White heat-curable silicone/epoxy hybrid resin composition for optoelectronic use, making method, premolded package, and LED device

a hybrid resin and optoelectronic technology, applied in the direction of solid-state devices, dyeing processes, textiles and paper, etc., can solve the problems of reducing mechanical strength, unable to solve the problem of yellowing in long-term, and encapsulant and substrate degradation in a substantial way, so as to achieve effective curability and improve strength, the effect of maintaining heat resistance and light resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

[0102]A 1-L flask was charged with 100 parts of methyltrichlorosilane and 200 parts of toluene. Under ice cooling, a mixture of 8 parts of water and 60 parts of isopropyl alcohol was added dropwise over 5 to 20 hours while maintaining an internal temperature between −5° C. and 0° C. The reaction mixture was then heated and stirred at the reflux temperature for 20 minutes. The reaction mixture was cooled to room temperature, after which 12 parts of water was added dropwise below 30° C. over 30 minutes, followed by 20 minutes of stirring. Further 25 parts of water was added dropwise, after which the mixture was stirred at 40-45° C. for 60 minutes. Thereafter, 200 parts of water was added whereupon the organic layer was separated. The organic layer was washed until neutral. This was followed by azeotropic dehydration, filtration and vacuum stripping, yielding 36.0 parts of a heat-curable silicone resin (A-1) having the following formula (5) as a colorless transparent solid (m.p. 76° C....

synthesis example 2

[0103]A 1-L flask was charged with 80 parts of methyltrichlorosilane, 20 parts of tetraethoxysilane, and 200 parts of toluene. Under ice cooling, a mixture of 8 parts of water and 60 parts of isopropyl alcohol was added dropwise over 5 to 20 hours while maintaining an internal temperature between −5° C. and 0° C. The reaction mixture was then heated and stirred at the reflux temperature for 20 minutes. The reaction mixture was cooled to room temperature, after which 12 parts of water was added dropwise below 30° C. over 30 minutes, followed by 20 minutes of stirring. Further 25 parts of water was added dropwise, after which the mixture was stirred at 40-45° C. for 60 minutes. Thereafter, 200 parts of water was added whereupon the organic layer was separated. The organic layer was washed until neutral. This was followed by azeotropic dehydration, filtration and vacuum stripping, yielding 36.0 parts of a heat-curable silicone resin (A-2) having the following formula (6) as a colorless...

synthesis example 3

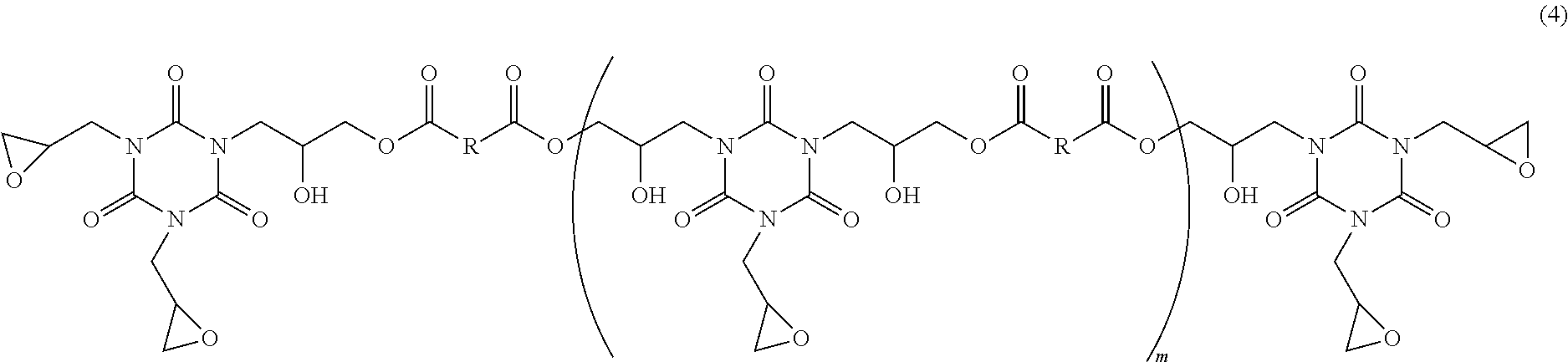

[0116]Preparation of Epoxy Resin Prepolymer

[0117]Reaction of an epoxy resin with an acid anhydride was carried out by combining suitable amounts of ingredients and heating under appropriate conditions as shown in Table 1.

TABLE 1Pre-reaction productFormulation (pbw)(1)(2)(3)PremixingTEPIC-S454545Rikacid MH5555Rikacid TH55Triphenyl33phosphiteMolar ratioepoxy / acid1.41.41.4anhydrideReaction conditions80° C. / 10 hr80° C. / 10 hr80° C. / 10 hrWeight average molecular300031003000weight

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com