Zirconia aluminosilicate glass

A zirconium aluminosilicate and glass technology, applied in the field of glass materials for screen surface protection, can solve problems such as affecting the display effect of display products, scratching the damaged surface of the screen, endangering the service life, etc., achieving excellent mechanical properties and prolonging use. Life and use effect, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

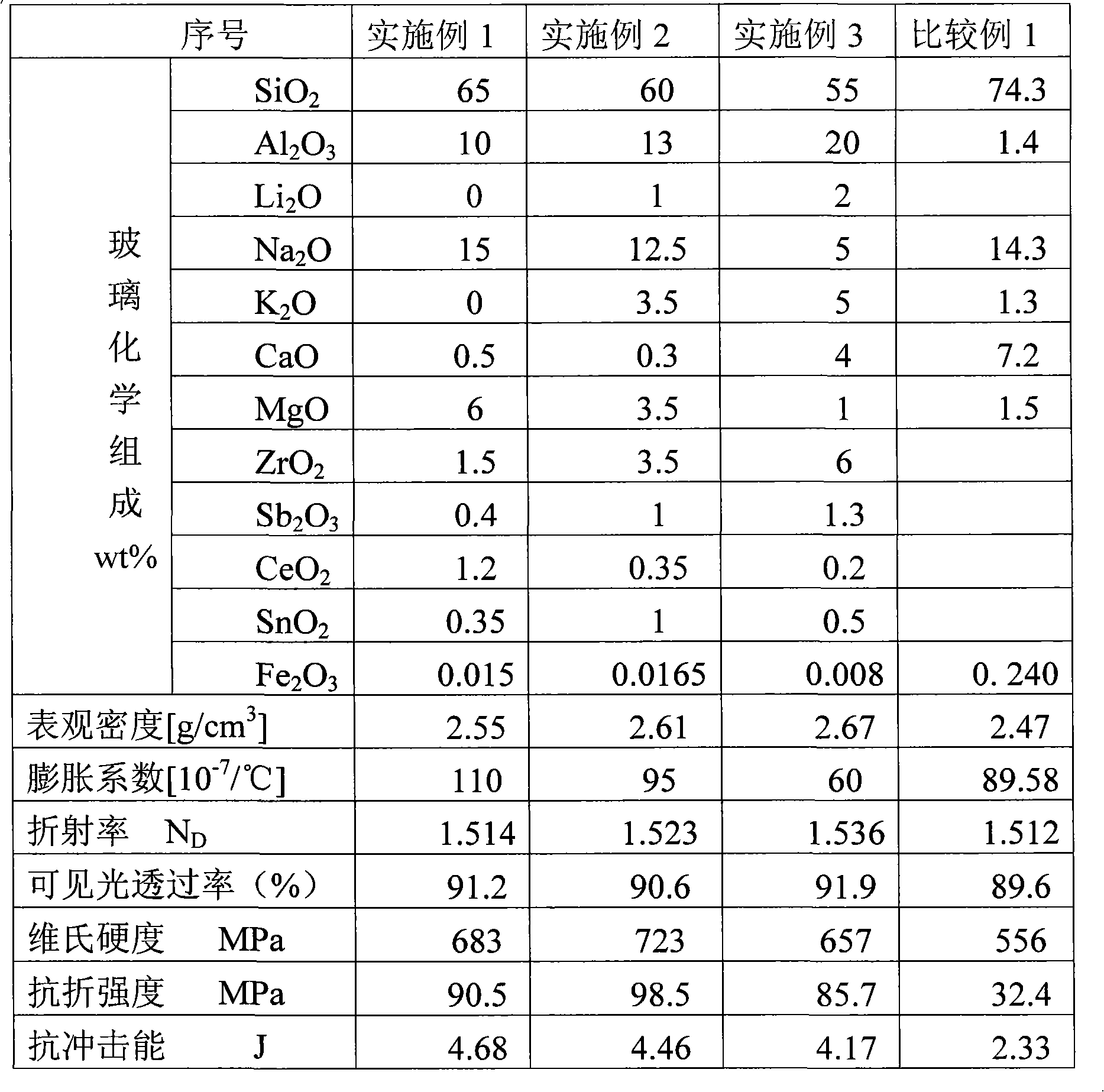

[0038] The present invention is described based on the embodiments, and Table 1 is the composition and performance of the embodiments of the present invention and comparative examples.

[0039] SiO 2 55~65

[0040] al 2 o 3 10~20

[0041] Li 2 O 0~2

[0042] Na 2 O 5~15

[0043] K 2 O 0~5

[0044] MgO 1~6

[0045] CaO 0.5~4

[0046] ZrO 2 1.5~6

[0047] SnO 2 0.35~1.0

[0048] CeO 2 0.2~1.2

[0049] Sb 2 o 3 0.4~1.3

[0050] First, select raw materials according to the glass composition of Example 1 in Table 1, so that the ingredients meet the glass composition of Example 1, and then use a platinum crucible to melt at a temperature of 1620 ° C for 24 hours. After melting, the melt is hydraulically formed into a specified plate glass product, then annealed, then ground and polished to make a glass sample, the sample thickness is 1.0mm, and then chemically tempered, the chemical strengthening temperature is 450 ℃, the chemical strengthe...

Embodiment 2

[0059] Refer to Example 2 in Table 1 for the actual composition of the glass, use the same raw materials and raw material requirements as in Example 1, mix according to the glass composition of Example 2, and then use a platinum crucible to melt at 1620°C for 24 hours. After melting, the melt is hydraulically formed into a specified plate glass product, then annealed, ground and polished to make a glass sample, the sample thickness is 1.0mm, and then chemically tempered, the chemical strengthening temperature is 450°C , The chemical strengthening time is 3 hours. Table 1 shows the basic properties of the sample, the visible light transmittance is 90.6%, the Vickers hardness is 723Mpa, the flexural strength is 98.5Mpa, and the impact energy is 4.46J. From the perspective of performance, the mechanical strength has been greatly improved, and the mechanical properties after chemical strengthening treatment have completely exceeded the chemical strengthening treatment results of C...

Embodiment 3

[0061] For the actual composition of the glass, refer to Example 3 in Table 1, use the same raw materials as in Example 1, mix according to the glass composition of Example 3, and then use a platinum crucible to melt at 1620°C for 24 hours. After melting, the melt is hydraulically formed into a specified plate glass product, then annealed, ground and polished to make a glass sample, the sample thickness is 1.0mm, and then chemically tempered, the chemical strengthening temperature is 450°C , The chemical strengthening time is 3 hours. Table 1 shows the basic properties of the sample, the visible light transmittance is 91.9%, the Vickers hardness is 657Mpa, the flexural strength is 85.7Mpa, and the impact resistance is 4.17J. From the perspective of performance, the mechanical strength has been greatly improved, and the mechanical properties after chemical strengthening treatment have completely exceeded the chemical strengthening treatment results of Comparative Example 1 (com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com