Patents

Literature

273 results about "Sodium bismuth titanate" patented technology

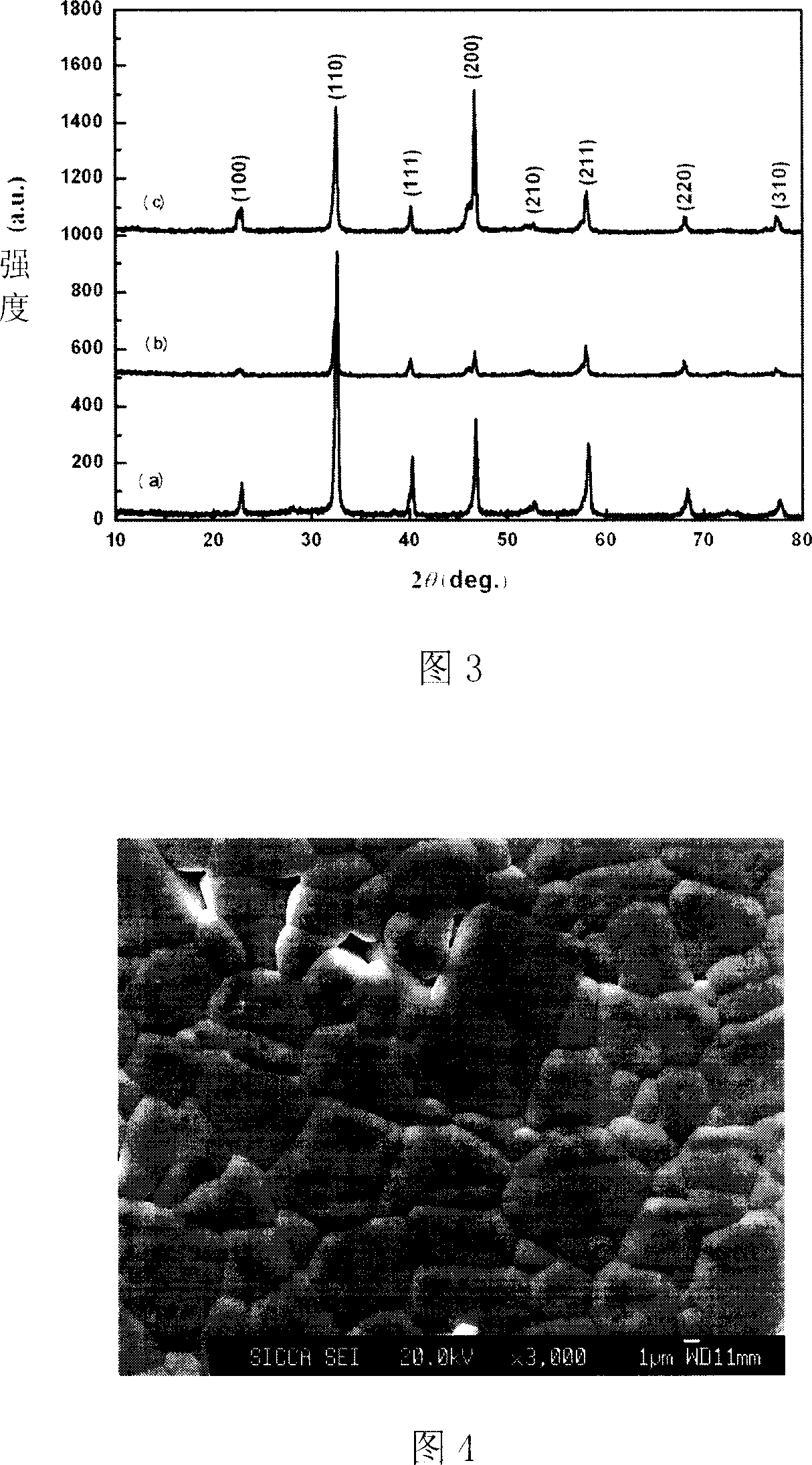

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

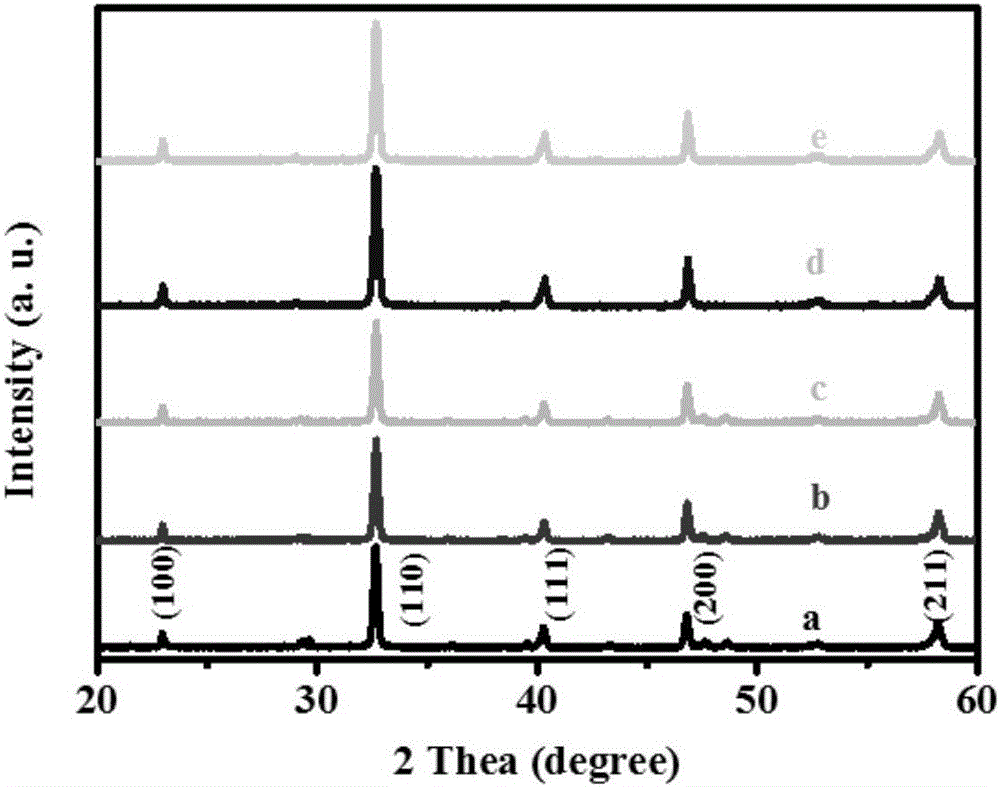

Sodium bismuth titanate or bismuth sodium titanium oxide (NBT or BNT) is a solid inorganic compound of sodium, bismuth, titanium and oxygen with the chemical formula of Na0.5Bi0.5TiO₃ or Bi0.5Na0.5TiO₃. This compound adopts the perovskite structure.

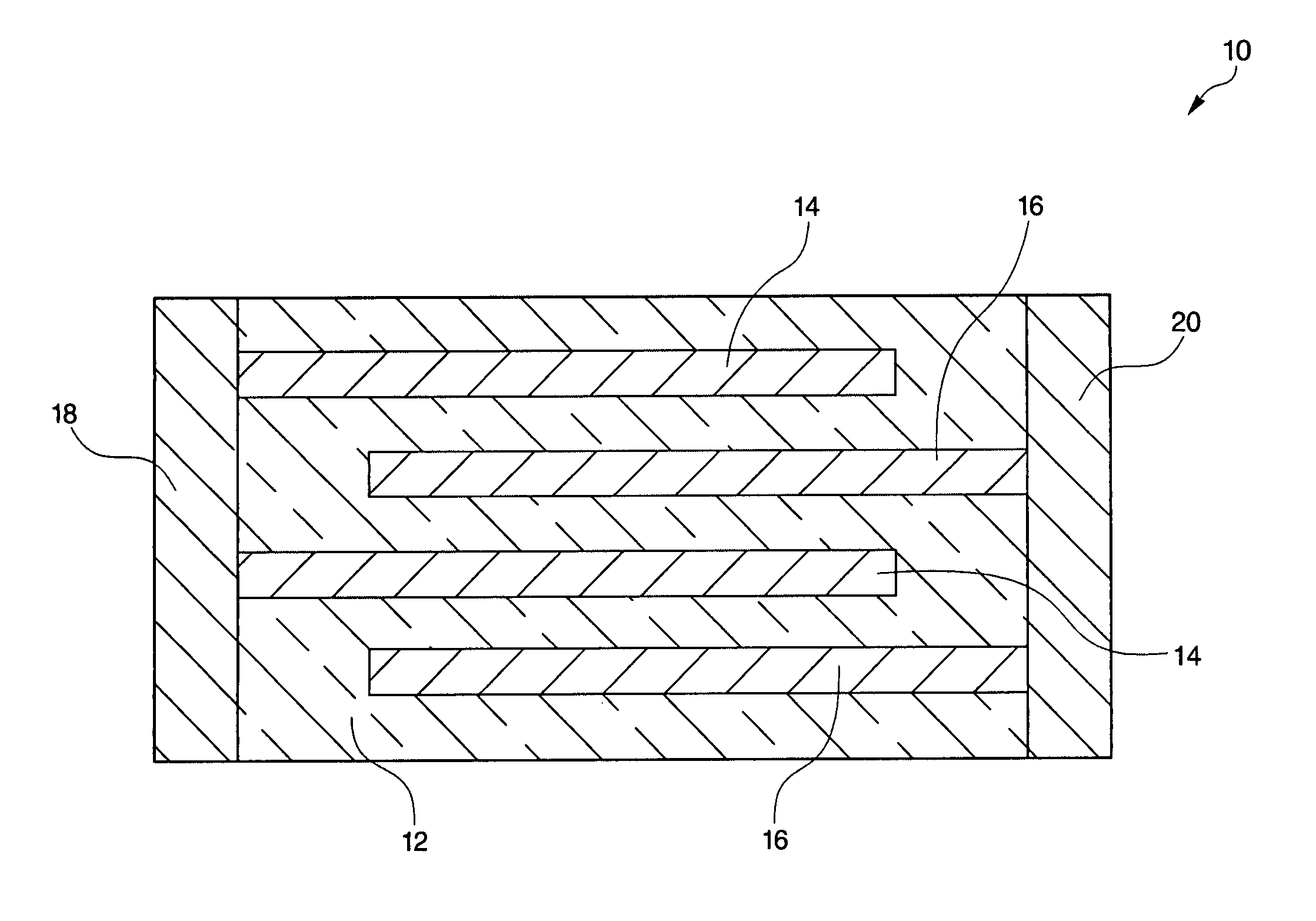

High temperature ceramic dielectric composition and capacitors made from the composition

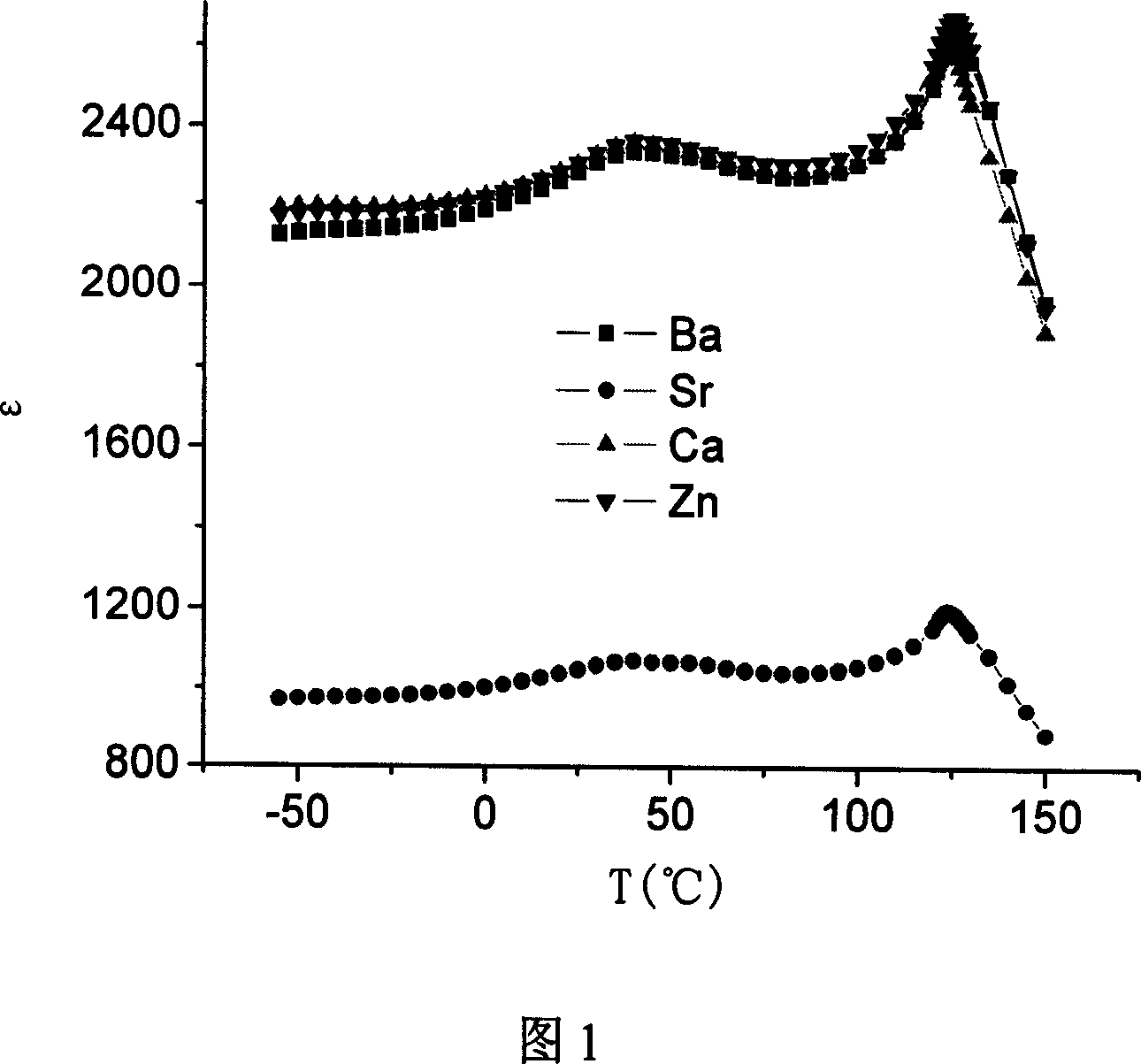

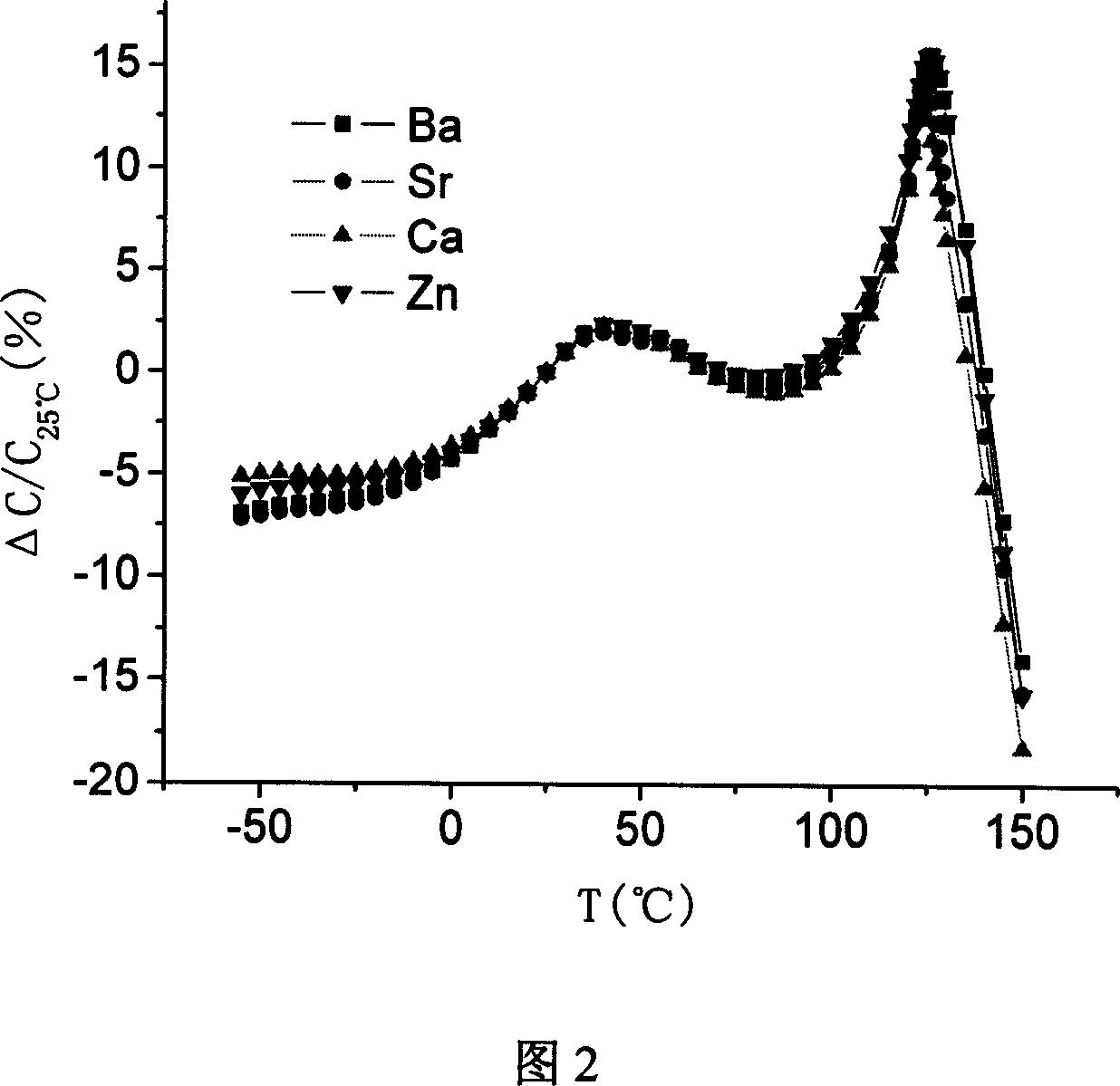

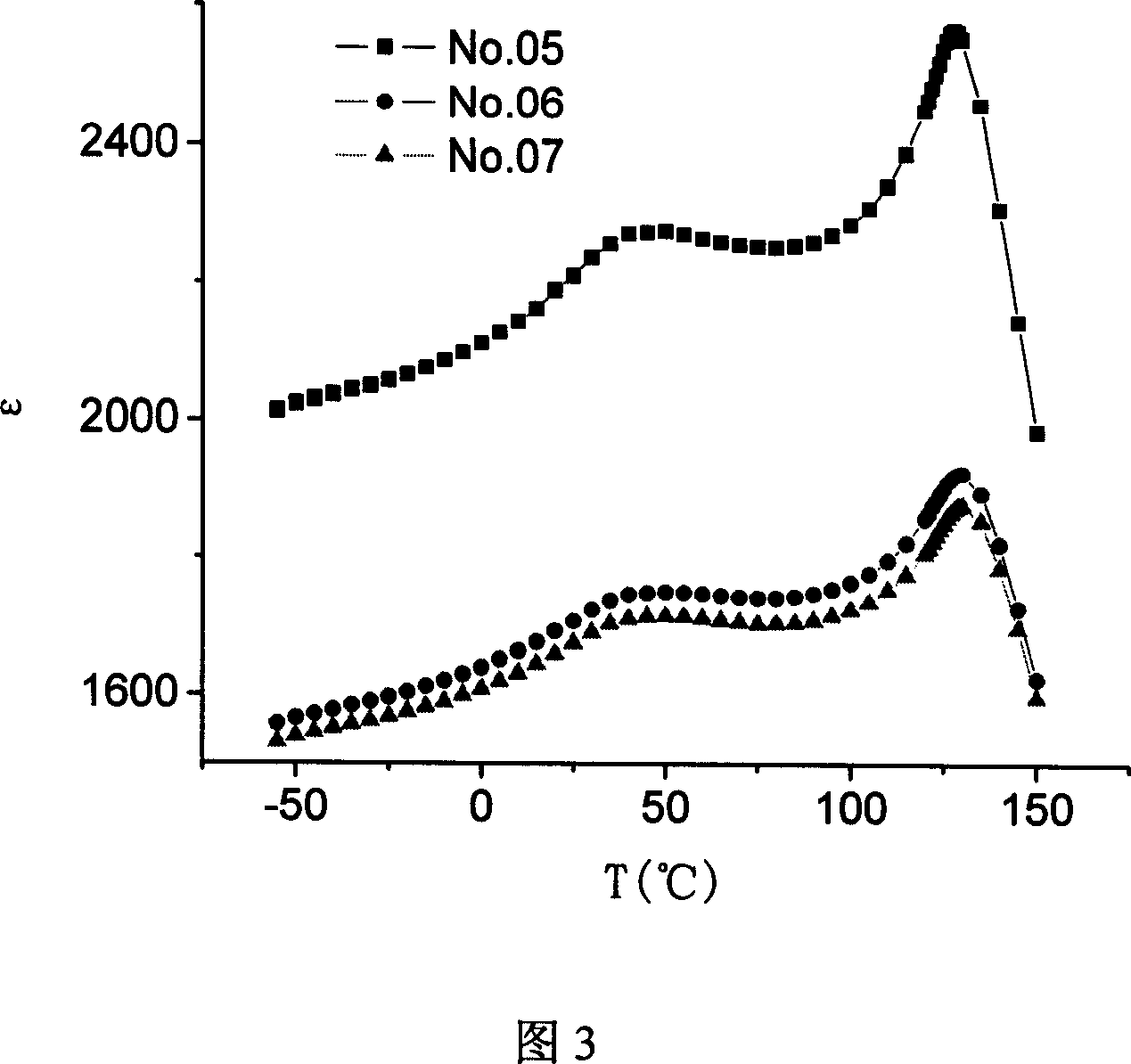

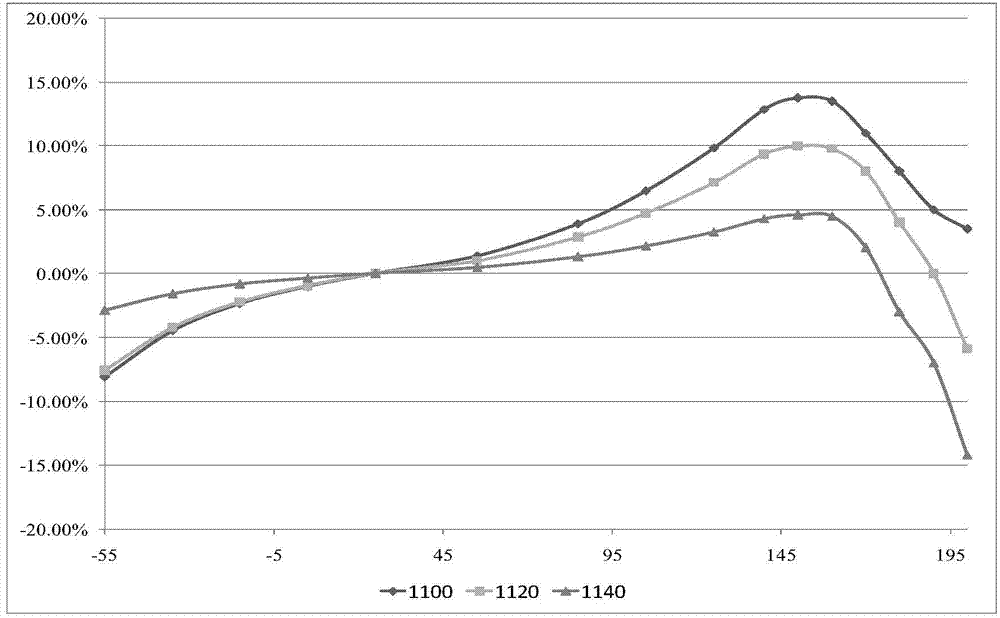

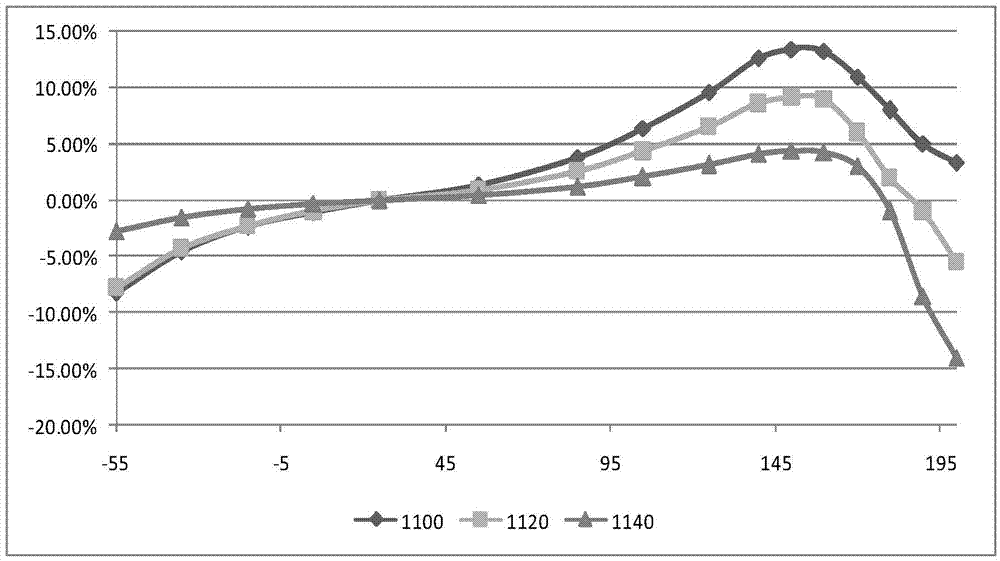

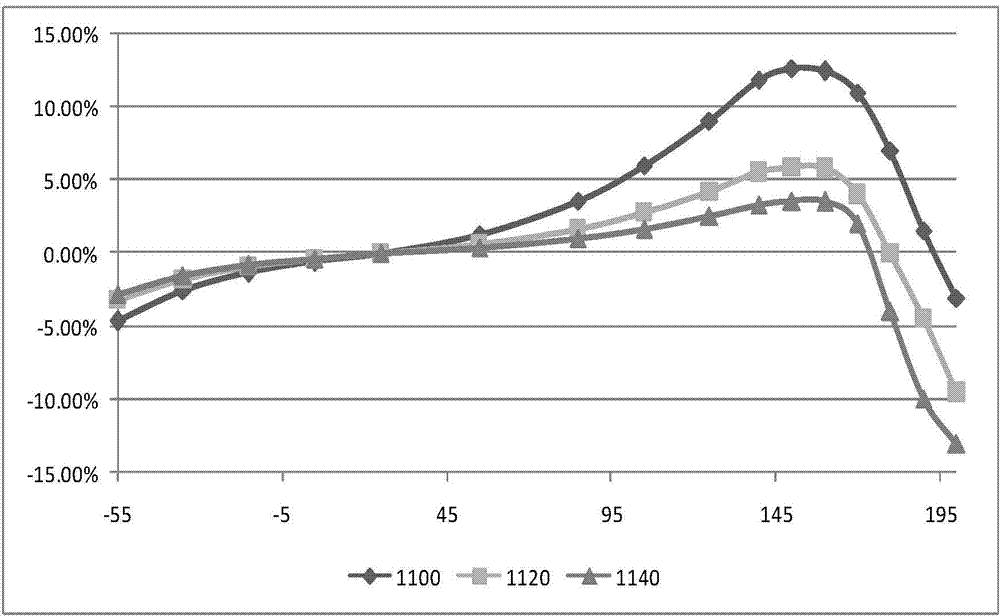

ActiveUS8076257B1Highly desirable propertyExcellent dielectric constant/voltage characteristicFixed capacitor dielectricStacked capacitorsCapacitanceDielectric

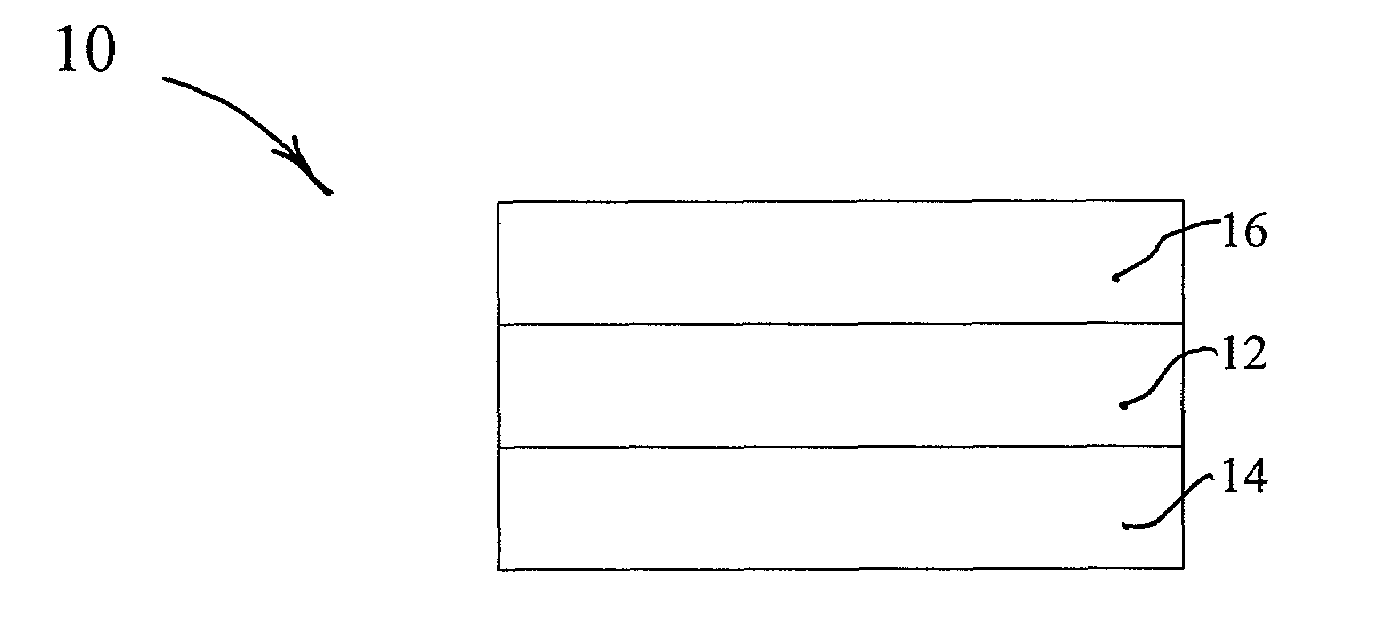

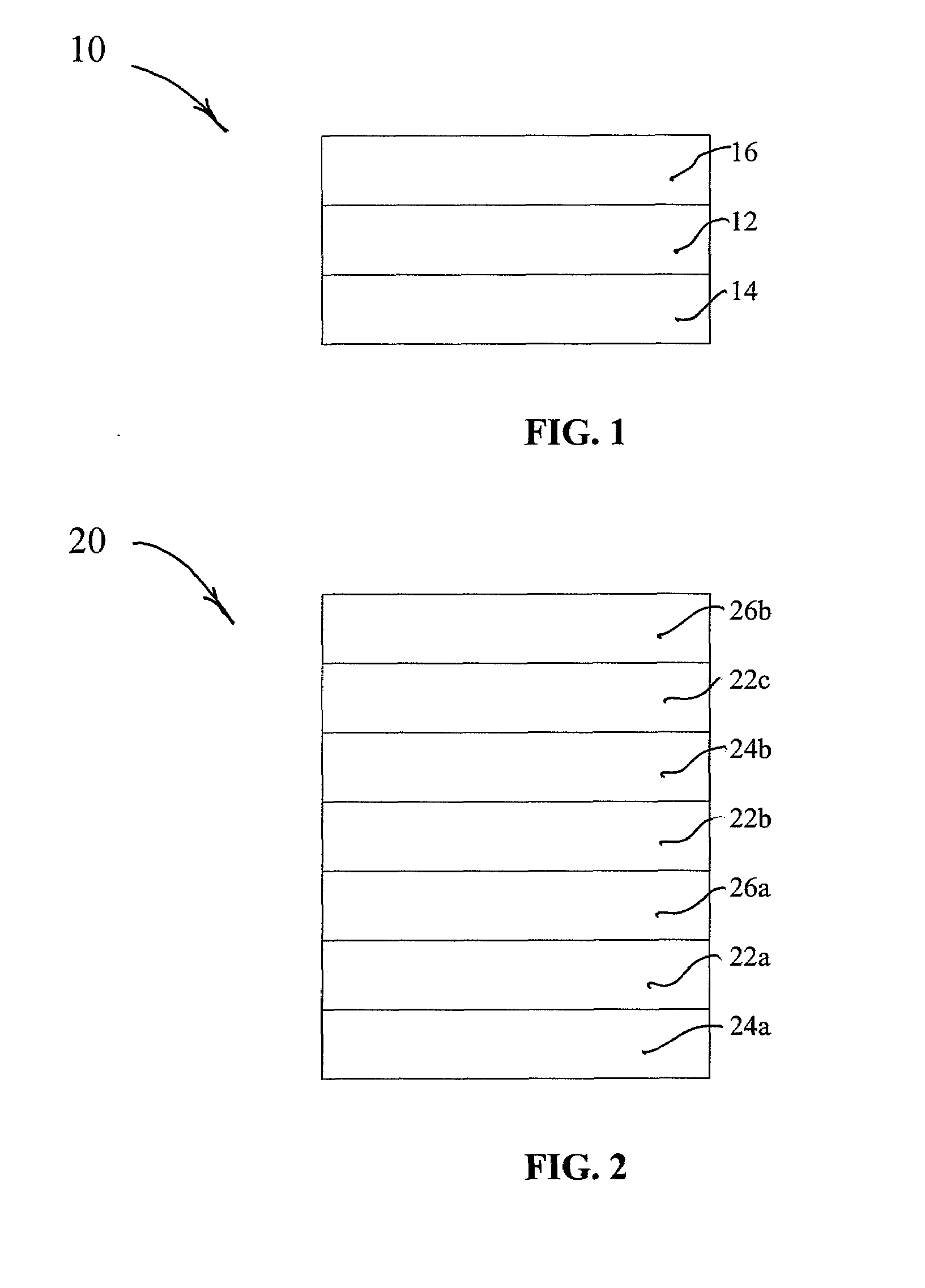

A bismuth sodium titanate (Bi0.5Na0.5TiO3) base material is modified by the partial substitution of aliovalent A-site cations such as barium (as BaO) or strontium (as SrO), as well as certain b-site donor / acceptor dopants and sintering aids to form a multi-phase system, much like known “core / shell” X7R dielectrics based solely on BaTiO3. The resulting ceramic dielectric composition is particularly suitable for producing a multilayer ceramic capacitor (10) that maintains high dielectric constant (and thus the capability of maintaining high capacitance) over a broad temperature range of from about 150° C. to about 300° C. Such capacitors (10) are appropriate for high temperature power electronics applications in fields such as down-hole oil and gas well drilling.

Owner:FERRO CORP

Ternary system sodium-bismuth titanate lead-free piezoelectric ceramics

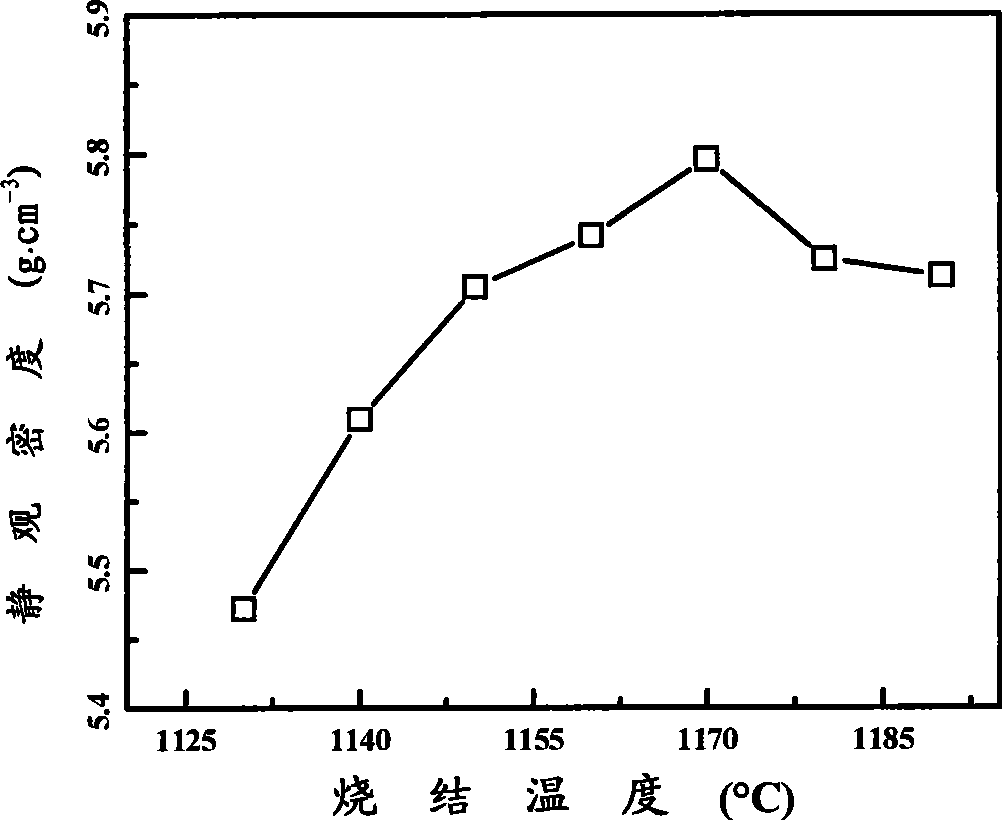

InactiveCN101200370AExcellent piezoelectric propertiesPracticalDevice material selectionElectricityVolumetric Mass Density

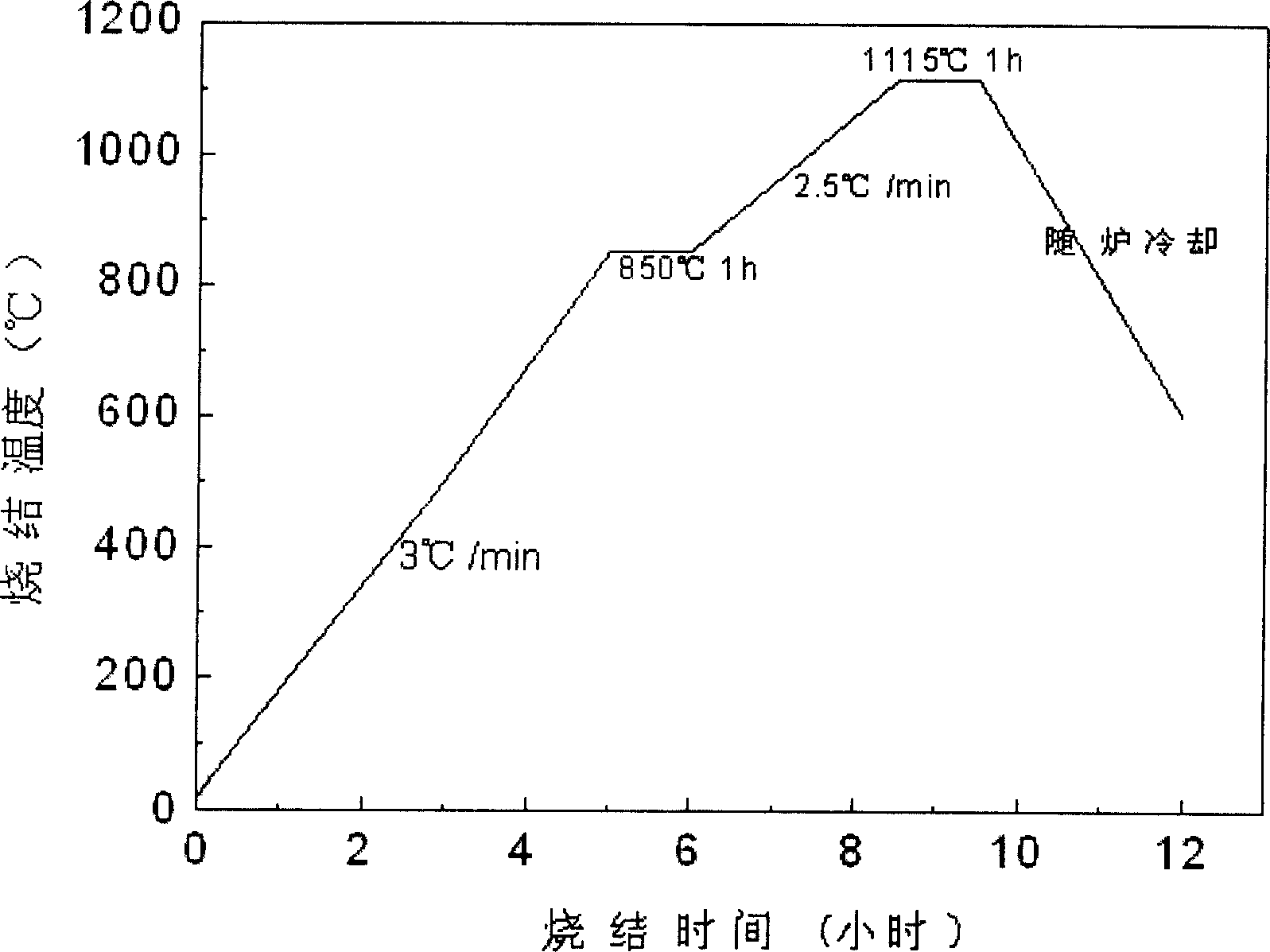

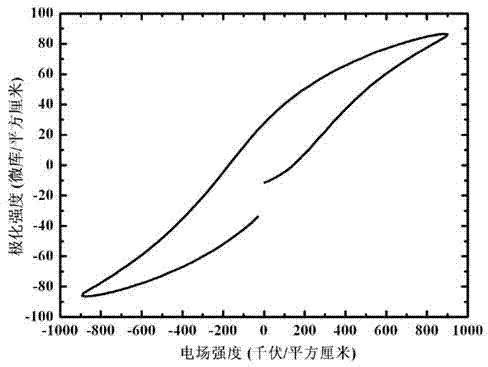

The invention discloses a triple system (Na,Bi)TiO3-based lead-free piezoelectric ceramic material, the formula of the disclosed lead-free piezoelectric ceramic component is denoted with (1-x-y)(Bi0.5Na0.5)TiO3-x(Bi0.5K0.5)TiO3-yBi(Me)O3 and (1-x-y)(Bi0.5Na0.5)TiO3-x(Bi0.5K0.5)TiO-yBi(Me)O3+zM(a)O(b), in the formula x,y and z denote molar fractions, wherein x is bigger than or equal to 0 and smaller than or equal to 1.0, y is bigger than or equal to 0 and smaller than or equal to 0.2, z is bigger than or equal to 0 and smaller than or equal to 0.1, Me is trivalent metal element, M(a)O(b) is one or more oxides, wherein M is +1 to +6 valence and is an element that can be integrated with oxygen to form a solid oxide. The lead-free piezoelectric ceramic has high ceramic density and excellent performance, piezoelectric constant d33 can reach above 180pC per N, Kp can reach above 0.36. The lead-free piezoelectric ceramic adopts traditional electronic ceramic preparation process, and has low sintering temperature, simple and stable manufacture process and is suitable for industrialization production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Lead-less piezoelectric sodium bismuth titanate-bariumtitanate ceramic and its prepn process

InactiveCN101020608AEasy to prepareEasy to printPiezoelectric/electrostrictive/magnetostrictive devicesScreen printingBarium titanate

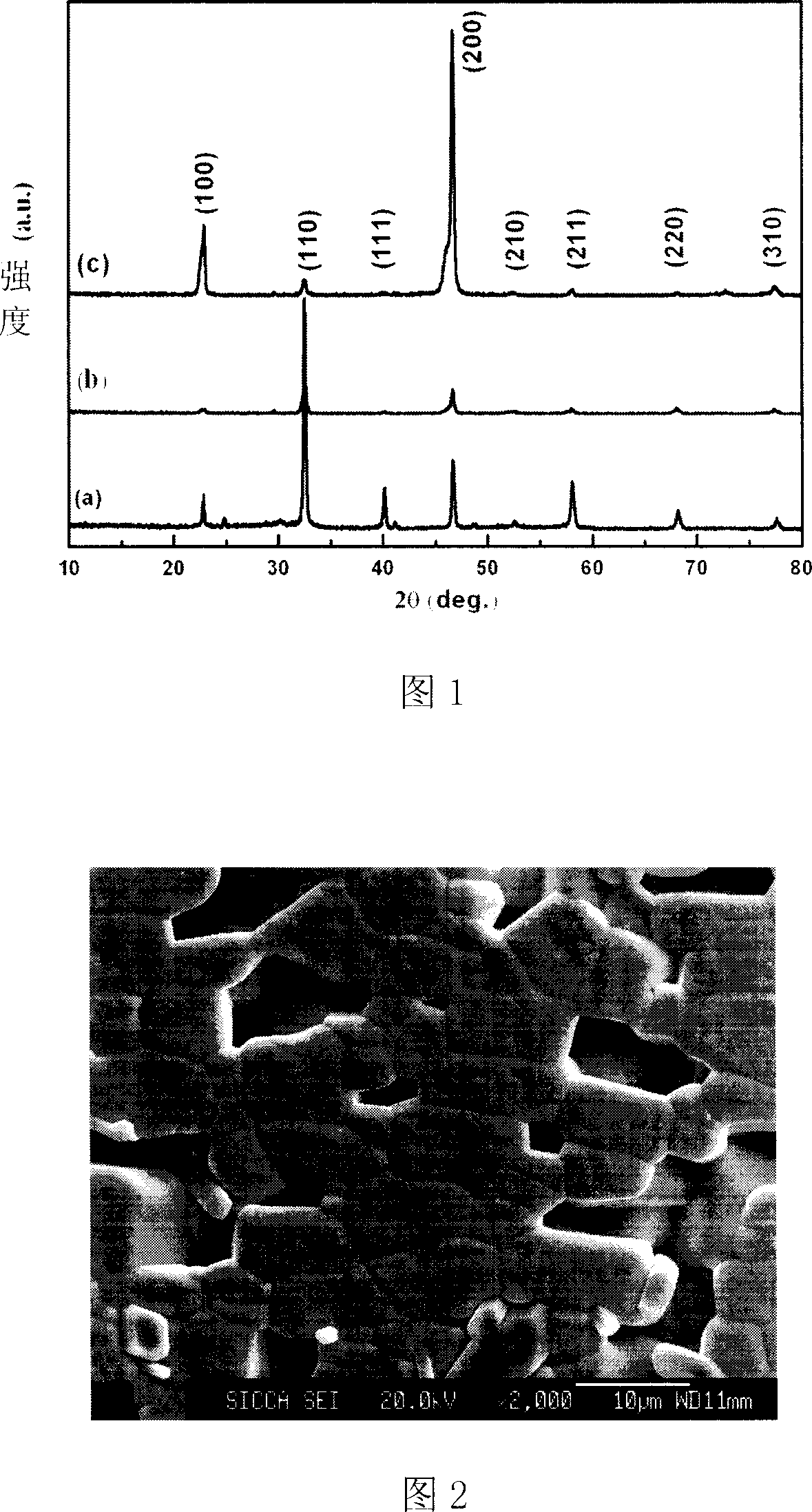

The present invention is one kind of lead-less piezoelectric sodium bismuth titanate-barium titanate ceramic, and belongs to the field of lead-less piezoelectric ceramic. The lead-less piezoelectric sodium bismuth titanate-barium titanate ceramic has the chemical formula of (Na1 / 2Bi1 / 2)1-xBaxTiO3, where, x is 0.05-0.1, and has ceramic crystal grains parallel to the grain boundary. Its preparation process includes the following steps: molten salt procedure to synthesize Bi4Ti3O12 template or solid phase reaction procedure to synthesize Na0.5Bi4.5Ti4O15 precursor material powder; preparing slurring with Na2CO3, BaCO3, Bi2O3 and nanometer TiO2; silk screen printing to obtain thick ceramic film; cutting, superposing and sintering.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Middle-temperature sintering high temperature stabilization type ceramic capacitor dielectric material

InactiveCN101033132ARealize separate mass productionCompliant with large capacityCeramicsBarium titanateRare earth

This invention relates to a mid-temperature calcined and high temperature stabilized ceramic medium material of capacitors composed of barium titanate main material, a first additive, a second additive and a third additive, in which, the first additive is a microcrystal glass, the second additive includes lead-free piezoelectric material bismuth titanate sodium or boron silicate and the third additive includes: a rare earth oxide, ZnO and Nb2O5, and said rare earth oxide includes Ce or Nd oxide. Advantage: batch production is realized to basic materials and dopants so as to simplify the production process.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-energy-storage sodium bismuth titanate-strontium titanate matrix material and preparation method thereof

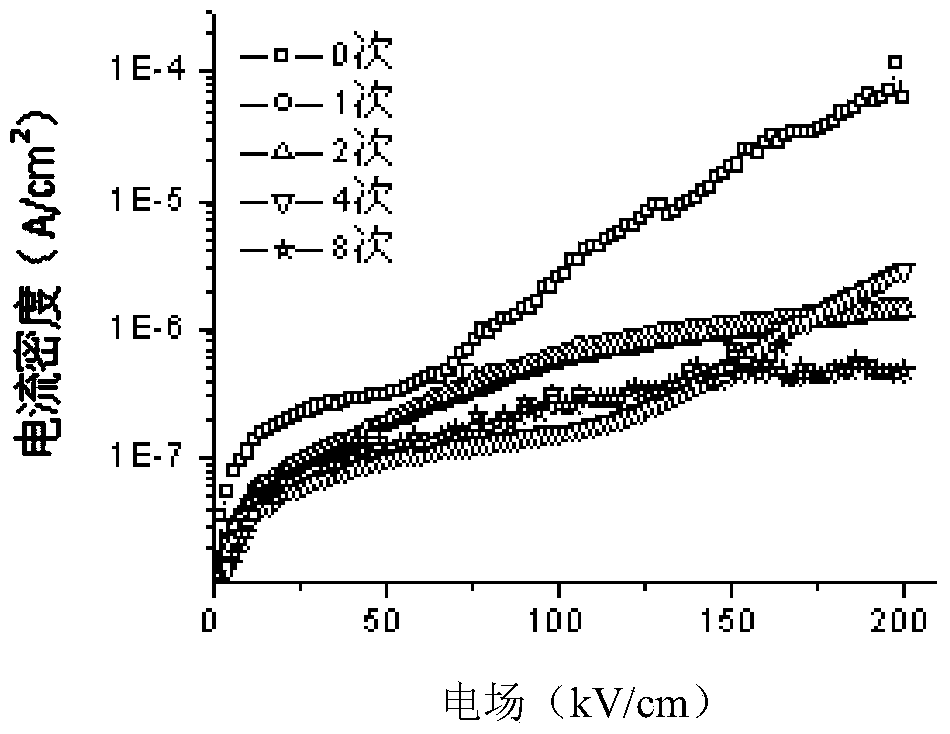

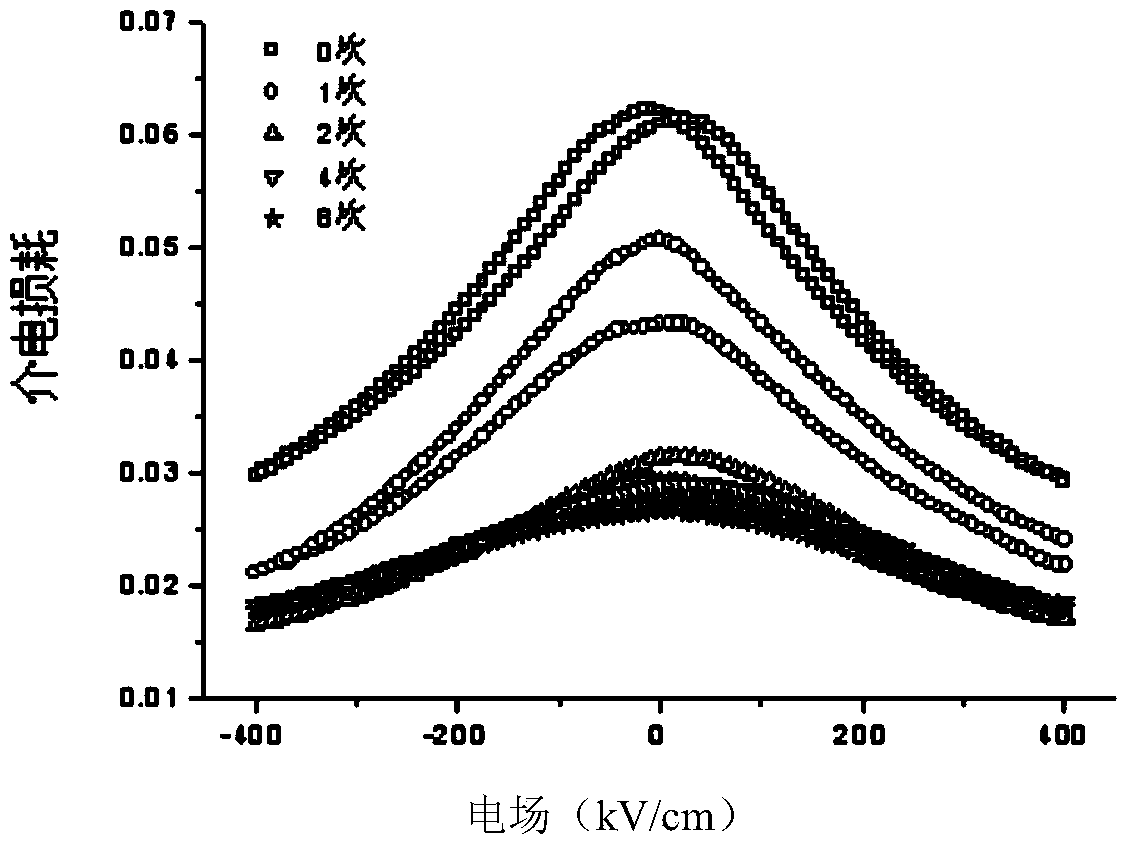

InactiveCN109574656AImprove energy storage characteristicsHigh breakdown strengthBreakdown strengthStrontium titanate

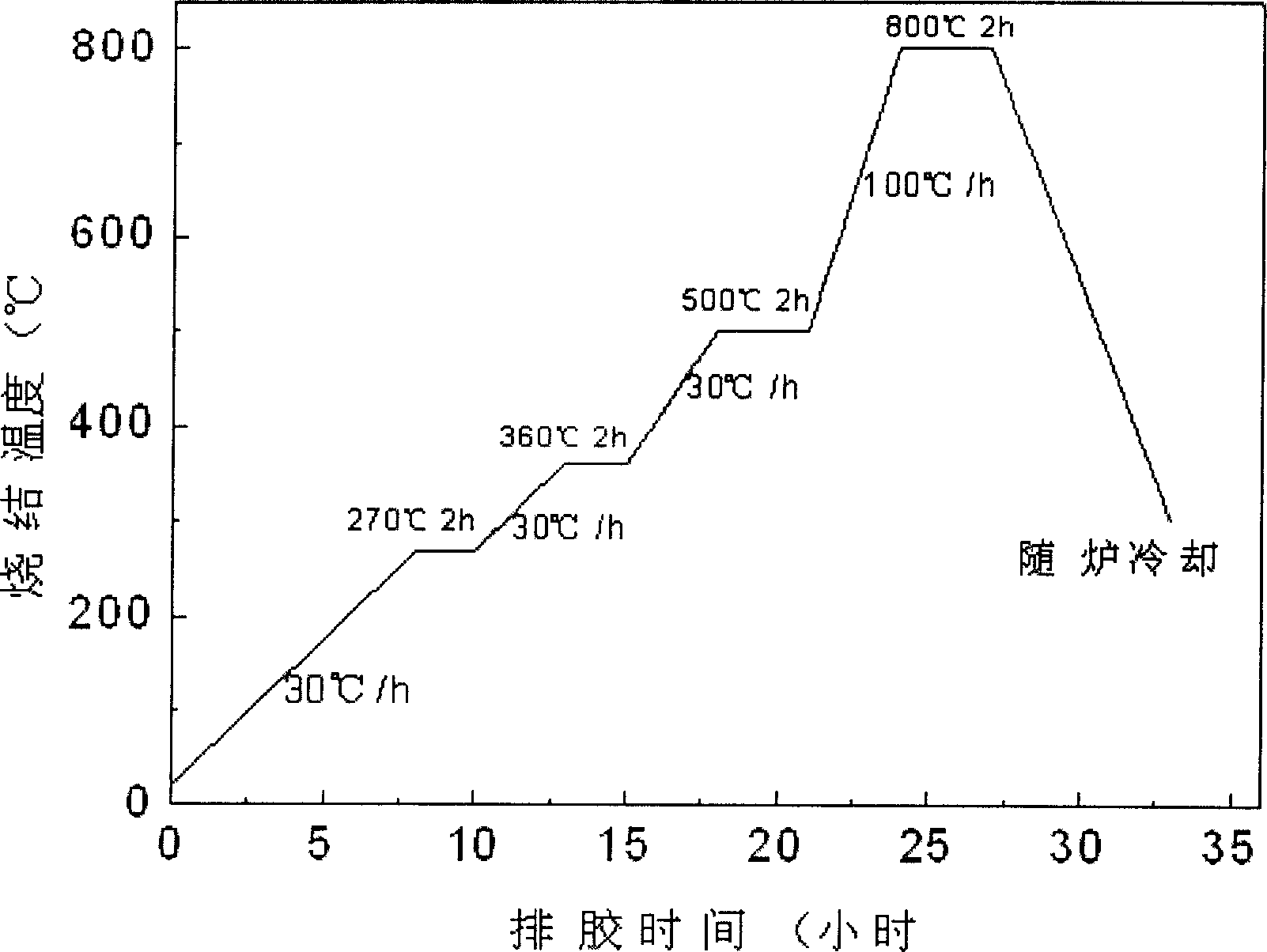

The invention discloses a high-energy-storage sodium bismuth titanate-strontium titanate matrix material. The chemical formula of the high-energy-storage sodium bismuth titanate-strontium titanate matrix material is 0.5Bi0.5Na0.5TiO3-0.5SrTiO3-x wt%MgO, wherein x=0.5-3.0. A preparation method of the high-energy-storage sodium bismuth titanate-strontium titanate matrix material comprises the following steps of preparing SrCO3, TiO2, Bi2O3, Na2CO3 and MgO by weight ratio according to the chemical formula into a ceramic powder, performing ball milling, drying and pelletizing, and then pressing the ceramic powder in a tablet press into a ceramic blank; rubber-discharging and sintering the ceramic blank inside a muffle furnace to obtain a ceramic sample. The preparation method of the high-energy-storage sodium bismuth titanate-strontium titanate matrix material is simple in preparation process, low in cost and free from pollution; the prepared high-energy-storage sodium bismuth titanate-strontium titanate matrix material achieves a high discharging energy storage density of 1.61-2.17 J / cm3 and a high breakdown strength of 137-226 KV / cm.

Owner:WUHAN UNIV OF TECH

X9R ceramic capacitor dielectric material and preparation method thereof

ActiveCN102199035AImprove temperature stabilityRaise the Curie transition temperatureBarium titanatePotassium

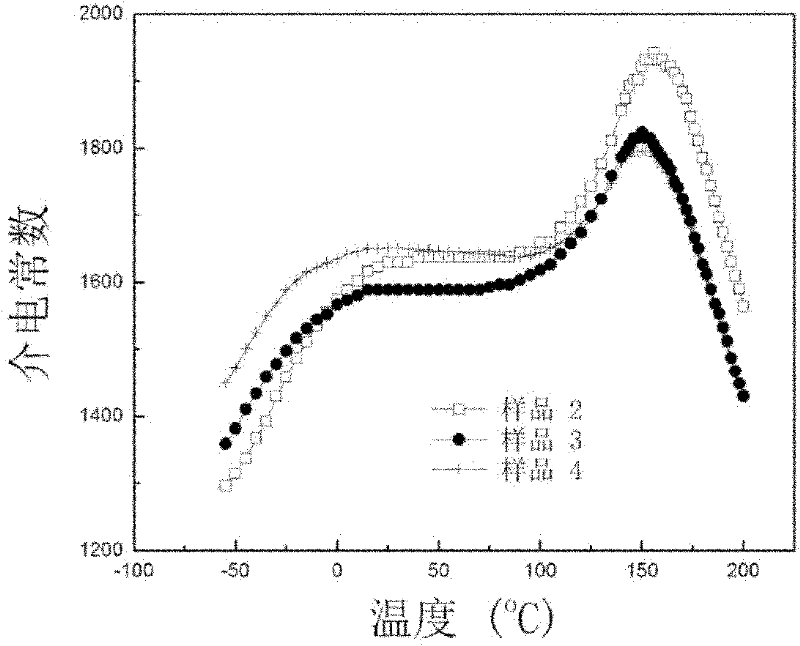

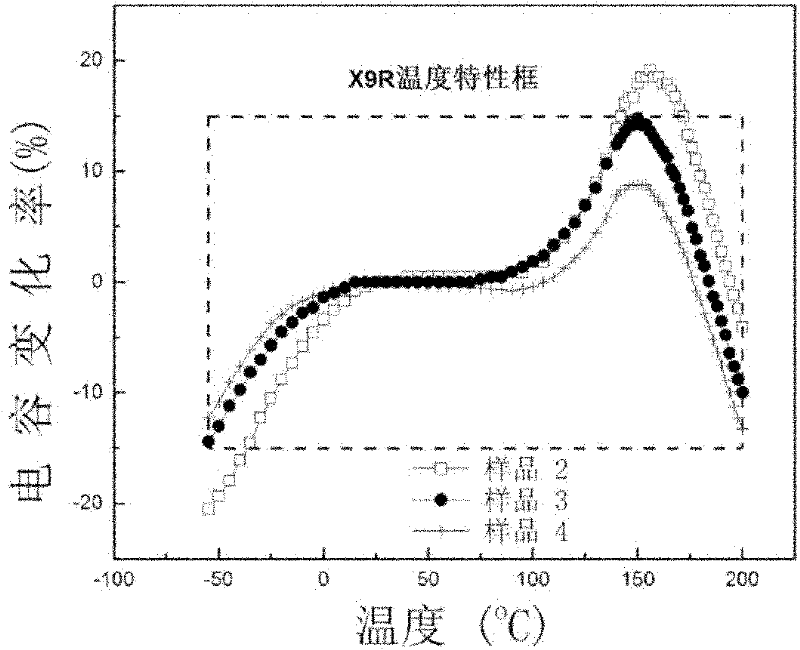

The invention discloses an X9R ceramic capacitor dielectric material and a preparation method thereof. The material comprises 95 to 98 molar percent of barium titanate-sodium bismuth titanate complex or barium titanate-potassium bismuth titanate complex serving as a main component, and 2 to 5 molar percent of secondary additive consisting of at least one of Nb2O5, CaZrO3 and SrZrO3. According to the preparation method of the invention, the dielectric ceramic material with high property can be obtained, meeting the electronic industries association (EIA) X9R standard; the process is simple, and intermediate temperature sintering can be performed; and the material has the room temperature dielectric constant of 1,500 to 1,700, the room temperature loss of about 2 percent, the room temperature resistivity of more than or equal to 1,013omega.cm, the breakdown voltage of more than or equal to 5kV / mm, and a good industrial prospect.

Owner:TSINGHUA UNIV

Bismuth sodium titanate based leadless piezoelectric ceramic and preparation technique thereof

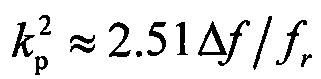

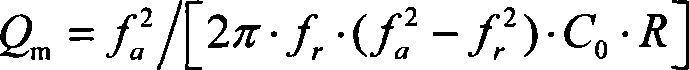

InactiveCN101462875AImprove performanceHigh electromechanical coupling coefficientPiezoelectric/electrostrictive/magnetostrictive devicesAlkaline earth metalElectromechanical coupling coefficient

The invention discloses a sodium bismuth titanate based lead-free piezoelectric ceramic and a preparation process thereof. The general formula of the piezoelectric ceramic composition is (1-x)(Na0.5Bi0.5)1-aMaTiO3-xNaNbO3, wherein, x is the mol content of NaNbO3 in a ceramic system, a is the atom number of composite ions (Na0.5Bi0.5) which are replaced by M in (Na0.5Bi0.5)TiO3, x is not less than 0 but less than 0.3, a is more than 0 but less than 0.3, and M represents divalent alkaline earth metal elements Ba, Sr and Ca. As a secondary isostatic pressing forming method is adopted in the preparation process, the piezoelectric ceramic has the advantages of simple operation, high stability and low cost; and the method helps easily obtain high-density microcrystal ceramic materials, obviously improve the piezoelectric parameter and electromechanical coupling factor of the materials, and meet the practical requirement of the piezoelectric ceramic materials used in a micro-displacement actuator.

Owner:XIAN UNIV OF SCI & TECH

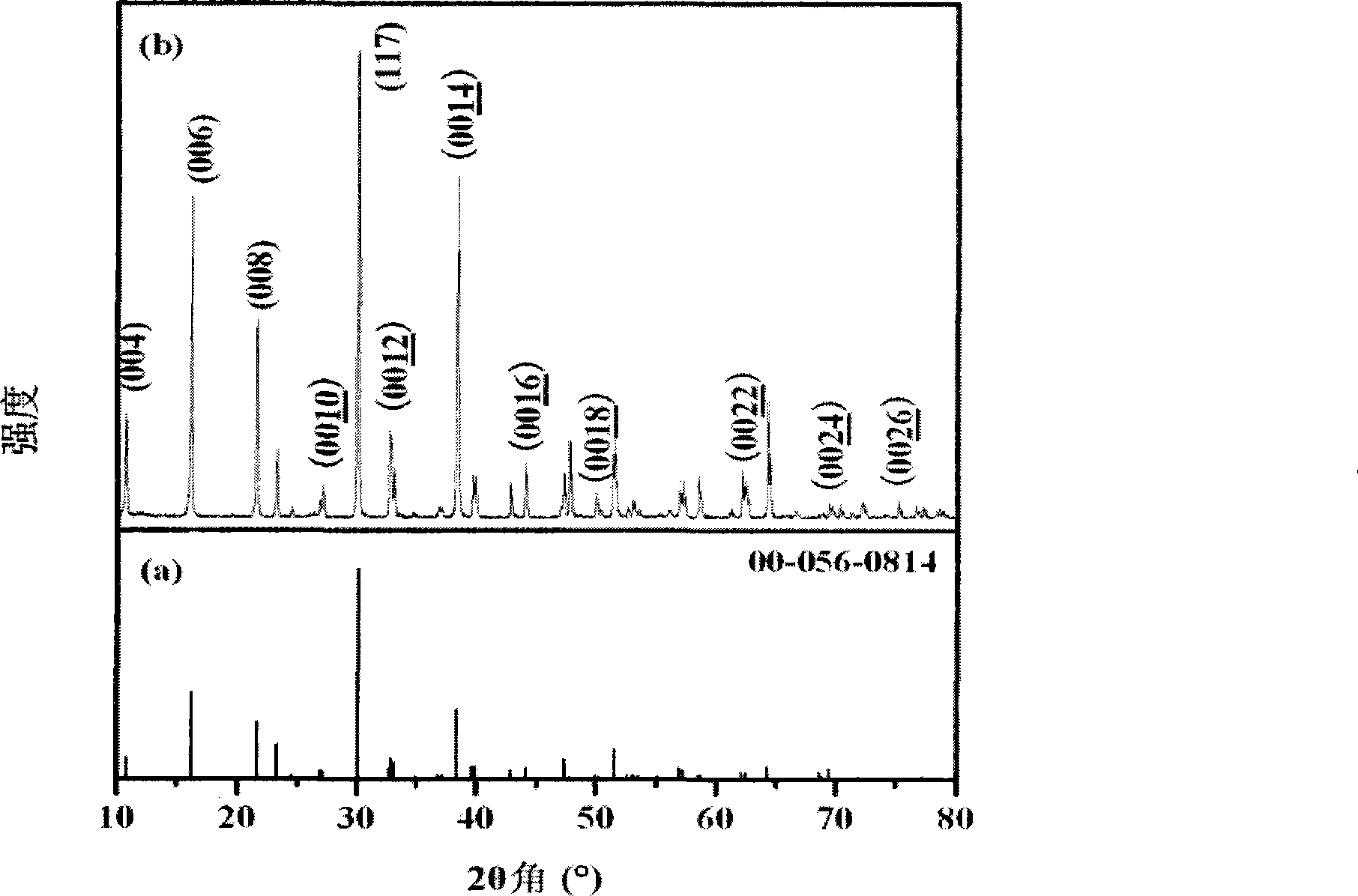

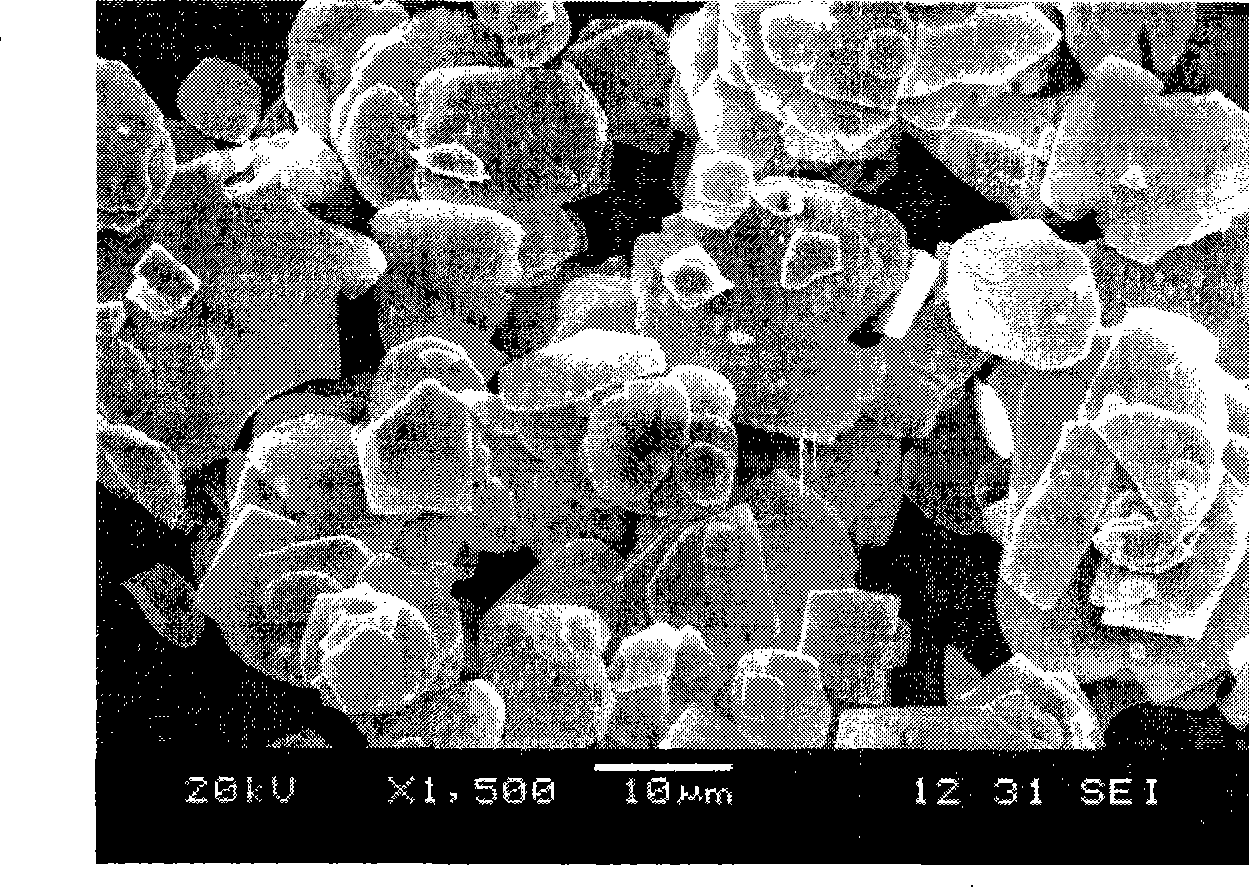

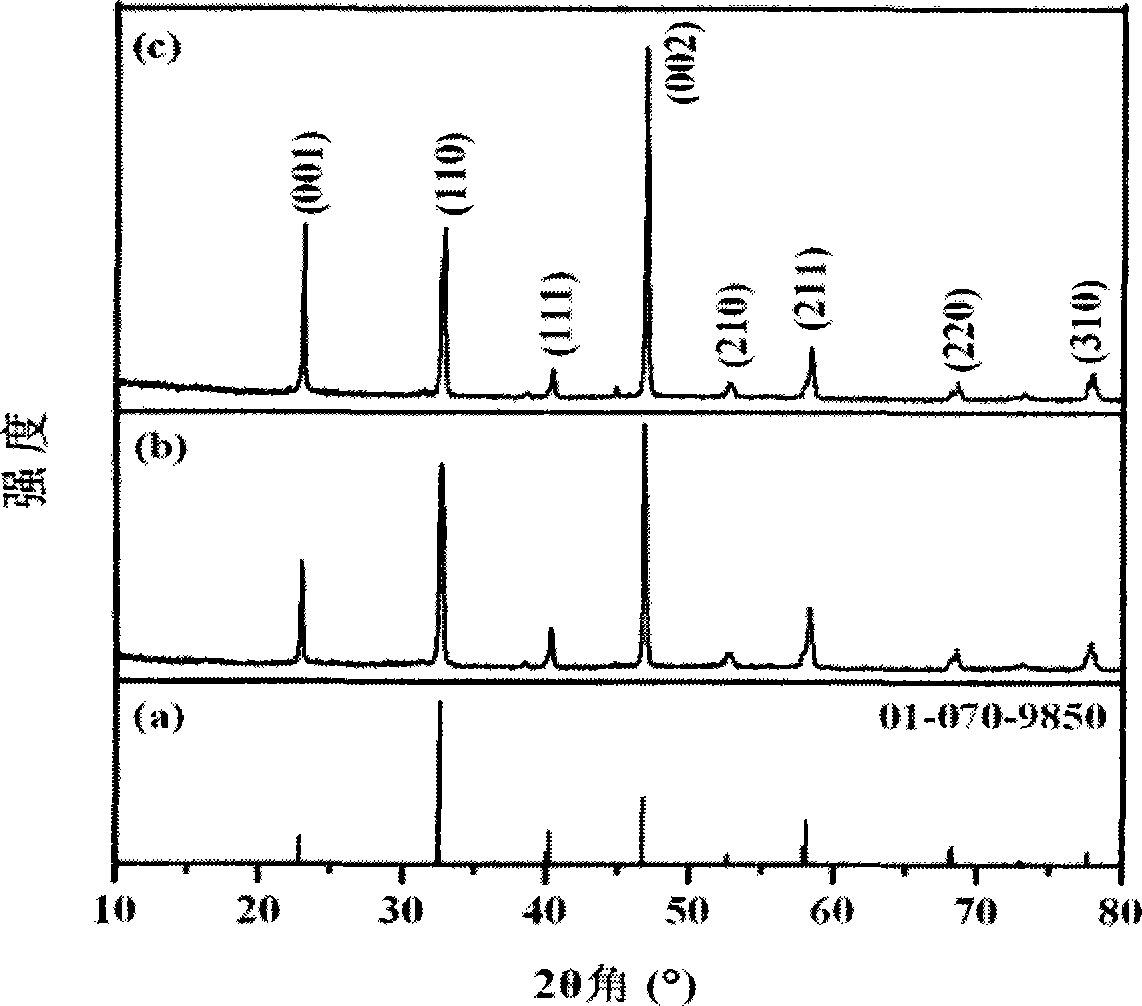

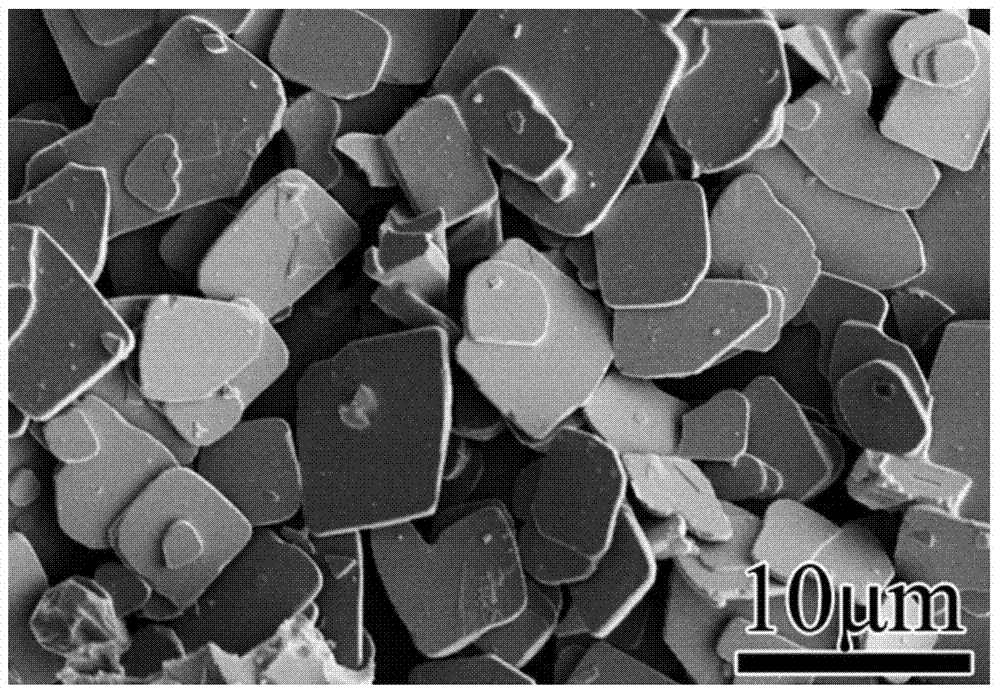

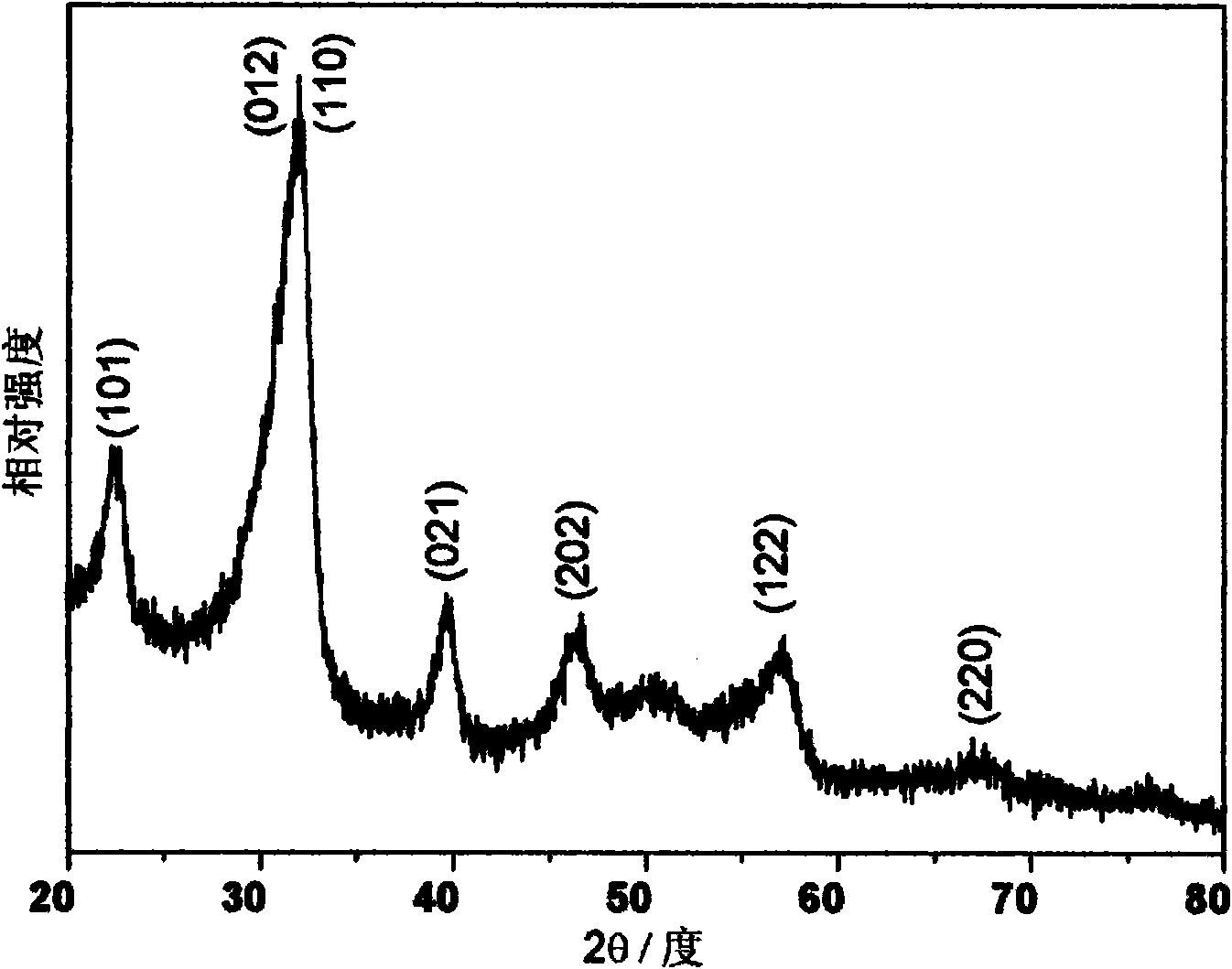

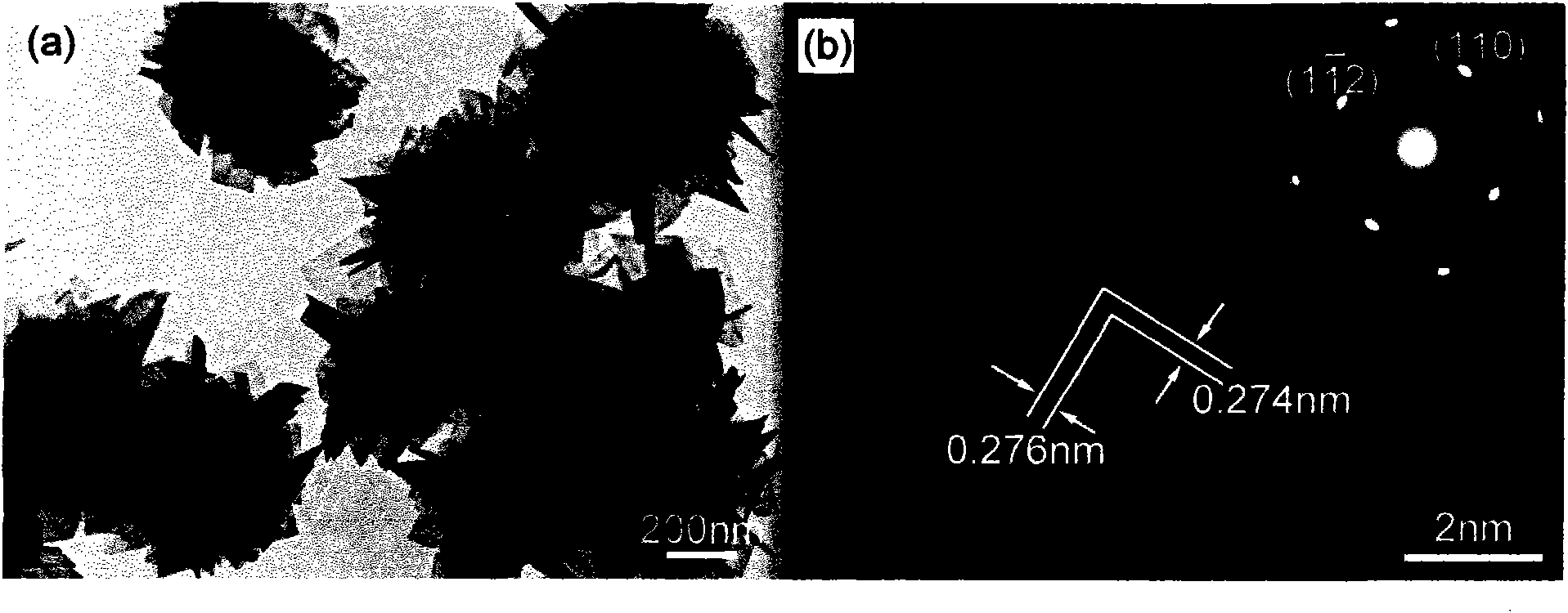

Sheet bismuth sodium titanate mould plate grain and manufacture method thereof

The invention relates to a schistic bismuth sodium titanate template crystal grain and a preparation method thereof, belonging to the preparation field of textured non-lead piezoelectric ceramic template crystal grain, the chemical formula of the template grains is Na0.5Bi0.5TiO3, the appearance of the crystal grain is schistic, the radial length is 5 to 15Mum, the thickness is 0.5 to 1.0Mum, the crystal grain has large aspect ratio and strong orientation, which is an ideal template crystal grain. The crystal grain adopts schistic Bi4Ti3O12 as a precursor which is synthesized by molten salt method, in the molten salt system of NaCl, the crystal grain can have topological chemical reaction with Na2CO3, TiO2 so as to produce schistic polycrystalline Na0.5Bi0.5TiO3 template crystal grain and the crystal grain can be regarded as the template for various textured bismuth sodium tianate non-lead piezoelectric ceramics, which has positive effect for improving the density, the orientation and piezoelectric properties of textured bismuth sodium tianate non-lead piezoelectric ceramics.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

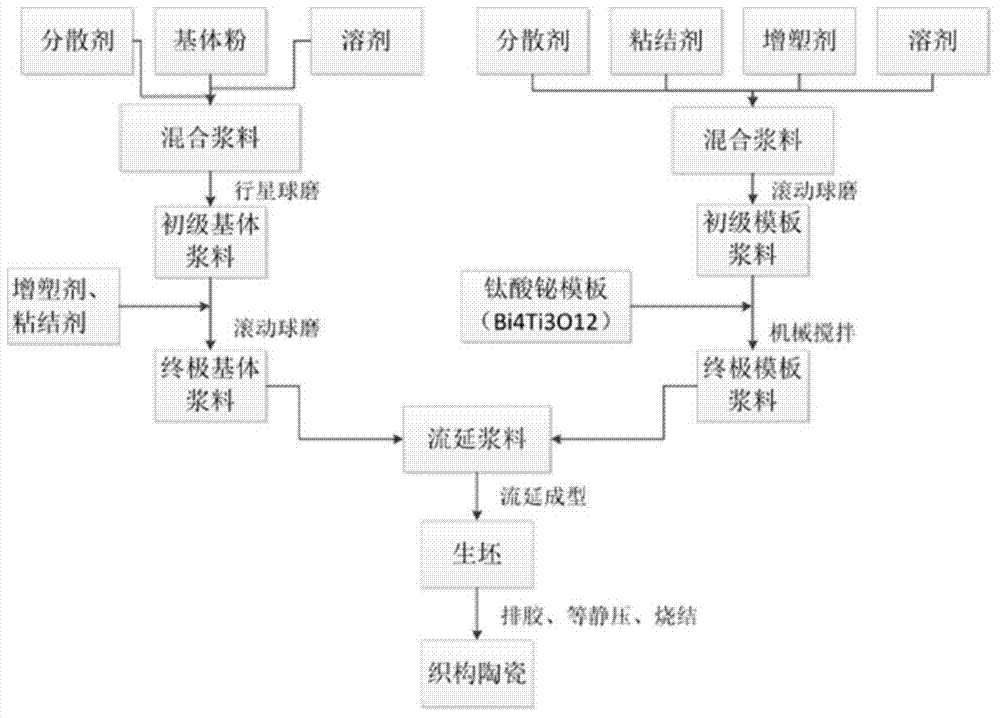

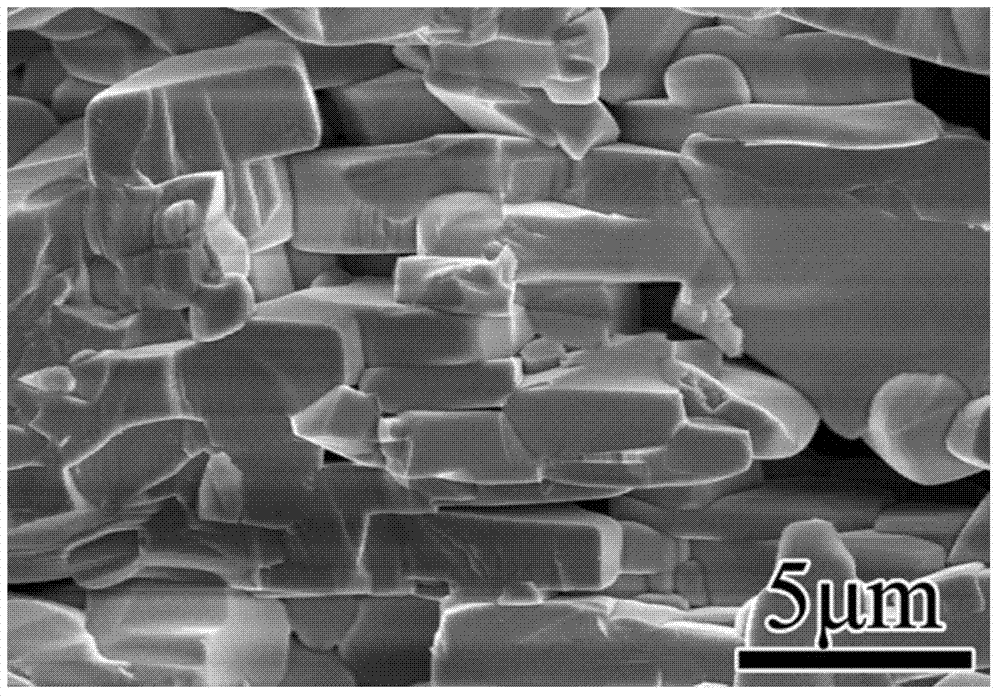

Sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and preparation method thereof

InactiveCN103613382AExcellent piezoelectric propertiesThe original composition does not changeBarium titanatePotassium

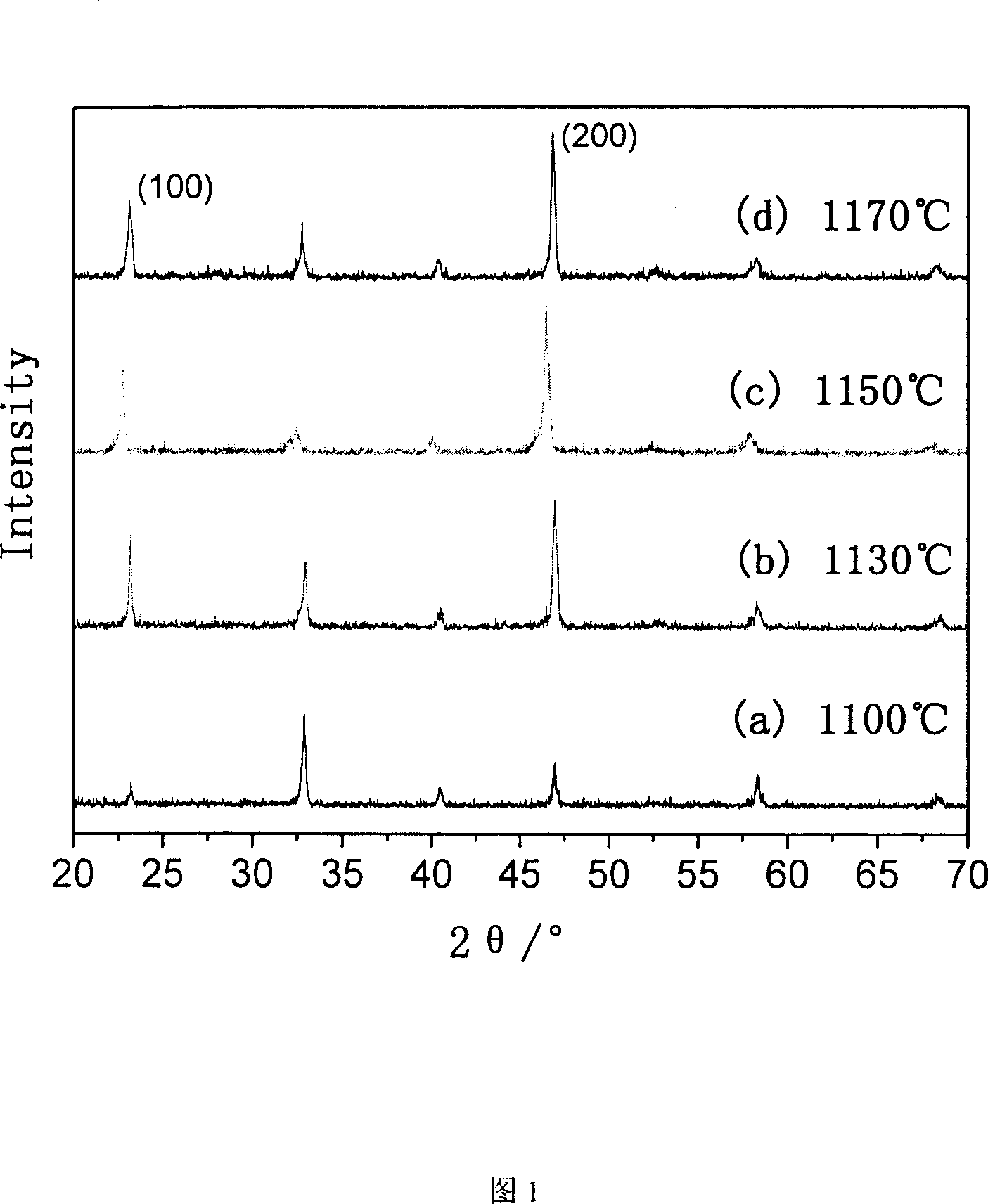

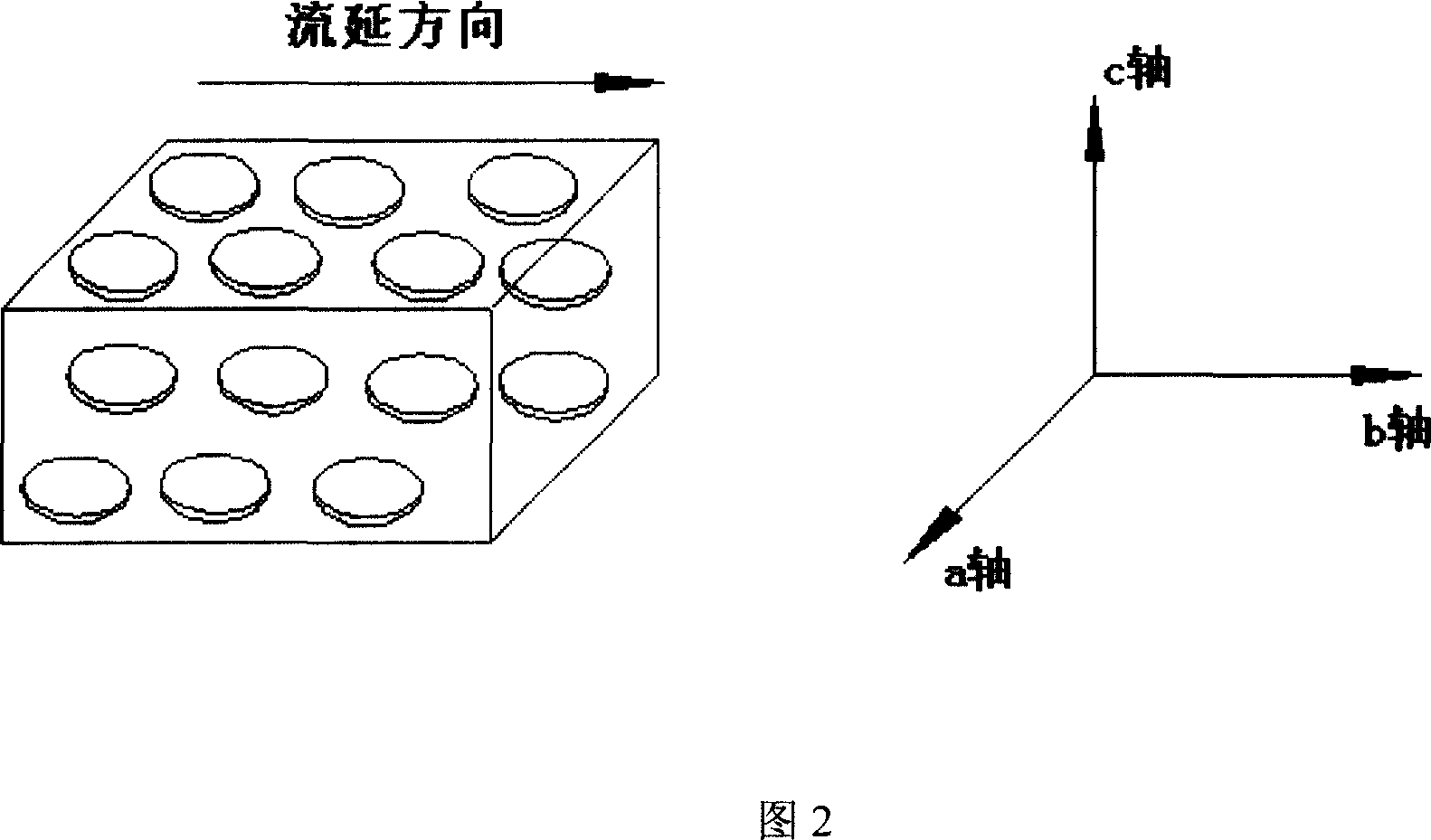

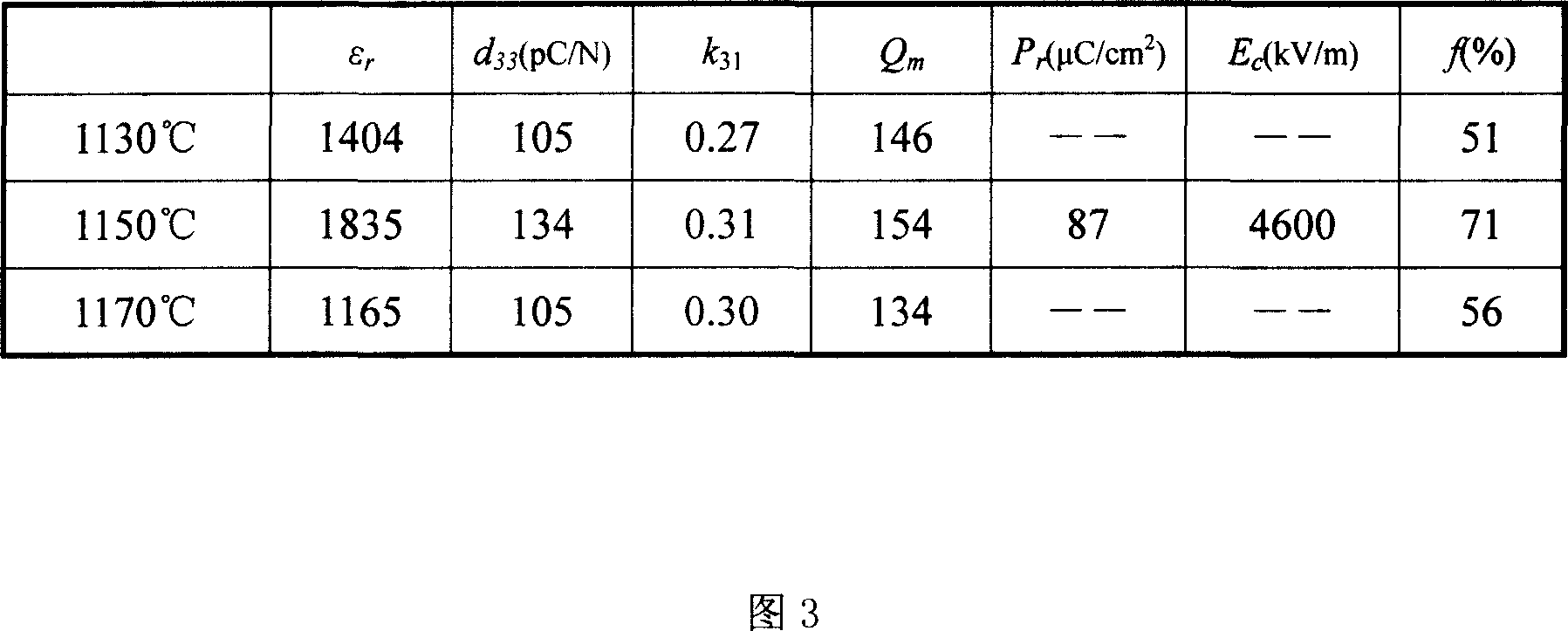

The invention provides sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and a preparation method thereof. The preparation method comprises the following steps: mixing a template with organic additives such as matrix powder, an organic solvent and a binder to obtain slurry by taking a Bi4Ti3O12 crystal as the template; preparing the slurry into a film sheet with thickness of 30 mu m-60 mu m through a curtain coating process; and sintering the film sheet after laminating, cutting, rubber exhausting and isostatic cool pressing to prepare a BNBK texture ceramic material with high oriented growth, wherein original components of the materials are not changed due to precise control in the process. The prepared sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic constitutes a (1-x-y)Na0.5Bi0.5TiO3-xBaTiO3-Yk0.5Bi0.5TiO3 ternary system, has good crystalline grain orientation effect, excellent performances in the lead-free piezoelectric field, a piezoelectric constant of over 210 pC / N and a Curie temperature of over 320 DEG C.

Owner:TIANJIN UNIV

Sodium bismuth titanate base nonleaded piezoelectric ceramic

InactiveCN1541977AExcellent piezoelectric ferroelectric propertiesImprove performanceCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesSodium titanateOxygen

The lead-free bismuth sodium titanate piezoelectric ceramic composition is one perovskite type environment consistency piezoelectric ceramic composition. The composition has the general expression of (1-x-y-z)Bi1-wNawTiO3+xBi0.5K0.5TiO3+yBaTiO3+zSrTiO3+aMalphaObeta, where x is 0-1, y 0-1, z 0-1, (x+y+z) 0-1, w 0.3-0.7; MalphaObeta is doping oxide(s) in the content an of 0-10 %; M is +1~+6 valent element capable of forming solid oxide, such as Na, K, Li, Al, Cu, etc. with alpha and beta being atom number. The piezoelectric ceramic composition has d33 up to 190 pC / N, kp up to 24.0 % and stable technological process, may be produced via traditional piezoelectric ceramic preparation process and industrial material, and is practical.

Owner:SICHUAN UNIV

High-Temperature Dielectric Materials and Capacitors Made Therefrom

InactiveUS20080239627A1Reduce lossHigh dielectric constantFixed capacitor dielectricFixed capacitor terminalsCapacitanceLow voltage

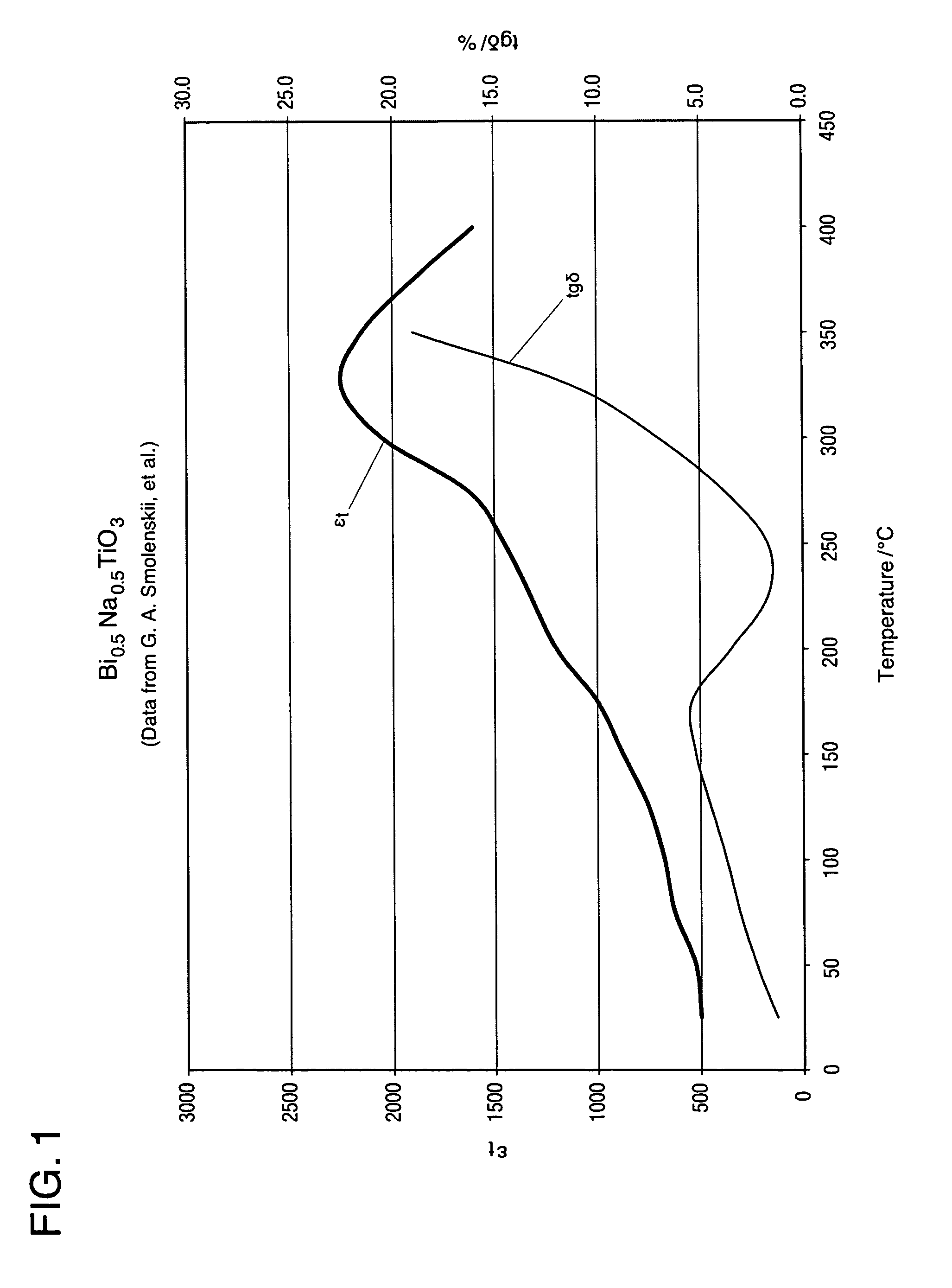

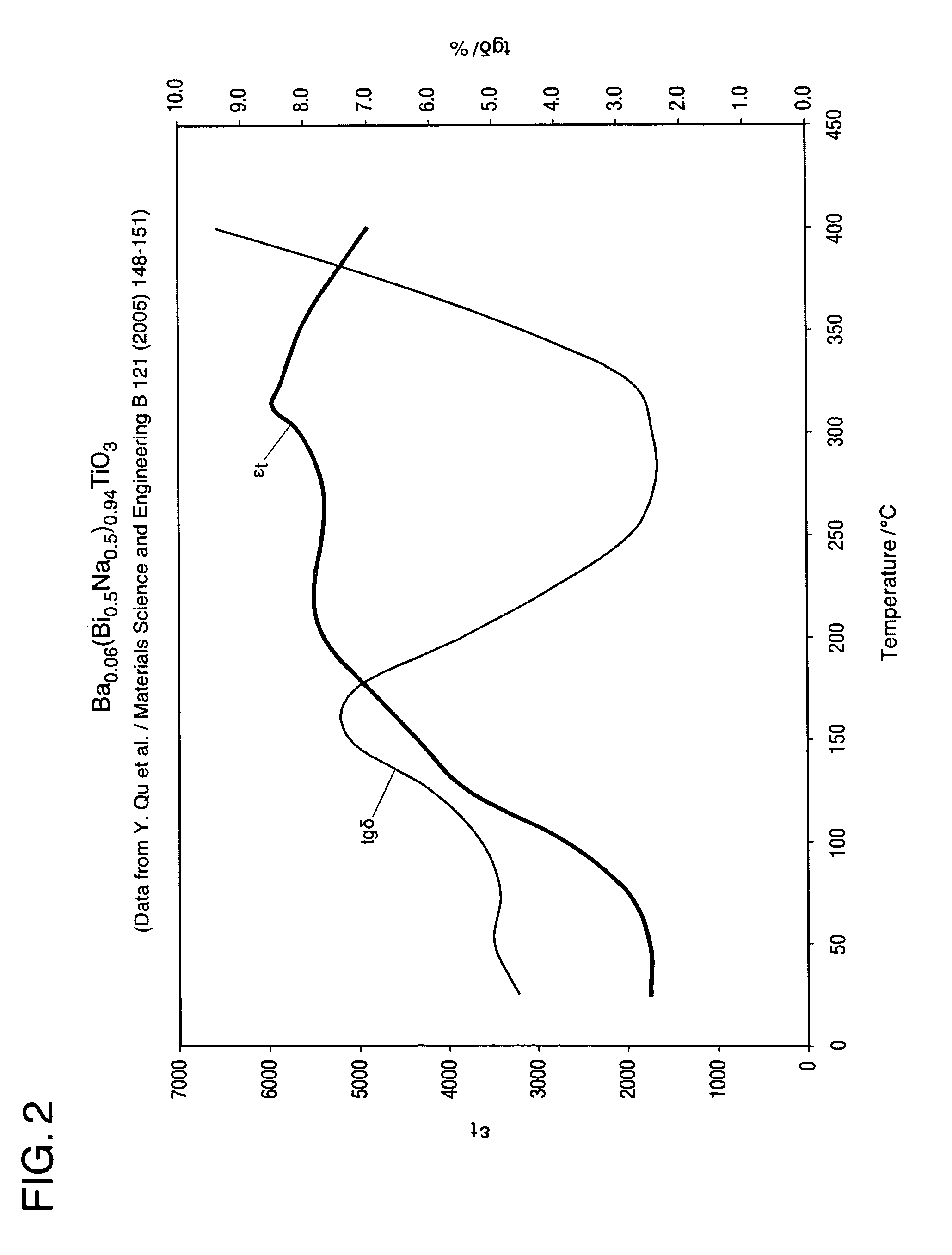

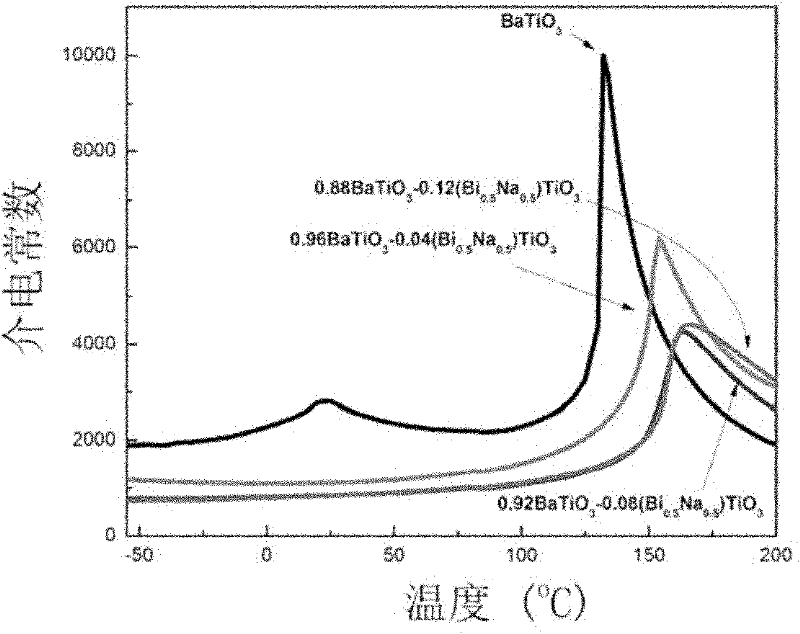

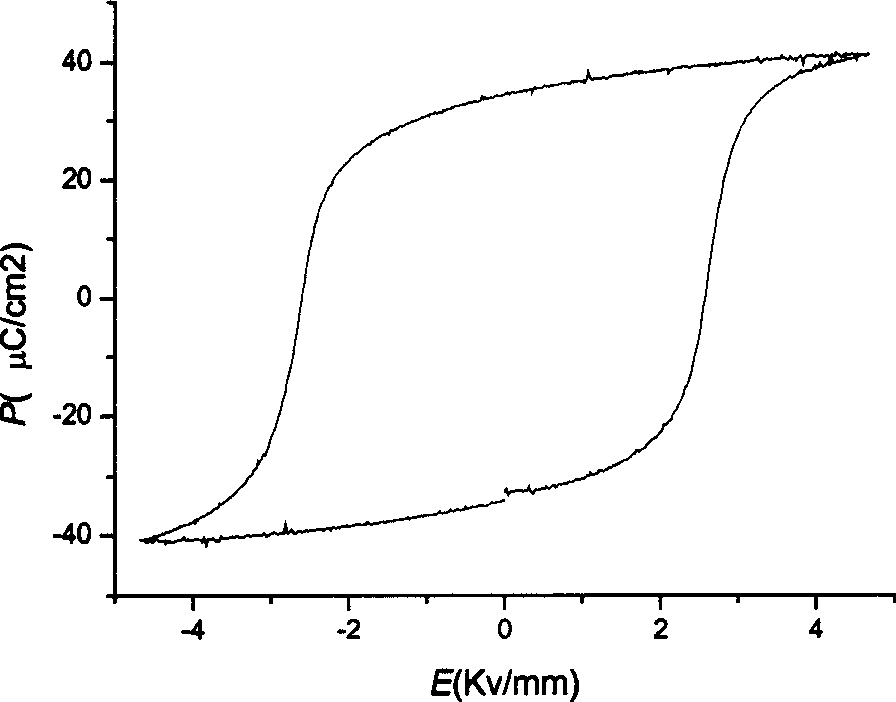

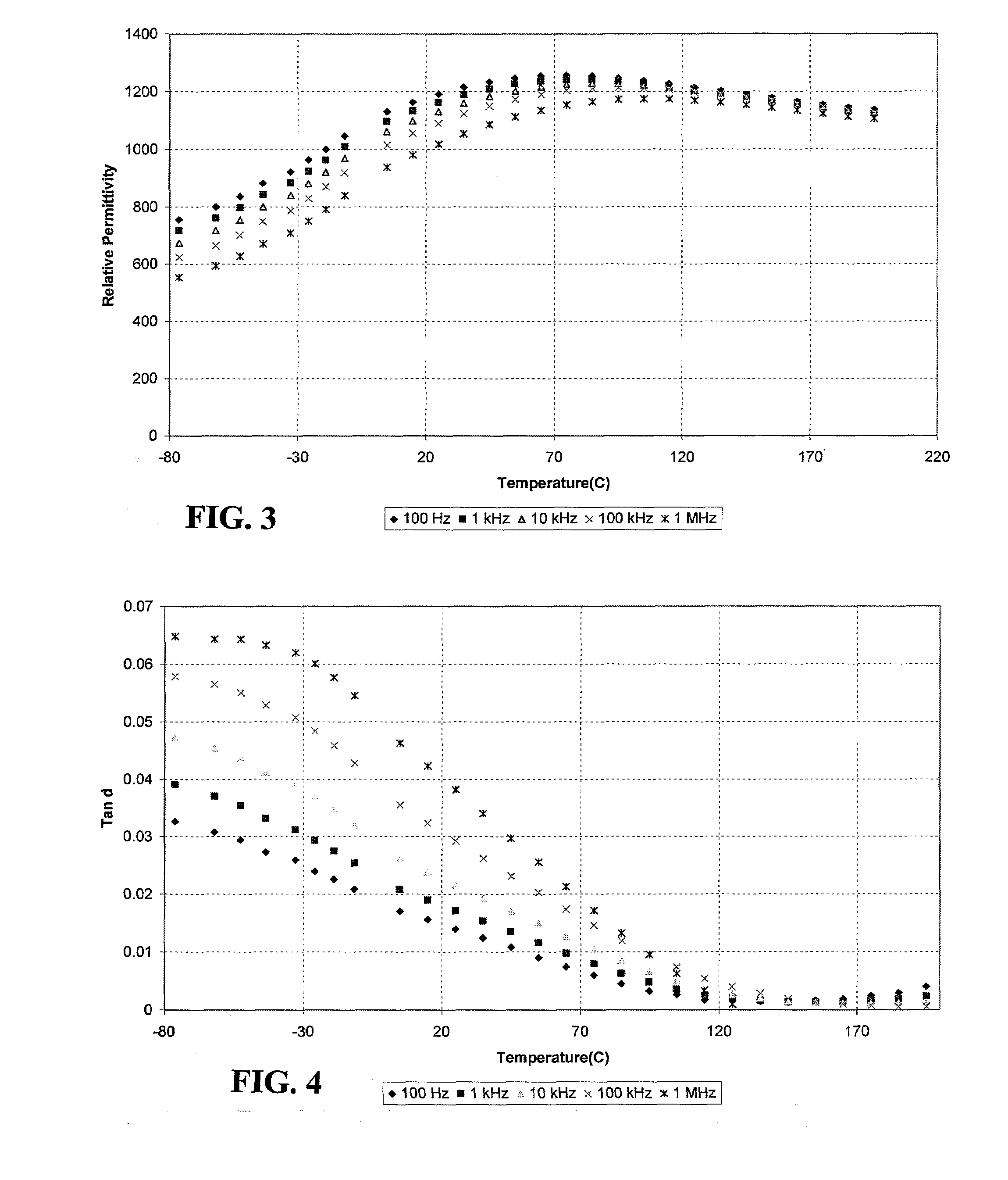

A ceramic dielectric composition suitable for preparing capacitors for use in high-temperature service conditions is disclosed. The ceramic material and capacitors made from it exhibit unique and heretofore unrealizable properties including low variation in capacitance with voltage up to high fields, low variation in capacitance with temperature over a broad temperature range, retained high permittivity at temperatures up to 200° C. and beyond, low loss, low field-induced strain and adequate capacitance to retain performance at very low service temperatures. The material is based on sodium bismuth titanate (NBT) with selected additions of substituents and dopants to broaden and flatten its dielectric response, lower loss, lower strain, lower voltage coefficient and increase resistivity.

Owner:ALFRED UNIVERSITY +1

High-electrostriction sodium-bismuth-titanate-base lead-free piezoelectric material and preparation method thereof

InactiveCN102633503AHigh electrostrainApplicable displacement controlChemical compositionSolid-state drive

The invention discloses a high-electrostriction sodium-bismuth-titanate-base lead-free piezoelectric material. The invention is characterized in that the chemical composition is (0.935-x)Bi0.5Na0.5TiO3-0.065BaTiO3-xSrTiO3, wherein 0<=x<=0.30. On the basis of a binary morphotropic phase boundary (MPB) component solid solution 0.935Bi0.5Na0.5TiO3-0.065BaTiO3, SrTiO3 is introduced to prepare a ternary system solid solution, thereby preparing a high-electromechanical-responsiveness lead-free system. Compared with the existing lead-free system, the invention can disclose the MPB component of the ternary solid solution, obtain the high-electrostriction system, can acquire high strain capacity in a small electric field, and is prospected to be applied to novel environment-friendly solid state drives.

Owner:SHANGHAI NORMAL UNIVERSITY

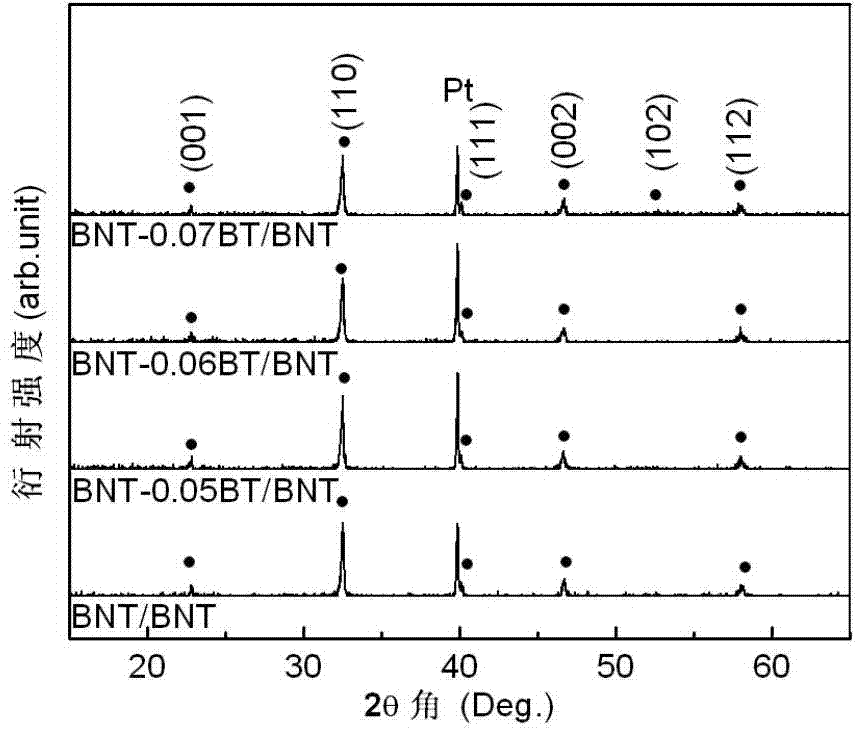

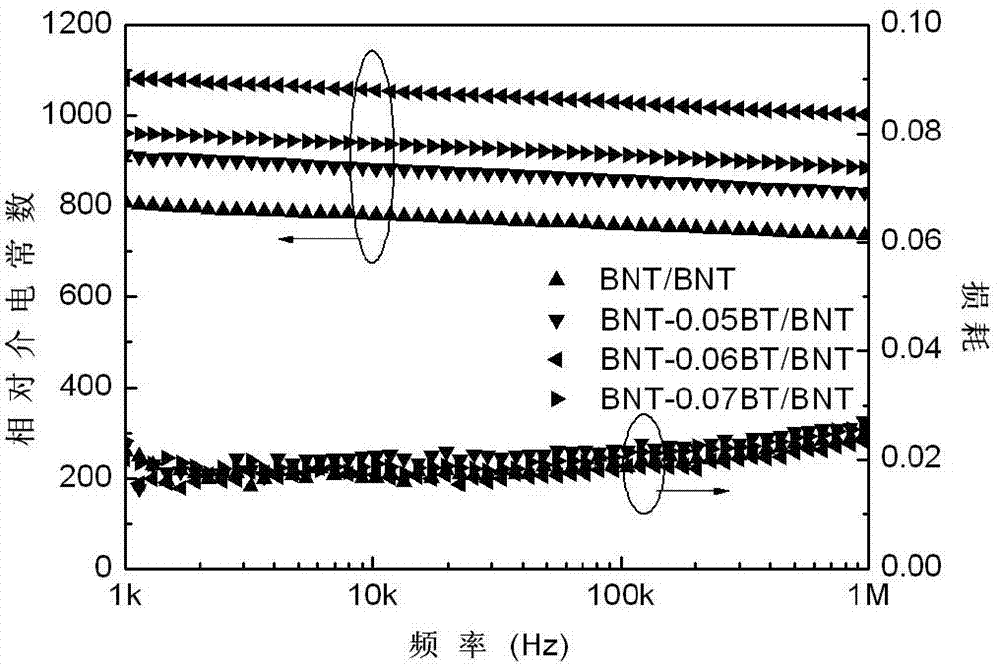

Sodium bismuth titanate base and barium titanate base multilayer composite piezoelectric film and making method thereof

InactiveCN104045340AOvercome harmHigh electrostrain characteristicsPiezoelectric/electrostrictive device manufacture/assemblyMicro actuatorBarium titanate

The invention relates to a sodium bismuth titanate base and barium titanate base multilayer composite piezoelectric film. The chemical general formula of a sodium bismuth titanate base material is Bi1 / 2Na1 / 2TiO3-xBaTiO3-ySrTiO3(BNT-BT-ST), the chemical general formula of a barium titanate base material is Ba(1-x)CaxTi(1-y)SnyO3(BCTS), and a Pt / Ti / SiO2 / Si substrate is spin-coated by adopting a sol-gel process to prepare a multilayer structure compounded lead-free piezoelectric film. Compared with composite piezoelectric films in the prior art, the sodium bismuth titanate base and barium titanate base multilayer composite piezoelectric film has the advantages of high piezoelectric activity, low loss, low leakage conductance and high performance, and has very good practical prospects in the fields of micro actuators and drivers.

Owner:TONGJI UNIV

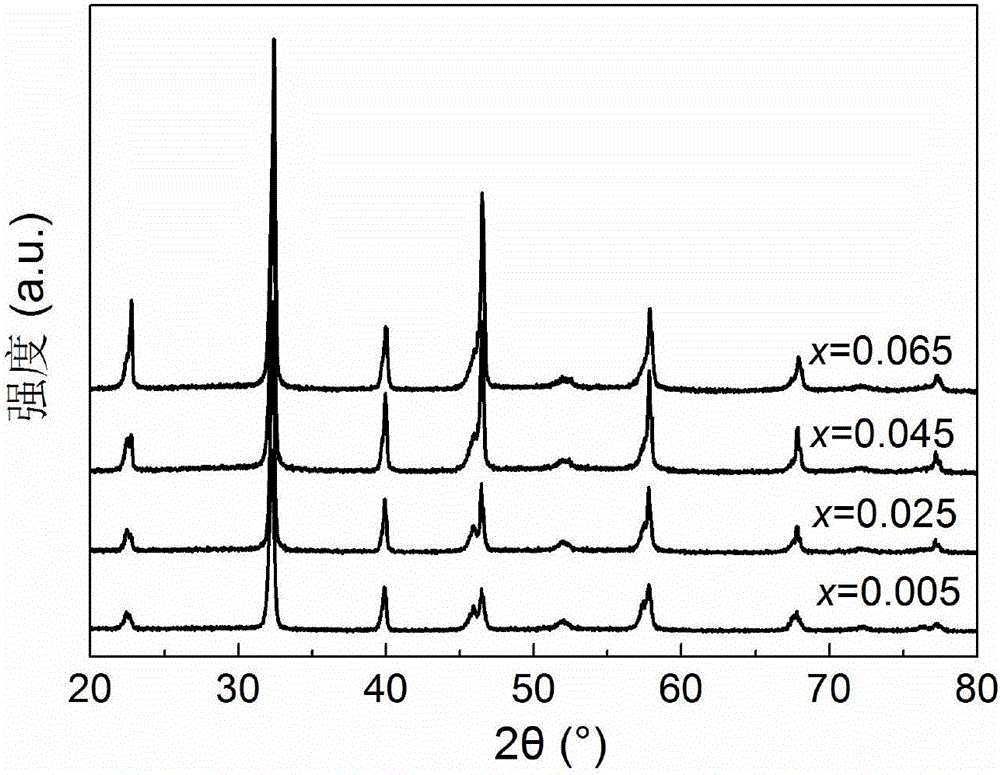

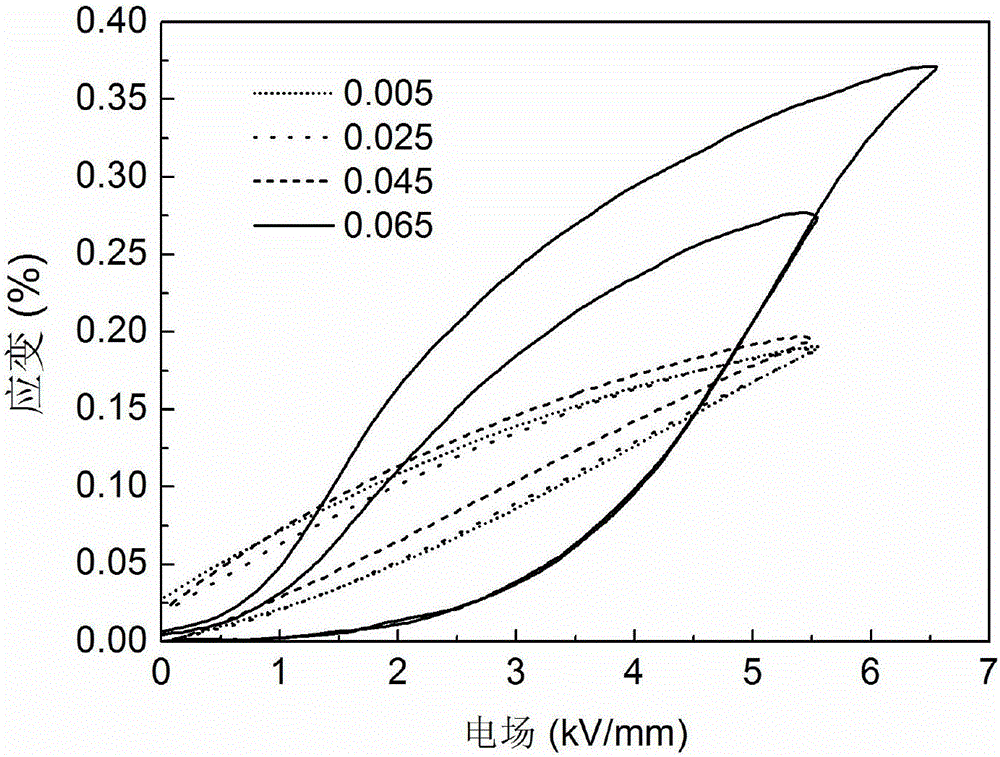

Sodium bismuth titanate-system lead-free piezoelectric ceramic and preparation method thereof

InactiveCN105837205AReduce manufacturing costExcellent piezoelectric propertiesSodium bismuth titanateCeramic

The invention discloses a bismuth-sodium titanate system lead-free piezoelectric ceramic and a preparation method thereof. The raw material components and their molar percentages are 0.96 (Bi 0.5 Na 0.44‑x K 0.06 Li x )TiO 3 ‑0.04BaTiO 3 , where x=0.005~0.065. Bi first 2 o 3 、K 2 CO 3 、Na 2 CO 3 、TiO 2 , Li 2 CO 3 , and Ba 2 CO 3 , mixed ingredients, after ball milling, drying, pre-fired at 850 ° C, and then after the second ball milling, drying, granulation, molding, debinding, sintering at 1100 ~ 1200 ° C, and then after being silvered and polarized, Lead-free piezoelectric ceramics were prepared. The main crystal phase of the material of the invention is a perovskite structure, and there is a maximum strain of 0.37% under an electric field of 6.5 kilovolts per millimeter, and has good piezoelectric performance, and the preparation process is stable, repeatable and practical. The lead-free piezoelectric ceramic material can be used in various fields such as piezoelectric lighters, drivers, and sensors.

Owner:TIANJIN UNIV

High temperature stable X9R type multilayer ceramic capacitor dielectric material and preparation method thereof

ActiveCN103936414AOvercome the high temperature reduction effectReduce lossBarium titanateCeramic capacitor

The invention discloses a high temperature stable X9R type multilayer ceramic capacitor dielectric material and a preparation method of the high temperature stable X9R type multilayer ceramic capacitor dielectric material. The high temperature stable X9R type multilayer ceramic capacitor dielectric material disclosed by the invention is prepared by the steps of adding a calcium-boron-silicon compound to a barium titanate-sodium bismuth titanate-niobium pentoxide eutectic compound serving as a matrix, compounding one or more of Ce, Nd and La oxides, and compounding one or more of barium-manganese oxide, magnesium oxide and zinc oxide; and the invention provides the preparation method of the high temperature stable X9R type multilayer ceramic capacitor dielectric material. The X9R type multilayer ceramic capacitor dielectric material prepared by using the material and the method provided by the invention has high temperature resistance (above 200 DEG C), and good temperature stability, and enable components and parts such as multilayer ceramic capacitors, tuners and duplexers to be suitable for the application at a high temperature (above 200 DEG C), thus having extremely high industrialization prospect and industrial application value.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Preparation method of bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film

InactiveCN103708828AHigh viscosityIncreasing the thicknessPiezoelectric/electrostrictive device manufacture/assemblyMicro nanoComposite film

The invention discloses a preparation method of a bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film and belongs to the technical field of the preparation of piezoelectric materials. The preparation method includes the following steps: 1) preparing a micro-nano bismuth sodium titanate-barium titanate powder according to a stoichiometric ratio of (1-x) Bi0.5Na0.5TiO3-xBaTiO3; 2) preparing a sodium bismuth titanate precursor sol according to a stoichiometric ratio of Bi0.5Na0.5TiO3; 3) dispersing the bismuth sodium titanate-barium titanate powder in the sodium bismuth titanate precursor sol to prepare a mixed slurry; 4) conducting spin coating deposition of the bismuth sodium titanate precursor sol, heat treatment, spin coating deposition of the mixed slurry and heat treatment, so as to prepare a single-layer composite film; and 5) repeating the step 4) to prepare the sodium bismuth titanate-barium titanate lead-free composite piezoelectric thick film with thickness of 1-20 mum. The invention makes improvement to the existing sol gel technology, has the advanategs of low process cost, flexible film thickness and good repeatability, and breaks the critical thickness restriction of the ordinary sol-gel technology.

Owner:XI AN JIAOTONG UNIV

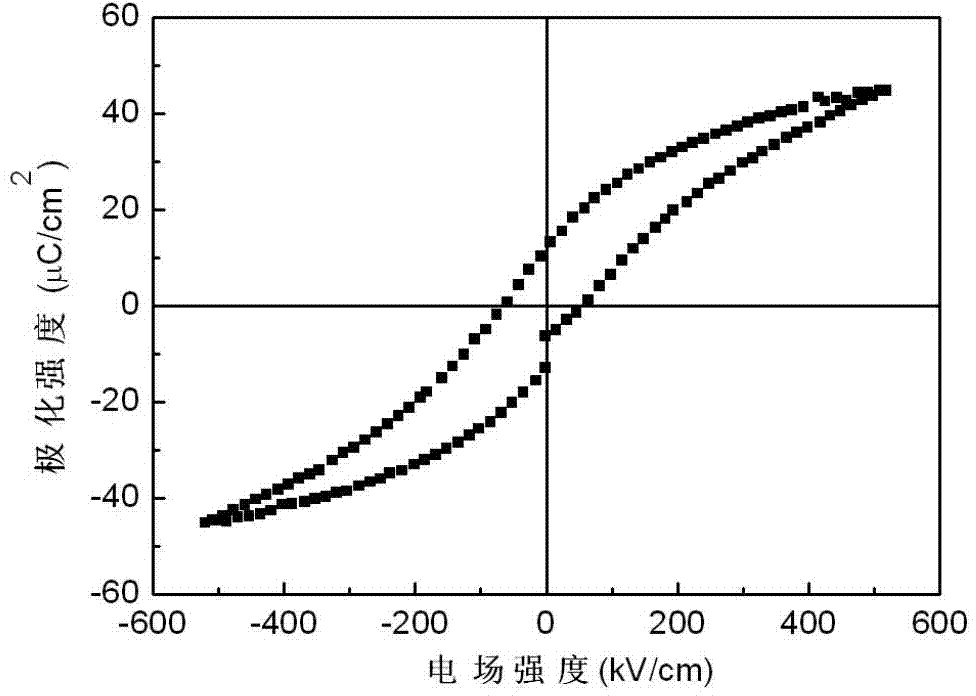

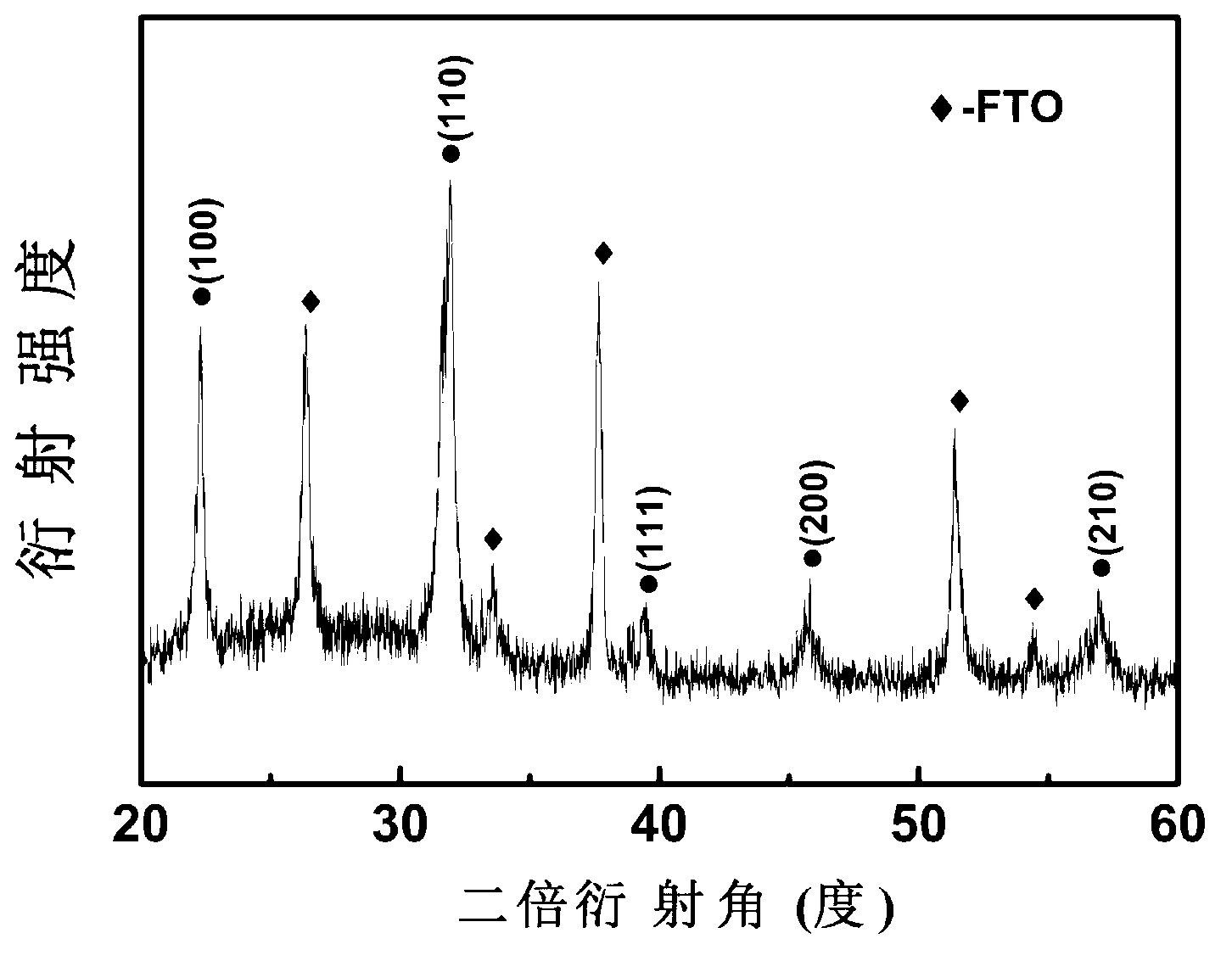

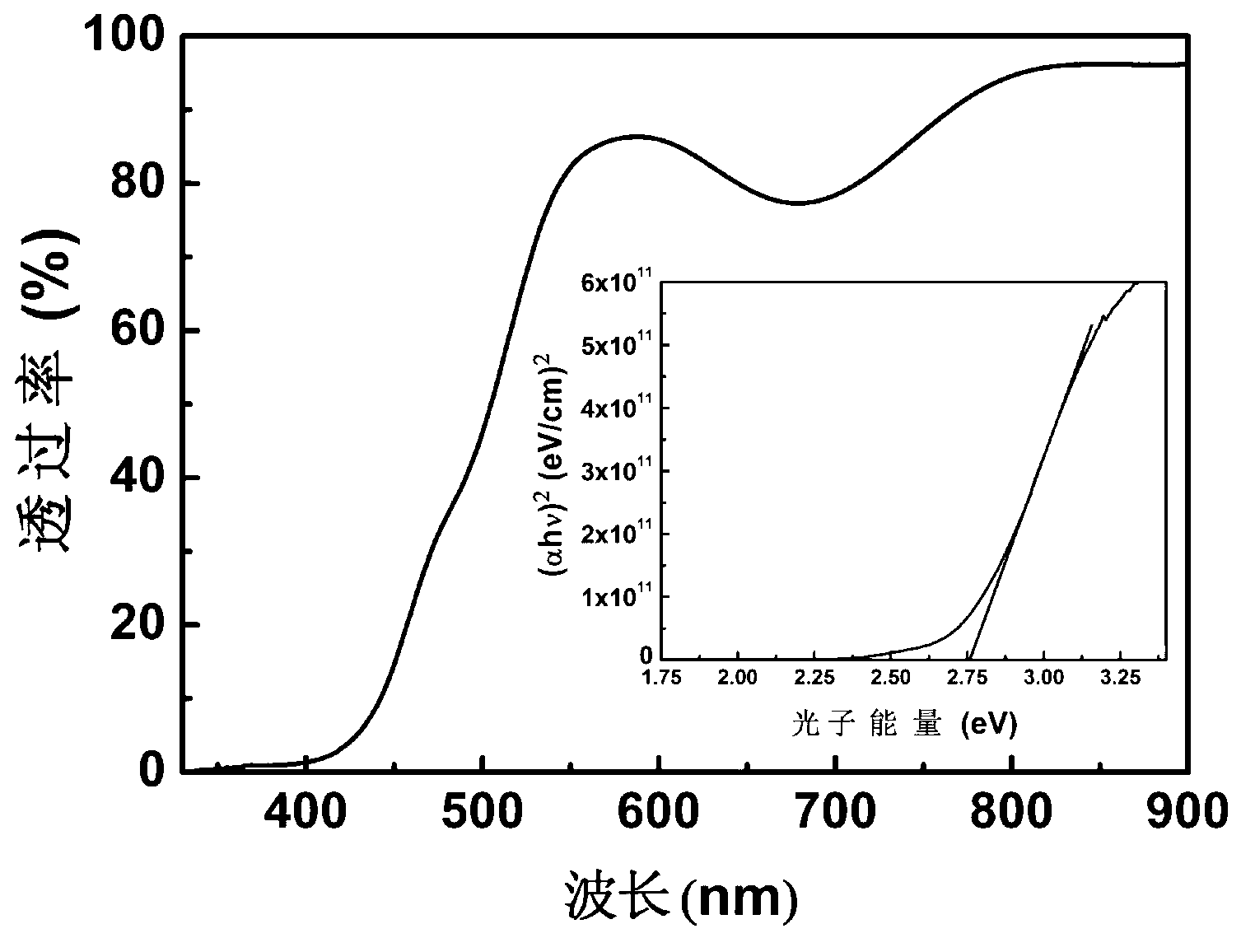

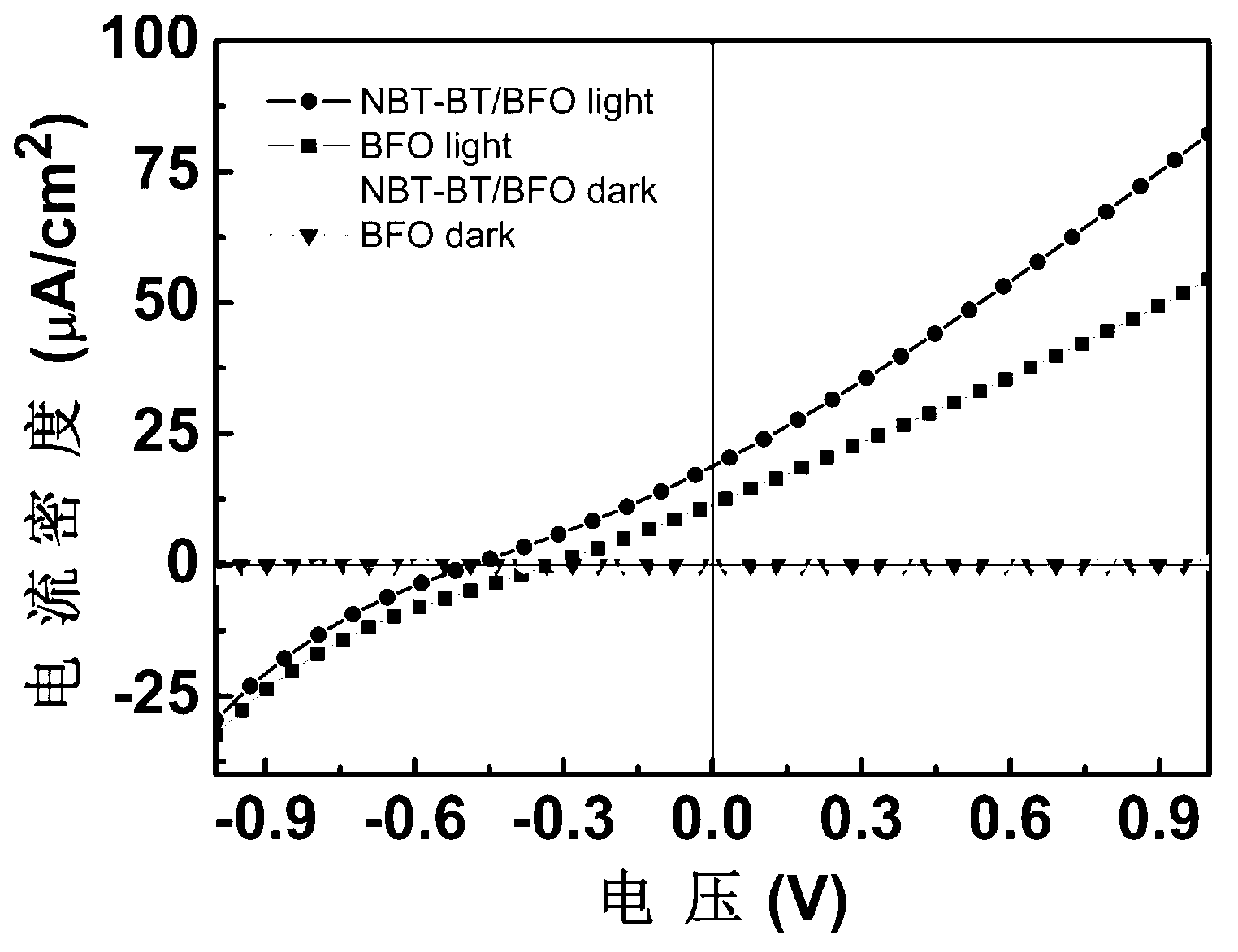

Preparation method of solar battery with bismuth ferrite/sodium bismuth titanate-barium titanate heterostructure ferroelectric film

InactiveCN103078014AUniform grainReduce manufacturing costRenewable energy productsSemiconductor devicesBarium titanateSolar battery

The invention relates to a preparation method of a solar battery with a bismuth ferrite / sodium bismuth titanate-barium titanate heterostructure ferroelectric film. The preparation method comprises the following steps of: selecting SnO2 transparent conducting glass doped with fluorine (FTO for short) as a substrate, preparing the (Na0.5Bi0.5)0.94Ba0.06TiO3 and BiFeO3 ferroelectric film by a chemical solution deposition method, then preparing an electrode on the surface of the film by a physical sputtering method. Compared with the prior art, the preparation method has the advantages that the ferroelectric photoelectric film with high consistency and good repeatability is prepared on the FTO substrate by low cost. The prepared heterostructure film has more excellent photovoltaic performance than that of the pure BiFeO3, and can be applied in the fields of photoelectric batteries and photoelectronic devices.

Owner:SHANGHAI JIAO TONG UNIV

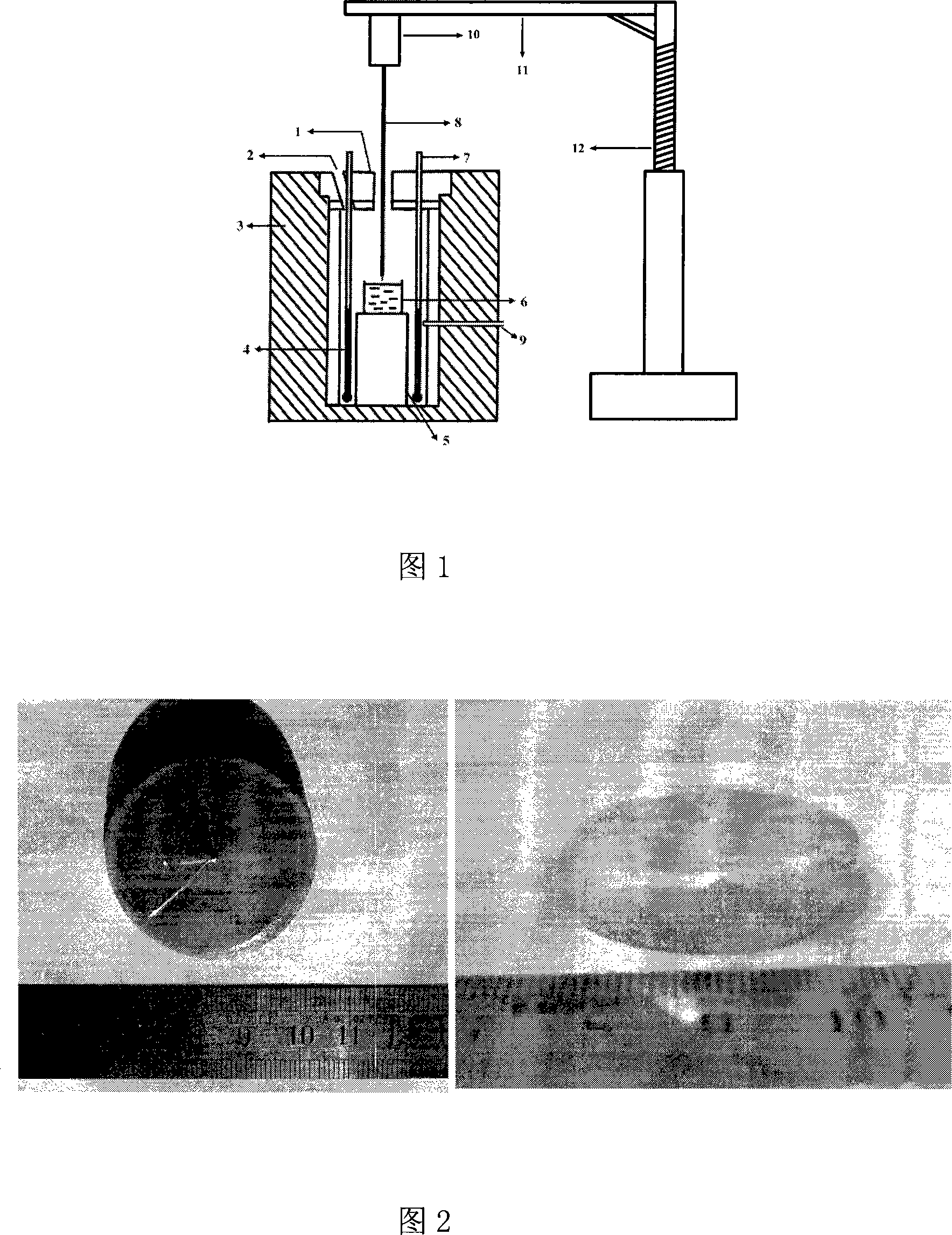

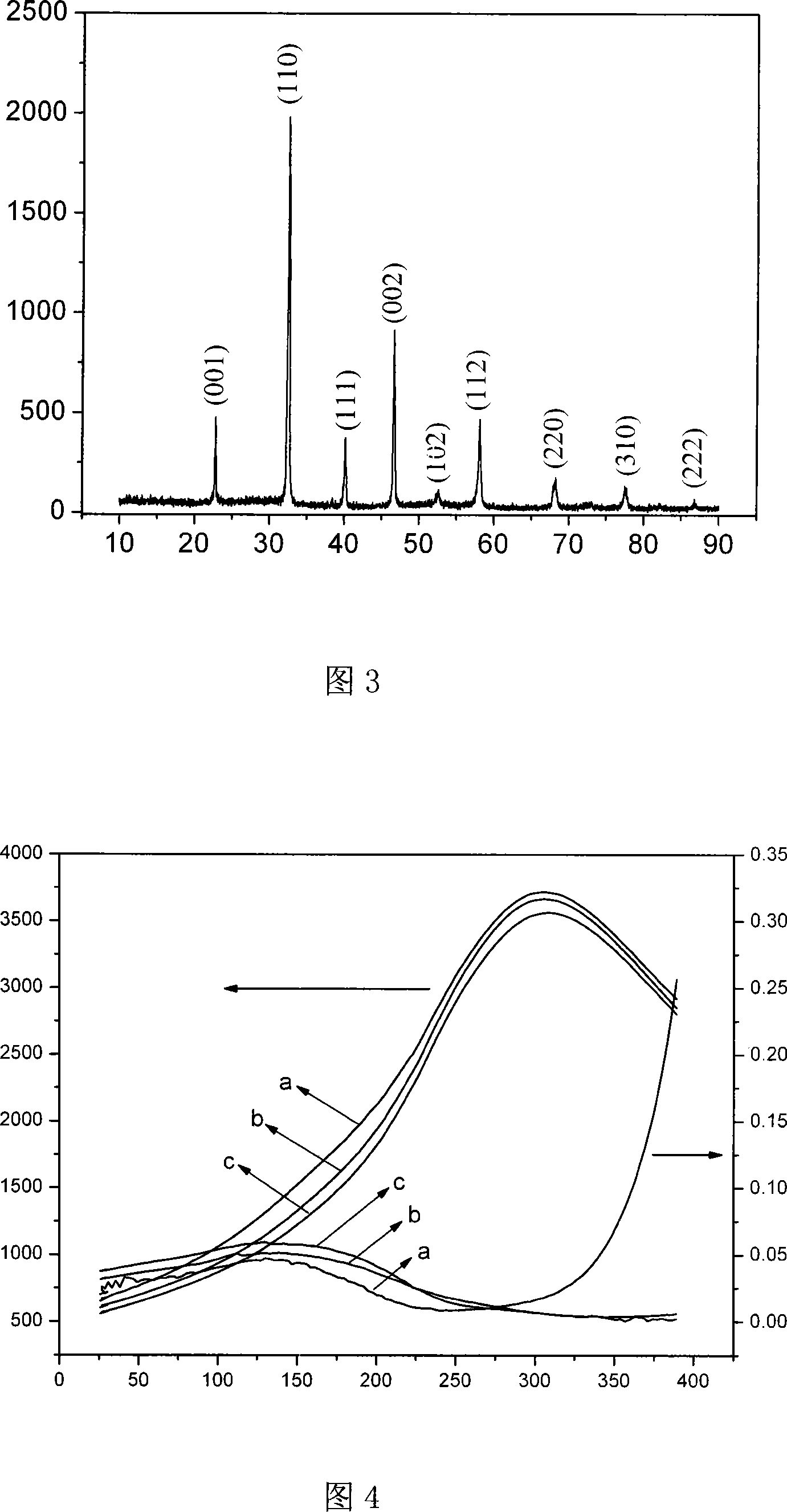

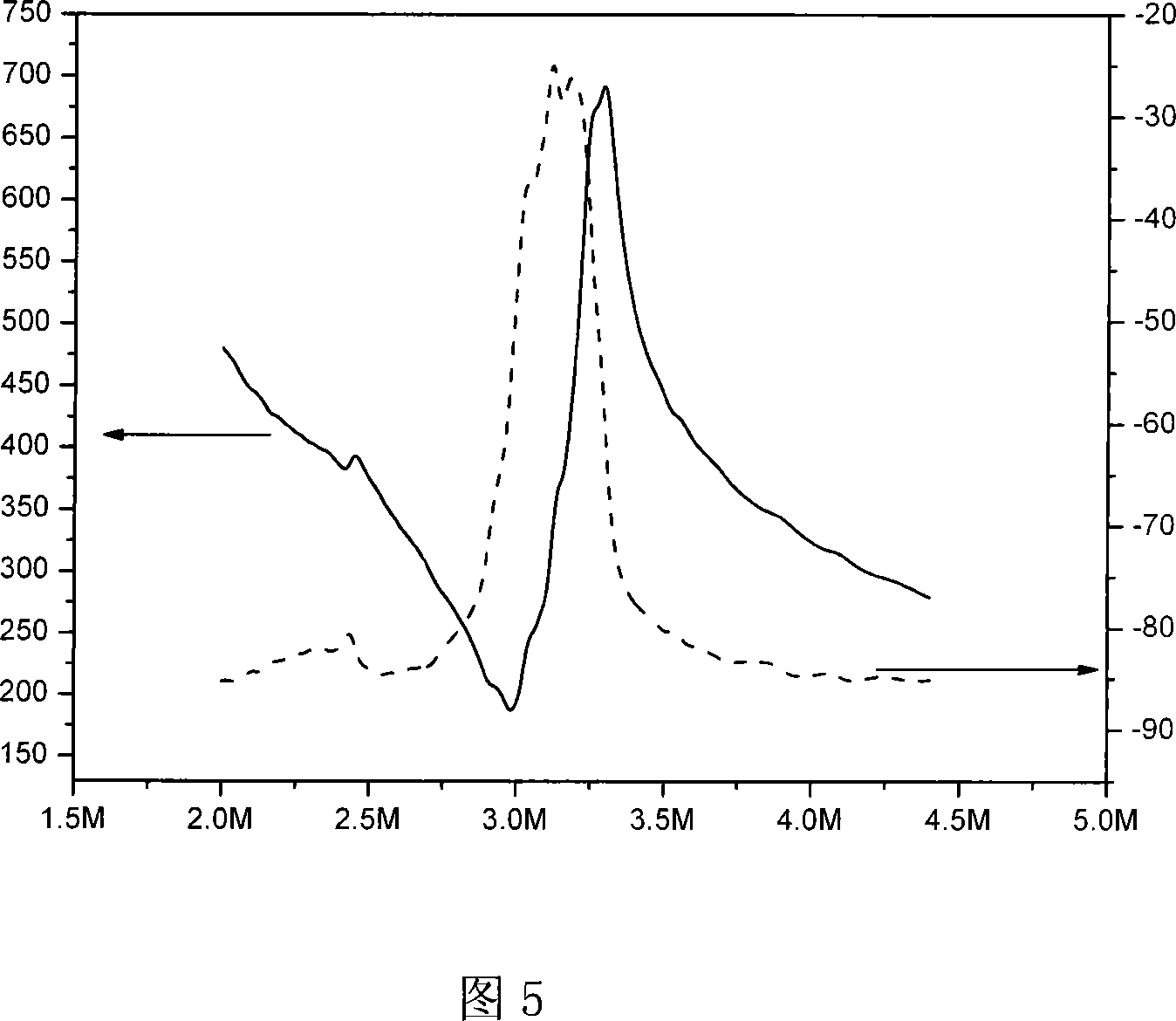

Method for manufacturing bismuth sodium titanate-barium titanate ferro-electricity single crystal

ActiveCN101220511AImprove performanceComplete structurePolycrystalline material growthBy pulling from meltElectromechanical coupling coefficientBarium titanate

A preparing method of bismuth sodium titanate-barium titanate ferroelectric single crystal belongs to the field of crystal growth. The preparing method provided by the invention comprises a series of single crystal growth processes: raw material treatment, heating and melting, growing and cooling. The rotational speed of a seed rod is 10 to 50rpm, and the drawing rate is 0.1mm to 20mm per day, and the cooling rate is 1 to 20 DEG C per day; the cooling rate is 10 to 150 DEG C per hour after the crystal finishes growing. The technology provided by the invention can grow bismuth sodium titanate-barium titanate ferroelectric single crystal (NBBT) with the diameter larger than 40mm and the length larger than 10mm, and the piezoelectric constant d33 can reach 280pC / N, and the electromechanical coupling factor kt can reach 50 percent. The material with the piezoelectric property which reaches the level of leaded piezoelectric materials of PZT ceramics, etc., can be applied in practice.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Bismuth-sodium-potassium-lithium titanate lead-free piezoelectric ceramics

InactiveCN1511800AExcellent piezoelectric ferroelectric propertiesProcess stabilityInorganic insulatorsPiezoelectric/electrostrictive/magnetostrictive devicesOxygenSodium bismuth titanate

The present invention belongs to environment concordant piezoelectric ceramic in perovskite structure. The lead-free piezoelectric ceramic of the present invention may be expressed in the general expression of [Bi1-z(Na1-x-yKxLiy)z]TiO3+ aMalphaObeta, where, x is 0-1, y 0-1, (x+y) is 0-1, z 0.3-0.7, MalphaObeta multiple doping oxides in the amount of 0-10 wt% of the main component [Bi1-z(Na1-x-yKxLiy)z]TiO3, M is +1-+6 valance element capable of forming solid oxide, and alpha and beta express the atom number of M and O separately. The piezoelectric ceramic has d33 up to 150 pC / N and kp up to 26.0 %, may be prepared with industrial material and through traditional piezoelectric ceramic process, and has practical application value.

Owner:SICHUAN UNIV

Preparation method of low-loss high-energy-density sodium bismuth titanate based ceramic

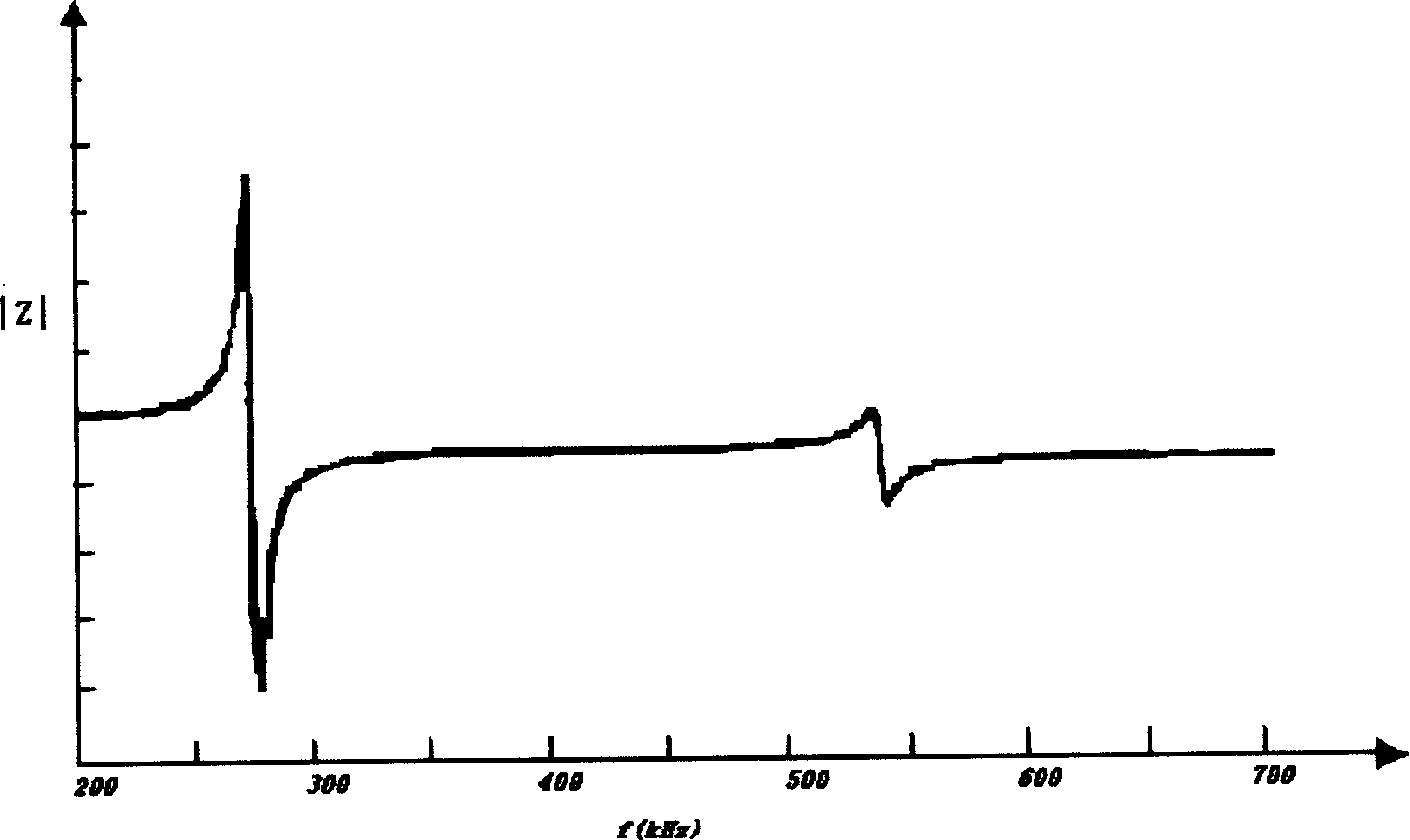

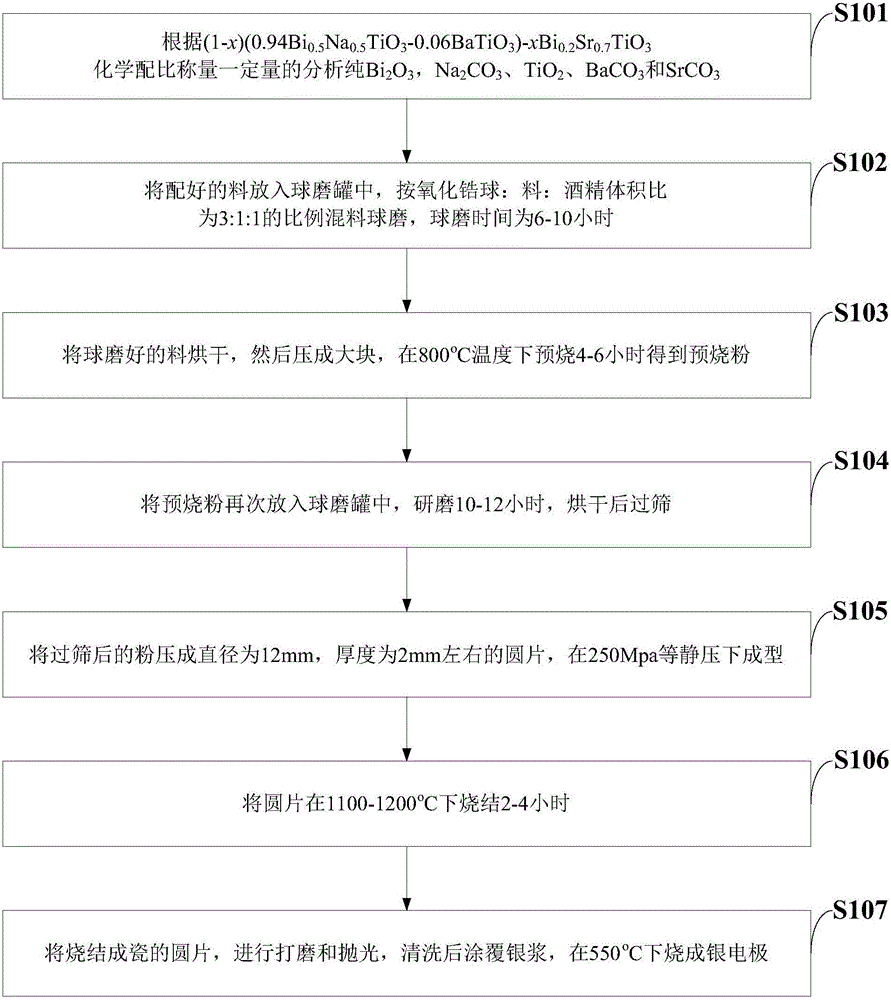

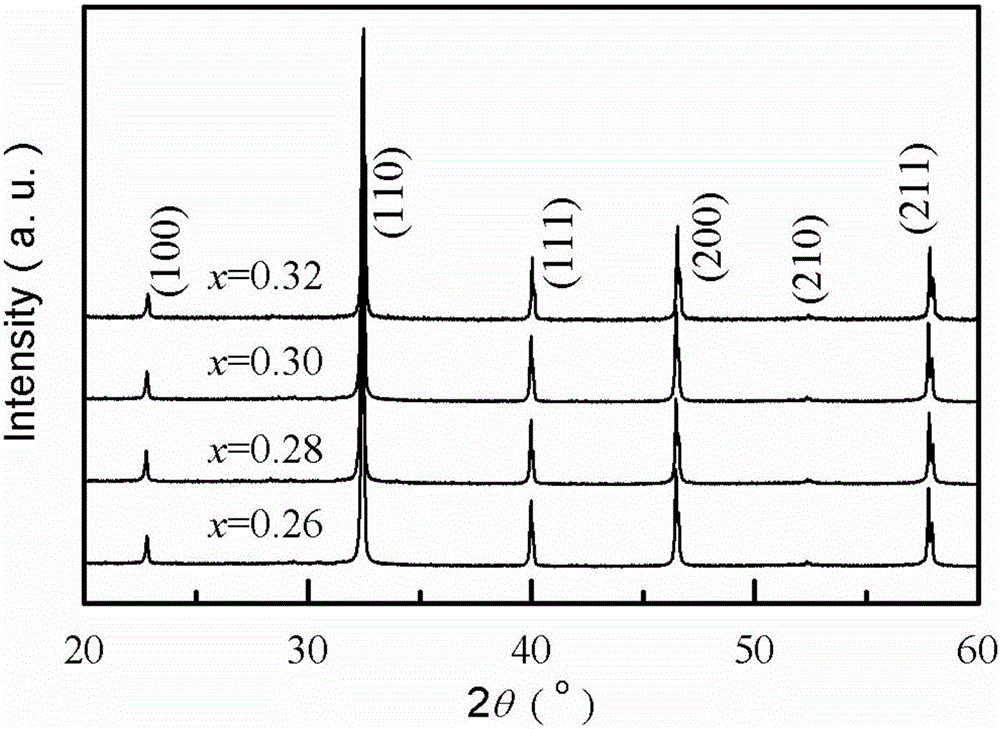

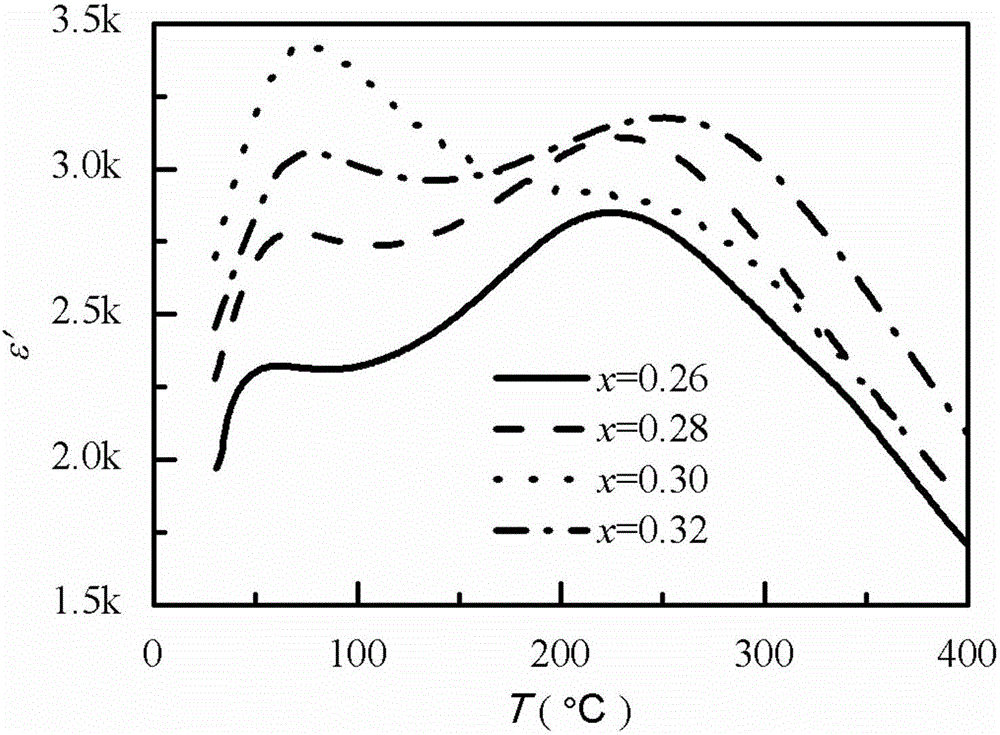

The invention discloses a preparation method of low-loss high-energy-density sodium bismuth titanate based ceramic. The preparation method includes: weighing certain amounts of analytically pure Bi2O3, Na2CO3, TiO2, BaCO3 and SrCO3 according to a chemical proportion; mixing and ball-milling zirconium oxide ball, material and alcohol according to a volume ratio of 3:1:1; drying the ball-milled material, pressing the material into blocks, and pre-sintering to obtain pre-sintered powder; placing the pre-sintered powder in a ball-milling tank for milling for 10-12h, and drying before sieving; pressing sieved powder for forming; sintering a wafer at temperature of 1100-1200 DEG C; polishing the wafer sintered into ceramic, cleaning, coating silver size, and sintering at temperature of 550 DEG C to obtain a silver electrode. By optimizing ceramic formulation, energy density and energy efficiency of BNT-based ceramic are both improved. When an electric field at room temperature is 95kV / cm, the energy density of the ceramic is up to 1.22J / cm3, and energy storage efficiency is up to 91%.

Owner:XIDIAN UNIV +1

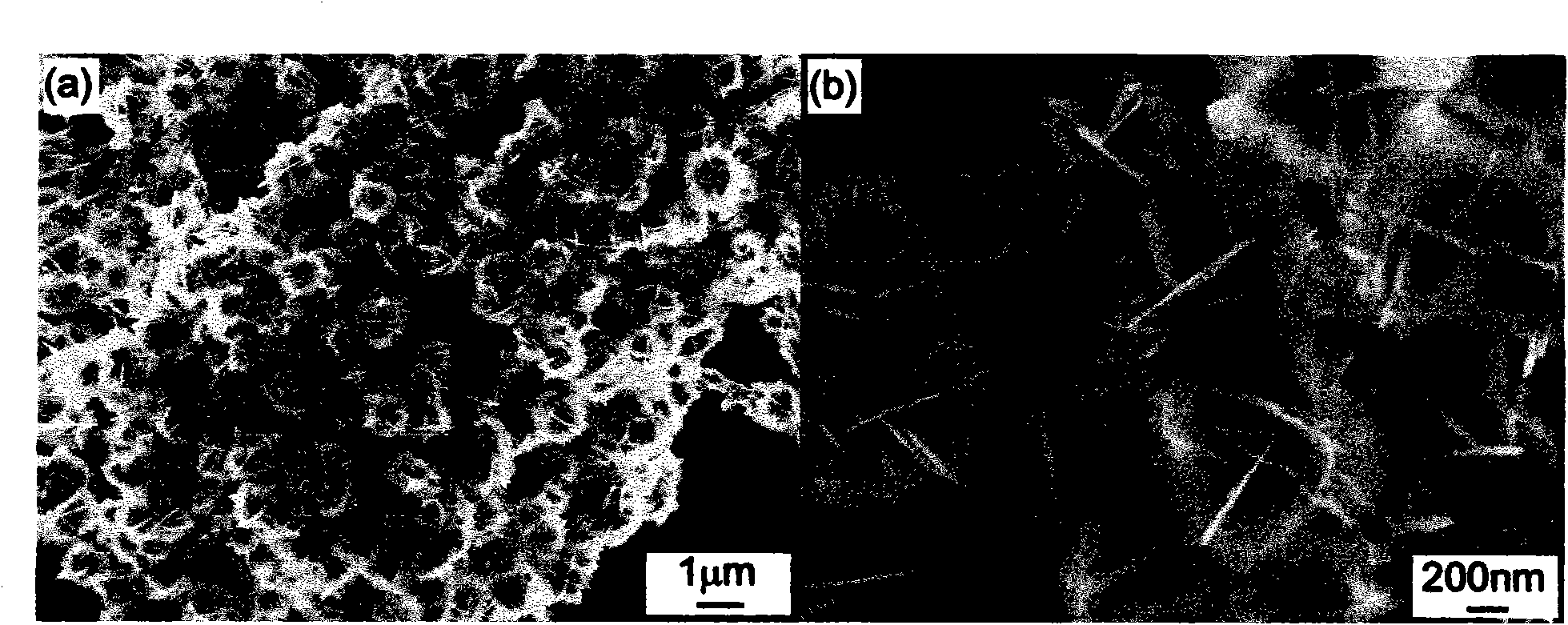

Bismuth sodium titanate nanometer flower and preparation method thereof

InactiveCN101565203ALow dielectric lossGood single crystalTitanium compoundsBismuth compoundsSodium titanateAmmonia

The invention discloses a bismuth sodium titanate nanometer flower and a preparation method thereof. The nanometer flower comprises crossed vertical nanometer sheets which have the length of 250 nm to 350 nm, the height of 50 nm to 150 nm and the thickness of 5 nm to 15 nm and are made of monocrystal perovskite bismuth sodium titanate. The method comprises the following steps: firstly, adding ammonia to a citric acid aqueous solution with the density of 0.8M to 1.2M and adjusting a pH value to be between 4.5 and 6; adding tetrabutyl titanate and stirring at 50 DEG C to 70 DEG C for longer than 5 hours to obtain a clear solution; then, mixing a bismuth nitrate pentahydrate aqueous solution with the clear solution and stirring at 80 DEG C to 100 DEG C for longer than 30 minutes to obtain a mixed solution; afterwards, adding sodium hydroxide to the mixed solution and continuously stirring for longer than 15 minutes to obtain a synthetic solution; later, keeping the synthetic solution at 80 DEG C to 180 DEG C for 0 to 10 hours and washing to be neutral to obtain a product; and finally, drying the product to obtain the bismuth sodium titanate nanometer flower. The invention can be widely applied to the fields of machinery, electrons, precise control, and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Bi.Na.K.Li Ag titanate series lead-free piezoelectric ceramics

InactiveCN1814570AExcellent piezoelectric propertiesThe preparation process is stablePiezoelectric/electrostrictive/magnetostrictive devicesLithiumPotassium

The invention relates to bismuth titanate natrium-potassium-lithium-silver series leadless piezoelectric ceramics. The general equation of the compound is Bi0.5(Na1-x-y-zKxLiyAgz)0.5TiO3+aM alpha O beta(wt%), and in the equation, 0 alpha Obeta is one or plural doping oxide. The main constituent is 0-5 of Bi0.5(Na1-x-y-zKxLiyAgz)SUB>0.5TiO3, M could be Na, K, Li, Ni, Zn, Cr, Co, Nb, Ta, Al, Cu, Fe, Ce, Pr, Nd, Sm, Gd, Dy, Er, Yb, In, Y, Sc, La, Ho, Lu, Sn, Sb, Mn, Ca, Ba, Sr, Mg, Si, Bi, Ag, etc. Alpha and beta mean the M element and atomicity corresponding to the relative oxide. The optimal value of the compound of d33 could be over 210pC / N, kp could be over 40%. And the technology is stable, and it would be made from traditional technology and raw material.

Owner:SICHUAN UNIV

Method for preparing strontium sodium bismuth titanate piezoelectric ceramic by sol-gel auto-igniting process

The invention discloses a method for preparing strontium sodium bismuth titanate piezoelectric ceramic by a sol-gel auto-igniting process. The method comprises the steps of: by using a complexing agent, nitric acid, acetic acid or carbonate and butyl titanate as raw materials, adjusting pH value by adopting ammonium hydroxide, carrying out complexing hydrolysis reaction in water and alcohol solution, performing microwave heating for dehydration condensation to obtain xerogel, and heating the xerogel at 500 DEG C to perform auto-igniting reaction to obtain strontium sodium bismuth titanate ceramic powder with narrow particle size (10-40nm). The ceramic can be densely sintered at 980-1020 DEG C due to nanometer small-size effect and can keep good piezoelectric property, the equipment required by the method is simple and has no special environment requirement, the process is stable at normal temperature, the repeatability is strong, the synthesized powder has high purity and the heat treatment temperature is low, therefore, the ceramic can be widely applied to the fields such as piezoelectric vibrators, micro positioners, ultrasonic transducers and the like.

Owner:XIAN UNIV OF SCI & TECH

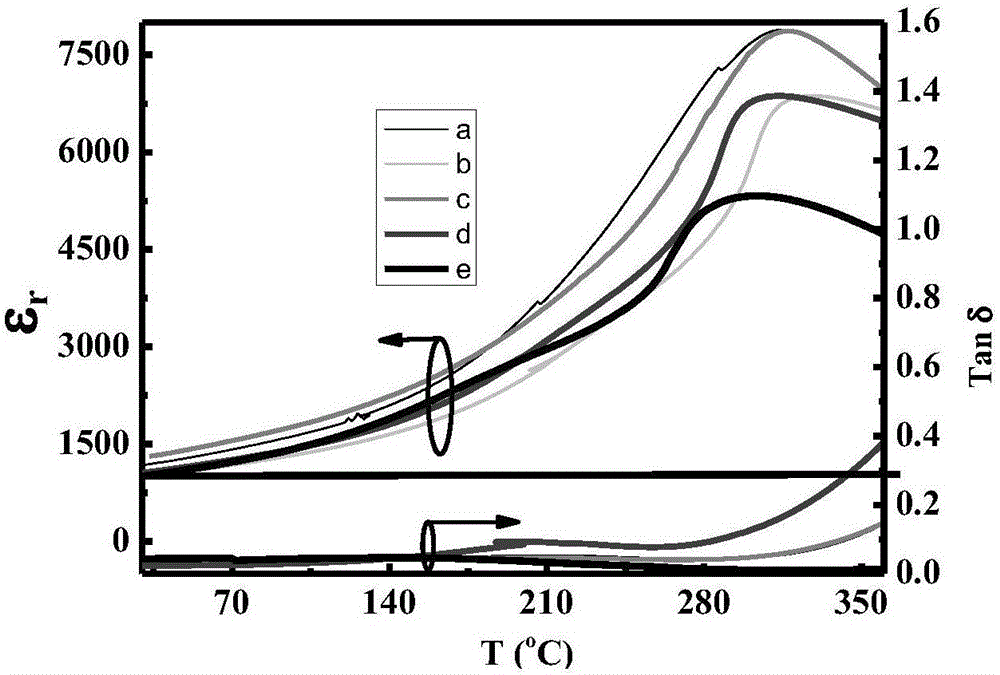

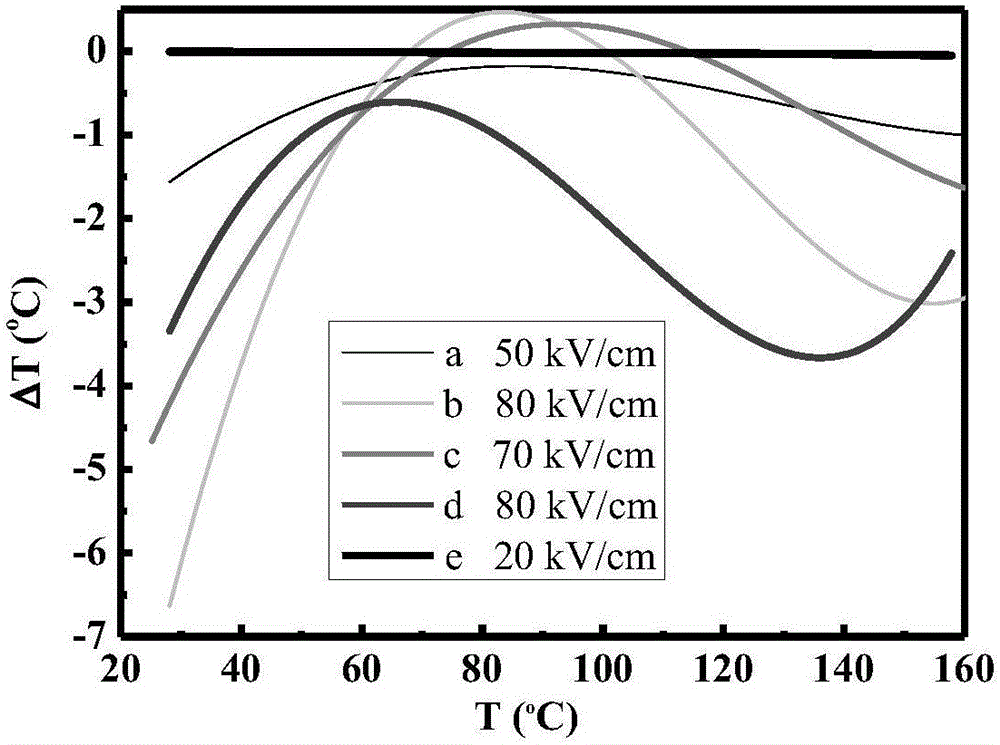

Sodium-bismuth-titanate-based unleaded ceramic with negative electrocaloric effect and preparing method of sodium-bismuth-titanate-based unleaded ceramic

The invention relates to a sodium-bismuth-titanate-based unleaded ceramic with the negative electrocaloric effect and a preparing method of the sodium-bismuth-titanate-based unleaded ceramic. The chemical composition of the ceramic is (1-x)(Na0.5Bi0.5)TiO3-xSrTiO3, wherein x is larger than or equal to 0 but smaller than or equal to 0.10. The ceramic is prepared through combination of a sol-gel method and a microwave sintering method, lead is not contained in the ceramic material, the ceramic has the advantages of being environmentally friendly and nuisanceless, meanwhile, the ceramic material has the high negative refrigerating performance and also has the low dielectric loss energy, the negative electrocaloric effect near the room temperature can reach up to 0-minus 7 DEG C, and the ceramic can be widely applied to development of environment-friendly micro-refrigerators high in refrigerating efficiency and energy conversion efficiency.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Lead-free piezoelectric knitting ceramic of titanic acid bismuth sodium-titanic acid bismuth potassium and its production

InactiveCN101028979AMeet environmental protection requirementsMeet practical requirementsPiezoelectric/electrostrictive/magnetostrictive devicesAdhesivePotassium

A lead-free piezoelectric sodium bismuth titanate-potassium bismuth titanate texture ceramics is prepared from the microcrystalline template (bismuth titanate) prepared from TiO2, bismuth oxide, sodium chloride and potassium chloride, the raw powder of sodium carbonate, potassium carbonate, TiO2 and bismuth oxide, organic solvent, and adhesive through mixing, ball grinding, doctor blading, laminating, isostatic pressing in hot water, cutting pre-calcining, and coating Ag.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Bismuth sodium titanate-barium titanate base piezoelectric ceramic and its prepn process

InactiveCN1673178ALower coercive fieldLow resistivityPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateAdhesive

Owner:NORTHWESTERN POLYTECHNICAL UNIV

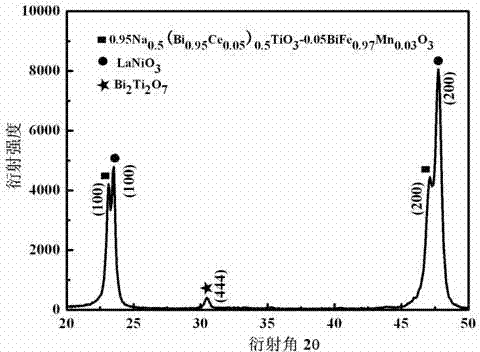

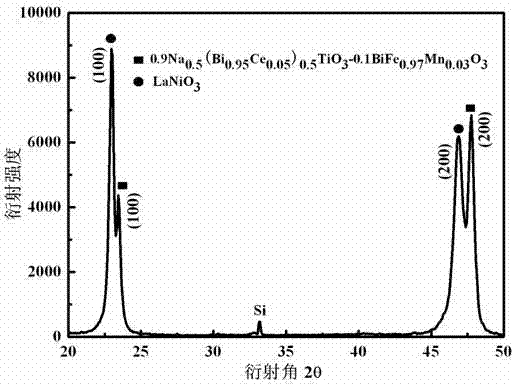

Composite solid solution film based on sodium bismuth titanate and bismuth ferric and preparation method thereof

InactiveCN102244192APiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionHigh densityFilm base

The invention discloses a composite solid solution film based on sodium bismuth titanate and bismuth ferric and a preparation method thereof. The film is represented by the general formula: (1-x)Na0.5(Bi0.95Ce0.05)0.5TiO(3-x)BiFe0.97Mn0.03O3, the sodium bismuth titanate is Na0.5(Bi0.95Ce0.05)0.5TiO3, and the bismuth ferric is BiFe0.97Mn0.03O3, wherein x is the molar content of BiFe0.97Mn0.03O3, which is greater than 0 and less than 1. According to the invention, the composite solid solution film is prepared by the spinning method-layer by layer annealing process, and does not have an impurityphase except that a pyrochlore impurity phase exists when x is less than or equal to 0.05; and moreover, the film has the advantages of low crystallizing temperature, low electric leakage, great residual polarization, stable dielectric property and the like, and can be well applied to novel high-density integrated piezoelectric ferroelectric devices in the future.

Owner:UNIV OF JINAN

Ternary system sodium bismuth titanate base leadless piezoelectric ceramics material and preparation method thereof

InactiveCN101381231AHigh depolarization temperatureGood piezoelectricSesquioxideIntermediate frequency

The invention discloses a trinary sodium bismuth titanate based lead-free piezoelectric ceramic material and a method for preparing the same, and belongs to the field of functional ceramics and manufacture thereof. The invention aims to improve the depolarization temperature and mechanical quality factor of the prior trinary sodium bismuth titanate based lead-free piezoelectric ceramic material. The component of ceramic material of the invention is (100-x)Bi1 / 2Na1 / 2TiO3-xBaTiO3-yCo2O3, wherein x is more than or equal to 2 and less than or equal to 4, and y is more than or equal to 0.25 and less than or equal to 2.0. The method is to prepare the ceramic material from raw materials of natrium carbonicum calcinatum, anhydrous potassium carbonate, bismuth oxide, titanium dioxide, barium carbonate and cobalt sesquioxide through pre-synthesis, roll forming and sintering. The ceramic material prepared by the method has high depolarization temperature which is 157 DEG C, high mechanical quality factor which is 626, and excellent piezoelectric and dielectric properties and can be used for manufacturing intermediate frequency ceramic filters, resonators, piezoelectric gauges and actuators.

Owner:BEIJING UNIV OF TECH

Bismuth sodium lithium titanate barium titanate strontium titanate calcium titanate based lead-free piezoelectric ceramics

InactiveCN1541978AExcellent piezoelectric ferroelectric propertiesImprove performanceCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesStrontium titanateBarium strontium titanate

The lead-free bismuth sodium lithium barium strontium titanate piezoelectric ceramic is one polycomponent perovskite type environment consistency piezoelectric ceramic composition. The composition has the general expression of (1-y-z-u)Bi1-w(Na1-xLix)wTiO3+yBaTiO3+zSrTiO3+uCaTiO3+aMalphaObeta, where x is 0-0.5, y 0-1, z 0-1, u 0-1, (y+z+u) 0-1, w 0.3-0.7; MalphaObeta is doping oxide(s) in the content an of 0-10 %; M is +1~+6 valent element capable of forming solid oxide, such as Na, K, Li, Ni, Zn, etc. with alpha and beta being atom number. The piezoelectric ceramic composition has d33 up to 200 pC / N, kp up to 35.0 % and stable technological process, may be produced via traditional piezoelectric ceramic preparation process and industrial material, and is practical.

Owner:SICHUAN UNIV

Sodium bismuth titanate based lead-free piezoelectric ceramic with high piezoelectric coefficient and method for preparing sodium bismuth titanate based lead-free piezoelectric ceramic

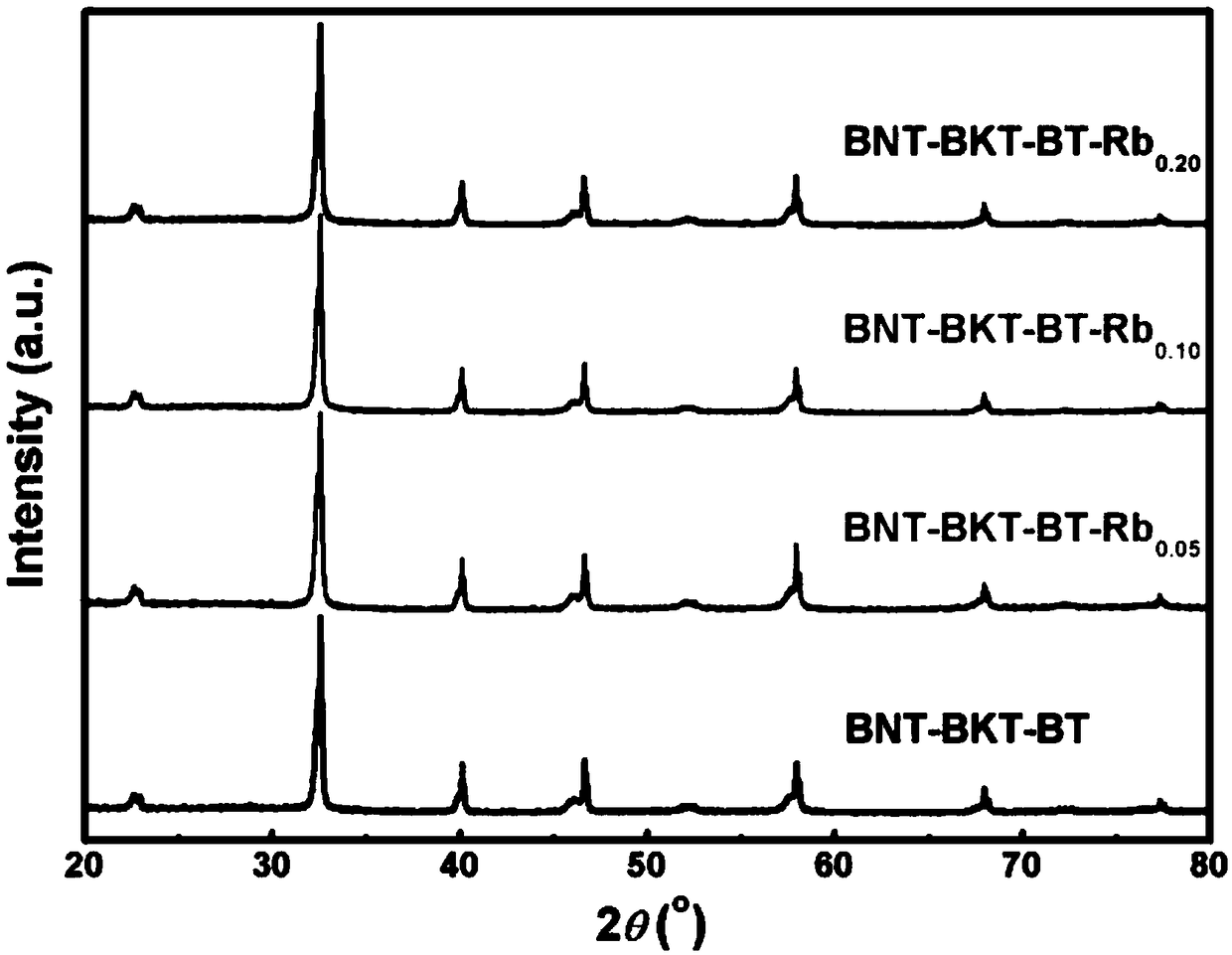

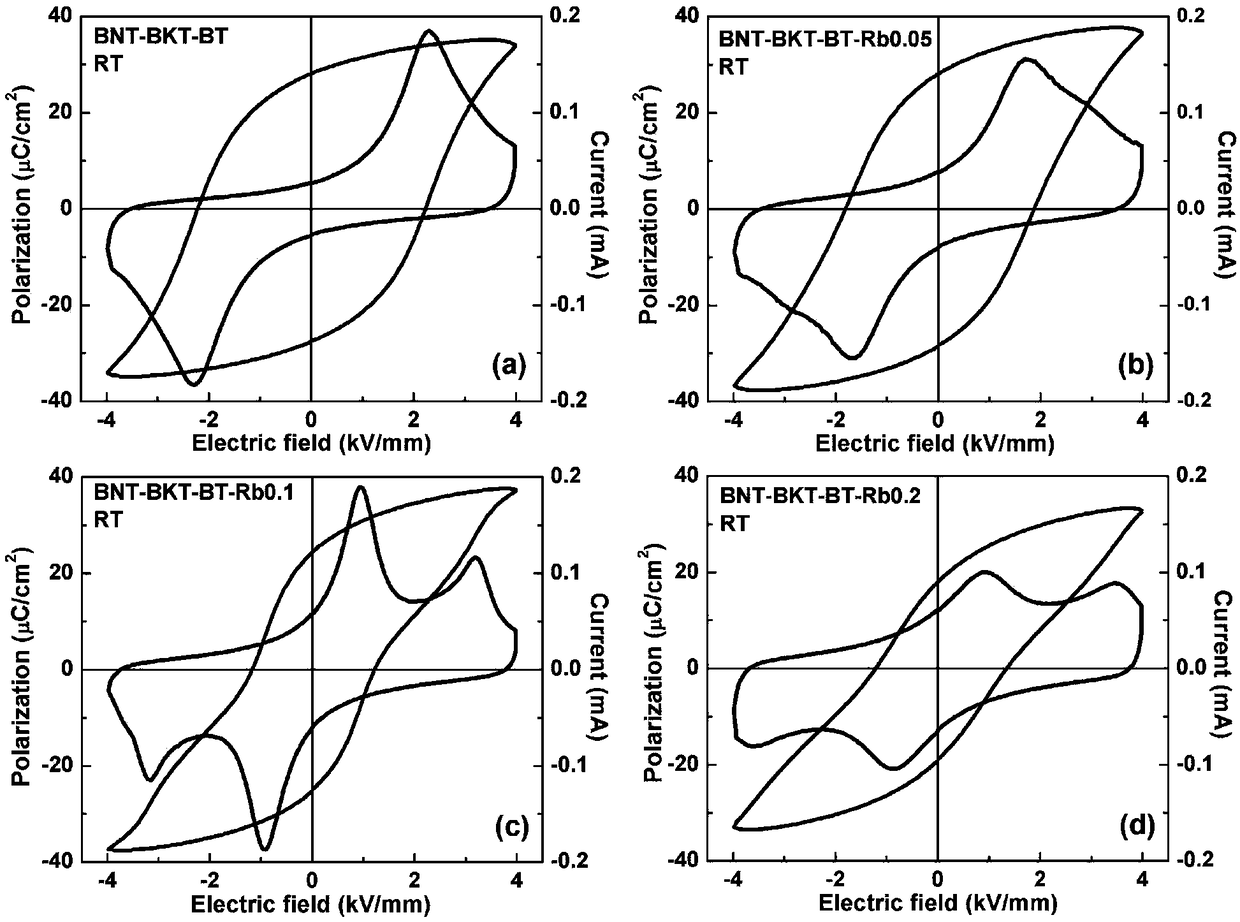

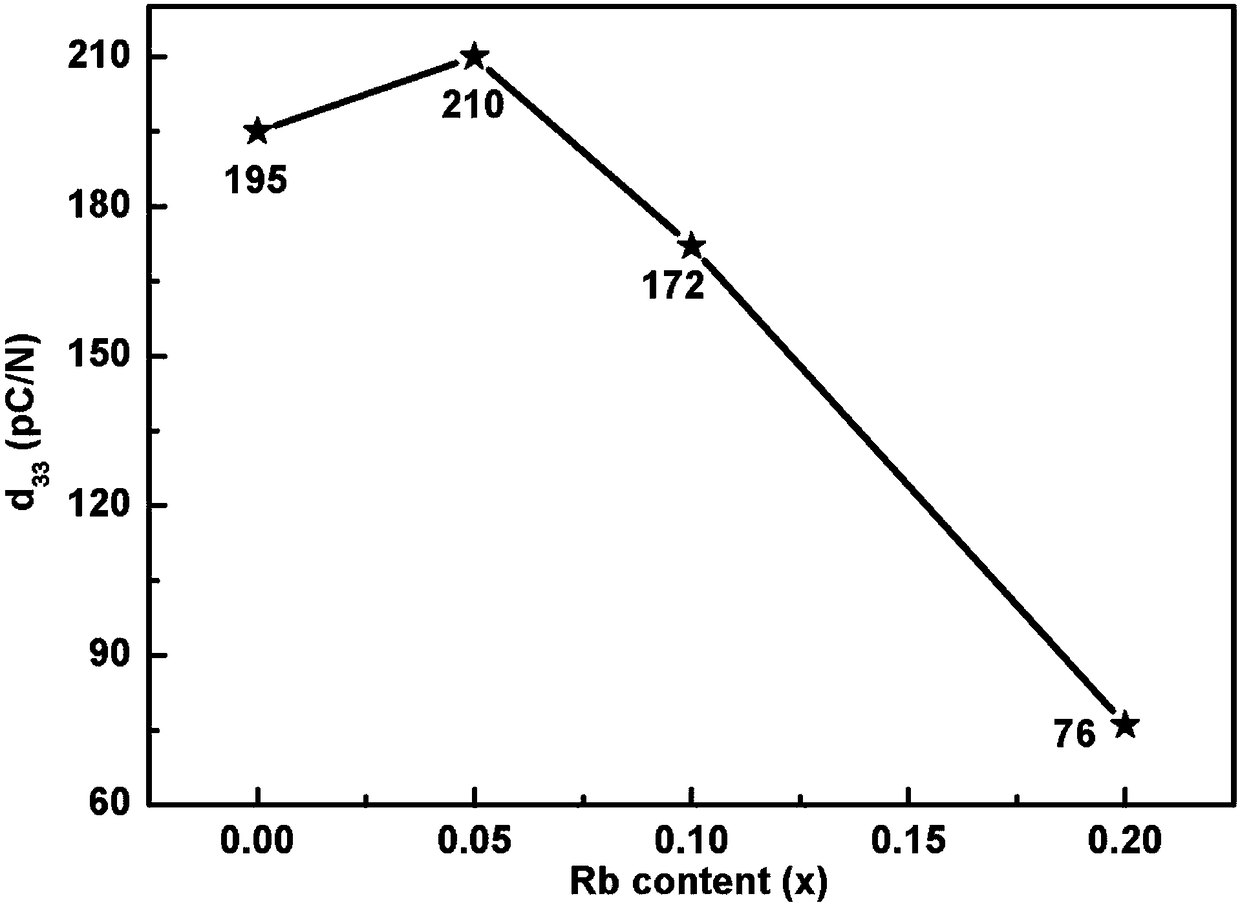

ActiveCN108147813AReduce manufacturing costExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyRubidiumActuator

The invention discloses sodium bismuth titanate based lead-free piezoelectric ceramic with a high piezoelectric coefficient and a method for preparing the sodium bismuth titanate based lead-free piezoelectric ceramic. A stoichiometric ratio of the sodium bismuth titanate based lead-free piezoelectric ceramic (BNT-BKT-BT-Rb<x>, wherein the x can be equal to 0, 0.05, 0.10 and 0.20) with the high piezoelectric coefficient is shown as 0.85Bi<0.5>Na<0.5>TiO<3>-0.11 Bi<0.5>K<0.5-x>Rb<x>TiO<3>-0.04BaTiO<3>. The method includes uniformly mixing Bi<2>O<3> powder, Na<2>CO<3> powder, K<2>CO<3> powder, BaCO<3> powder, Rb<2>CO<3> powder and TiO<2> powder with one another according to the stoichiometric ratio; carrying out ball-milling and drying and carrying out pre-burning at the temperature of 850 DEG C for 3 h to obtain pre-burned powder; carrying out secondary ball-milling, drying, granulating, compressing and glue discharging and then carrying out sintering at the temperature of 1160-1180 DEGC; carrying out silver firing and polarization to obtain the sodium bismuth titanate based lead-free piezoelectric ceramic. The sodium bismuth titanate based lead-free piezoelectric ceramic and the method have the advantages that rubidium elements are doped in the sodium bismuth titanate based lead-free piezoelectric ceramic, and accordingly the piezoelectric coefficient d33 of the sodium bismuthtitanate based lead-free piezoelectric ceramic can be increased; the piezoelectric coefficient of BNT-BKT-BT-Rb<0.05> ceramic can reach 210 pC / N, and the sodium bismuth titanate based lead-free piezoelectric ceramic which is a lead-free piezoelectric material can be effectively applied to diversified fields of actuators, sensors and the like.

Owner:广州光鼎科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com