PVC-O (oriented polyvinyl chloride) pipe magnetic suction controlled radial stretching device and processing method thereof

A PVC-O and radial stretching technology, applied in the field of PVC-O pipe processing equipment, can solve the problems of not ensuring the uniformity of the pipe, affecting the strength of the pipe, uneven wall thickness of the pipe, etc., to ensure the overall uniformity, The effect of ensuring the strength of use and the accuracy of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

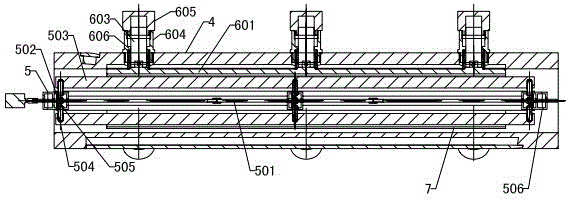

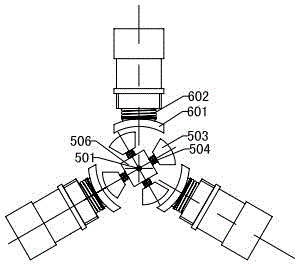

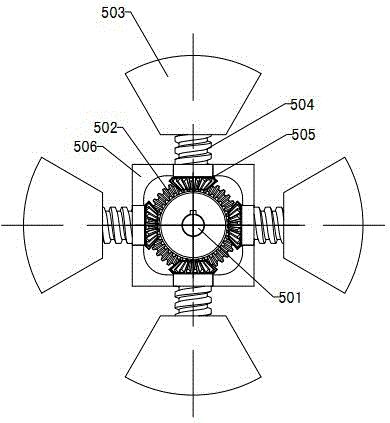

[0040] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0041] Refer to attached Figure 1~5 : A PVC-O pipe magnetically controlled radial stretching device, including a workbench 1, a processing cylinder 4, a heating device and a stretching mechanism 5, the processing cylinder 4 is laterally installed on the workbench 1 through a fixed support 2, and the working Taiwan 1 can be as figure 1 As shown, it is divided into left and right parts. The processing cylinder 4 is installed between the left and right worktables 1. The two ends of the processing cylinder 4 are respectively provided with detachable end caps, or the processing cylinder 4 is closed on one side and an end cap is installed on the other side. , one side of the processing cylinder 4 is connected to a power supply device, the power supply device is a motor, and the processing cylinder 4 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com