Patents

Literature

324 results about "Sodium titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature ceramic dielectric composition and capacitors made from the composition

ActiveUS8076257B1Highly desirable propertyExcellent dielectric constant/voltage characteristicFixed capacitor dielectricStacked capacitorsCapacitanceDielectric

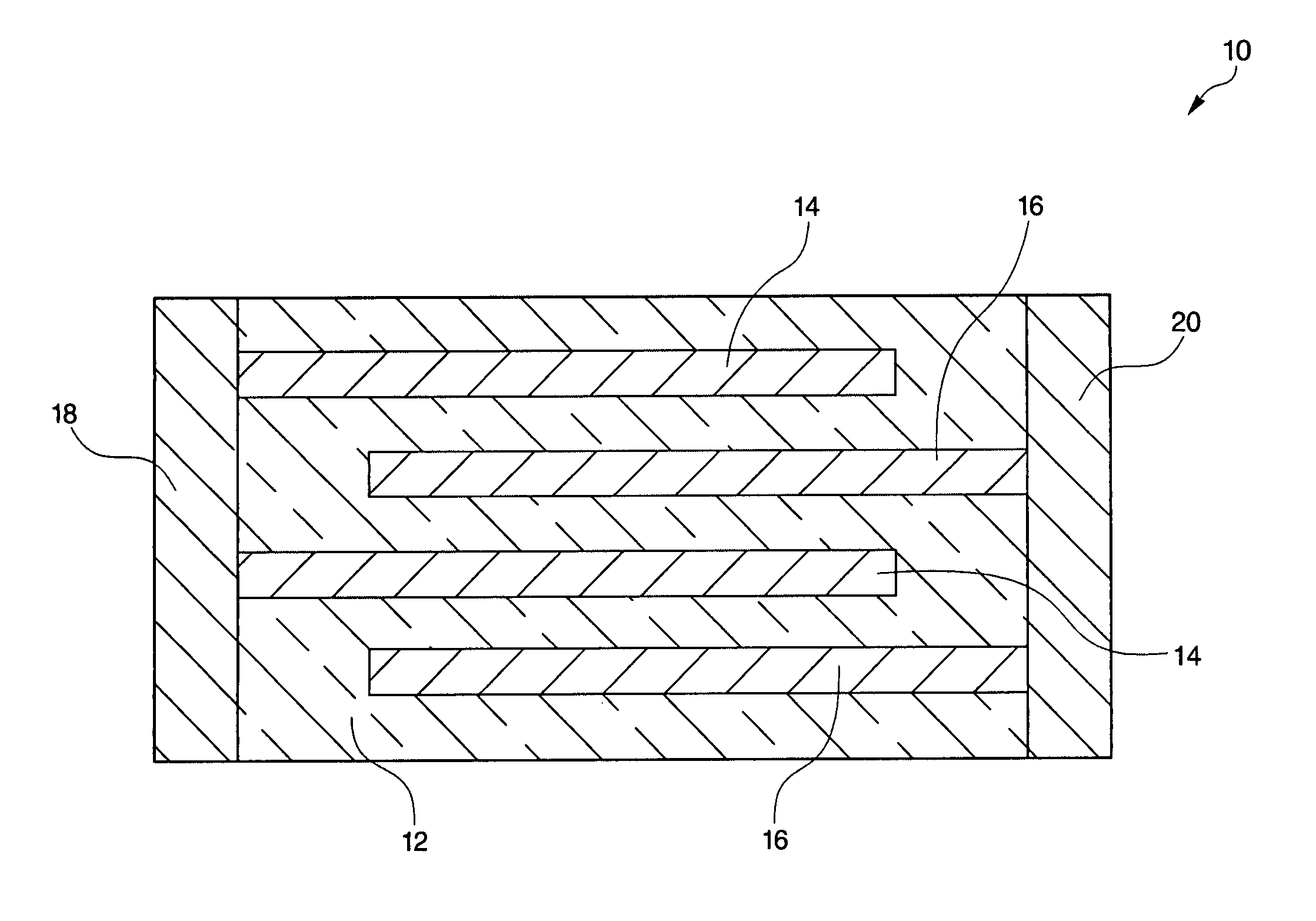

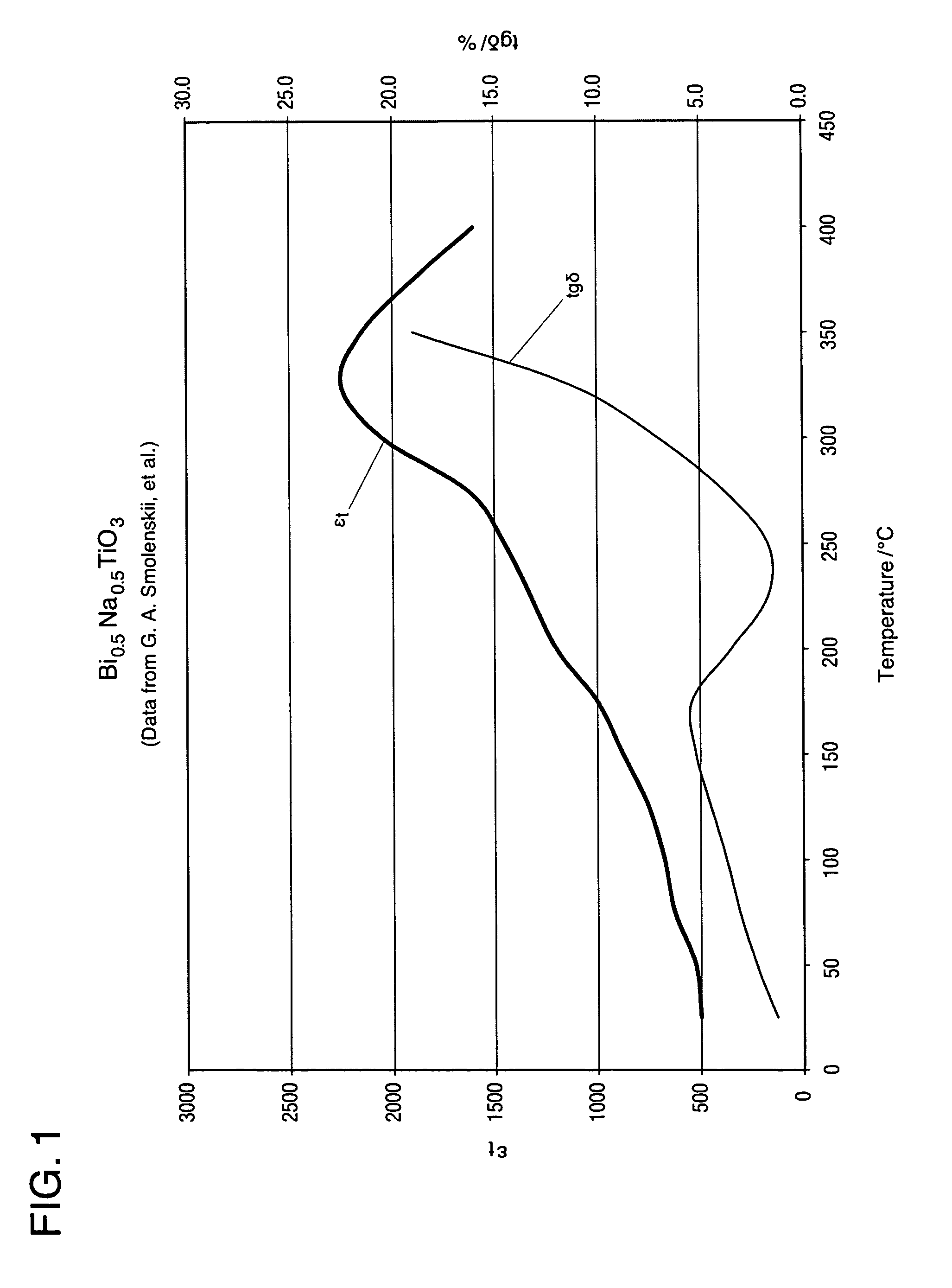

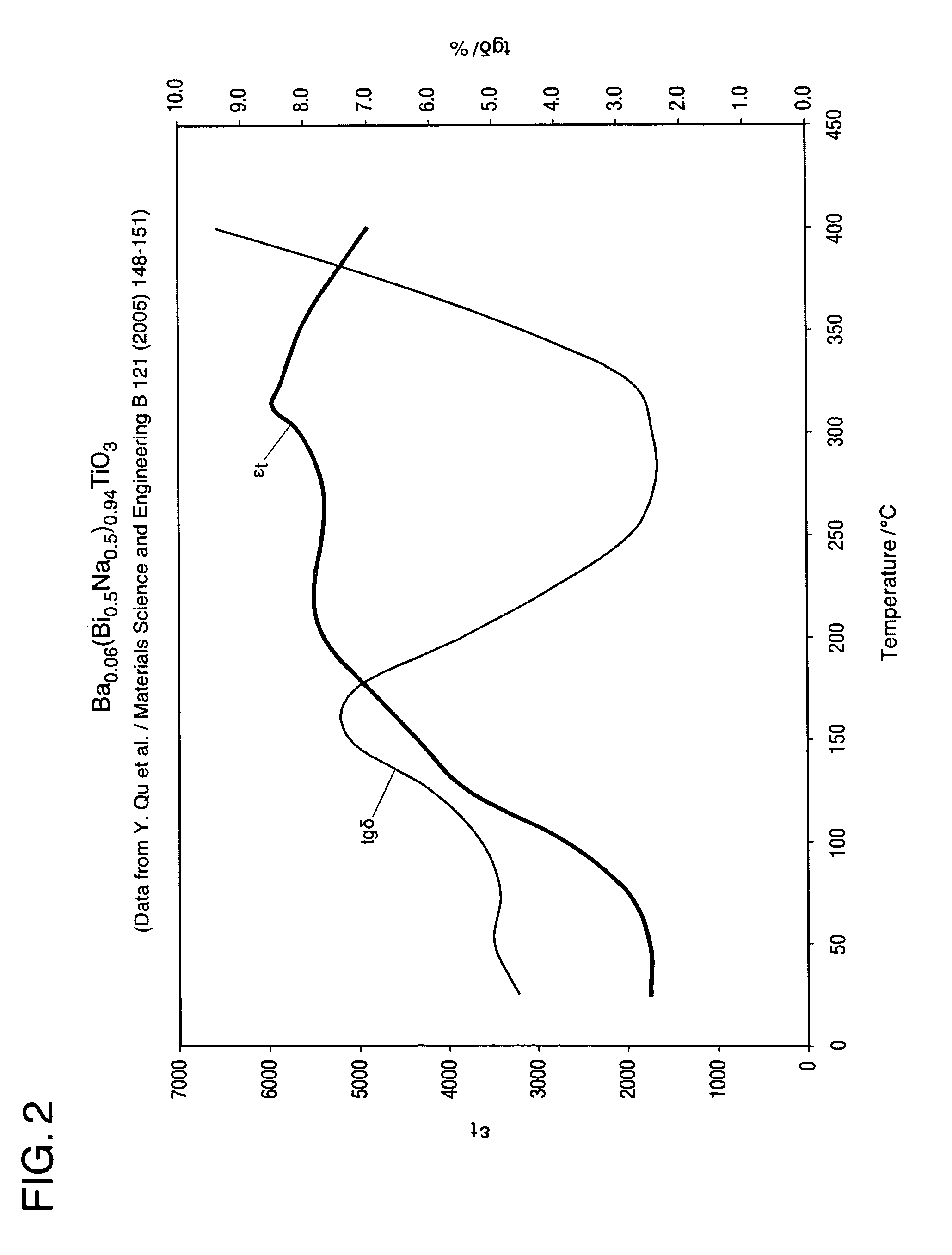

A bismuth sodium titanate (Bi0.5Na0.5TiO3) base material is modified by the partial substitution of aliovalent A-site cations such as barium (as BaO) or strontium (as SrO), as well as certain b-site donor / acceptor dopants and sintering aids to form a multi-phase system, much like known “core / shell” X7R dielectrics based solely on BaTiO3. The resulting ceramic dielectric composition is particularly suitable for producing a multilayer ceramic capacitor (10) that maintains high dielectric constant (and thus the capability of maintaining high capacitance) over a broad temperature range of from about 150° C. to about 300° C. Such capacitors (10) are appropriate for high temperature power electronics applications in fields such as down-hole oil and gas well drilling.

Owner:FERRO CORP

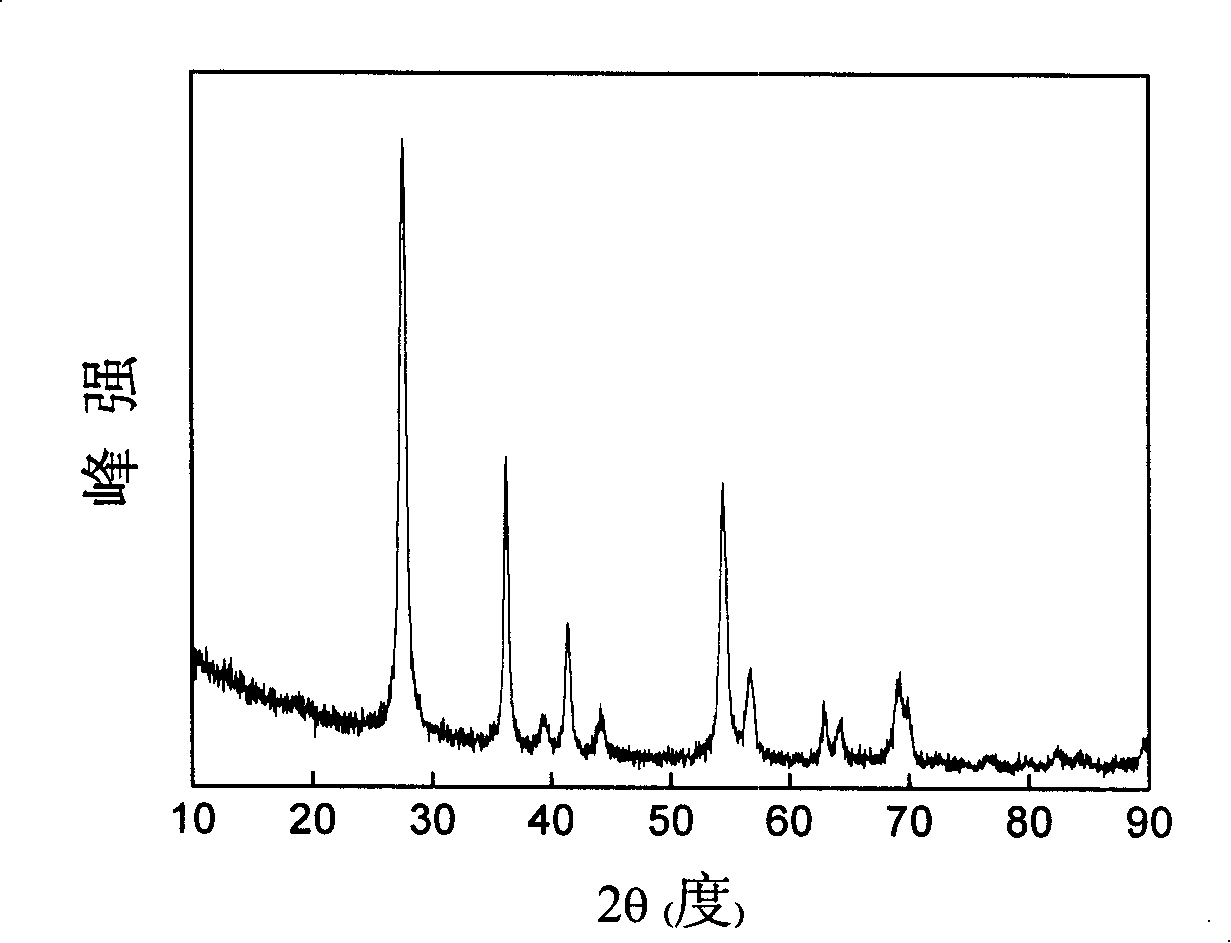

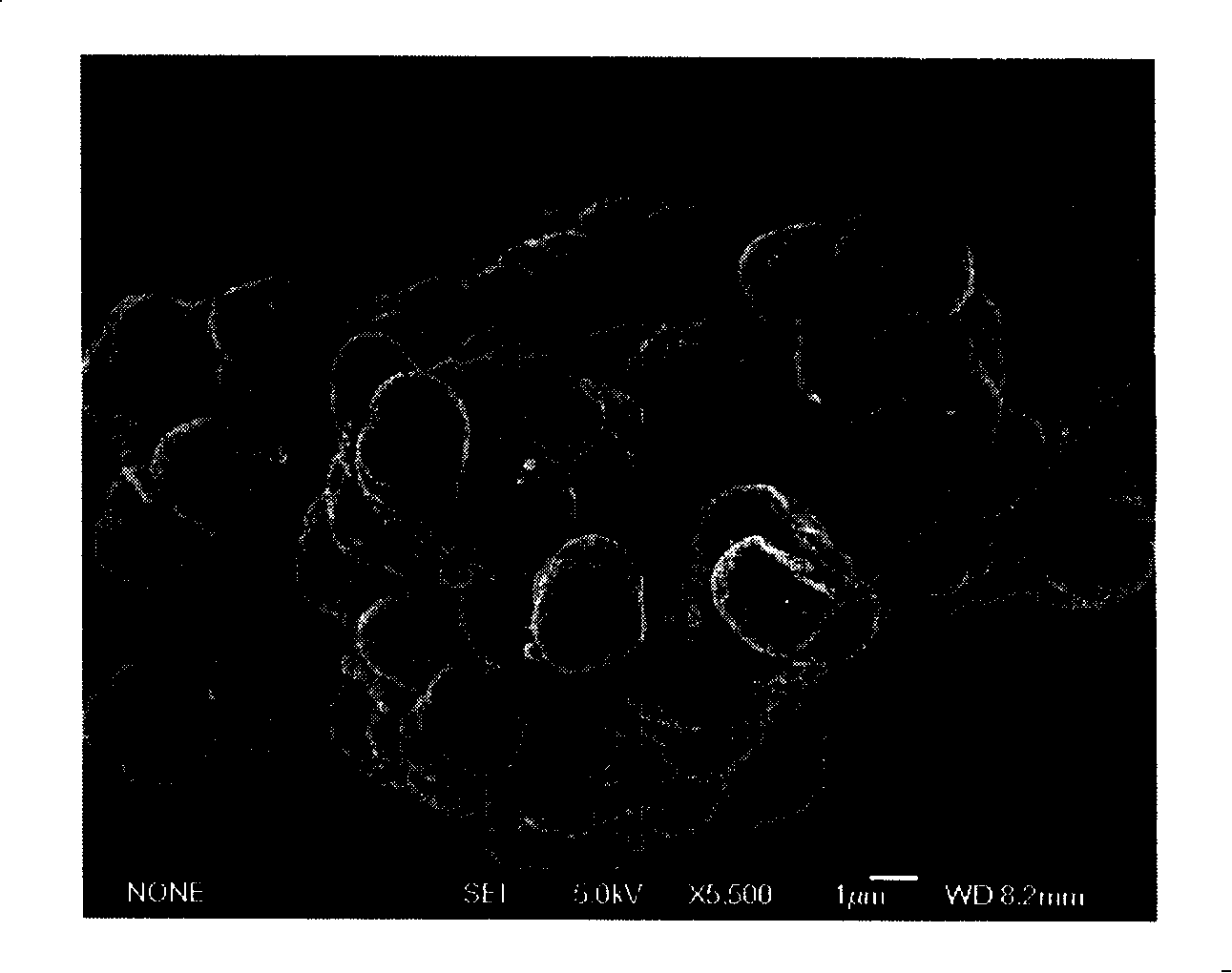

Process for preparing hydrated sodium titanate and nano titanate tube series

InactiveCN1378977AWith ion exchangeLarge specific surface areaTitanium compoundsSodium titanateThermal stability

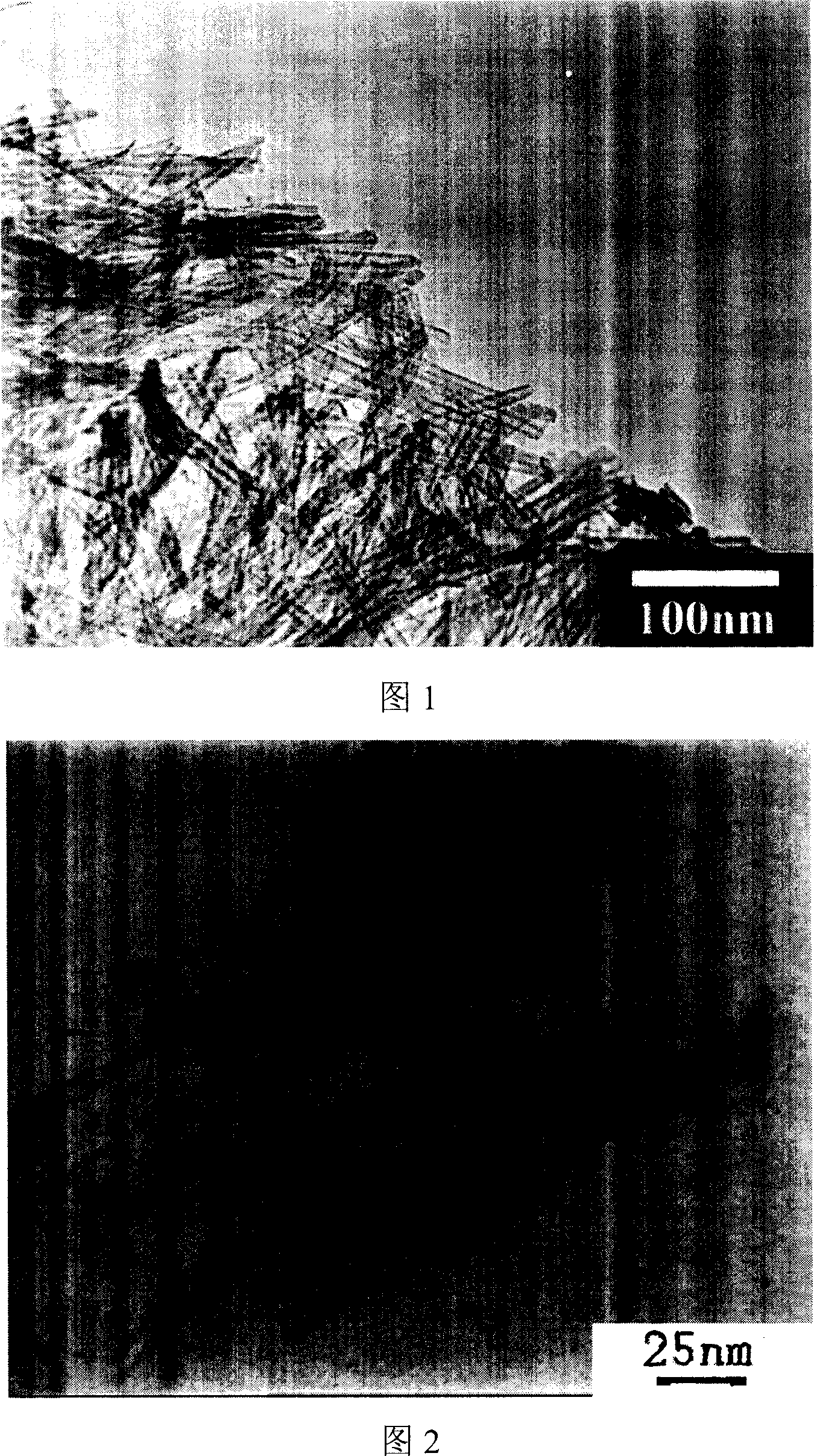

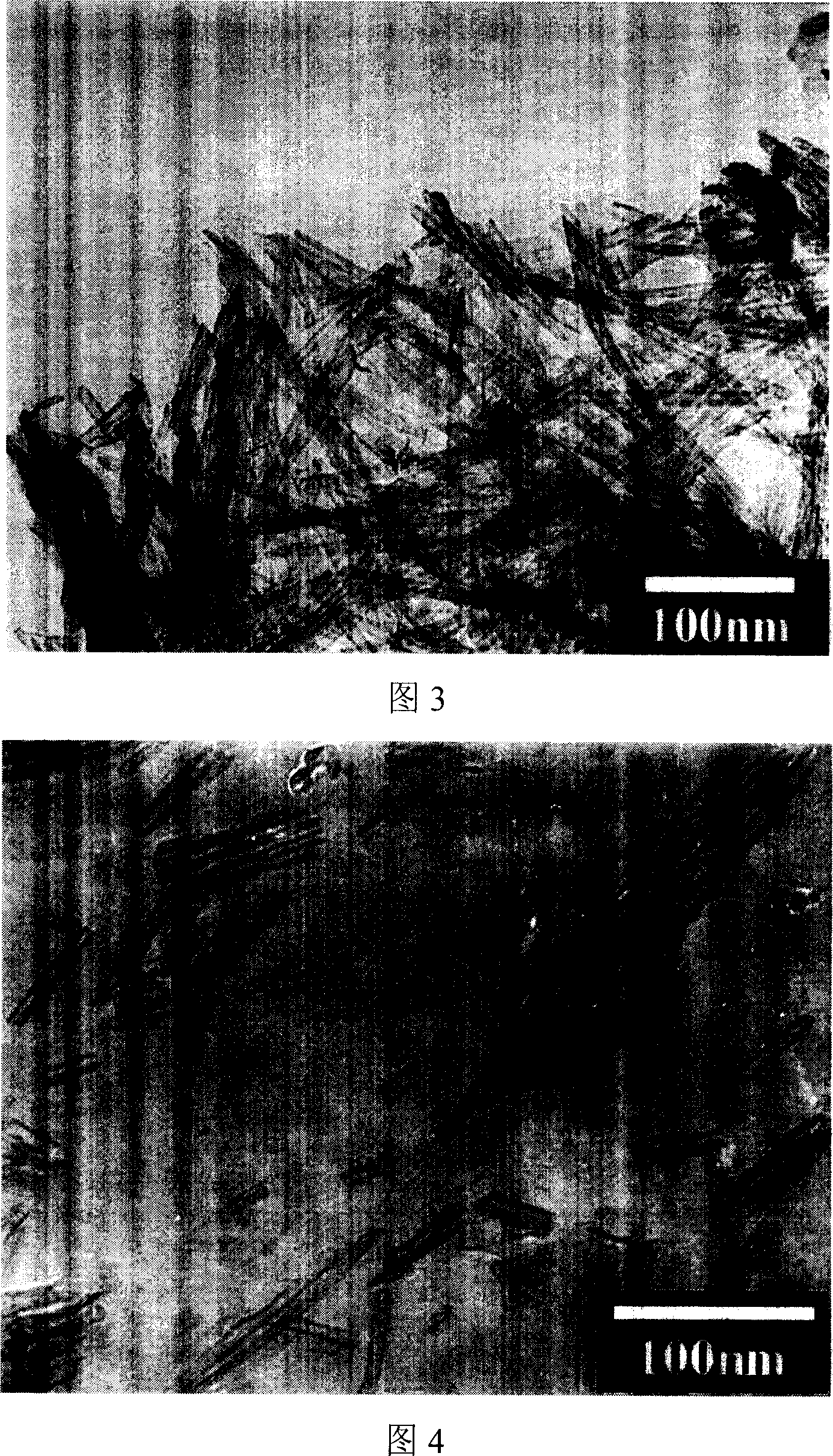

A process for preparing the nanometre tubes of hydrated sodium titanate and titanate series includes such steps as hydrothermal reaction of TiO2 or metatitanic acid to obtain the nanometre tubes of hydrated sodium titanate, mixing them with the solution containing one or two kinds of metal ions to convert them to the nanometre tubes of hydrated titanate or composite hydrated titanates of the saidmetal ions, and thermal dewatering to obtain the nanometre tubes of corresponding titanate or composite titanates. Its advantages are uniform shape, large specific surface area, high thermal stability and regulatable catalytic performance.

Owner:TSINGHUA UNIV

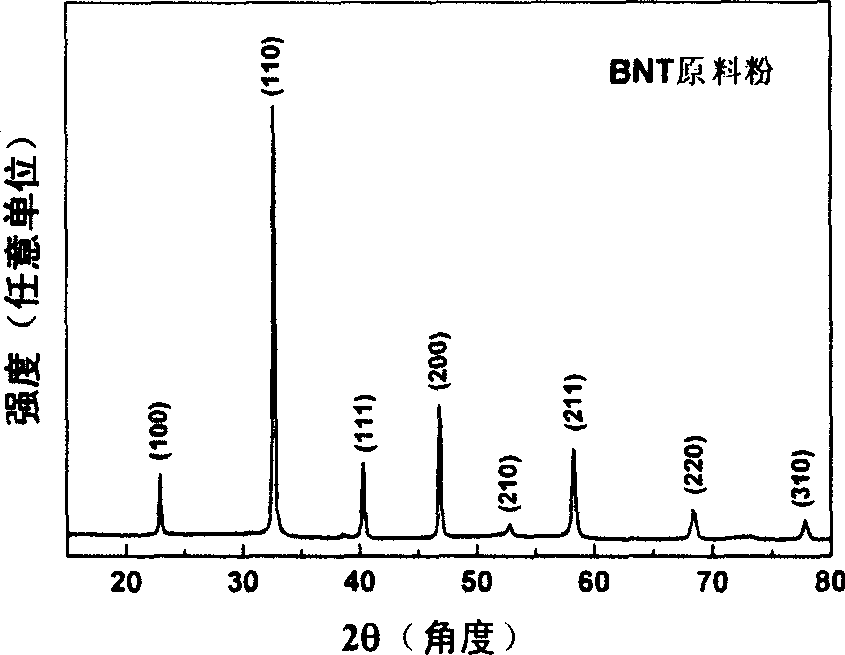

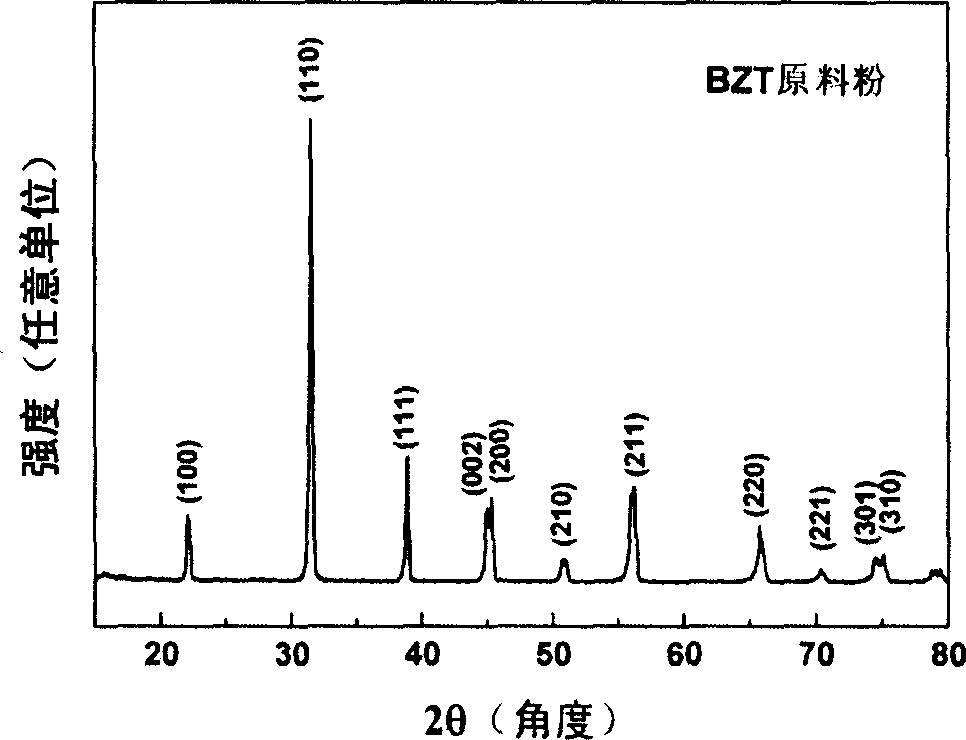

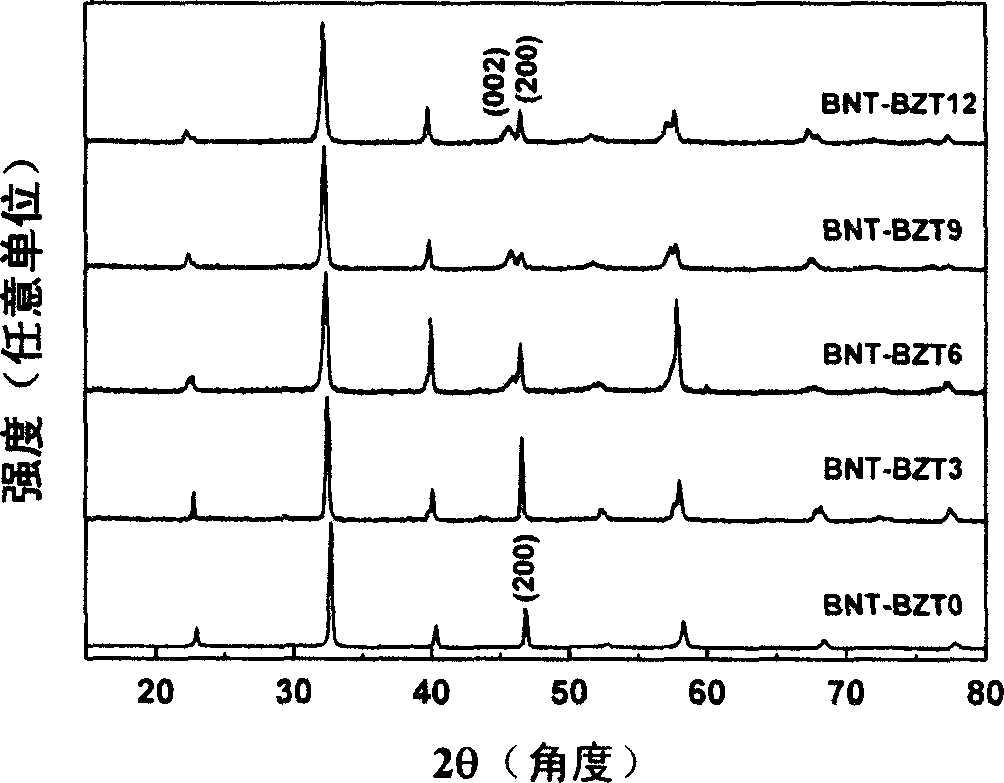

Sodium bismuth phthalate-barium zirconium phthalate leadless piezoelectric ceramic and its preparation method

InactiveCN1623954AExcellent piezoelectric propertiesReduce leakage currentPiezoelectric/electrostrictive/magnetostrictive devicesHigh densitySodium titanate

A non-Pb piezoelectric bismuth sodium titanate-barium zirconate titatate ceramics, (Bi0.5Na0.5)TiO3-xBa(Ti1-yZry)O3 (BNT-BZT), is prepared by two-step sinter method. Its advantages are high density, low leakage current in polarizing procedure, and high piezoelectric and ferroelectric performance.

Owner:TSINGHUA UNIV +1

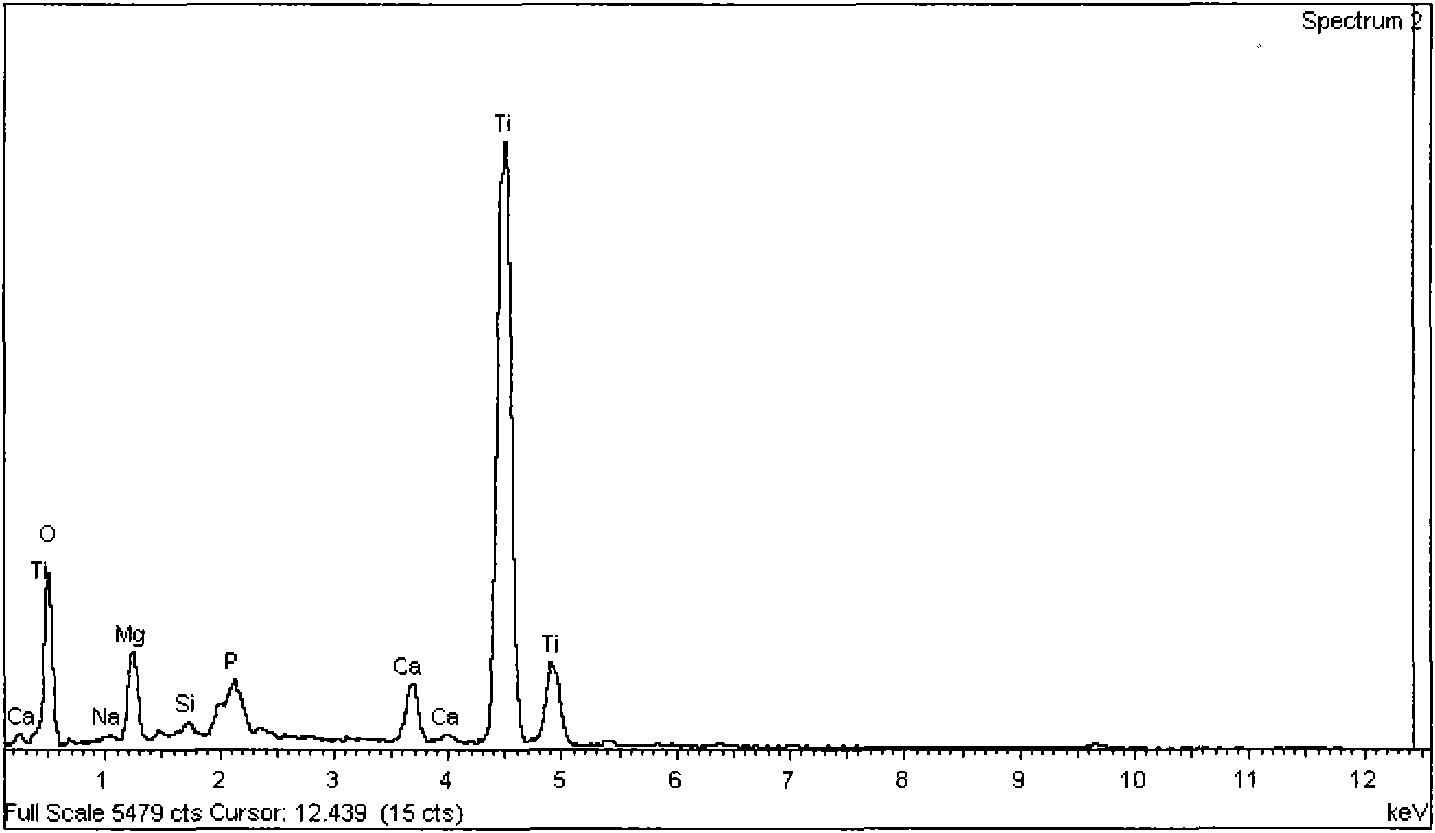

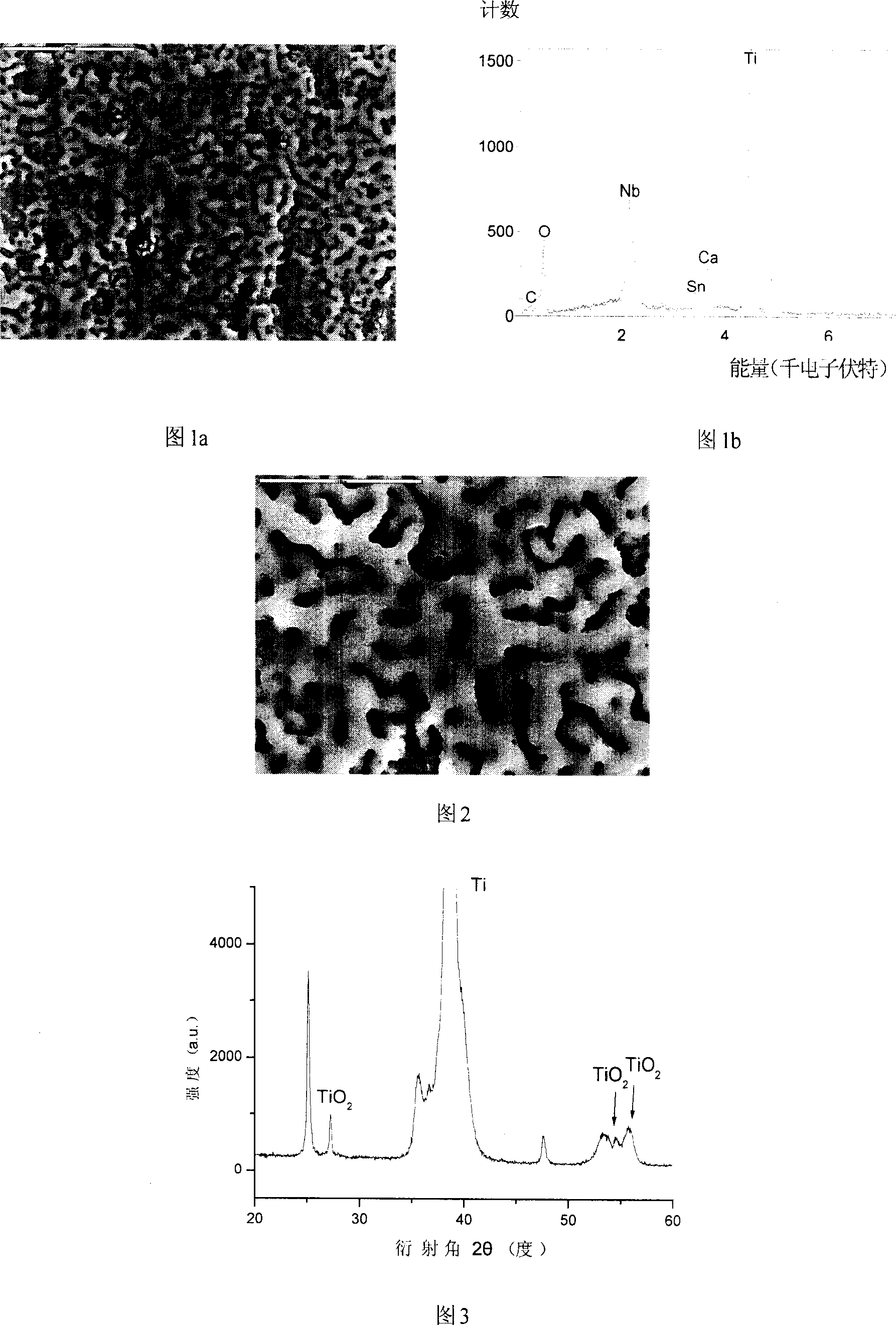

Biological active coating on surface of titanium or titanium alloy and preparation method thereof

InactiveCN101537208AImprove surface bioactivityImprove bindingSurface reaction electrolytic coatingProsthesisHydroxylapatiteSodium titanate

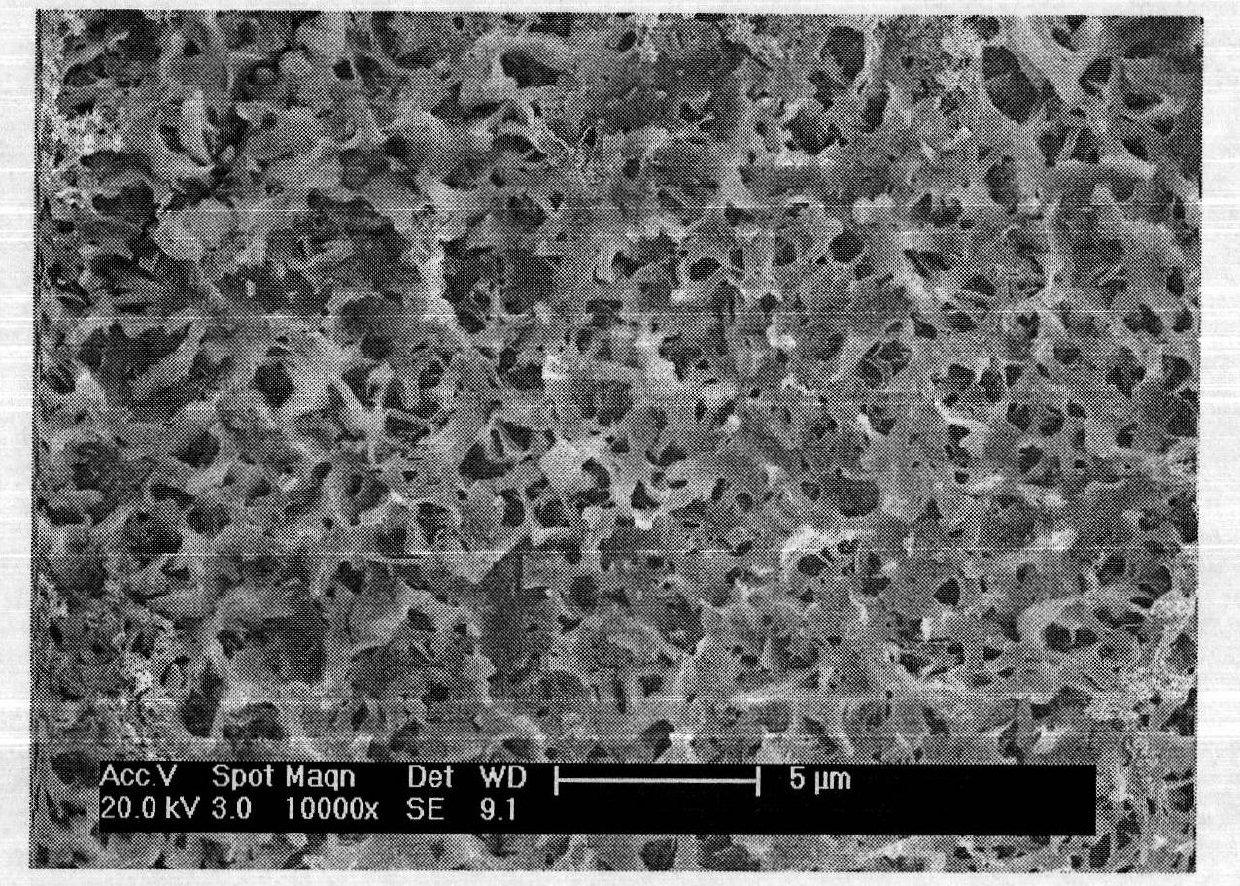

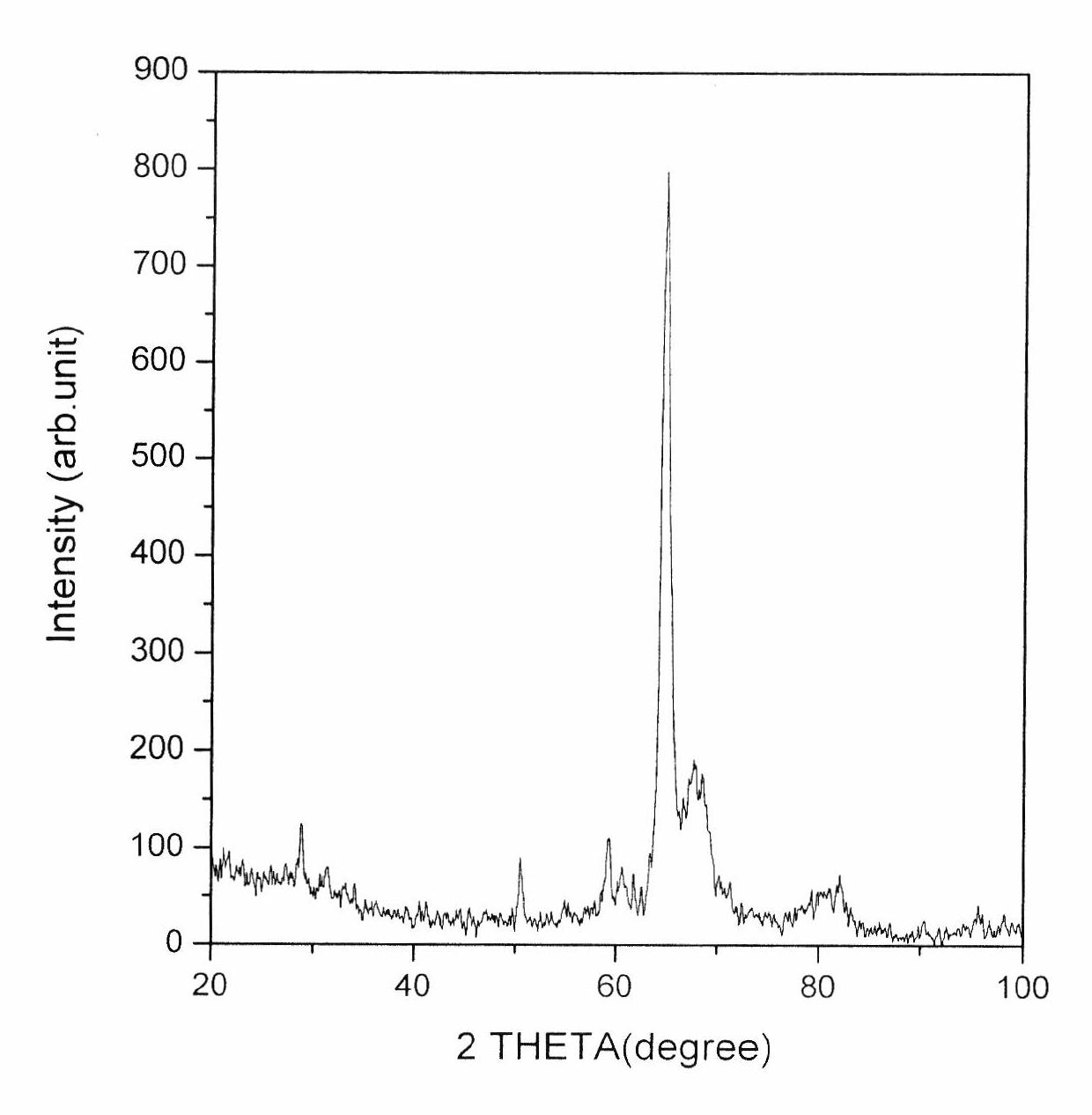

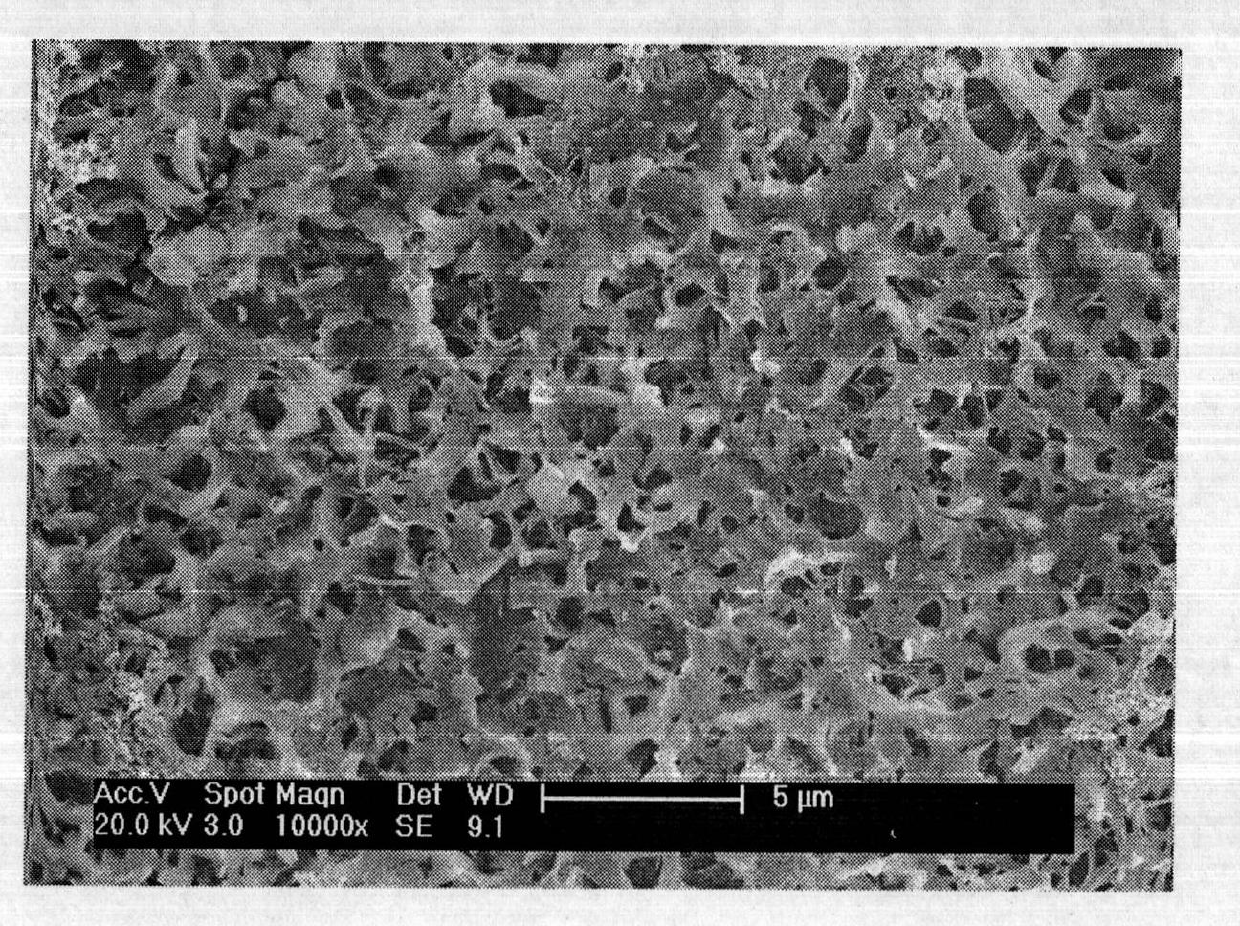

The invention relates to the field of surface modification of biomedical materials, in particular to a biological active coating on the surface of titanium or a titanium alloy and a preparation method thereof. The coating is a composite gradient coating; the inner layer is a titanium oxide film layer with the thickness between 0.5 and 10 mu m; the intermediate layer is a sodium titanate gel film layer with the thickness between 0.1 and 10 mu m; and the outer layer is a hydroxylapatite layer with the thickness between 1 and 15 mu m. A method combining anodization and alkali treatment is adopted to prepare the biological active coating on the surface of the titanium or the titanium alloy, which comprises the following steps: firstly, preparing an oxide film with certain thickness on the surface of the titanium or the titanium alloy by an anodization method; secondly, forming a layer of porous netty sodium titanate gel film layer on the surface of the oxide film by an alkali treatment method; and finally, depositing the bone-like hydroxylapatite layer on the surface of a sample after the treatments in a simulated body fluid. The method can effectively improve the biological activity on the surface of the titanium or the titanium alloy; and the surface has a coarse porous structure, so the bonding force of the hydroxylapatite layer and the adhesive ability of cells are improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

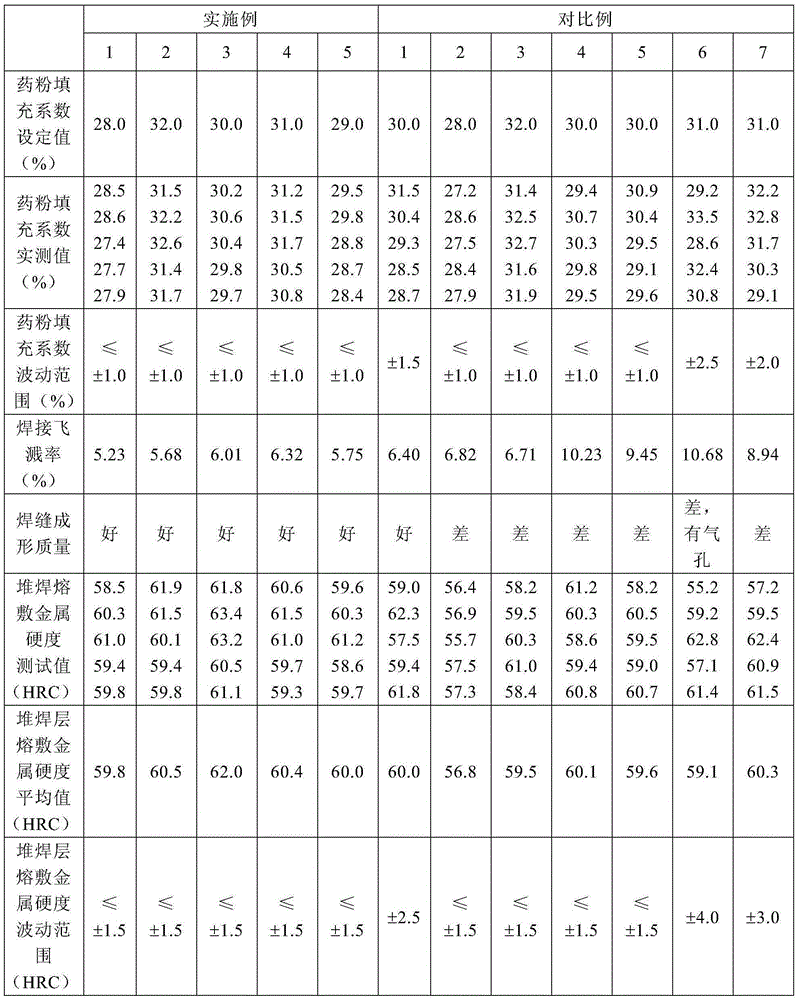

Weather-proof flux core wire used for coating-free bridge steel and preparing method of weather-proof flux core wire

ActiveCN106475706AImprove mechanical propertiesStable welding arcWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a weather-proof flux core wire used for coating-free bridge steel and a preparing method of the weather-proof flux core wire. The weather-proof flux core wire is composed of a steel skin and a powder core. The powder core comprises, by weight percent, 2%-8% of ferro-boron, 0.01%-2% of ferromolybdenum, 1%-6% of fluoride, 1.5%-8% of zircon sand, 2%-7% of magnesium powder, 2%-5% of quartz sand, 2%-8% of silicon iron, 5%-19% of electrolytic manganese, 1%-5% of ferromanganese, 1%-6% of nickel powder, 1%-8% of chromium metal, 1%-8% of copper powder, 2%-9% of ferrotitanium, 0.1%-5% of feldspar, 2%-8% of sodium titanate, 20%-40% of rutile and the balance iron powder. Compared with the prior art, the weather-proof flux core wire is stable in welding arc and little in splashing, slag removing is easy, a welding joint is formed attractively, the weather-proof flux core wire is suitable for all-position welding, the mechanical performance of the welding joint is good, the impact toughness at the temperature of minus 40 DEG C is larger than 80 J, and very high corrosion resistance is achieved.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Method for preparing uniform dispersion square phase barium titanate nanocrystal

InactiveCN101045554ANanostructure manufactureTitanium compoundsBarium titanateHydrothermal synthesis

A process for preparing the uniformly dispersed square barium sodium titanate nanocrystals by hydrothermal synthesis method includes using inorganic alkali or the combination of organ alkali and inorganic alkali to regulate the pH value of reaction system, respectively preparing the homogeneous solutions of the reactant precursors (TiO2 or tetrabutyl titanate and barium hydroxide) at 80-100 deg.C, and two-stage hydrothermal reaction in high-pressure reactor at 100-200 deg.C while crystallizing.

Owner:胜利油田华鑫石油材料有限公司

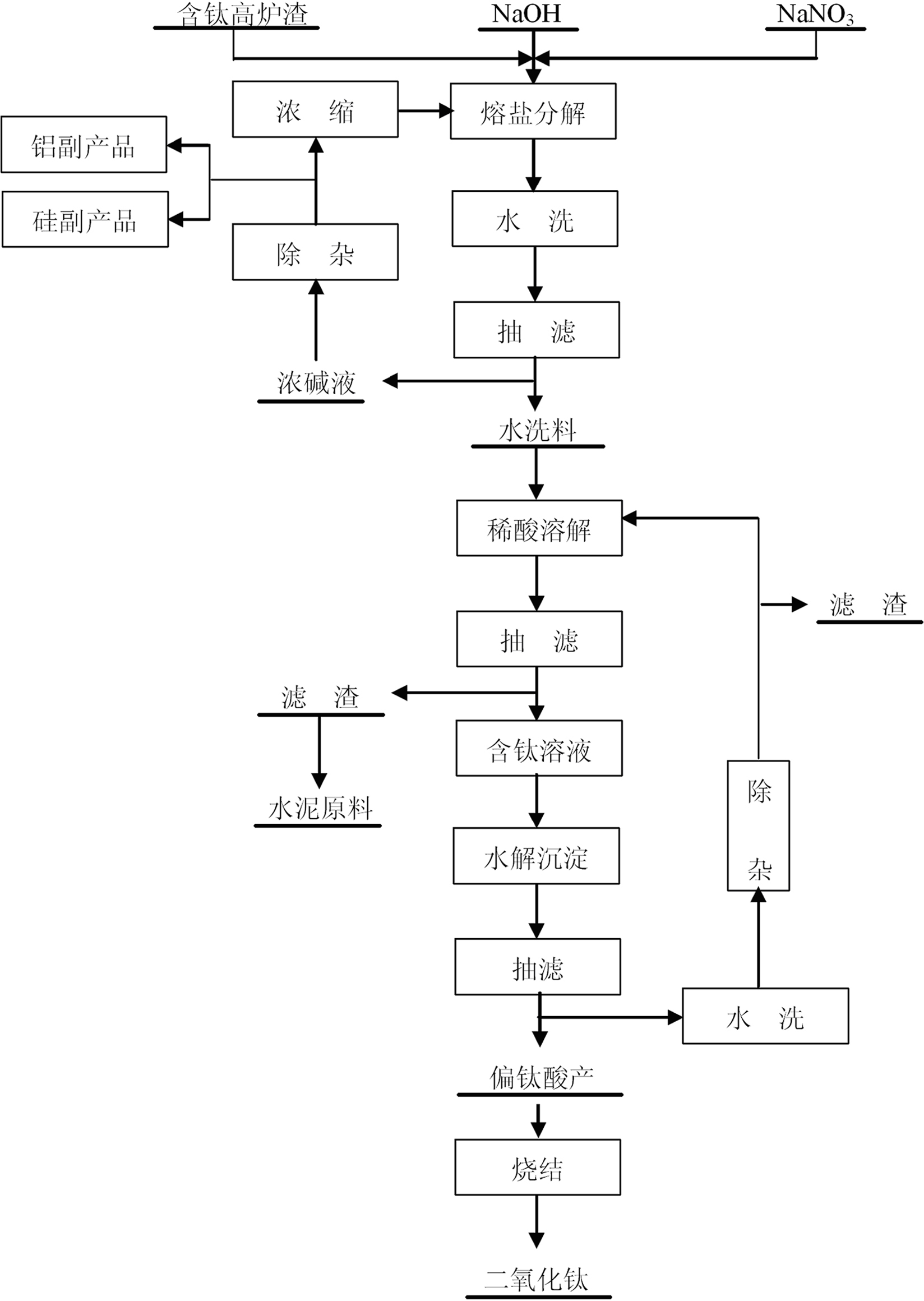

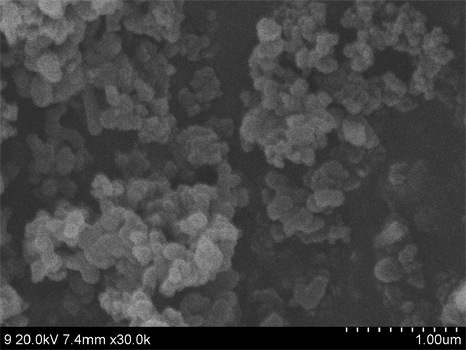

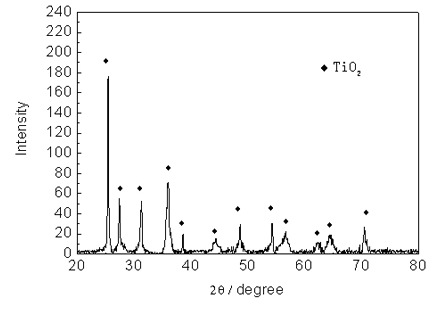

Method for producing titanium dioxide by using titanium-containing blast furnace slag

InactiveCN101994012AEasy to operateLow reaction temperatureProcess efficiency improvementSlagSodium titanate

The invention relates to a comprehensive utilization technology of blast furnace slag, in particular to a method for producing titanium dioxide by using titanium-containing blast furnace slag. The technical scheme comprises the following steps of: crushing, ball milling and screening titanium-bearing blast furnace slag, and placing in a molten salt system containing NaOH and NaNO3; washing the intermediate product in water at 60-75 DEG C, and filtering; removing impurities of a NaOH and NaNO3 alkaline solution containing sodium silicate and sodium metaaluminate, concentrating, and returning to the NaOH and NaNO3 molten salt system; dissolving the washing material containing solid phase sodium titanate by using an inorganic acid, adding a reducing agent for a reduction reaction, and then filtering; filtering the titanium-containing solution to obtain an inorganic acid filtrate and a metatitanic acid product; and calcining the metatitanic acid product at 600-1300 DEG C to obtain the final product of titanium dioxide powder. The invention realizes high conversion rate of titanium, and furthest reduces environmental pollution at the same time.

Owner:NORTHEASTERN UNIV

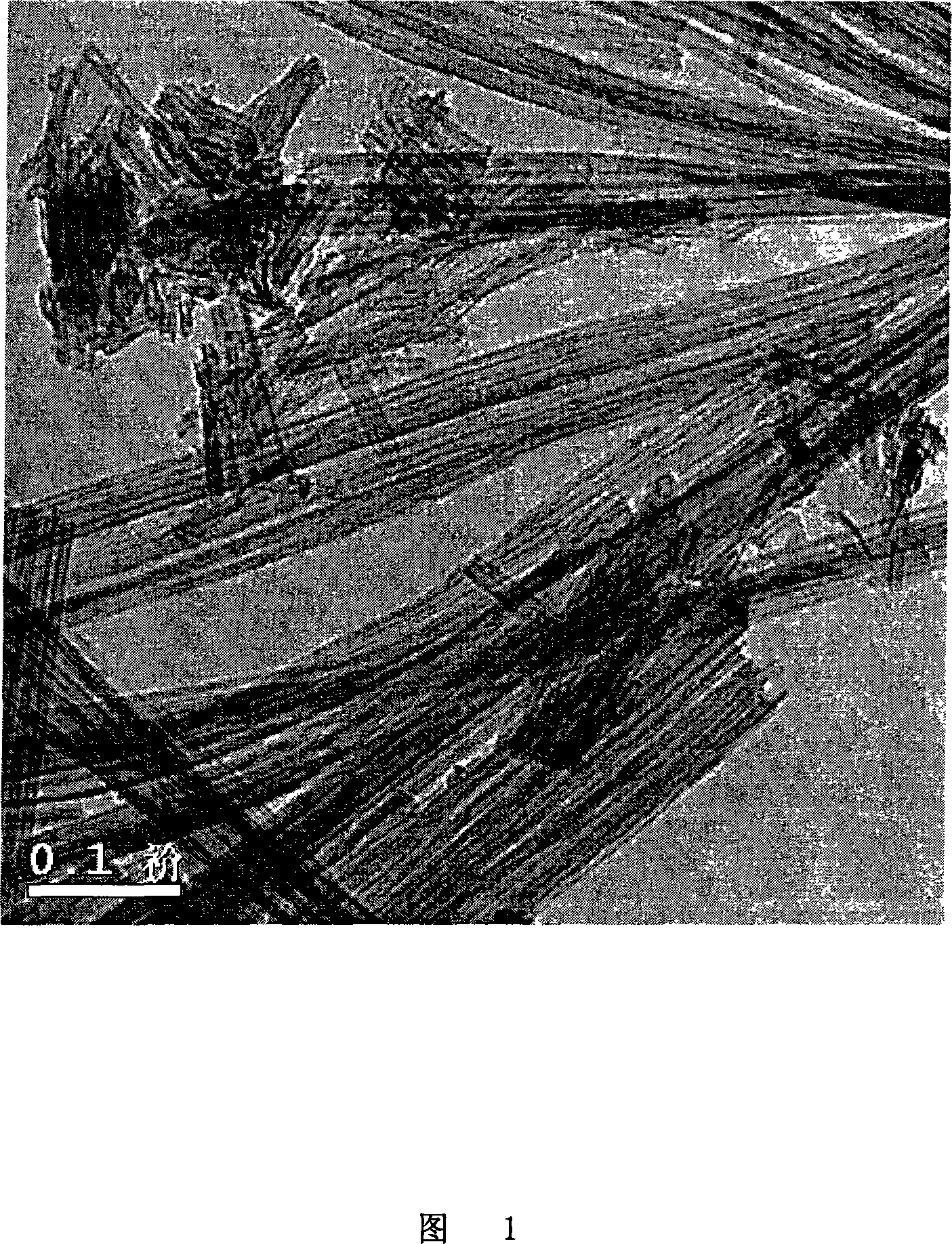

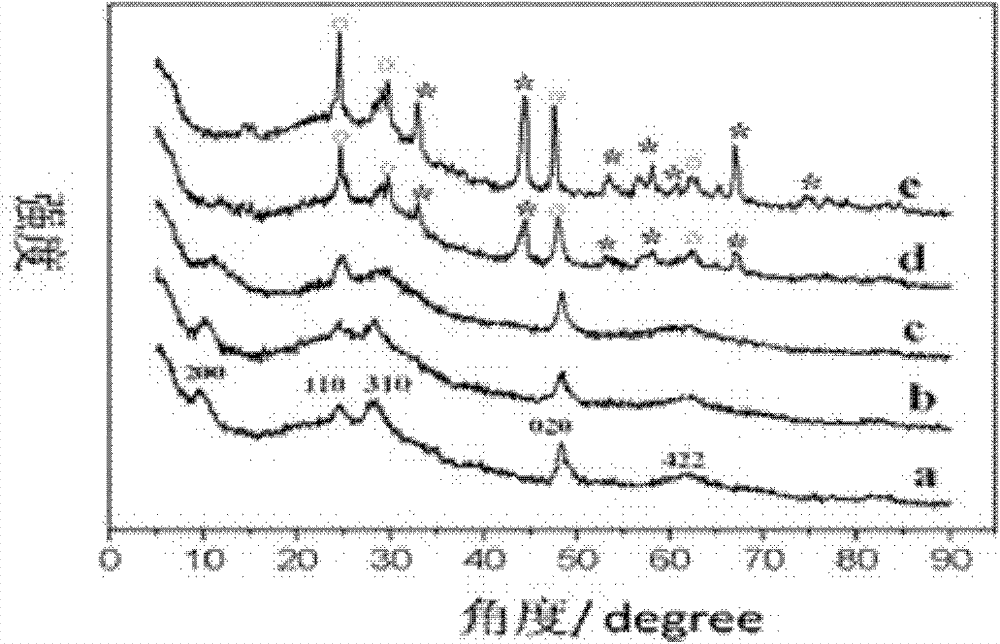

Method for preparing Nano tube of titanate

InactiveCN101003385ALarge specific surface areaImproved electrical and catalytic propertiesPolycrystalline material growthTitanium compoundsCopper nitrateSodium titanate

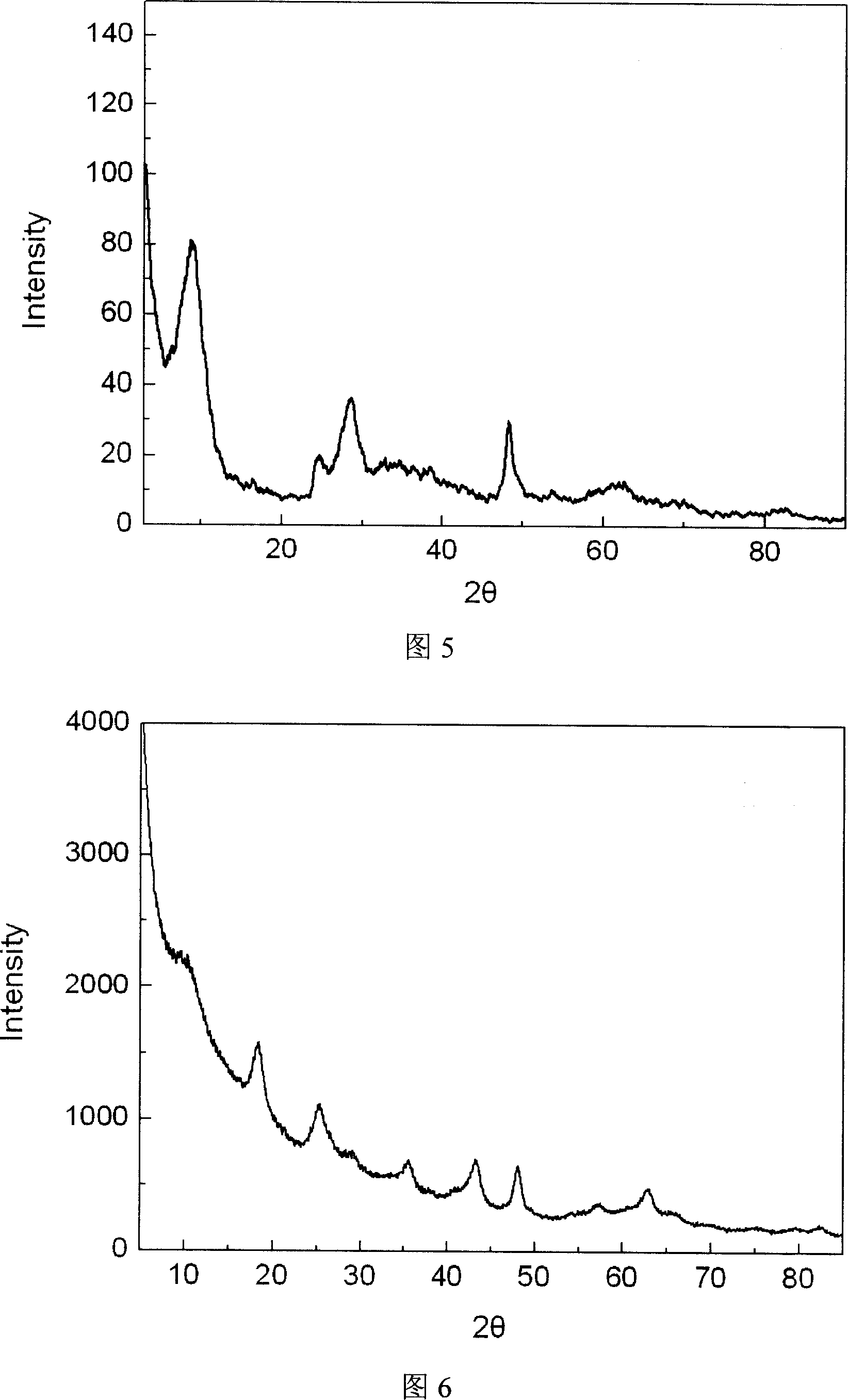

This invention discloses a method for preparing titanate nanotubes. The method comprises: uniformly mixing nitrate and power of sodium titanate nanotubes at a mol ratio of (5-100):1, performing melt-reaction at 50-450 deg.C for 3-48 h, cooling, washing to remove unreacted nitrate, and drying to obtain titanate nanotubes. The nitrate is lithium nitrate, and drying to obtain titanate nanotubes. The nitrate is lithium nitrate, potassium nitrate, rubidium nitrate, cesium nitrate, silver nitrate, nickel nitrate, thallium nitrate, copper nitrate, zinc nitrate or cobalt nitrate. The precursor of sodium titanate nanotubes is prepared by: reacting titanium dioxide, metatitanic acid or titanate ester in 20-80 wt. % NaOH aqueous solution at 100-140 deg.C for 12-72 h, washing with water, filtering and drying. This invention can prepare titanate nanotubes with large specific surface area by melt-exchange method.

Owner:HENAN UNIVERSITY

Bismuth sodium titanate based leadless piezoelectric ceramic and preparation technique thereof

InactiveCN101462875AImprove performanceHigh electromechanical coupling coefficientPiezoelectric/electrostrictive/magnetostrictive devicesAlkaline earth metalElectromechanical coupling coefficient

The invention discloses a sodium bismuth titanate based lead-free piezoelectric ceramic and a preparation process thereof. The general formula of the piezoelectric ceramic composition is (1-x)(Na0.5Bi0.5)1-aMaTiO3-xNaNbO3, wherein, x is the mol content of NaNbO3 in a ceramic system, a is the atom number of composite ions (Na0.5Bi0.5) which are replaced by M in (Na0.5Bi0.5)TiO3, x is not less than 0 but less than 0.3, a is more than 0 but less than 0.3, and M represents divalent alkaline earth metal elements Ba, Sr and Ca. As a secondary isostatic pressing forming method is adopted in the preparation process, the piezoelectric ceramic has the advantages of simple operation, high stability and low cost; and the method helps easily obtain high-density microcrystal ceramic materials, obviously improve the piezoelectric parameter and electromechanical coupling factor of the materials, and meet the practical requirement of the piezoelectric ceramic materials used in a micro-displacement actuator.

Owner:XIAN UNIV OF SCI & TECH

Silver-loaded antibacterial artificial joint and preparation method thereof

InactiveCN101766839ABroad-spectrum antibacterialImprove sterilization efficiencyTitanium compoundsCoatingsSodium titanateTitanium alloy

Owner:江苏广达医材集团有限公司 +1

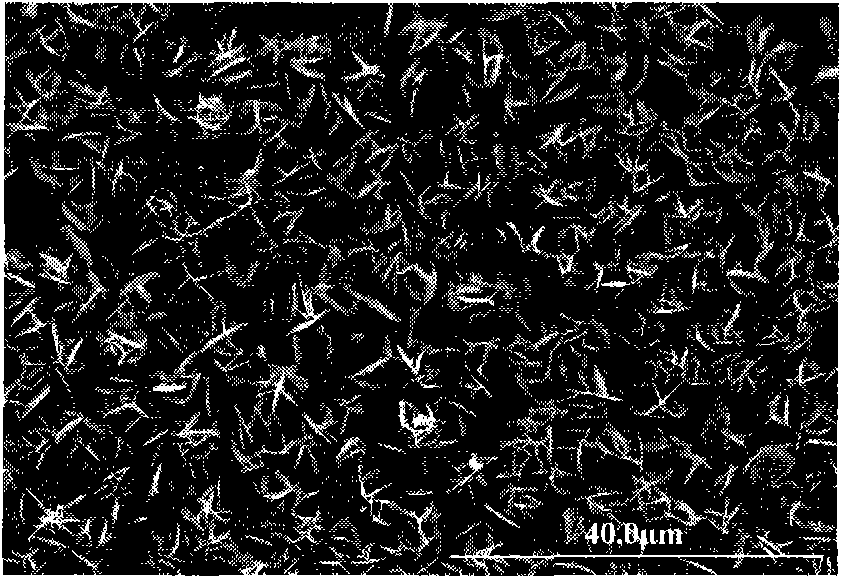

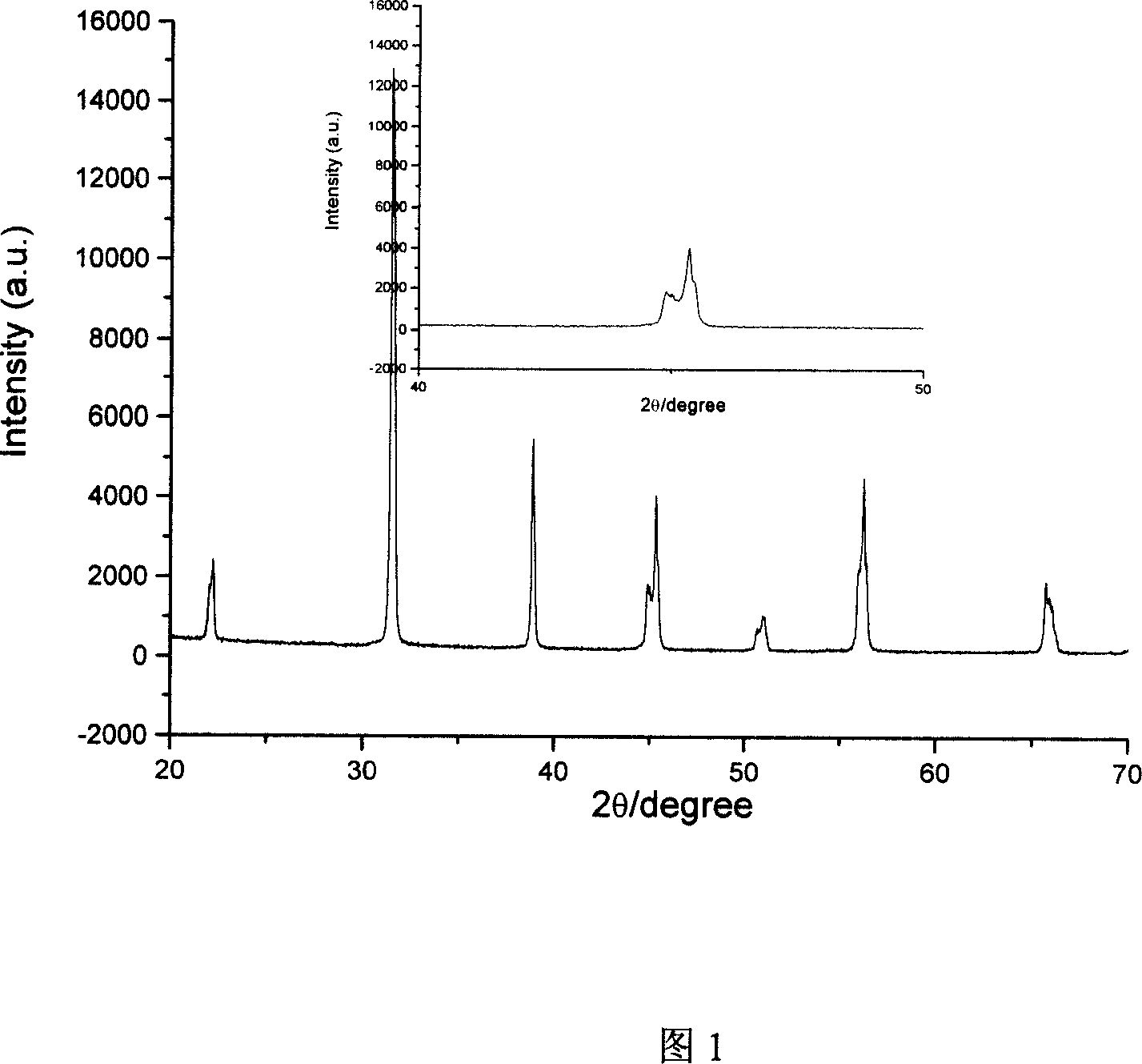

Sheet bismuth sodium titanate mould plate grain and manufacture method thereof

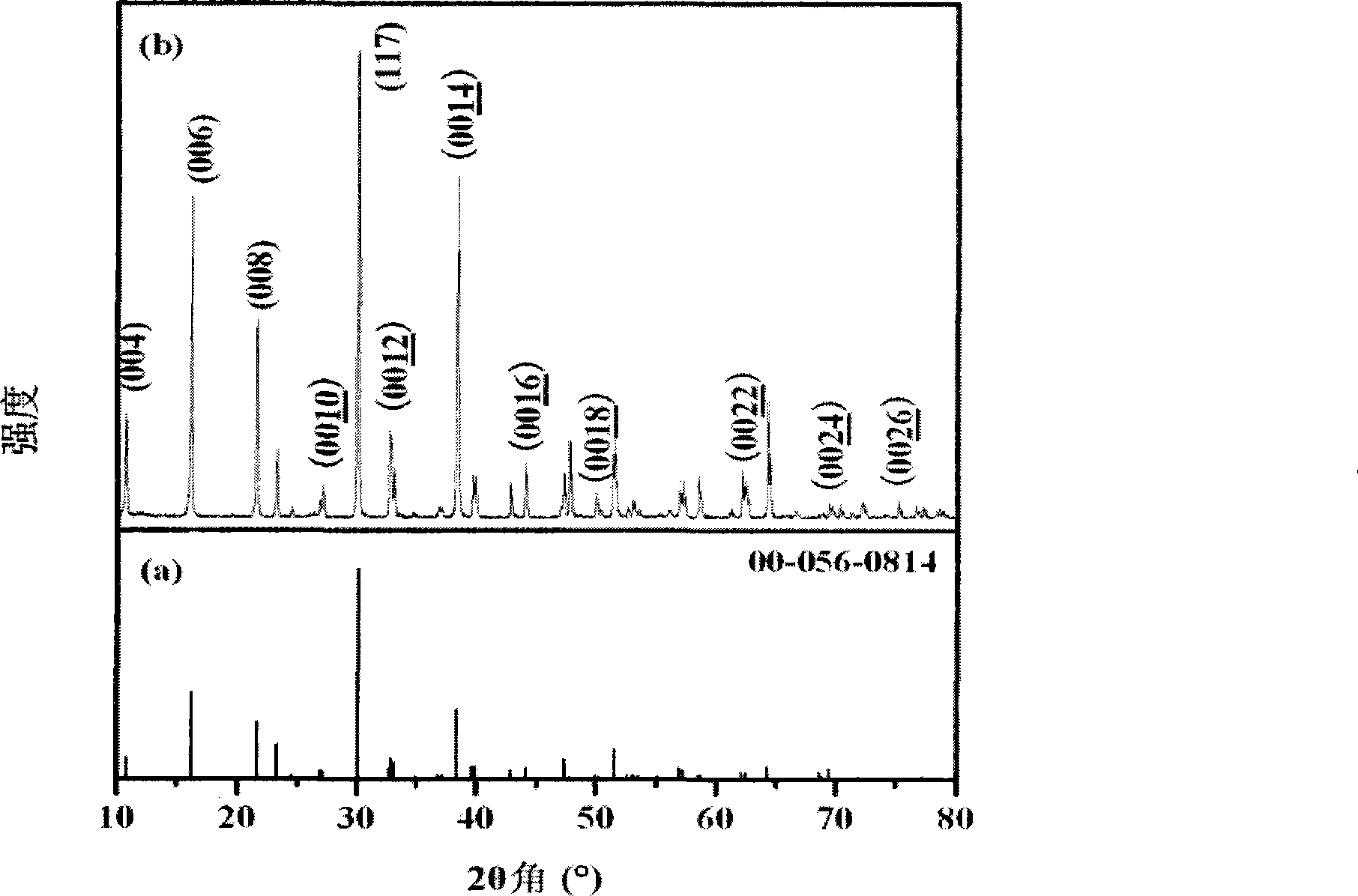

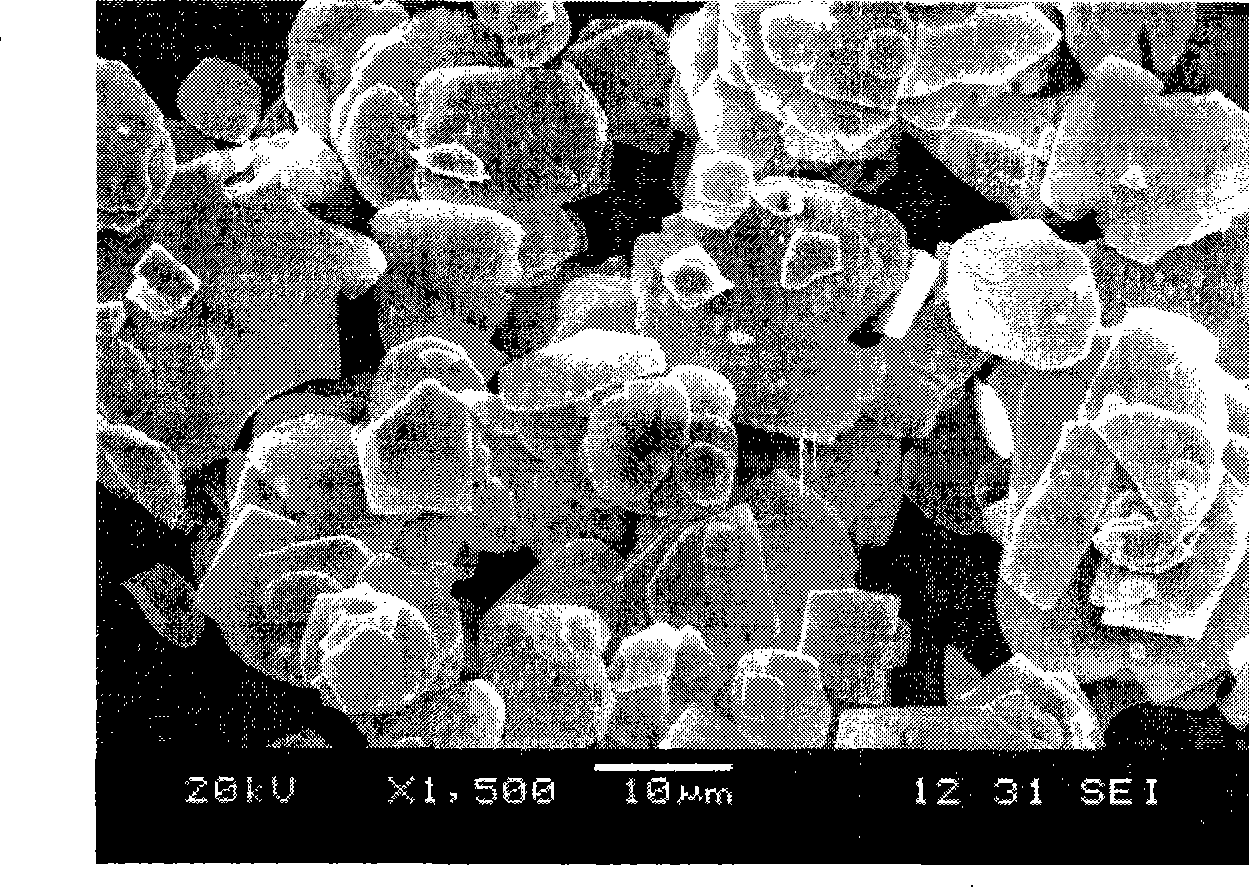

The invention relates to a schistic bismuth sodium titanate template crystal grain and a preparation method thereof, belonging to the preparation field of textured non-lead piezoelectric ceramic template crystal grain, the chemical formula of the template grains is Na0.5Bi0.5TiO3, the appearance of the crystal grain is schistic, the radial length is 5 to 15Mum, the thickness is 0.5 to 1.0Mum, the crystal grain has large aspect ratio and strong orientation, which is an ideal template crystal grain. The crystal grain adopts schistic Bi4Ti3O12 as a precursor which is synthesized by molten salt method, in the molten salt system of NaCl, the crystal grain can have topological chemical reaction with Na2CO3, TiO2 so as to produce schistic polycrystalline Na0.5Bi0.5TiO3 template crystal grain and the crystal grain can be regarded as the template for various textured bismuth sodium tianate non-lead piezoelectric ceramics, which has positive effect for improving the density, the orientation and piezoelectric properties of textured bismuth sodium tianate non-lead piezoelectric ceramics.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

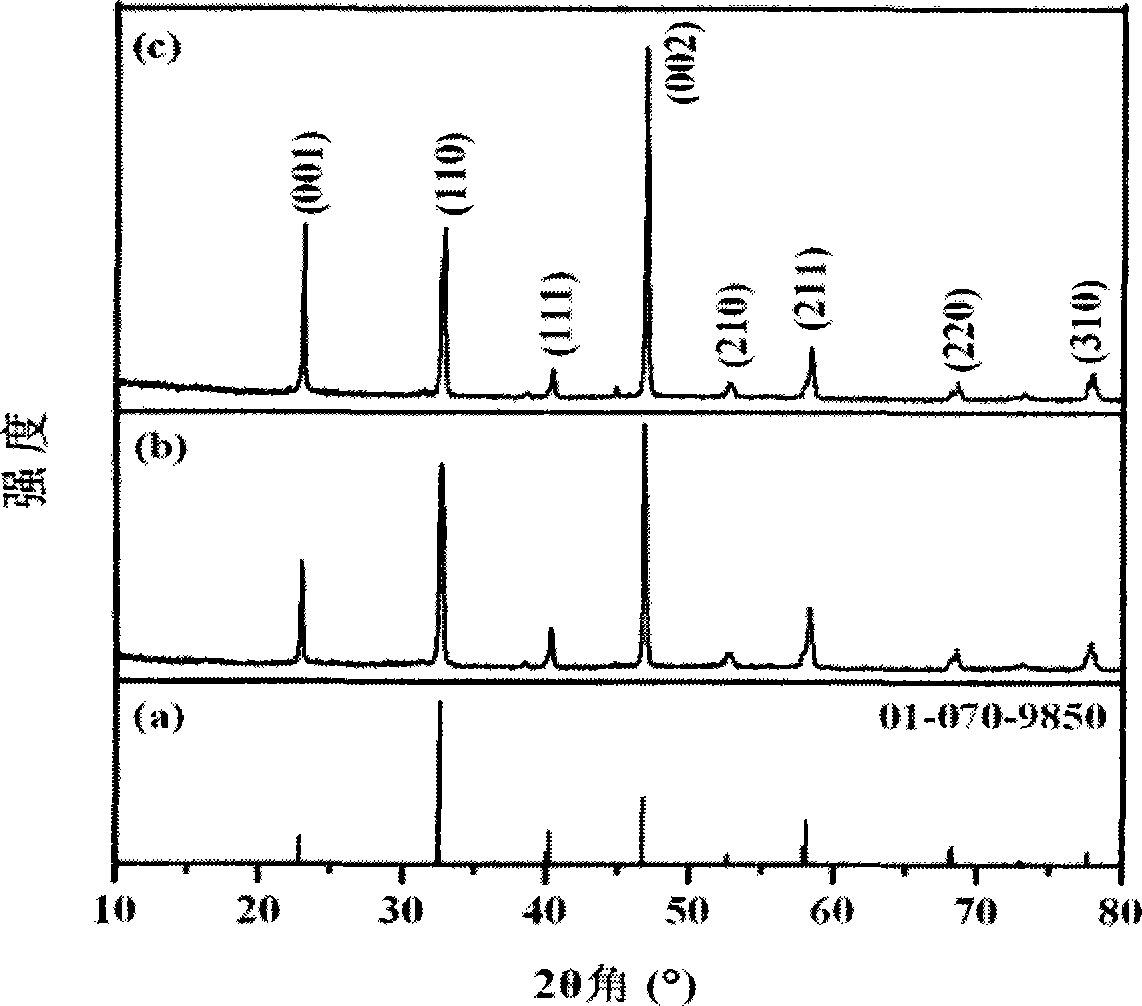

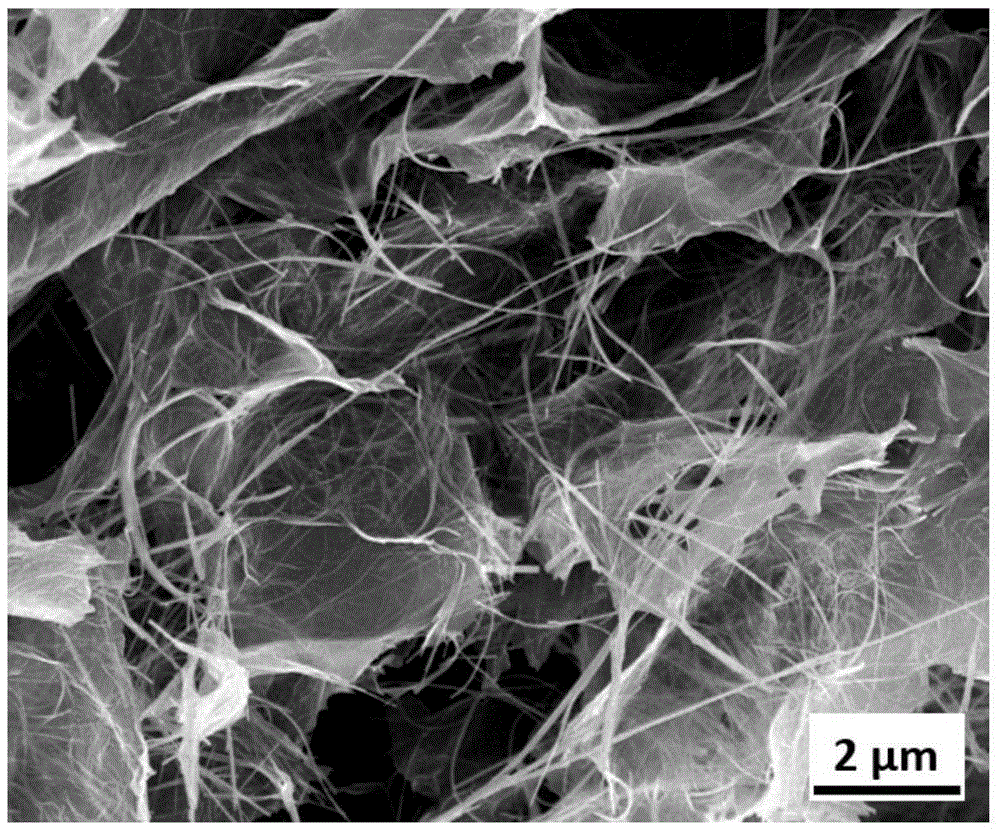

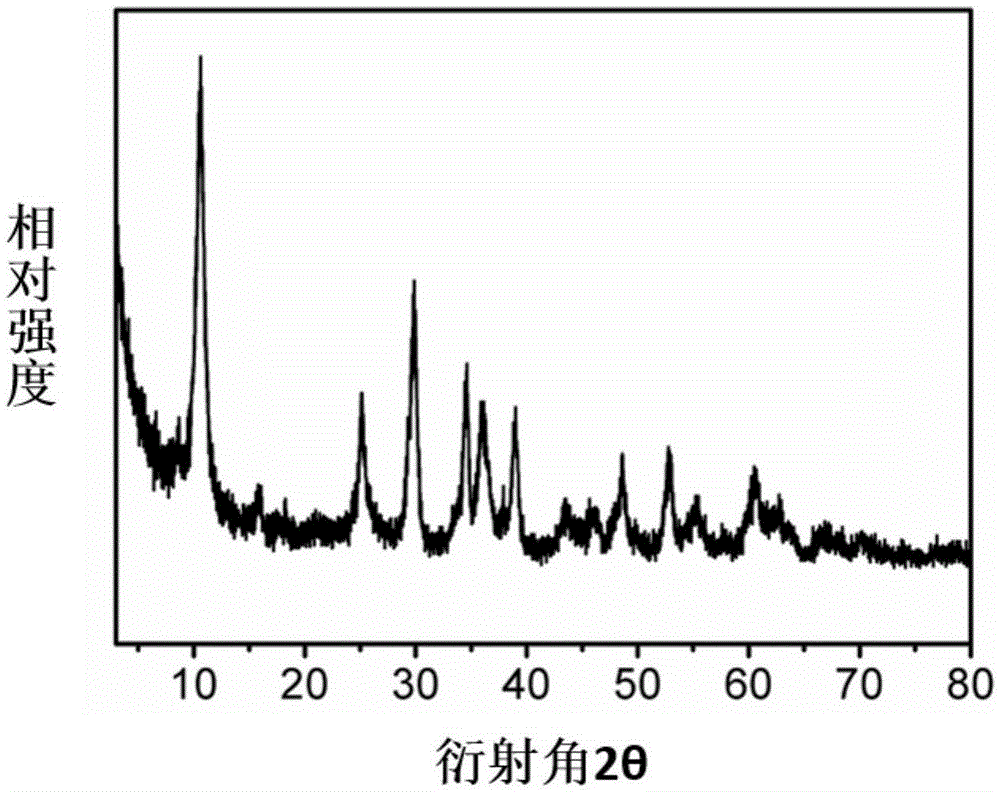

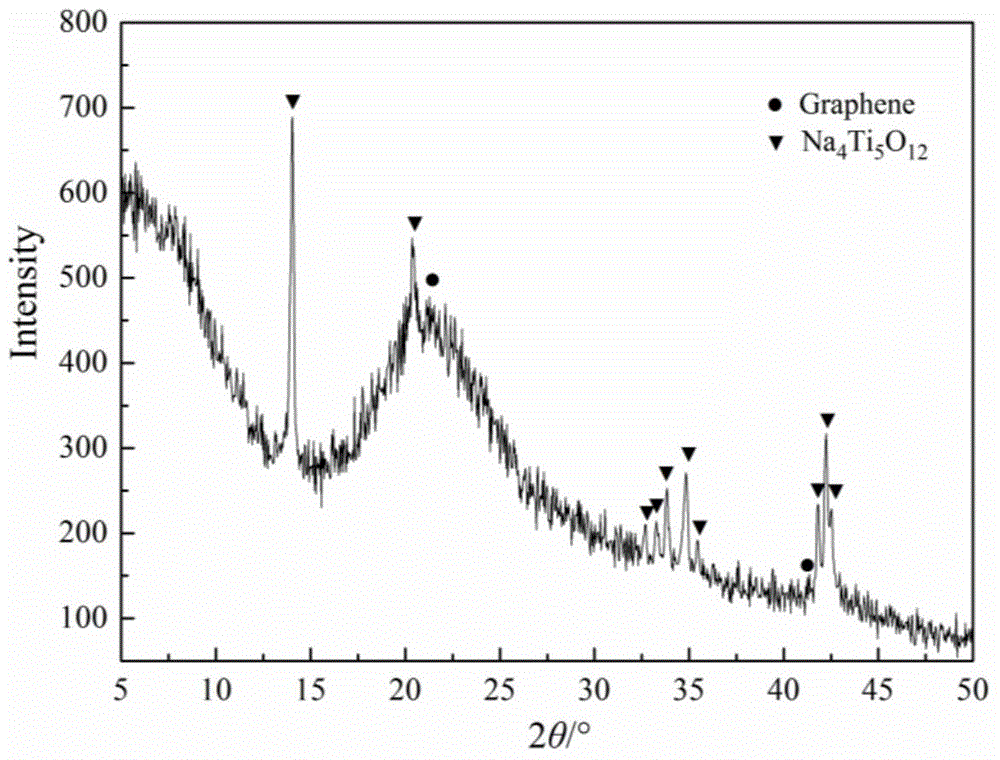

Sodium titanate nanowire/graphene composite negative electrode material, and preparation method thereof

ActiveCN105336940AGood lookingImprove sodium storage performanceNon-aqueous electrolyte accumulatorsCell electrodesNanowireSodium-ion battery

The invention belongs to the field of sodium ion battery negative electrode material, and provides a sodium titanate nanowire / graphene composite negative electrode material, and a preparation method thereof. The preparation method of the sodium titanate nanowire / graphene composite negative electrode material comprises following steps: graphite oxide is dissolved in an organic solvent so as to obtain a graphene oxide solution; a titanium source is added into the graphene oxide solution, a first time solvothermal reaction is carried out after mixing treatment so as to obtain a titanium dioxide / graphene compound; a NaOH aqueous solution is added into the titanium dioxide / graphene compound for a second time of solvothermal reaction so as to obtain a sodium titanate nanowire / graphene crude product; the sodium titanate nanowire / graphene crude product is washed with water until pH value is 7, and is dried so as to obtain the sodium titanate nanowire / graphene composite negative electrode material.

Owner:REAL POWER IND LTD

Method for improving surface hydrophilicity of medical titanium or titanium alloy

InactiveCN101880874AImprove surface hydrophilicityImprove bindingMetallic material coating processesUltravioletSodium titanate

The invention relates to a method for improving the surface hydrophilicity of medical titanium or a titanium alloy, which is characterized by comprising the following steps of: placing the titanium or the titanium alloy in 1.0-5.0 M of NaOH solution and then treating 12-24 hours at 60-80 DEG C to form a nano porous sodium titanate gel layer on the surface; and then soaking the alkali liquor-treated sample in 0.1 M of diluted hydrochloric acid for 12 hours at the room temperature to transform the nano porous sodium titanate gel layer into a nano porous titanium oxide gel layer. The titanium oxide gel layer can be crystallized by thermally treating 0.5-2.0 hours at 500-600 DEG C. After a nano porous titanium oxide film is irradiated for 3-4 hours by ultraviolet rays (the wavelength is 253 nm) or is treated for 2-4 minutes by atmosphere plasmas, the superhydrophilicity can be obtained, and the high hydrophilicity of the superhydrophilic sample can be maintained after the superhydrophilic sample is preserved in deionized water. When used for improving the surface hydrophilicity of the medical titanium or the titanium alloy, the method has the characteristics of simple and easy feasibility, stable process, reliable performance, firm combination of a titanium dioxide layer, suitability for various titanium alloys and the like.

Owner:XI AN JIAOTONG UNIV

Sodium bismuth titanate base nonleaded piezoelectric ceramic

InactiveCN1541977AExcellent piezoelectric ferroelectric propertiesImprove performanceCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesSodium titanateOxygen

The lead-free bismuth sodium titanate piezoelectric ceramic composition is one perovskite type environment consistency piezoelectric ceramic composition. The composition has the general expression of (1-x-y-z)Bi1-wNawTiO3+xBi0.5K0.5TiO3+yBaTiO3+zSrTiO3+aMalphaObeta, where x is 0-1, y 0-1, z 0-1, (x+y+z) 0-1, w 0.3-0.7; MalphaObeta is doping oxide(s) in the content an of 0-10 %; M is +1~+6 valent element capable of forming solid oxide, such as Na, K, Li, Al, Cu, etc. with alpha and beta being atom number. The piezoelectric ceramic composition has d33 up to 190 pC / N, kp up to 24.0 % and stable technological process, may be produced via traditional piezoelectric ceramic preparation process and industrial material, and is practical.

Owner:SICHUAN UNIV

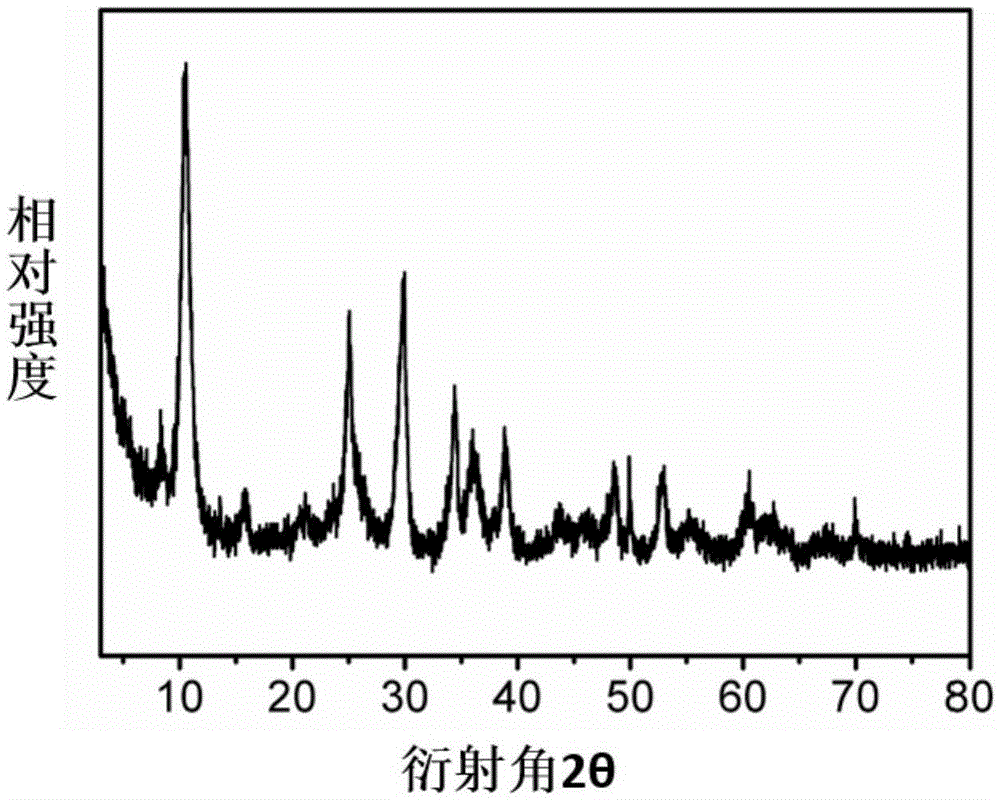

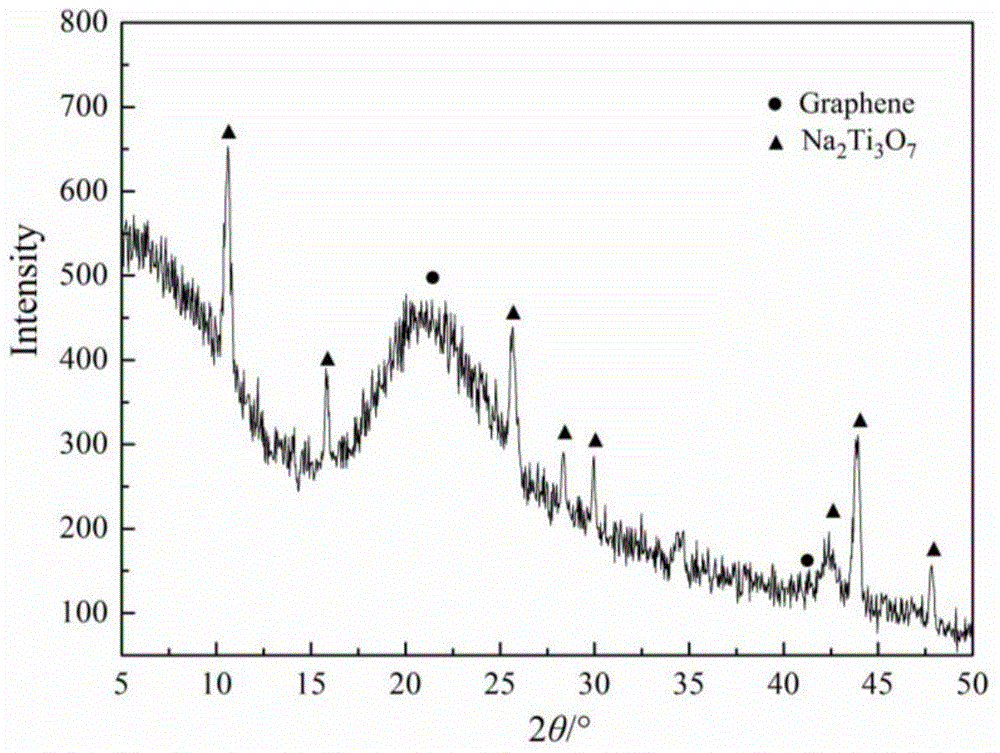

Preparation method of sodium titanate/graphene composite cathode material of sodium ion battery

ActiveCN104600271AEasy to storeFacilitated DiffusionCell electrodesSecondary cellsStrontium titanateHigh sodium

The invention provides a preparation method of a sodium titanate / graphene composite cathode material of a sodium ion battery, which is used for solving the problems in the prior art that no sodium ion battery cathode material with excellent comprehensive performance is provided, and belongs to the field of sodium ion secondary batteries. The method comprises the steps of dispersing graphene oxide to obtain a graphene oxide solution, mixing the graphene oxide solution, a sodium-containing compound and a titanium-containing compound, carrying out reaction to obtain a composite precursor, mixing the composite precursor with a binder, carrying out atomizing drying and granulating to obtain a spherical composite precursor, and finally burning the spherical composite precursor in an inert atmosphere to obtain a micro-scale spherical sodium titanate / graphene composite cathode material. The composite cathode material has the advantages of high sodium storage capacity, long cycle life, good large-current discharge property, high compaction density and the like, and the requirement of the high-performance sodium ion battery for the comprehensive performance of the cathode material can be met.

Owner:LIAONING TECHNICAL UNIVERSITY

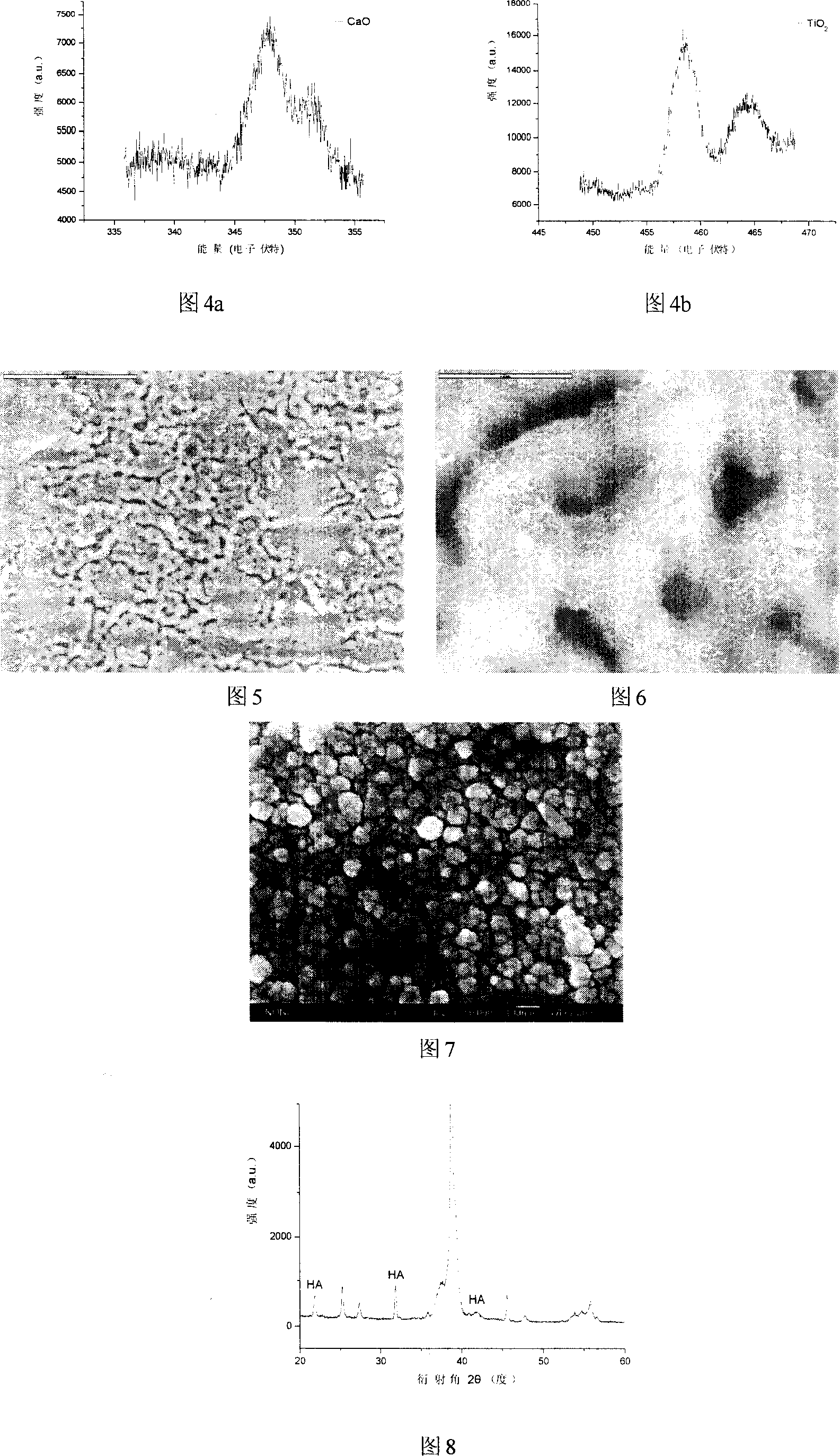

Bioactive coating on surface of Titanium or titanium alloy and its preparing method

InactiveCN1986003AGood biocompatibilityImprove biological activityCoatingsHigh cellBiocompatibility Testing

The present invention relates to bioactive coating on the surface of titanium or titanium alloy and its preparation process. The process includes the following steps: the first anode oxidation, alkali treatment and heat treatment of titanium or titanium alloy to form surface gradient coating in the thickness of 3 micron and comprising one inner thin and compact titania film and one outer porous titania film; introducing Ca element by means of the electrolyte solution into the coating to raise the biocompatibility; boiling in NaOH solution for 1-5 hr to form thin surface sodium titanate and calcium titanate layer; and final depositing a bone-like hydroxyapatite layer. The present invention raises the bioactivity of titanium or titanium alloy surface, and has high binding force of hydroxyapatite layer and high cell adhering capacity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

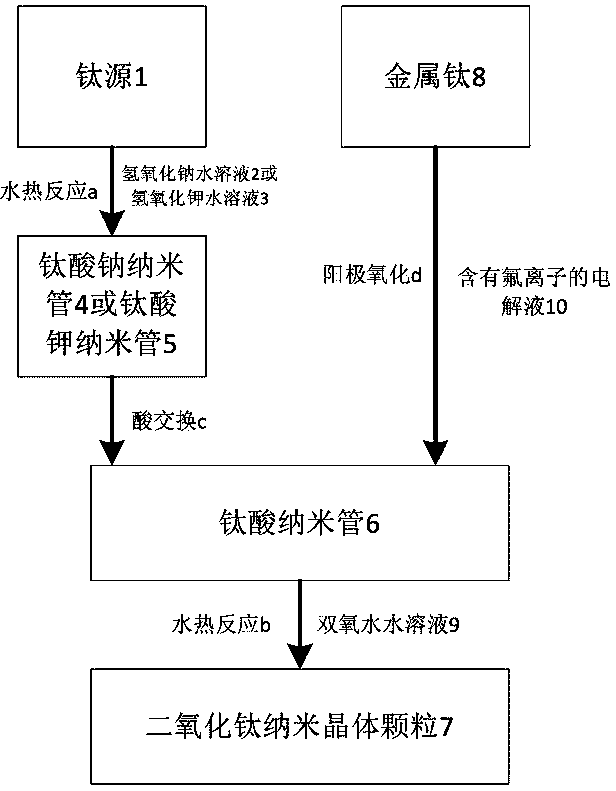

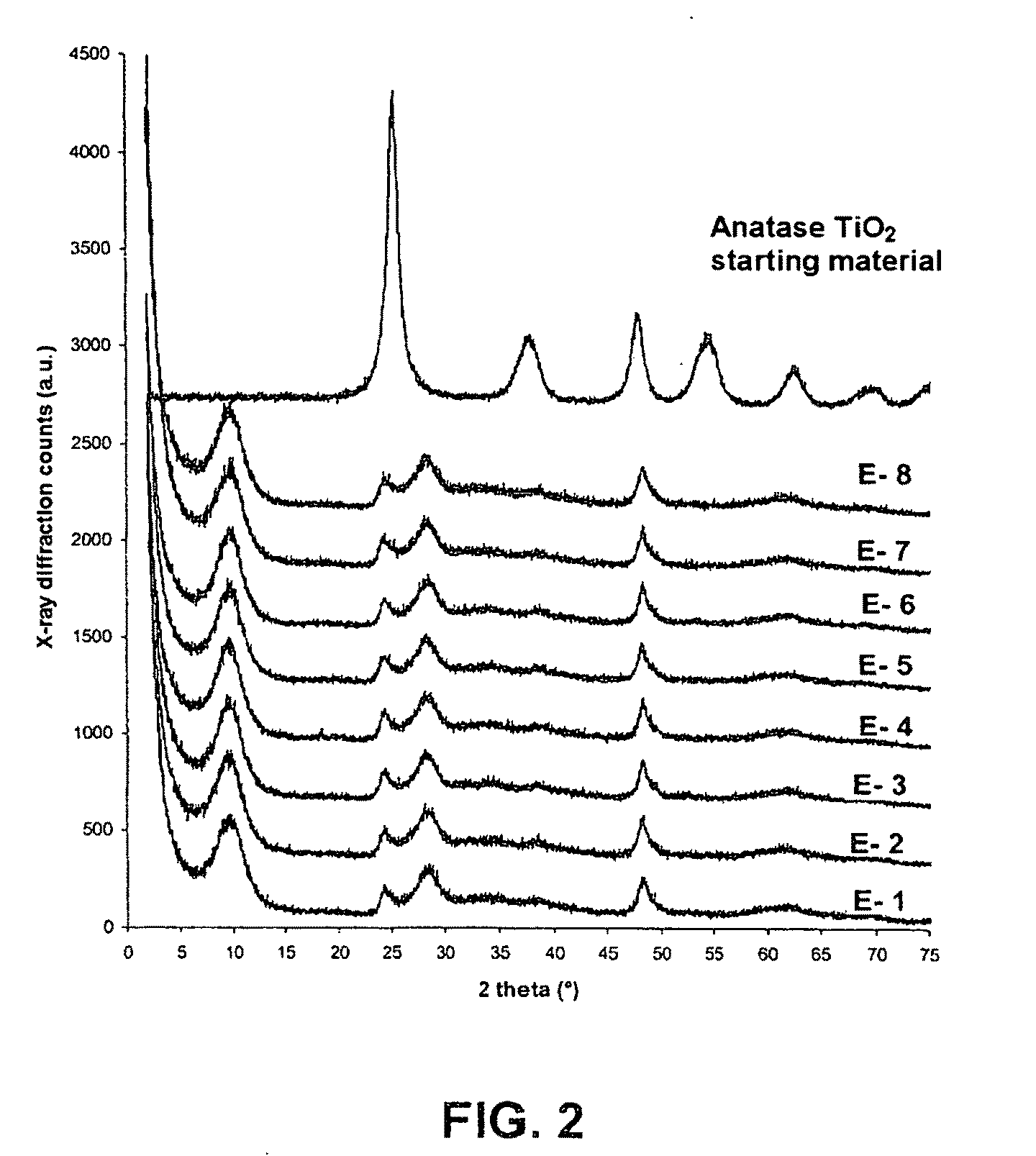

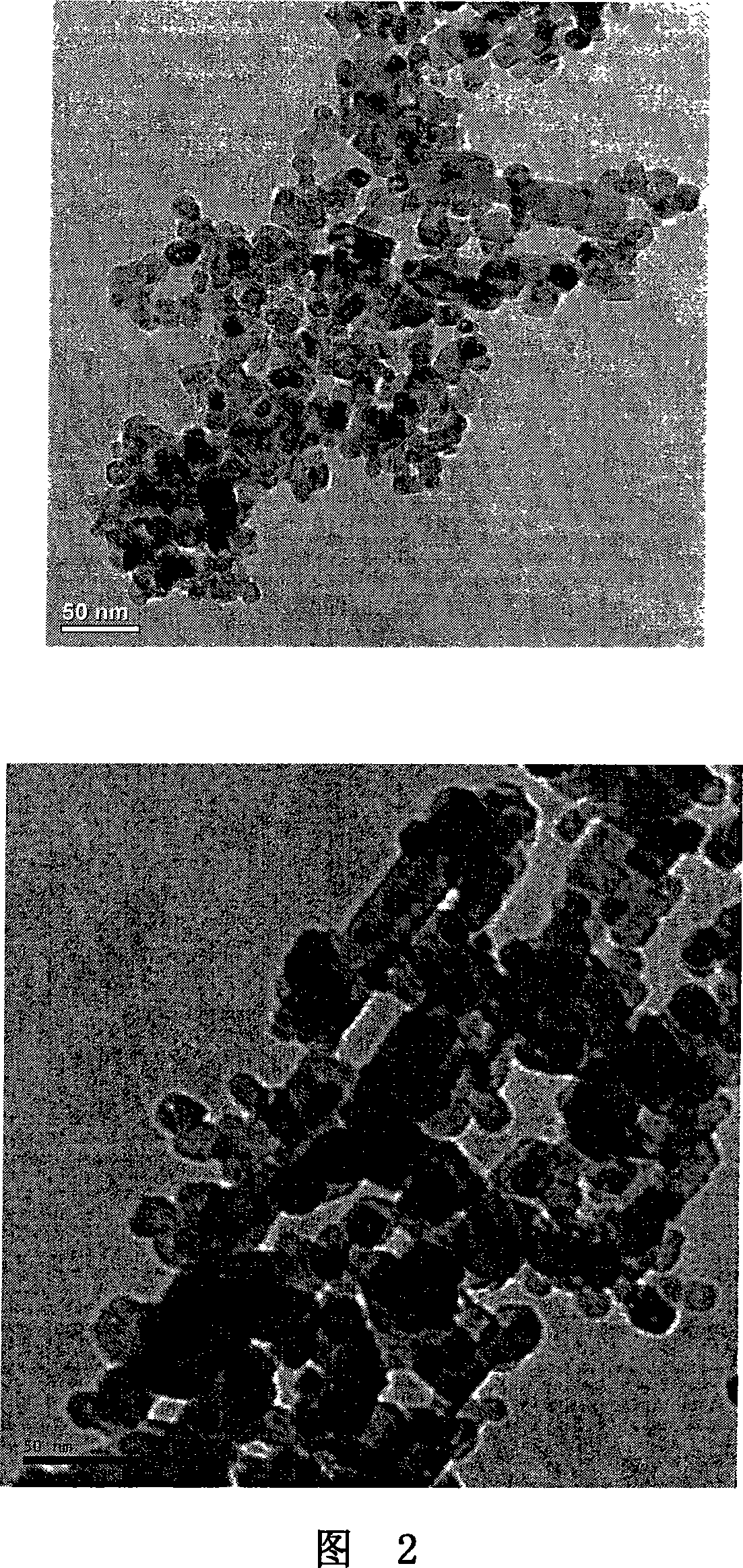

Method for preparing TiO2 nanocrystal particles

ActiveCN104192899AGood monodispersityHigh crystallinityMaterial nanotechnologyTitanium dioxidePotassium hydroxideSodium titanate

The invention discloses a method for preparing TiO2 nanocrystal particles, which comprises the following steps: dispersing titanic acid nanotubes in an oxydol water solution, and carrying out hydrothermal reaction to obtain monodisperse high-photocatalytic-activity anatase TiO2 nanocrystal particles. The process for preparing the titanic acid nanotubes comprises the following steps: mixing a titanium source and a sodium hydroxide water solution, carrying out hydrothermal reaction to obtain sodium titanate nanotubes, and carrying out acid exchange on the sodium titanate nanotubes to obtain the titanic acid nanotubes; or mixing a titanium source and a potassium hydroxide water solution, carrying out hydrothermal reaction to obtain potassium titanate nanotubes, and carrying out acid exchange on the potassium titanate nanotubes to obtain titanic acid nanotubes; or carrying out anode oxidation on metal titanium in a fluorion-containing electrolyte to obtain the titanic acid nanotubes.

Owner:NINGBO NANOJP NEW MATERIAL TECH CO LTD

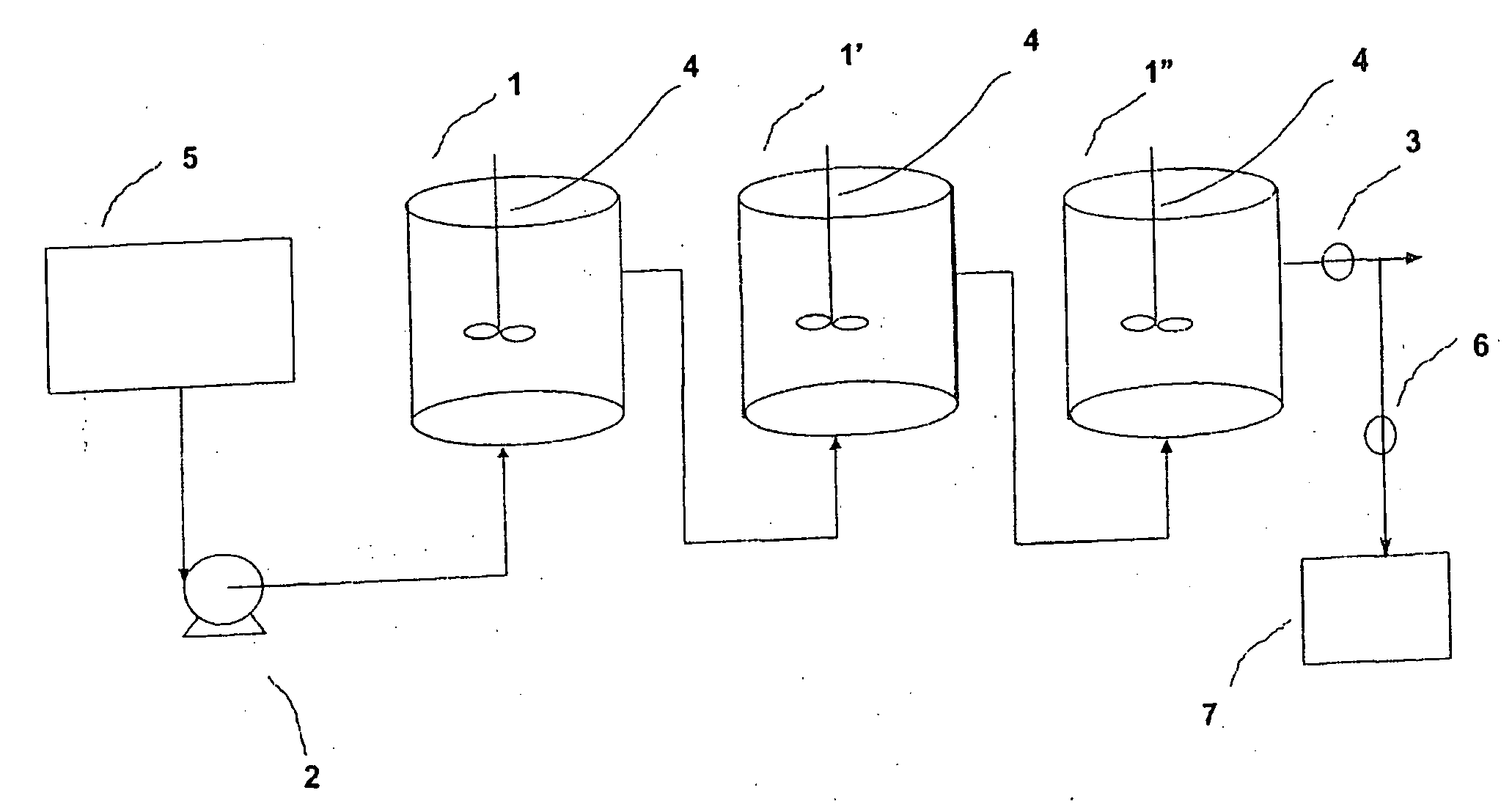

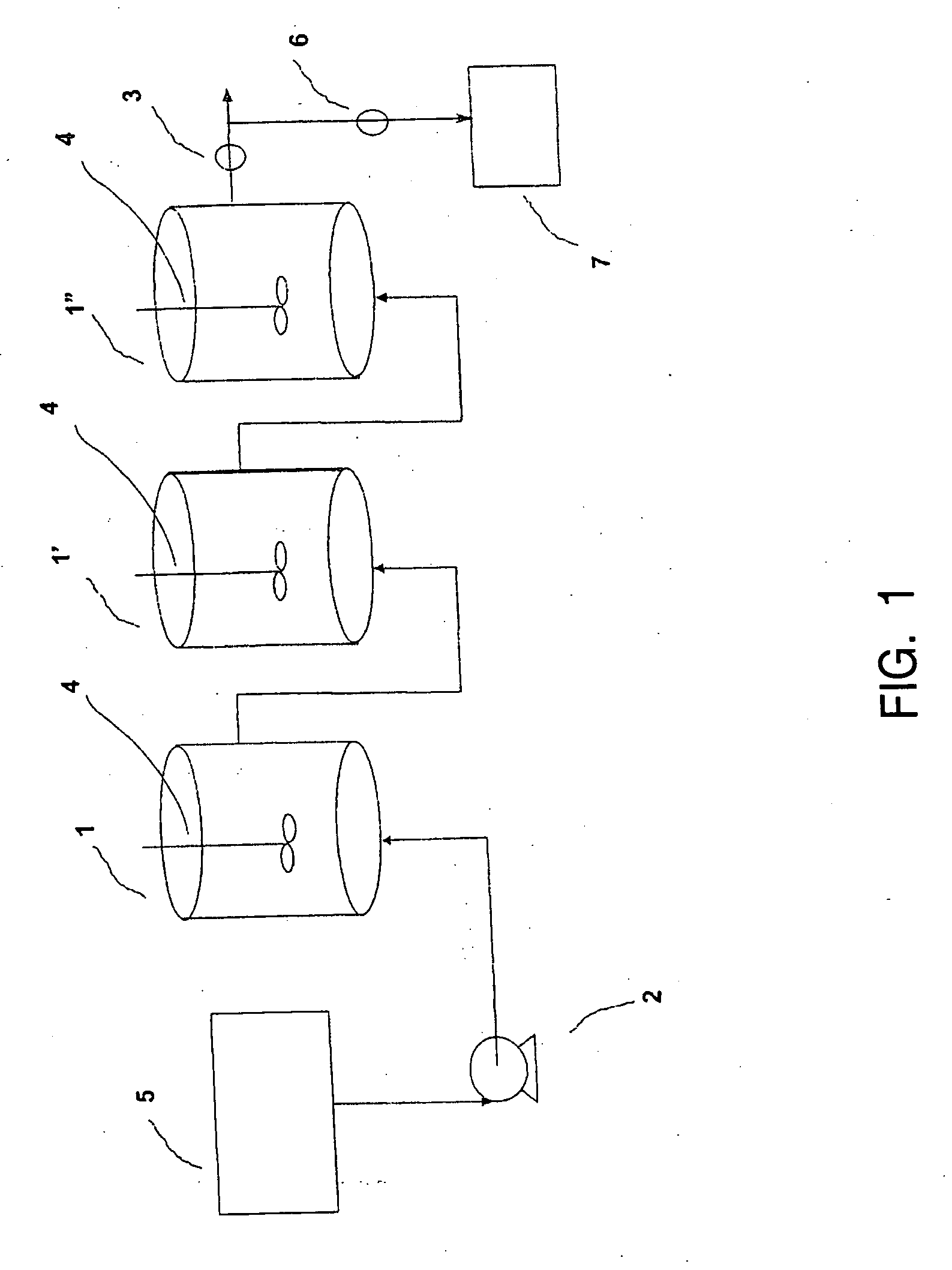

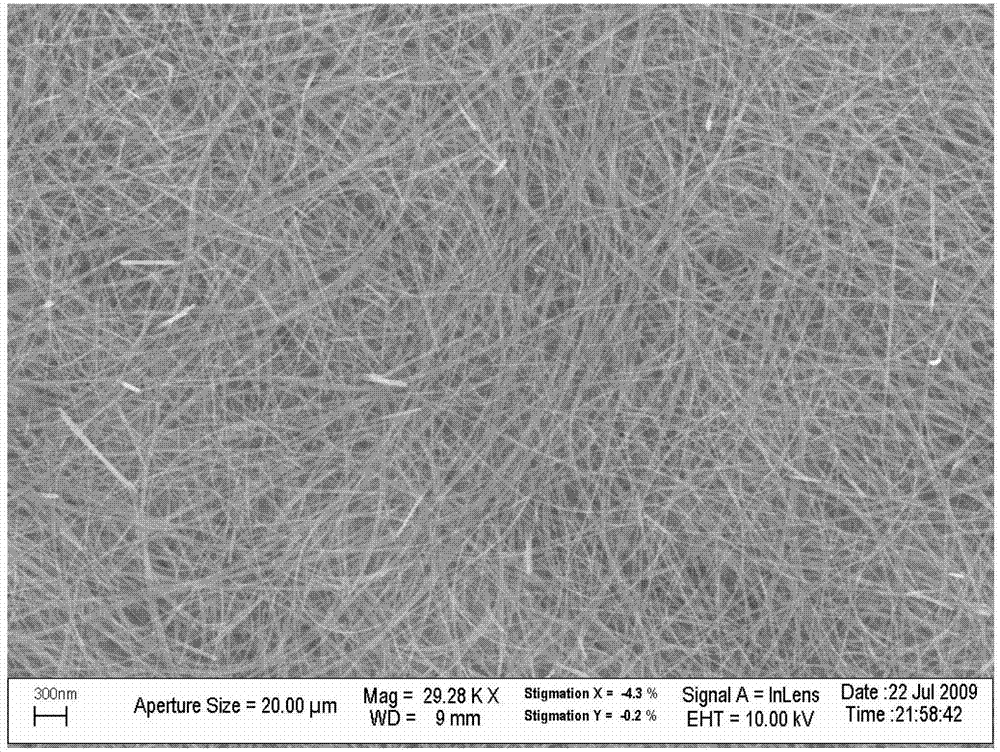

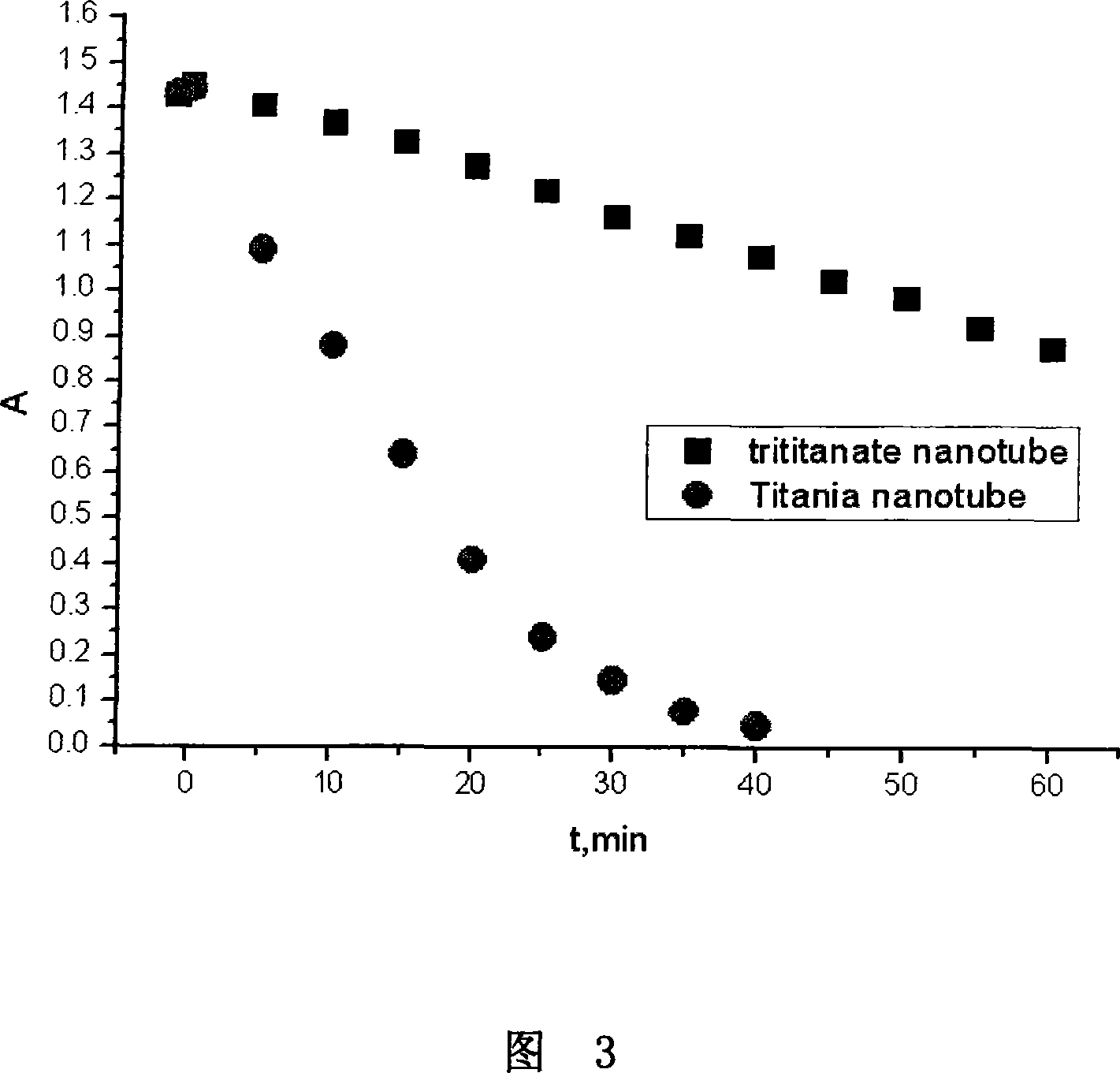

Continuous process for the preparation of sodium titanate nanotubes

The invention relates to a continuous process for the preparation of sodium titanate nanotubes and their derivatives obtained by ion exchange and / or thermal treatment, by reacting titanium oxides with sodium hydroxide under suitable hydrothermal conditions to obtain or control the morphology of nanostructural titanates.The method is carried out continuously in one or more reactors connected in series, where the reaction mixture is introduced continuously into the reactor at a feed rate that is the same as the rate of discharge of the product. When more than one reactor is used, the material leaving the first reactor is used to feed the next reactor, and preferably a temperature differential is applied between the reactors in such a way as to obtain a mean temperature of between 60 and 180° C., and the overall reaction time is short, being about 90 minutes or less.The nanostructures obtained can be later subjected to ion exchange and / or thermal treatment in an inert, oxidizing or reducing atmosphere in order to prepare adsorbents, catalysts, photocatalysts, electrocatalysts, or else electrodes for photovoltaic cells, lithium batteries, gas sensors and systems for the separation and storage of hydrogen.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

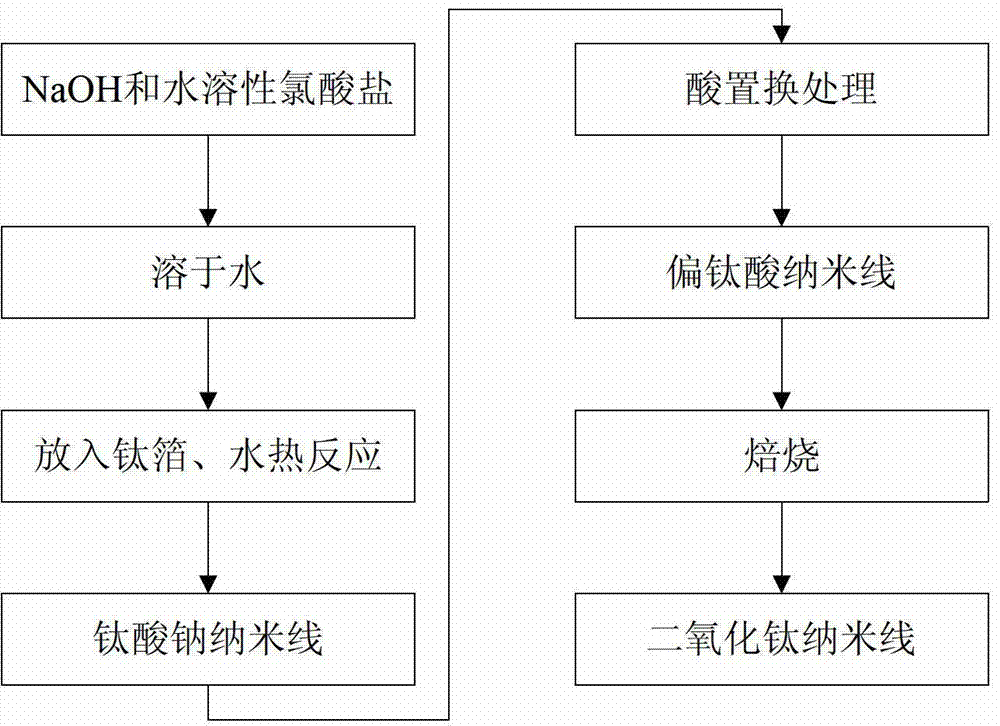

Method for preparing titanium dioxide nanowire

InactiveCN102826600ARegular size arrangementHigh crystallinityMaterial nanotechnologyTitanium dioxideNanowireSodium titanate

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Method for preparing titanium dioxide nano-tube

InactiveCN101182033AImprove photocatalytic activityGood light transmissionNanostructure manufacturePhysical/chemical process catalystsTio2 nanotubeSodium titanate

The invention discloses a preparation method of TiO2 nanotubes, which comprises the following steps: an appropriate amount of sodium titanate nanotubes obtained by a hydrothermal synthesis method is dispensed to be fully dipped in mixed solution of ammonium fluorotitanate and boric acid with the filtered molar concentration ratio of 1:1-1:5 for deposition with the deposition time of 10-120mins; the mixed solution is reacted to obtain the sodium titanate nanotubes with TiO2 films formed which are then dried in an oven and next treated with heat treatment in a muffle furnace and cooled naturally so as to obtain the anatase type TiO2 nanotubes. The TiO2 nanotubes prepared by the method has anatase crystal form and relatively high catalytic activity, so the hydrogen yield of photocatalysis hydrogen production can be increased and the photoelectric transformation efficiency of dye-sensitized solar cells can be improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

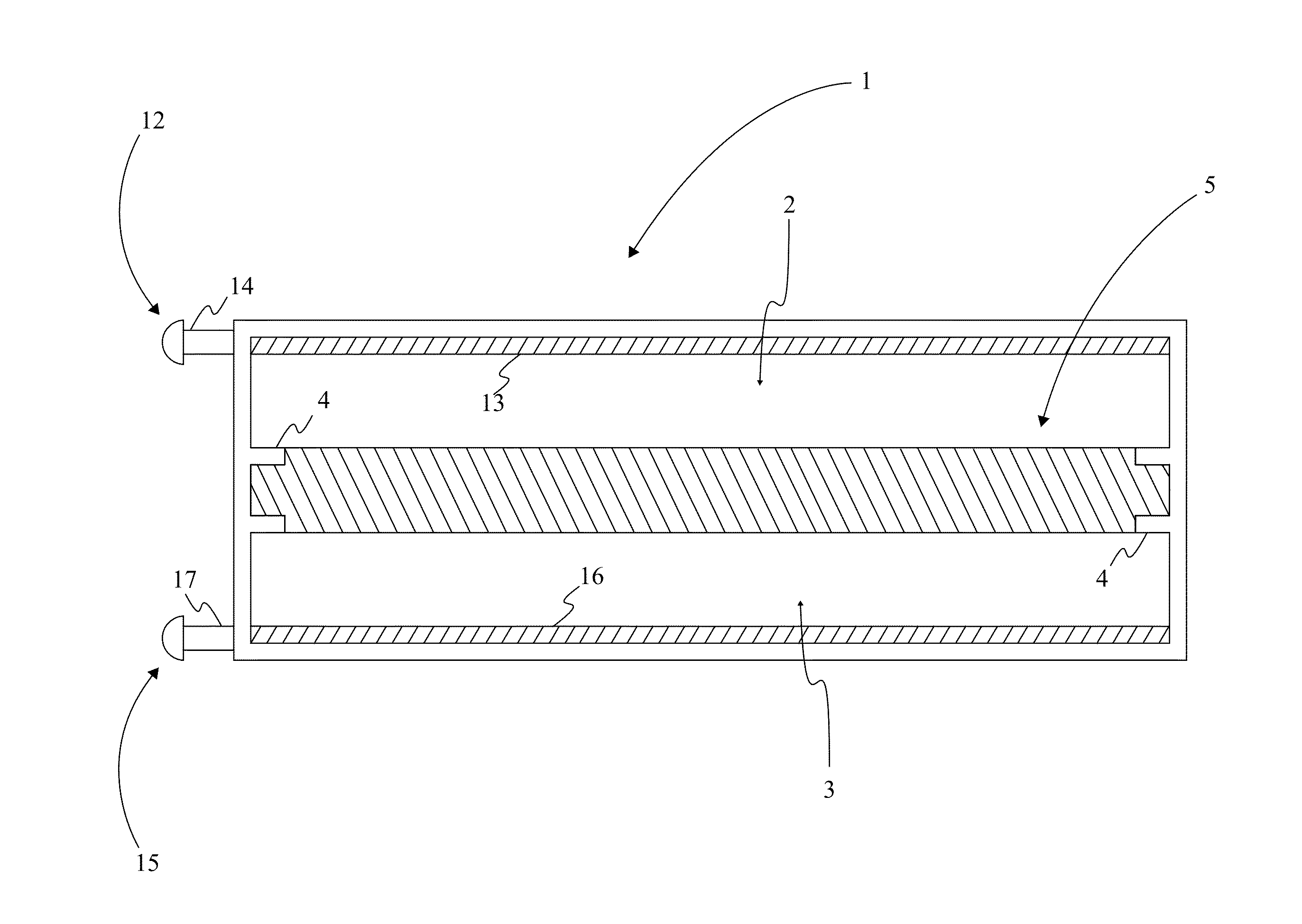

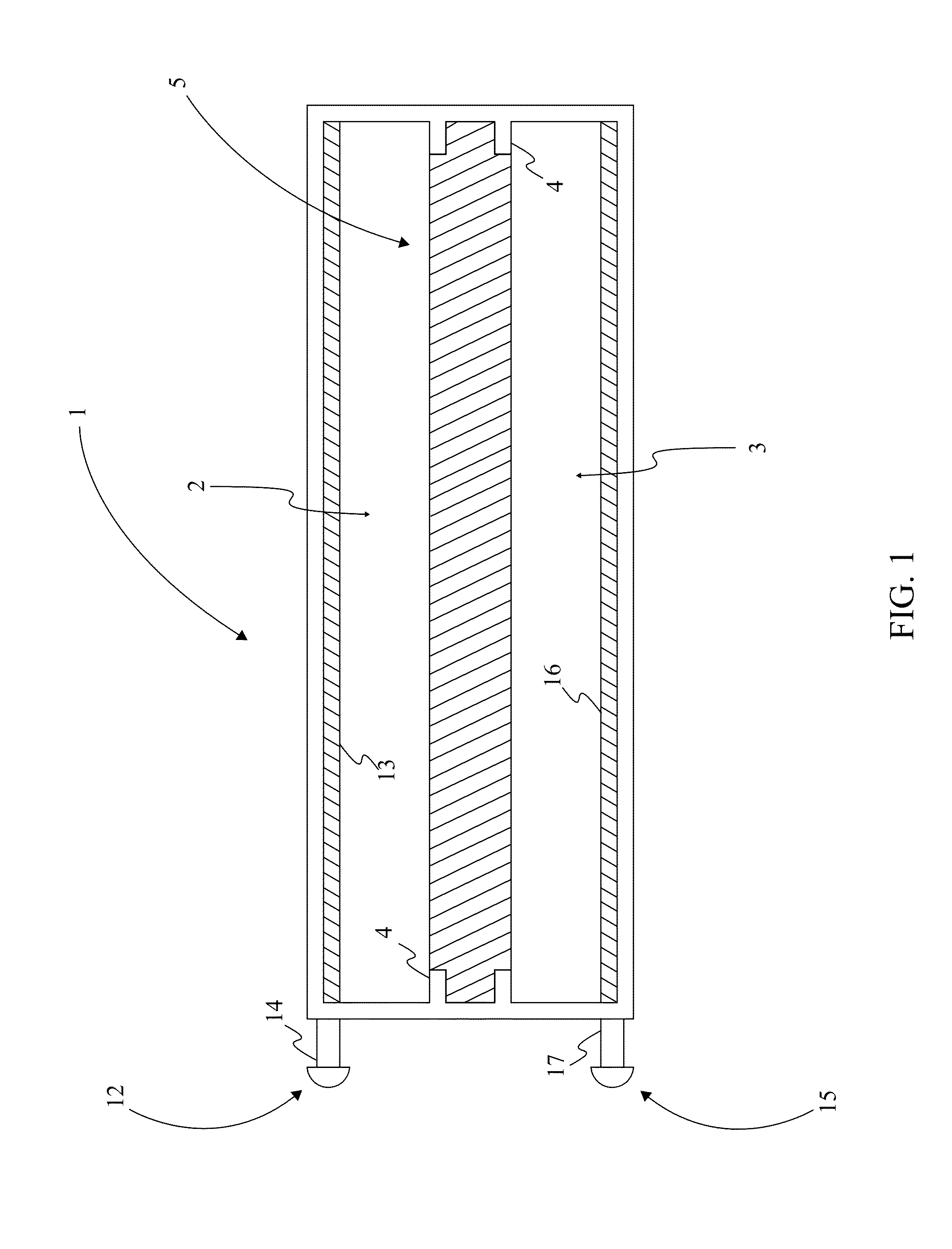

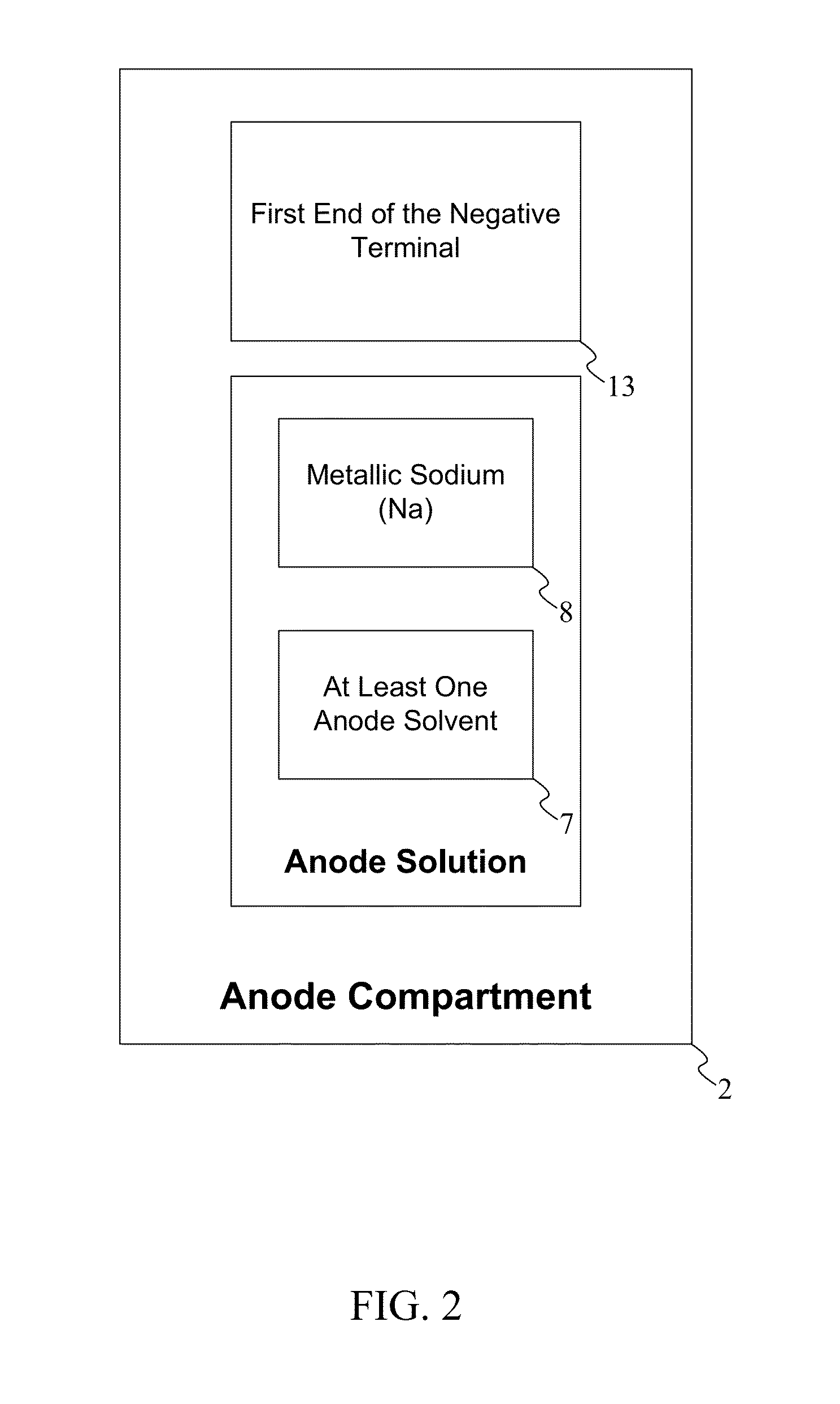

Sodium-Sulfur Battery

InactiveUS20130288153A1High operating cell potentialReduce the temperatureRegenerative fuel cellsSecondary cellsElectrode potentialNanowire

A sodium sulfur secondary battery is a battery that operates at a comparatively lower temperature, while maintaining a high operating cell potential comparable to existing sodium sulfur battery configurations. The apparatus accomplishes this through the arrangement of component materials selected based on experimentation results demonstrating favorable performance in a secondary battery configuration. The sodium sulfur battery comprises a housing, containing an anode solution, a cathode solution, and a sodium ion conductive electrolyte membrane. The anode solution contains metallic sodium and anode solvent. The cathode solution contains elemental sulfur and a cathode solvent. The sodium ion conductive electrolyte membrane is a Sodium Titanate Nano-membrane formed from long TiO2-nanowires. The electrolyte membrane is positioned between the anode solution and the cathode solution. The electrolyte membrane is able to selectively transports of sodium ion between the anode solution and the cathode solution at temperatures below 75° C. generating an electrode potential.

Owner:MORIS TECH CENT

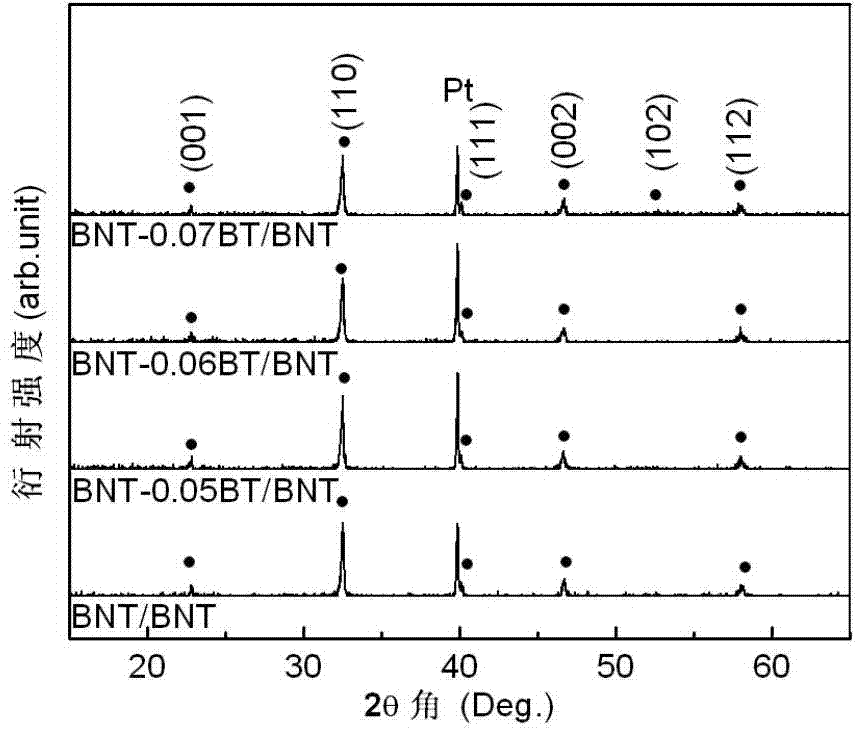

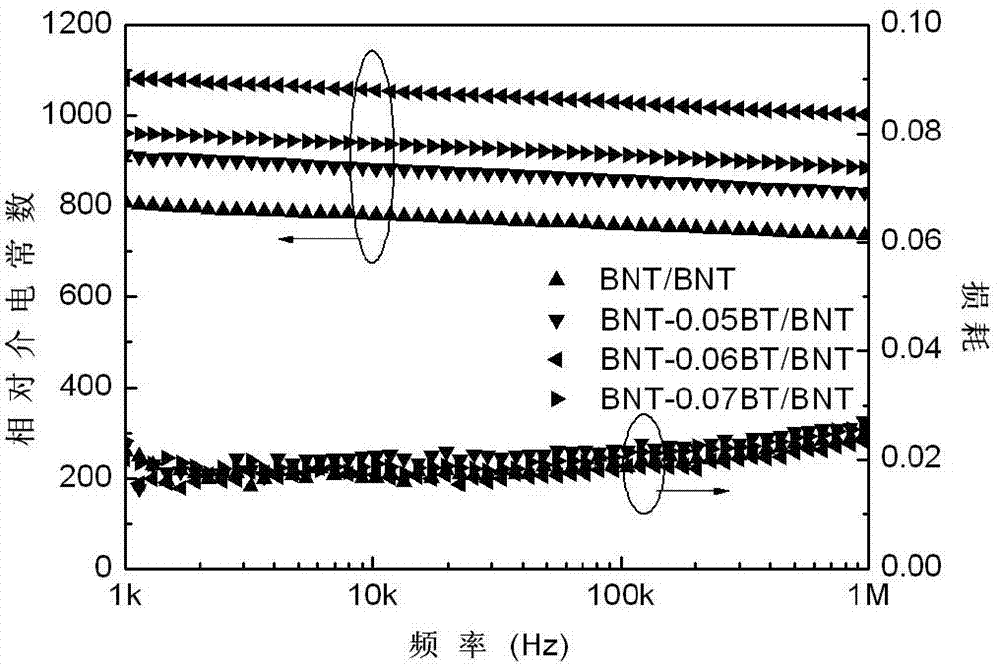

Preparation method of bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film

InactiveCN103708828AHigh viscosityIncreasing the thicknessPiezoelectric/electrostrictive device manufacture/assemblyMicro nanoComposite film

The invention discloses a preparation method of a bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film and belongs to the technical field of the preparation of piezoelectric materials. The preparation method includes the following steps: 1) preparing a micro-nano bismuth sodium titanate-barium titanate powder according to a stoichiometric ratio of (1-x) Bi0.5Na0.5TiO3-xBaTiO3; 2) preparing a sodium bismuth titanate precursor sol according to a stoichiometric ratio of Bi0.5Na0.5TiO3; 3) dispersing the bismuth sodium titanate-barium titanate powder in the sodium bismuth titanate precursor sol to prepare a mixed slurry; 4) conducting spin coating deposition of the bismuth sodium titanate precursor sol, heat treatment, spin coating deposition of the mixed slurry and heat treatment, so as to prepare a single-layer composite film; and 5) repeating the step 4) to prepare the sodium bismuth titanate-barium titanate lead-free composite piezoelectric thick film with thickness of 1-20 mum. The invention makes improvement to the existing sol gel technology, has the advanategs of low process cost, flexible film thickness and good repeatability, and breaks the critical thickness restriction of the ordinary sol-gel technology.

Owner:XI AN JIAOTONG UNIV

Air-sensitive material compounded by titanium dioxide nanometer lines and stannic oxide nanometer particles and preparation method thereof

The invention discloses an air-sensitive material compounded by titanium dioxide nanometer lines and stannic oxide nanometer particles and a preparation method thereof. A material core layer is made of the titanium dioxide nanometer lines with good crystallinity, and a layer of stannic oxide nanometer particles with high specific surface area characteristics is formed on the surface of the core layer through in-situ reaction. Firstly, a hydrothermal method is used for synthetizing sodium titanate nanometer lines, the stannic oxide nanometer particles are synthetized on the nanometer lines in in-situ mode, and reaction products are liquid-solid separated, washed and dried and thermally processed for 1 hour to 3 hours at the temperature of 500 DEG C to 700 DEG C. The air-sensitive material is stable in performance, simple in manufacture process and high in flexibility at the low working temperature of 250 DEG C.

Owner:ZHENGZHOU UNIV

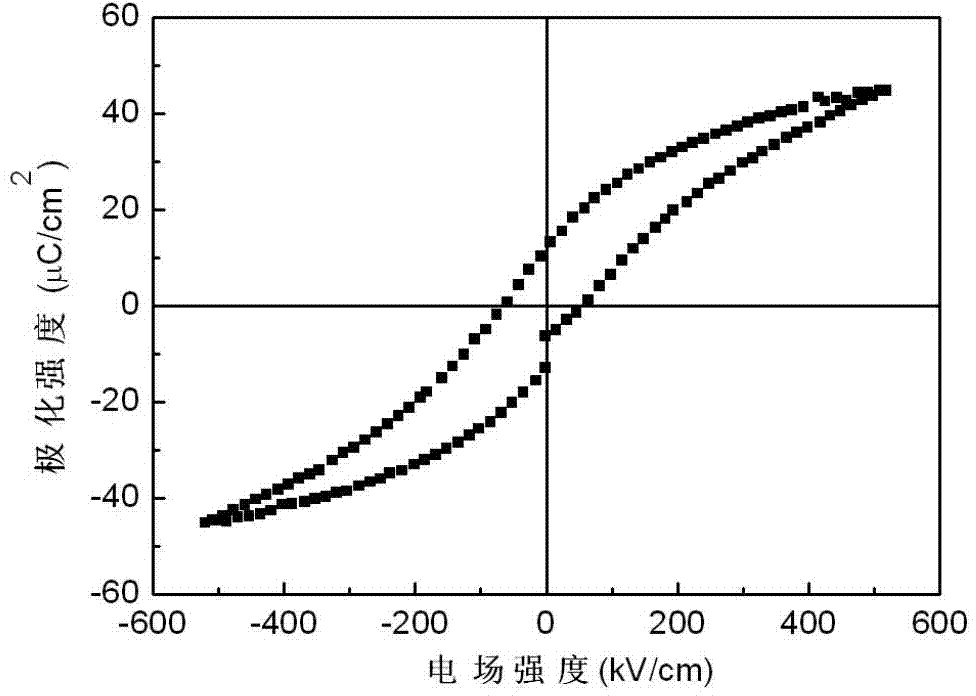

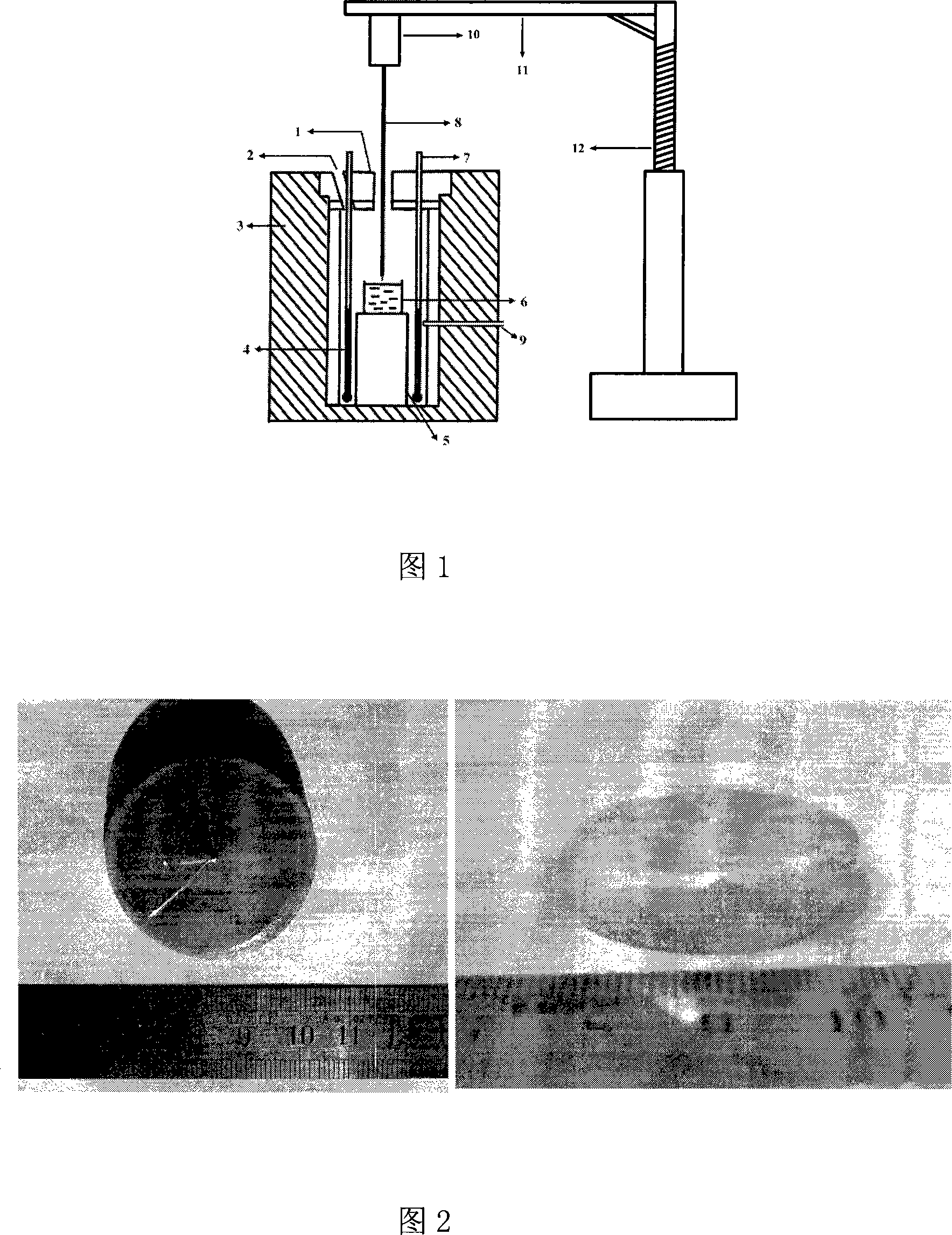

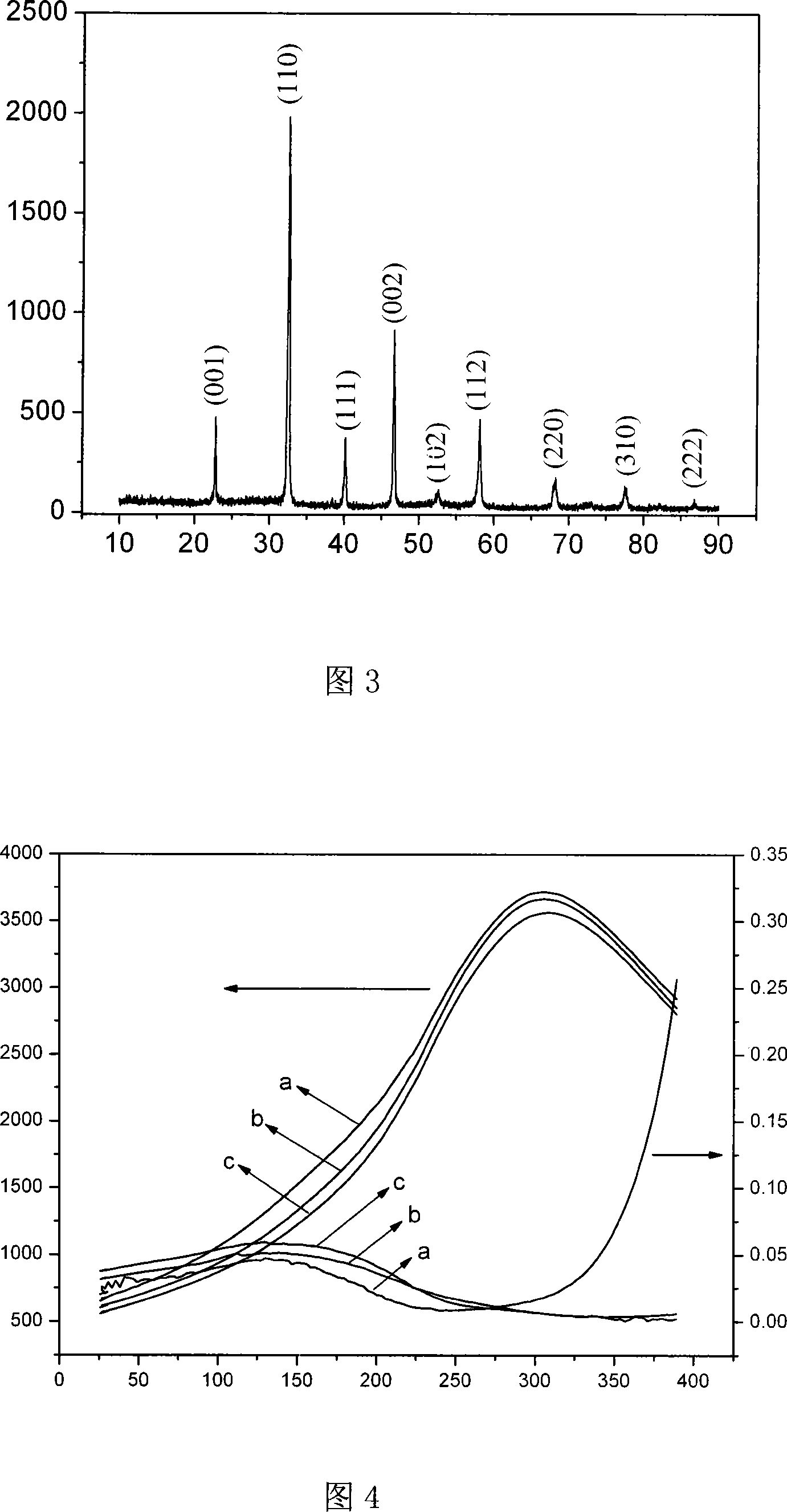

Method for manufacturing bismuth sodium titanate-barium titanate ferro-electricity single crystal

ActiveCN101220511AImprove performanceComplete structurePolycrystalline material growthBy pulling from meltElectromechanical coupling coefficientBarium titanate

A preparing method of bismuth sodium titanate-barium titanate ferroelectric single crystal belongs to the field of crystal growth. The preparing method provided by the invention comprises a series of single crystal growth processes: raw material treatment, heating and melting, growing and cooling. The rotational speed of a seed rod is 10 to 50rpm, and the drawing rate is 0.1mm to 20mm per day, and the cooling rate is 1 to 20 DEG C per day; the cooling rate is 10 to 150 DEG C per hour after the crystal finishes growing. The technology provided by the invention can grow bismuth sodium titanate-barium titanate ferroelectric single crystal (NBBT) with the diameter larger than 40mm and the length larger than 10mm, and the piezoelectric constant d33 can reach 280pC / N, and the electromechanical coupling factor kt can reach 50 percent. The material with the piezoelectric property which reaches the level of leaded piezoelectric materials of PZT ceramics, etc., can be applied in practice.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

High-niobium high-chromium alloy cast ion self-protection flux-cored wire for grinding roller surfacing and preparation method thereof

ActiveCN105312795AReduce liquidityReduced service lifeArc welding apparatusWelding/cutting media/materialsSodium titanateHigh stress

The invention discloses a high-niobium high-chromium alloy cast ion self-protection flux-cored wire for grinding roller surfacing and a preparation method thereof. The flux-cored wire is composed of a ferrite stainless steel band and flux powder wrapped with the ferrite stainless steel band. The flux powder is prepared from, by weight, 42.0-48.0% of high-carbon chromium iron, 13.0-16.0% of niobium iron, 4.5-5.0% of graphite, 1.5-2.0% of silicon iron, 2.0-3.0% of electrolytic manganese, 1.5-2.0% of medium-carbon ferroboron, 1.0-2.0% of aluminum-magnesium alloy, 0.5-1.0% of cryolite, 0.5-1.0% of fluorite, 1.0-1.5% of lithium carbonate, 0.5-1.0% of zircon sand, 1.0-1.5% of potassium titanate, 1.5-2.0% of sodium titanate and the balance iron powder. The preparation method includes the steps that the flux powder is added into a U-type tank after being preprocessed; and four times of continuous drawing and diameter reducing are sequentially carried out after the opening of the U-type tank is closed, and the flux-cored wire is obtained. The flux-cored wire has the advantages that the hardness of deposited metal of a surfacing layer is stable, welding spatter is little and high-stress abrasive wear resistance is good, and is particularly suitable for surfacing repair and remanufacturing of cement grinding rollers.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Sodium ion electrochemical capacitor

ActiveCN103198928AIncrease layer spacingLow costHybrid capacitor electrolytesHybrid capacitor electrodesBarium titanateSodium titanate

The invention provides a sodium ion electrochemical capacitor which comprises a positive pole, a negative pole, an electrolyte, and a membrane arranged between the positive pole and the negative pole, wherein the negative pole of the sodium ion electrochemical capacitor is made of coke or molybdenum sulfide or molybdenum oxide or niobium oxide or sodium titanate, and the electrolyte is an organic solution of neutral sodium salt. The five negative pole materials are all of layered structures, so sodium ions in the electrolyte can be intercalated and released from the surfaces of negative pole materials, and namely a redox reaction is generated. Interlamellar spacing of the negative pole materials is large, rapid intercalation and releasing of the sodium ions with large sizes are benefited, accordingly energy density and power density of the sodium ion electrochemical capacitor are improved, and the cycle life of the sodium ion electrochemical capacitor is prolonged. Meanwhile, the negative pole of the sodium ion electrochemical capacitor is made of the coke or the molybdenum sulfide or the molybdenum oxide or the niobium oxide or the sodium titanate, and the electrolyte is the organic solution of the neutral sodium salt, so cost of the capacitor is effectively reduced.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Surface treatment method for improving biological property of medical metallic titanium

ActiveCN101603196APromote rapid formationGood biocompatibilitySurface reaction electrolytic coatingTitanium metalBiocompatibility Testing

The invention discloses a surface treatment method for improving biological property of medical metallic titanium, and relates to a new method for controllably constructing a titanium dioxide film layer with a specific nano-micro ordered structure and greatly improving biocompatibility and bioactivity of a hard tissue material through alkali thermal treatment for the surface of medical metallic titanium. The invention provides the surface treatment method for improving the biological property of the medical metallic titanium. After the surface of a titanium metal substrate is pretreated, the titanium metal substrate is subjected to alkali treatment, and then a nano-micro ordered sodium titanate film layer can be obtained on the surface of the titanium metal substrate, wherein the alkali treatment solution is NaOH solution; and the obtained titanium metal substrate with the nano-micro ordered sodium titanate film layer on the surface is calcined to obtain an anatase type TiO2 film layer with a specific structure.

Owner:BEIJING NATON TECH GRP CO LTD

Method for truncating sodium titanate nanotubes

InactiveCN101602483AUniform lengthAdjustable lengthNanostructure manufactureTitanium compoundsAcetic acidEthylenediamine

The invention relates to a method for truncating sodium titanate nanotubes. The lengths of sodium titanate nanotubes obtained by the prior method are not uniform. The method comprises the concrete steps of: dispersing the sodium titanate nanotubes into water solution of soluble heavy metallic salt; stirring the mixture at normal temperature; performing precipitation separation, washing and drying on the sodium titanate nanotubes absorbed with heavy metal ions; dispersing the obtained product into saturated water solution of disodium ethylene diamine tetraacetate to obtain mixed solution; stirring the mixed solution at normal temperature, and removing the heavy metal ions absorbed in the sodium titanate nanotubes; obtaining a sodium titanate nanotube precipitate after the mixed solution is subjected to centrifugal separation; and obtaining the truncated sodium titanate nanotubes by washing and drying. The lengths of the sodium titanate nanotubes obtained by the truncation are uniform, and can reach 20nm at shortest.

Owner:NANTONG JINNIU MACHINERY MFR

Clean method for preparing rutile-type titanium dioxide from high-titanium slag by hydrothermal method

InactiveCN101190802AProduced (processed) lessHigh titanium contentTitanium dioxideEconomic benefitsCleaning methods

The invention relates to a clean production method by high titanium slag hydrothermal method to prepare rutile titanium oxide. The method adopts high titanium slag as raw material and sodium hydroxide hydrothermal method to prepare the intermediate product of sodium titanate which is then separated from the solution and washed and hydrolyzed to obtain the rutile titanium oxide. The method of the invention adopts simple preparation technique to prepare the rutile TiO2, which spares high temperature calcination in the traditional technique; the conversion rate of titanium in the high titanium slag is of over 99.0 percent and the alkali circulation and the acid circulation are realized, which has good economic benefit and environmental benefit. Additionally, the sodium titanate which can be taken as the intermediate product for preparing titanium series obtained from the method is expected to have wide application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for synthesizing sodium titanate whisker

InactiveCN101117728ALow costLow thermal conductivityPolycrystalline material growthSingle crystal growth detailsSodium titanateQuenching

The present invention discloses a manufacturing method for sodium hexa-titanate whiskers. Adopting the melting-quenching method of synthesis, the method comprises: mixing titanium-containing raw material, sodium-containing raw material and fluxing agents first; sintering in a high-temperature container until the mixture becomes molten; taking out the molten mixture and quenching on a special quenching device; dissolving part sodium ions in an acid solution; sintering after filtering, washing and drying, then finished product can be obtained; the technological flow is simple and feasible; and the whole process has no pollution. The sodium hexa-titanate whiskers synthesized with the method of the present invention has low cost, low thermal conductivity and high infrared-ray reflectivity. The sodium hexa-titanate whiskers are 10-50 micrometers in average length and 1-5 micrometers in average diameter and can be used as enhancing material, friction material, heat insulation material, etc.

Owner:上海秀普复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com