High strength aluminosilicate glass and chemically toughening process thereof

An aluminosilicate glass, chemical tempering technology, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems affecting the service life of the whole machine and the screen display effect, roughness, damaged surface of the display screen, etc. The mechanical strength is enhanced, the flexural strength is improved, and the effect of safe use is satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

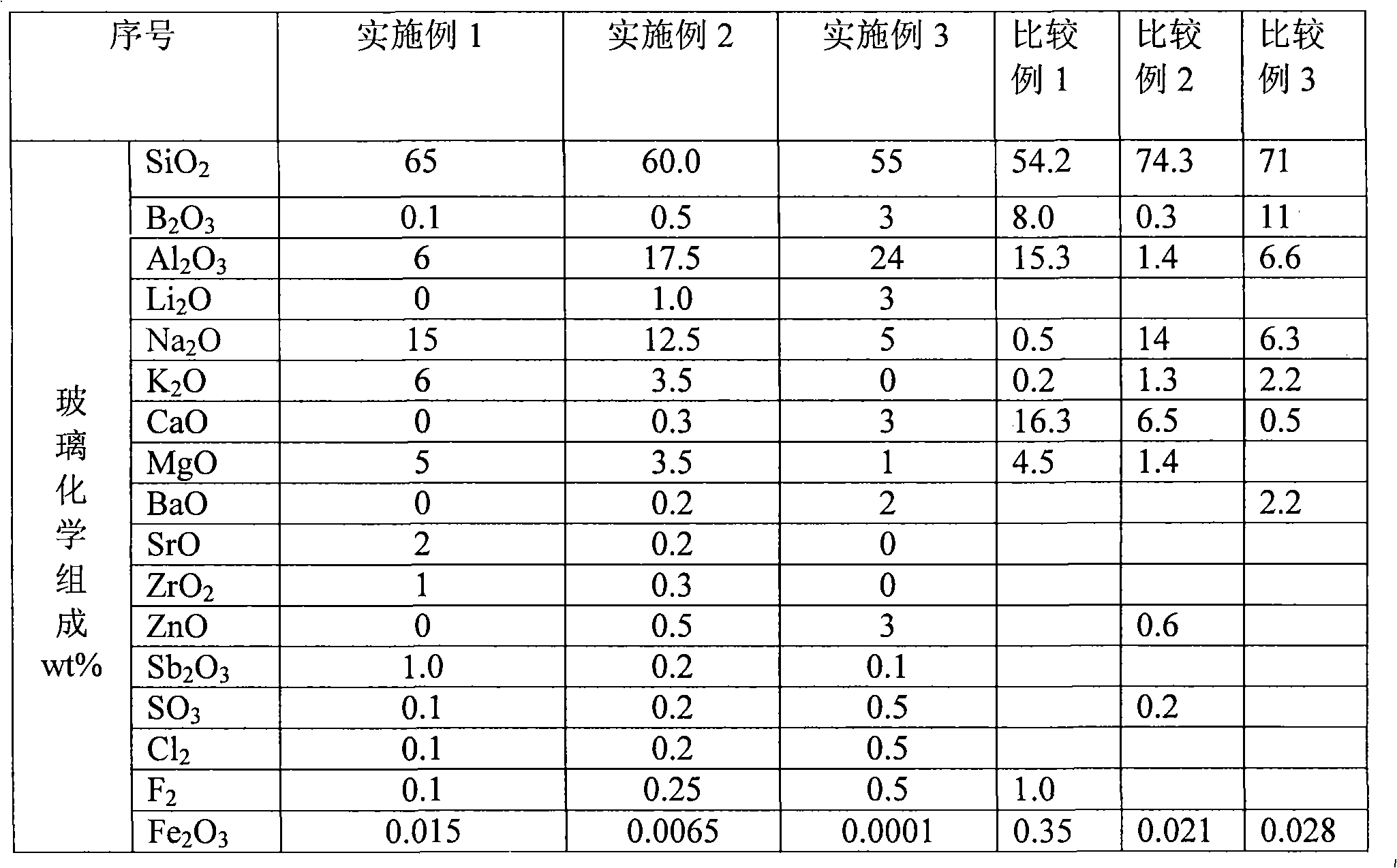

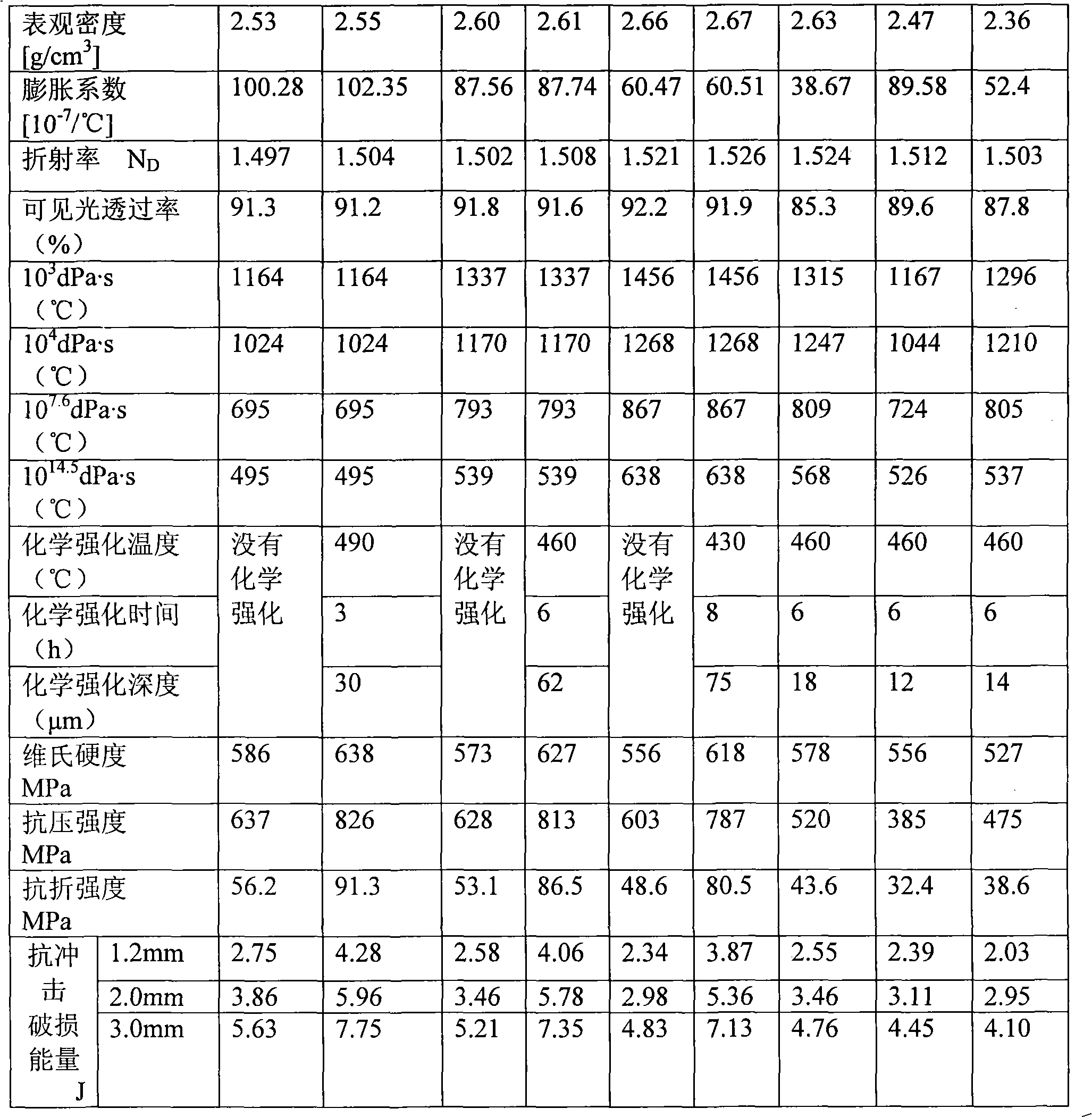

[0082] Refer to Example 2 in Table 1 for the actual composition of the glass, use the same raw materials and raw material requirements as in Example 1, mix according to the glass composition of Example 2, and then use a platinum crucible to melt at 1600 ° C for 24 hours. After melting, the melt is hydraulically formed into a specified plate glass product, then annealed, ground and polished to make a glass sample, which is divided into two groups, one group is not chemically strengthened, and the other group is chemically tempered Treatment, the chemical strengthening temperature is 460°C, and the chemical strengthening time is 6 hours. The basic properties of the samples are shown in Table 1. In terms of performance, there is almost no difference in apparent density, expansion coefficient, refractive index, transmittance, and glass characteristic viscosity point before and after chemical strengthening treatment. However, in terms of mechanical strength, there is a big differe...

Embodiment 3

[0084] For the actual composition of the glass, refer to Example 3 in Table 1, use the same raw materials as in Example 1, mix according to the glass composition of Example 3, and then use a platinum crucible to melt at 1670°C for 24 hours. After melting, the melt is hydraulically formed into a specified plate glass product, and then annealed, ground and polished to make glass samples. The samples are divided into two groups, one group without chemical strengthening treatment, and one group with chemical strengthening treatment. Chemical tempering treatment, chemical strengthening temperature 430°C, chemical strengthening time 8 hours. The basic properties of the samples are shown in Table 1. In terms of performance, there is almost no difference in apparent density, expansion coefficient, refractive index, transmittance, and glass characteristic viscosity point before and after chemical strengthening treatment. However, in terms of mechanical strength, there is a big differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com