Composite-material tube, manufacturing method, hydraulic cylinder barrel and piston rod

A composite material and manufacturing method technology, applied in the direction of fluid pressure actuating devices, etc., can solve problems such as enhancing connection strength, and achieve the effects of increasing connection strength, saving reinforcing fiber materials, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

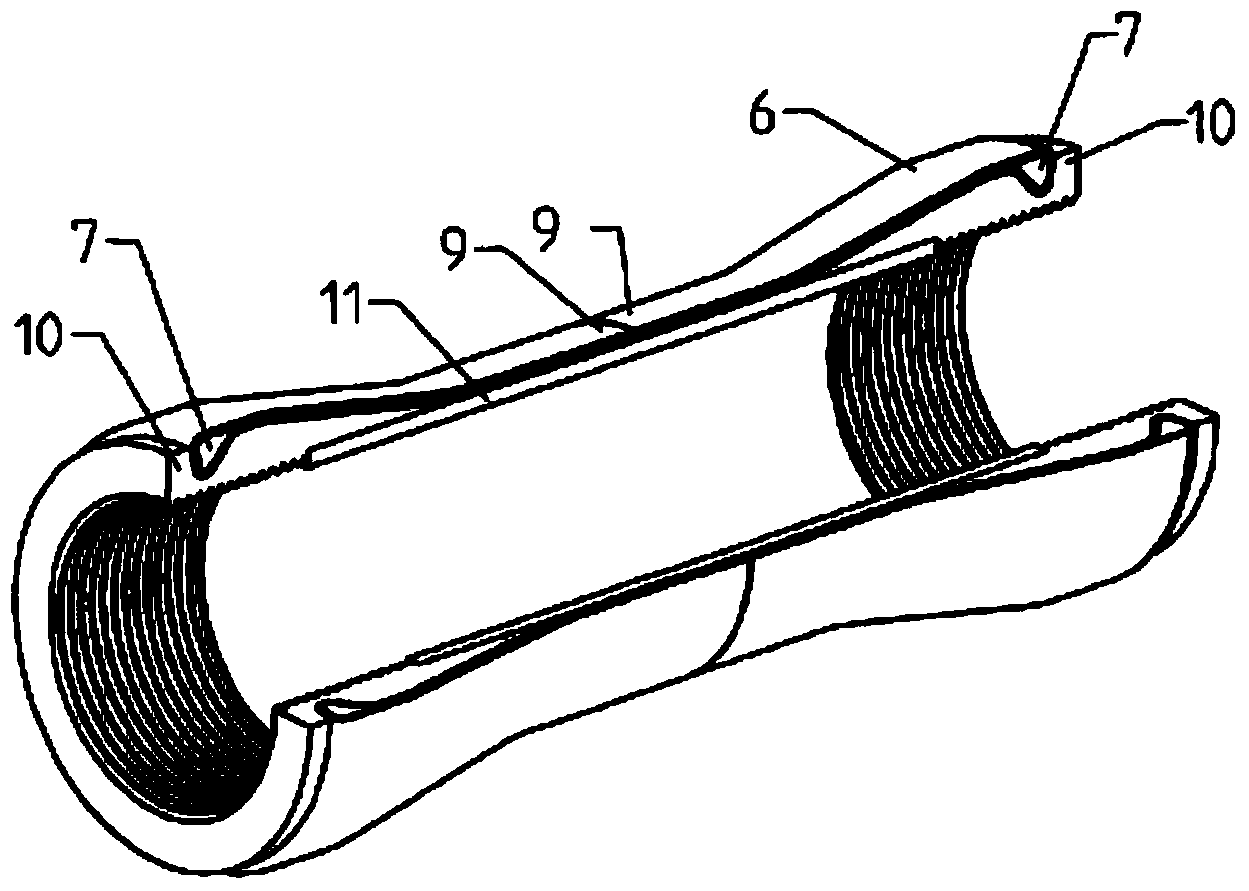

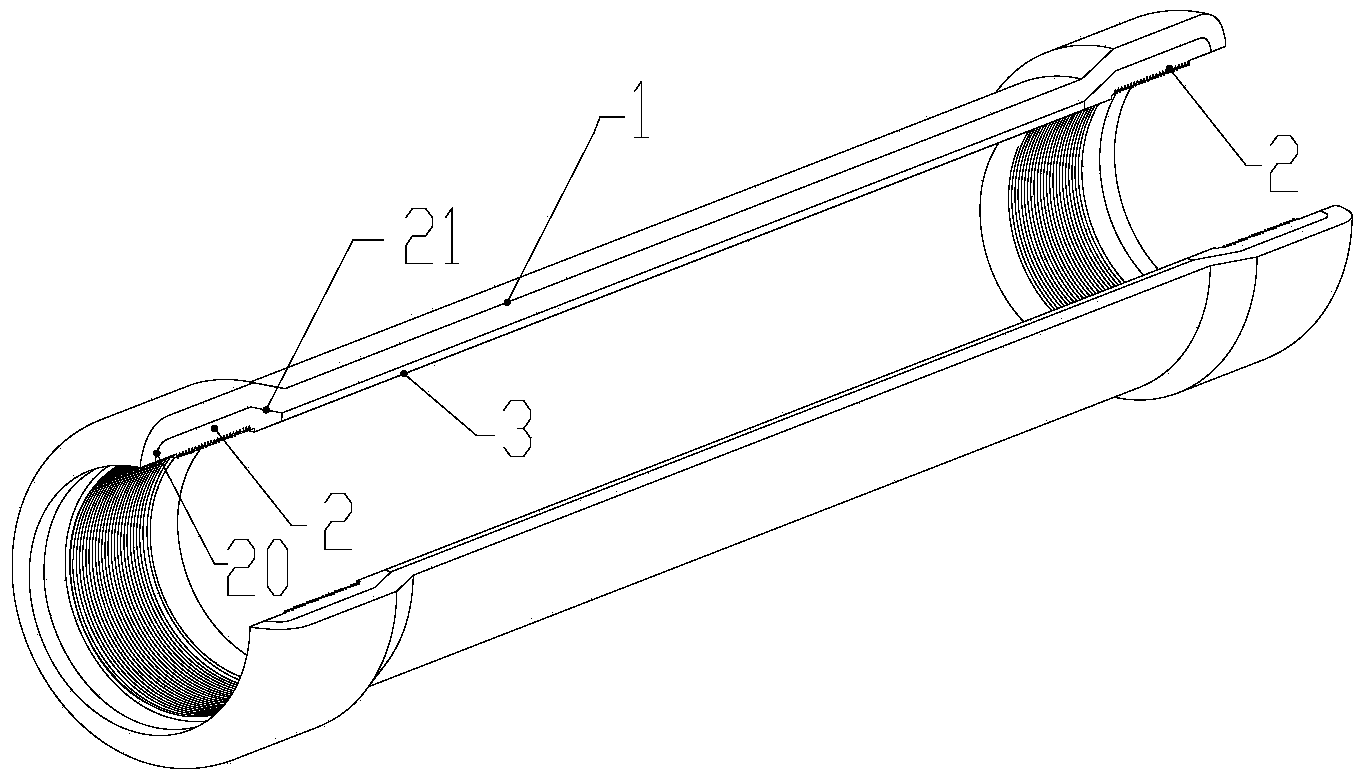

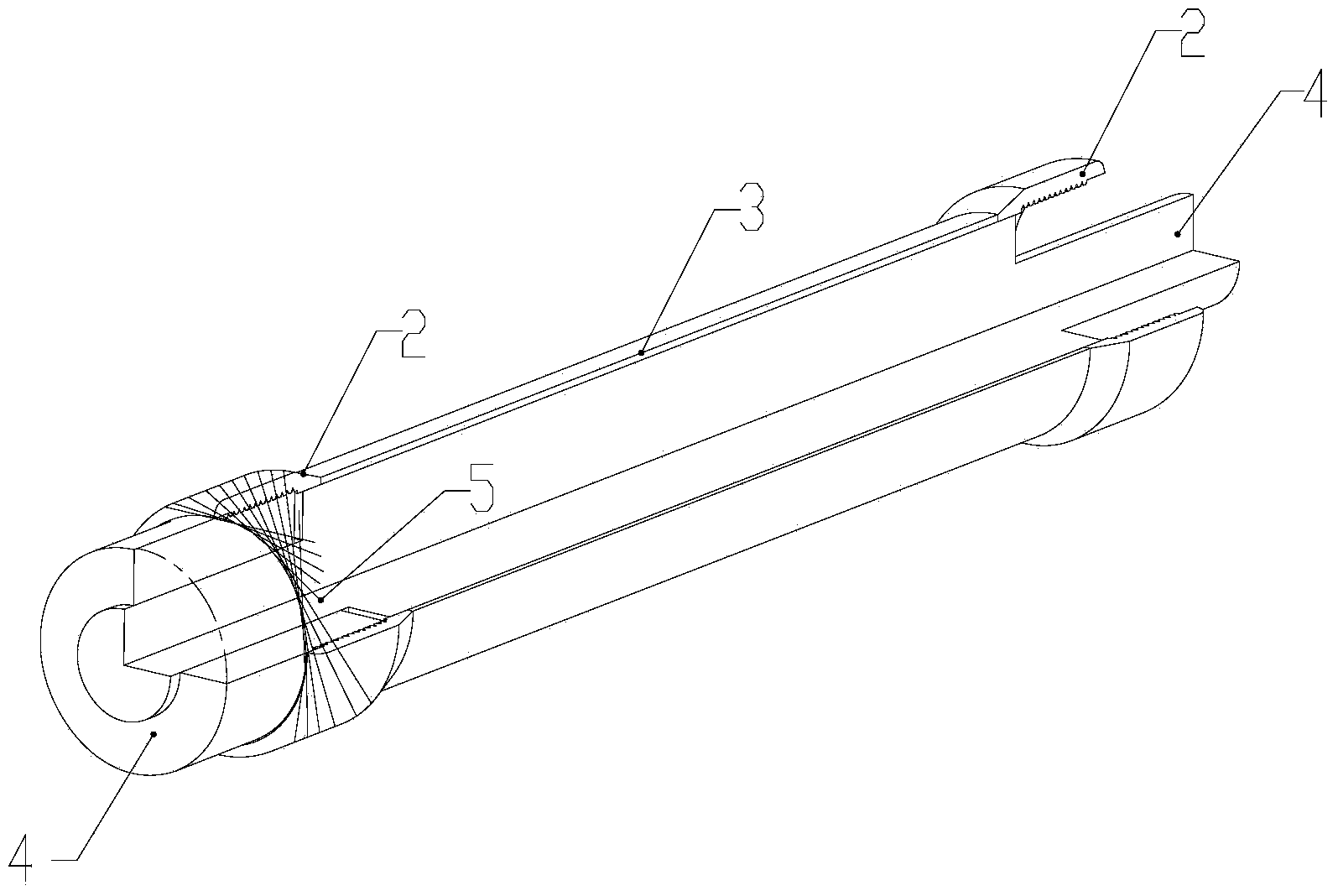

[0029] Such as figure 2 As shown, a hydraulic cylinder tube includes two connecting rings 2, a tube tube 1, a wear-resistant lining 3,

[0030] The wear-resistant lining 3 is located between the two connecting rings 2, and the two connecting rings 2 and the wear-resistant lining 3 are nested in the tube 1. The connecting ring 2 is provided with internal threads or a keyway. The outer diameter of the connecting ring 2 is larger than the outer diameter of the wear-resistant inner lining 3. A transition cone 21 is provided at the connection between one end of the connecting ring 2 and the wear-resistant inner lining 3. A circular arc transition surface 20 is adopted at one end. The bob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com