A pvc-o pipe radial stretching device and its processing method

A radial stretching, PVC-O technology, applied in the field of PVC-O pipe processing equipment, can solve the problems of uneven pipe wall thickness, easy deformation of the pipe body, and affecting the use strength of the pipe, so as to ensure the overall uniformity and guarantee Effect of using strength, preventing random radial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

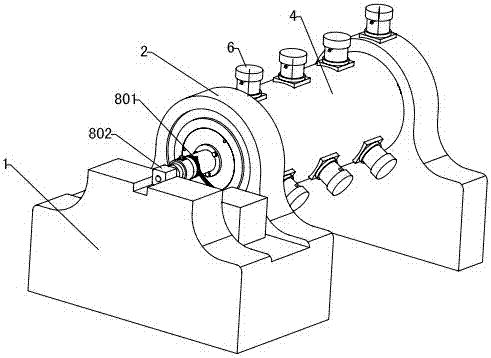

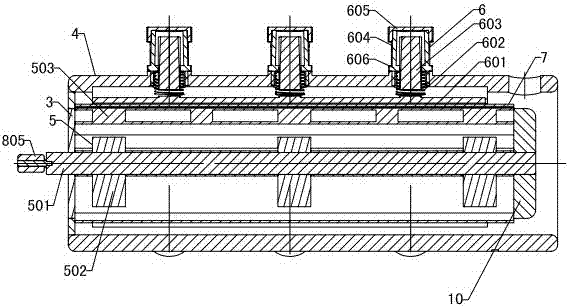

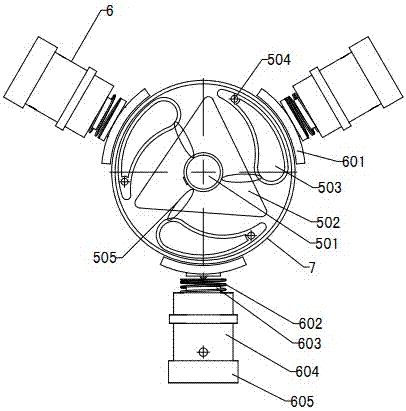

[0039] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0040] Refer to attached Figure 1~4 : a PVC-O pipe radial stretching device, including a workbench 1, a processing cylinder 4, a heating device and a stretching mechanism 5, the processing cylinder 4 is horizontally installed on the workbench 1 through a fixed support 2, and the workbench 1 can be Such as figure 1 As shown, it is divided into left and right parts. The processing cylinder 4 is installed between the left and right worktables 1. One side of the processing cylinder 4 is connected to a power supply device. The power supply device is a motor. The stretching mechanism 5 of the O tube body 7 and the compression mechanism 6 for pressing the PVC-O tube body 7, the stretching mechanism 5 is axially installed in the processing cylinder 4, the compression mechanism 6 is arranged on the processing cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com