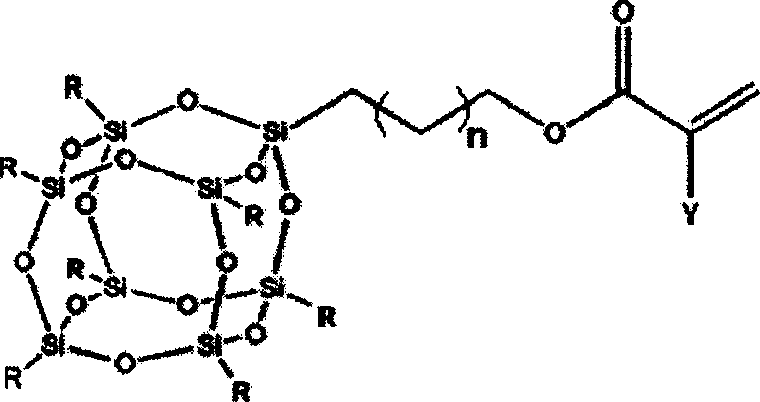

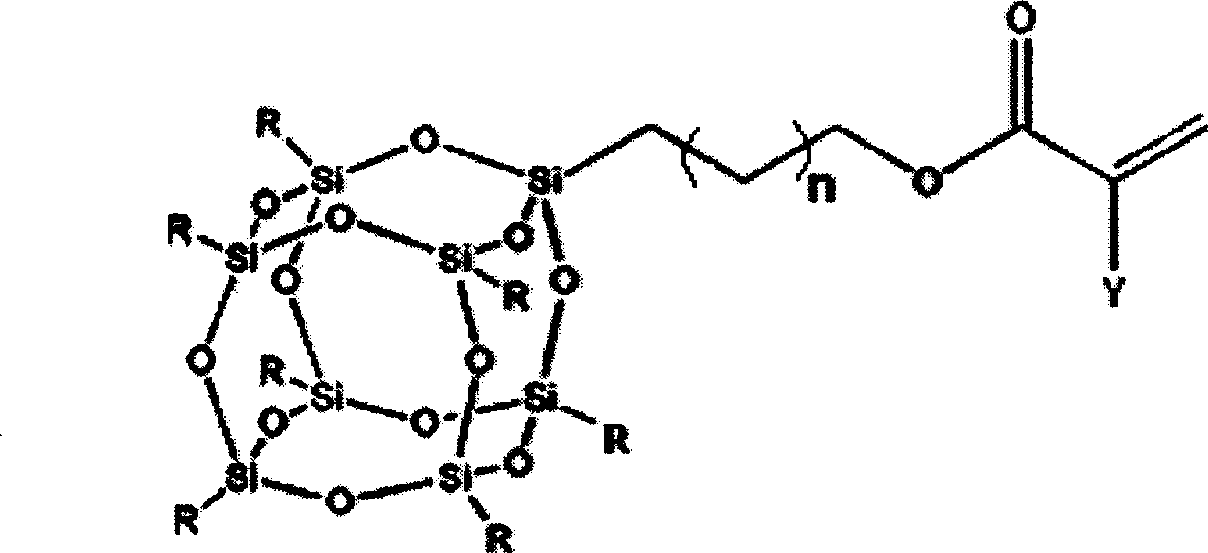

Coating material containing POSS acrylate copolymer and preparing method

A coating material, acrylate technology, applied in the direction of coating, etc., can solve problems such as difficult industrialization, insufficient wear resistance, and decreased impact strength, so as to increase crosslinking density, increase surface hardness, and reduce shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1. Into a 100ml three-necked bottle, add 50ml of xylene, feed nitrogen, heat to 120°C under stirring, and then add 5.0g of polyhedral oligomeric silsesquioxane-containing methacrylate monomers (wherein R=-CH 3 , n=1, Y=-CH 3 ) and initiator dicumyl peroxide 0.7g, first react 1h.

[0022] Step 2. Mix the monomer mixed with 30.0 g of methyl methacrylate, 5.0 g of butyl acrylate, 1.0 g of methyl acrylate, and 8.0 g of glycidyl methacrylate and chain transfer agent 0.5 isooctyl 3-mercaptopropionate g, was added dropwise to a three-necked flask, and continued to react for 8h.

[0023]Step 3. After cooling to room temperature, add hydroquinone 0.5g, DMF 20ml, and acrylic acid equivalent to glycidyl methacrylate, heat up to 80°C, and react for 7h.

[0024] Step 4. After cooling to room temperature, add 300ml of ethanol to precipitate the copolymer, filter, stir and wash with hot water and suction filter to remove the polymerization inhibitor hydroquinone, and rinse wit...

Embodiment 2

[0028] Step 1: As in Step 1 of Example 1, heat to 80° C. under stirring, add 1.0 g of acrylate monomers containing polyhedral oligomeric silsesquioxane (wherein R=-C 6 h 5 , n=6, Y=-H) and 0.5g initiator dicumyl peroxide were reacted for 1h.

[0029] Step 2: As in step 2 of Example 1, add 40.0 g of methyl methacrylate, 5.0 g of butyl acrylate, 1.0 g of methyl acrylate, and 10.0 g of glycidyl acrylate, and continue the reaction for 16 hours.

[0030] Step 3. After cooling to room temperature, add 0.8 g of hydroquinone, 30 ml of DMF, and acrylic acid equivalent to glycidyl methacrylate, raise the temperature to 120° C., and react for 4 hours.

[0031] Step 4: with embodiment 1;

[0032] Step 5: 50g of epoxy acrylate oligomer, 15g of (meth)acrylate copolymer active modifier containing polyhedral oligomeric silsesquioxane, 20g of hexanediol diacrylate and pentaerythritol diacrylate 15g, 3g of photoinitiator 2-hydroxyl-2-methyl-1-propiophenone (HMPP), 5g of Dow Corning 163 silox...

Embodiment 3~12

[0035] Steps 1 to 4: the specific operations are the same as steps 1 to 4 described in Example 1, except that the amount of each component is changed, and in the structural formula of the POSS monomer, R=-n-C 4 h 9 , n=2, Y=-CH 3 . The specific formula of modifier in each embodiment is shown in Table 1.

[0036] Table 1

[0037] Reality

apply

example

POSS

(g)

Methacrylic

methyl ester

(g)

acrylic

Butyl ester

(g)

acrylic

methyl ester

(g)

glycidyl ester

(g)

(g)

(g)

3

1.0

30.0

10.0

1.0

5.0

0.0

0.5

4

2.0

40.0

5.0

10.0

8.0

0.5

0.7

5

3.0

45.0

1.0

5.0

10.0

0.7

1.0

6

4.0

30.0

10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com