Polypropylene composition, and preparation method and application thereof

A technology for polypropylene composition and homopolypropylene, which is applied in the field of polypropylene composition and its preparation, can solve the problems of destroying polypropylene crystallinity, decreasing rigidity, hardness and heat resistance, and increasing haze.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

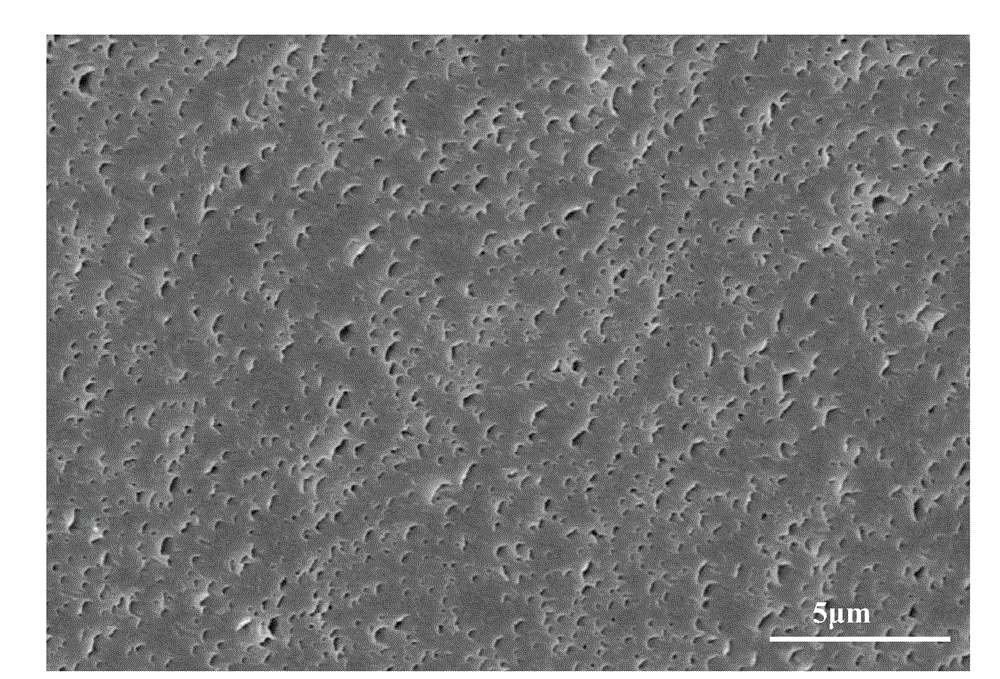

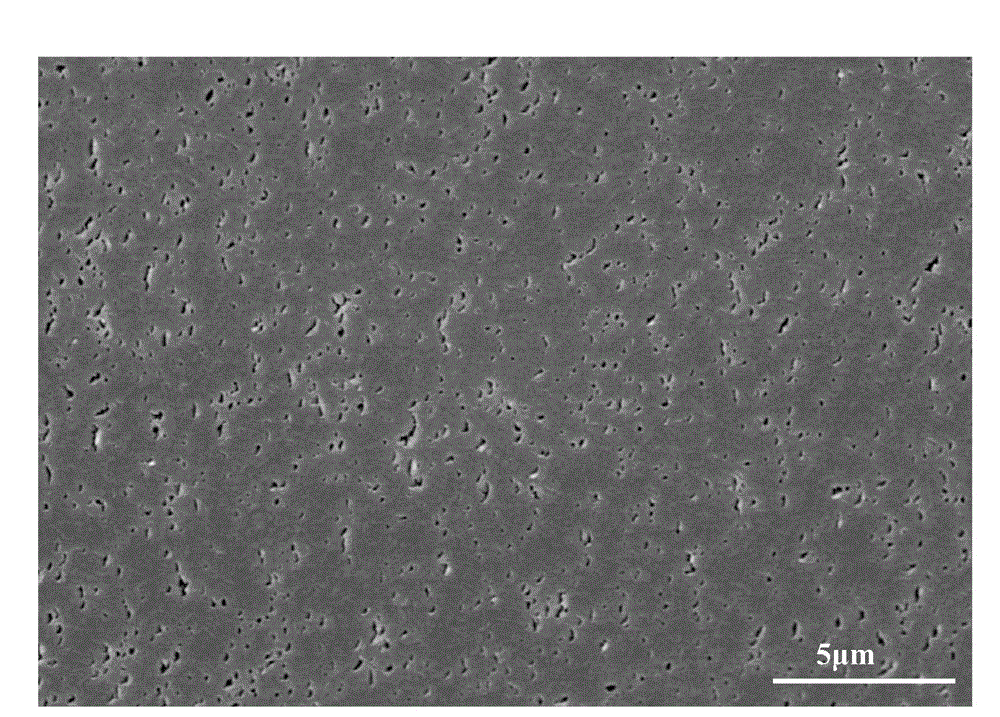

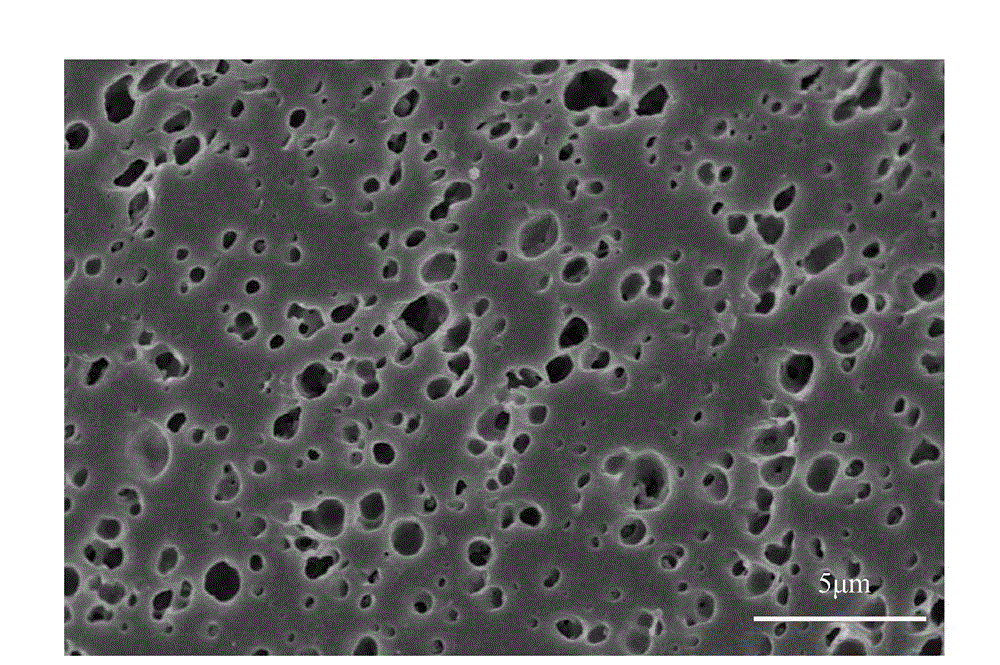

Image

Examples

Embodiment 1

[0062] The polypropylene composition in the present invention and its embodiment obtains by following method:

[0063] The main catalyst (titanium-containing active solid catalyst component) is obtained by the method described in Example 1 of Chinese patent CN93102795, its Ti content: 2.4wt%, Mg content 18.0wt%, di-n-butyl phthalate content: 13wt %.

[0064] The polymerization reaction was carried out on a polypropylene pilot plant.

[0065] Polymerization method and steps are as follows:

[0066] Pre-polymerization: After the main catalyst, co-catalyst (triethylaluminum) and external electron donor are pre-contacted at 10°C for 20 minutes, they are continuously added to the pre-polymerization reactor for pre-polymerization reactor, and the triethyl aluminum that enters the pre-polymerization reactor The flow rate of base aluminum (TEA) is 6.33g / hr, the flow rate of methylcyclohexyldimethoxysilane (CHMMS) is 0.63g / hr, and the flow rate of main catalyst is 0.01g / hr. The pre-...

Embodiment 2

[0073] The catalyst used in embodiment 2, pre-complexation and polymerization process conditions are identical with embodiment 1. The difference from Example 1 is that in Example 2, the hydrogen concentration in the loop reactor is 400ppm, and the hydrogen concentration in the gas phase reactor is 160000ppm. The specific process conditions are shown in Table 1. The obtained polymer product was measured according to the same method as in Example 1, and the results are shown in Table 2.

Embodiment 3

[0075] The catalyst used in embodiment 3, pre-complexation and polymerization process conditions are identical with embodiment 1. The difference from Example 1 is that in Example 3, the hydrogen concentration in the loop reactor is 800ppm, the ethylene / (ethylene+propylene)=0.1 (volume ratio) in the gas phase reactor, and the hydrogen concentration is 47000ppm. The specific process conditions are shown in Table 1. The obtained polymer product was measured according to the same method as in Example 1, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com