nbt-bt crystal piezoelectric film and piezoelectric laminated structure including the film

A piezoelectric body and crystal technology, applied in the field of piezoelectric laminated structures, can solve the problem of undisclosed depolarization temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

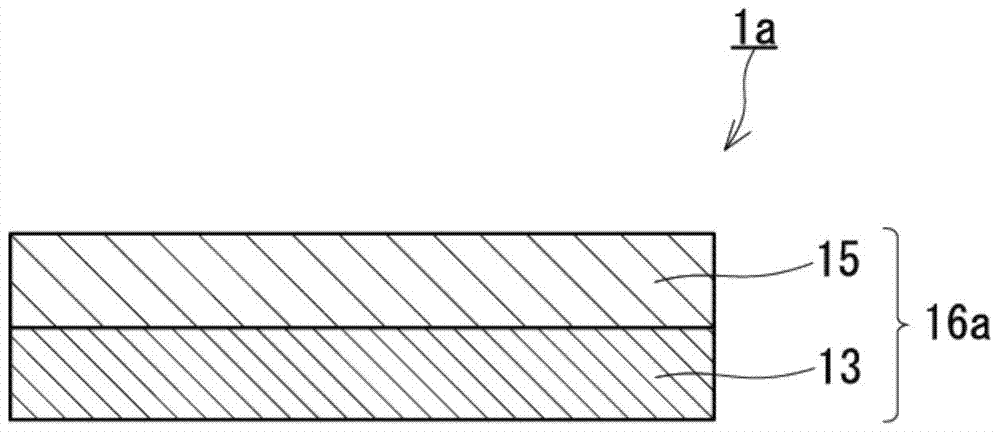

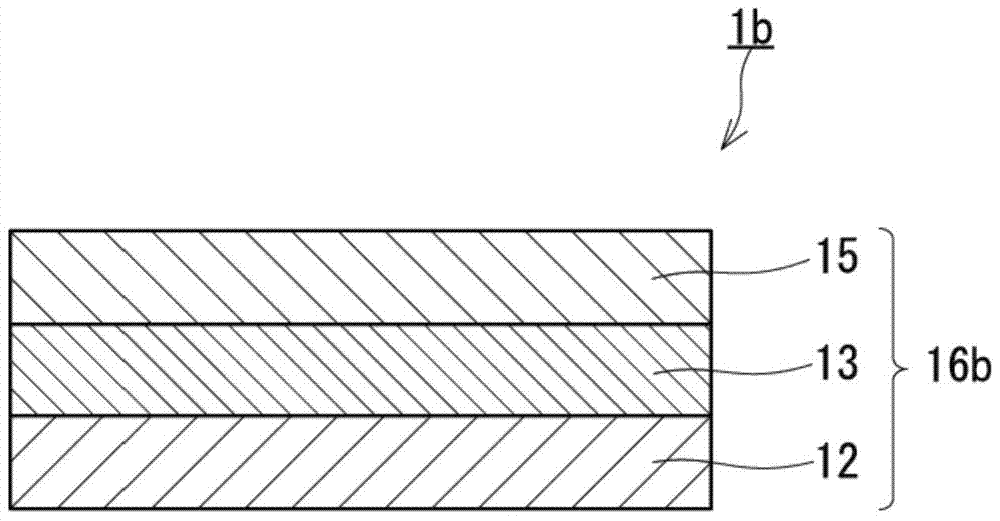

[0116] In Example A1, the Figure 1E The piezoelectric stack structure shown. [(Na, Bi) contained in the piezoelectric laminate structure of Example A1 0.93 Ba 0.07 ] TiO 3 Layer 15 has an a-axis length of 0.392 nanometers, and a c-axis length of 0.410 nanometers. The piezoelectric multilayer structure of Example A1 was produced as follows.

[0117] A platinum layer having a (111) orientation and a thickness of 100 nm was formed on the surface of a silicon single crystal substrate having a (100) orientation by RF magnetron sputtering. This platinum layer functions as the metal electrode layer 12 .

[0118] The sputtering conditions of the platinum layer are described below.

[0120] Atmosphere: Argon

[0121] RF output power: 15W

[0122] Substrate temperature: 300 degrees Celsius

[0123] Before forming the platinum layer, a titanium layer having a thickness of 2.5 nm was formed on the surface of the silicon single crystal substrate t...

Embodiment A2

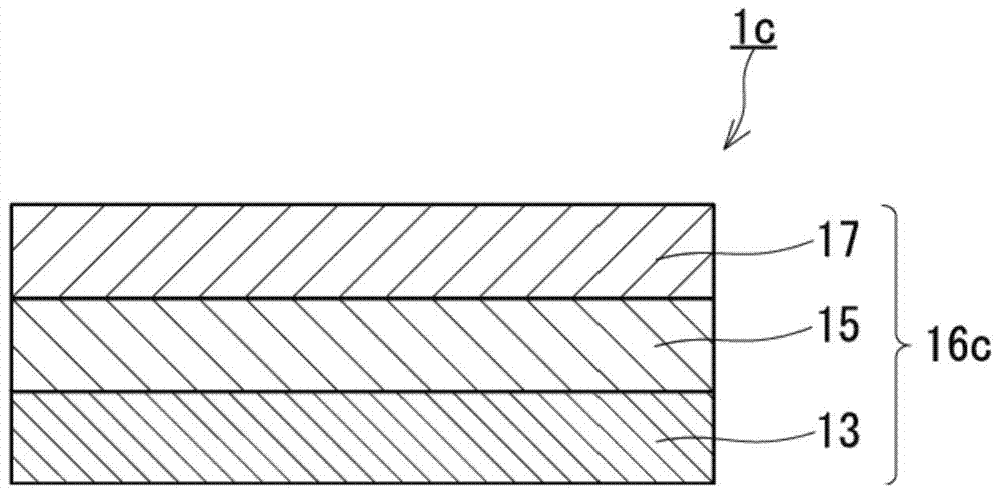

[0161] Except La 1+y Ni 1-y o 3 Except that layer 13 was formed under the condition of the substrate temperature of 275 degrees centigrade, [(Na, Bi) was produced in the same manner as in Example A1. 1-x Ba x ] TiO 3 Layer 15.

Embodiment A3

[0163] Except La 1+y Ni 1-y o 3 Except that layer 13 was formed under the condition of the substrate temperature of 225 degrees centigrade, [(Na, Bi) was produced in the same manner as in Example A1. 1-x Ba x ] TiO 3 Layer 15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com