Patents

Literature

105results about How to "Maintain heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

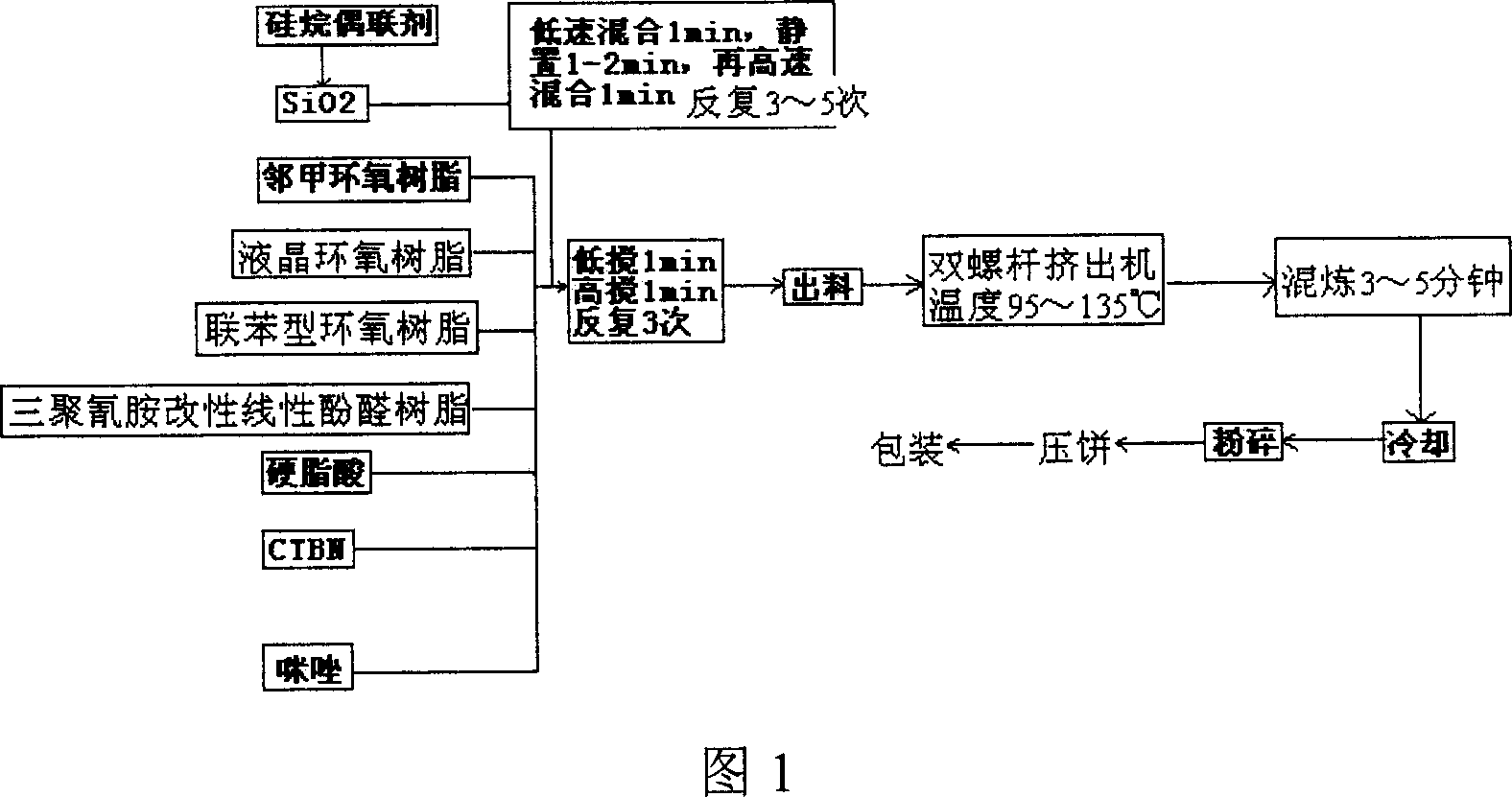

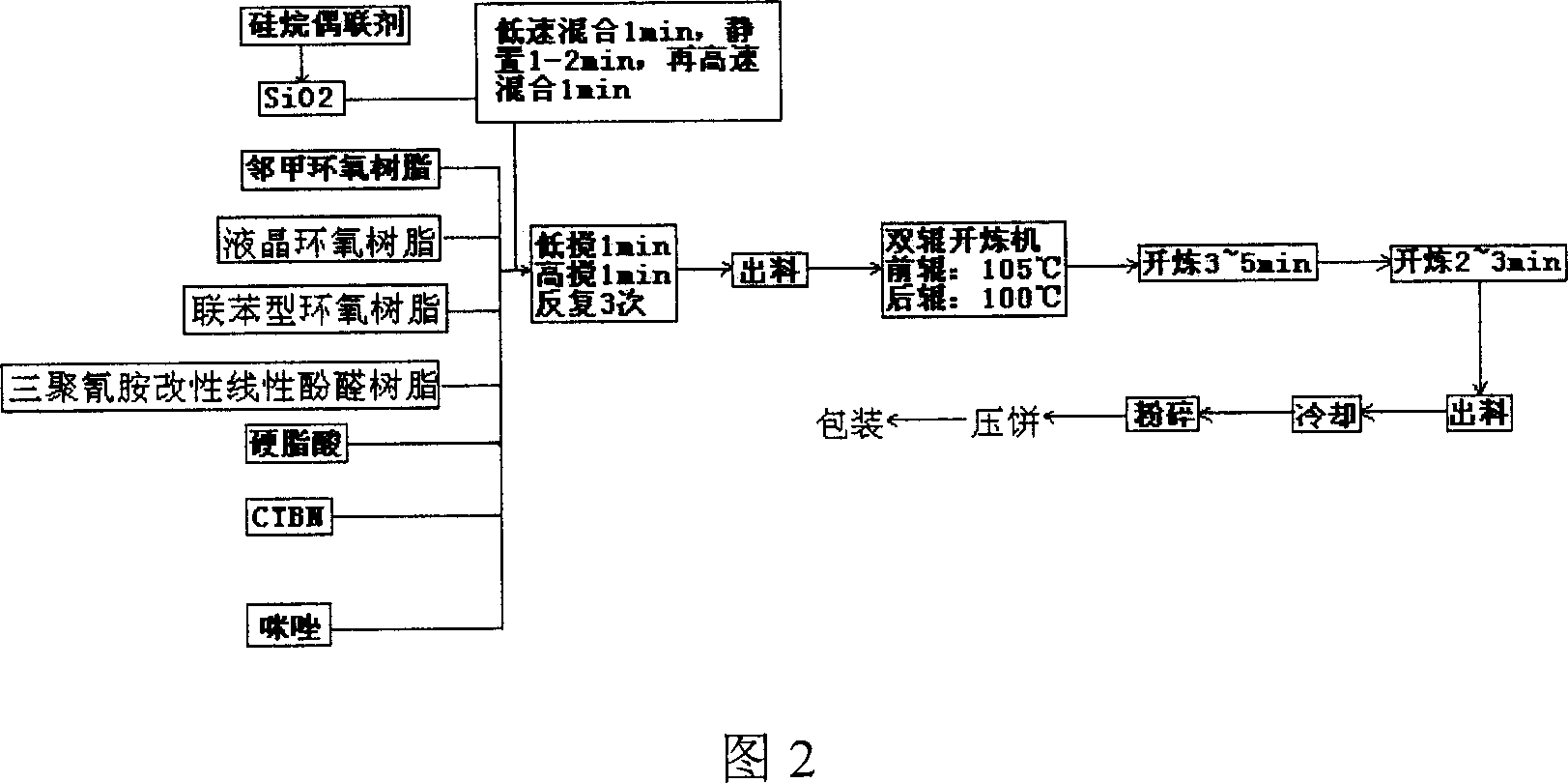

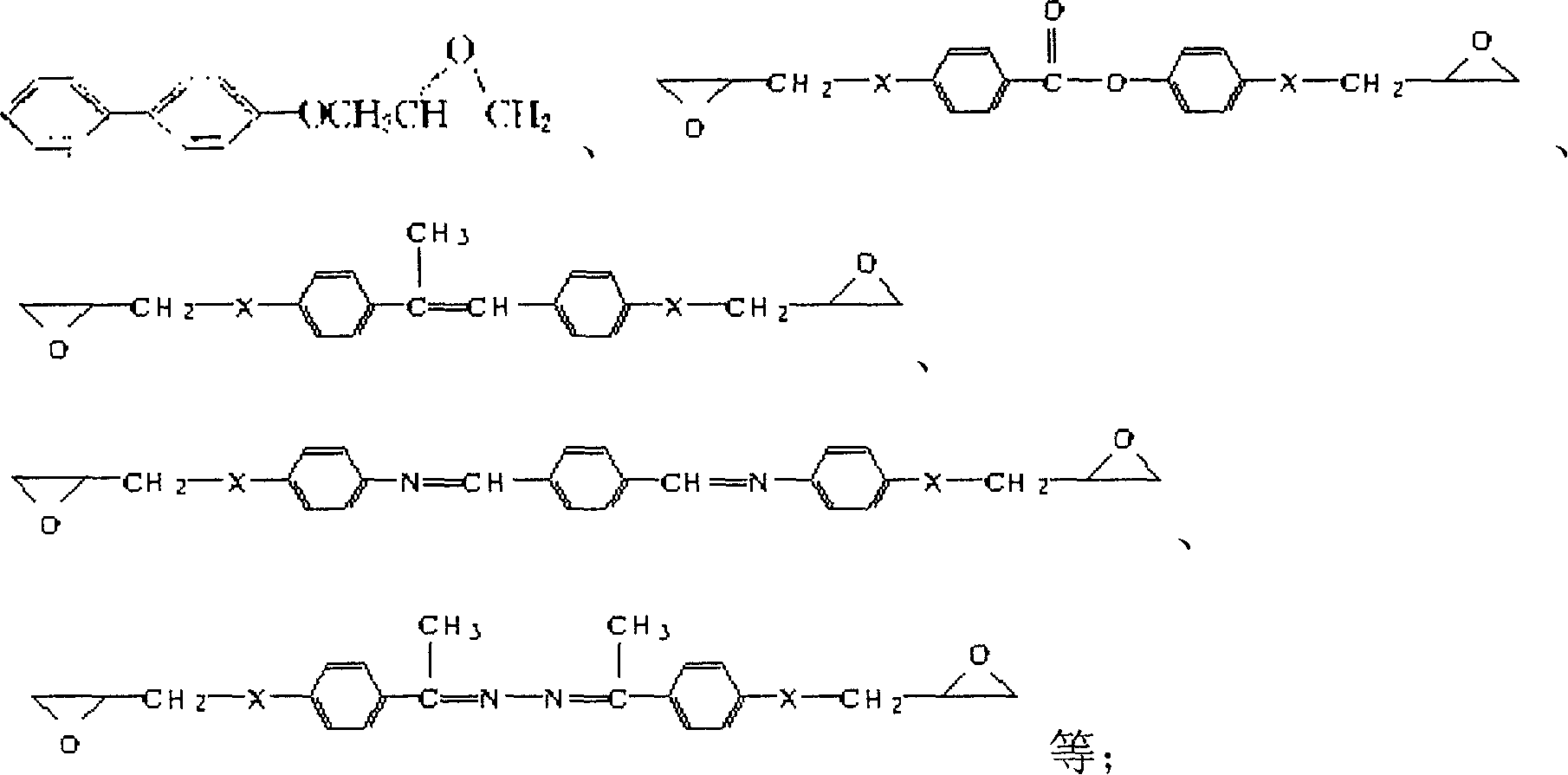

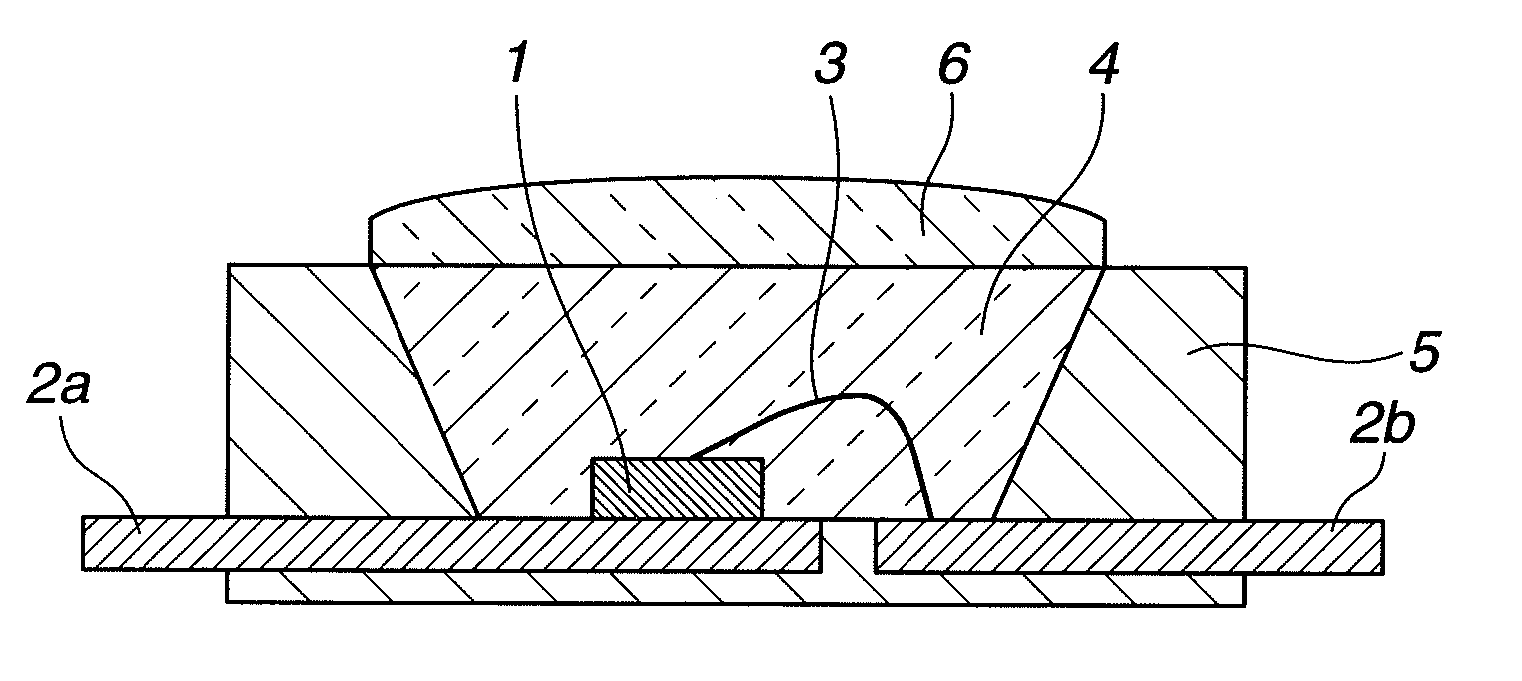

Epoxy-resin mould plastic for packing IC circuit and its production

InactiveCN101029165AHigh glass transition temperatureReduce melt viscositySemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal expansion

An epoxy resin mold plastic and its production are disclosed. The mold plastic consists of liquid-crystal epoxy resin, methyl-phenolic epoxy resin, epoxy resin containing biphenyl unit structure, melamine modified linear phenolic resin, silicone micro-powder, imidazo curing improver, toughening agent and silane coupling agent. The process is carried out by treating silicone micro-powder in mixer by coupling agent for 2-5mins, adding into other components, mixing for 3-5mins, melt milling at 95-135 degree for 3-5mins, cooling, crushing, mesh screening, pressing into material cake and storing below 6degree. Its advantages include low thermal expansion coefficient, excellent heat and fire resistances, better toughness and fluidity, no phosphor, no antimony and environmental pollution. It can be used to pack large-scale circuit and electronic devices.

Owner:GUANGDONG RONGTAI IND

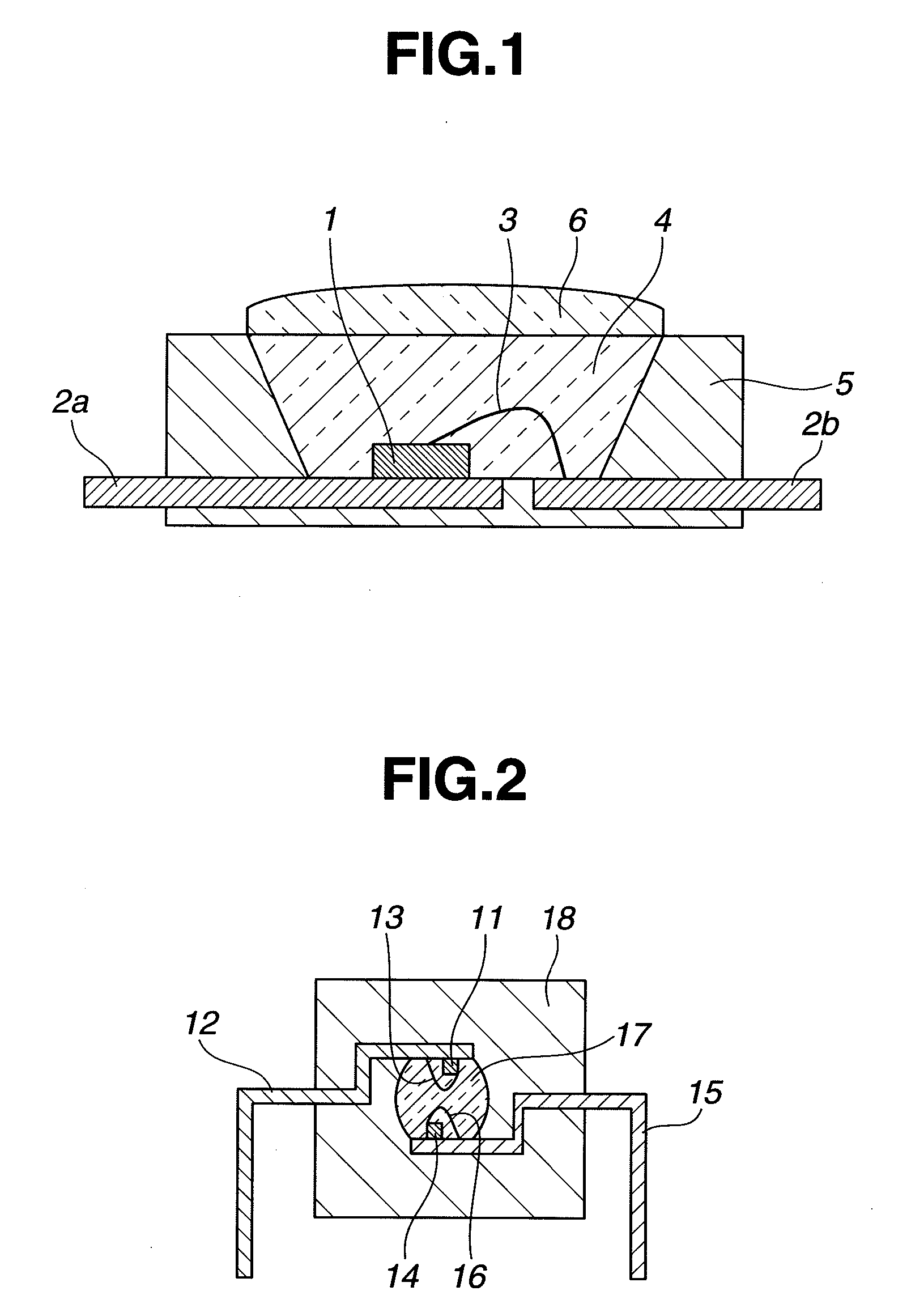

White heat-curable silicone/epoxy hybrid resin composition for optoelectronic use, making method, premolded package, and LED device

ActiveUS20110054072A1High strengthEffectively curableSolid-state devicesDyeing processEpoxyAntioxidant

A white heat-curable silicone / epoxy hybrid resin composition is provided comprising (A) a heat-curable silicone resin, (B) a triazine derived epoxy resin composition, (C) a white pigment, (D) an inorganic filler, and (E) an antioxidant. Antioxidant (E) is a phosphite compound having formula: P(OR1)(OR2)2 wherein R1 and R2 are organic groups of at least 6 carbon atoms. Components (A) and (B) are present in a weight ratio of from 5:95 to 95:5. The composition effectively cures into a product maintaining heat resistance, light resistance and improved strength over a long term.

Owner:SHIN ETSU CHEM IND CO LTD

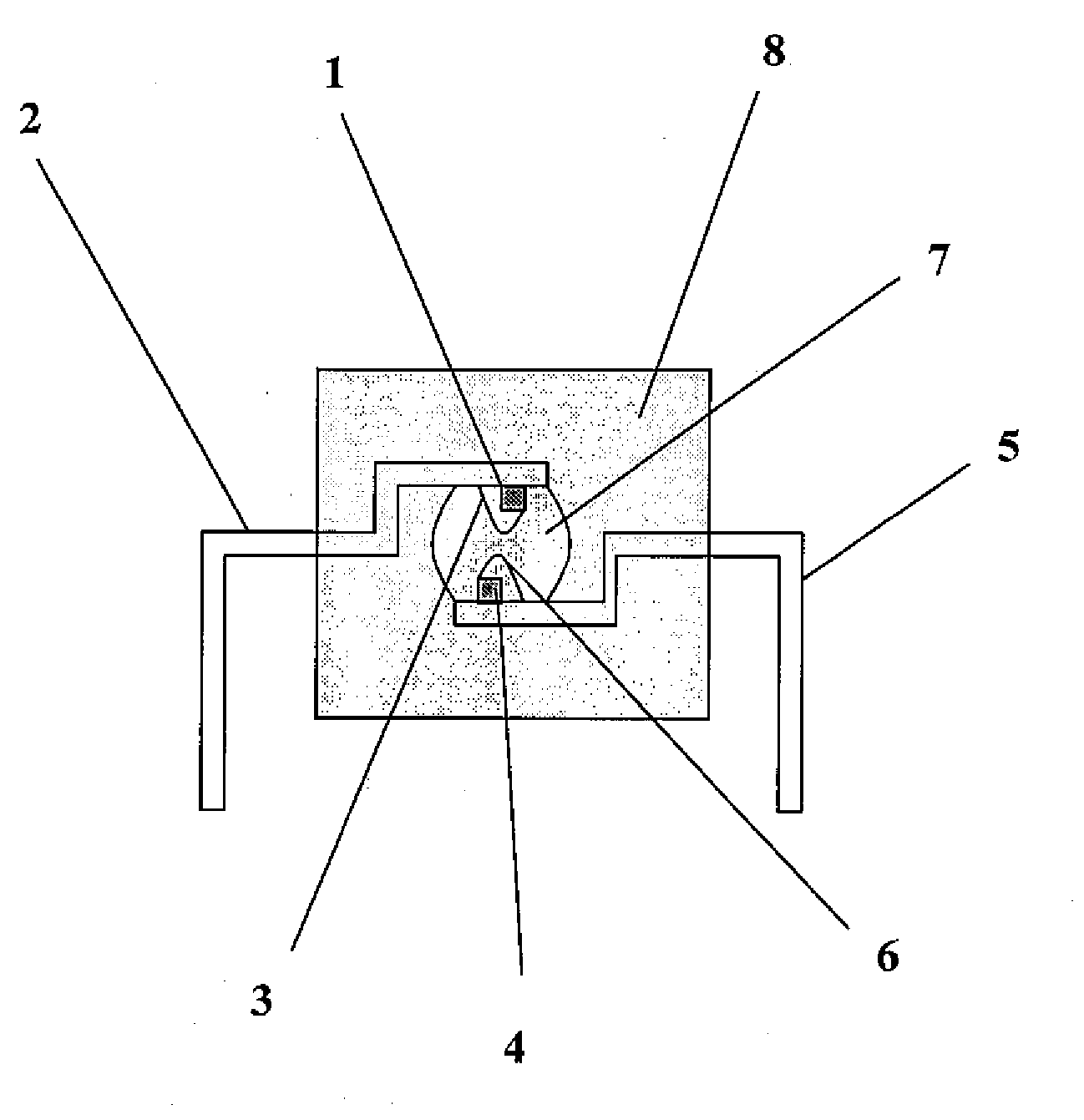

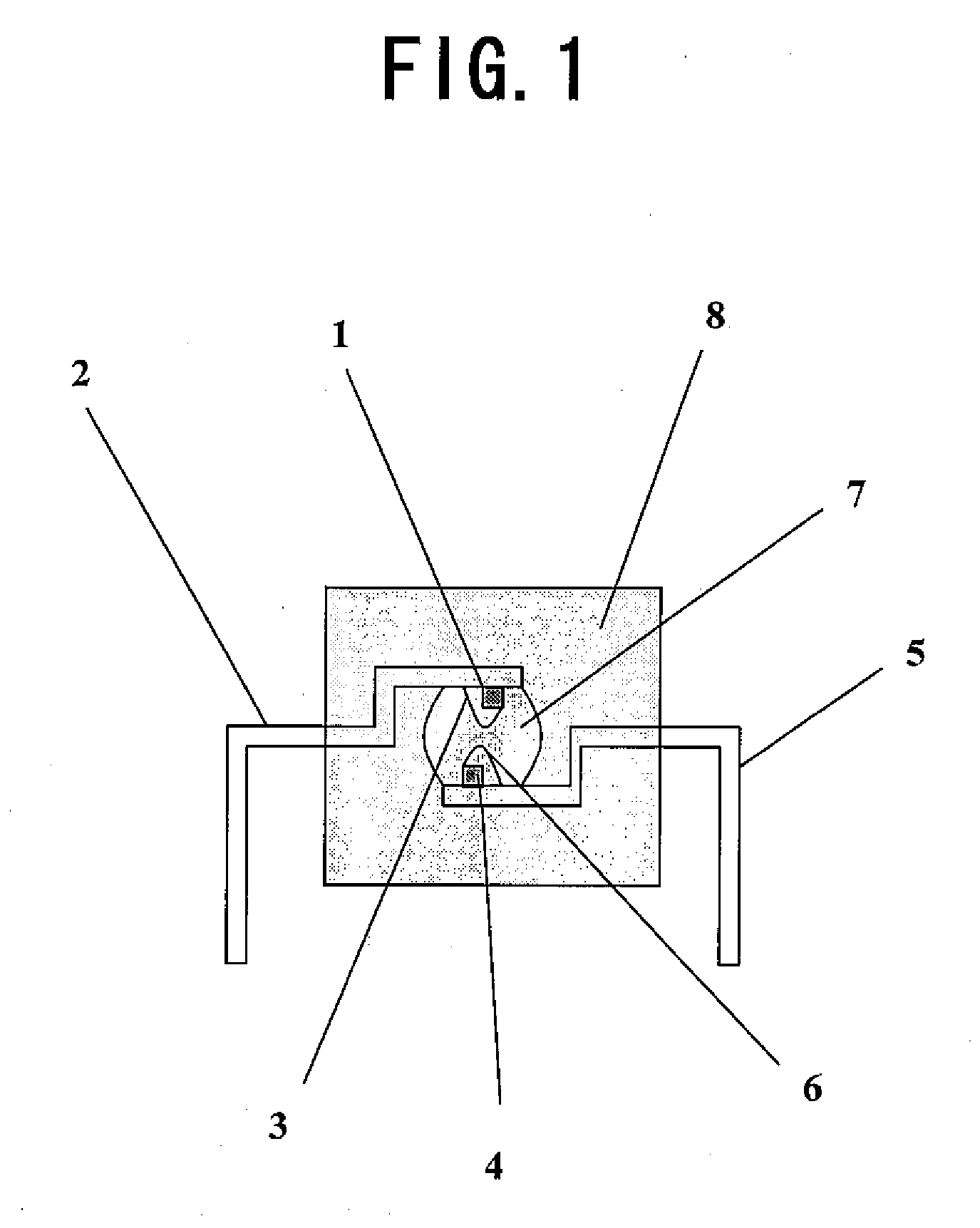

Thermosetting epoxy resin composition and semiconductor device

InactiveUS20080255283A1Minimal yellowingSatisfactory strengthSemiconductor/solid-state device detailsSynthetic resin layered productsDevice materialTriazine

A thermosetting epoxy resin composition is provided comprising (A) a reaction product obtained through reaction of a triazine derived epoxy resin with an acid anhydride, (C) a reflective agent, (D) an inorganic filler, and (E) a curing catalyst. In one embodiment, (B) an internal parting agent having a melting point of 50-90° C. is included. In another embodiment, (I) inorganic whisker fibers having an average fineness of 0.05-50 μm and an average length of 1.0-1,000 μm are included.

Owner:SHIN ETSU CHEM IND CO LTD

Polyester Resin Film and Process for Producing the Same

InactiveUS20080193783A1Maintain good propertiesImproved easy opening propertySynthetic resin layered productsCeramic shaping apparatusMolten stateHeat resistance

A polyester stretch film having good tear property and good twistability, which is useful as a packaging film or a film for tape, as well as for stick packaging, PTP packaging, drug bag, folding packaging, and lid material is provided without losing heat resistance, cold resistance, moisture-proof properties, transparency, aroma retention and the like. This polyester resin film is produced by a method that includes mixing not less than two kinds of polyester resin starting materials having different melting points and extruding the mixture. The respective starting materials are cast in different extruders, melted, supplied to one mixer in a molten state, mixed and extruded to give a sheet, and the sheet is stretched at least in the monoaxial direction and heat-treated at a temperature of not lower than 3° C. lower than the melting point of the resin starting material having the lowest melting point.

Owner:TOYO TOYOBO CO LTD

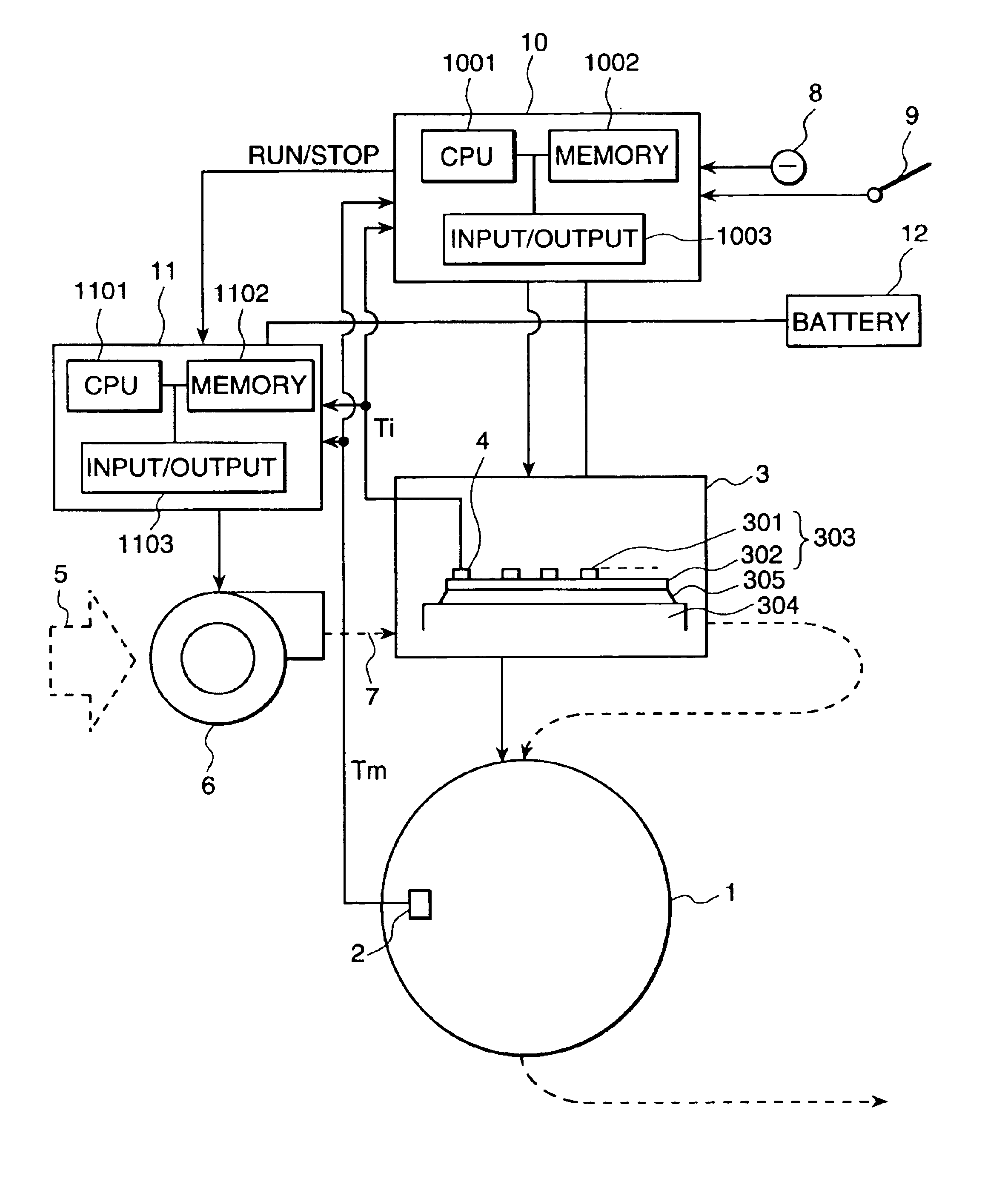

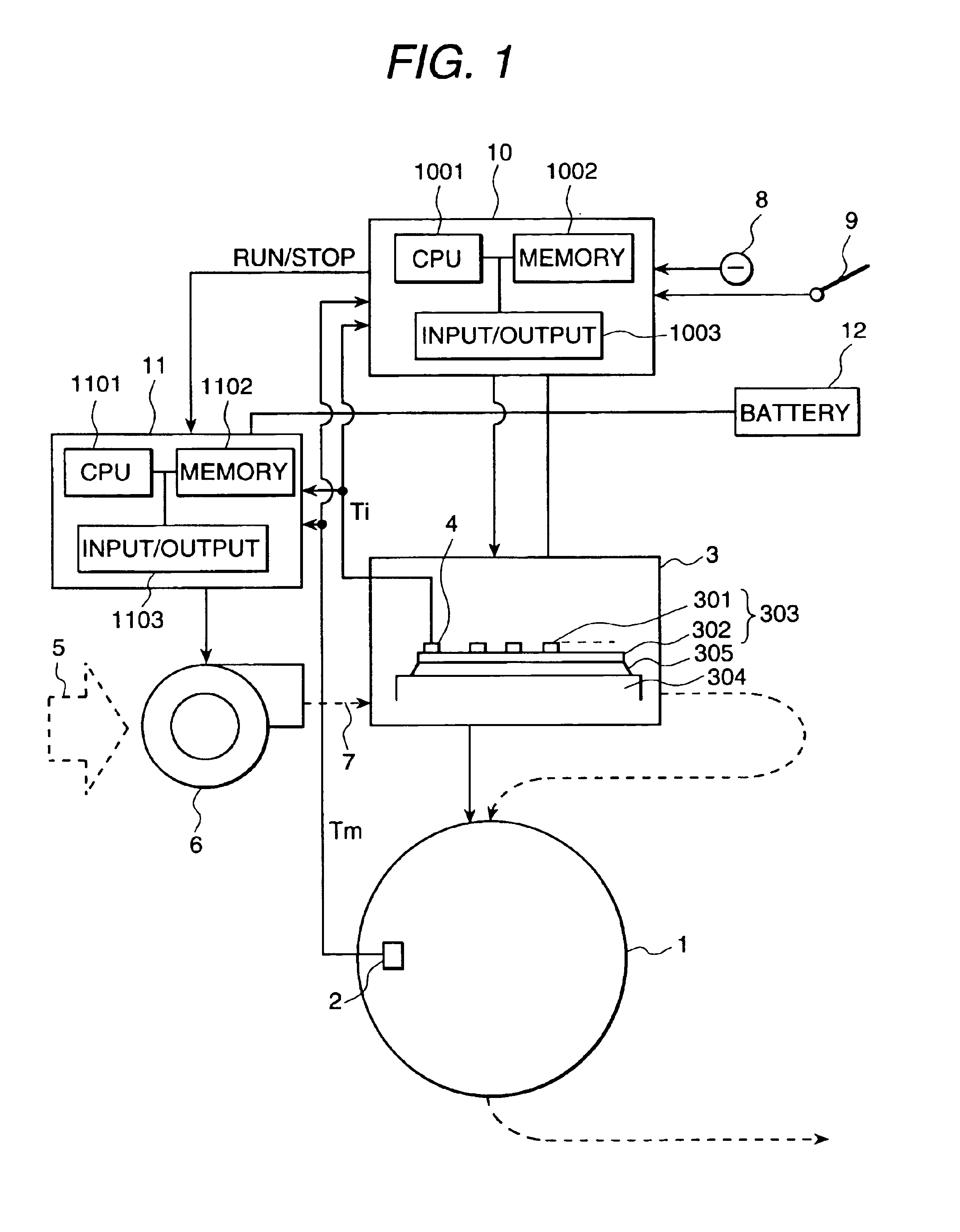

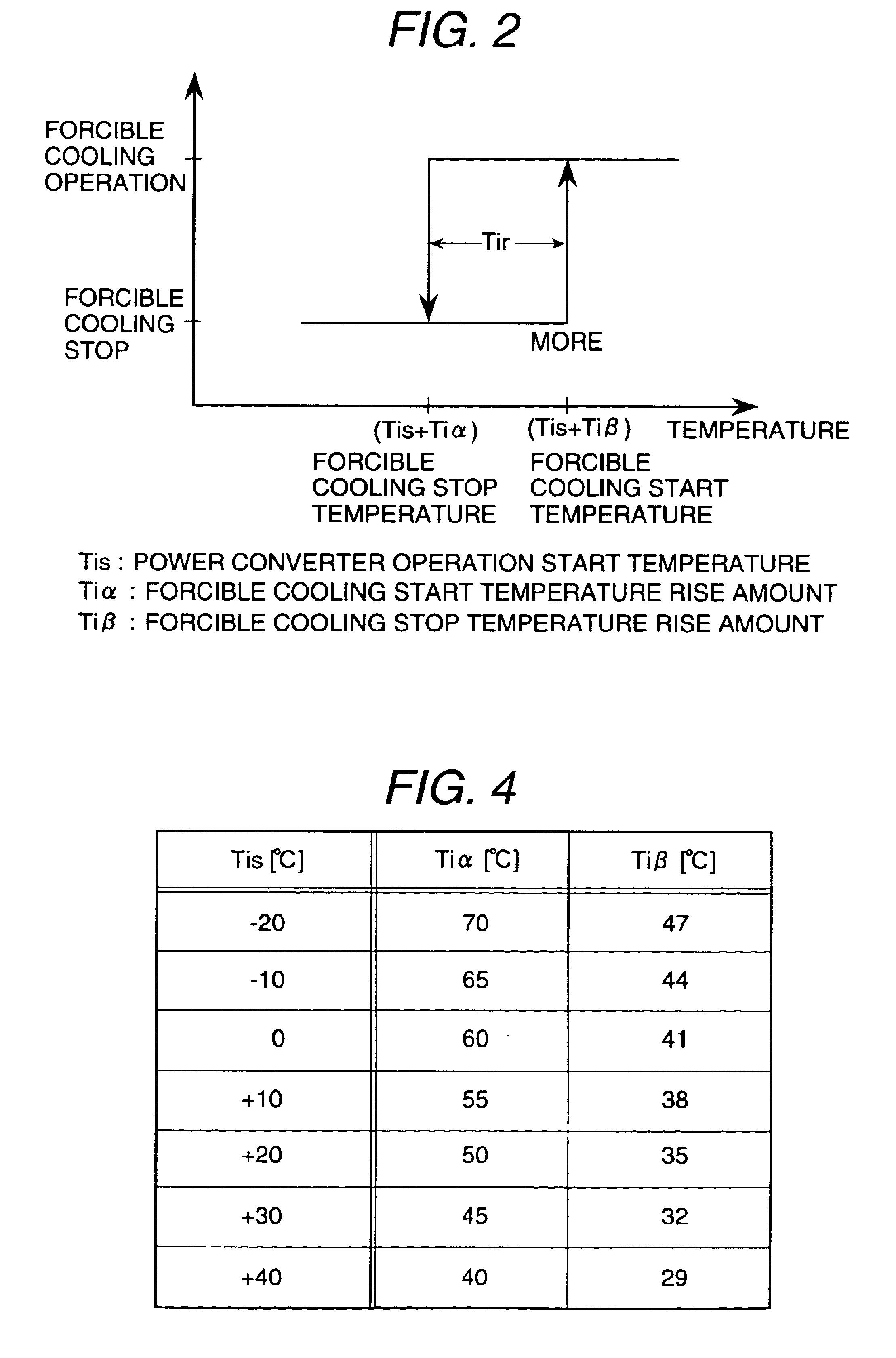

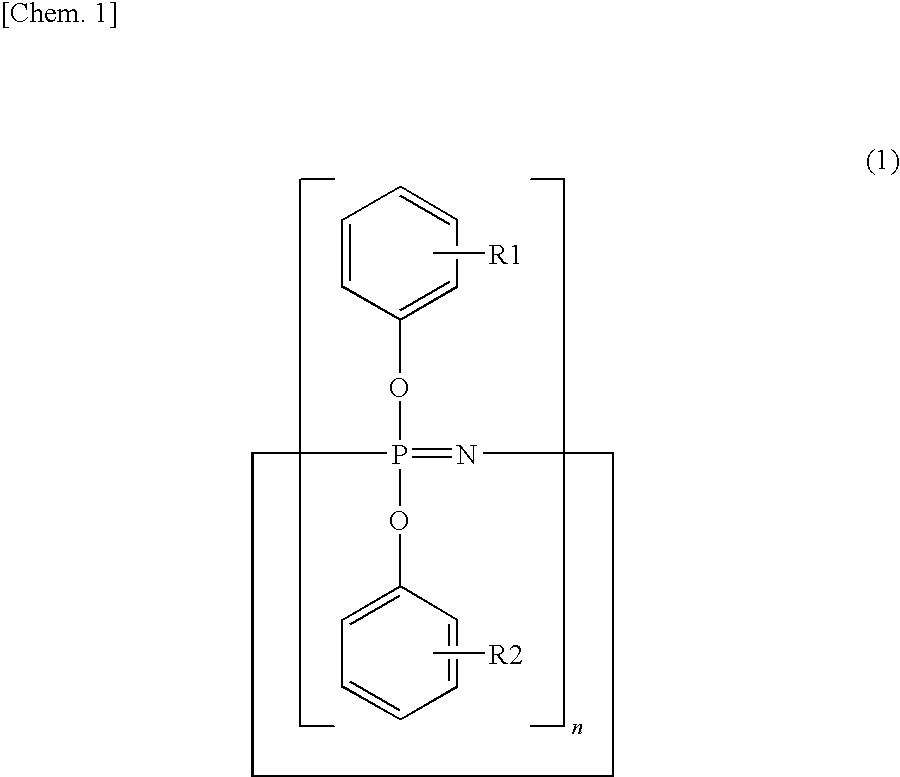

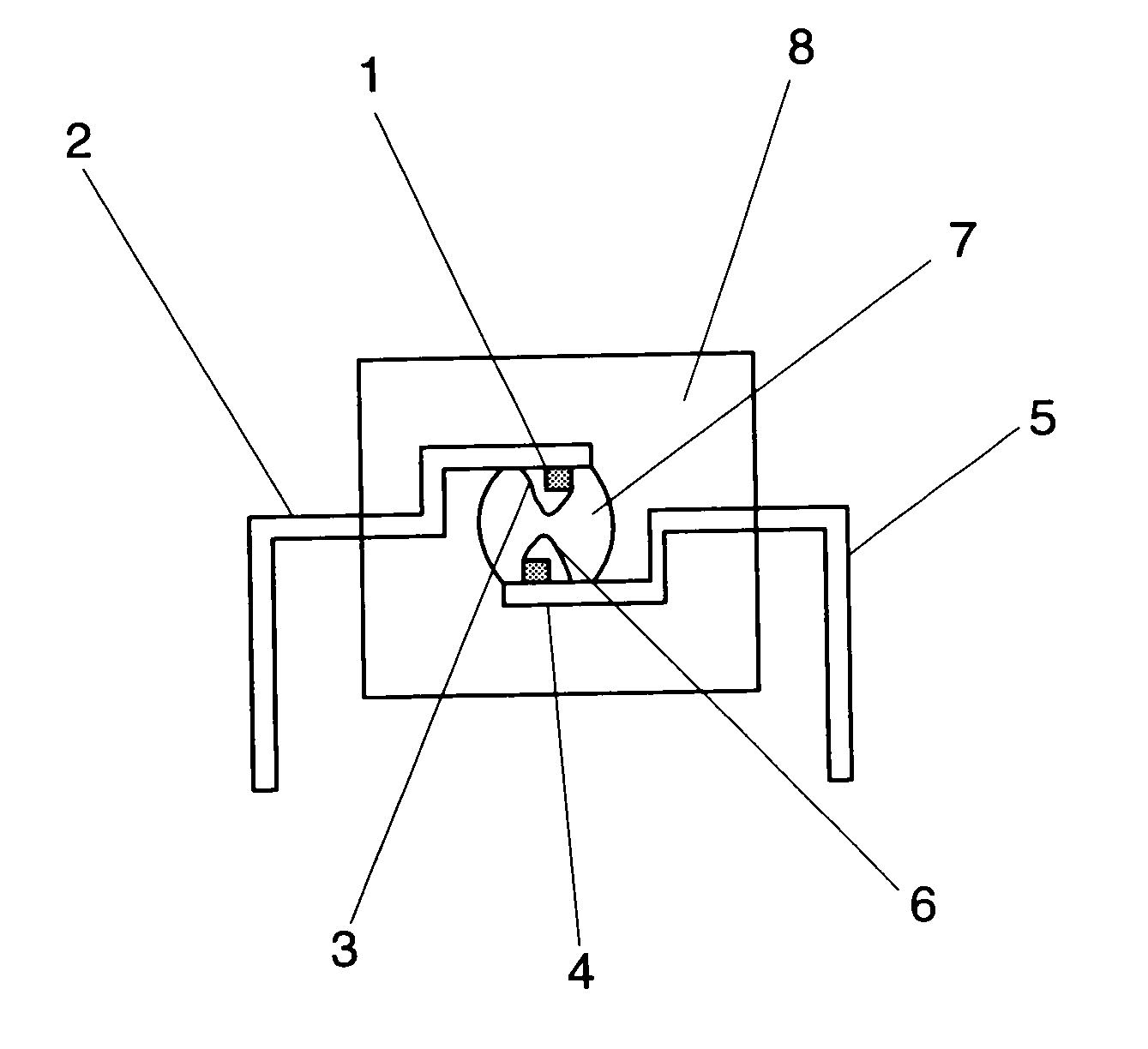

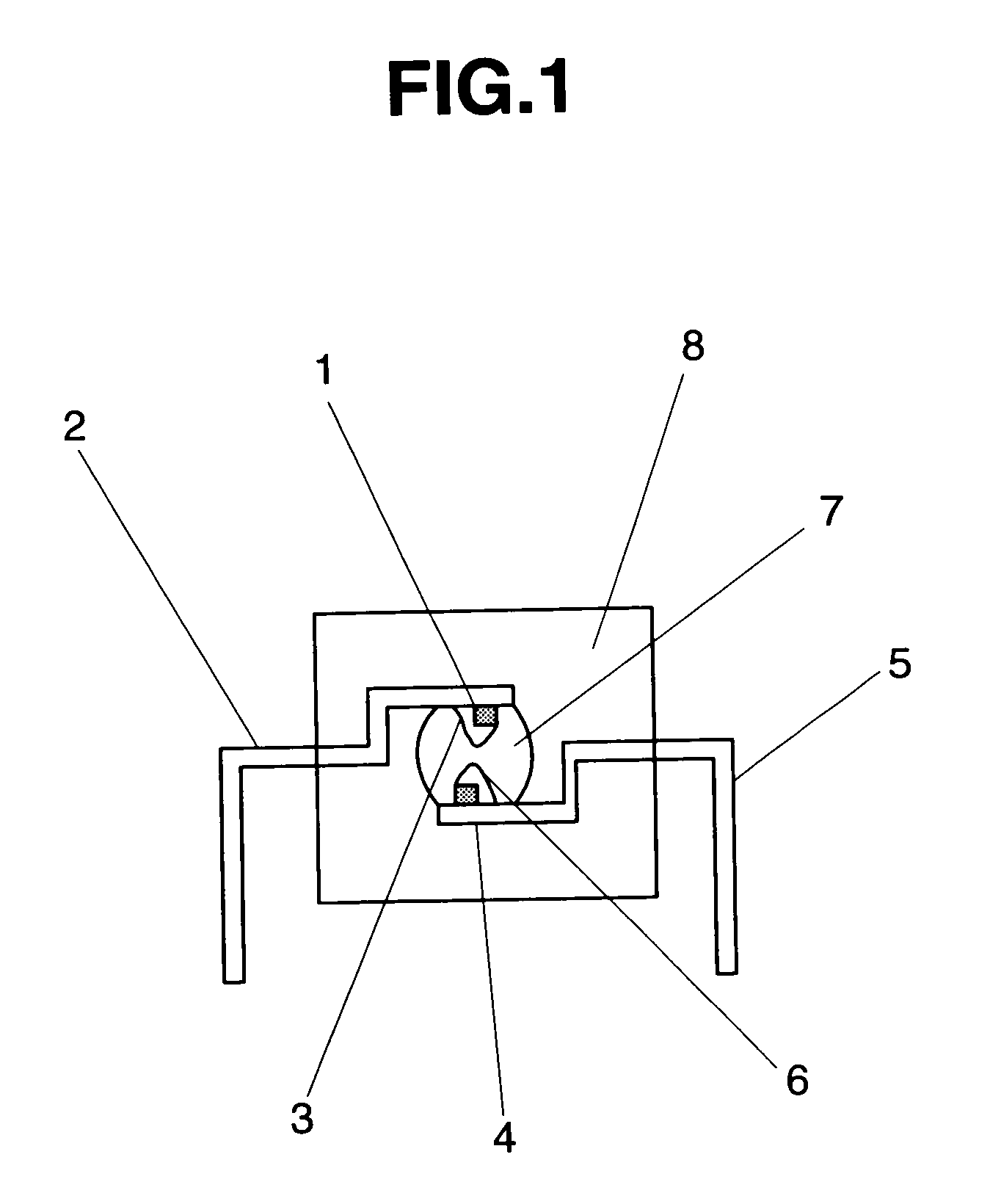

Cooling system for motor and cooling control method

InactiveUS6889516B2Avoid stress failureMaintain heat resistanceCompressorLiquid coolingThermal fatigueControl theory

A cooling system for a motor is prevented from exhibiting a thermal fatigue failure due to a temperature cycle. The operation or stopping of the cooling motor fan 6 of the forced cooling system is controlled using the difference between the temperature thereof and the operation start temperature Tis of the power converter 3. Thus expansion of the temperature range is suppressed.

Owner:HITACHI LTD

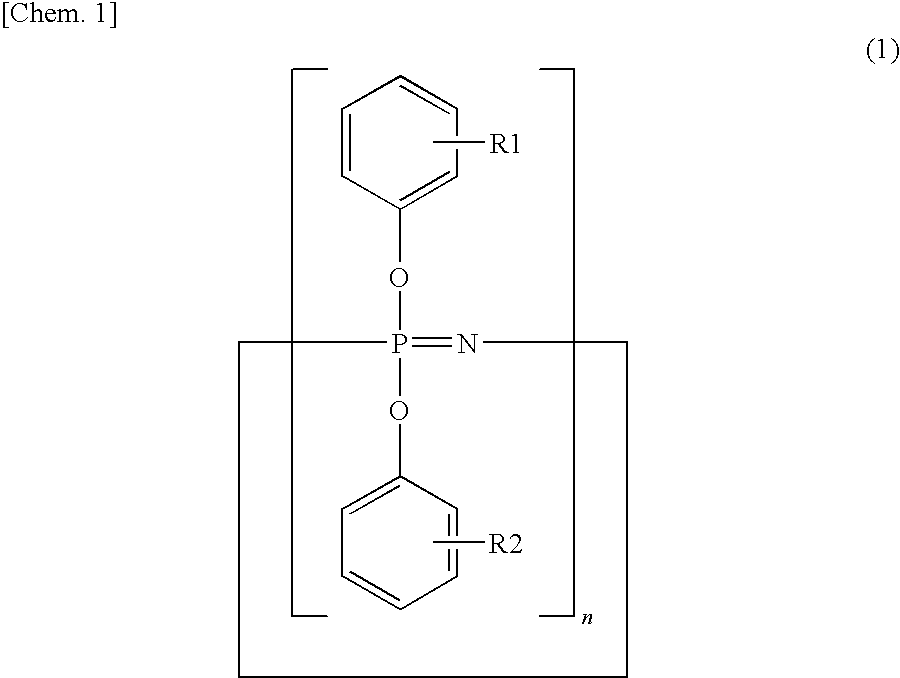

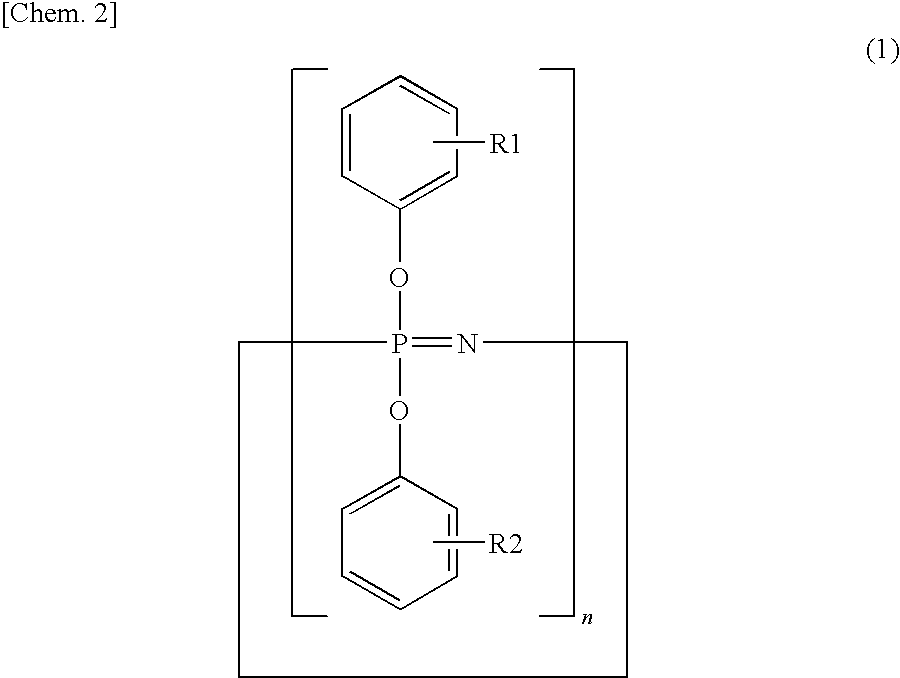

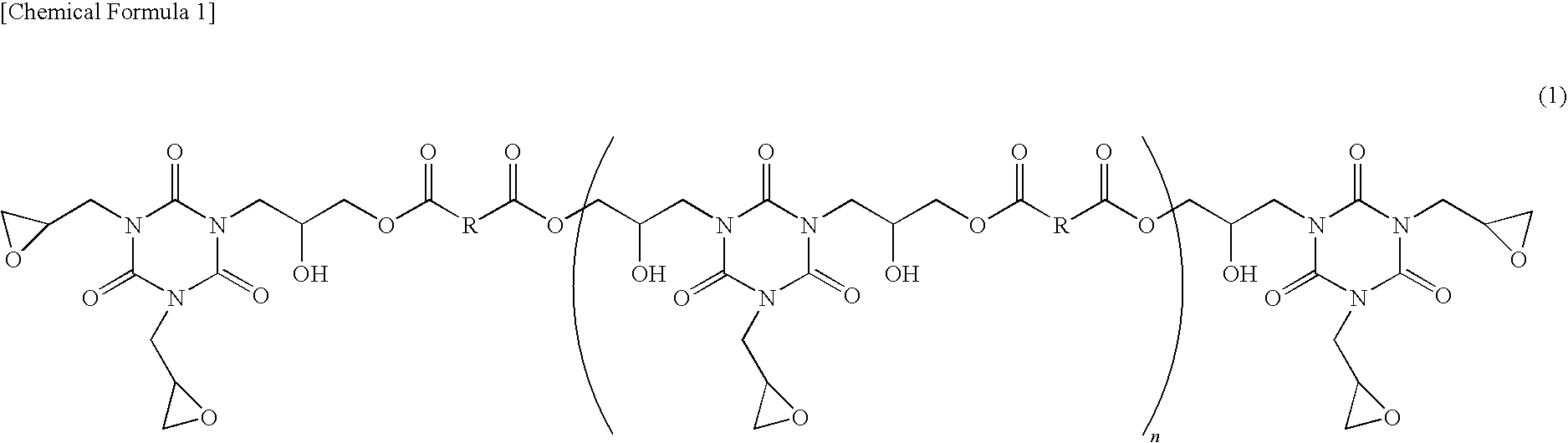

Flame-retardant resin composition, and prepreg, resin sheet and molded article using the same

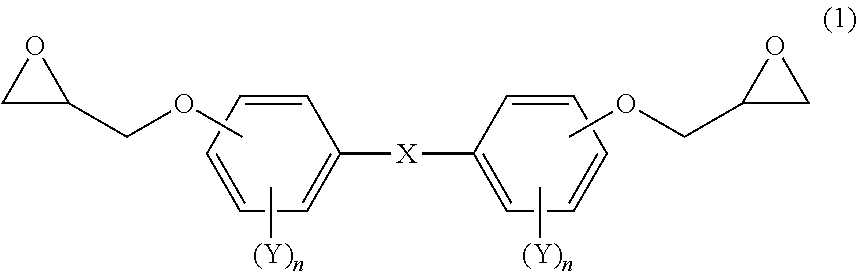

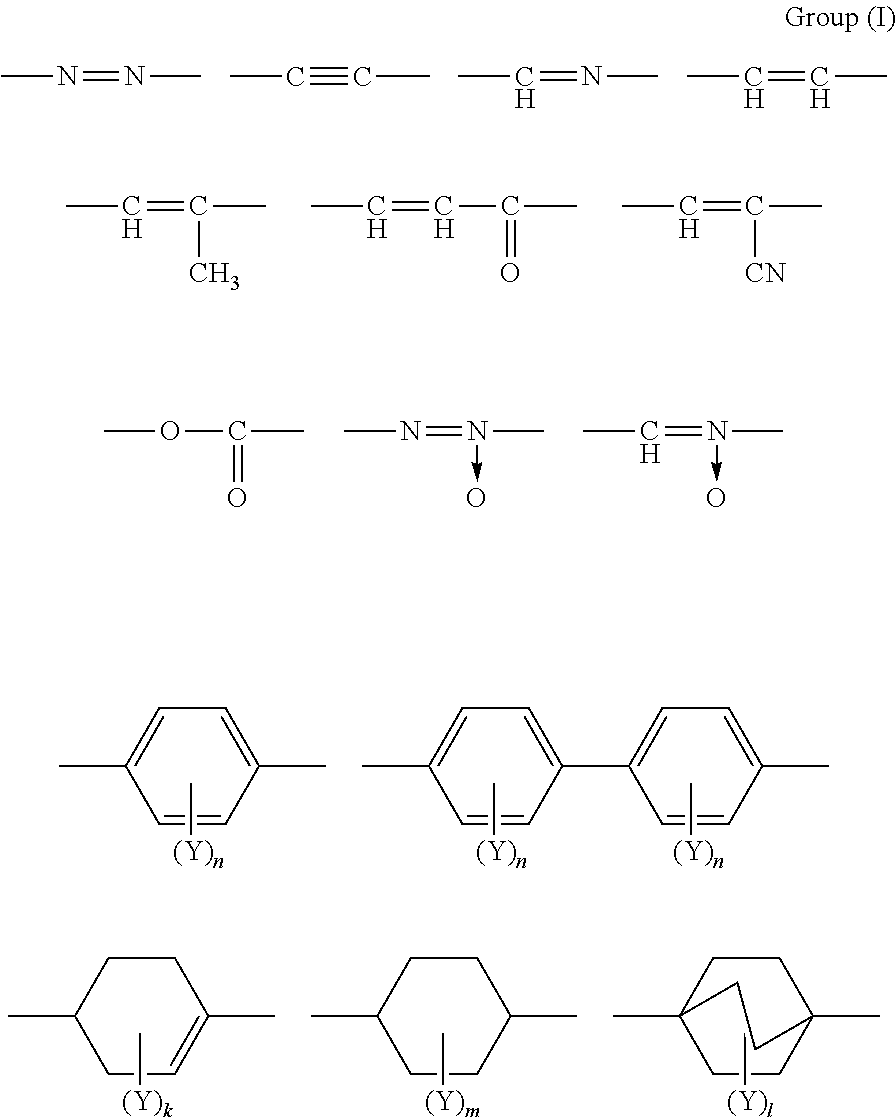

InactiveUS20100233486A1Maintain heat resistanceLow dielectric constantSynthetic resin layered productsPrinted circuit aspectsEpoxyHalogen

There is provided a flame-retardant resin composition which can maintain heat resistance at a high level and simultaneously provide low dielectric constant and low dielectric loss tangent while ensuring flame-retardancy without containing any halogen compound causing the generation of harmful substances. This flame-retardant resin composition comprises 0.1 to 200 parts by mass of a cyclophosphazene compound represented by the following formula (1):wherein n=3 to 25; and one of R1 and R2 is CN and the other is H, or both of R1 and R2 are CN, based on 100 parts by mass of a resin component containing a polyfunctional epoxy resin having a biphenyl aralkyl structure, wherein the ratio of cyanophenoxy groups in the compound is 2 to 98% of the total number of phenoxy groups and cyanophenoxy groups in the compound.

Owner:PANASONIC CORP

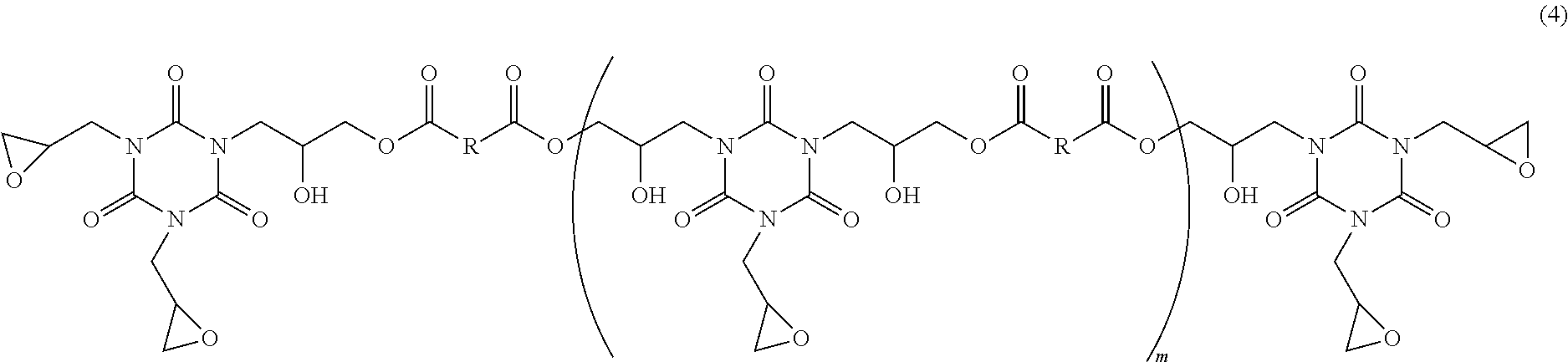

Thermosetting epoxy resin composition and semiconductor device

InactiveUS20100104794A1Satisfaction intensityMaintain heat resistanceLayered productsSemiconductor/solid-state device detailsPolymer chemistryTriazine derivative

A thermosetting epoxy resin composition characterized by containing as a resin ingredient a product of pulverization of a solid matter obtained by reacting a triazine derivative / epoxy resin with an acid anhydride in such a proportion that the amount of the epoxy groups is 0.6-2.0 equivalents to the acid anhydride groups.

Owner:SHIN ETSU CHEM IND CO LTD

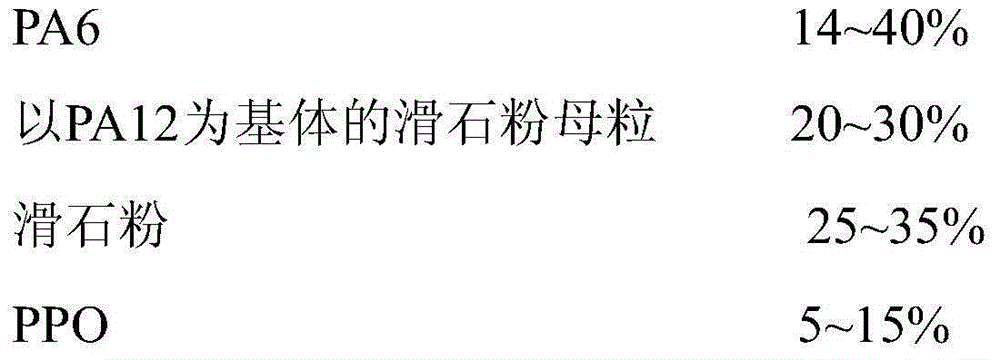

Low-shrinkage low water absorption nylon 6 composite material and preparation and application thereof

The invention discloses a low-shrinkage low water absorption nylon 6 composite material and preparation and application thereof. The nylon 6 composite material is prepared from 14-40% of nylon 6, 20-30% of talcum powder masterbatch taking PA12 as a matrix, 25-35% of talcum powder, 5-15% of polyphenyl ether, 2-4% of compatilizer and 2-8% of flexibilizer. The preparation method of the low-shrinkage low water absorption nylon 6 composite material comprises the steps that talcum powder masterbatch is prepared; the prepared talcum powder masterbatch, the nylon 6, the polyphenyl ether, the talcum powder, the compatilizer and the flexibilizer are mixed together, and the low-shrinkage low water absorption nylon 6 composite material is prepared. According to the low-shrinkage low water absorption nylon 6 composite material and the preparation and application thereof, part talcum powder filling adopts a masterbatch form to add, dust pollution is reduced, and high filling of high mesh talcum powder in the nylon 6 is achieved; meanwhile, the polyphenyl ether is added, and the low shrinkage and the low water absorption of the nylon 6 are further reduced. According to the low-shrinkage low water absorption nylon 6 composite material and the preparation and application thereof, the technique is simple, the processing performance is good, and the prepared nylon sis has excellent low shrinkage and excellent low water absorption.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

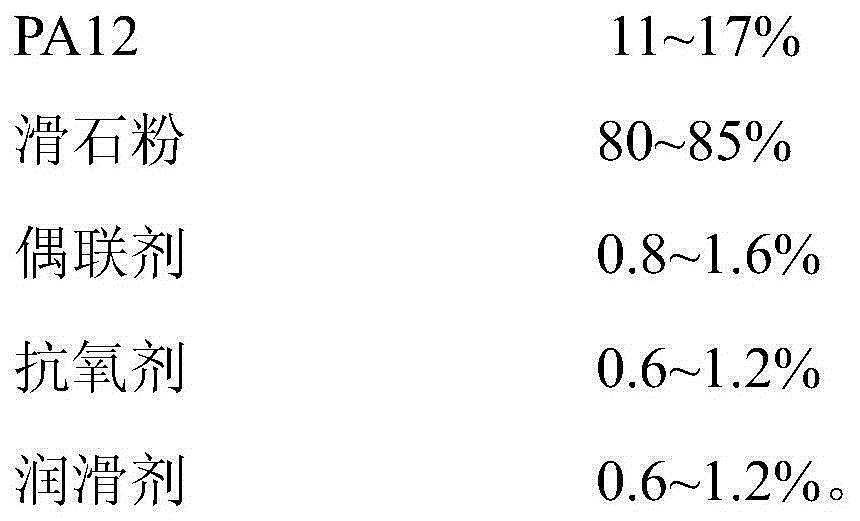

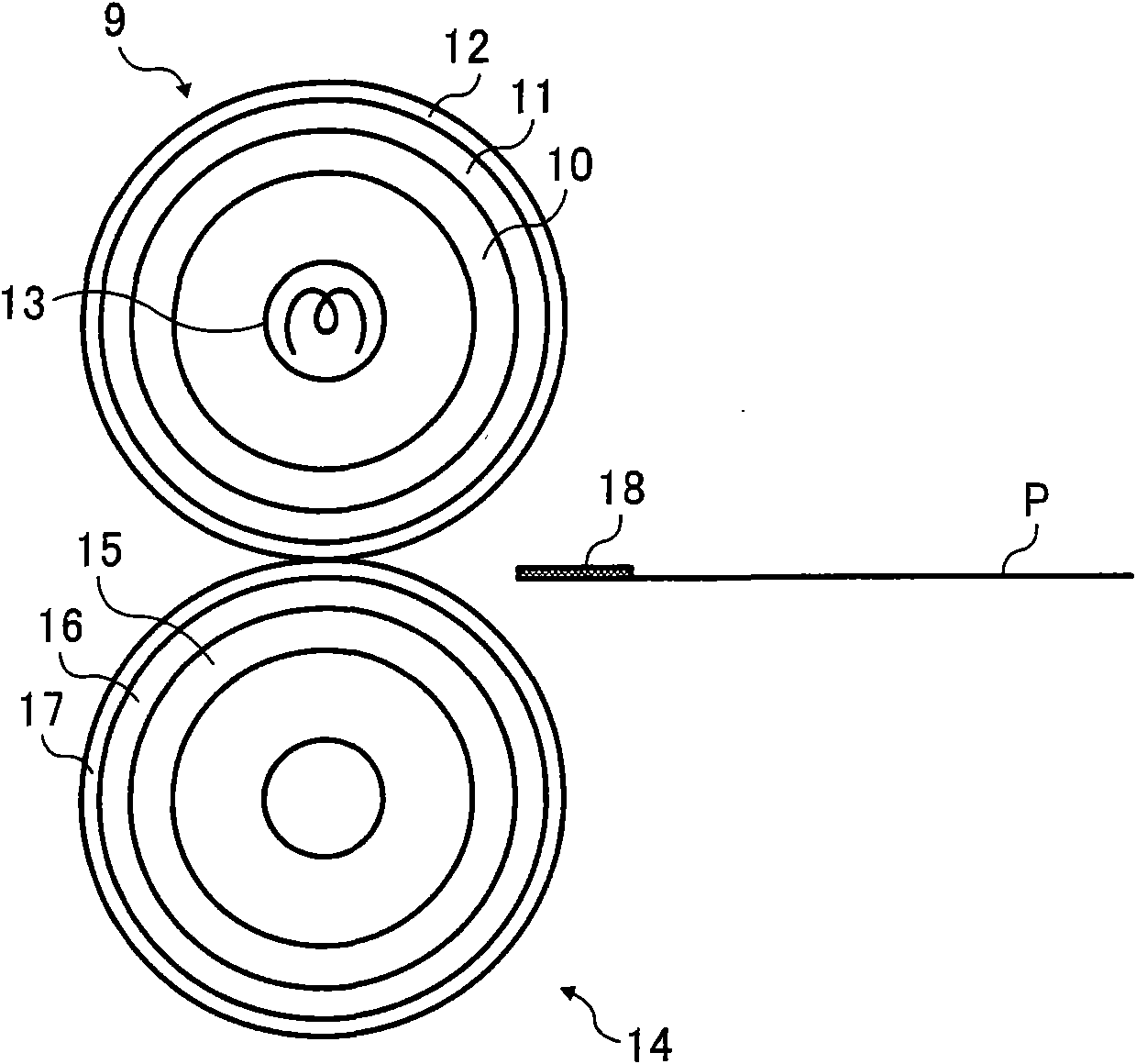

Toner, method of manufacturing the same, image forming apparatus and image forming method

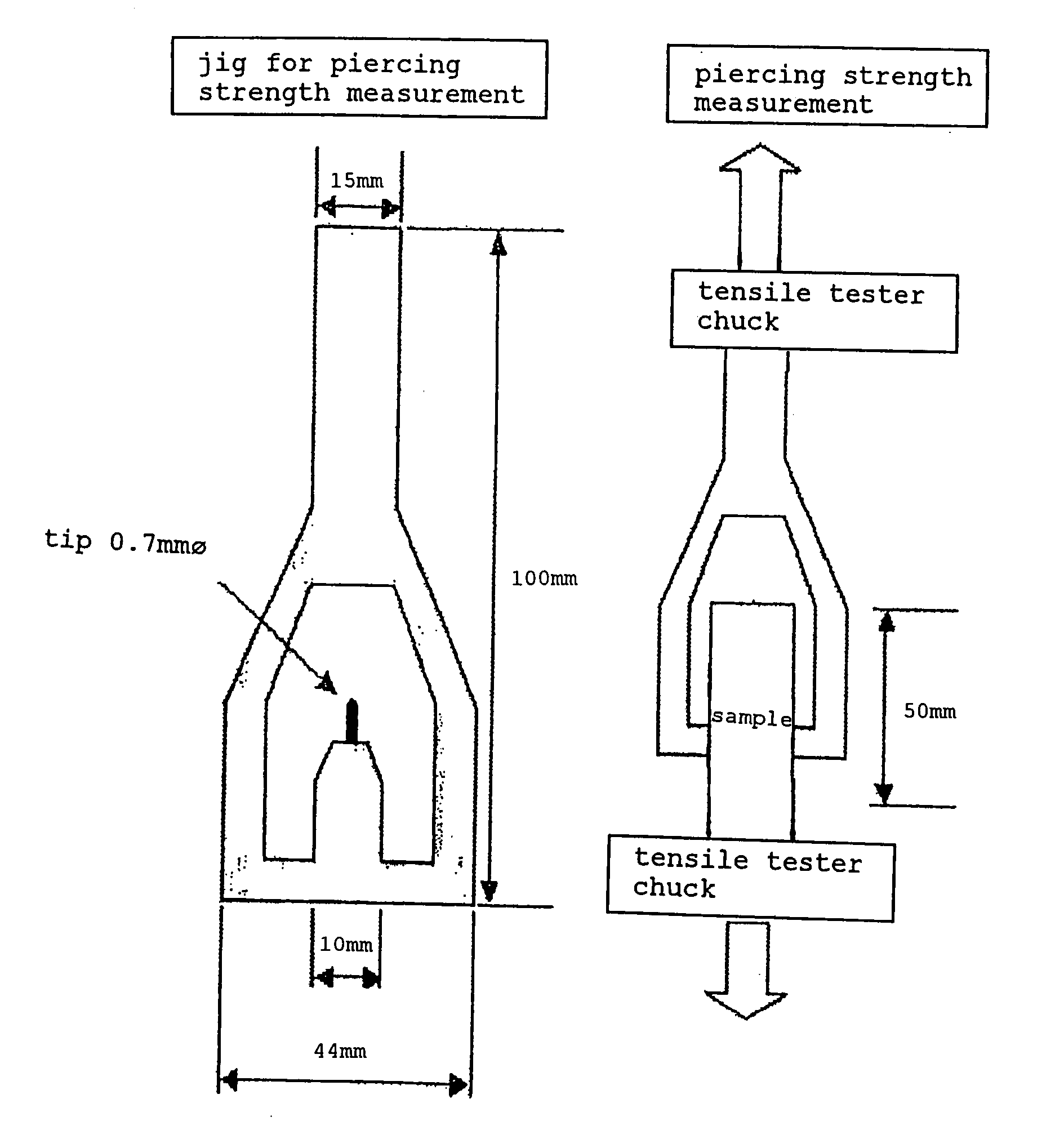

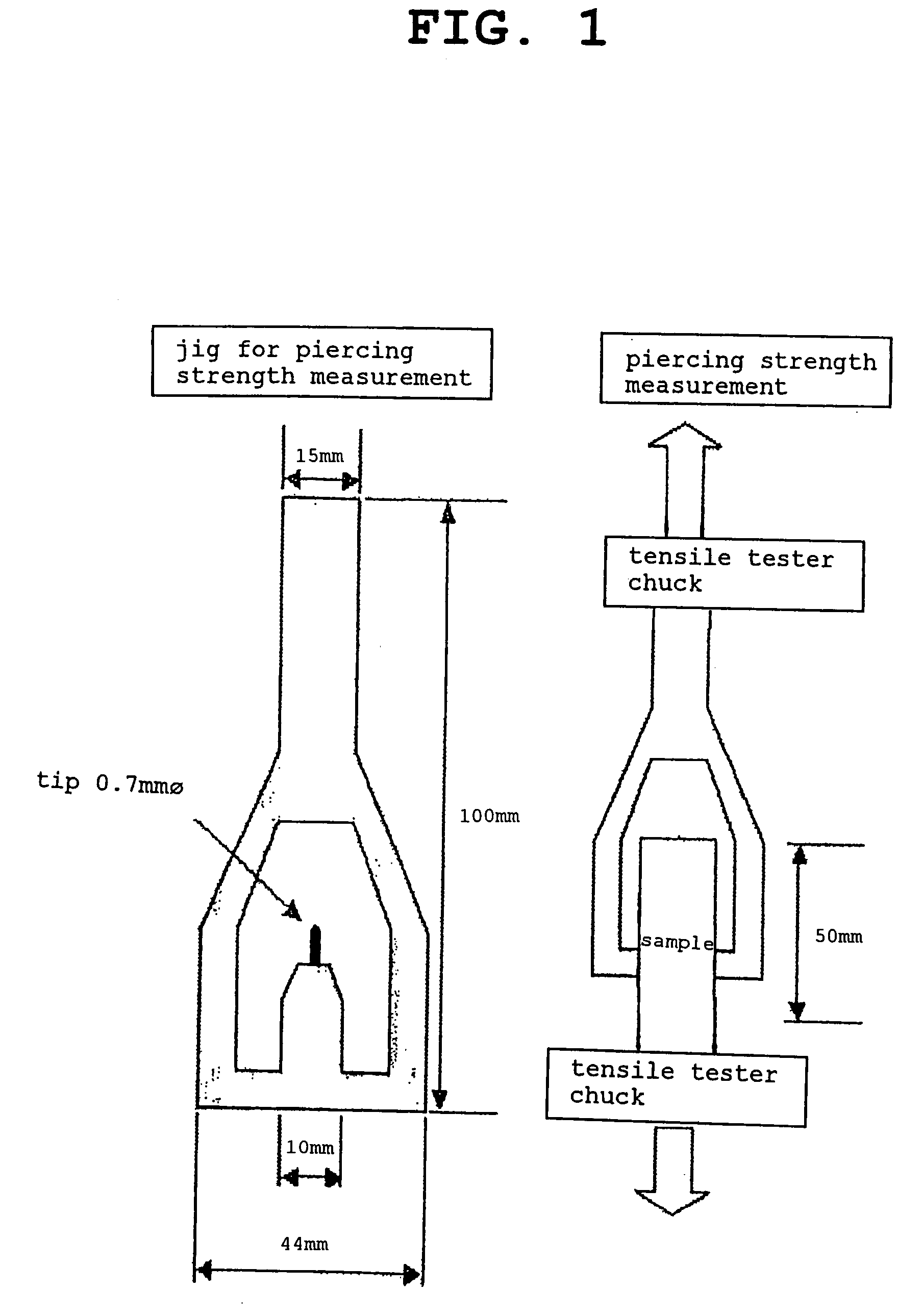

InactiveCN101840169AGood fixabilityImprove heat resistanceElectrographic process apparatusDevelopersPolyesterMeasuring instrument

The present invention relates to a toner, a method of manufacturing the same, an image forming apparatus and an image forming method. The aim of the invention is to provide the toner with the advantages of good environment stability, good uniformity on chargeability, and a good balance between the fixing property and the heat resistance. The toner of the invention has a structure of core and contains at least two kinds of resins having a polyester skeleton and a releasing agent. The invention is characterized in that no peak that derives from magnesium, calcium, or aluminum in the mother toner particle is observed in a qualitative analysis using an X-ray fluorescence measuring instrument. Preferably the core particle which forms the structure of core comprises a first resin having a first polyester skeleton, and the core material which covers the core particle contains a second resin that is different from the first resin and has a second polyester skeleton.

Owner:RICOH KK

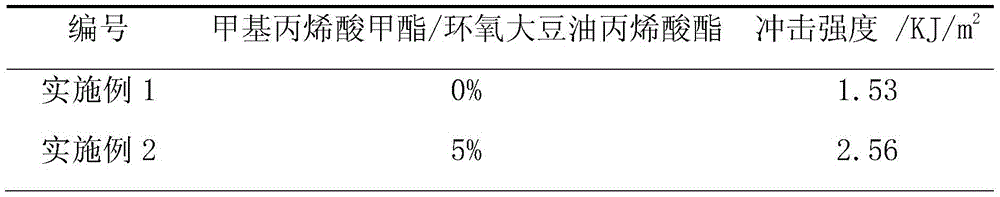

Preparation method of epoxidized soybean oil modified PMMA (polymethylmethacrylate)

The invention relates to a preparation method of epoxidized soybean oil modified PMMA (polymethylmethacrylate). Epoxidized soybean oil acrylate is firstly synthesized, then, epoxidized soybean oil acrylate and methyl methacrylate are polymerized, and modified methyl methacrylate is obtained. The preparation method has the benefits as follows: (methyl) acrylate epoxidized soybean oil serving as a modified comonomer can remarkably improve the impact strength of organic glass under the condition that little (methyl) acrylate epoxidized soybean oil is used, and the transparency and the heat resistance of PMMA are kept.

Owner:CHANGZHOU UNIV

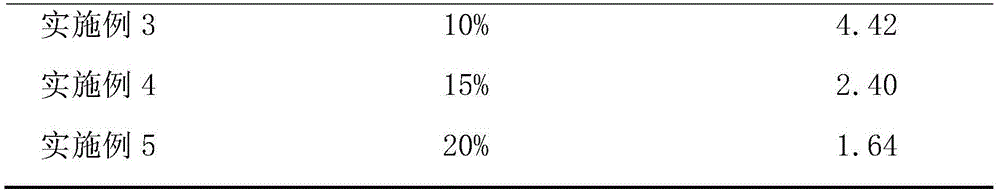

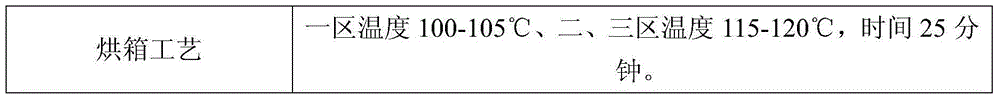

Colored polyester concentric sheath-core composite fiber and manufacturing method thereof

ActiveCN104532399AGuaranteed chemical stabilityMaintain gas barrier propertiesMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention provides a colored PEN / PET concentric sheath-core composite fiber. The sheath layer comprises a colored master batch and PEN, wherein the weight ratio of the colored master batch to the PEN is 5-15:95-85, and the colored master batch comprises colored powder and PEN, and the weight ratio of the colored powder to the PEN is 25-35:75-65. The core layer comprises PET. The weight ratio of the sheath layer components to the core layer component is 15-25:85-75. The defect that PEN fiber forming and dyeing are difficult is overcome, and the fiber keeps the unique chemical stability, gas barrier property, flame retardance, heat resistance and the like of the PEN fiber. The PET economical efficiency and favorable PEN fiber properties are organically combined, the PEN using cost is greatly reduced, the application range of the PEN in the fiber field is enlarged, and meanwhile the application range of the PET fiber in the industrial field can be broadened further.

Owner:SHANGHAI DEFULUN CHEM FIBER

Gas-shielded flux-cored wire for welding of SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device

ActiveCN107971657AAdjust the melting pointAdjustable viscosityArc welding apparatusWelding/cutting media/materialsManganeseSodium titanate

The invention discloses a gas-shielded flux-cored wire for welding of a SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device and the preparation method thereof. The as-shielded flux-cored wire comprises a steel strip and a flux core wrapped in the steel strip, and the flux core comprises the following components of, by weight, 4.25-5.85 parts of natural rutile, 0.8-1.9 parts of quartz sand, 0.7-1.8 parts of sodium titanate, 0.25-0.3 part of sodium fluoride, 0.125-0.275 part of calcined alpha alumina, 0. 27wt% of calcined alpha aluminaand 0.025-0.15 part of nitrogen-containing ferrochromium, 0.085-0.05 part of spray silicon iron, 1.05-1.45 parts of electrolytic manganese, 3.6-4.85 parts of metal chromium, 6.42-6.85 parts of atomized iron powder, 1. 9-2.5 parts of nickel powder, and 1.0-1.35 parts of molybdenum. The gas-shielded flux-cored wire has the advantages that efficient semi-automatic and automatic welding technologies are achieved, the welding efficiency is high, splashing is low, the appearance is attractive, the welding current is wide, and the voltage adaptability strong.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Aging-resistant PPO (Polyphenylene Oxide) - PPS (Polyphenylene Sulfite) plastic alloy

The invention discloses an aging-resistant PPO-PPS plastic alloy, which is composed of the following components in weight part: 100 parts of PPO, 40-60 parts of PPS, 4-8 parts of compatibilizer and 0.5-1.5 parts of age resister. The aging-resistant PPO-PPS plastic alloy disclosed by the invention is an alloy material with excellent overall performances, mostly retains the advantages of PPS in respects of mechanical property, thermal tolerance, flame retardance and the like, and integrates excellent electrical performances of PPO. The aging-resistant PPO-PPS plastic alloy is suitable for fields of electric appliances such as thermotolerant breaker frameworks and electric appliance connectors.

Owner:浙江丞达新材料科技有限公司

Flame-retardant polyethylene terephthalate resin composition

A flame-retardant polyethylene terephthalate resin composition which comprises A 100 parts by weight of a polyethylene terephthalate resin, B 5 to 60 parts by weight of a bromine compound flame retardant having a 5 wt.% heating loss temperature of 360 DEG C or higher as measured in a nitrogen stream at a heating rate of 10 DEG C / min, C 0.01 to 20 parts by weight of a crystallization accelerator, D 0.01 to 20 parts by weight of a colorant, and E 0.01 to 5 parts by weight of an antioxidant. The resin composition has high resistance to thermal discoloration. When heated at 210 DEG C for 24 hours, the composition has a color difference DELTAE of 15 or less. The resin composition may contain an antimony compound flame retardant aid and / or an inorganic filler. The resin composition can be effectively inhibited from changing in color and can combine mechanical properties with resistance to thermal discoloration.

Owner:WIN TECH POLYMER LTD

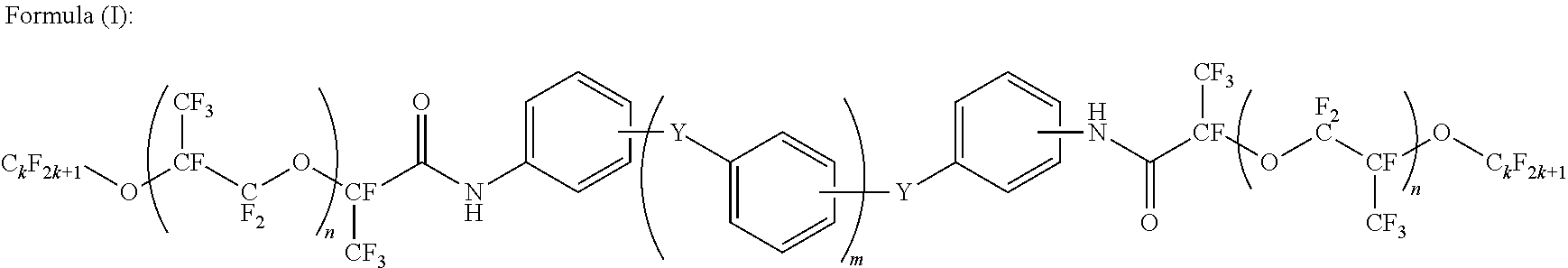

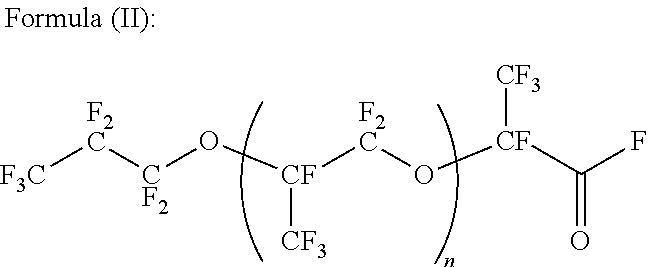

Hydrophilic modification method of polytetrafluoroethylene porous membrane

ActiveCN103483618AGood compatibilityImprove the effect of hydrophilic treatmentTetrafluoroethylenePolyol

The invention relates to a hydrophilic modification method of a polytetrafluoroethylene porous membrane. The method comprises the following steps: infiltrating the polytetrafluoroethylene porous membrane by using a fluorine-containing polyether polyol solution, polymerizing with polyisocyanate on the polytetrafluoroethylene porous membrane to generate a hydrophilic crosslinked-network polyurethane polymer in order to prepare a hydrophilic polytetrafluoroethylene porous membrane. The fluorine-containing polyether polyol is used to prepare polyurethane in order to process the polytetrafluoroethylene porous membrane in the invention, so the compatibility between polyurethane macromolecules and the polytetrafluoroethylene membrane is improved, and the hydrophilic processing effect is improved; the crosslinked-network polymer can be formed through solidification, so the hydrophilic effect endurance of the polytetrafluoroethylene porous membrane can be maintained; and the method is simple and easy to implement, and can maintain the acid resistance, the alkali resistance, the oxidation resistance and the heat resistance of the polytetrafluoroethylene membrane.

Owner:南京三生境新材料科技有限公司

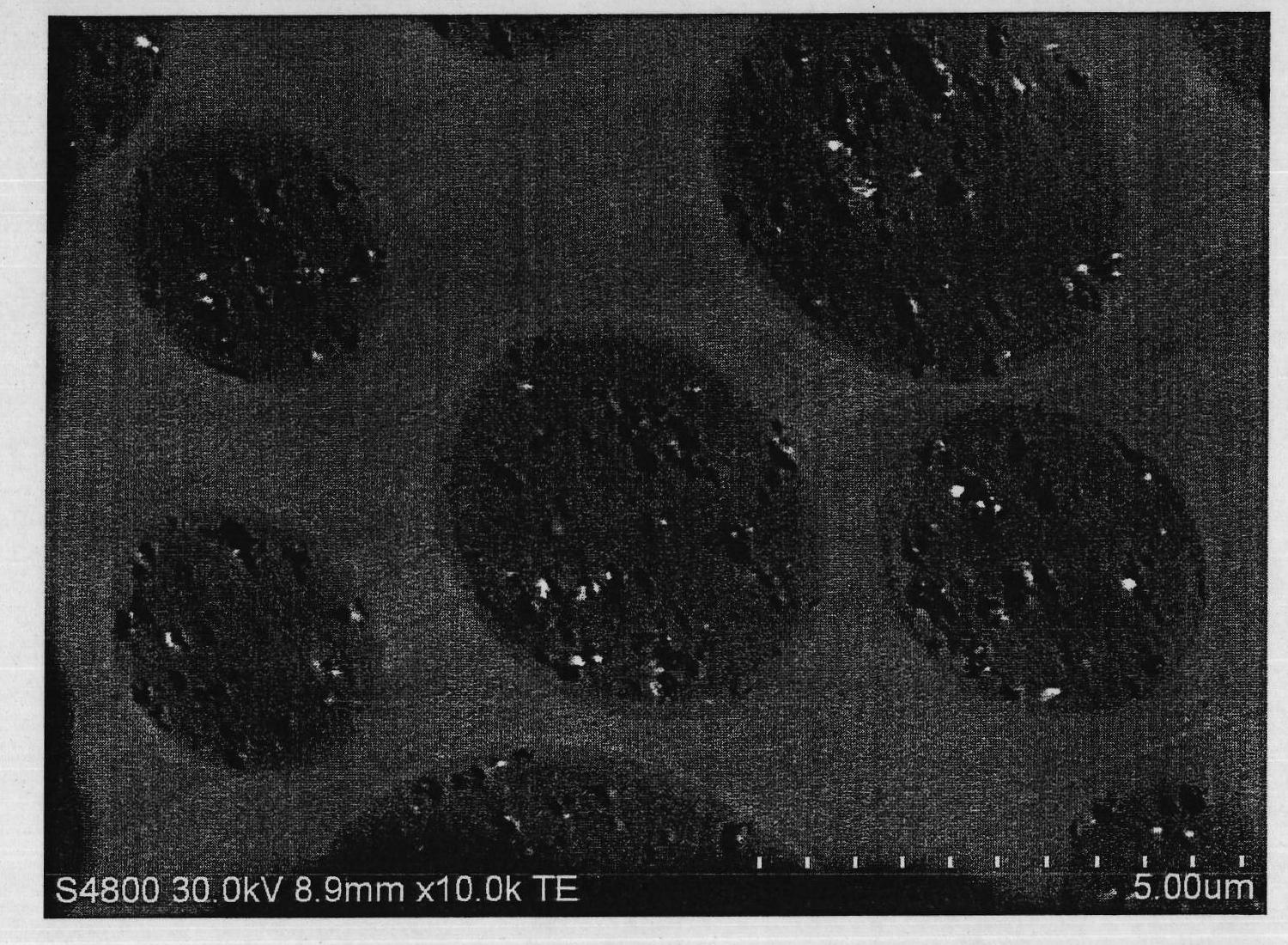

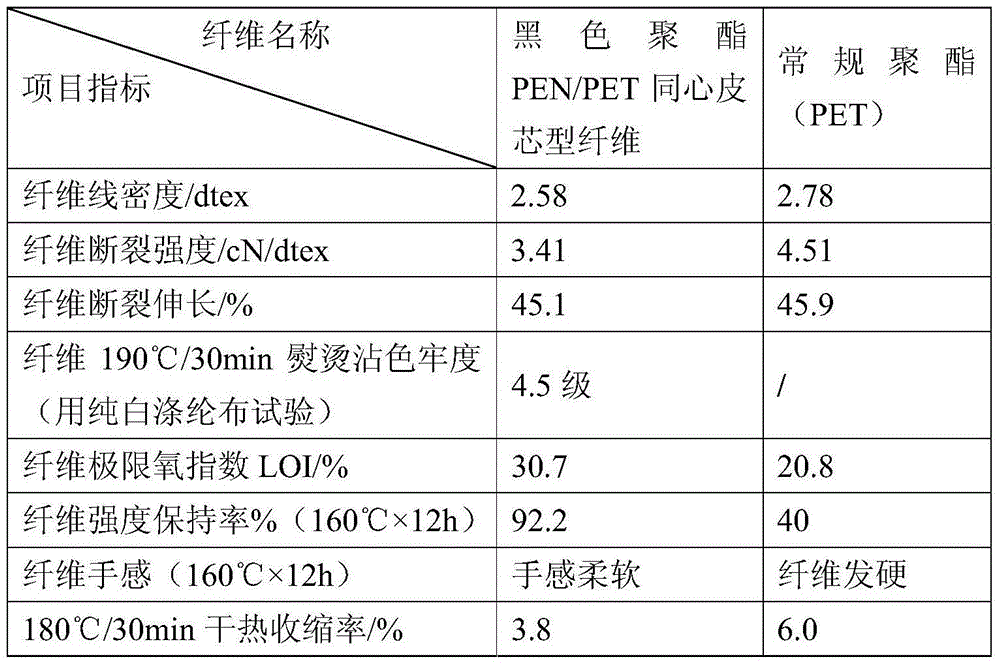

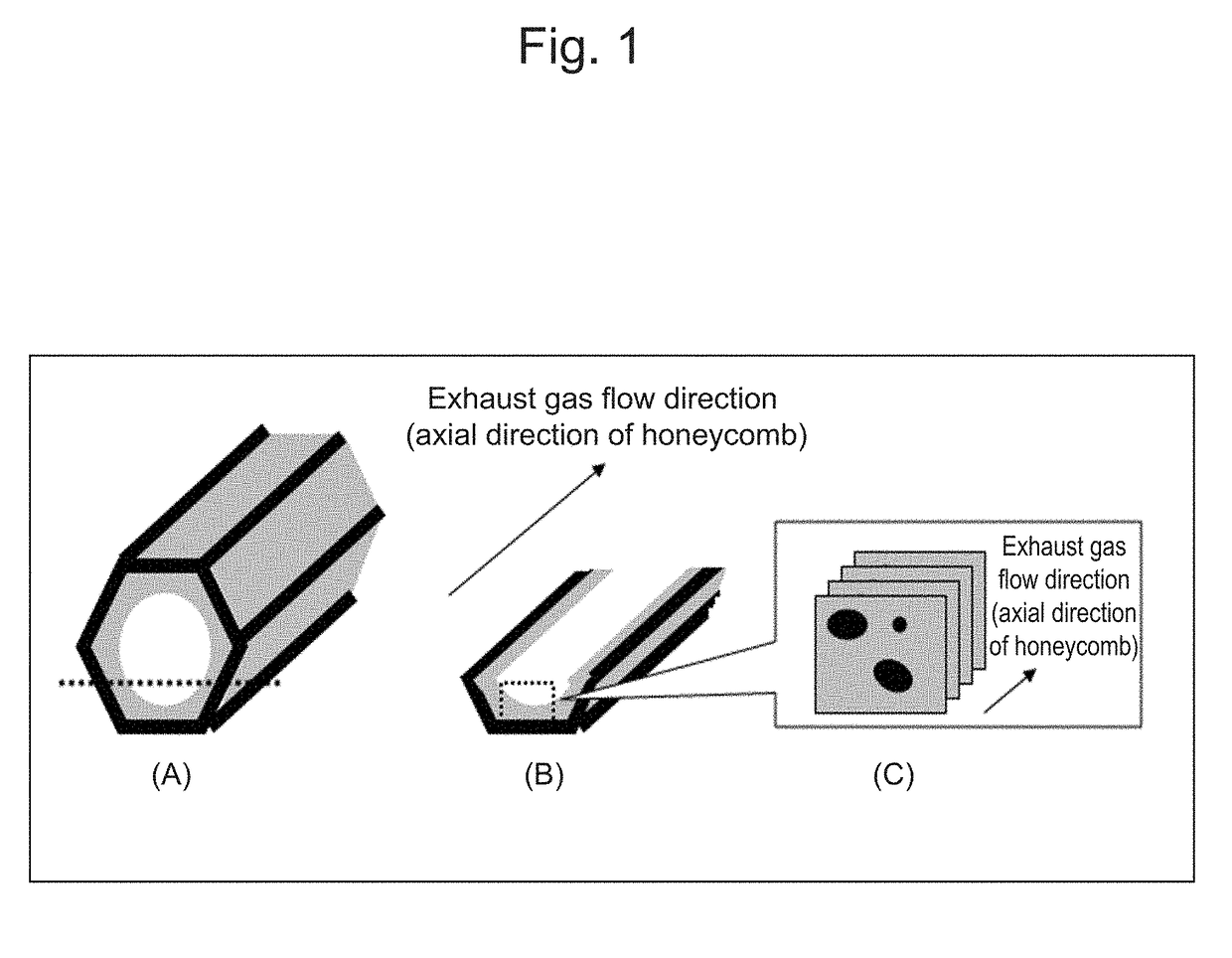

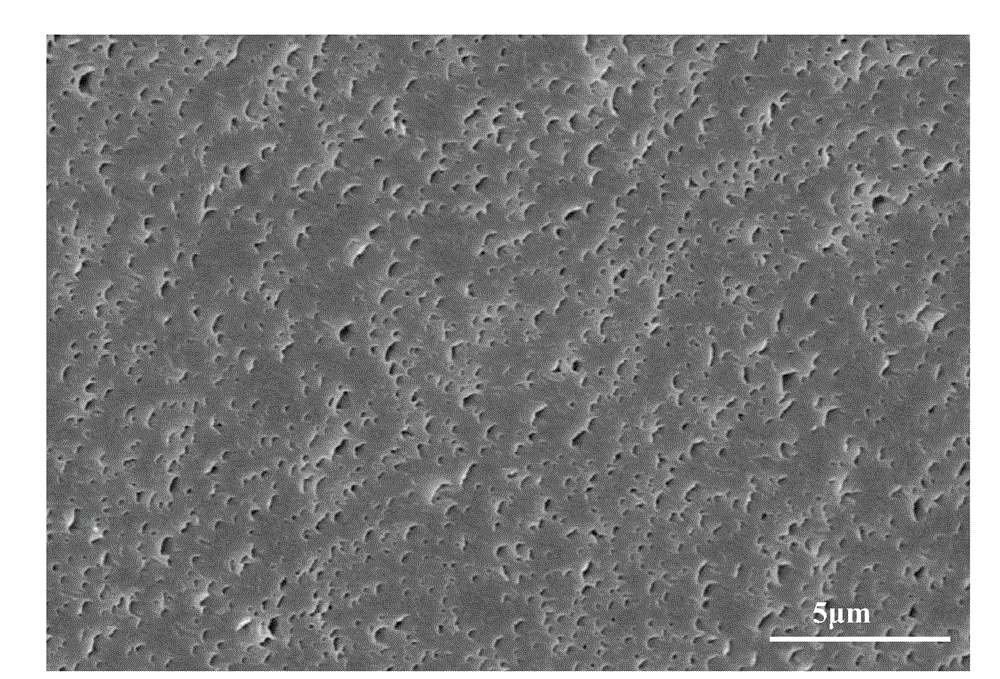

Exhaust gas purification catalyst

ActiveUS20180252132A1Improve diffusivityGood preheating effectInternal combustion piston enginesExhaust apparatusExhaust gasCoating

An object of the present invention is to provide an exhaust gas purification catalyst which can exhibit high durability and warm-up performance. The present invention relates to an exhaust gas purification catalyst comprising a substrate and a catalyst coating layer formed on the substrate, wherein the catalyst coating layer comprises catalyst particles, the catalyst coating layer having an upstream region extending by 40 to 60% of the entire length of the substrate from an upstream end of the catalyst in the direction of an exhaust gas flow and a downstream region corresponding to the remainder portion of the catalyst coating layer, the composition of the catalyst particle of the upstream region being different from that of the downstream region. The upstream region in the direction of an exhaust gas flow has a structure where a void is included in a large number, and furthermore high-aspect-ratio pores having an aspect ratio of 5 or more account for a certain percentage or more of the whole volume of voids. Thus, the exhaust gas purification catalyst exhibits enhanced purification performance.

Owner:TOYOTA JIDOSHA KK +1

Urea grease

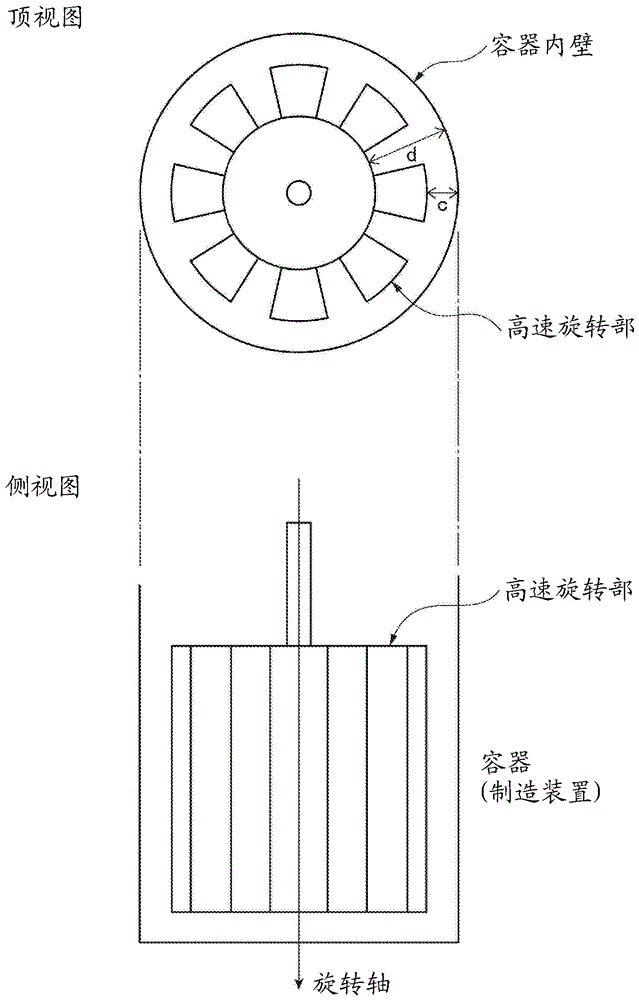

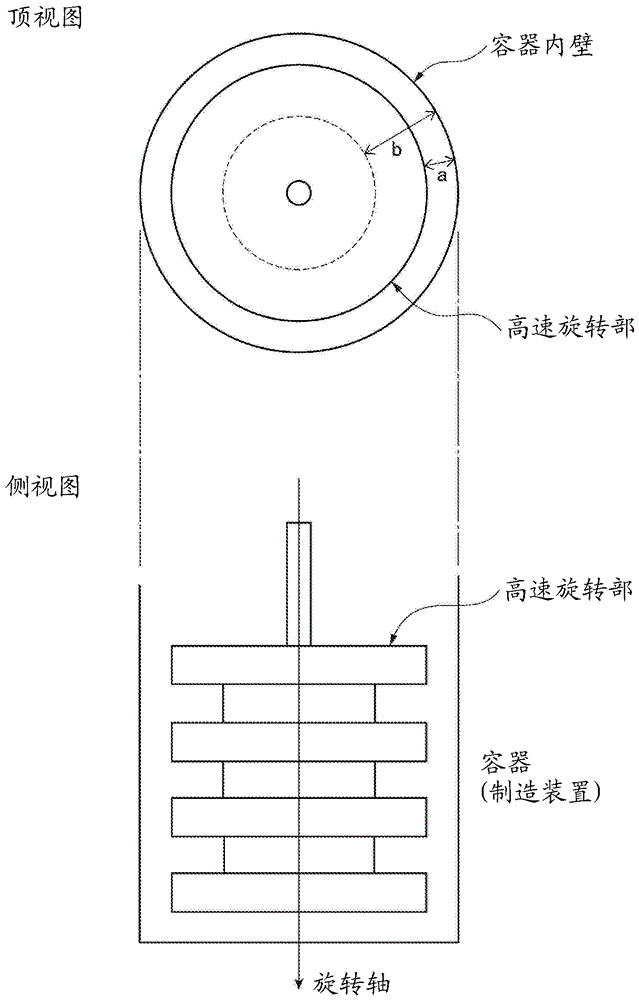

A urea grease, which is obtained by shearing a liquid mixture at a shear rate of 102 s-1 or greater, said liquid mixture comprising an amine mixture containing an alicyclic monoamine and a chain aliphatic monoamine together with a diisocyanate compound, and thus reacting the liquid mixture, characterized in that, when measured by the FAG method, the urea grease shows Peak High 32-64s of 1.5 or smaller and Level High 32-64s of 10 or smaller.

Owner:IDEMITSU KOSAN CO LTD

Process for preparing low water absorption epoxy resin type packaging material

InactiveCN106520041AGood dispersionExtension of timeNon-macromolecular adhesive additivesOther chemical processesEpoxyPolymer science

A process for preparing a low water absorption epoxy resin type packaging material comprises the following steps: (1) taking 5 g of clay and 2.5 g of tetradecyl trimethylammonium chloride to prepare lipophilic organic modified clay; (2) adding 1g of bisphenol A diglycidyl ether and a proper amount of the clay, then adding 5 g of N, N-dimethylacetamide, then adding 1, 3-bis(3-aminopropyl)-1, 1, 3, 3-tetramethyldisiloxane, and forming a film at 120 DEG C for 5 hours. The packaging material prepared by the method can prolong water through time and effectively reduces water absorption rate because that water through paths are more winding due to layered arrangement of the clay dispersed in epoxy resin material.

Owner:HUIAN COUNTY GAOZHI MOLD TECH SERVICES

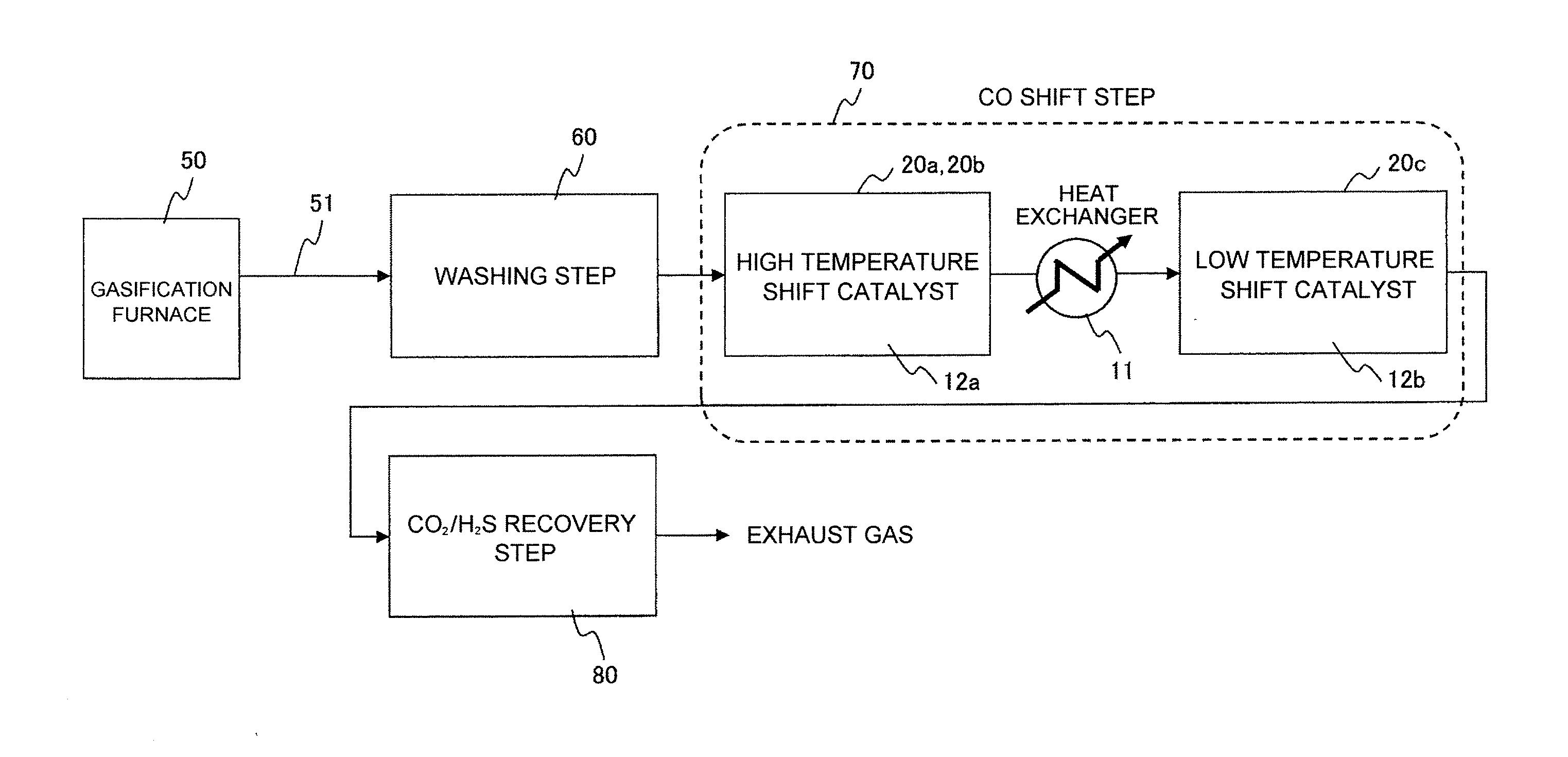

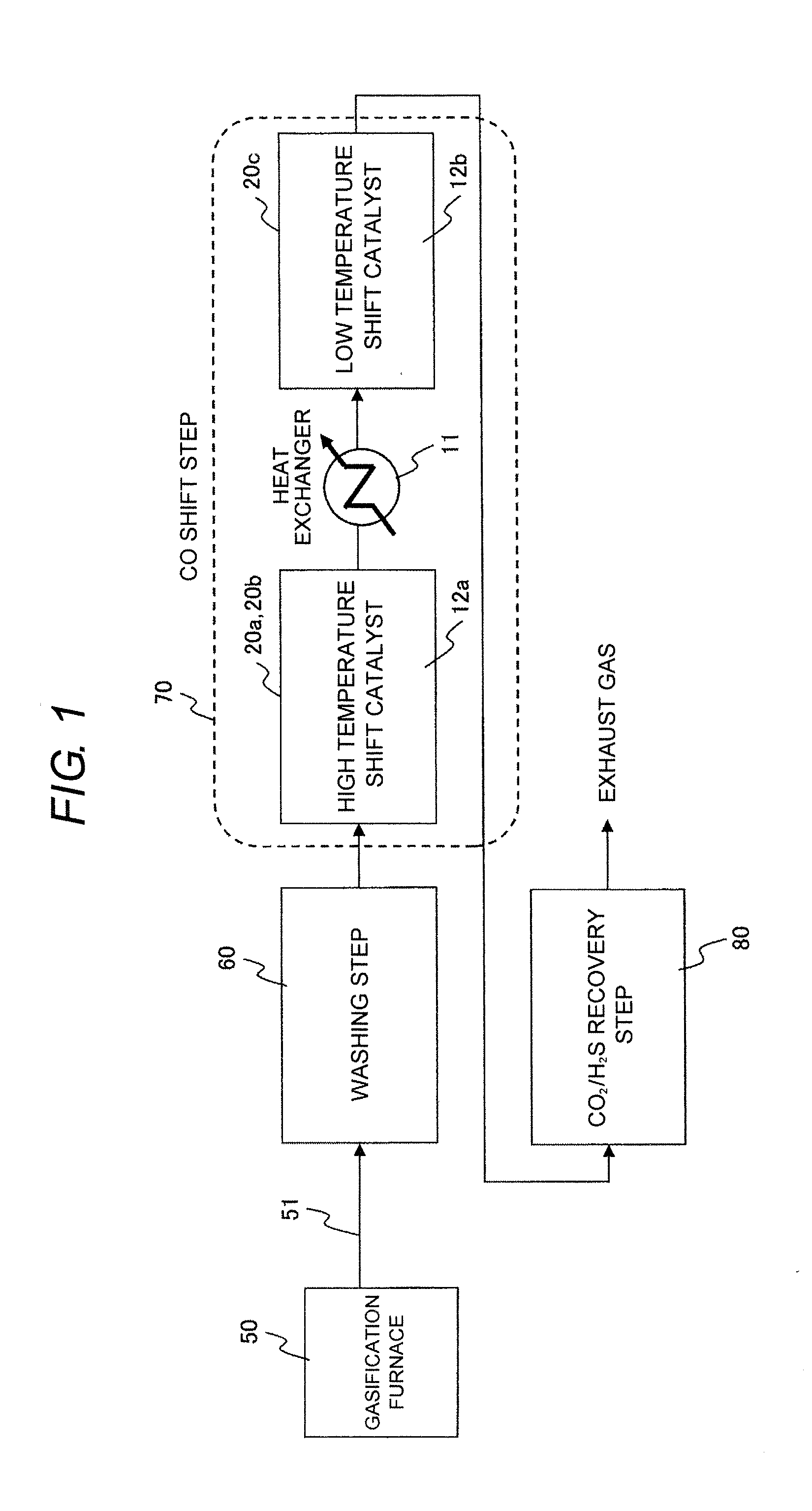

Shift Catalyst, Gas Purification Method and Equipment of Coal Gasifier Plant

InactiveUS20140147362A1Decrease efficiencyMaintain heat resistanceCarbon compoundsHydrogen separation using solid contactProcess engineeringCoal gasifier

A gas purification method is disclosed for a coal gasifier plant, with which energy loss accompanying recovery of CO2 can be suppressed and soundness of a CO shift catalyst can be maintained in the plant. The method includes a scrubbing step for a product gas produced by gasification of a carbon-containing solid fuel and containing at least CO and H2S to remove water-soluble substances contained in the product gas; a CO shift step to react CO in the product gas after scrubbing with steam using a shift catalyst and converting the gas into CO2 and H2; and a CO2 / H2S recovery to remove CO2 and H2S from the product gas after the CO shift step, wherein the CO shift step is constituted by a multistage shift reactor which includes multiple stages of shift reactors, and shift reactors upstream and downstream have high- and low-temperature shift catalysts, respectively.

Owner:HITACHI LTD

Polypropylene composition, and preparation method and application thereof

The invention relates to a polypropylene composition. The polypropylene composition includes 60-95wt% of highly stereoregular polypropylene homopolymer and 5-40wt% of propylene-ethylene copolymer elastomer, wherein a ratio of the melt mass flow rate of the highly stereoregular polypropylene homopolymer to the melt mass flow rate of the polypropylene composition is 0.1-1.1, and preferably 0.3-0.8; and the molecular weight distribution of the polypropylene composition is greater than 5. The invention also provides a preparation method of the polypropylene composition, and an application of the polypropylene composition in packaging materials or molded products as a transparent anti-impact material.

Owner:CHINA PETROLEUM & CHEM CORP +1

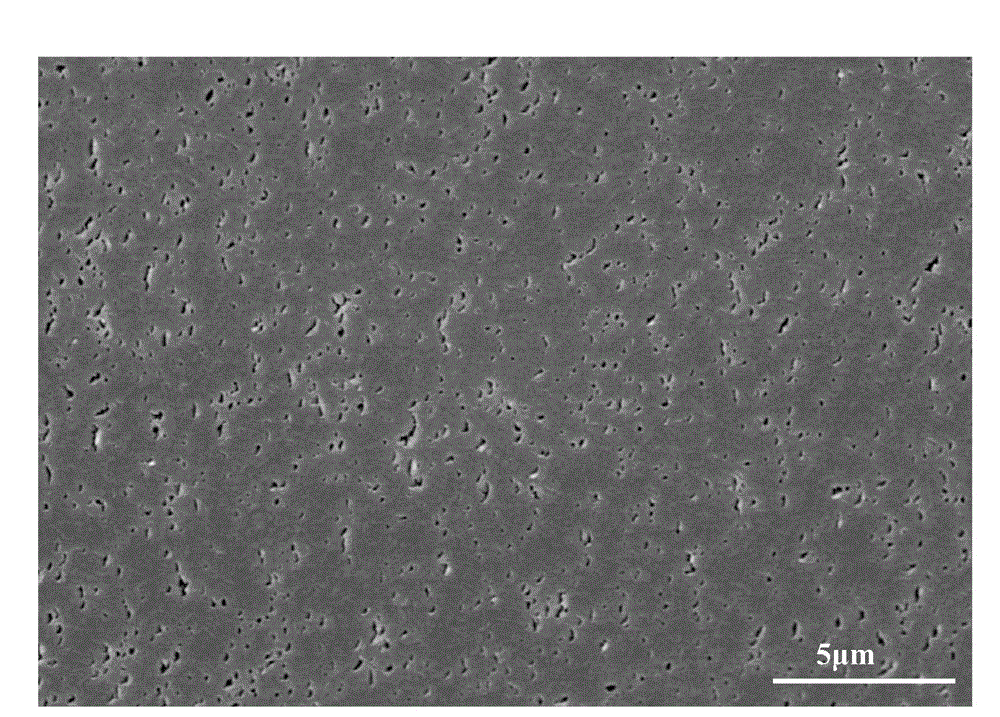

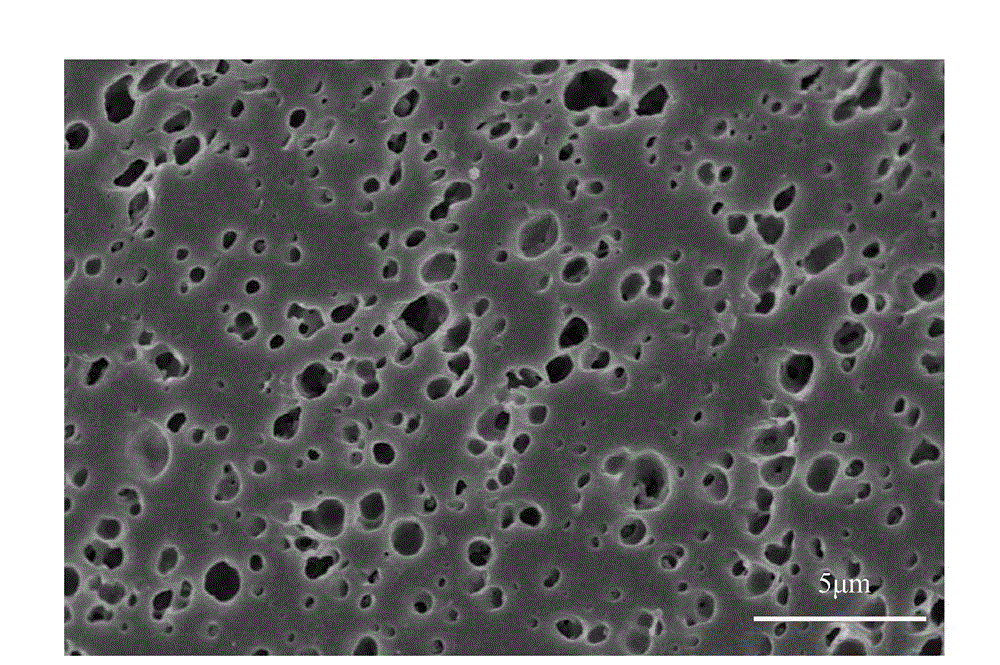

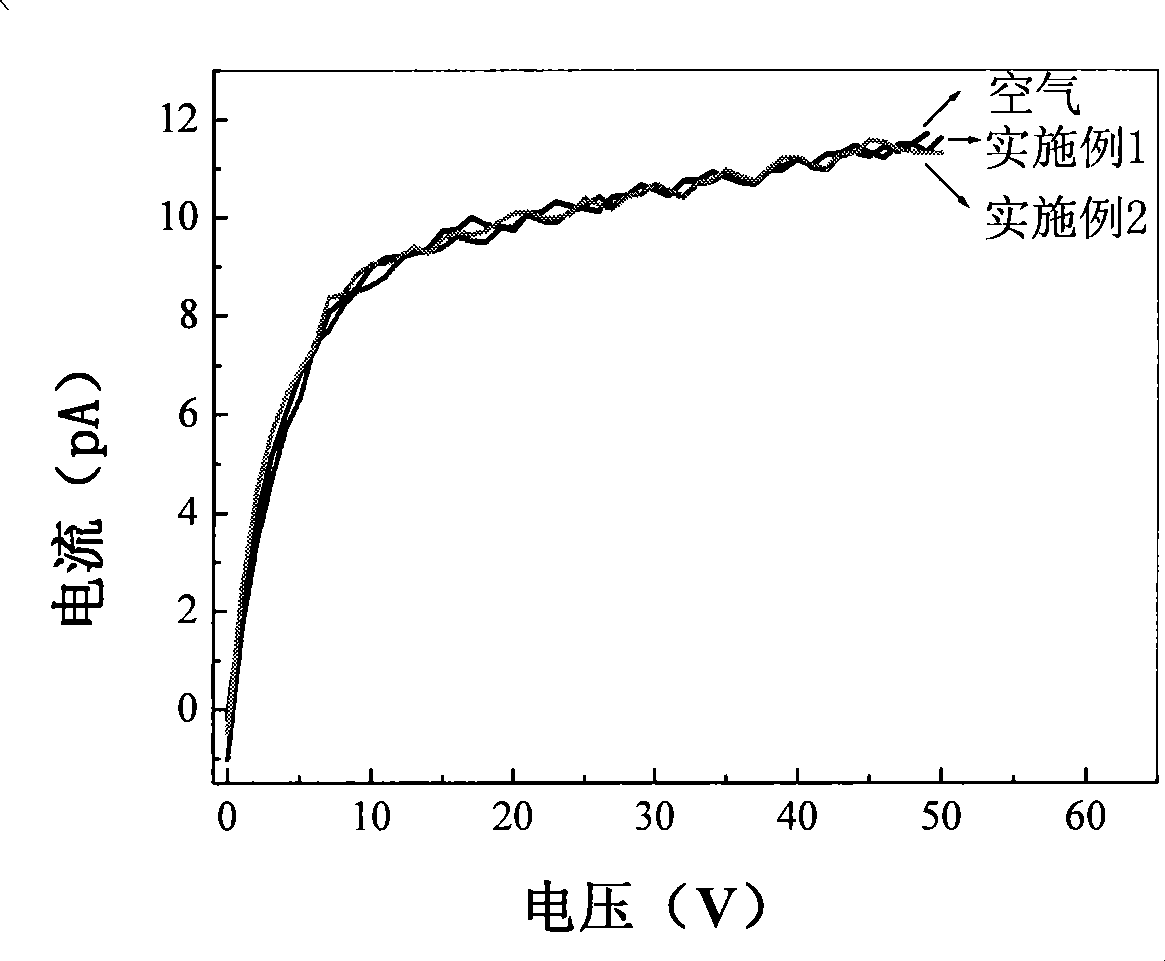

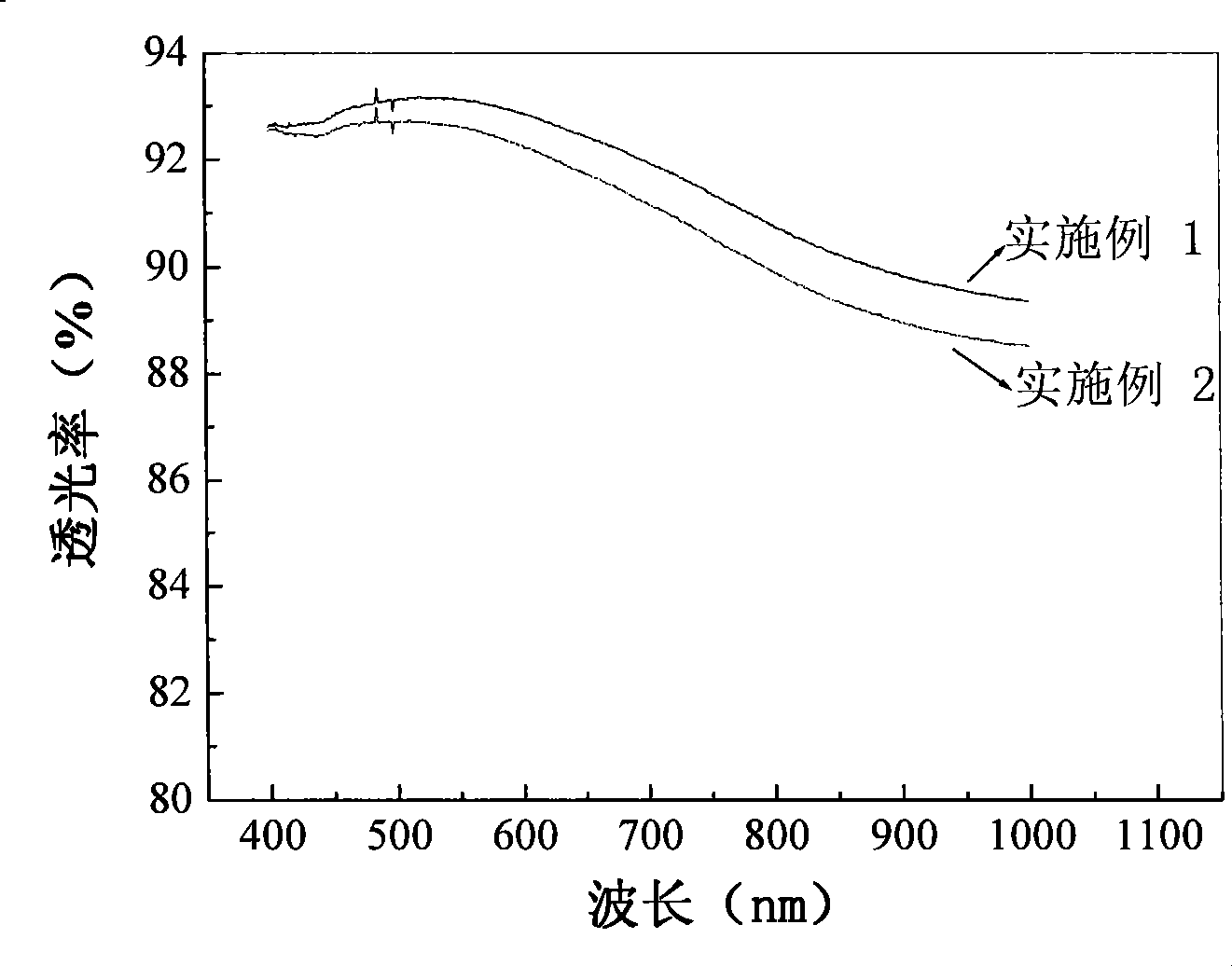

Modified silicone resin and preparation method thereof

The invention discloses a modified silicone resin and a preparation method thereof. The modified silicone resin provided by the invention is a compound consisting of silicon oil and polysilsesquioxane, the flexural modulus of the modified silicon resin is 160 to 280 MPa, the transmittance in visible light (400 to 800 nm) range is 88 to 93 percent, and the insulativity of the modified silicon resin is the same as that of air. The preparation method for the modified silicone resin comprises the following steps: 1) dissolving the silicon oil and the polysilsesquioxane into a solvent to obtain a mixed solution; 2) placing the mixed solution in the environment of the temperature of between 0 and 40 DEG C and the relative humidity of 10 to 40 percent, and volatilizing the solvent to make that the percentage composition of gross mass of the polysilsesquioxane and the silicon oil in the mixed solution is 50 to 80 percent; and 3) placing the solution obtained in the step 2) in the acid environment with the relative humidity of more than 80 percent and pH of 0 to 3 to obtain the modified silicone resin.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Laminated sheet for interior material of vehicle

InactiveUS20130059146A1Prevent surface bendingAvoid depressionAdhesive processesSynthetic resin layered productsSurface layerThermoplastic elastomer

The present invention provides a laminated sheet for interior materials of vehicles. The laminated sheet includes a surface layer and an inside layer combined with the surface layer and receiving an injection resin. In particular, the inside layer includes two or more types and foaming ratios of thermoplastic elastomer in a multi-layer.

Owner:HYUNDAI MOTOR CO LTD +1

Hydrophilic modification method of polytetrafluoroethylene porous membrane

ActiveCN103483618BGood compatibilityImprove the effect of hydrophilic treatmentTetrafluoroethylenePolyol

The invention relates to a hydrophilic modification method of a polytetrafluoroethylene porous membrane. The method comprises the following steps: infiltrating the polytetrafluoroethylene porous membrane by using a fluorine-containing polyether polyol solution, polymerizing with polyisocyanate on the polytetrafluoroethylene porous membrane to generate a hydrophilic crosslinked-network polyurethane polymer in order to prepare a hydrophilic polytetrafluoroethylene porous membrane. The fluorine-containing polyether polyol is used to prepare polyurethane in order to process the polytetrafluoroethylene porous membrane in the invention, so the compatibility between polyurethane macromolecules and the polytetrafluoroethylene membrane is improved, and the hydrophilic processing effect is improved; the crosslinked-network polymer can be formed through solidification, so the hydrophilic effect endurance of the polytetrafluoroethylene porous membrane can be maintained; and the method is simple and easy to implement, and can maintain the acid resistance, the alkali resistance, the oxidation resistance and the heat resistance of the polytetrafluoroethylene membrane.

Owner:南京三生境新材料科技有限公司

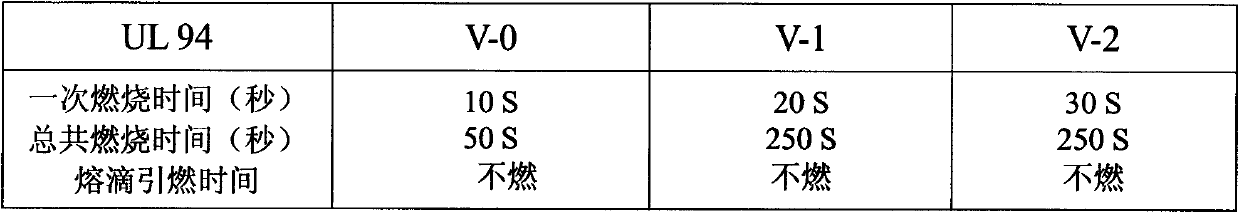

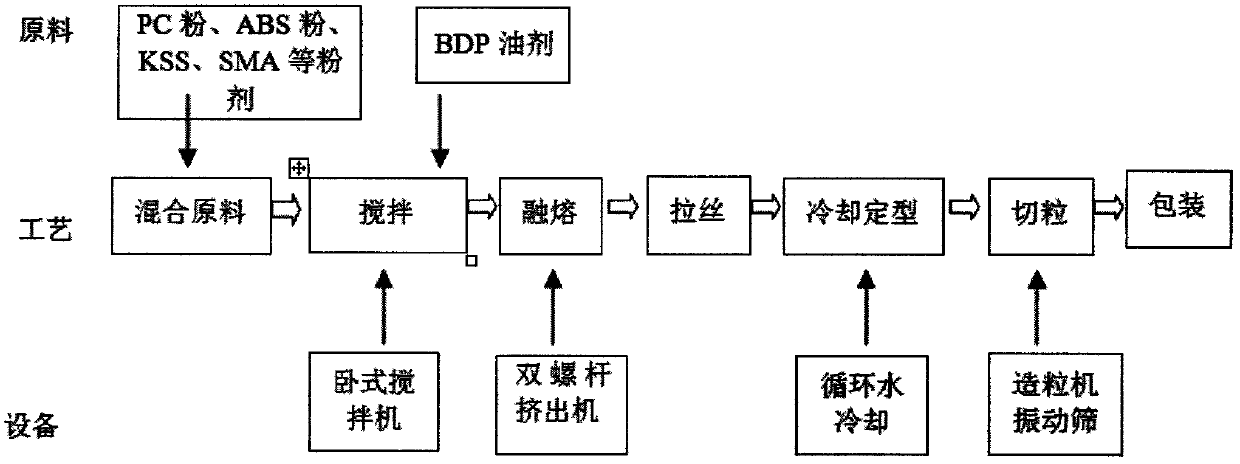

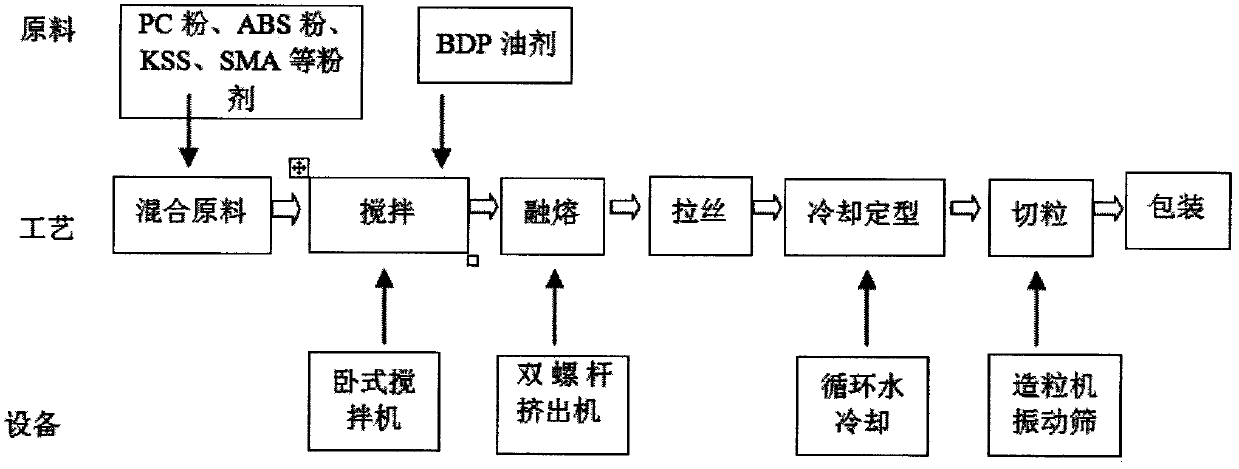

Efficient flame-retardant plastic alloy and preparation method thereof

The invention discloses an efficient flame-retardant plastic alloy and a preparation method thereof. The method comprises the following steps of: drying 45-80 parts by weight of polycarbonate powder and 10-20 parts by weight of acrylonitrile-butadiene-styrene plastic powder respectively for 3-4 hours; (2) pouring the polycarbonate powder, the acrylonitrile-butadiene-styrene plastic powder, 0.1-0.2 part by weight of benzenesulfonyl potassium sulfonate and 2-5 parts by weight of a styrene-maleic anhydride copolymer into a horizontal stirrer, and mixing and stirring for 10-15 minutes; and (3) adding 8-10 parts by weight of phosphoric acid ester, mixing, stirring, pouring into an extruder for heating and melting, drawing, cooling and extruding efficient flame-retardant plastic alloy particles. Due to the adoption of a halogen-free flame retardant, the plastic alloy product is nontoxic and environmental-friendly, and has efficient flame retardancy, excellent mechanical property and excellent heat resistance.

Owner:HUIZHOU 3U PC PLASTIC

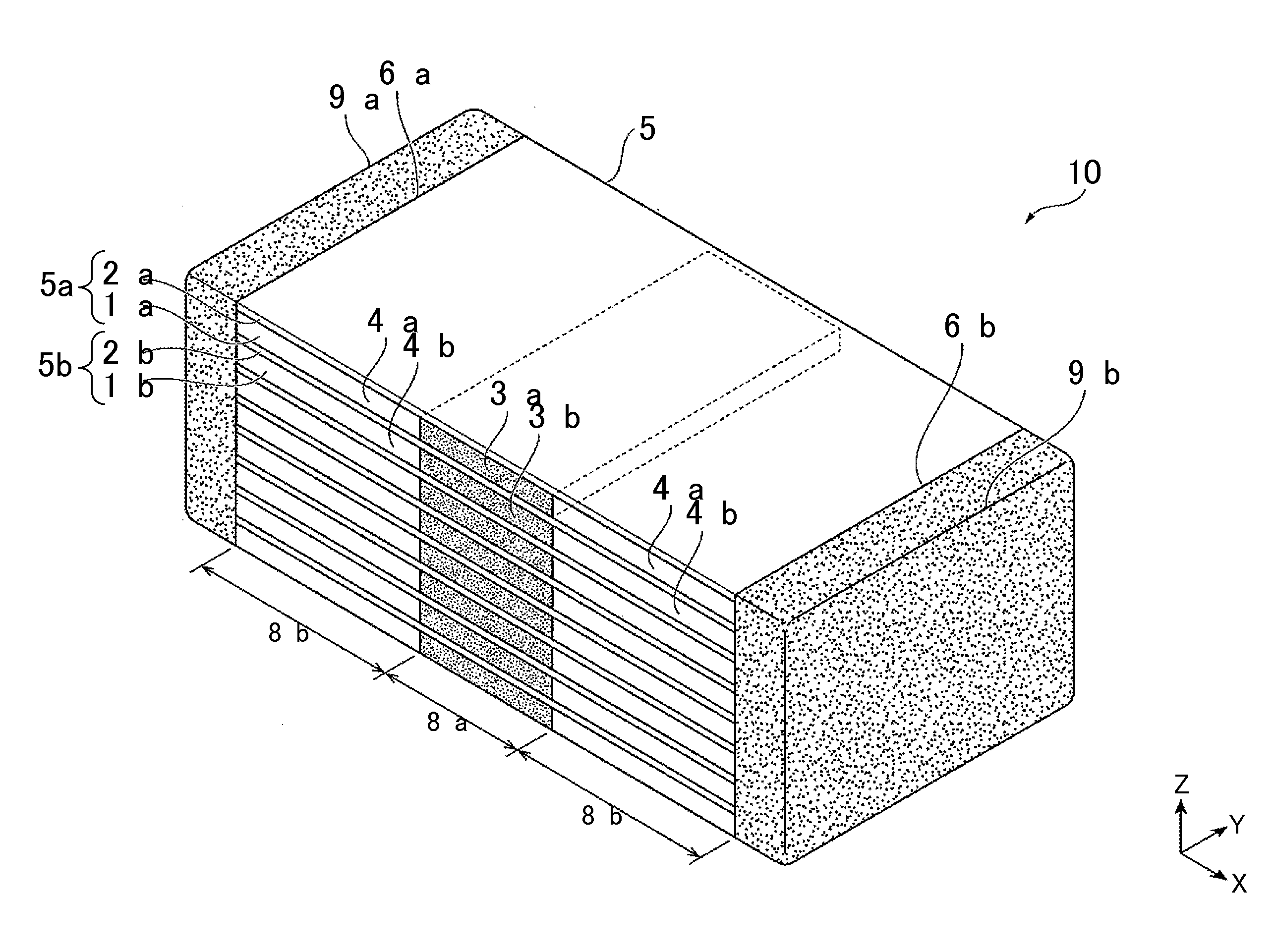

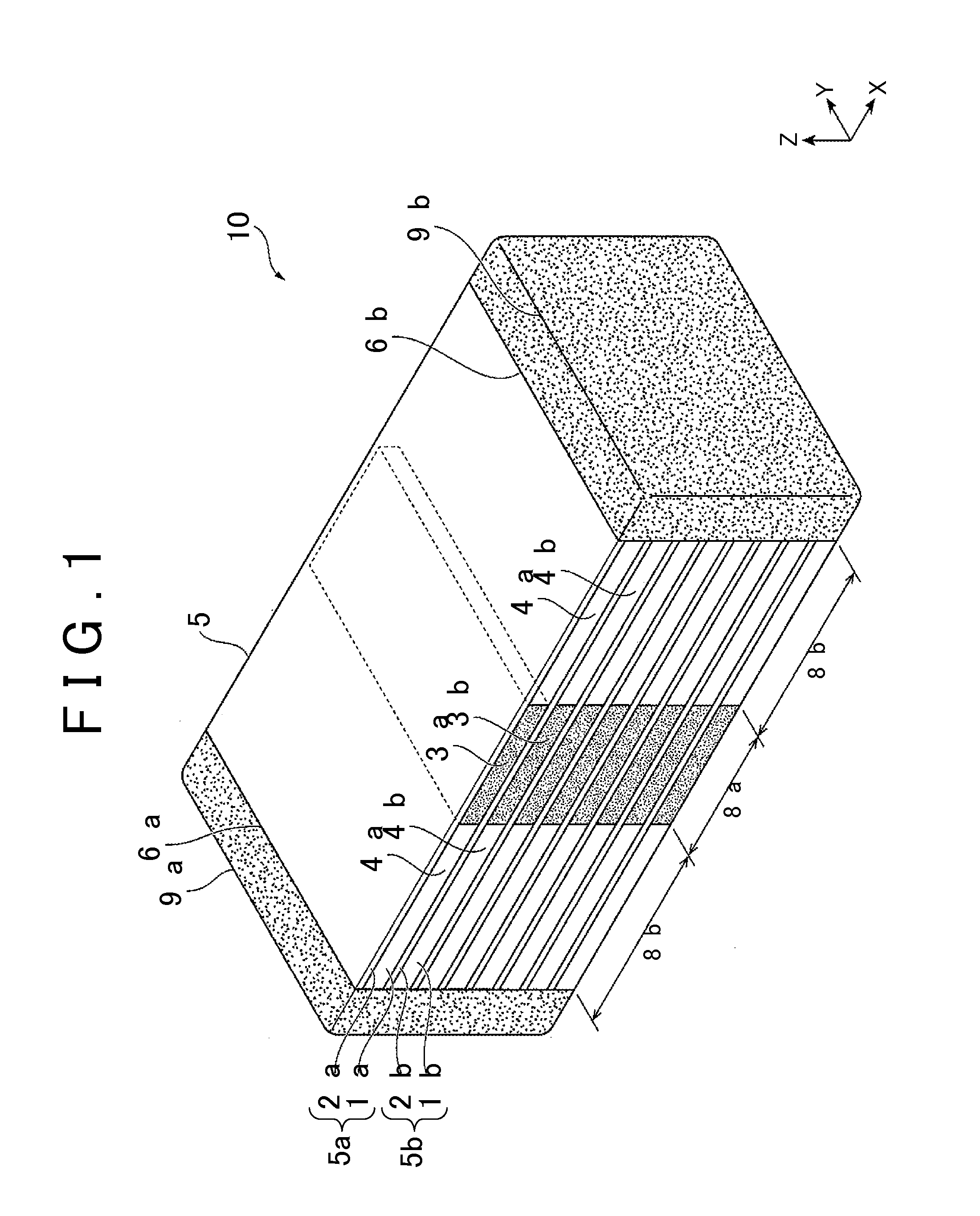

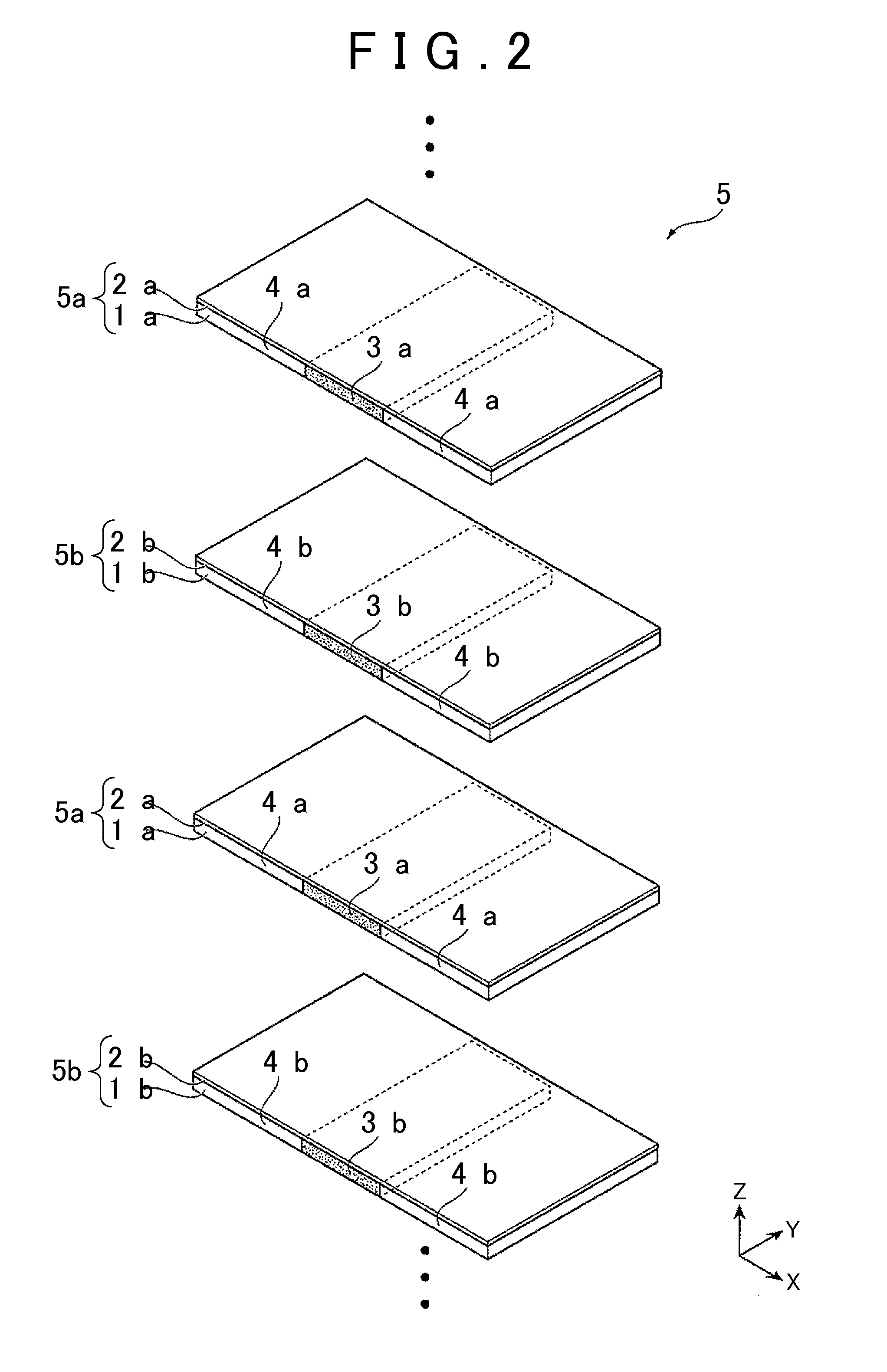

Film capacitor

ActiveUS20160099109A1Simple configurationHeat resistantFixed capacitor dielectricStacked capacitorsMetal electrodesFilm capacitor

A film capacitor includes a stacked body formed by stacking metalized films in each of which a metal electrode is formed on a surface of a dielectric film, at least one of the dielectric films containing a high thermal conductive filler; and external electrodes formed at electrode forming ends provided at opposed positions in the stacked body. The stacked body includes a high thermal conductive portion in which a content of the high thermal conductive filler in the at least one dielectric film is relatively high, and a low thermal conductive portion in which the content of the high thermal conductive filler in the at least one dielectric film is relatively low, or the high thermal conductive filler is not contained. The high thermal conductive portion is provided to continuously extend from an inside of the stacked body to a side portion other than the electrode forming ends.

Owner:TOYOTA JIDOSHA KK

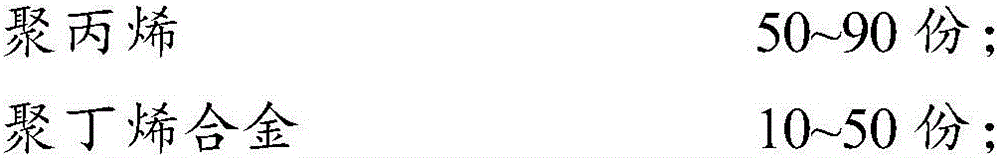

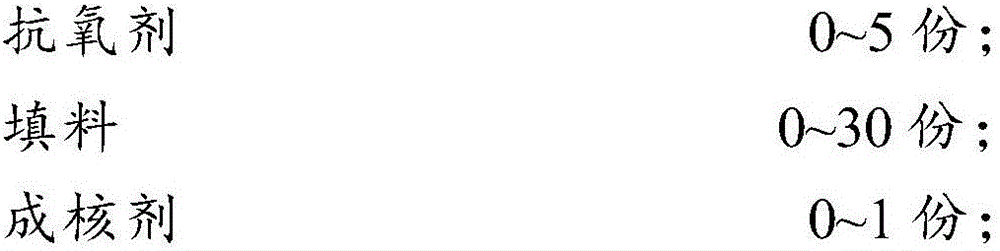

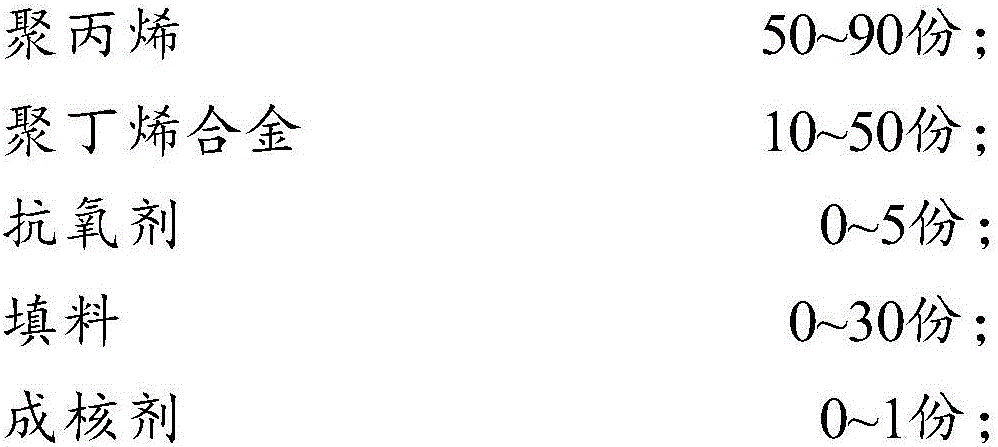

Highly impact-resistant polypropylene resin composition and preparation method thereof

The invention belongs to the field of synthetic resin and particularly relates to a highly impact-resistant polypropylene resin composition and a preparation method thereof. The highly impact-resistant polypropylene resin composition comprises the following components in parts by weight: 50-90 parts of polypropylene, 10-50 parts of polybutylene alloy, 0-5 parts of an antioxidant, 0-30 parts of packing and 0-1 part of a nucleating agent; the polybutylene alloy comprises the following components in percentages by weight: 60-90wt% of polybutylene, 9.9-35wt% of polypropylene and 0.1-5wt% of a polybutylene-polypropylene block copolymer. By adding the specific polybutylene alloy into polypropylene, the toughness and impact-resistance of the composition are remarkably improved while heat deformation resistance and rigidity of polypropylene are maintained. In addition, in the resin composition provided by the invention, the compatibility of the polybutylene alloy and polypropylene is good, and a coupling agent needs not to be additionally added or the polybutylene alloy needs not to be treated on the surface, so that the production cost can be lowered.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Lubricant Composition

ActiveUS20120264663A1Improve stabilityImprove rust resistanceThickenersAdditivesHeat resistanceLubricant

Owner:NOK KLUEBER CO LTD

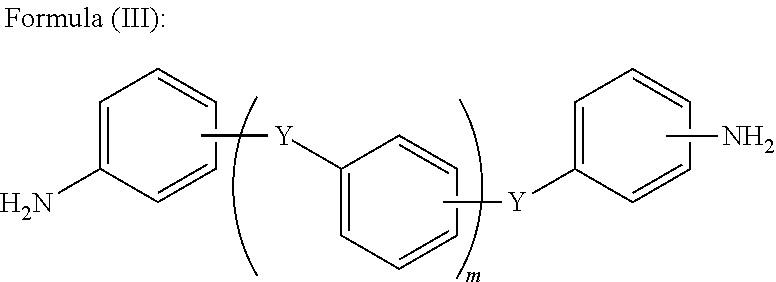

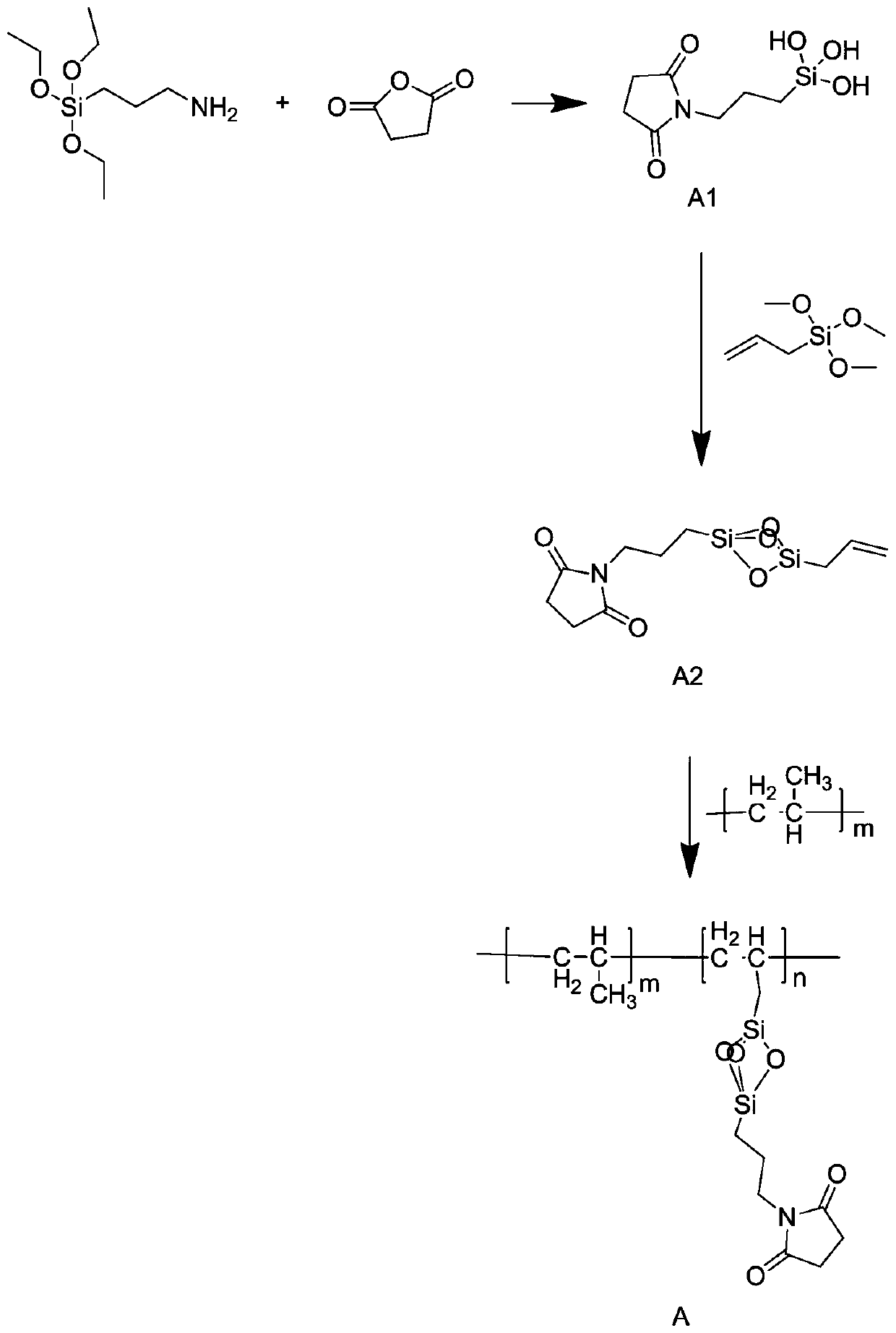

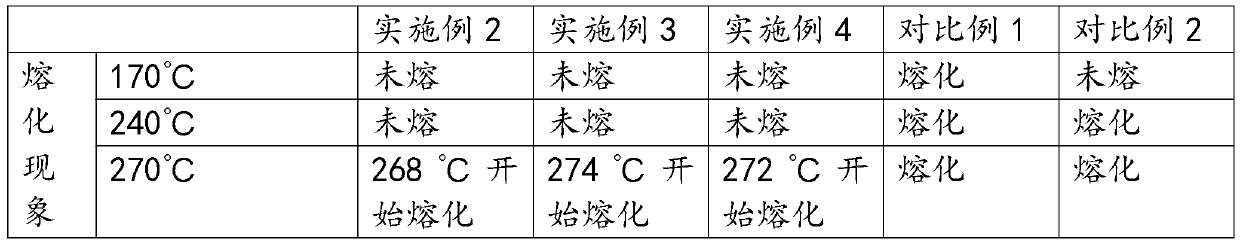

Heat-resistant polypropylene plastic pipe and preparation method thereof

InactiveCN111534035AImprove high temperature resistanceMaintain heat resistancePolymer scienceAntioxidant

The invention discloses a heat-resistant polypropylene plastic pipe and a preparation method thereof. The polypropylene plastic pipe is prepared from the following raw materials in parts by weight: 120 to 140 parts of modified polypropylene, 25 to 40 parts of a filler, 2 to 4 parts of a stabilizer, 3 to 5 parts of a plasticizer and 2 to 5 parts of an antioxidant. The modified polypropylene is prepared in a graft copolymerization manner; firstly, a modifier A2 is prepared and carbon-carbon double bonds are reserved in the modifier A2; the modifier A2 is added into a grafting reaction of polypropylene for copolymerization to obtain modified polypropylene. Organic silicon and amide functional groups are connected in a chemical bond manner; an amide bond has relatively high bond energy; Si-O bonds have good thermal stability, although organosilicon has low surface tension, organosilicon is connected to polypropylene in a chemical bond mode, and therefore the compatibility problem of organosilicon is solved, the high temperature resistance of polypropylene is greatly improved, good thermal stability is achieved, and the heat resistance and weather resistance of the polypropylene plasticpipe can be maintained for a long time.

Owner:马健珂

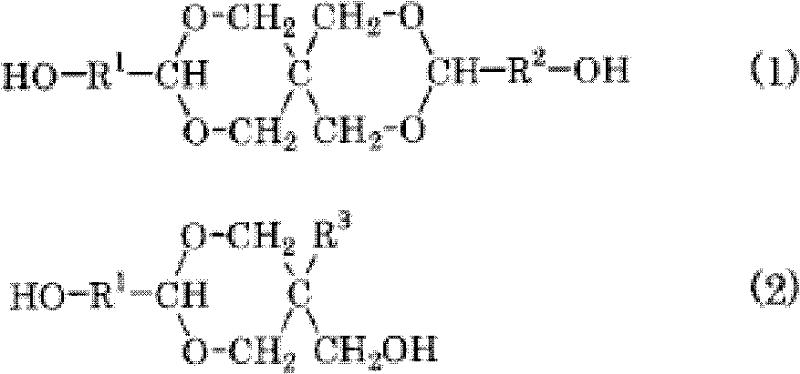

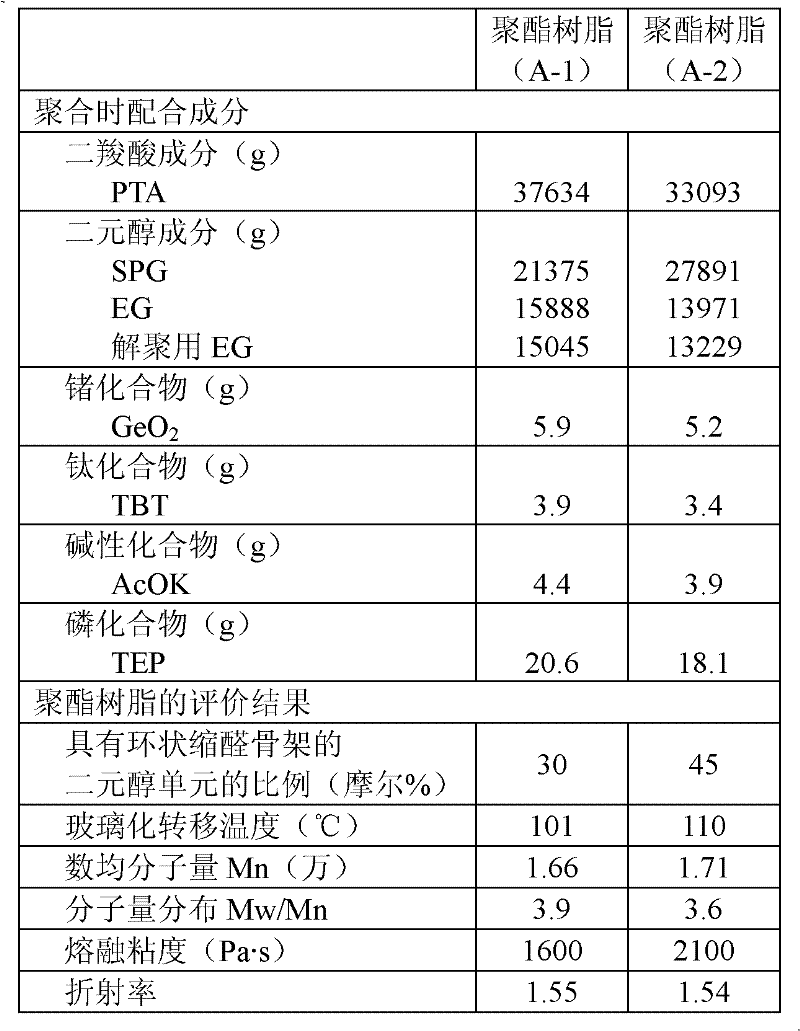

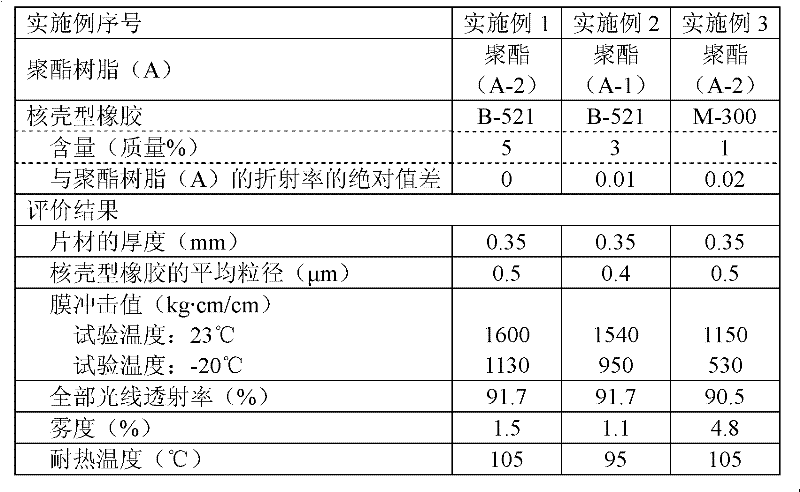

Polyester resin composition

ActiveCN102471563AMaintain transparencyMaintain heat resistanceSynthetic resin layered productsDomestic containersAbsolute differenceRefractive index

The present invention provides a polyester resin composition comprising (A) 70 to 99.5% by mass of a polyester resin which comprises dicarboxylic acid units and diol units and in which 1 to 60 mol% of the diol units are diol units that each contain a cyclic acetal skeleton and 0.5 to 30% by mass of a core-shell type rubber which has a mean particle diameter of 1[mu]m or less and which exhibits an absolute difference in refractive index of 0.02 or less with respect to the refractive index of the polyester resin (A).

Owner:MITSUBISHI GAS CHEM CO INC

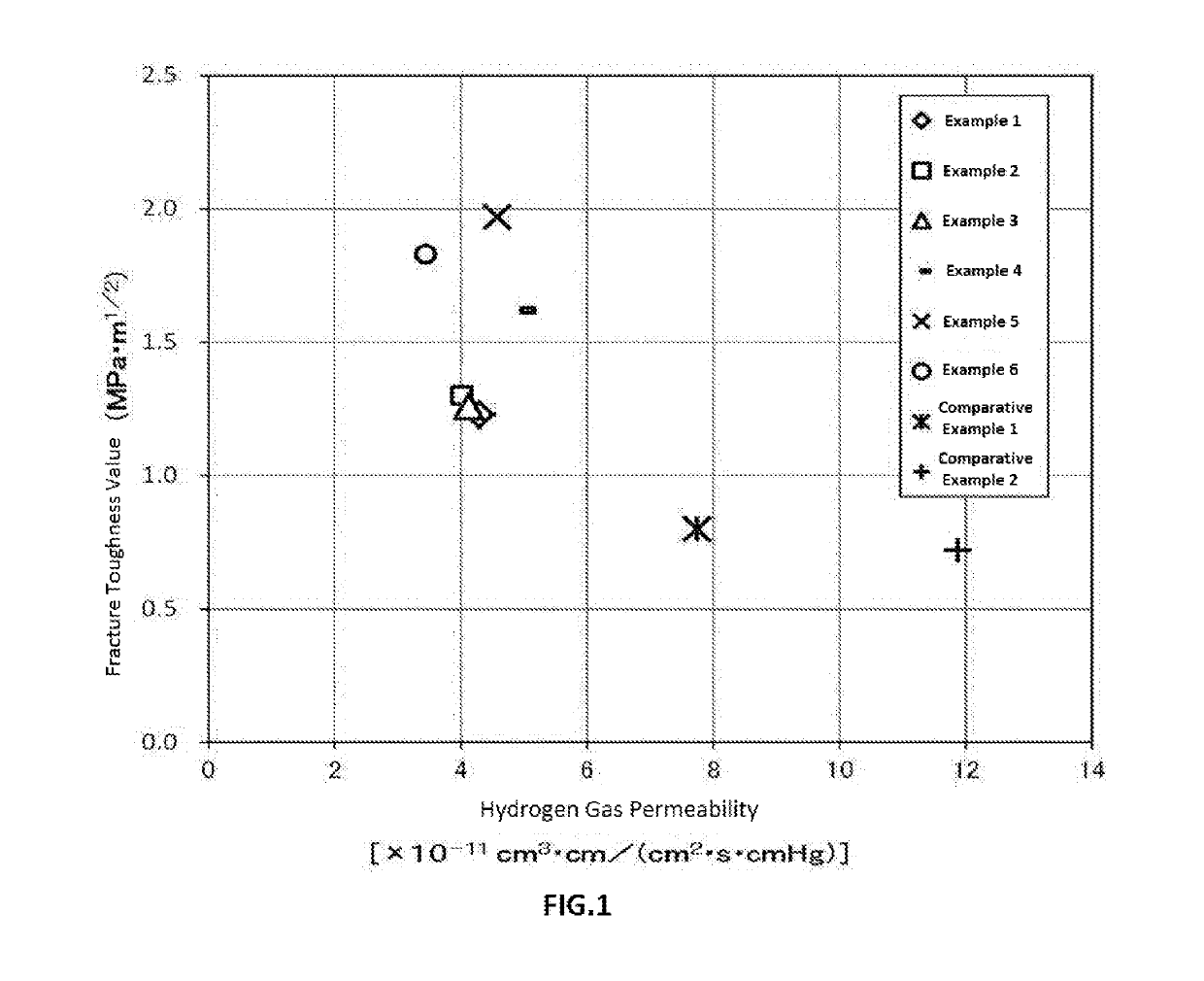

Gas barrier material, resin composition, gas barrier member, cured product, and composite material

InactiveUS20190225794A1Improve fracture toughnessExcellent in hydrogen gas barrier propertySynthetic resin layered productsVehicle componentsChemistryGas barrier

A gas barrier material, comprising: a thermosetting resin capable of forming a smectic structure via a curing reaction; and an amine curing agent.

Owner:HITACHI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com