Toner, method of manufacturing the same, image forming apparatus and image forming method

A manufacturing method and technology of toner, applied in the field of toner, can solve the problems of increasing charging uniformity, insufficient smoothness of toner surface, poor environmental stability, etc., and achieve good charging uniformity and good environmental stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

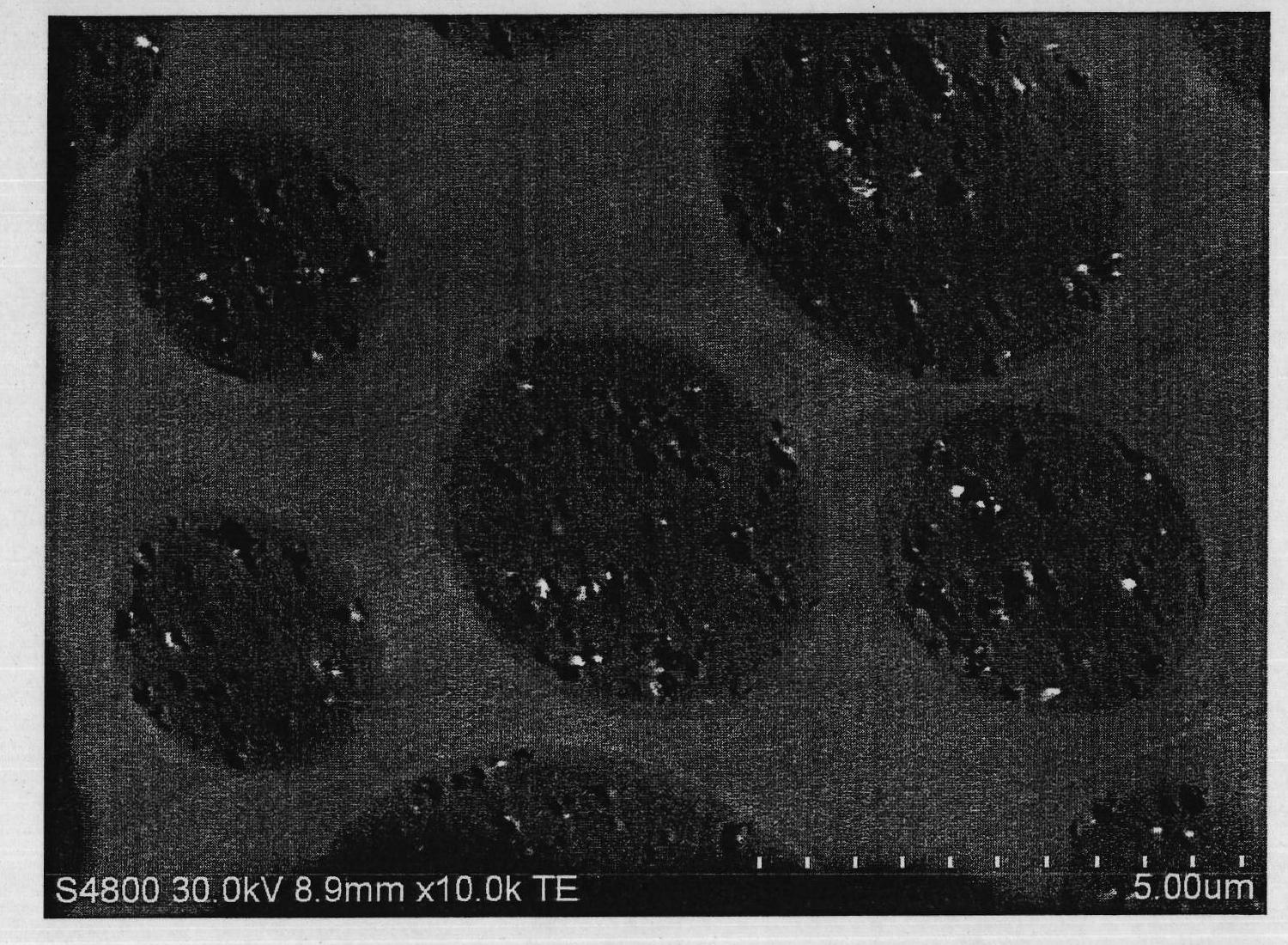

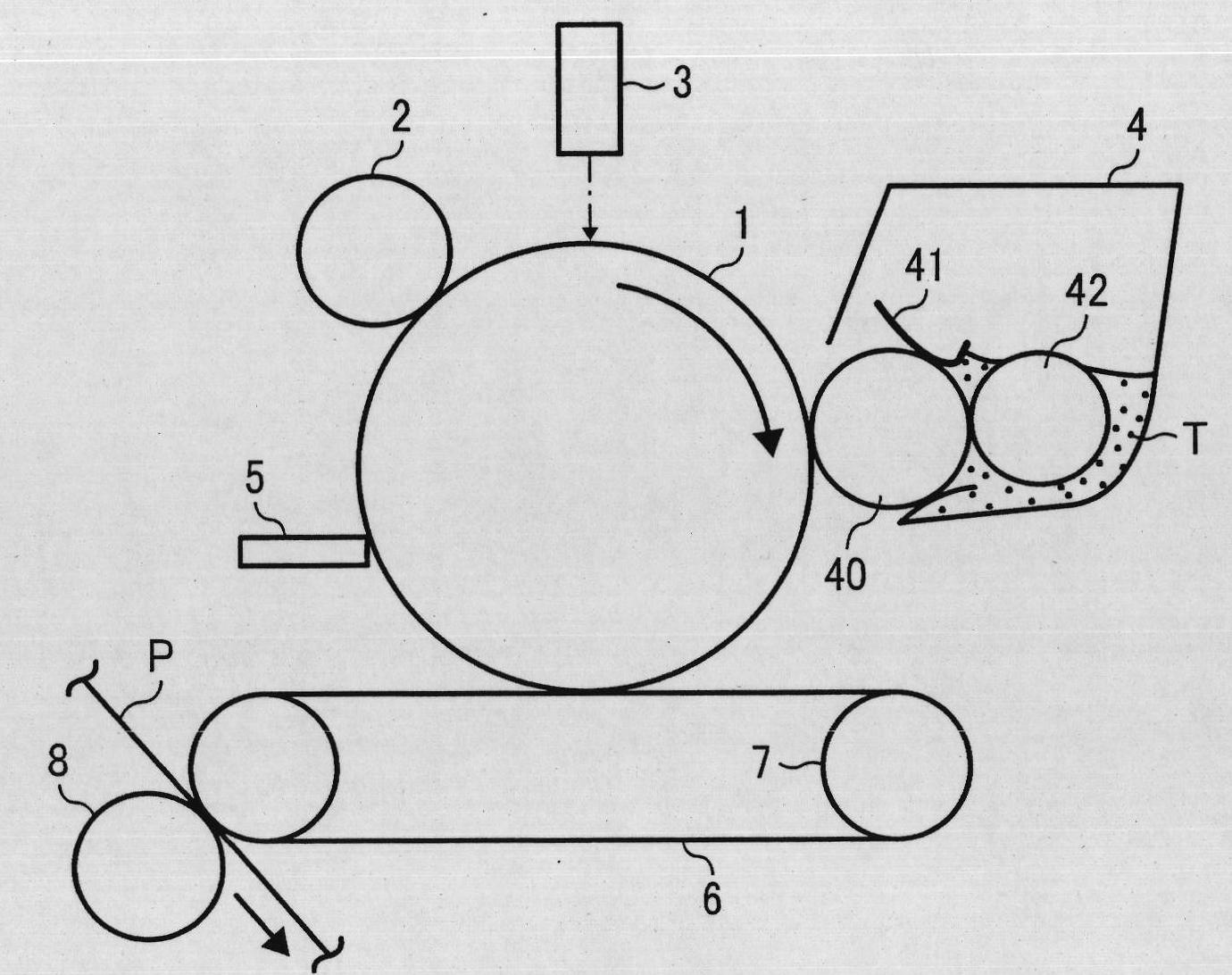

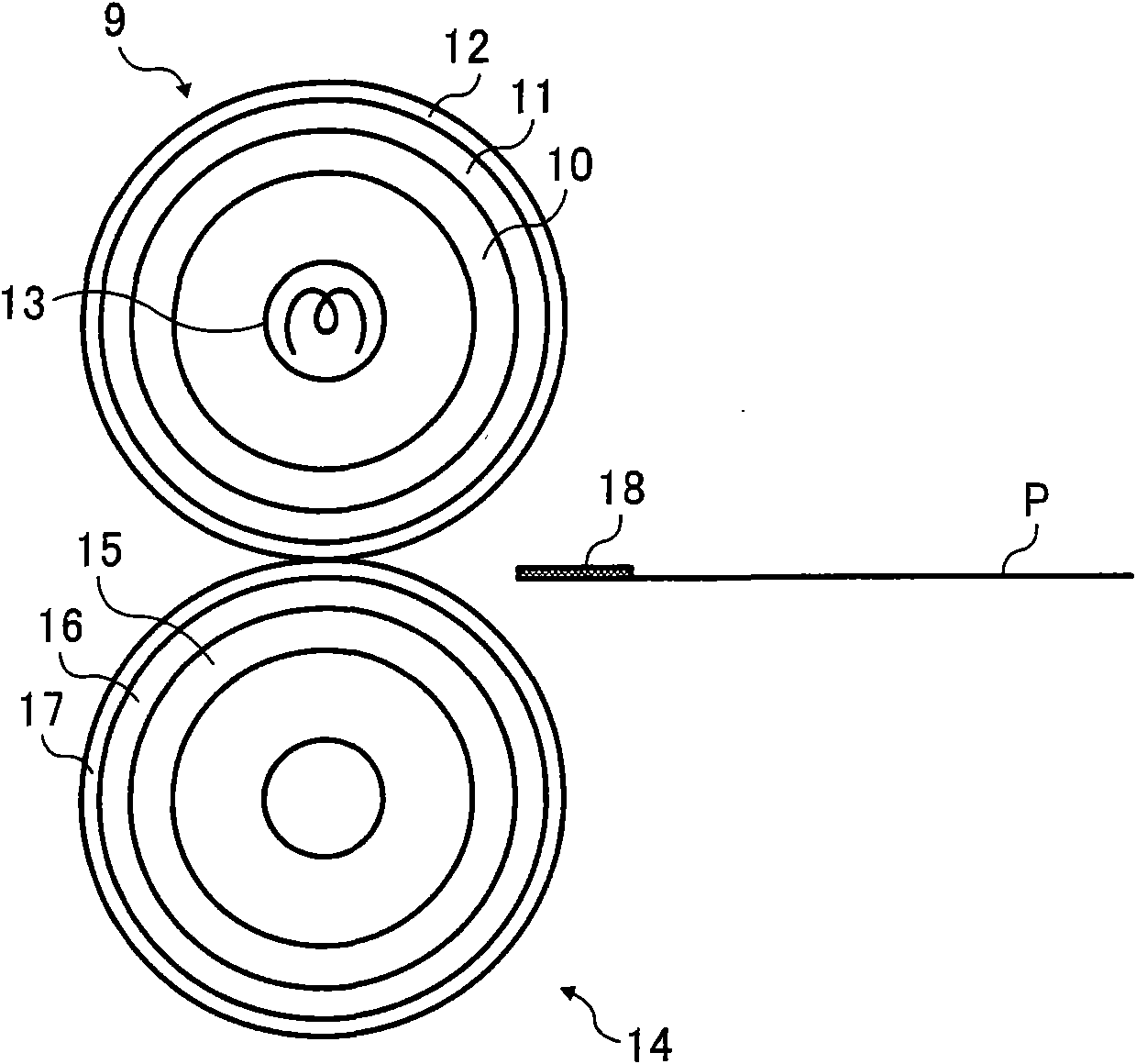

Image

Examples

Embodiment 1

[0323]

[0324] Put 24 parts of [polyester resin 1], 8 parts of paraffin (melting point: 72°C), and 96 parts of ethyl acetate in a container with a stirring rod and a thermometer, raise the temperature to 80°C under stirring, and keep it at 80°C After 5 hours, cool to 30° C. within 1 hour. Next, add 35 parts of [Master Batch 1], mix for 1 hour, replace the container, and use a bead mill (Ultrabeadmill, manufactured by IMEX Co. Ltd.) to disperse under the following conditions, that is, the infusion rate is 1kg / hr, Speed 6m / sec, filling 0.5mm zirconia grinding beads 80% by volume, and 3 channels to obtain [raw material solution 1]. Next, 76.5 parts of a 70% ethyl acetate solution of [polyester 1] was added to 81.5 parts of [raw material solution 1], and stirred for 2 hours with a Sany motor to obtain [oil phase 1]. Ethyl acetate was added to [Oil Phase 1], and the solid content concentration therein (measured at 130° C., 30 min) was adjusted to 50%.

[0325]

[0326] 202...

Embodiment 2

[0341]

[0342] Add 61.0 parts of [polyester 1] 70% ethyl acetate solution to 81.5 parts of [raw material solution 1], and stir for 2 hours with a Sany motor to obtain [oil phase 2]. Ethyl acetate was added to [oil phase 2], and the solid content concentration therein (measured at 130° C., 30 min) was adjusted to 50%.

[0343]

[0344] Add 0.4 parts of isophorone diamine and 23.2 parts of [prepolymer] to the entire amount of the above [oil phase 2], mix at 5000 rpm for 1 minute with a TK emulsifying homogenizer (manufactured by special mechanism), and then add [water phase 1] The whole amount was mixed with a TK emulsifying homogenizer in the range of 8000-13000rpm while adjusting for 20 minutes to obtain [nuclear particle paste 2].

[0345]

[0346] While stirring the above-mentioned [nuclear particle paste 2] at 200 rpm with a Sany motor, 60 parts of [polyester microparticle dispersion liquid 1] was added dropwise over 5 minutes, and the stirring was continued for 30 m...

Embodiment 3

[0348]

[0349] Add 53.2 parts of [polyester 1] 70% ethyl acetate solution to 81.5 parts of [raw material solution 1], and stir for 2 hours with a Sany motor to obtain [oil phase 3]. Ethyl acetate was added to [oil phase 3], and the solid content concentration therein (measured at 130° C., 30 min) was adjusted to 50%.

[0350]

[0351] Add 0.4 parts of isophorone diamine and 21.3 parts of [prepolymer] to the entire amount of the above [oil phase 3], mix at 5000 rpm for 1 minute with a TK emulsifying homogenizer (manufactured by special mechanism), and then add [water phase 1] The whole amount was mixed with a TK emulsifying homogenizer in the range of 8000-13000 rpm for 20 minutes while adjusting to obtain [nuclear particle paste 3].

[0352]

[0353] While stirring the above-mentioned [nuclear particle paste 3] at 200 rpm with a Sany motor, add 80 parts of [polyester microparticle dispersion 1] dropwise over 5 minutes, and continue stirring in this state for 30 minutes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com