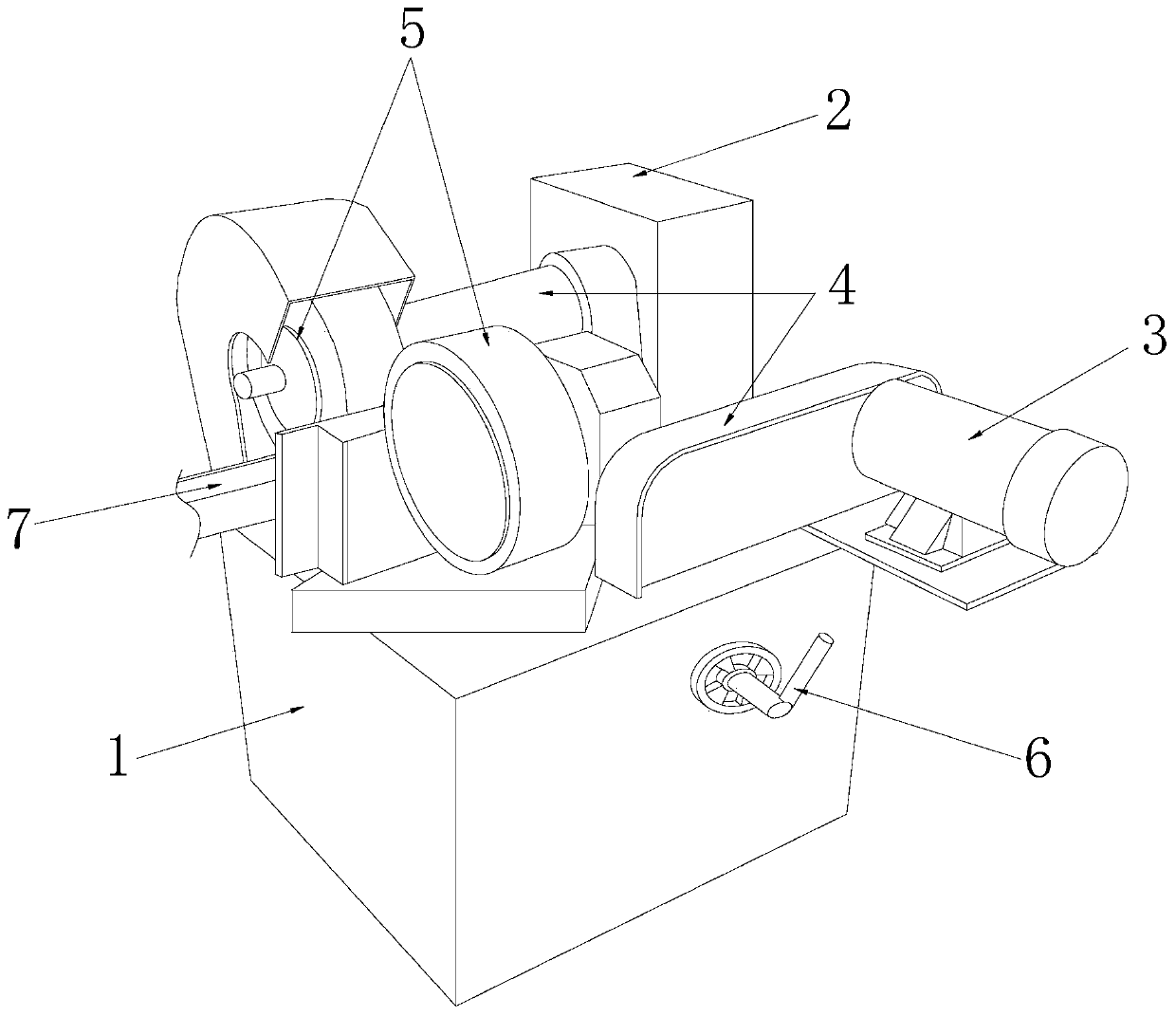

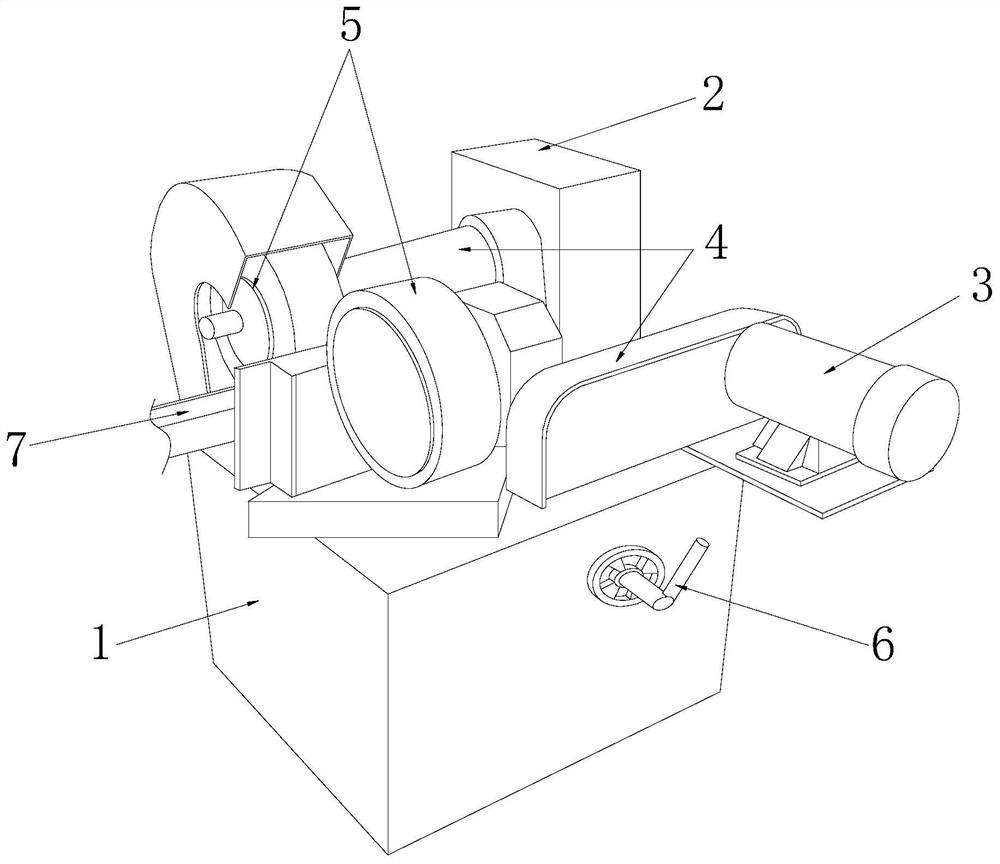

Grinding machine for high-strength titanium alloy production

ActiveCN111015440ANo shaking imbalanceAvoid irregular deformationGrinding carriagesGrinding machinesDrive shaftElectric machinery

The invention discloses a grinding machine for high-strength titanium alloy production. The grinding machine structurally comprises a machine body, a controller, a transmission motor, a transmission shaft, a grinding disc, an adjusting disc and a containing plate. The grinding machine has the beneficial effects that through cooperation of an arranged stabilizing and protecting mechanism and a tightening structure, when a titanium alloy rod is ground, pressing acting force is provided while the gravity of the tail end force is unbalanced, the phenomenon of shaking unbalance cannot happen when the gravity of the tail end of the titanium alloy rod is small and the gravity of the front end of the titanium alloy rod is small, and the situation that the tail end of the titanium alloy rod irregularly deforms after being ground is prevented; and through cooperation of an arranged scraping strip and a grinding magnetic assembly of the tightening structure, heat generated during grinding of thetitanium alloy rod is converted into magnetism, the surface with the iron scrap adsorption function is magnetically weakened, grinding sand is removed and collected, and the situation that the thickness of the titanium alloy rod is increased while iron scraps attached to the surface are ground is avoided.

Owner:江苏鼎尚精密电子有限公司

Automatic u-shape shaping device

ActiveCN108856373BHigh precisionAvoid irregular deformationMetal-working feeding devicesPositioning devicesGear wheelEngineering

The invention discloses an automatic U-shaped part truing device. The device comprises a workbench. A first gear and a second gear engaged with the first gear are rotationally connected to the workbench. A plectrum is arranged on the first gear. A transmission plate is rotationally connected to the workbench. The workbench is in sliding connection with a sliding plate used for pulling the transmission plate to rotate. The lower end of the transmission plate abuts against the plectrum tightly. A cam used for driving the sliding plate to slide is arranged on the workbench. A first oscillating bar and a second oscillating bar are arranged on the first gear and the second gear correspondingly. A first pressure claw and a second pressure claw are arranged at the lower ends of the first oscillating bar and the second oscillating bar correspondingly, and a reset pressure spring is arranged between the first oscillating bar and the second oscillating bar. A first limit plate used for abuttingagainst the first pressure claw tightly and a second limit plate used for abutting against the second pressure claw tightly are connected to the workbench in a sliding mode. The first limit plate andthe second limit plate are located in a gap between the first pressure claw and the second pressure claw. The automatic U-shaped part truing device can be used for improving the precision of U-shapedparts.

Owner:姚奇圣

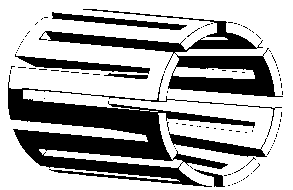

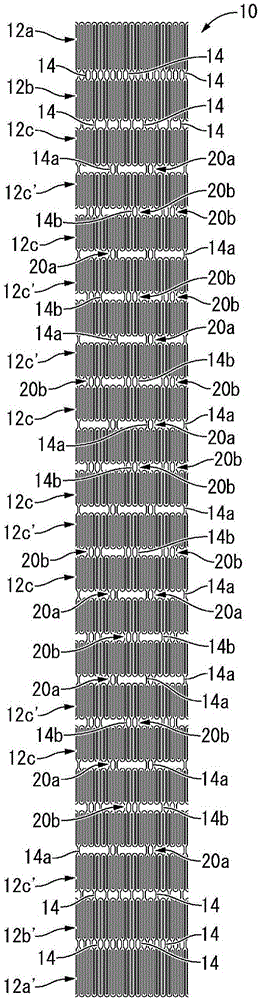

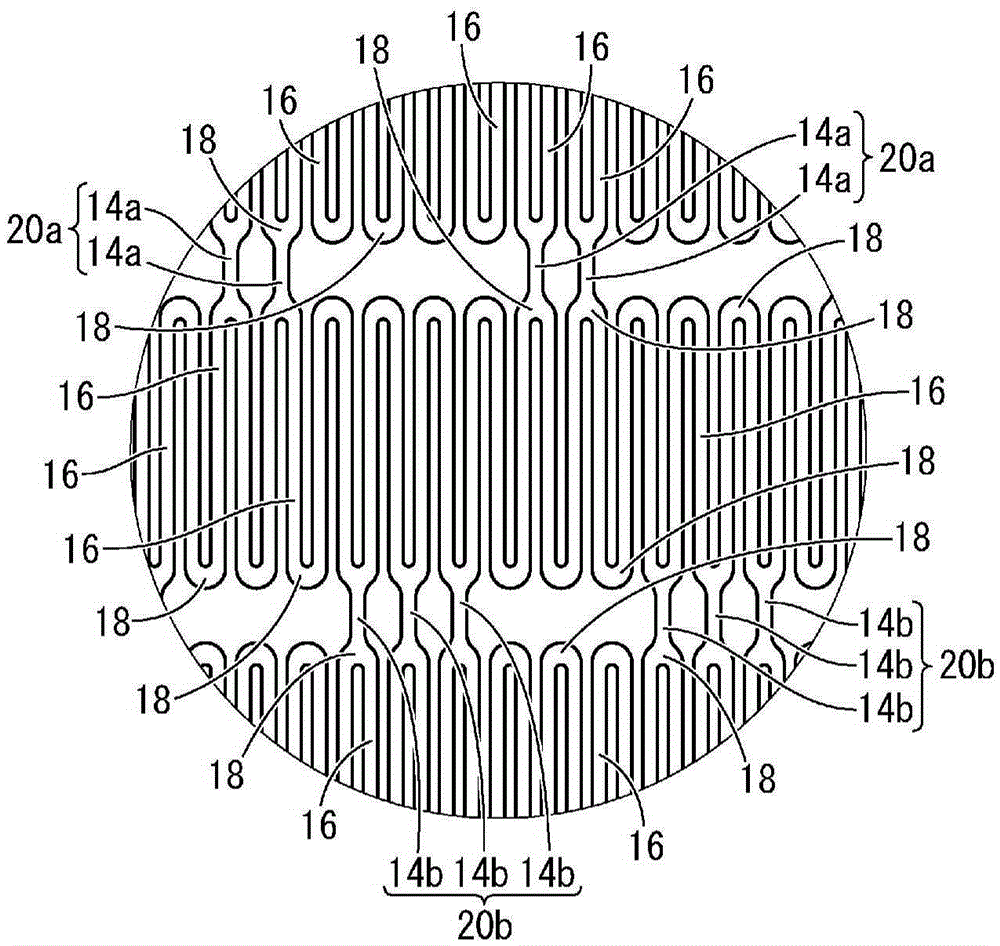

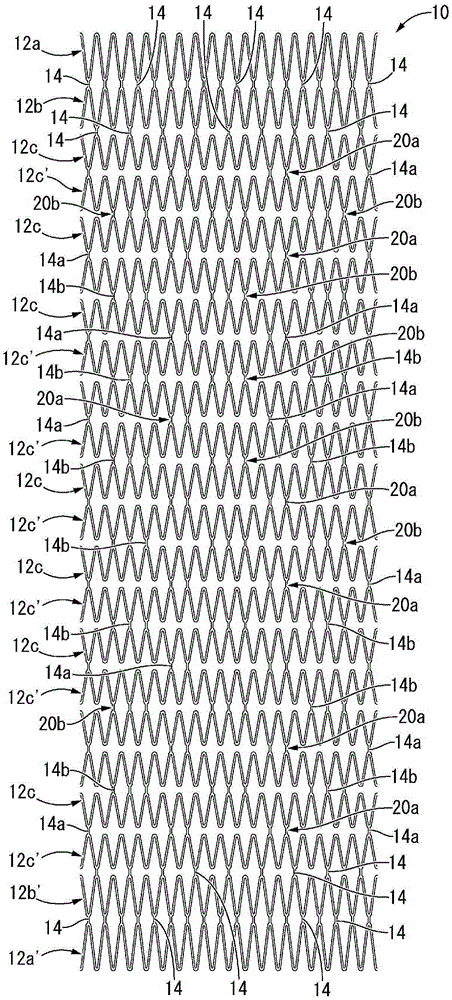

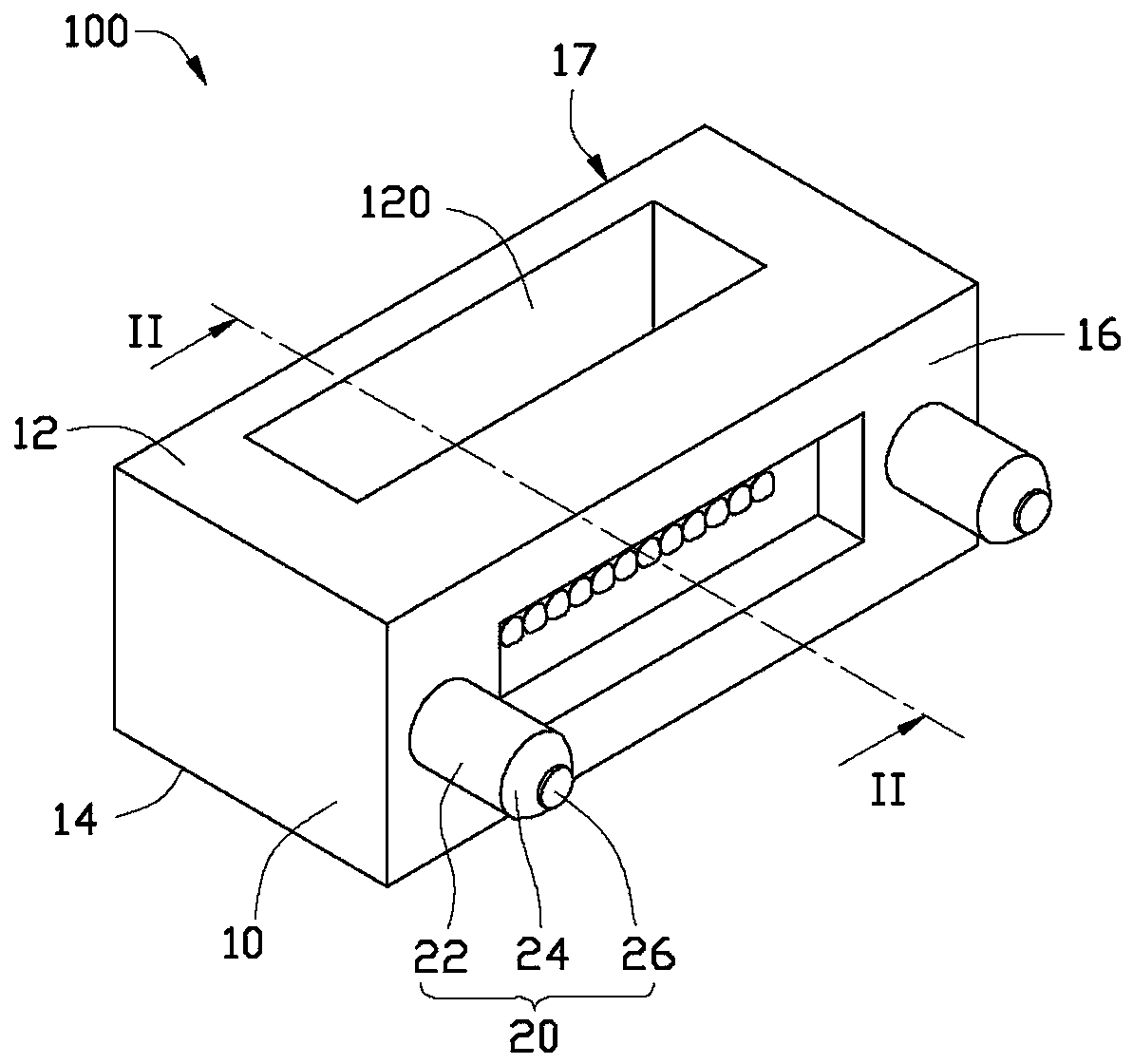

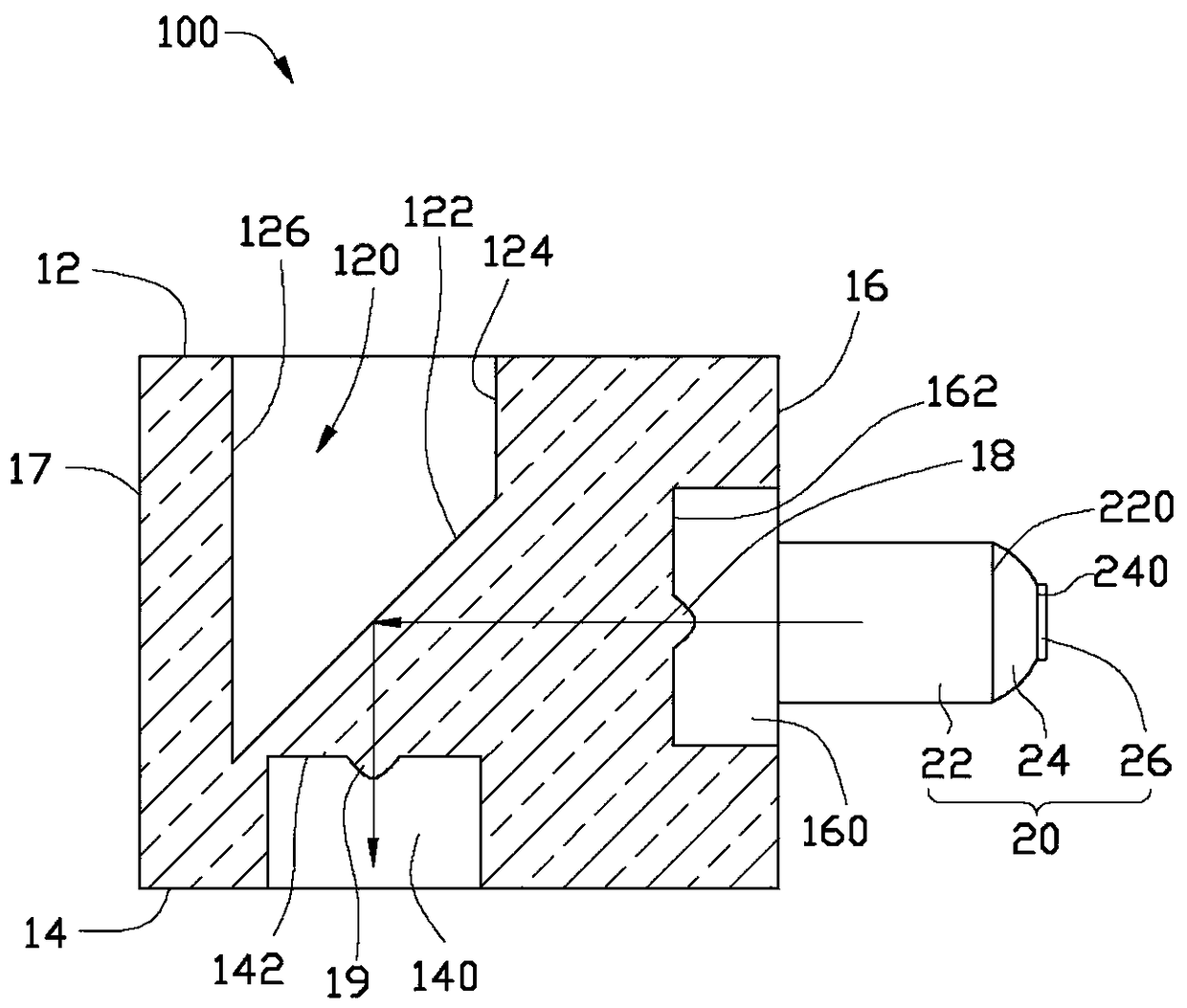

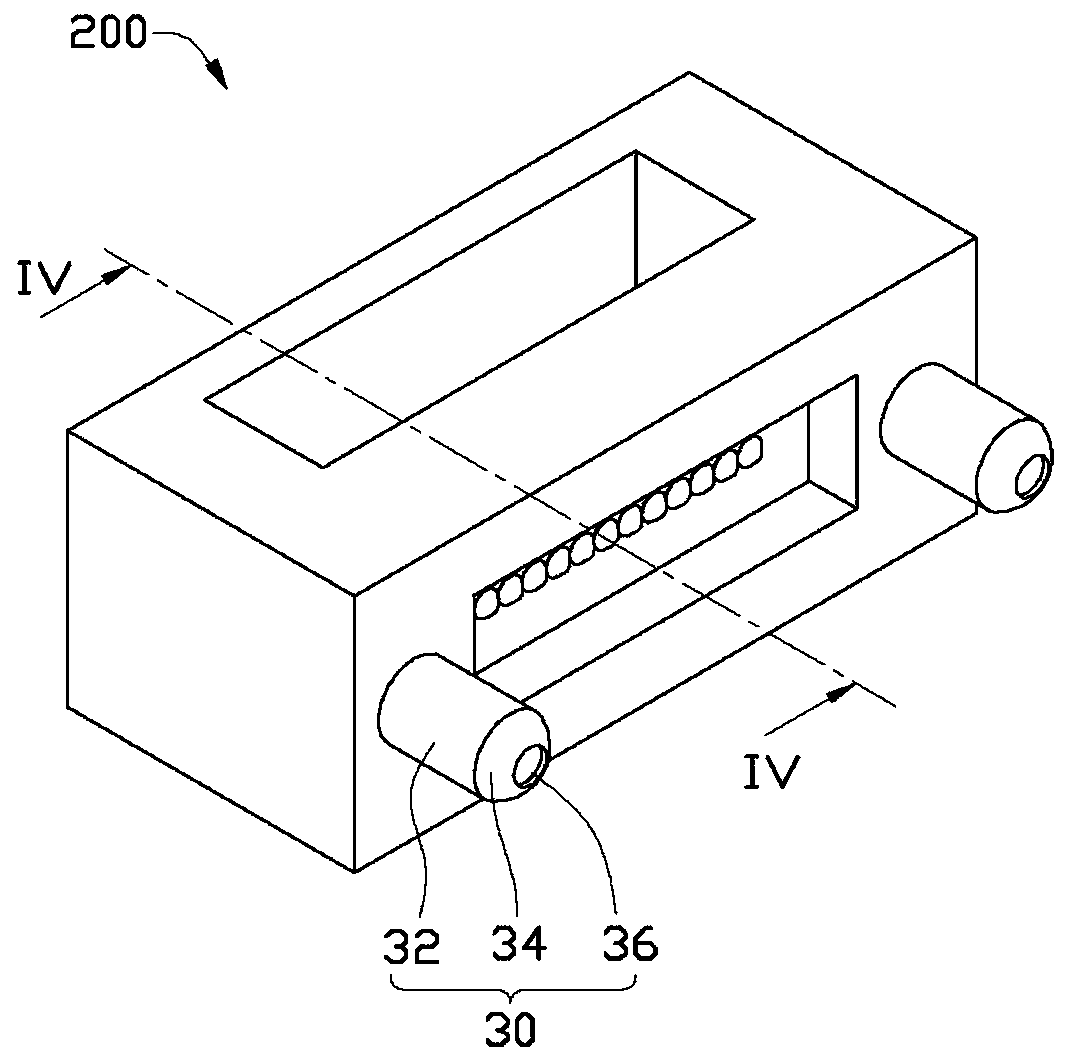

Stent

Provided is a stent having a novel structure, the stent simultaneously having both the stability of shape against the action of external force, such as compression force, tensile force, or torsional force, and high flexibility in the direction of twisting of the stent. Connection groups (20) are provided at three or more positions set at circumferentially equally-spaced intervals, the connection groups (20) each comprising connection sections (14) which are disposed circumferentially close to each other between axially adjacent cylindrical divided bodies (12c). The connection groups on both sides axially of each of the cylindrical divided bodies (12c) are provided at positions circumferentially offset from each other while at least one bend (18) is present between the connection groups.

Owner:TOKAI UNIV +1

Stretching device for shell of automobile silencer

InactiveCN111001697AAvoid irregular deformationSmooth deformationShaping toolsMetal-working feeding devicesPower apparatusMuffler

The invention discloses a stretching device for a shell of an automobile silencer and relates to the technical field of manufacturing of automobile silencers. The stretching device comprises a bottomplate, wherein a lower pressing plate is arranged on the bottom plate, a lower pressing power device is also arranged on the bottom plate, an upper pressing plate is arranged on the lower pressing power device, and two heating devices are also arranged on the lower pressing power device; each heating device comprises a first cylinder and a second cylinder; positioning plates are arranged on pistonrods of the first cylinders, and are fixedly connected with fan-shaped electric heating plates; connecting plates are arranged on piston rods of the second cylinders, and comprise first plate bodiesarranged on the corresponding piston rods of the second cylinders; second plate bodies are rotationally arranged at the ends, away from the positioning plates, of the electric heating plates; threadedholes are formed in the first plate bodies and the second plate bodies, and the first plate bodies and the second plate bodies are mutually fixed by screws connected with the threaded holes. The stretching device has the advantages of being convenient to use, good in stretching effect and the like.

Owner:浙江加文汽车零部件有限公司

A mill for producing high-strength titanium alloys

ActiveCN111015440BNo shaking imbalanceAvoid irregular deformationGrinding carriagesGrinding machinesDrive shaftElectric machinery

The invention discloses a grinding machine for high-strength titanium alloy production. The grinding machine structurally comprises a machine body, a controller, a transmission motor, a transmission shaft, a grinding disc, an adjusting disc and a containing plate. The grinding machine has the beneficial effects that through cooperation of an arranged stabilizing and protecting mechanism and a tightening structure, when a titanium alloy rod is ground, pressing acting force is provided while the gravity of the tail end force is unbalanced, the phenomenon of shaking unbalance cannot happen when the gravity of the tail end of the titanium alloy rod is small and the gravity of the front end of the titanium alloy rod is small, and the situation that the tail end of the titanium alloy rod irregularly deforms after being ground is prevented; and through cooperation of an arranged scraping strip and a grinding magnetic assembly of the tightening structure, heat generated during grinding of thetitanium alloy rod is converted into magnetism, the surface with the iron scrap adsorption function is magnetically weakened, grinding sand is removed and collected, and the situation that the thickness of the titanium alloy rod is increased while iron scraps attached to the surface are ground is avoided.

Owner:江苏鼎尚精密电子有限公司

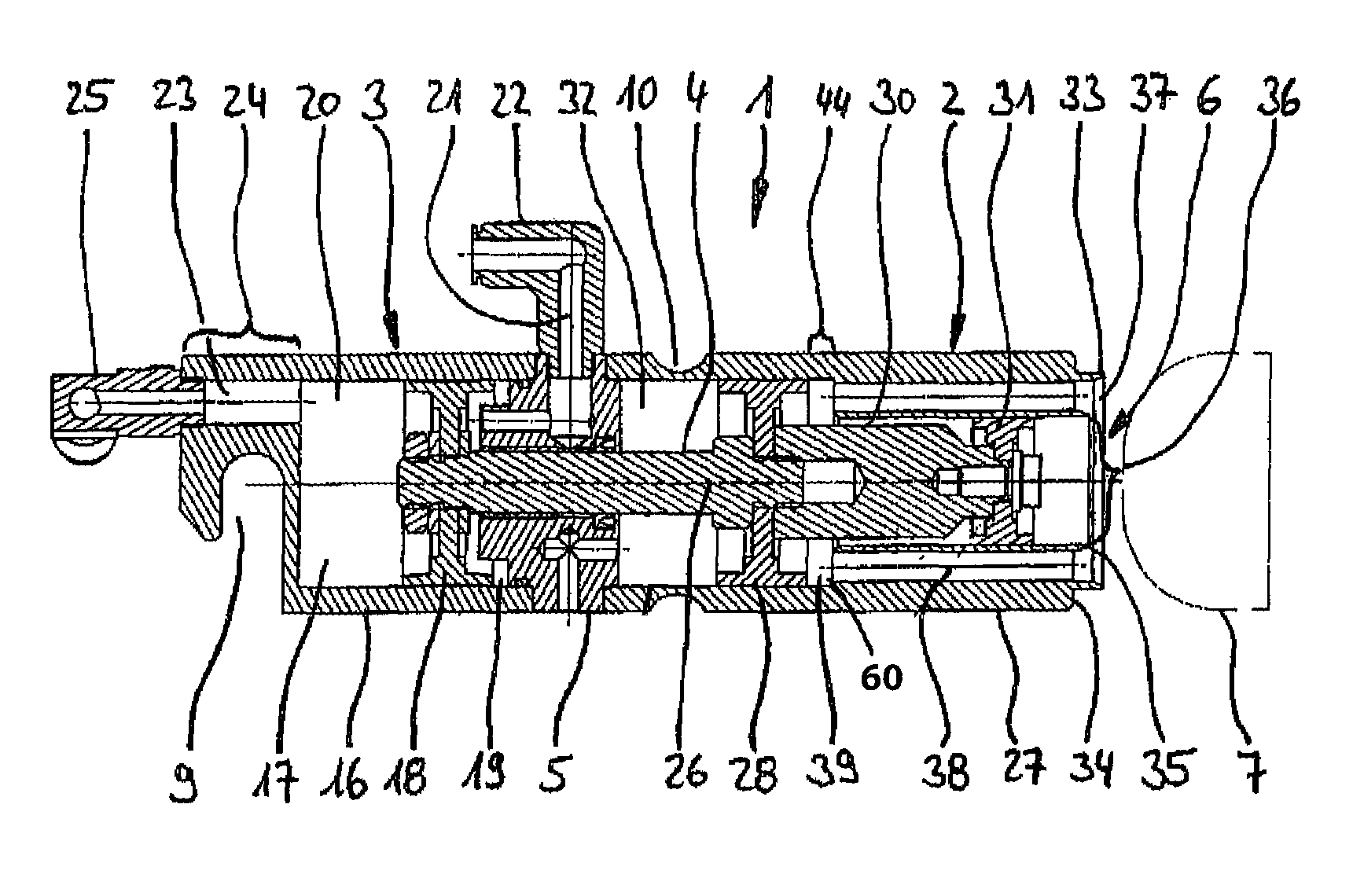

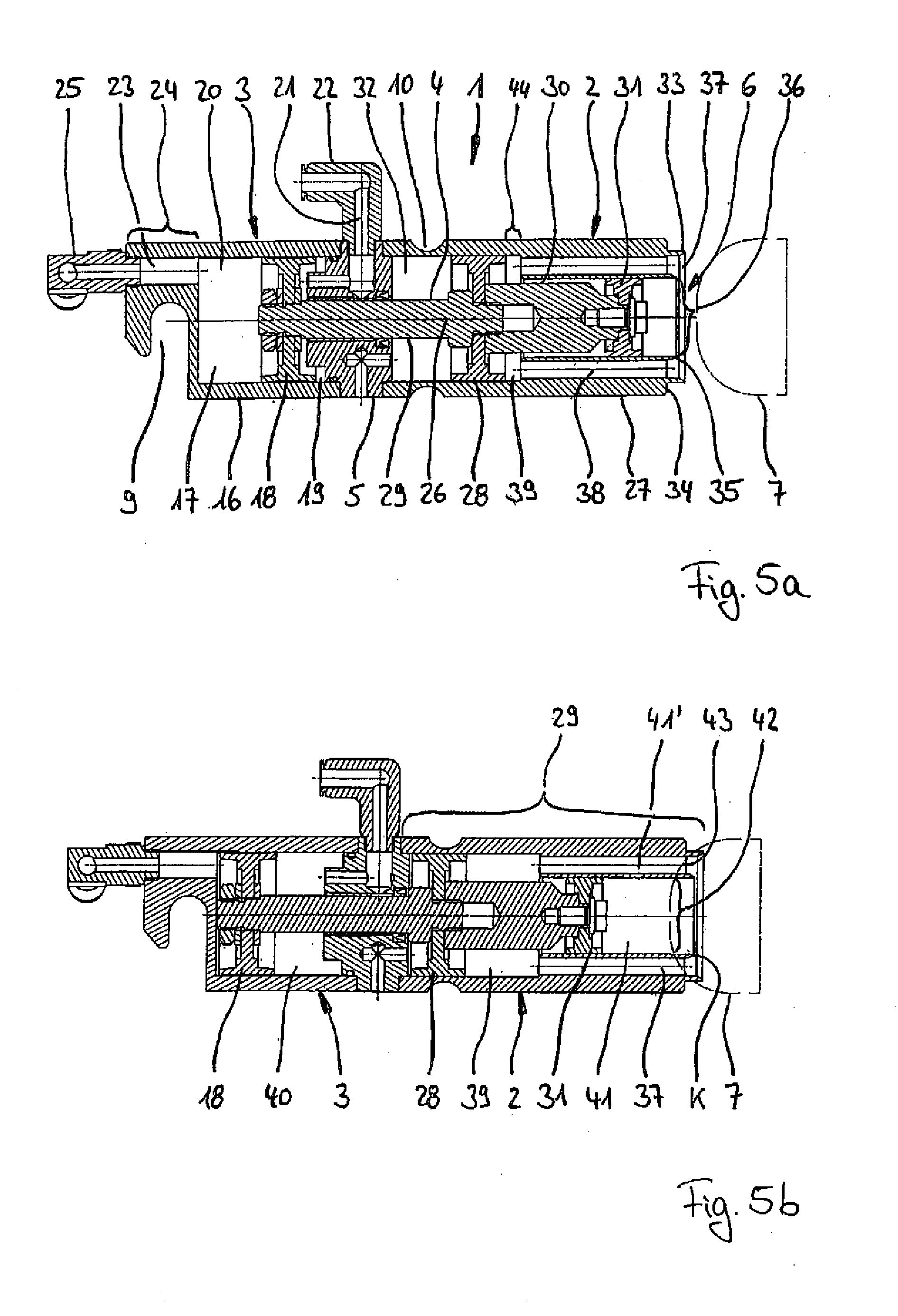

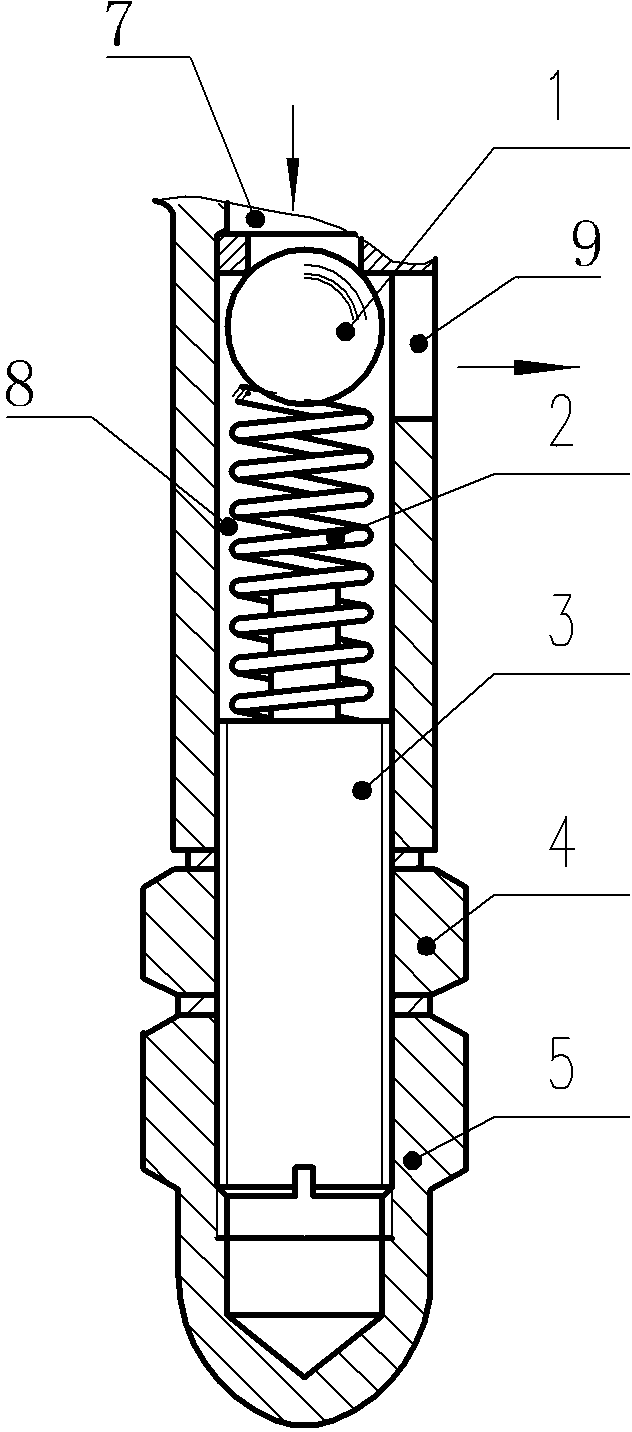

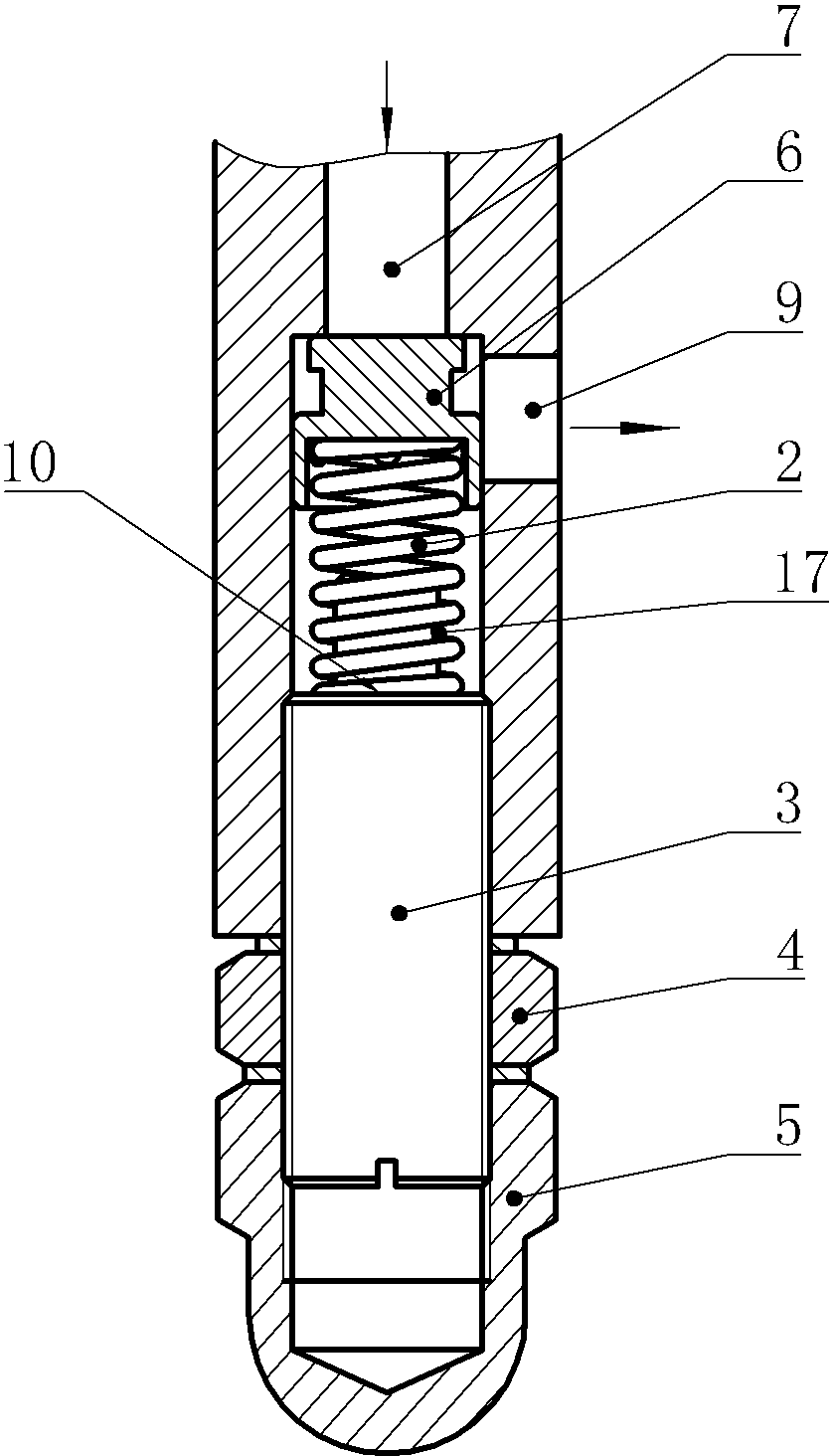

Regulator components

ActiveCN103527283BRestricted degrees of freedomAvoid irregular deformationLubrication pressure controlScrew threadThreaded rod

The invention provides a pressure adjusting assembly. The pressure adjusting assembly can solve the problem that an existing pressure adjusting assembly cannot effectively stabilize the pressure of engine oil in a main oil duct all the time. The pressure adjusting assembly comprises an adjusting threaded rod and a spring, wherein the adjusting threaded rod and the spring are installed in a pressure adjusting assembly section arranged at the tail end of the main oil duct, the adjusting threaded rod is connected with the inner wall of a slide way of the pressure adjusting assembly section in a threaded mode, and is tightly locked through a lock nut, a locating shaft of the adjusting threaded rod is sleeved with the spring, the bottom end of the spring is fixedly connected with the top surface of the adjusting threaded rod, the tail end of the pressure adjusting assembly section is sealed through an oil seal nut, and an oil drainage port is formed in the oil duct wall, close to the main oil duct, of the pressure adjusting assembly section. The pressure adjusting assembly is characterized in that an adjusting plunger is further installed in the pressure adjusting assembly section, a restraining groove is formed in the bottom end of the adjusting plunger, the top of the spring is embedded into the restraining groove, the top end of the spring is fixedly connected with the groove bottom surface of the restraining groove, the area of the top surface of the adjusting plunger is larger than the sectional area of the main oil duct, the height of the adjusting plunger is larger than that of the oil drainage port, and the adjusting plunger and the oil duct wall of the pressure adjusting assembly section are in clearance fit.

Owner:WUXI POWER ENG

optical coupling lens

InactiveCN104570234BImprove manufacturing yieldAvoid irregular deformationCoupling light guidesOptical couplingOptical surface

The invention relates to an optical coupling lens. The optical coupling lens comprises a coupling body and two plug pins, wherein the coupling body comprises a front surface, a back surface, a first optical surface, a second optical surface, a reflecting surface, a plurality of first converging parts and a plurality of second converging parts, wherein the front surface and the back surface are parallel to each other and are back to each other; the first optical surface is sunken from the front surface towards the back surface; the second optical surface is perpendicular to the first optical surface; the reflecting surface is inclined relative to the first optical surface and the second optical surface; the first converging parts and the second converging parts are respectively positioned on the first optical surface and the second optical surface. The first converging parts are positioned between the two plug pins and are in one-to-one correspondence with the second converging parts. Each plug pin comprises a cylindrical body part, a boss part which extends from the end surface of the body part, and a buffer part. The boss part is of a bowl-shaped structure and comprises a top surface which is far away from the body part; the diameter of the boss part is gradually reduced in the direction from the end surface to the top surface. The buffer part is arranged on the top surface so as to buffer the methane gas which is concentrated at the top surface when the optical coupling lens is formed.

Owner:武汉冠宇世纪科技技术有限公司

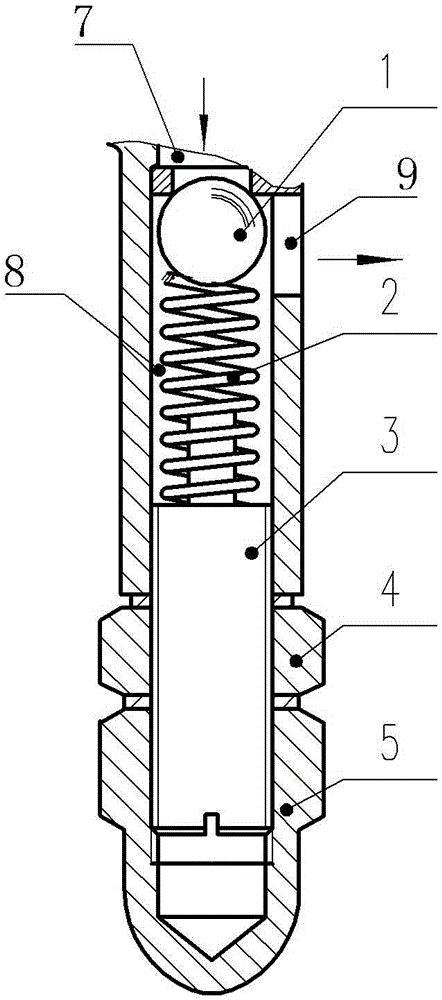

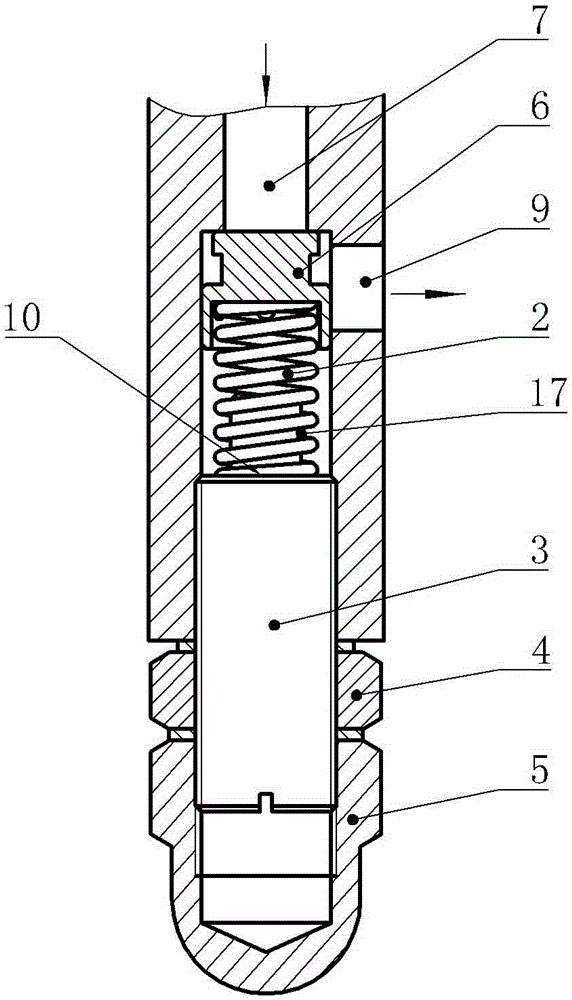

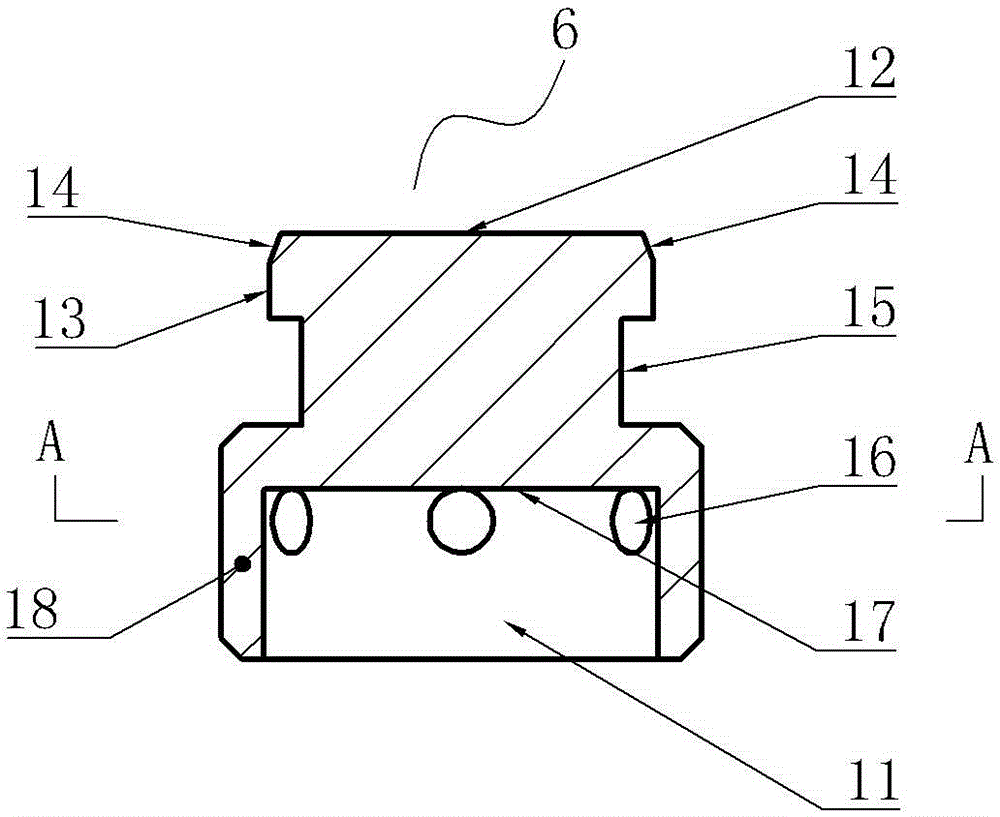

Pressure adjusting assembly

ActiveCN103527283ARestricted degrees of freedomAvoid irregular deformationLubrication pressure controlScrew threadThreaded rod

The invention provides a pressure adjusting assembly. The pressure adjusting assembly can solve the problem that an existing pressure adjusting assembly cannot effectively stabilize the pressure of engine oil in a main oil duct all the time. The pressure adjusting assembly comprises an adjusting threaded rod and a spring, wherein the adjusting threaded rod and the spring are installed in a pressure adjusting assembly section arranged at the tail end of the main oil duct, the adjusting threaded rod is connected with the inner wall of a slide way of the pressure adjusting assembly section in a threaded mode, and is tightly locked through a lock nut, a locating shaft of the adjusting threaded rod is sleeved with the spring, the bottom end of the spring is fixedly connected with the top surface of the adjusting threaded rod, the tail end of the pressure adjusting assembly section is sealed through an oil seal nut, and an oil drainage port is formed in the oil duct wall, close to the main oil duct, of the pressure adjusting assembly section. The pressure adjusting assembly is characterized in that an adjusting plunger is further installed in the pressure adjusting assembly section, a restraining groove is formed in the bottom end of the adjusting plunger, the top of the spring is embedded into the restraining groove, the top end of the spring is fixedly connected with the groove bottom surface of the restraining groove, the area of the top surface of the adjusting plunger is larger than the sectional area of the main oil duct, the height of the adjusting plunger is larger than that of the oil drainage port, and the adjusting plunger and the oil duct wall of the pressure adjusting assembly section are in clearance fit.

Owner:WUXI POWER ENG

Container consisting of synthetic resin

A synthetic resin container with a bottom structure in which a bottom portion uniformly and mildly deforms responsive to a change in the internal pressure, and exhibits pressure reducing / absorbing capability to reliably cope with even a large change in the internal pressure. The synthetic resin container forms, in the bottom portion thereof, an outer circumferential wall that is continuing from the body portion, an annular leg portion inclusive of a grounding portion and an inner circumferential wall, and a raised bottom portion positioned over the grounding portion on the inside of the inner circumferential wall of the leg portion, wherein the raised bottom portion is protruding downward beyond the root portion where the leg portion is continuing to the inner circumferential wall, a plurality of arcuate protuberances are formed in a spiral shape heading from the outer edge of the central portion of the raised bottom portion toward the outer circumferential side, and arcuate dents are formed among the arcuate protuberances that are neighboring each other.

Owner:TOYO SEIKAN GRP HLDG LTD

Electric hydraulic modeling clamp

The invention relates to the field of buildings, in particular to an electric hydraulic modeling clamp. The electric hydraulic modeling clamp comprises a support. A pressure bearing piece is arrangedat the top of the support, provided with a detachable pressure applying device and further provided with a pressure bearing plate which bears the pressure conducted by the pressure bearing piece. Thepressure bearing plate is arranged above the support, and the two ends of the pressure bearing plate are connected with transmission strips which are provided with extruding pieces. The extruding pieces and the support are in transmission connection with each other, and extruding heads are arranged at the bottoms of the extruding pieces. A return spring matched with the pressure bearing piece is arranged in the support. Compared with the prior art, a color steel tile can be quickly modeled, the color steel tile is evenly stressed during modeling, the strength loss is small, breakage is avoided, a photovoltaic device can be mounted directly, and the problems that during mounting of the photovoltaic device, punching needs to be conducted on the color steel tile, the time and labor are wasted, and water leakage hidden danger exists are solved.

Owner:宁波建工建乐工程有限公司

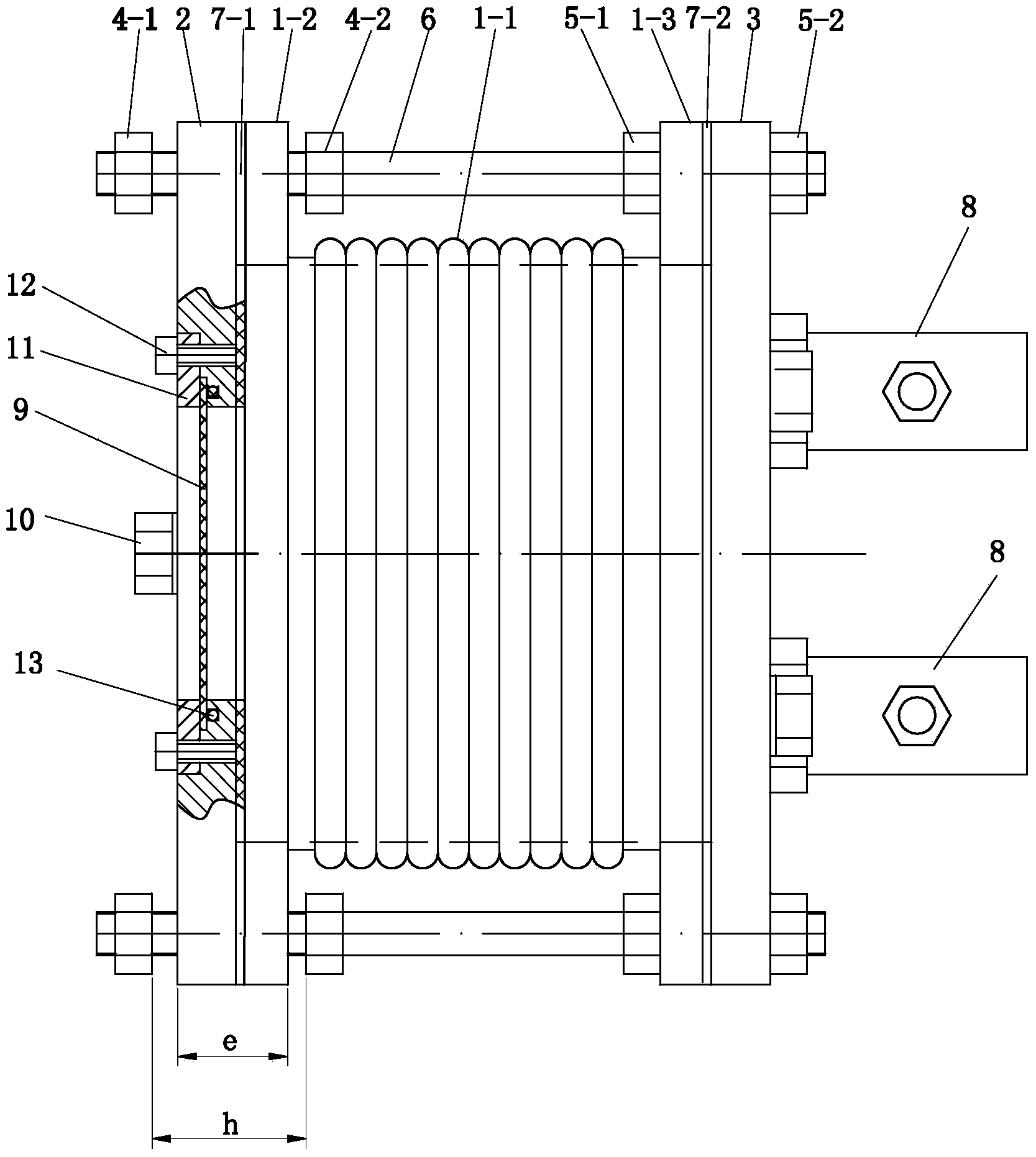

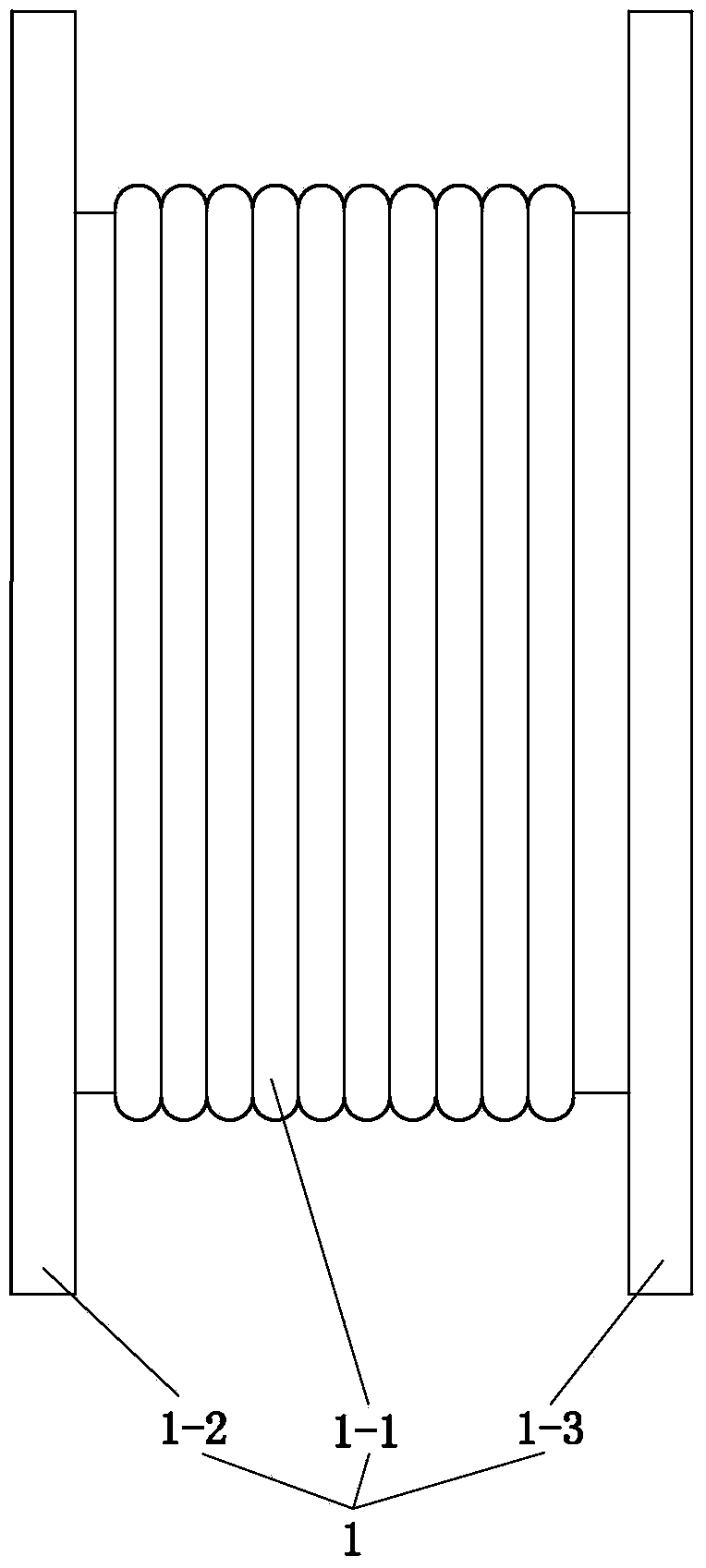

Container for material and oil compatibility tests

InactiveCN103675000AAvoid safety hazardsAvoid irregular deformationMaterial thermal analysisEngineeringVacuum pumping

A container for material and oil compatibility tests comprises a main body, a front close cover, a rear close cover and three or four guide bars each possessing screw threads at two ends; the main body consists of a bellows, and a front flange disc and a rear flange cover respectively welded at the front end and the rear end of the bellows; the front close cover covers a front flange and is connected with the front flange disc via bolts; the rear close cover covers a rear flange; each guide bar penetrates the front close cover, the front flange disc, the rear flange disc and the rear close cover; the positions of each guide bar, which are at the front side of the front close cover and at the rear side of the front flange disc, are respectively provided with a front spacing nut and a rear spacing nut, and the distance between the front spacing nut and the rear spacing nut is larger than the thickness of the front close cover and the front flange disc; the positions of each guide bar, which are at the front side of the rear flange disc and the rear side of the rear close cover, are respectively provided with a front locking nut and a rear locking nut, and the front locking nut and the rear locking nut fixes the corresponding guide bar, the rear flange disc and the rear close cover together; and the rear close cover is provided with two through holes respectively for oiling and vacuum pumping, and the through holes are connected with gate valves. The container for the material and oil compatibility tests is capable of effectively isolating air and compensating the volume needed by oil thermal expansion.

Owner:CHANGZHOU TOSHIBA TRANSFORMER

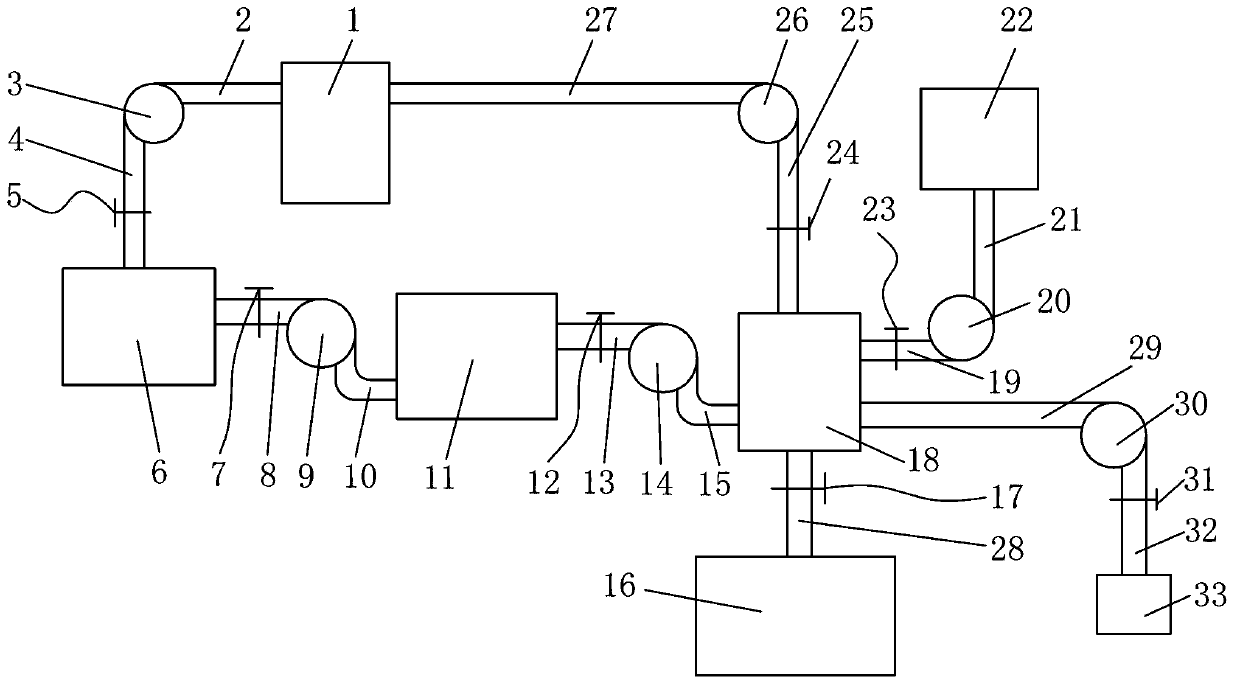

Forming process and system for manufacturing packaging expanded polystyrene

The invention relates to a forming process and system for manufacturing packaging expanded polystyrene. The process comprises the steps of (1) first-stage expansion, (2) second-stage expansion, (3) material feeding, (4) three-stage expansion, (5) thermal insulation, (6) primary cooling, (7) secondary cooling, (8) final cooling and (9) mould removing. The system comprises a first-stage expansion machine, a second-stage expansion machine, an expanded polystyrene forming machine, a water bin used for the primary cooling, a drying purifier for the secondary cooling, a negative pressure cooling device for the final cooling, and a boiler used for generating water vapor. According to the process and the system, two purposes can be realized by one system, so that the cost of production and manufacturing can be lowered; water in the packaging expanded polystyrene can be dried by thermal insulation, so that the forming quality is improved; the water cooling and the negative pressure cooling are combined, so that the cooling of a mould is accelerated, the processing and manufacturing period is shortened, and the production efficiency is improved; the cooling of the mould is divided into three stages, the phenomena of holes, and incompleteness and irregular deformation of the packaging expanded polystyrene caused by abrupt temperature drop can be avoided, so that the forming quality of the packaging expanded polystyrene can be effectively improved.

Owner:芜湖市京桥精密智造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com