Ternary system sodium bismuth titanate base leadless piezoelectric ceramics material and preparation method thereof

A technology based on lead-free piezoelectric and ceramic materials, applied in the field of ternary sodium bismuth titanate-based lead-free piezoelectric ceramic materials and their preparation, can solve the problem of low depolarization temperature, small mechanical quality factor, limited development, etc. problem to achieve good piezoelectric and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) raw material anhydrous sodium carbonate, anhydrous potassium carbonate, bismuth oxide, titanium dioxide, barium carbonate and dicobalt oxide are pressed chemical formula 85Bi 1 / 2 Na 1 / 2 TiO 3 -12Bi 1 / 2 K 1 / 2 TiO 3 -3BaTiO 3 -0.5Co 2 o 3 Carry out material preparation and mix, obtain mixture powder;

[0024] 2) Using absolute ethanol as the medium, ball mill the mixture powder for 8 hours, discharge and dry, extrude into a block with a pressure of 40MPa, heat up to 850°C, and keep warm for 2 hours to pre-synthesize the block; Dehydrated alcohol is the medium ball mill for 12 hours, and the material is discharged and dried to obtain a powder, and the concentration of 18% polyvinyl alcohol binder solution accounting for 20% of the powder weight is added to the powder, and the mixture is mixed, combined, and coarsely prepared. Rolling and finishing rolling to obtain ceramic diaphragms;

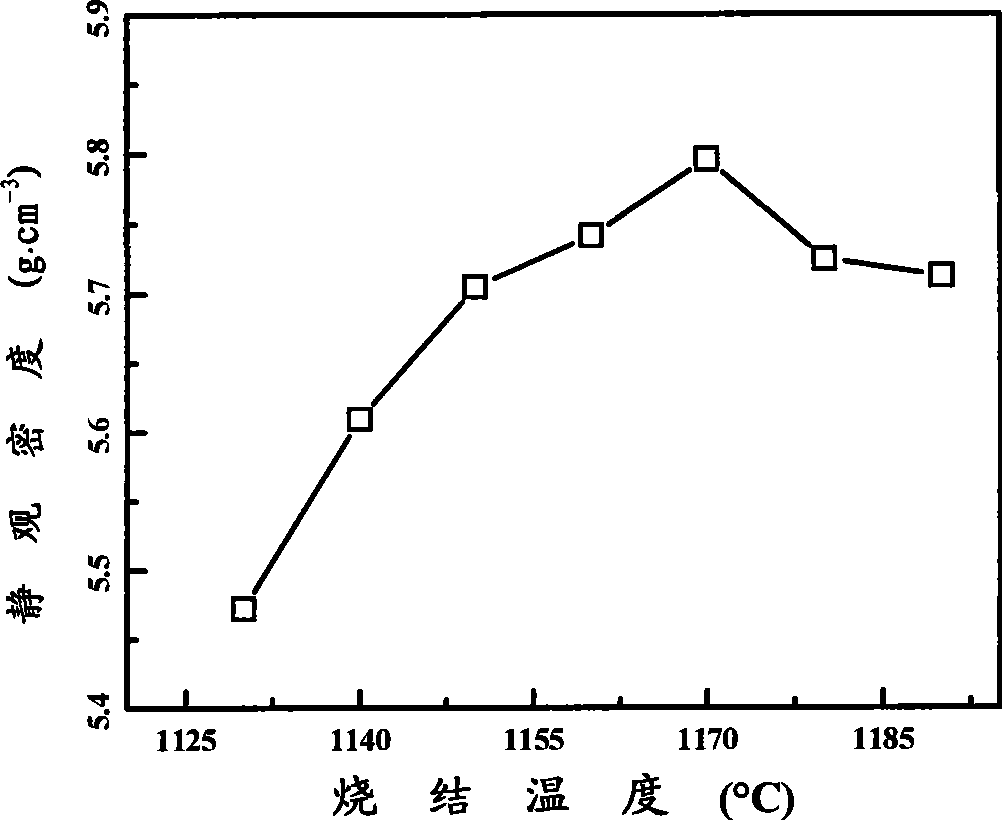

[0025] 3) Discharge the ceramic diaphragm at 720°C, heat it for 4 hours, pl...

Embodiment 2

[0028] 1) raw material anhydrous sodium carbonate, anhydrous potassium carbonate, bismuth oxide, titanium dioxide, barium carbonate and dicobalt oxide are pressed chemical formula 85Bi 1 / 2 Na 1 / 2 TiO 3 -12Bi 1 / 2 K 1 / 2 TiO 3 -3BaTiO 3 -1.5Co 2 o 3Carry out material preparation and mix, obtain mixture powder;

[0029] 2) Using absolute ethanol as the medium, ball mill the mixture powder for 8 hours, discharge and dry, extrude into a block with a pressure of 50 MPa, heat up to 800°C, and keep warm for 1 hour to pre-synthesize the block; Dehydrated alcohol is the medium ball mill for 12 hours, and the material is discharged and dried to obtain a powder, and the concentration of 18% polyvinyl alcohol binder solution accounting for 20% of the powder weight is added to the powder, and the mixture is mixed, combined, and coarsely prepared. Rolling and finishing rolling to obtain ceramic diaphragms;

[0030] 3) Discharge the ceramic diaphragm at 710°C, heat it for 2 hours, pla...

Embodiment 3

[0033] 1) raw material anhydrous sodium carbonate, anhydrous potassium carbonate, bismuth oxide, titanium dioxide, barium carbonate and dicobalt oxide are pressed chemical formula 90Bi 1 / 2 Na 1 / 2 TiO 3 -8Bi 1 / 2 K 1 / 2 TiO 3 -2BaTiO 3 -2.0Co 2 o 3 Carry out material preparation and mix, obtain mixture powder;

[0034] 2) Using absolute ethanol as the medium, ball mill the mixture powder for 8 hours, discharge and dry, extrude into a block with a pressure of 50 MPa, heat up to 800°C, and keep warm for 3 hours to pre-synthesize the block; Dehydrated alcohol is the medium ball mill for 12 hours, and the material is discharged and dried to obtain a powder, and the concentration of 18% polyvinyl alcohol binder solution accounting for 20% of the powder weight is added to the powder, and the mixture is mixed, combined, and coarsely prepared. Rolling and finishing rolling to obtain ceramic diaphragms;

[0035] 3) Discharge the diaphragm at 700°C, heat it for 2 hours, place it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com