Low-shrinkage low water absorption nylon 6 composite material and preparation and application thereof

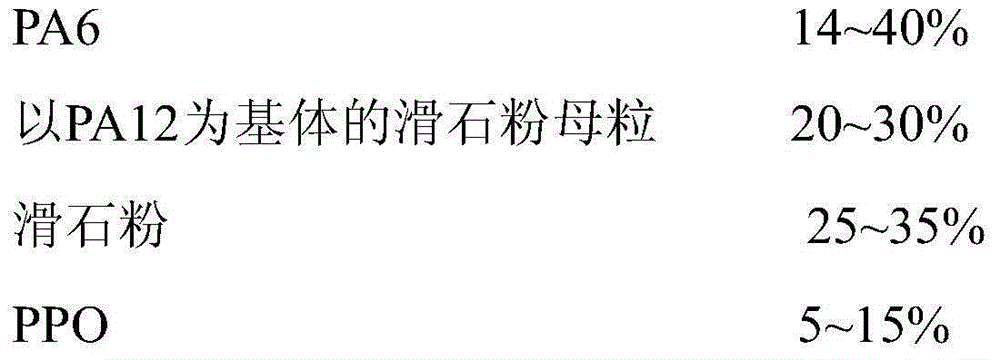

A technology of low water absorption and composite materials, applied in the field of modified plastics, can solve the problems of polyamide thermal deformation temperature drop, different horizontal and vertical shrinkage of materials, and low filling content, so as to improve bonding force, improve mechanical properties, and high talc The effect of powder content filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

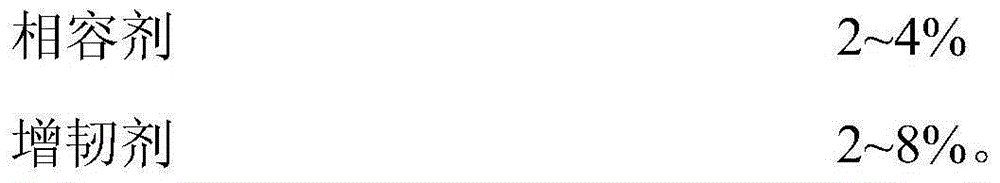

[0055] A preparation method of nylon 6 composite material with low shrinkage rate and low water absorption rate, comprising the steps of:

[0056] (1) Preparation of talcum powder masterbatch with PA12 as the matrix: prepare raw materials according to the composition and proportion of talc powder masterbatch 1 in Table 1, and then weigh PA12, coupling agent, antioxidant, lubricant and half Add talcum powder into a pressurized overturning mixer and knead it into a mass. Control the temperature of the mixing room at 160°C, the screw speed at 40r / min, and the mixing time for 15 minutes; Add it into the internal mixer, and then banbury for 15 minutes, as a spare material;

[0057] The spare material is sent to the hopper of the single-screw extruder through the conveyor belt, melted, kneaded and extruded by the single-screw extruder, and the talcum powder masterbatch based on PA12 is made through air-cooling, grinding and pelletizing; The rotating speed of the single-screw extrud...

Embodiment 2

[0060] A preparation method of nylon 6 composite material with low shrinkage rate and low water absorption rate, comprising the steps of:

[0061] (1) Preparation of talcum powder masterbatch with PA12 as the matrix: prepare raw materials according to the composition and proportion of talc powder masterbatch 1 in Table 1, and then weigh PA12, coupling agent, antioxidant, lubricant and half Add talcum powder into a pressurized overturning mixer and knead it into a mass. Control the temperature of the mixing room at 200°C, the screw speed at 80r / min, and the mixing time for 5 minutes; Add it to the internal mixer, and then banbury for 5 minutes, as a spare material;

[0062] The spare material is sent to the hopper of the single-screw extruder through the conveyor belt, melted, kneaded and extruded by the single-screw extruder, and the talcum powder masterbatch based on PA12 is made through air-cooling, grinding and pelletizing; The rotating speed of the single-screw extruder i...

Embodiment 3

[0065] A preparation method of nylon 6 composite material with low shrinkage rate and low water absorption rate, comprising the steps of:

[0066] (1) Preparation of talcum powder masterbatch with PA12 as the matrix: prepare raw materials according to the composition and proportion of talc powder masterbatch 1 in Table 1, and then weigh PA12, coupling agent, antioxidant, lubricant and half Add talcum powder into a pressurized overturning mixer and knead it into a mass. Control the temperature of the mixing room at 180°C, the screw speed at 100r / min, and the mixing time for 8 minutes; Add it into the internal mixer, and then banbury for 8 minutes, as a spare material;

[0067] The spare material is sent to the hopper of the single-screw extruder through the conveyor belt, melted, kneaded and extruded by the single-screw extruder, and the talcum powder masterbatch based on PA12 is made through air-cooling, grinding and pelletizing; The rotating speed of the single-screw extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com