Preparation method of epoxidized soybean oil modified PMMA (polymethylmethacrylate)

A technology of polymethyl methacrylate and epoxidized soybean oil, applied in the field of polymer materials, can solve the problems of difficult industrialization, insufficient material toughness, complicated preparation methods, etc., and achieves improved impact strength, maintained transparency and heat resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

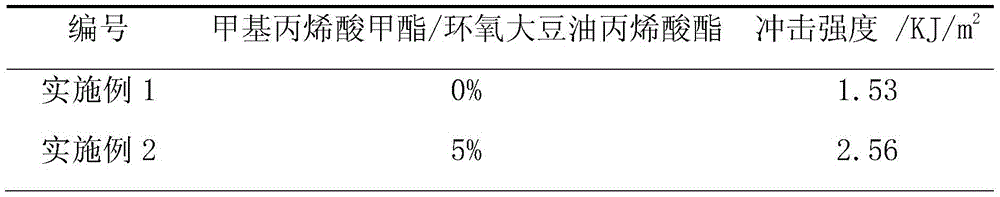

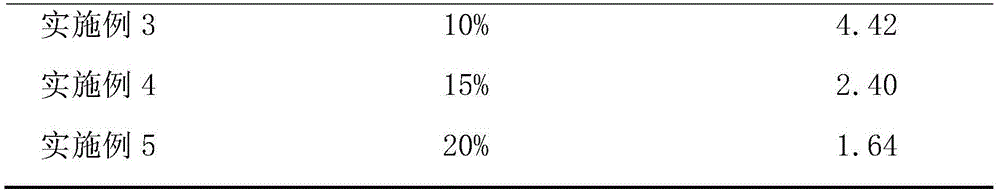

Examples

Embodiment 1

[0025] A. Preparation of Epoxy Soybean Oil Acrylate

[0026] (1), first add 100g epoxy soybean oil and 0.1050g polymerization inhibitor nitroxide free radical piperidinol in the 250 milliliter three-neck round-bottomed flask equipped with strong stirrer and thermometer, be heated to 80 ℃ and drop 5.1654g formazan Based on the mixture of acrylic acid and 0.1050g catalyst triethylamine, the rate of addition is controlled, and the addition is constant.

[0027] (2), after 30 minutes of dropwise addition, the temperature rose to 100° C., and after the esterification rate reached 90%, the reaction was stopped.

[0028] (3), after the reaction finishes, the product is passed through the column with basic alumina, and the underpressure distillation removes the polymerization inhibitor therein to obtain light yellow transparent oily thing epoxy soybean oil acrylate.

[0029] B. Polymerization of epoxy soybean oil acrylate and methyl methacrylate

[0030] (1), add 95g of toluene as s...

Embodiment 2

[0034] A. Preparation of Epoxy Soybean Oil Acrylate

[0035] (1), first add 100g epoxy soybean oil and 0.3207g polymerization inhibitor p-tert-butylcatechol to a 250ml three-necked round-bottomed flask equipped with a strong stirrer and a thermometer, heat to 85°C and add 6.8872g methyl The mixture of acrylic acid and 0.4276g catalyst tetrabutylammonium bromide, the rate of addition is controlled, and is added dropwise constantly.

[0036] (2), after 30 minutes of dropwise addition, the temperature rose to 105° C., and after the esterification rate reached 90%, the reaction was stopped.

[0037] (3), after the reaction finishes, the product is passed through the column with basic alumina, and the underpressure distillation removes the polymerization inhibitor therein to obtain light yellow transparent oily thing epoxy soybean oil acrylate.

[0038] B. Polymerization of epoxy soybean oil acrylate and methyl methacrylate

Embodiment 3

[0043] A. Preparation of Epoxy Soybean Oil Acrylate

[0044] (1), first add 100g epoxy soybean oil and 0.5350g polymerization inhibitor hydroquinone to a 250ml three-neck round bottom flask equipped with a strong stirrer and a thermometer, and add 7.2060g acrylic acid and 0.6430g dropwise when heated to 90°C The mixture of catalyst triphenylphosphine, control the rate of addition, constant drop.

[0045] (2) After 30 minutes of dropwise addition, the temperature rose to 110° C., and after the esterification rate reached 90%, the reaction was stopped.

[0046] (3), after the reaction finishes, the product is passed through the column with basic alumina, and the underpressure distillation removes the polymerization inhibitor therein to obtain light yellow transparent oily thing epoxy soybean oil acrylate.

[0047] B. Polymerization of epoxy soybean oil acrylate and methyl methacrylate

[0048] (1), add 95g of ethyl acetate as a solvent in a 500ml four-neck round bottom flask e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com