Patents

Literature

211 results about "Sodium niobate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

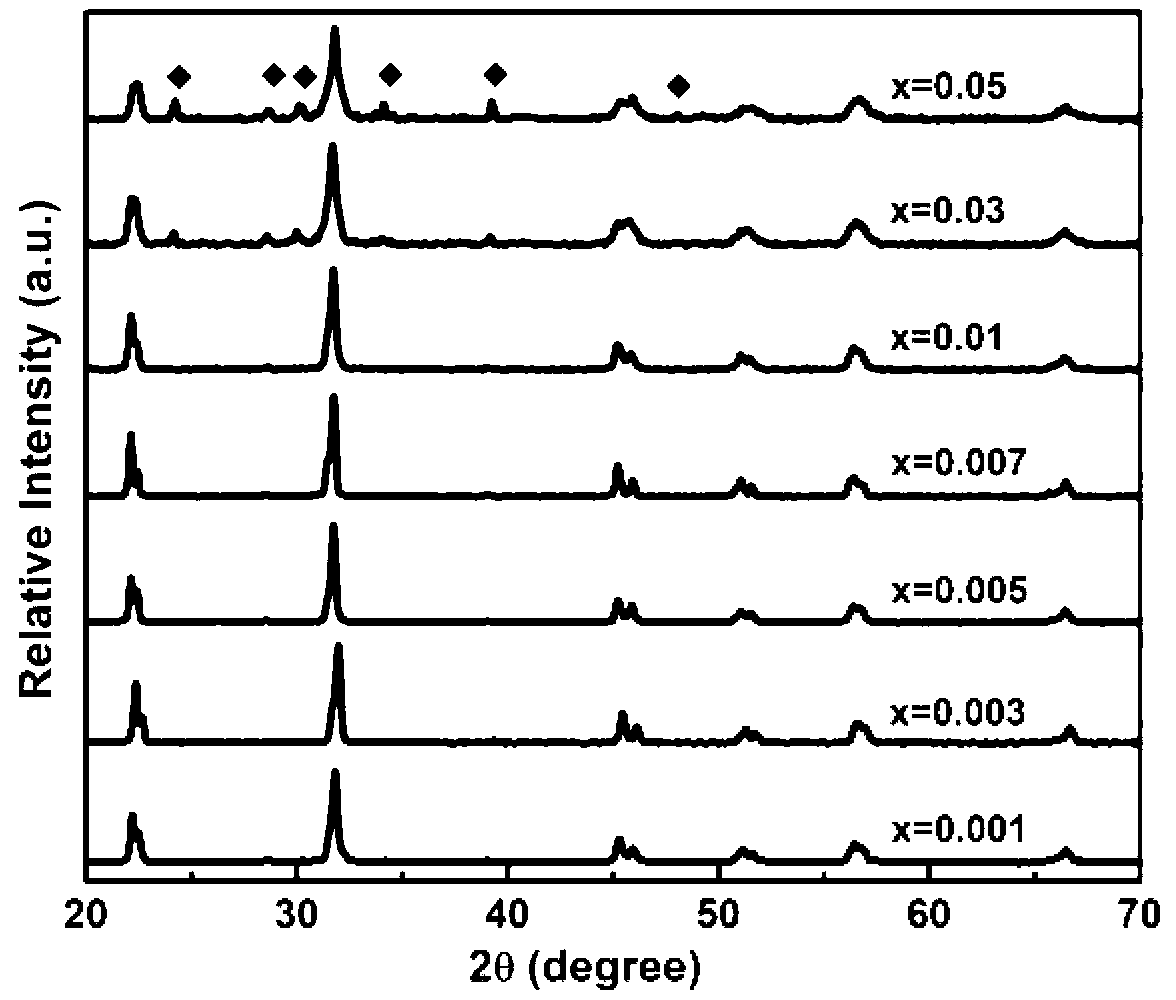

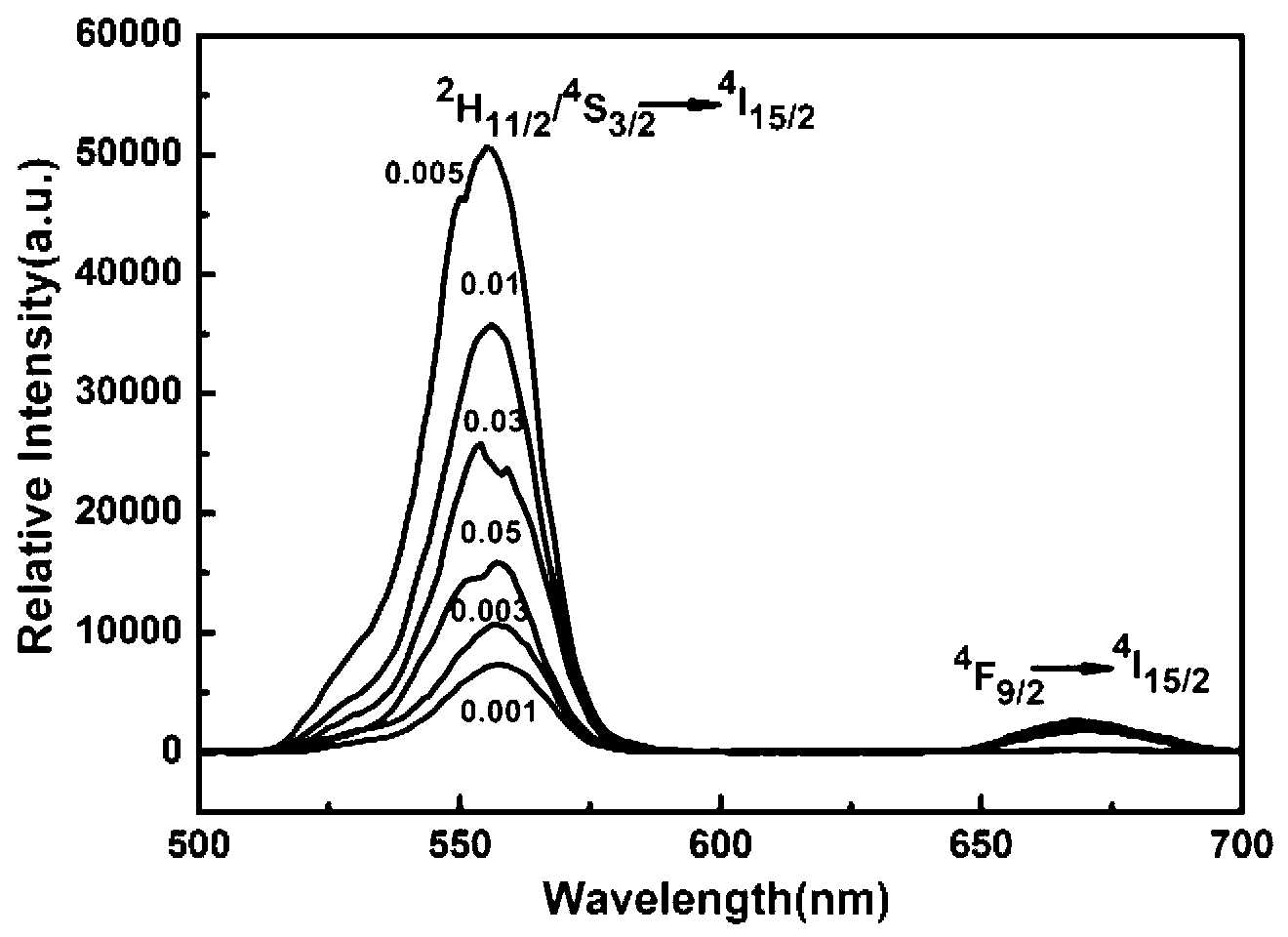

Potassium-sodium niobate based oxide up-conversion luminescent material and preparation method thereof

InactiveCN103265954AUpconversion Luminescence RealizationWith piezoelectricLuminescent compositionsRare-earth elementUpconversion luminescence

The invention discloses a potassium-sodium niobate based oxide up-conversion luminescent material with a chemical formula of (Na0.5+sigmaK0.5-yAy)1-x-zMxYbzNbO3:Phi C or (Na0.5-yAyK0.5+sigma)1-x-zMxYbzNbO3: Ph iC, wherein M is selected from one or more of Li, Na, K, Tl and Ag; C is selected from one or more of Li, Na, K, Tl and Ag; A is one or more of K, Na and Li; a value range of x is not smaller than 0.00001 and not bigger than 0.15, the value range of y is not smaller than 0 and not bigger than 0.5, the value range of z is not smaller than 0 and not bigger than 0.35, the value range of sigma is not smaller than 0 and not bigger than 0.1 and the value range of Phi is not smaller than 0 and not bigger than 0.1. The luminescent material disclosed by the invention further has up-conversion luminescent characteristic in addition to piezoelectric performances, ferroelectric performances and dielectric performances, belongs to photoelectric multifunctional materials, and not only can be applied to the piezoelectric field, but also can be applied to the sensor field, the information storage field, the biological detection field and the biomedical field.

Owner:TONGJI UNIV

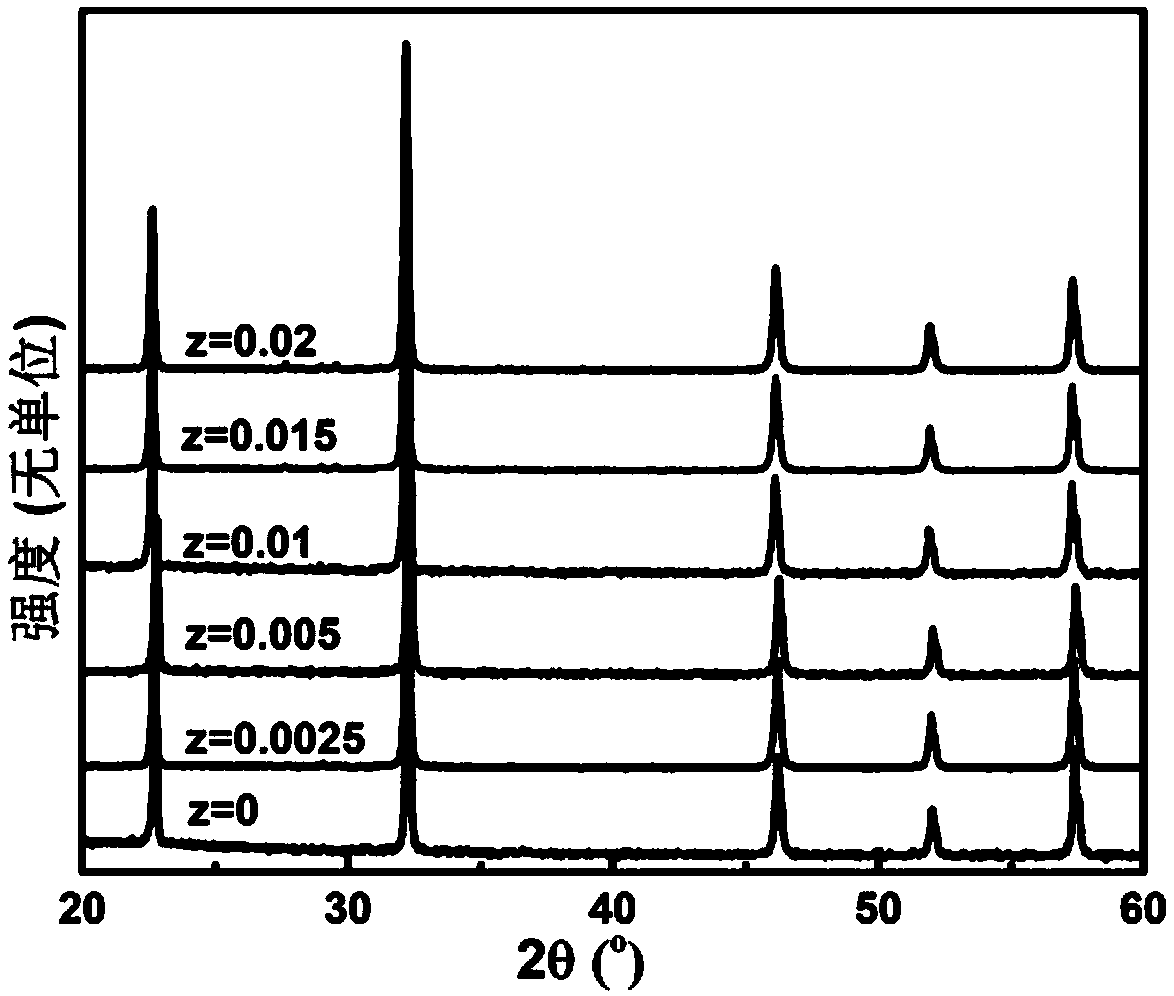

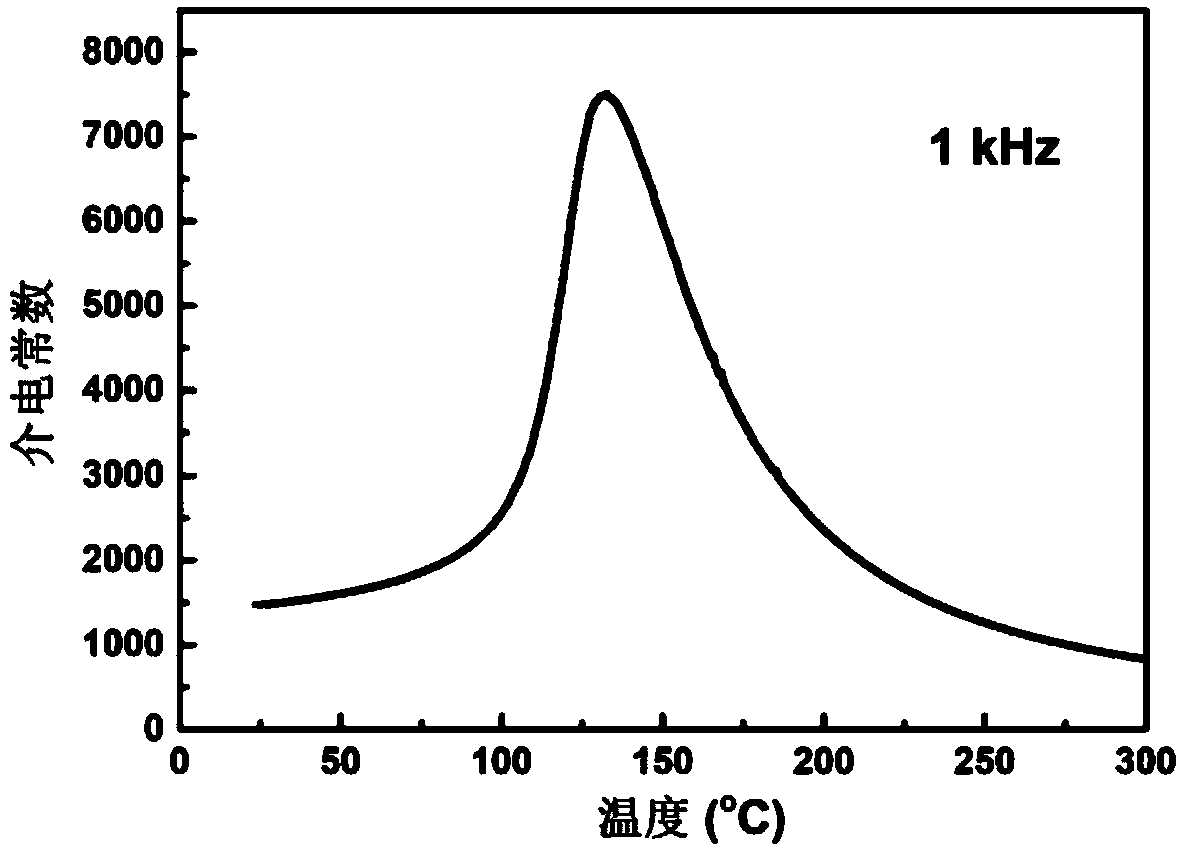

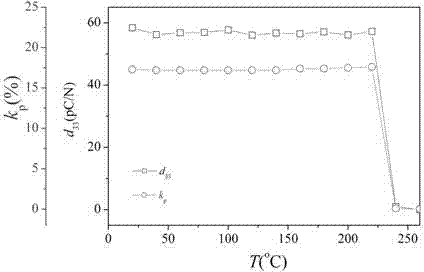

Thermal stable sodium niobate-based lead-free piezoelectric ceramic and preparation method thereof

The invention relates to a thermal stable sodium niobate-based lead-free piezoelectric ceramic and a preparation method thereof. The composition is shown as a general formula of (1-z)[(1-x-y)NaNbO3+xMI+yABO3]+zMII; in addition, the x is greater than 0.08 but smaller than 0.15; the y is greater than 0 but smaller than 0.1; the z is greater than 0 but smaller than 0.1; the MII is one or several kinds of metal oxides. The thermal stable sodium niobate-based lead-free piezoelectric ceramic belongs to the field of a functional ceramic material. The ceramic can be obtained by using a conventional piezoelectric ceramic preparation technology and by using industrial raw materials; the prepared sodium niobate-based lead-free piezoelectric ceramic composition has good piezoelectric performance, goodtemperature stability and good process stability, can realize the replacement on partial conventional lead-containing piezoelectric ceramic, and has the practicability.

Owner:HEFEI UNIV OF TECH

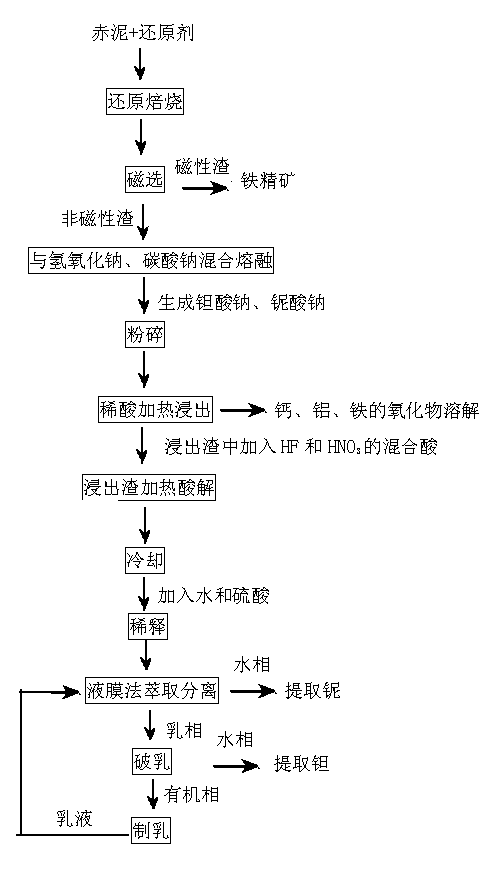

Method for comprehensive recovery of tantalum and niobium from red mud

The invention provides a method for comprehensive recovery of tantalum and niobium from red mud. The method comprises the following steps: mixing red mud with a reducing agent to carry out reducing roasting, and then carrying out magnetic separating to obtain magnetic iron ore concentrate and non-magnetic slag; fusing the non-magnetic slag and a mixture of sodium hydroxide and sodium carbonate at 500-800 DEG C to transform tantalum and niobium into sodium tantalum oxide and sodium niobate; crushing the molten massive melt, and heating, agitating and leaching by using a certain amount of acid, so that main ingredients of the non-magnetic slag, such as calcium, aluminum, silicon and a little of oxide of iron are dissolved, and the complicated compounds of tantalum and niobium are also decomposed to be transformed into hydroxide, but still reserved in the slag to be gathered; heating and dissolving the acid-leaching slag in a mixed acid of HF and HNO3; adding water and H2SO4 to dilute after cooling; carrying out tantalum and niobium separation and extraction on the diluted solution by adopting a liquid-film method. By adopting the method, not only can tantalum and niobium in the red mud be gathered, but also separate recovery and extraction of tantalum and niobium can be achieved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

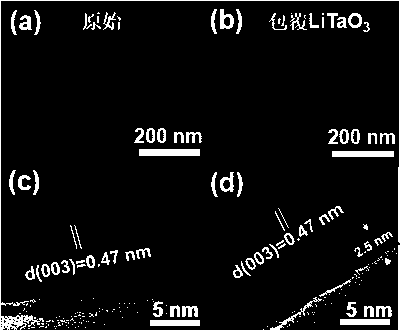

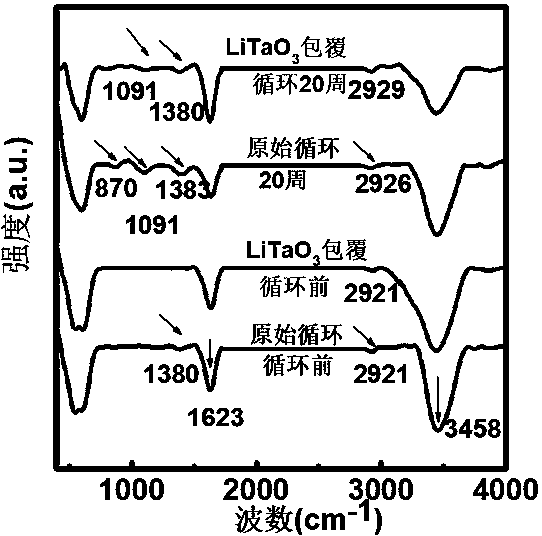

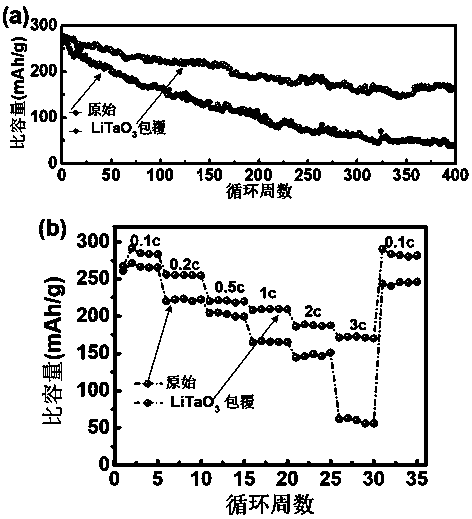

Lithium ion battery anode material coated with piezoelectric material on surface and preparation method thereof

PendingCN109921000AEasy to operateGood repeatabilityCell electrodesSecondary cellsBarium titanatePotassium

The invention provides a lithium ion battery anode material coated with piezoelectric material on the surface and a preparation method thereof. The surface of the battery anode material is coated witha layer of piezoelectric material with piezoelectric effect; the piezoelectric material comprises any one or more of barium titanate, lithium niobate, sodium niobate, lithium tantalite, sodium-potassium metaniobate and barium-strontium metaniobate with piezoelectric effect. The piezoelectric characteristic of the piezoelectric material is utilized to realize a coating modification function for the anode active materials so as to ensure that the volume phase structures of the anode active materials are not influenced and damaged, the growth of solid-electrolyte interface membranes is suppressed, and the diffusion speeds of active material-coating layer interface lithium ions are improved, thereby effectively improving the structure stability and electrochemical cycle performance of the lithium ion battery anode material, improving the pyrolysis temperature of the anode material and then enhancing the safety performance of the lithium ion batteries in the using process.

Owner:HENAN UNIVERSITY

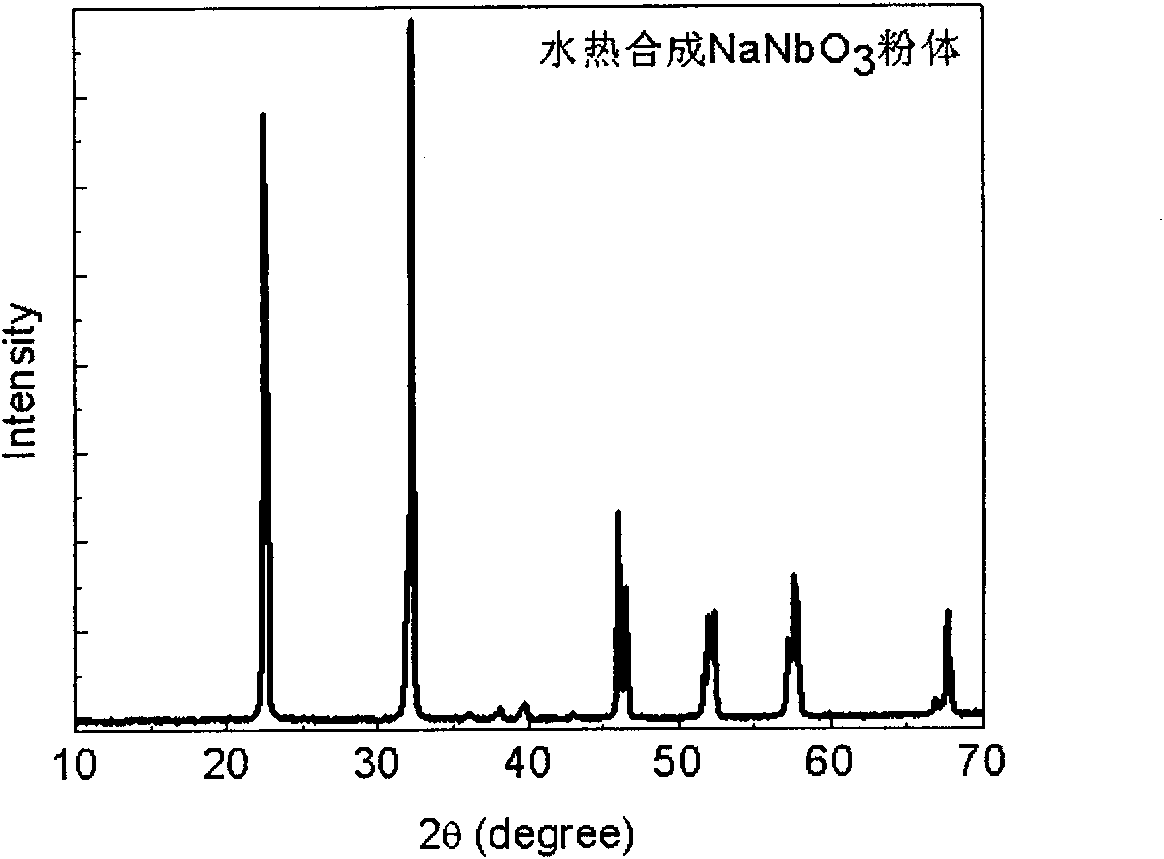

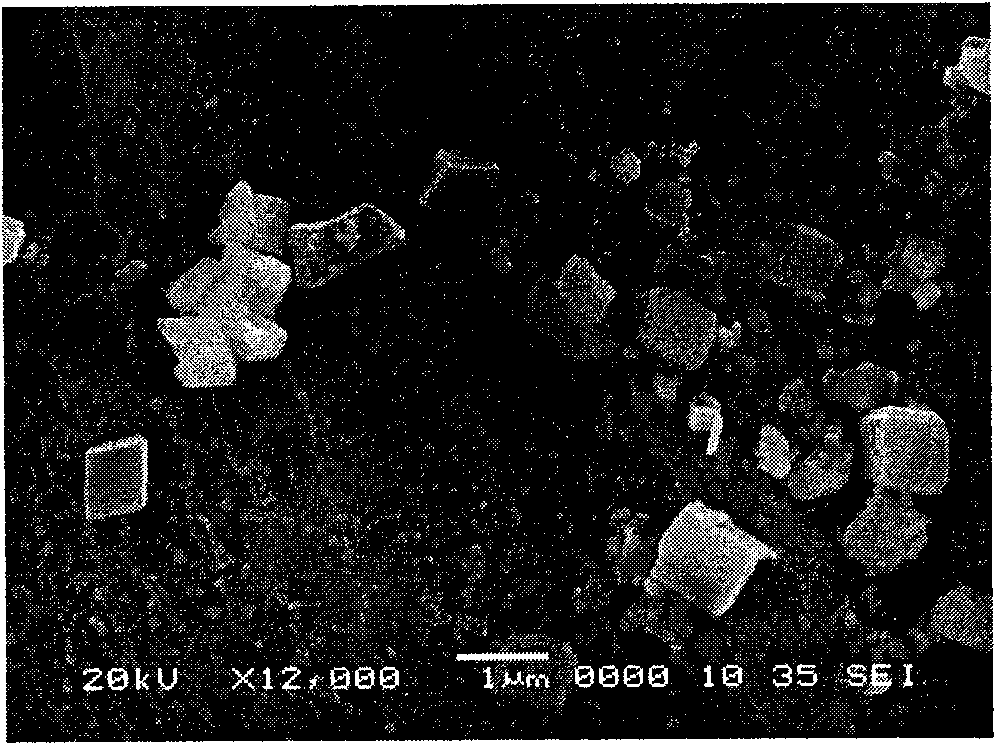

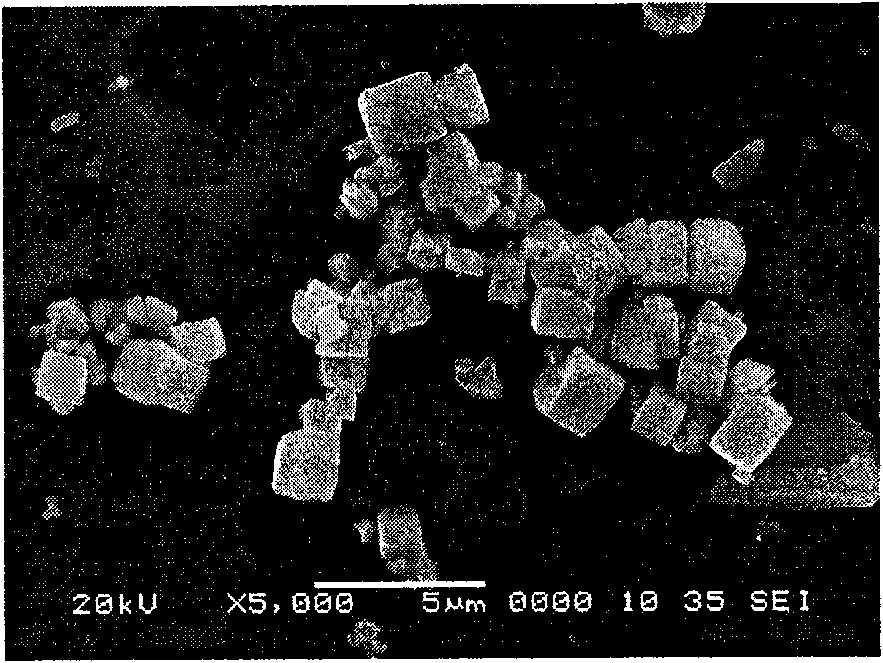

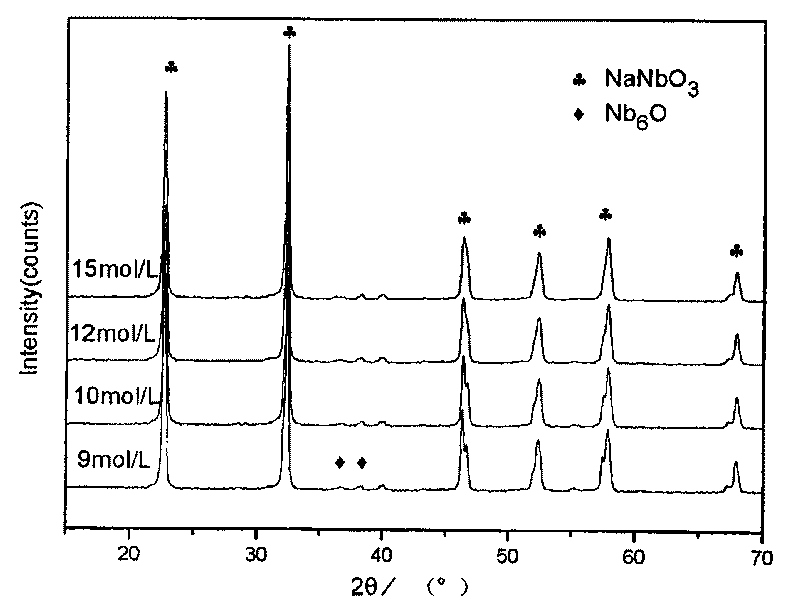

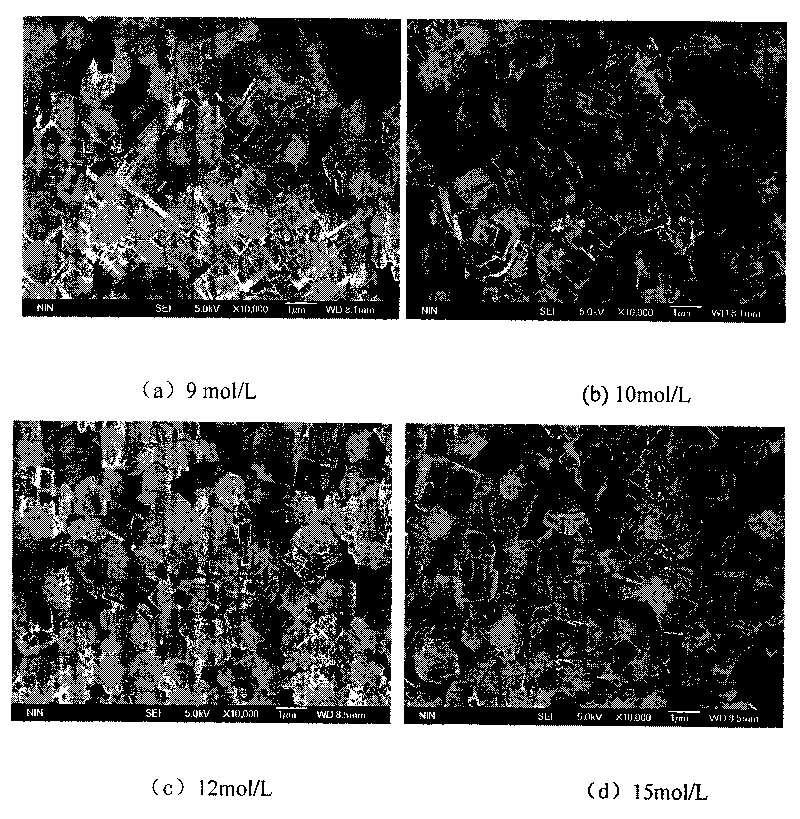

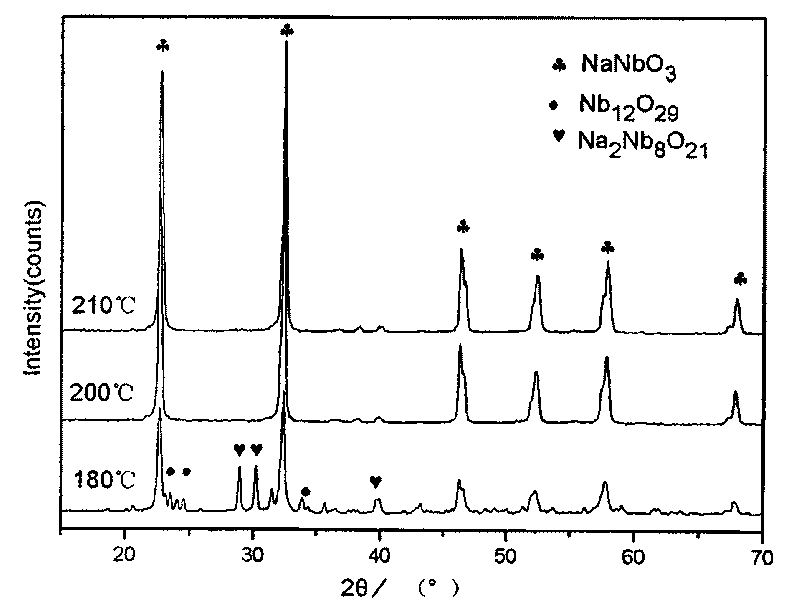

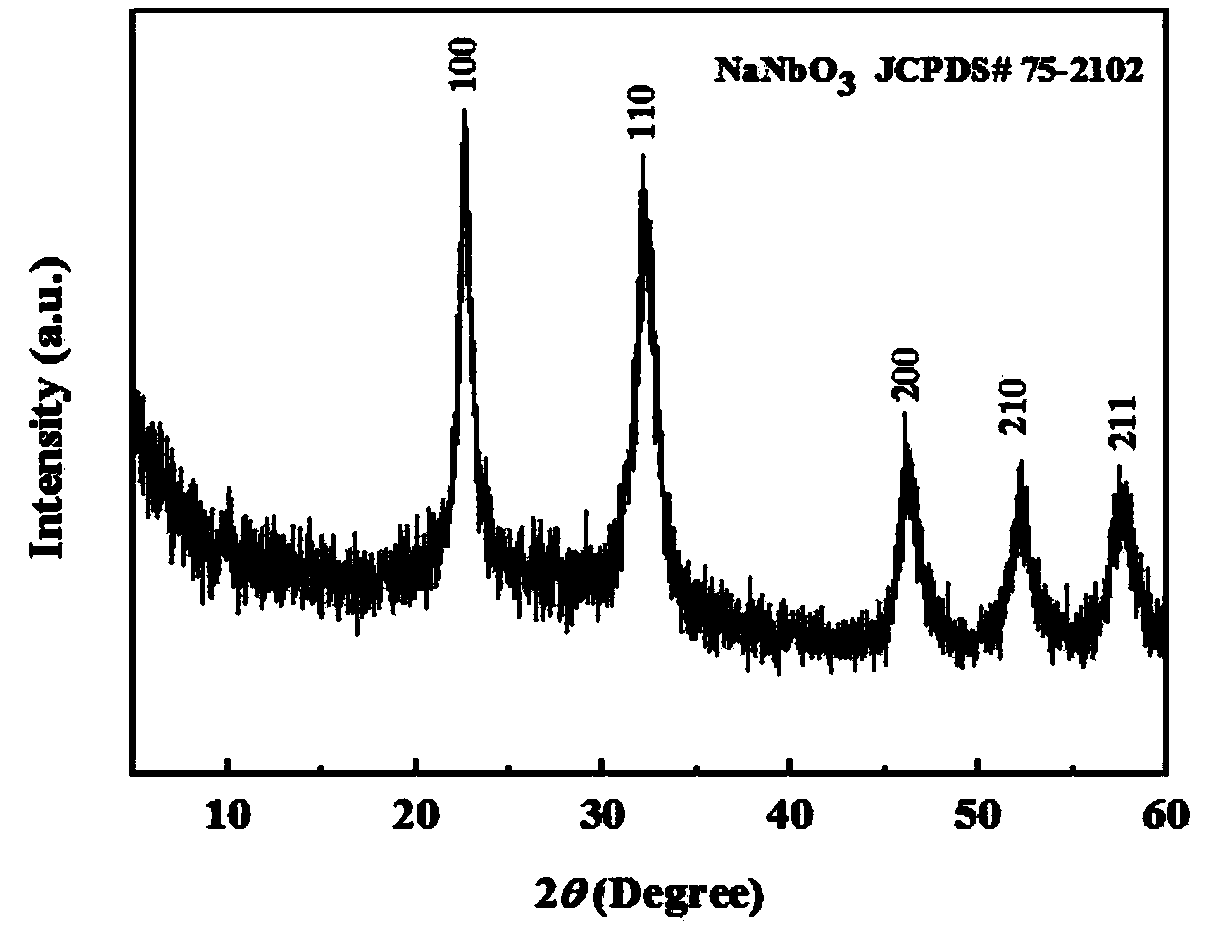

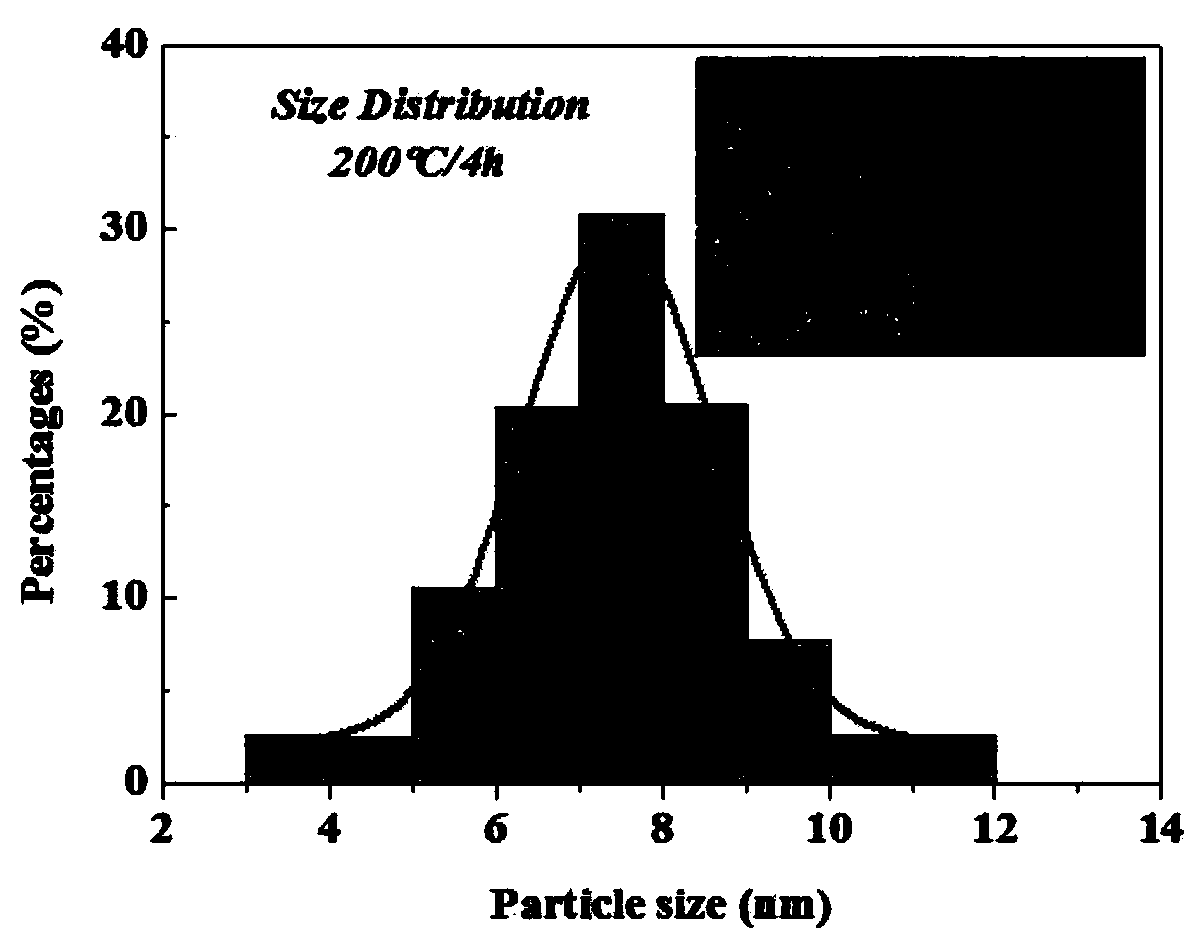

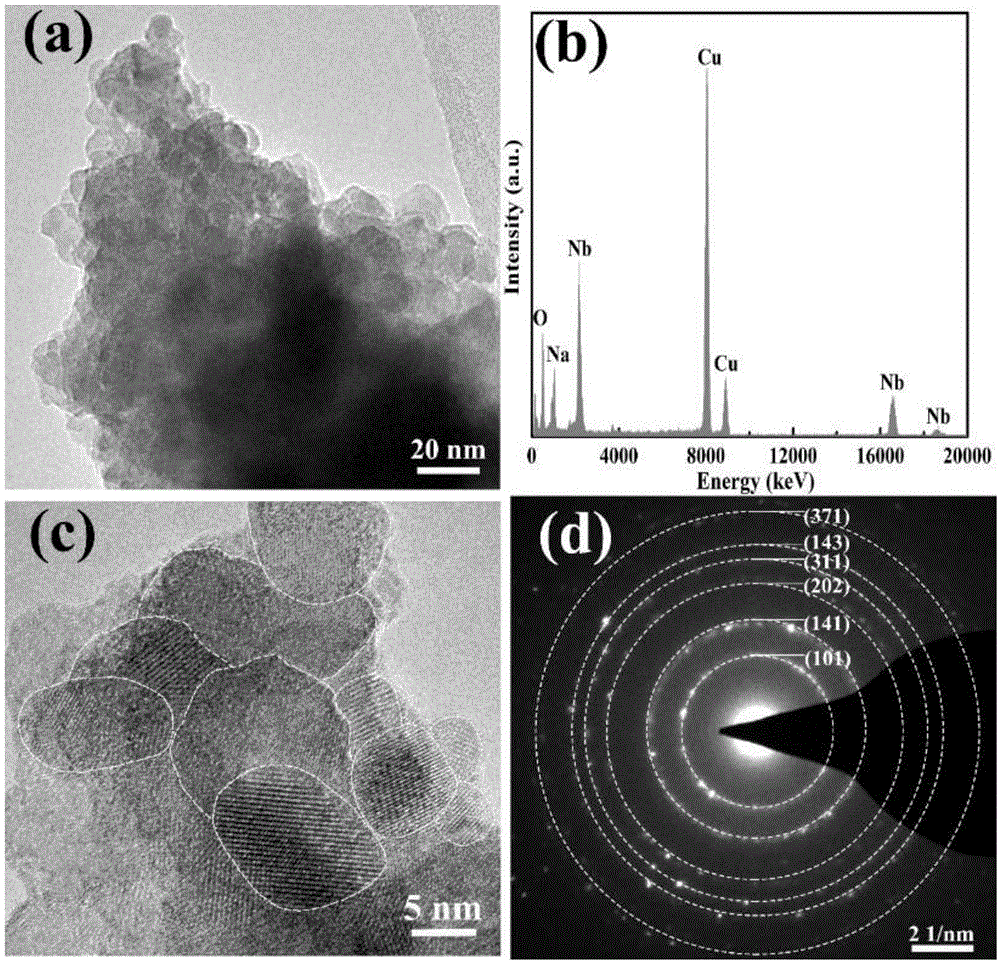

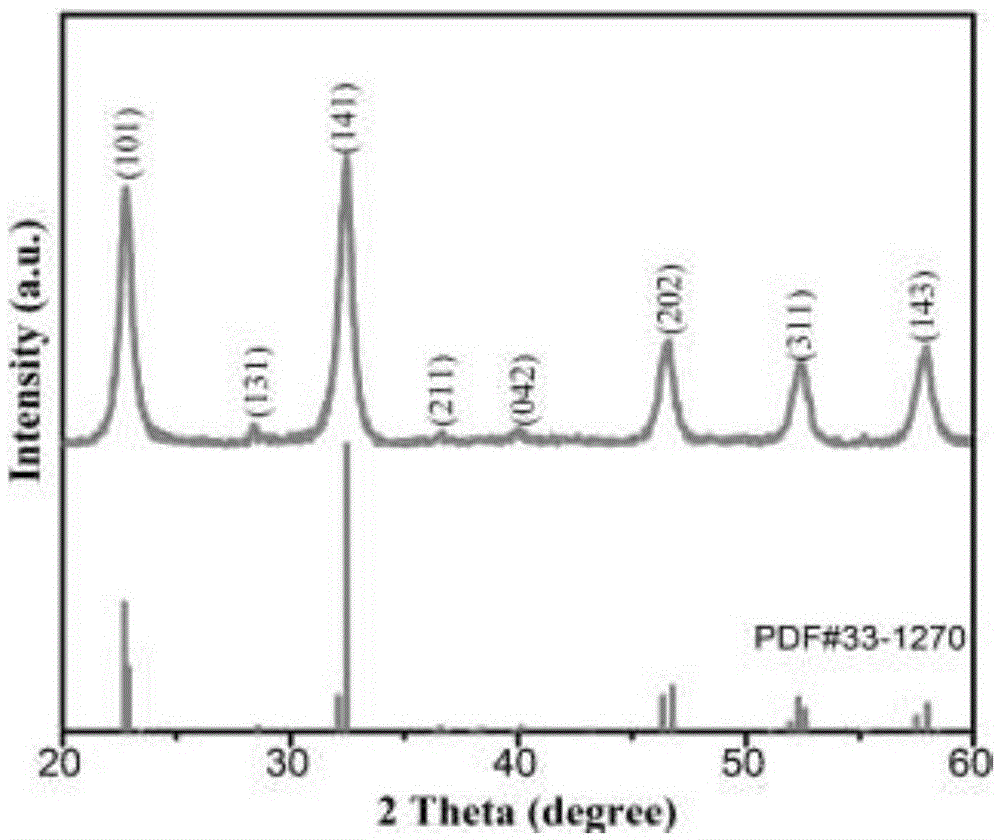

Hydrothermal synthesis method for sodium niobate powder

The invention discloses a hydrothermal synthesis method for sodium niobate powder, which comprises the following steps: putting niobium pentaoxide and sodium hydroxide in a molar ratio of 0.05-10 into an autoclave, and adding deionized water into the autoclave according to a filling rate between 50 and 90 percent to adjust the concentration of the sodium hydroxide to between 0.1 and 15 mol / L; sealing the autoclave, putting the autoclave into a pit furnace or an oven, raising the temperature to between 120 and 240 DEG C in a temperature rise rate of 1 to 5 DEG C per minute, preserving heat for 4 to 72 hours, and then cooling along with the furnace; and taking out and opening the autoclave, pouring an obtained product into a beaker, repeatedly filtering and washing with deionized water until the washed solution is neutral, putting obtained powder into an oven, and baking at a temperature of between 40 and 100 DEG C for 6 to 24 hours. The method is simple, saves energy, reduces emission, has low cost, and is suitable for mass production; and the prepared sodium niobate powder has high purity, good fluidity, narrow particle size distribution, low degree of particle agglomeration, and perfect crystal growth.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

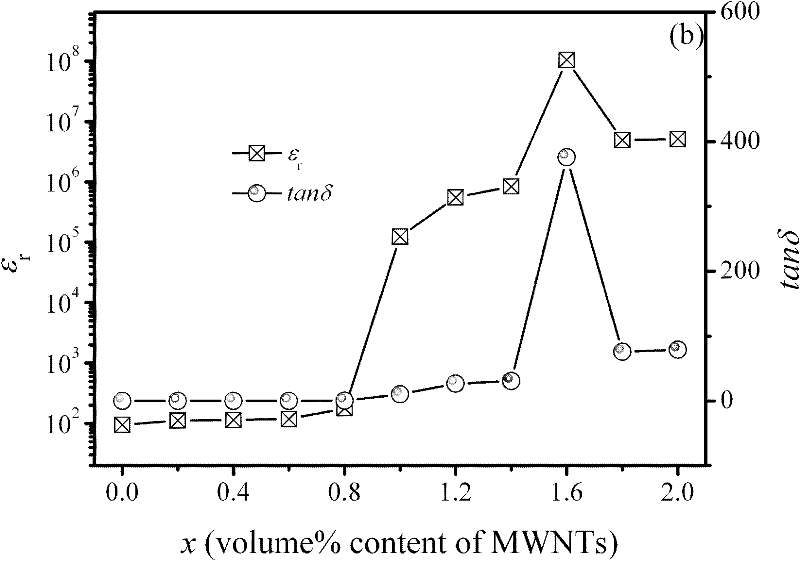

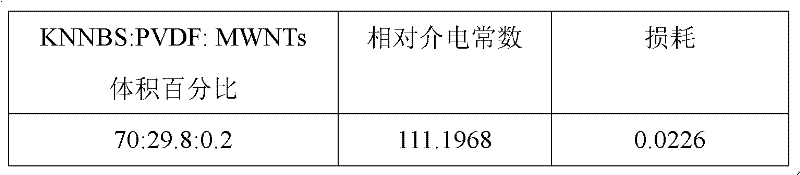

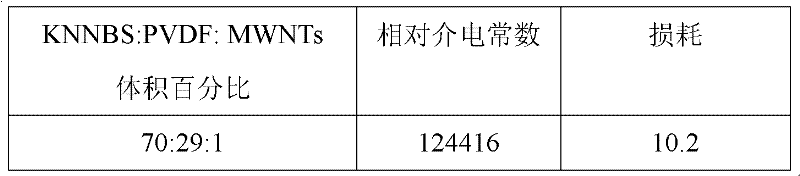

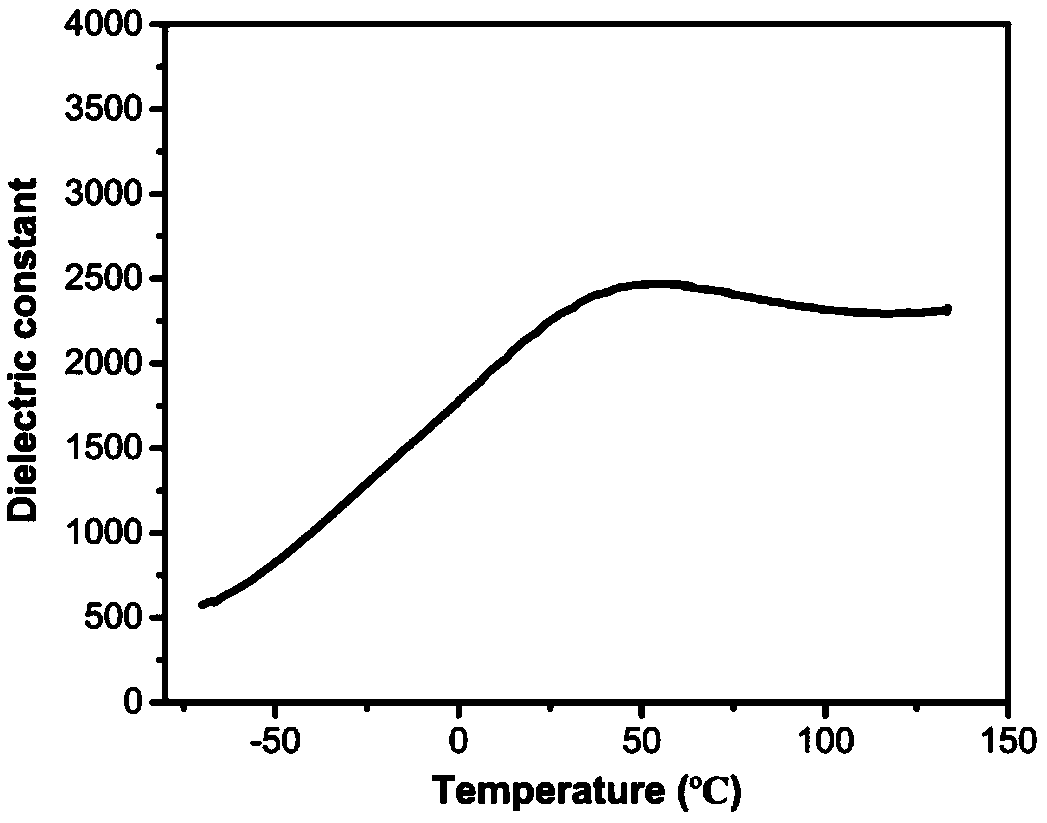

Niobate-series leadless piezoelectric ceramic-polymer three-phase composite material with high dielectric constant

The invention discloses a niobate-series leadless piezoelectric ceramic-polymer three-phase composite material with a high dielectric constant and a preparation method thereof. The method comprises the following steps of: burdening according to a formula, i.e., (1-x)(LiaNabK1-a-b)(Nb1-cSbc)O3-xABO3-yM and preparing sodium niobate kalium-based leadless piezoelectric ceramic powder by adopting the conventional solid phase method; and mixing ceramic powder, a polymer and a multiwall carbon nanotube into composite material powder according to a designed proportion, adding an organic solvent for dissolving the polymer, performing ultrasonic dispersion, adding ethanol for precipitating the polymer, filtering, performing cold press molding on the composite material powder, heating, and sputtering a gold electrode on the surface of the molded composite material powder to obtain a niobate-series leadless piezoelectric ceramic-polymer-multiwall carbon nanotube three-phase composite material with a high dielectric constant. The relative dielectric constant of the composite material can be up to 105-108 at 1kHz, and the three-phase composite material has a good application prospect.

Owner:SICHUAN UNIV

Copper oxide-doped potassium-sodium niobate antibacterial piezoelectric ceramic implant as well as preparation and application of implant

InactiveCN107721420AImprove stabilityImprove mechanical propertiesBiocideFungicidesCopper oxideSodium niobate

The invention belongs to the technical field of antibacterial implant materials, and discloses a copper oxide-doped potassium-sodium niobate antibacterial piezoelectric ceramic implant as well as preparation and application of the implant. The method comprises the following steps: (1) adding a solvent, niobium pentoxide, sodium carbonate and potassium carbonate into a ball milling device for ballmilling, standing, drying, calcining, and grinding into powder, to obtain potassium-sodium niobate precursor powder; (2) adding a solvent, copper oxide and the potassium-sodium niobate precursor powder into the ball milling device for ball milling, standing, drying, and calcining, to obtain copper oxide-doped potassium-sodium niobate ceramic powder; (3) evenly mixing the copper oxide-doped potassium-sodium niobate ceramic powder with a binder, granulating, forming, discharging glue, performing dense sintering, to obtain a ceramic sheet; and (4) polarizing the ceramic sheet, to obtain the copper oxide-doped potassium-sodium niobate antibacterial piezoelectric ceramic implant. The method is simple, and the prepared implant has a good antibacterial effect and stability.

Owner:SOUTH CHINA UNIV OF TECH

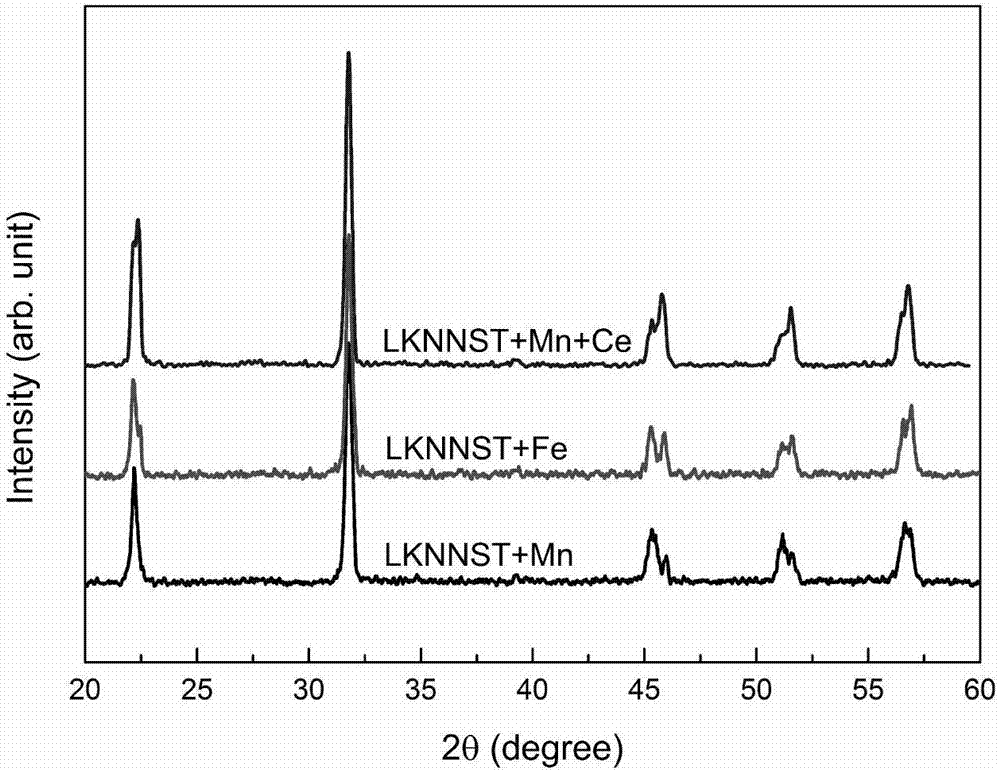

High-mechanical-strength potassium-sodium niobate based lead-free piezoelectric ceramic material, preparation method of material and application of material

InactiveCN107382318ASolve the problem of poor sinterabilityAchieving controllable equipmentPiezoelectric/electrostrictive/magnetostrictive devicesOxidePorosity

The invention provides a high-mechanical-strength potassium-sodium niobate based lead-free piezoelectric ceramic material, a preparation method of the material and an application of the material. The potassium-sodium niobate based lead-free piezoelectric ceramic material comprises [Li0.06(K0.47-xNa0.47+x)][(Nb0.893Sb0.057Ta0.05)O3, TMO (transition metal oxide) and REO (rare earth oxide), wherein the TMO is MnO2, Fe2O3, Ni2O3, CuO, Cr2O3 or Co2O3, and the REO is Ce2O3, Nd2O3 or Yb2O3. Li<+> co-substitutes A-site K<+> and Na<+>, Sb<5+> and Ta<5+> co-substitutes B-site Nb<5+>, synergistic modification is realized by transition / rare-earth metal oxide coping, the sintering property of the potassium-sodium niobate based ceramics is improved, and controllable preparation of low-porosity dense ceramics is realized, so that the potassium-sodium niobate based lead-free piezoelectric ceramic material has good mechanical strength and piezoelectric performance.

Owner:HUBEI UNIV

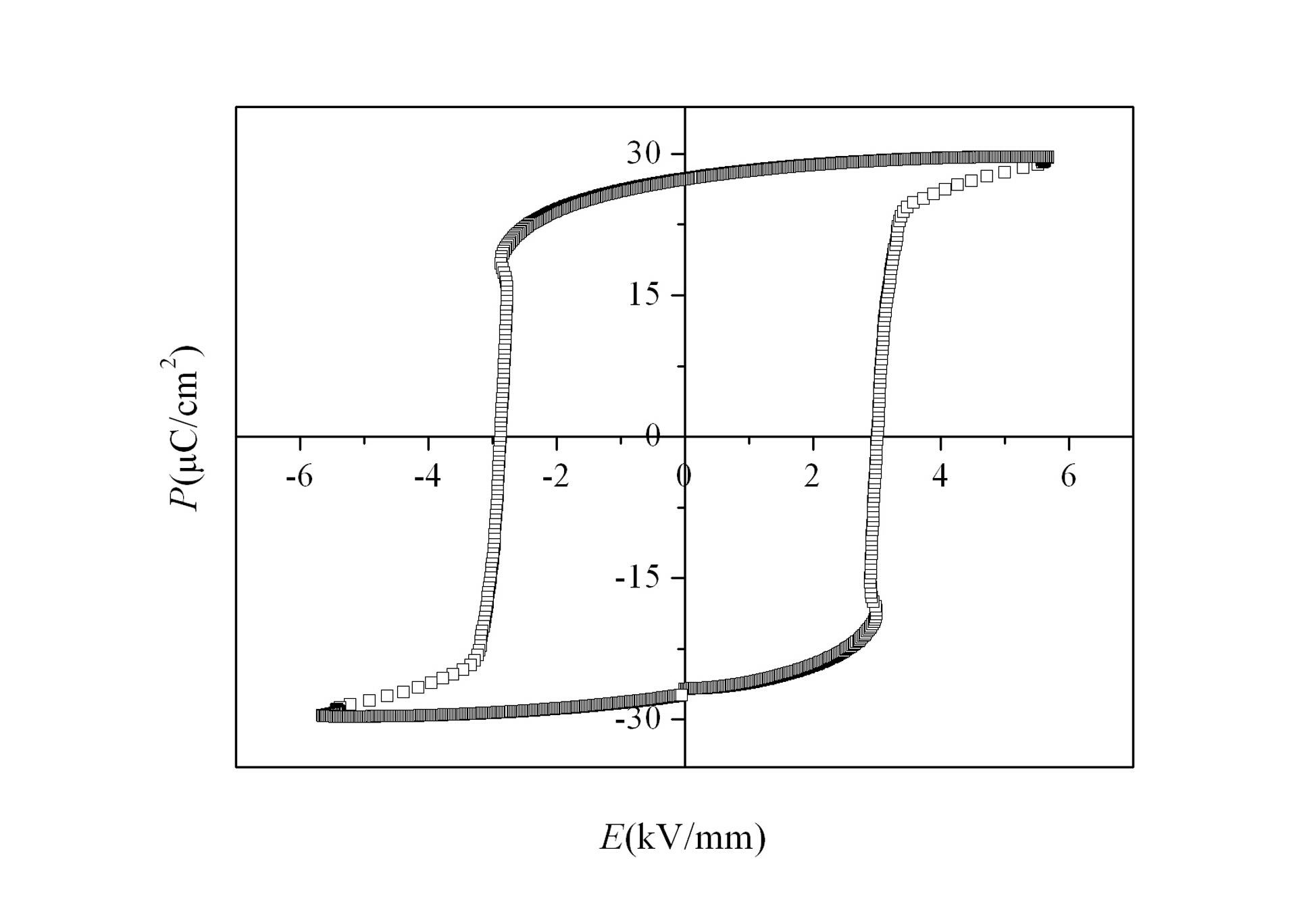

Sodium niobate barium-bismuth-potassium titanate lead-free piezoelectric ceramic composition

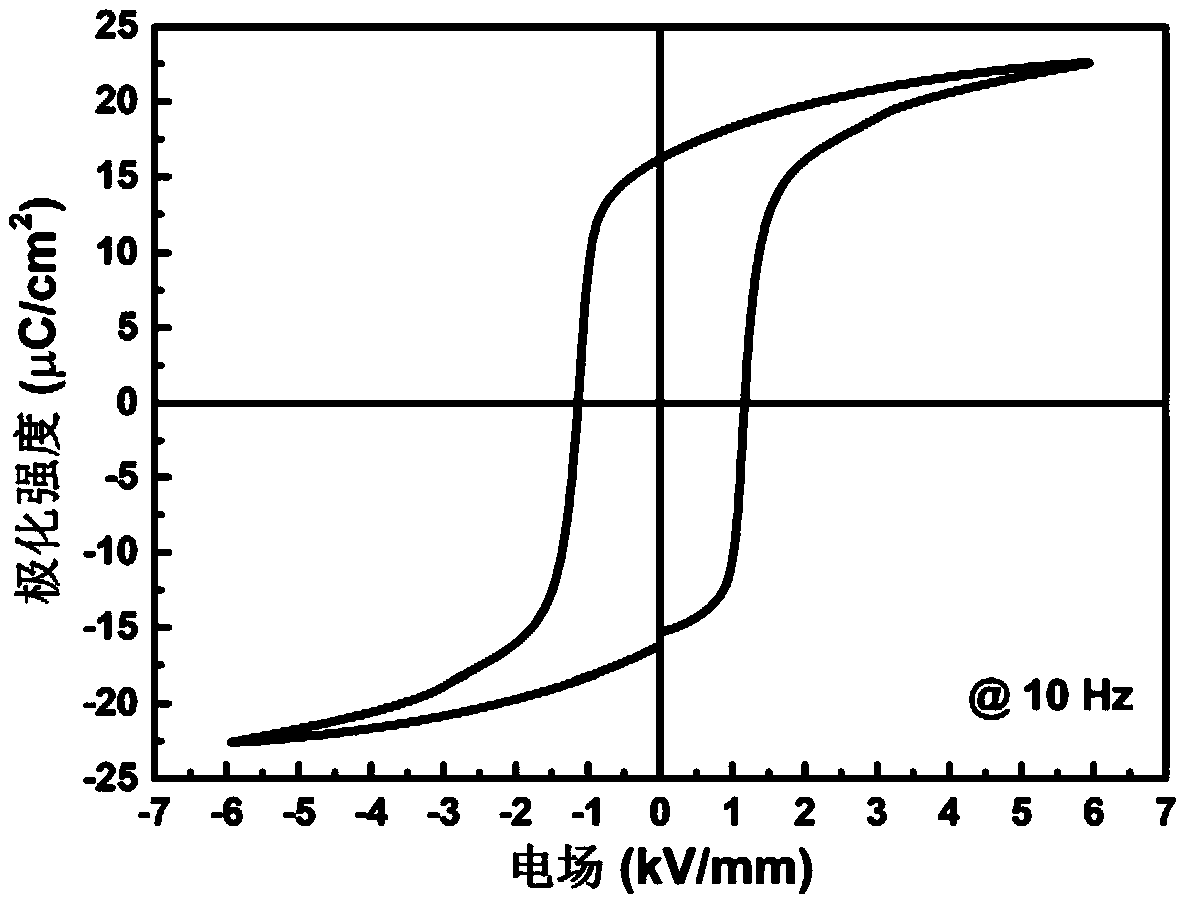

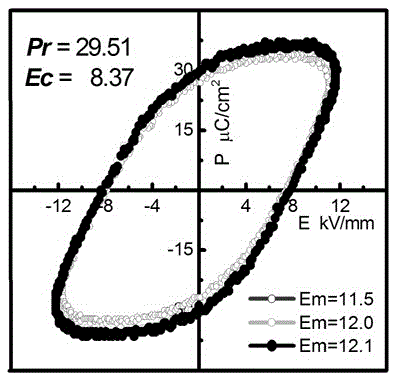

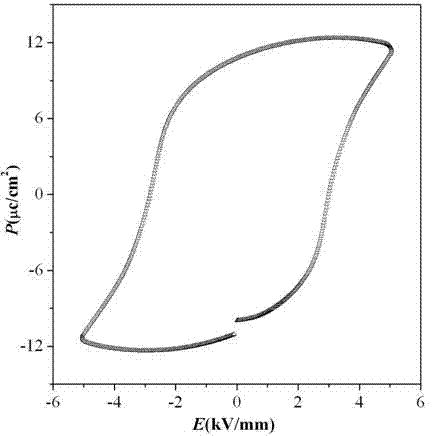

InactiveCN102515762AExcellent piezoelectric ferroelectric propertiesImprove ferroelectric propertiesOxygenSodium niobate

The invention provides a novel sodium niobate barium-bismuth-potassium titanate lead-free piezoelectric ceramic composition. The composition comprises perovskite antiferroelectric NaNbO3 and strong ferroelectric Ba1-y(Bi0.5K0.5)yTiO3. A general formula of the composition is (1-x)NaNbO3-xBa1-y(Bi0.5K0.5)yTiO3, wherein x and y in the formula satisfy the following equations: 0.025<=x<=0.25 and 0

Owner:SICHUAN NORMAL UNIVERSITY

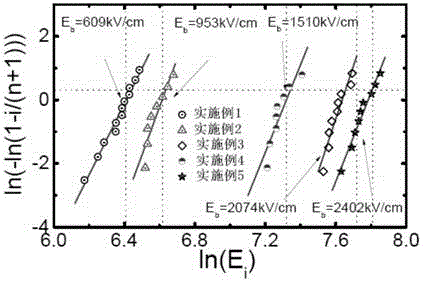

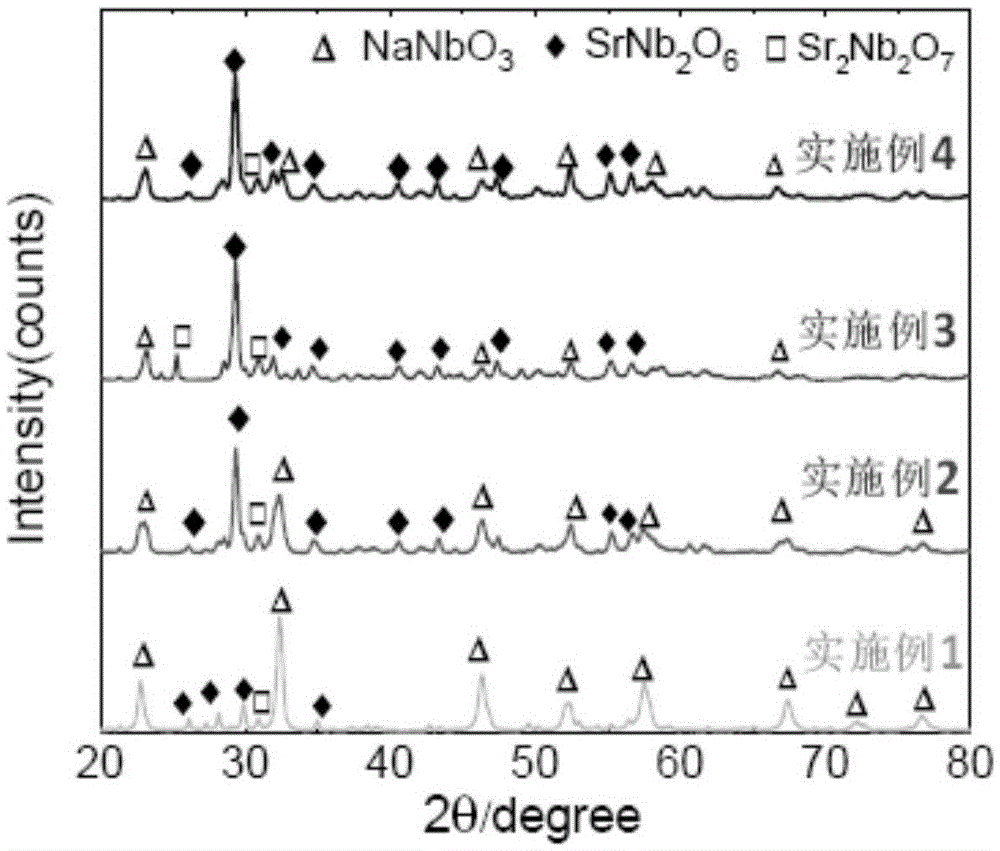

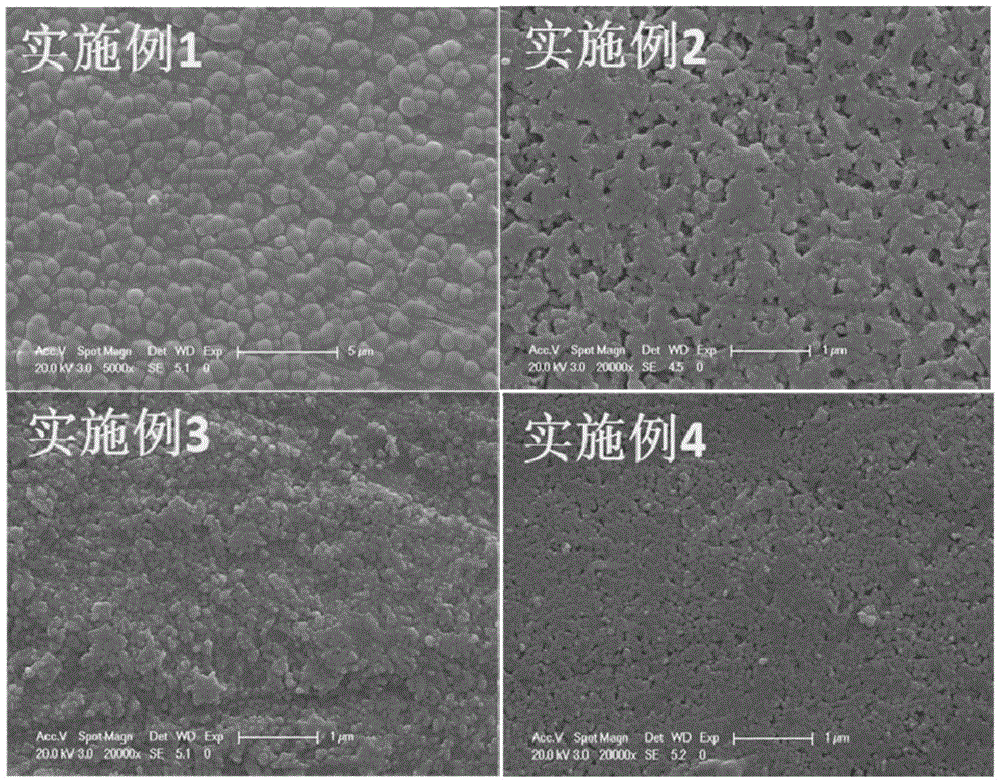

High-energy-storage-density strontium-sodium-niobate-base glass ceramic energy storage material, and preparation and application thereof

InactiveCN105645772ASimple structureImproved breakdown fieldFixed capacitor dielectricHigh energyGlass sheet

The invention relates to a high-energy-storage-density strontium-sodium-niobate-base glass ceramic energy storage material, and preparation and application thereof. The strontium-sodium-niobate-base glass ceramic energy storage material comprises SrO, Na2O, Nb2O5 and SiO2 in a mole ratio of 42x:42(1-x):28:30. The preparation method comprises the following steps: weighing the raw materials, mixing by ball milling, drying, and carrying out high-temperature melting to obtain a high-temperature melt; and casting the high-temperature melt into a preheated metal mold, carrying out stress-relief annealing to obtain transparent glass, cutting the transparent glass into glass sheets with the thickness of 0.9-1.2mm, and carrying out controlled crystallization to obtain the product. The product is applicable to an energy storage capacitor material. Compared with the prior art, the preparation method provided by the invention is simple, does not need complicated after-treatment steps, and is economical and practical. The prepared glass ceramic energy storage material has higher breakdown field strength resistance (2402kV / cm), and the energy storage density of the material is obviously enhanced to 16.86J / cm<3>. The strontium-sodium-niobate-base glass ceramic energy storage material is applicable to an energy storage capacitor material.

Owner:TONGJI UNIV

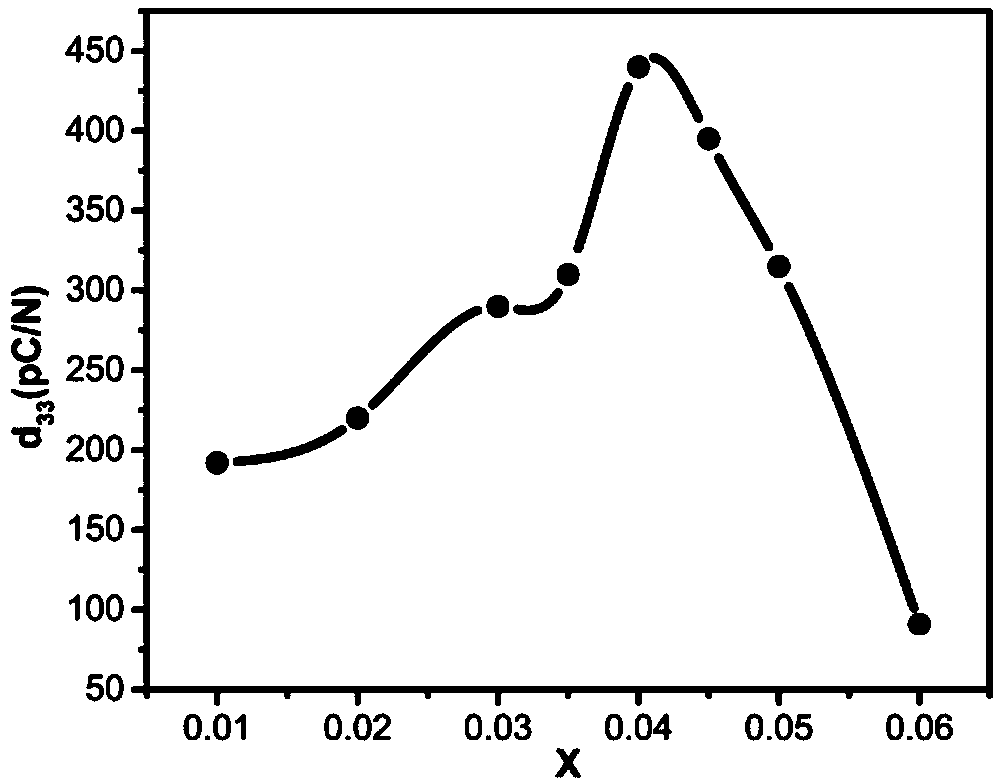

Lead-free piezoelectric ceramic material with high piezoelectricity and high electrogenerated strain and preparation method thereof

ActiveCN109608195ALower the holding temperatureHigh piezoelectric coefficientChemical compositionHigh pressure

The invention relates to a lead-free piezoelectric ceramic material with high piezoelectricity and high electrogenerated strain and a preparation method thereof. The chemical composition of the material accords with the chemical general formula (1-x)(K0.5Na0.5)0.98Ag0.02(Nb0.96Sb0.04) O3-x (Bi0.5Na0.5) ZrO3, wherein x represents the percentage of (Bi0.5Na0.5) ZrO3 in the potassium-sodium niobate-based lead-free piezoelectric ceramic, and x is more than or equal to 0.01 and less than or equal to 0.06. Compared with the prior art, the preparation method has the advantages of simplicity, good stability and low cost. The lead-free piezoelectric ceramic material obtained by the preparation method has excellent piezoelectric performance and electrogenerated strain, the d33 reaches 440 pC / N, thed33* reaches 553 pm / V, good temperature stability is shown, and the lead-free piezoelectric ceramic material can be used for piezoelectric sensors, piezoelectric motors and high-precision displacementcontrollers, the material has good application prospect.

Owner:TONGJI UNIV

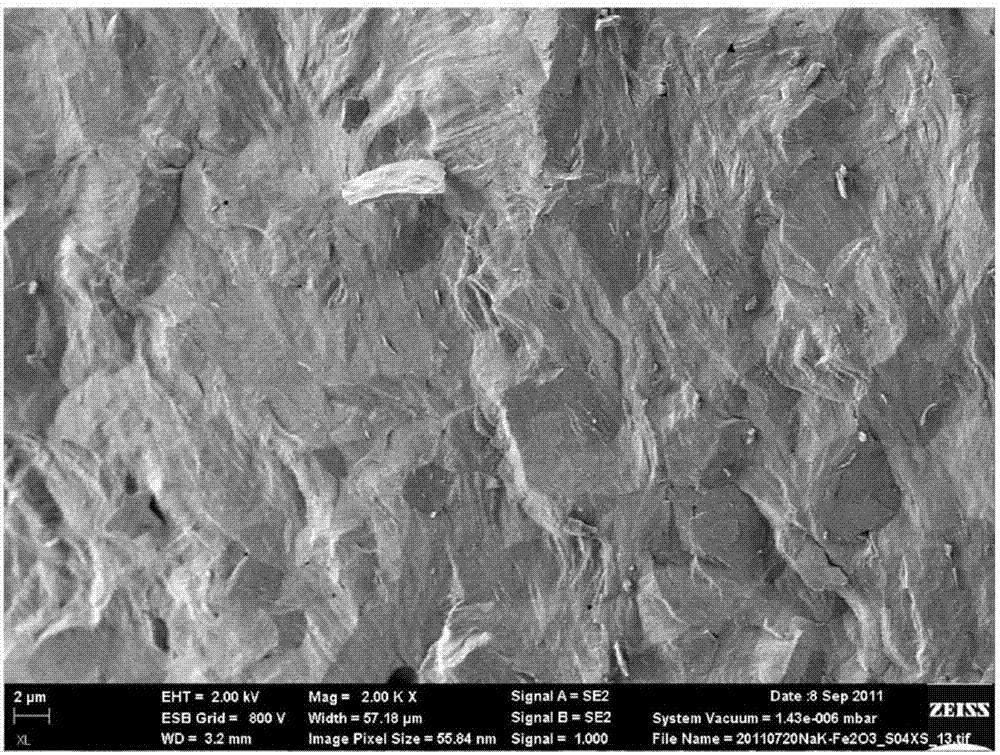

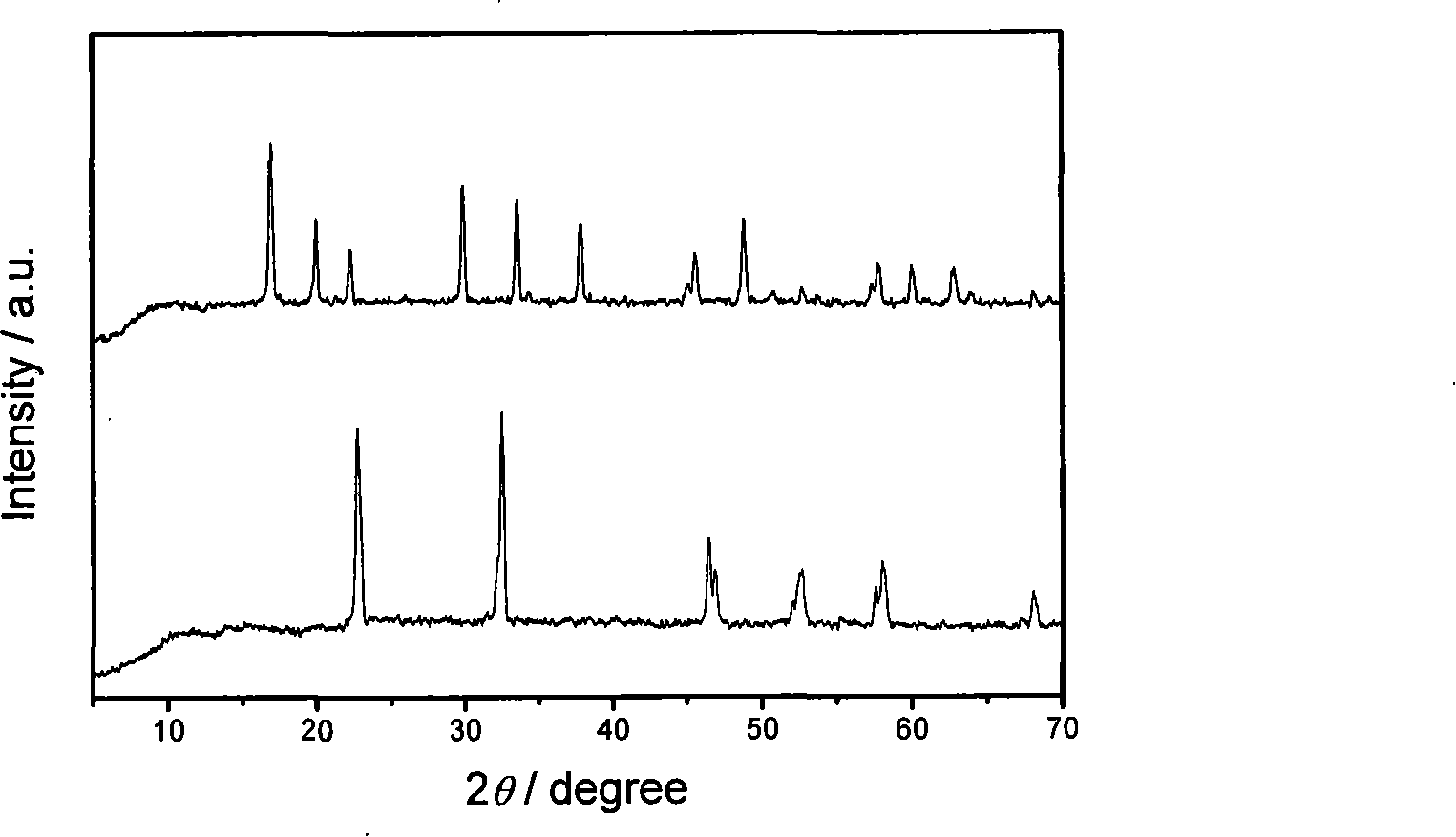

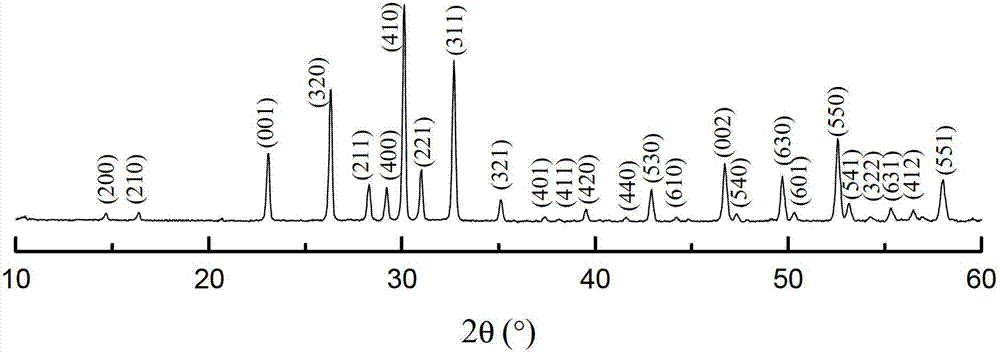

Controllable preparation method of orthorhombic-phase rhombohedral-phase sodium niobate having high Curie point

The invention belongs to the field of preparing inorganic functional materials, in particular relates to a preparing process for controlled systemization of rhombohedral phase sodium niobate powders and orthorhombic sodium niobate powders in the micro-growing environment which is adjusted by dentate organic amine under hydrothermal condition. The method comprises steps of employing the most common niobium pentoxide and sodium hydroxide as raw materials, adjusting the mole ratio of the niobium pentoxide to the sodium hydroxide and systemizing the rhombohedral phase sodium niobate and the orthorhombic sodium niobate in hydrothermal reaction system of adding the organic amine. The method has the advantages that the process is simple and convenient in operation and low in preparing cost, the prepared products are uniform in morphology and good in dispersity. The prepared rhombohedral phase sodium niobate is better in thermal stability, higher in Curie temperature and sound in ferroelectric property, which can be used for piezoelectric transducer, non-volatile memory and optical device.

Owner:DALIAN UNIV OF TECH

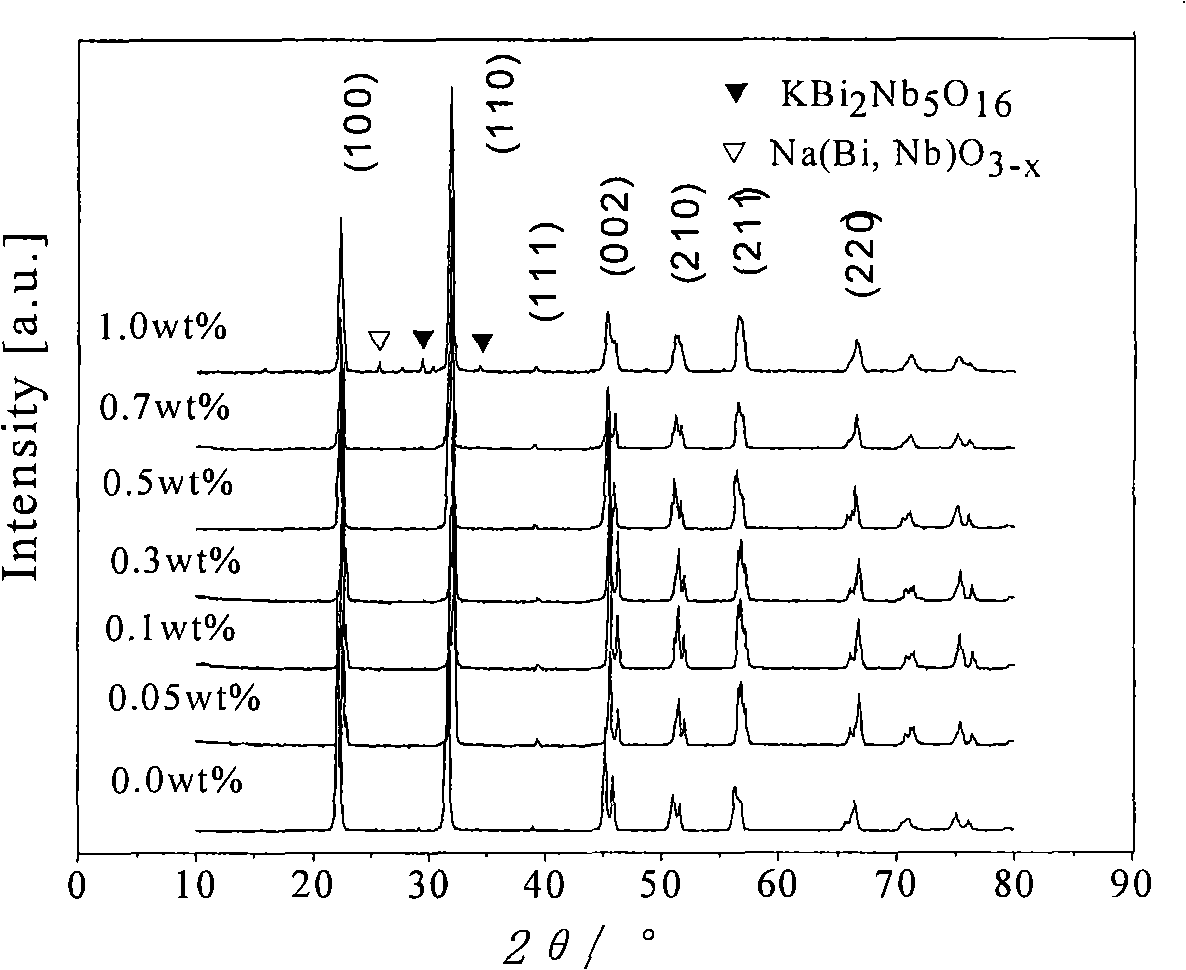

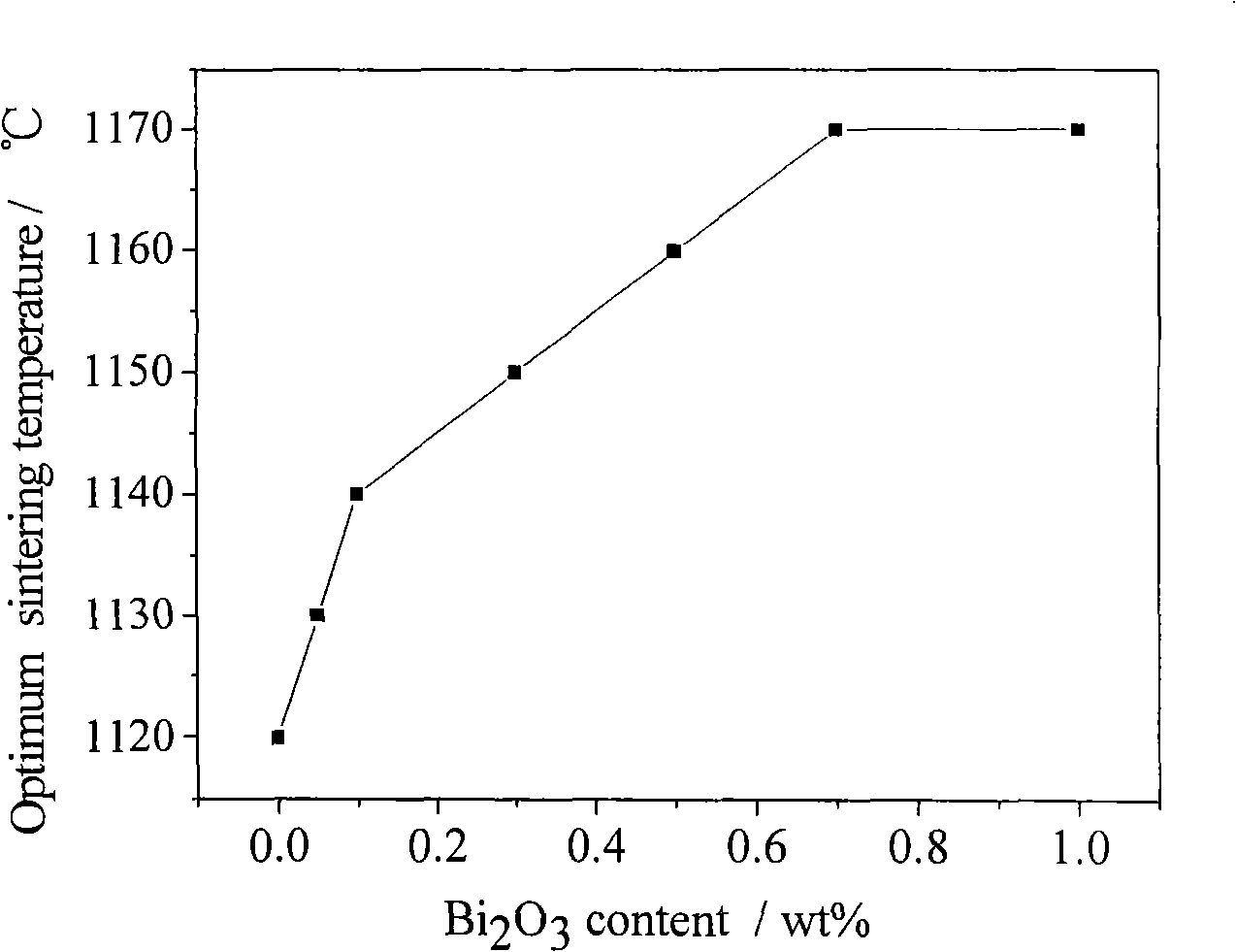

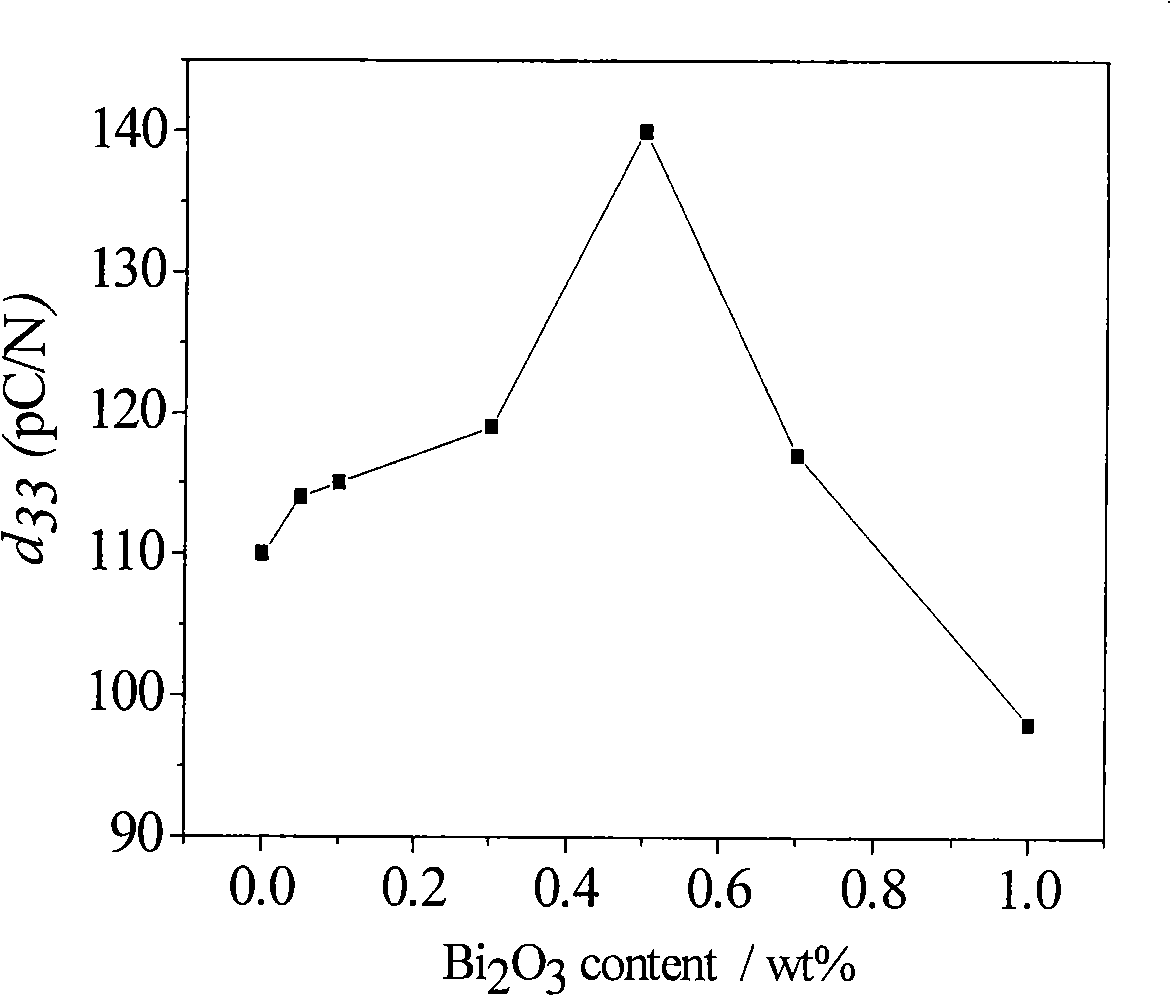

Potassium-sodium niobate-based leadless piezoelectric material and preparation thereof

InactiveCN101302106AImprove sintering propertiesHigh degree of densificationSilver electrodeDrain current

The invention discloses a piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate and a preparing method, which strengthens the ferroelectric performance of potassium-sodium niobate ceramic and further improves the piezoelectric performance. The material of the invention comprises anhydrous potassium carbonate, natrium carbonicum calcinatum, niobium pentaoxide and dibismuth trioxide, the stoichiometric proportion of the lead-free piezoelectric ceramic is (K0.5 Na0.5) Nb3 + x weight percent Bi 2O3, wherein the x is more than or equal to 0 and less than or equal to 1, the piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate is obtained through mixture making, drying and burnishing, granulation, molding, sintering and after polarization by a silver electrode; therefore, the densification of the ceramic is improved, polarized drain current of the ceramic is reduced, and the polarization process is carried out more easily; moreover, the piezoelectric material adopts the material from a conventional process and industry, has the characteristics of good process stability and no pollution.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing sodium niobate powder

InactiveCN101696035AHeating evenlyFast heating rateChemical industryNiobium compoundsDistilled waterSodium niobate

Owner:SHAANXI UNIV OF SCI & TECH

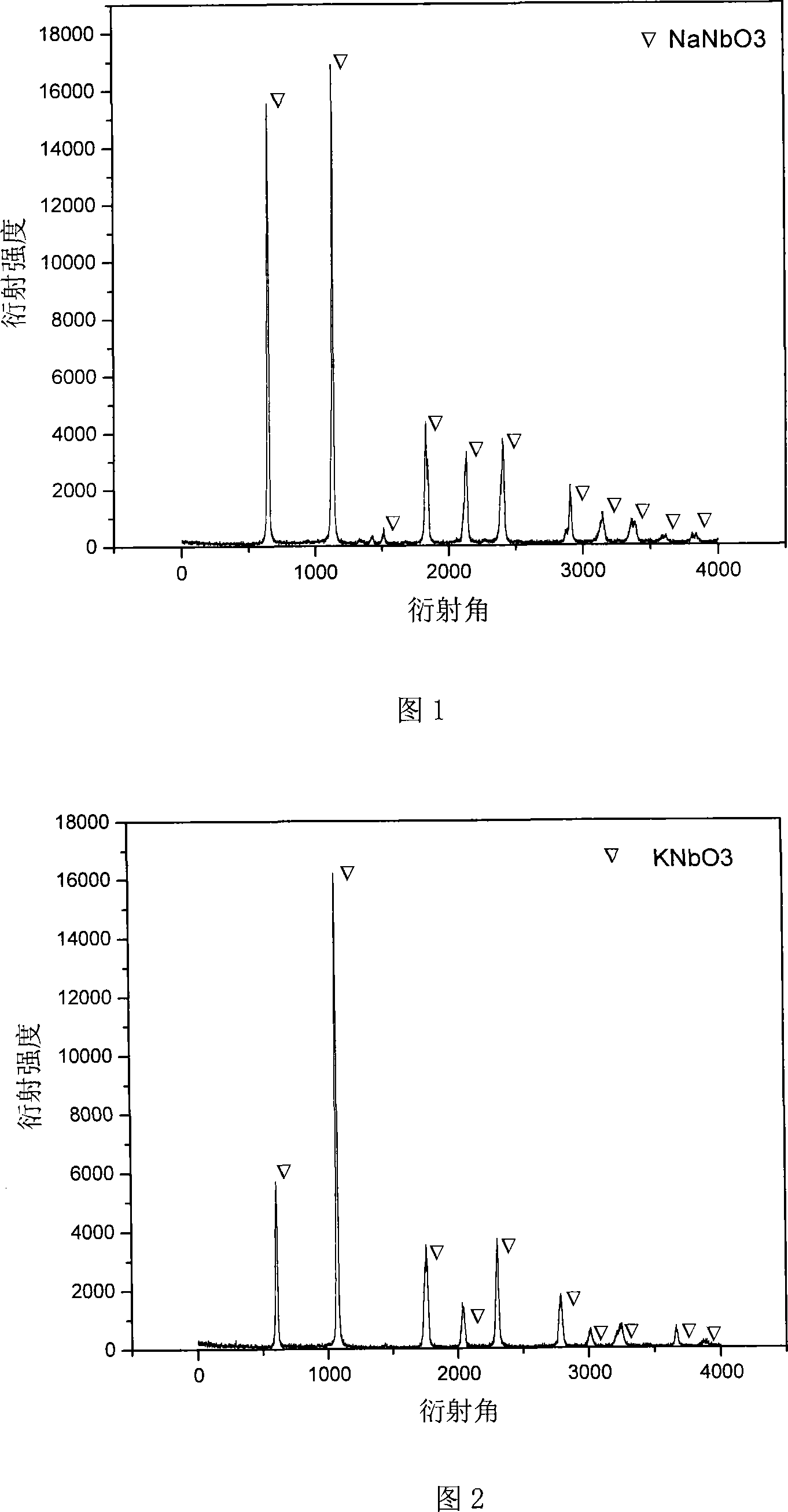

Microwave hydro-thermal synthesis method for sodium niobate potassium niobate leadless piezoelectric ceramic powder

InactiveCN101186339ASimple processLow costPiezoelectric/electrostrictive/magnetostrictive devicesNiobium compoundsMicrowaveSynthesis methods

The invention relates to a microwave hydrothermal synthesis method for preparation of sodium-potassium and niobate-potassium lead-free piezoelectric ceramic powder, which belongs to the functional material field. The invention is characterized in that: NaOH or KOH solution and Nb2O5 are used as reactants; NaNbO3 or KNbO3 ceramic powder is synthesized by microwave hydrothermal technology; the concentration of NaOH or KOH is 4-8mol / L while the input amount of the Nb2O5 is 0.01 to 0.02 mol; and the reaction temperature is 110 to 150 DEG C and the heat is preserved for 2 to 6 hours. The microwave hydrothermal synthesis method for preparation of sodium-potassium and niobate-potassium lead-free piezoelectric ceramic powder combines the unique heating features of a microwave and the advantage of the hydrothermal method, thus having simple technique, low cost, low consumption and very wide application prospect.

Owner:UNIV OF SCI & TECH BEIJING

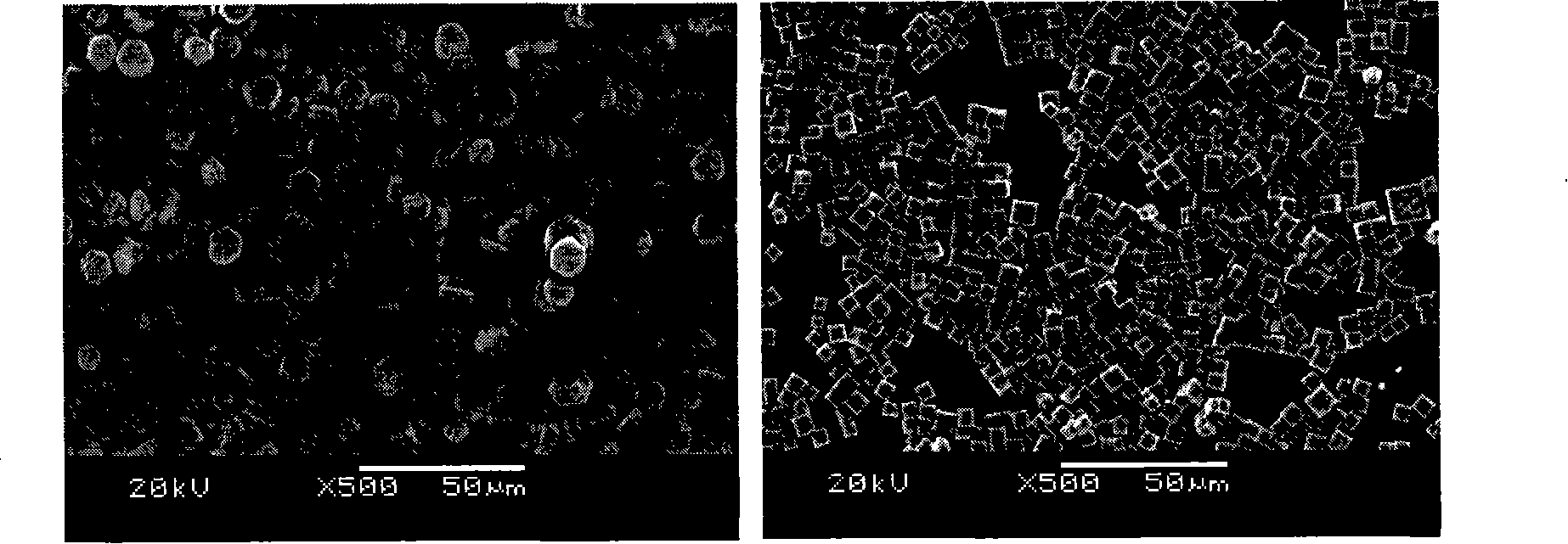

Preparation method of flaky sodium niobate microcrystalline powder

The invention relates to a preparation method of flaky sodium niobate microcrystalline powder; first, sodium carbonate, niobium oxide, bismuth oxide and sodium chloride serve as preparation raw materials, and flaky bismuth sodium niobate with excellent asymmetric shape is synthesized; and then flaky bismuth sodium niobate, sodium carbonate and sodium chloride serve as preparation raw materials, and the flaky sodium niobate microcrystalline powder is synthesized through a molten salt method, wherein the ratio of the total weight of the sodium carbonate and the flaky bismuth sodium niobate to the weight of the sodium chloride is 2:1; and the sodium carbonate is fully excessive, and the molar ratio of the sodium carbonate to the flaky bismuth sodium niobate is 1.0 to 1.25:1. The flaky sodium niobate microcrystalline powder prepared by the invention does not cohere and has good dispersion, the width and thickness uniformity of the microcrystalline powder is good, the asymmetric shape is good and the crystalline phase is single. The preparation method of the flaky sodium niobate microcrystalline powder is characterized by simple preparation process, little pollution, small formula error, low cost, easy control of the process, good repeatability and stability of the product, and easy realization of industrial production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Synthetic method of sodium niobate nanowire

ActiveCN104016408ALow priceSimple processMaterial nanotechnologyNiobium compoundsOrganic solventActive agent

The invention discloses a synthetic method of a sodium niobate nanowire. The synthetic method comprises the following steps: mixing NaOH and an organic solvent, carrying out hydro-thermal reaction, washing, centrifugally separating and drying. According to the synthetic method, used equipment is simple, reaction conditions are mild, the preparation of an intermediate phase precursor and the later annealing treatment are not needed, reaction raw materials are low in price, and expensive surface active agents are not need to be used as templates. The synthetic method has the main characteristics of simple technological process, capability of saving energy sources, low cost, easy control and operation, good repeatability and the like and can be put into industrial production easily, is capable of effectively shortening synthetic time and improving production efficiency and is an ideal environment-friendly synthetic technology.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

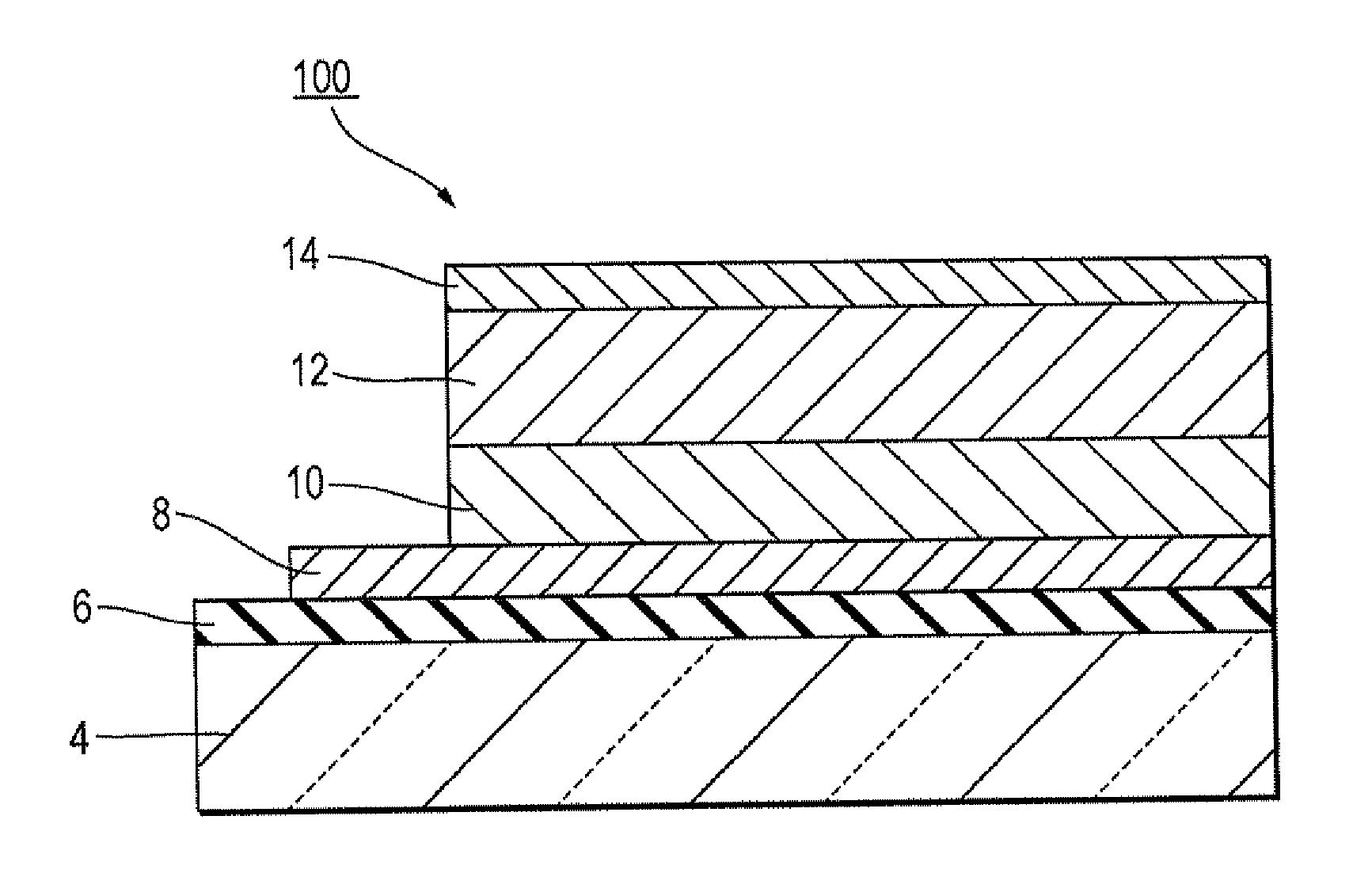

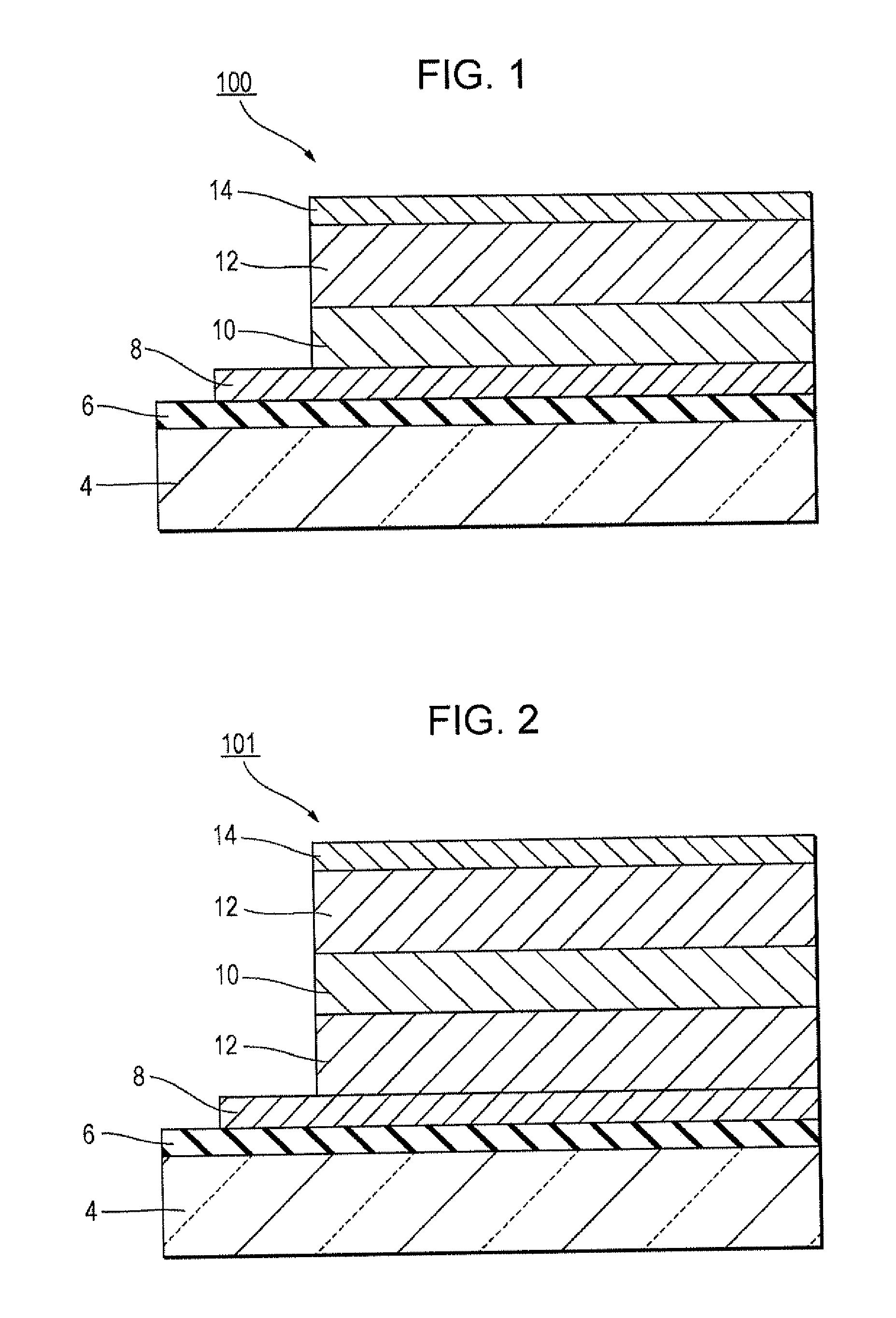

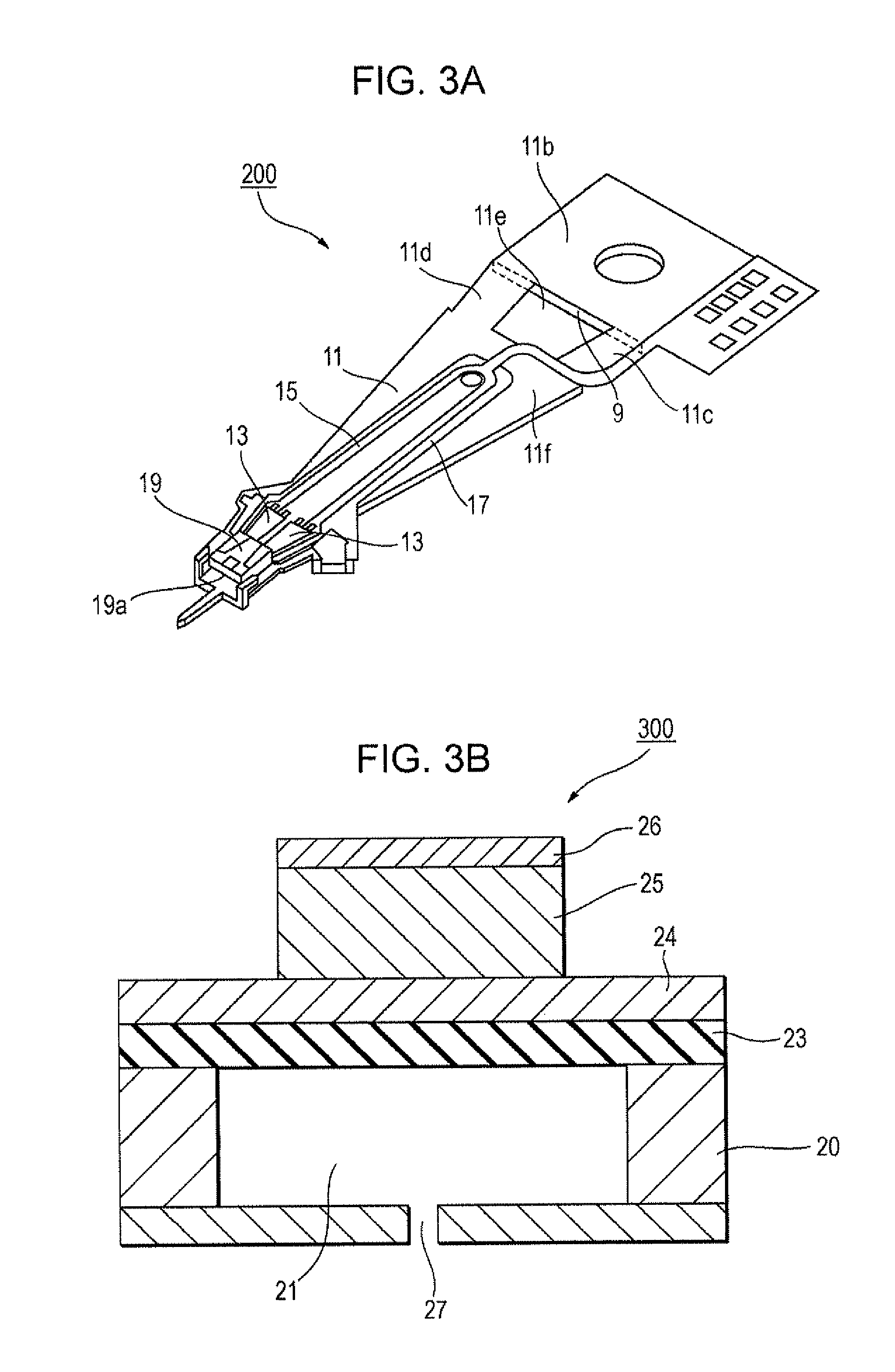

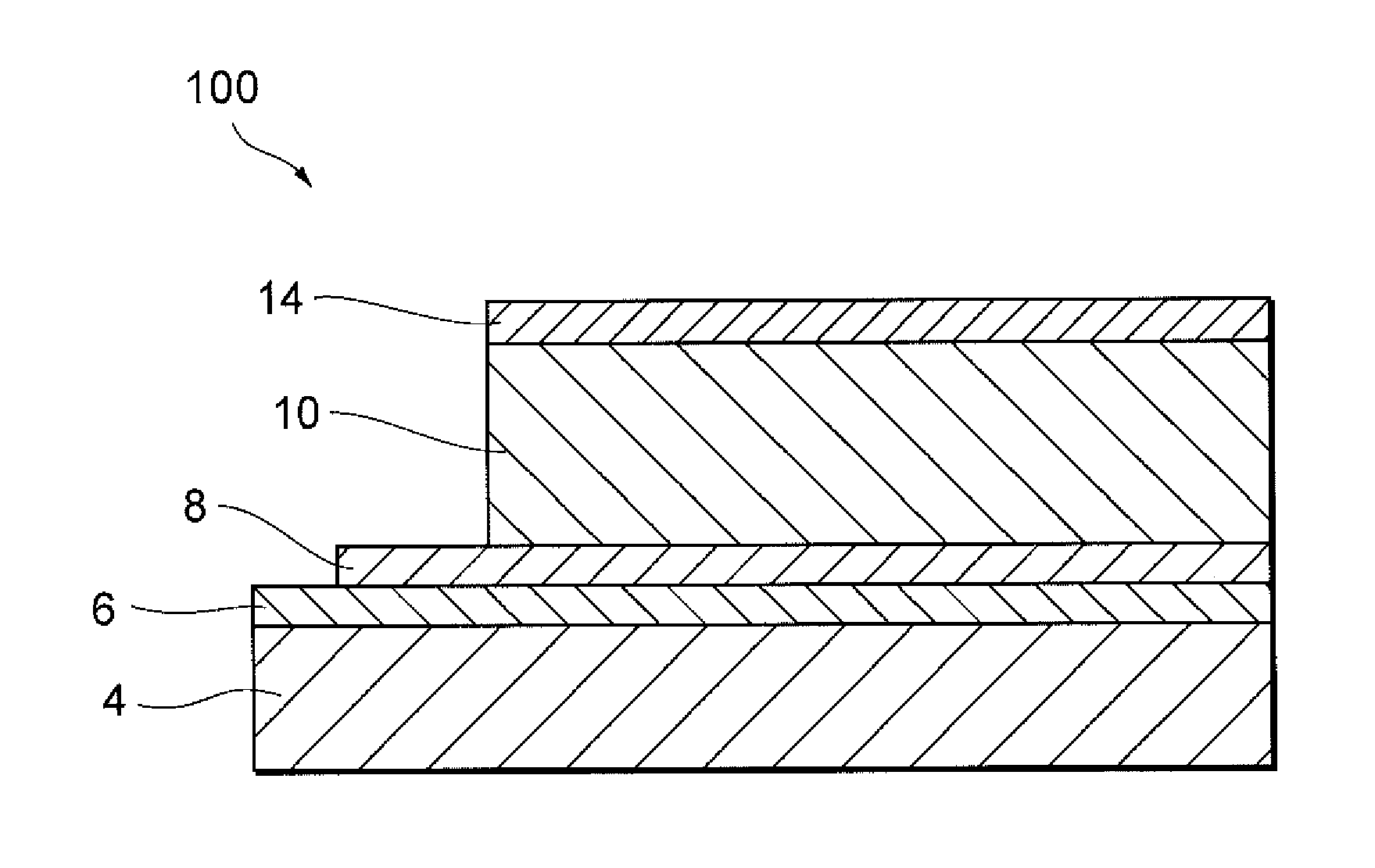

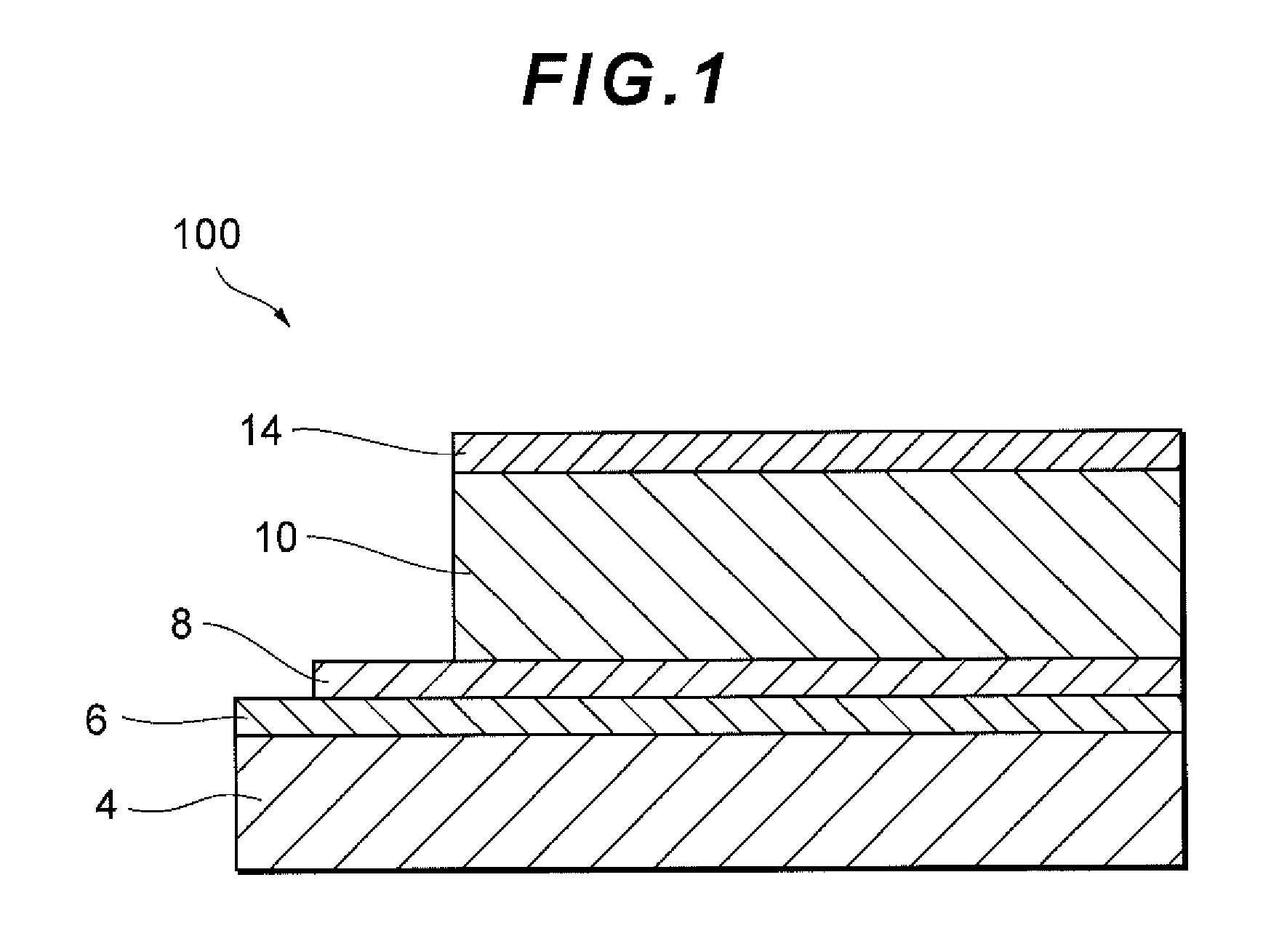

Piezoelectric element, piezoelectric actuator, piezoelectric sensor, hard disk drive, and inkjet printer device

ActiveUS20150194592A1Reduce leakage currentIncrease currentInking apparatusArm with actuatorsHard disc driveComputer printing

An object is to reduce the leakage current of a piezoelectric element including a potassium-sodium niobate thin film, enhance the reliability of the piezoelectric element and, in addition, enhance the withstand voltage by including a pair of electrodes and a piezoelectric layer sandwiched between the above-described pair of electrode layers, wherein the above-described piezoelectric layer is provided with at least one layer each of first piezoelectric layer which is a potassium-sodium niobate thin film substantially not containing Mn (manganese) and second piezoelectric layer which is a potassium-sodium niobate thin film containing Mn.

Owner:TDK CORPARATION

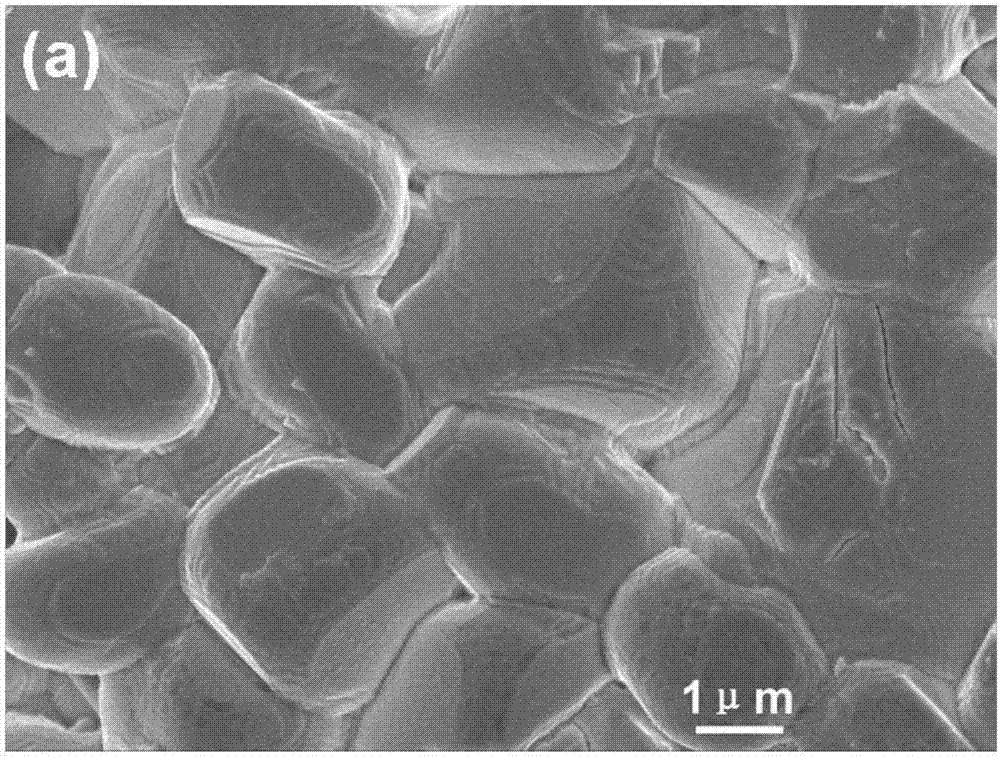

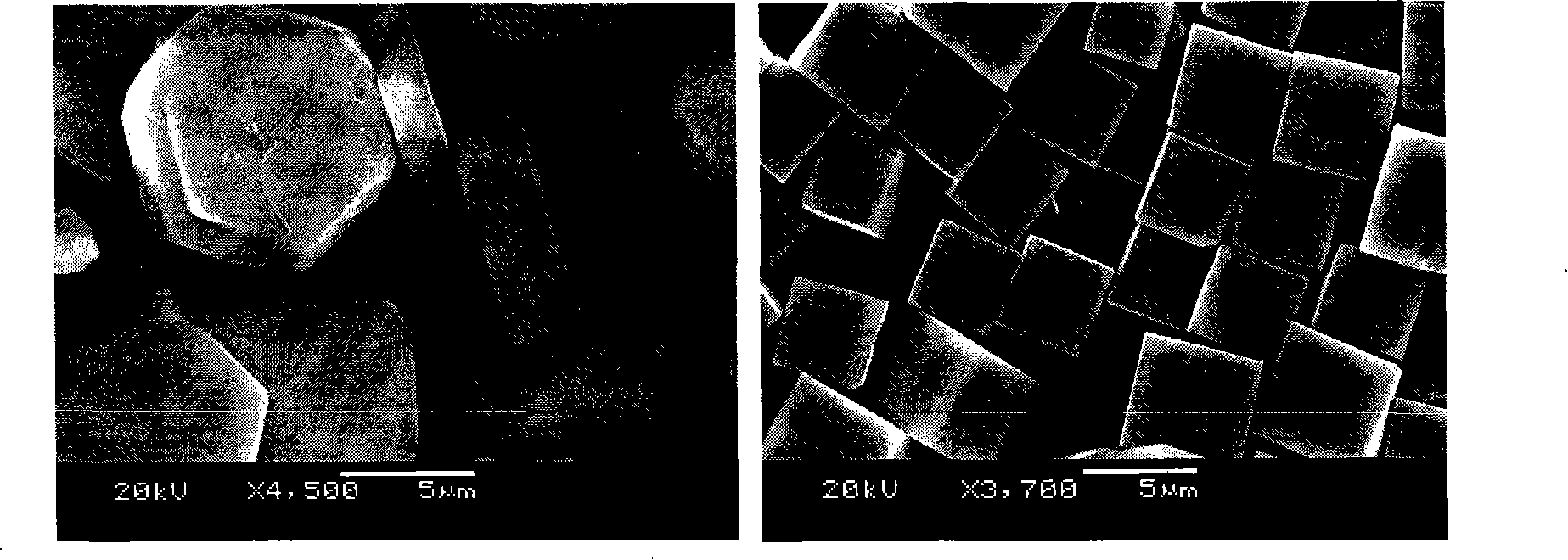

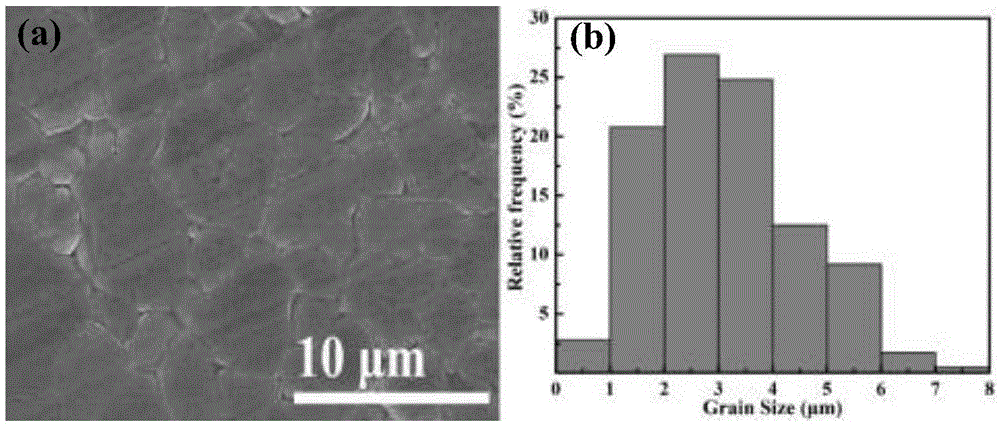

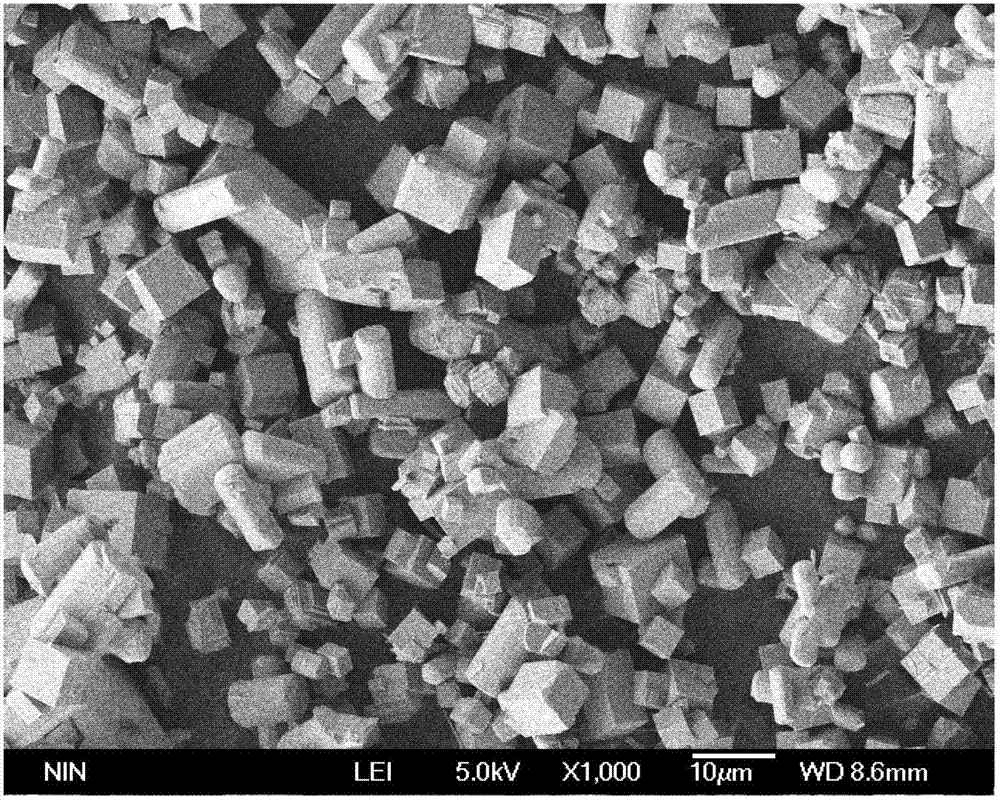

Preparation method of leadless antiferroelectric sodium niobate piezoelectric ceramic

The invention relates to a preparation method of sodium niobate ceramic with a diamond-shaped crystal grain morphology, and belongs to the field of leadless antiferroelectric piezoelectric ceramic crystal grain regulation and control. The chemical formula of the sodium niobate ceramic is NaNbO3 (called NN for short), the crystal grain morphology of the ceramic has a diamond shape, and the crystal grain has gradient anisotropy. The preparation method comprises the following steps: carrying out ball milling to prepare mixed raw material powder, processing the mixed raw material powder through an appropriate technology to prepare a mixing precursor, and carrying out a solid phase reaction through appropriate technology regulation and control in order to prepare the antiferroelectric piezoelectric ceramic with uniform micrometer crystal grain size. The dimension effect of the crystal grain makes the ceramic have an excellent ferroelectric performance not antiferroelectric performance. The ceramic has a strong demonstration effect in the crystal grin regulation and control field, so the ceramic has bright prospect; and the high-performance leadless antiferroelectric sodium niobate ceramic prepared through the method has wide application values in high voltage ceramic energy storage capacitors and electro-mechanical energy transducers.

Owner:CHINA JILIANG UNIV

Zirconium oxide-based ceramic tool material and preparation method thereof

The invention provides a zirconium oxide-based ceramic tool material, which is prepared from the following raw materials in parts by weight: 50-60 parts of zirconium oxide, 30-35 parts of aluminium oxide, 1-2 parts of borax, 4-5 parts of barium carbonate, 1-2 parts of sodium humate, 2-4 parts of carboxymethylcellulose, 2-3 parts of carbonyl nickel powder, 3-5 parts of LiSbO3, 4-6 parts of potassium-sodium niobate, 2-3 parts of cerium oxide, 1-1.5 parts of lanthanum nitrate, a proper amount of deionized water, 1-1.4 parts of polyacrylic acid, 0.7-1.2 parts of polyethylene glycol, a proper amount of ethanediol and 3-4 parts of an anti-abrasion aid. Due to addition of carbonyl nickel powder to the ceramic, the thermal conductivity of the ceramic is increased, a tool is prevented from overheating, the ceramic has very high hardness and abrasive resistance, the ceramic tool is suitable for cutting and chipping a high-hardness material and is hardly aged or broken off; due to use of the anti-abrasion aid, the surface smoothness, abrasive resistance and heat resistance of the ceramic are improved.

Owner:安徽上阡科技信息咨询有限公司

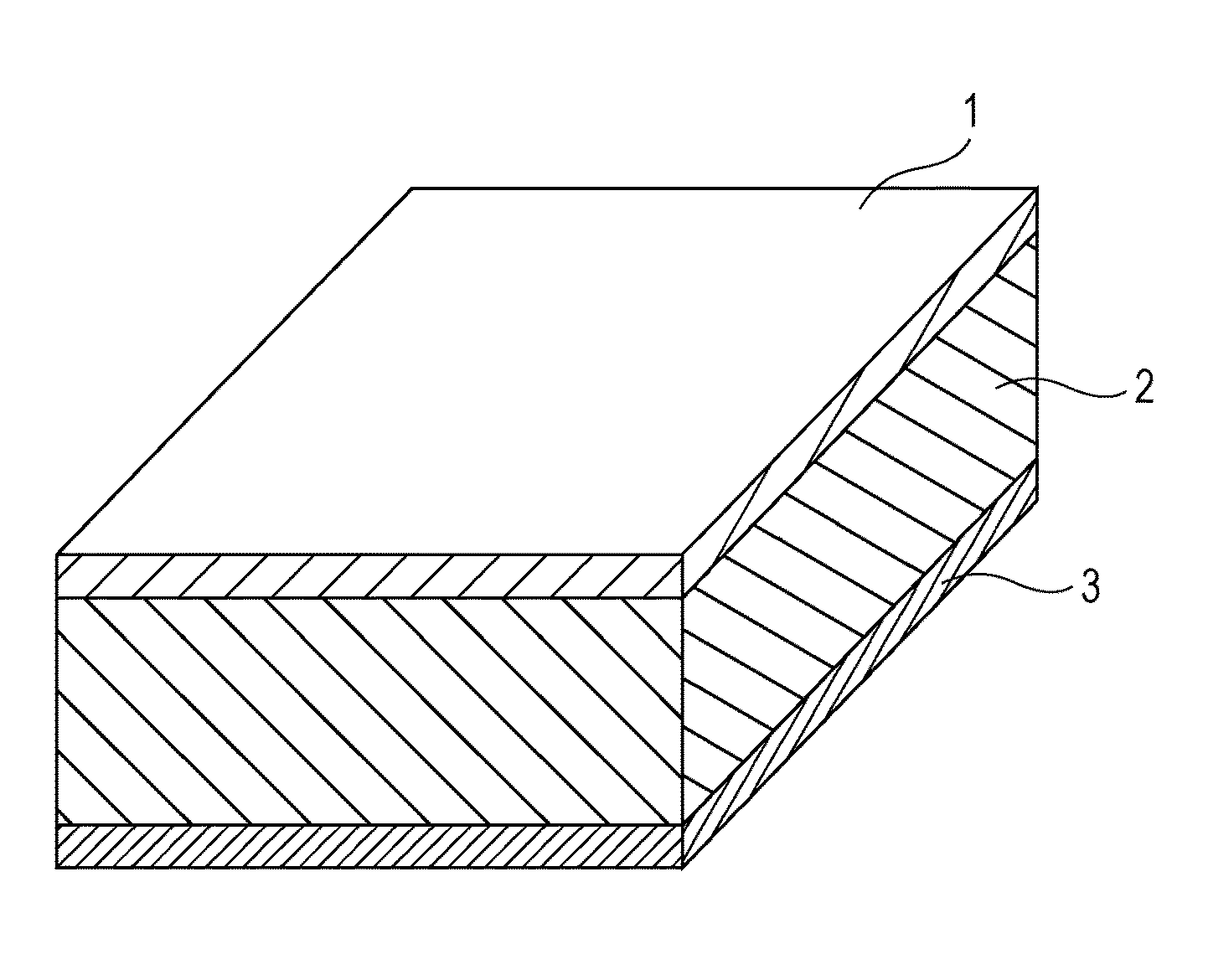

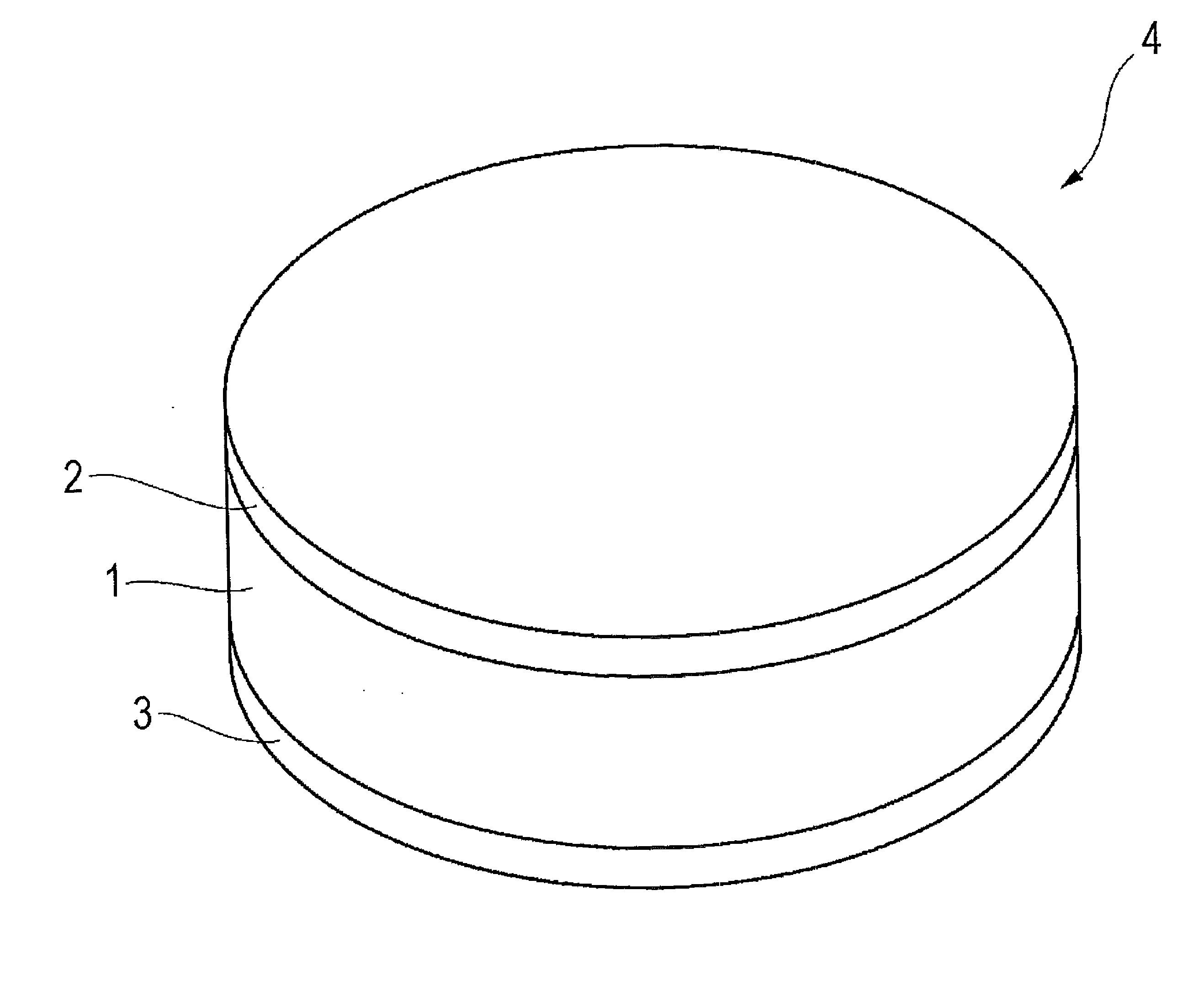

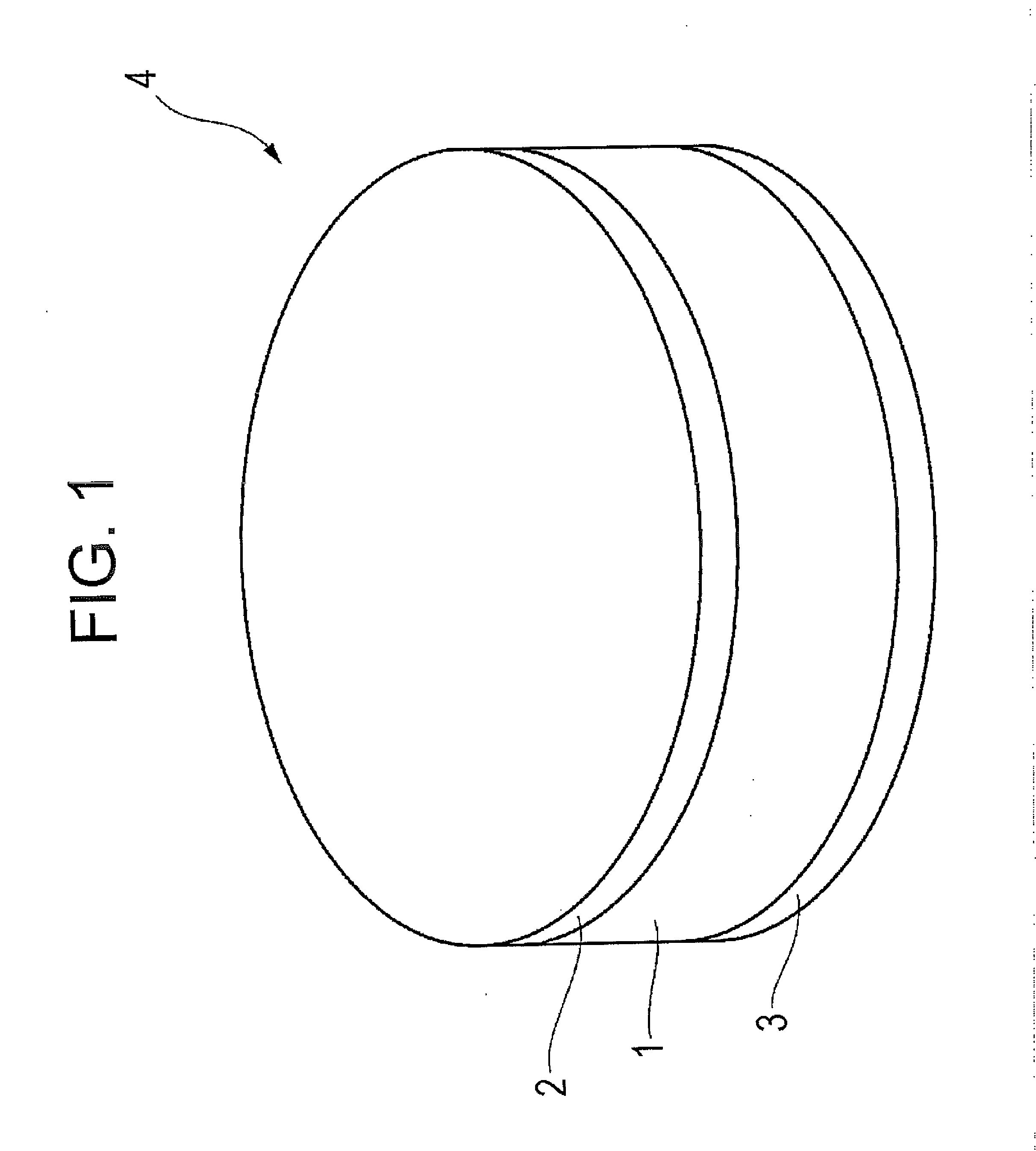

Potassium-sodium niobate-based lead-free piezoelectric ceramic with gradient components and preparation method thereof

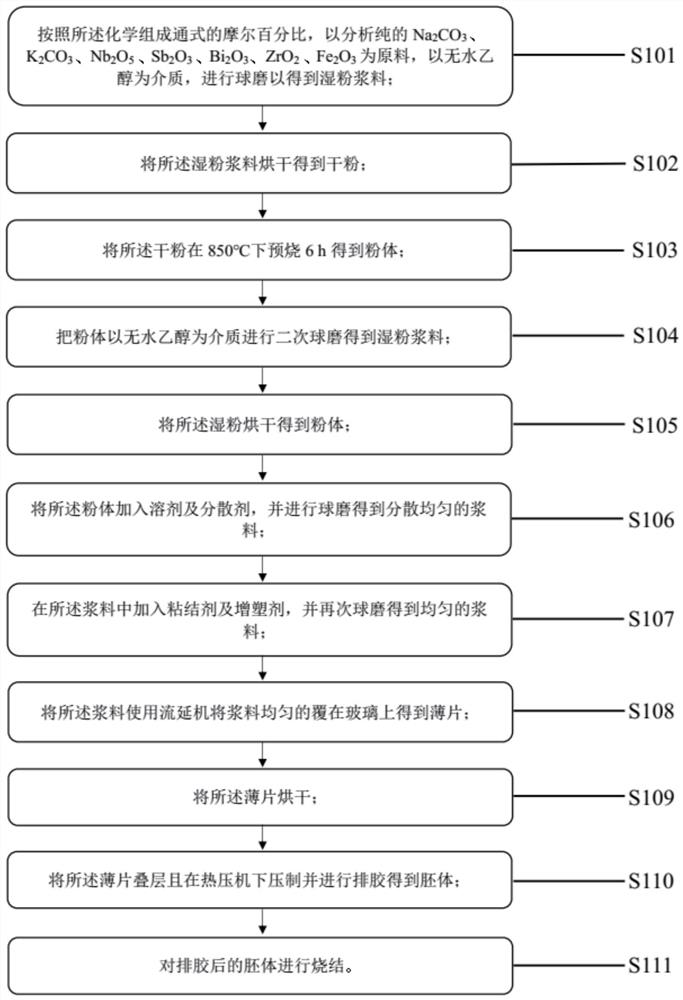

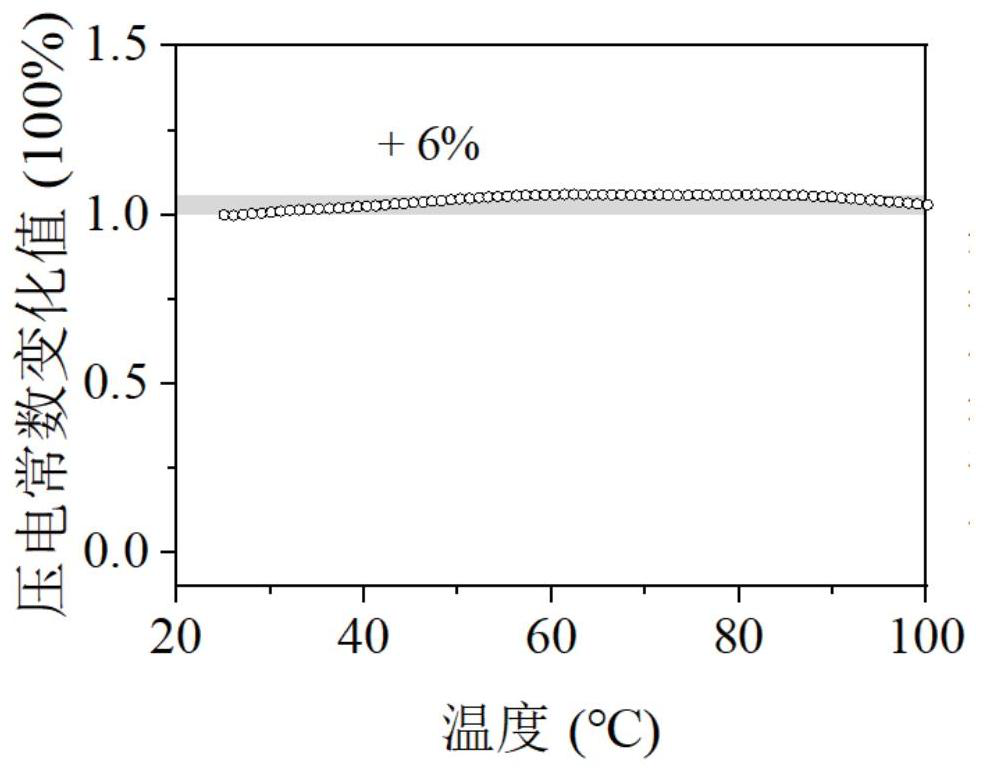

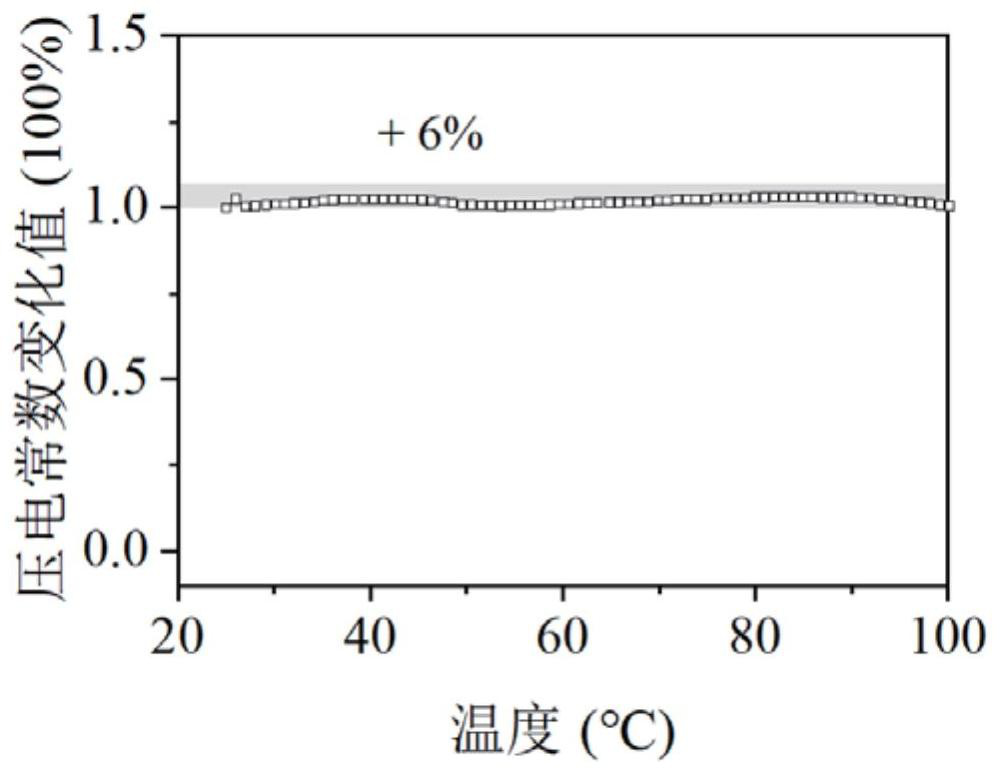

ActiveCN113666744ANo harmImprove stabilityPiezoelectric/electrostrictive device manufacture/assemblyChemical compositionSodium niobate

The invention discloses a potassium-sodium niobate-based lead-free piezoelectric ceramic with gradient components and a preparation method thereof. The piezoelectric ceramic is formed by compounding a plurality of component layers, the chemical composition general formula of each component layer is (1-x) K0. 48Na0. 52Nb0. 955Sb0. 045O3-xBi0. 5Na0. 5ZrO3-0.2 mol% Fe2O3 , wherein x is the molar fraction of the component Bi0. 5Na0. 5ZrO3 and is greater than or equal to 0.01 and less than or equal to 0.04; x values among the component layers are changed in a gradient manner. The preparation method of the piezoelectric ceramic comprises the following steps: preparing sheets forming a plurality of component layers by adopting a tape casting method according to the chemical composition of the component layers, then overlapping and pressing the sheets forming the component layers into a blank body according to a gradient change mode of x values, and carrying out glue discharging and sintering on the blank body. The piezoelectric ceramic is a lead-free environment-friendly material, and has excellent temperature stability of piezoelectric property and strain property.

Owner:SICHUAN UNIV

High-piezoelectric-property and high-stability anti-reduction potassium-sodium niobate-based leadless piezoelectric ceramic and preparation method thereof

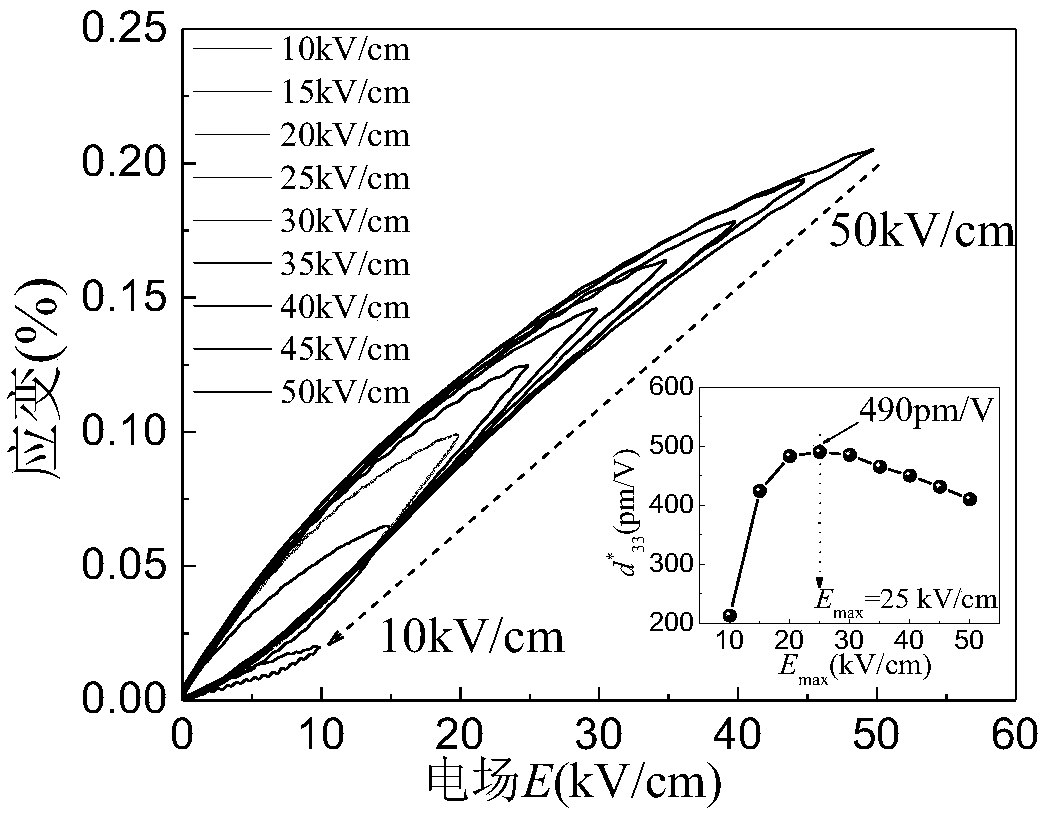

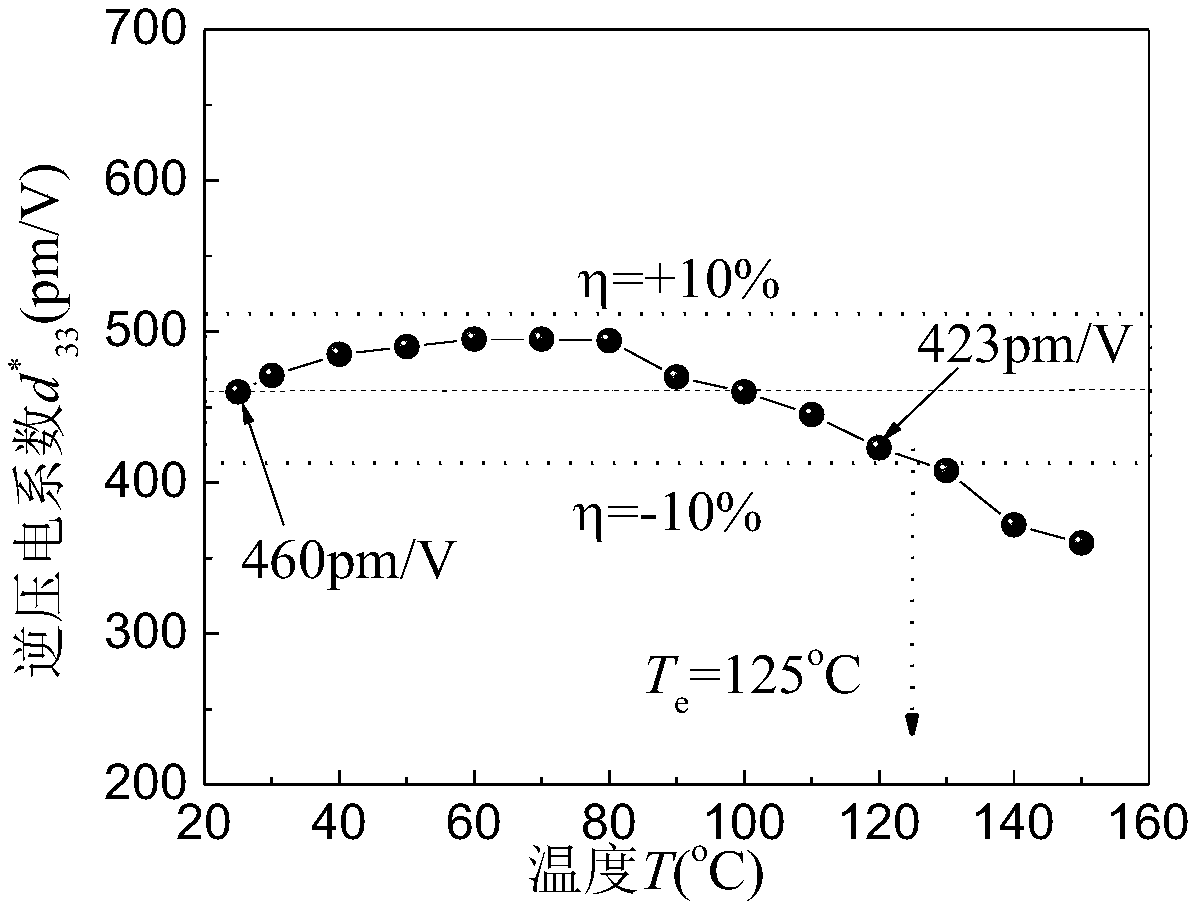

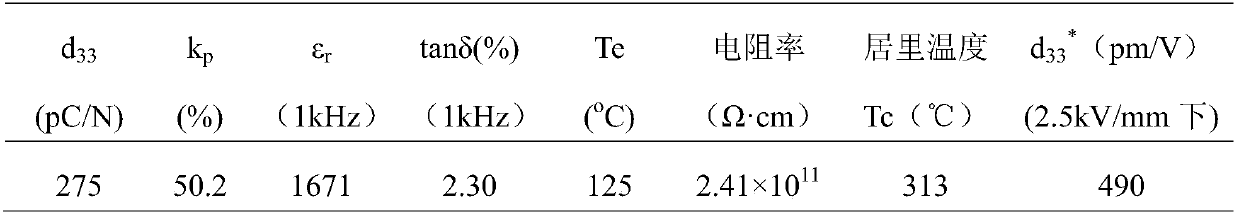

InactiveCN111393162AExcellent piezoelectric propertiesImprove performanceElectromechanical coupling coefficientManganese

The invention discloses a high-piezoelectric property and high-stability anti-reduction potassium-sodium niobate-based leadless piezoelectric ceramic and a preparation method thereof. The chemical formula of the piezoelectric ceramic is as follows: (1-x)[(1-y)K0.5Na0.5Nb<1-z>Ta<z>O<3-y>Bi0.5(Na0.82K0.18)0.5ZrO3]-xCaZrO<3+k%>M, wherein x, y, z and k represent molar fractions, x is greater than or equal to 0 and less than or equal to 0.03, y is greater than or equal to 0.02 and less than or equal to 0.05, z is greater than or equal to 0 and less than or equal to 0.12, k is greater than or equalto 0.2 and less than or equal to 0.6, x, y and z are not zero at the same time, and m represents a manganese compound. According to the anti-reduction potassium-sodium niobate-based leadless piezoelectric ceramic provided by the invention, the piezoelectric constant d33 reaches 275 pC / N or above, the planar electromechanical coupling coefficient kp can reach 0.50, the ceramic strain can reach 0.20% in a 50 kV / cm electric field, and the maximum inverse piezoelectric constant d33* reaches 500 pm / V (E = 25 kV / cm). Under a 35kV / cm electric field, the d33* of a sample at room temperature is equal to 460pm / V, and the temperature Te of the inverse piezoelectric coefficient d33* is stabilized within 125 DEG C within the fluctuation range of + / -10%.

Owner:TSINGHUA UNIV

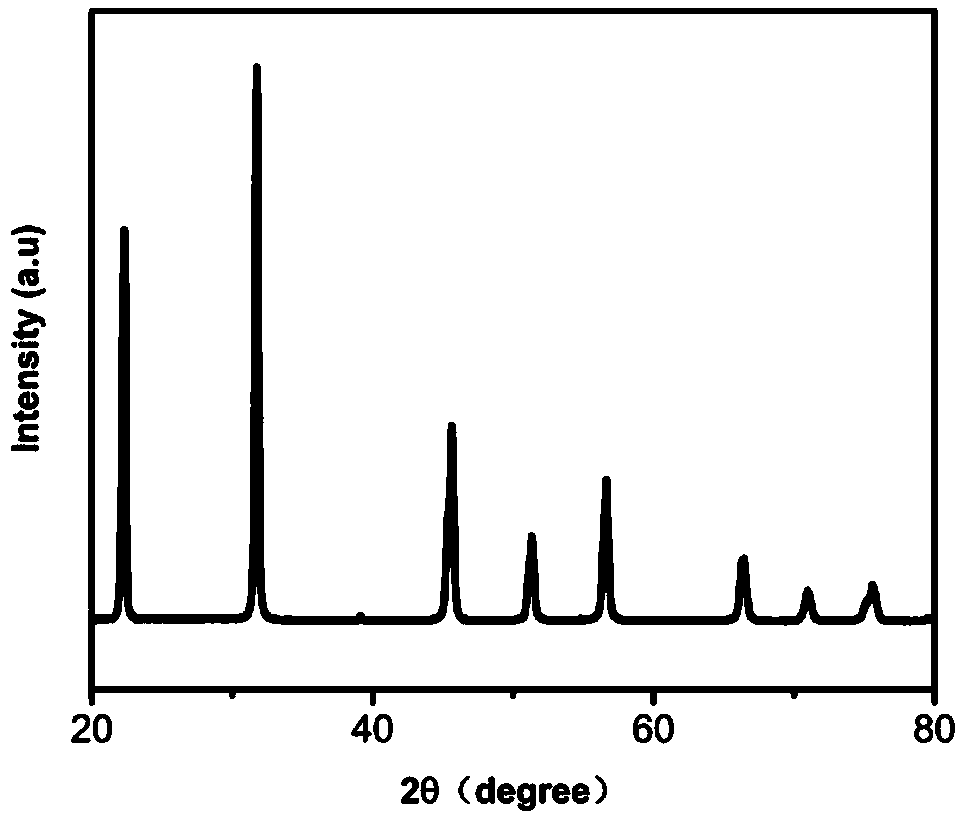

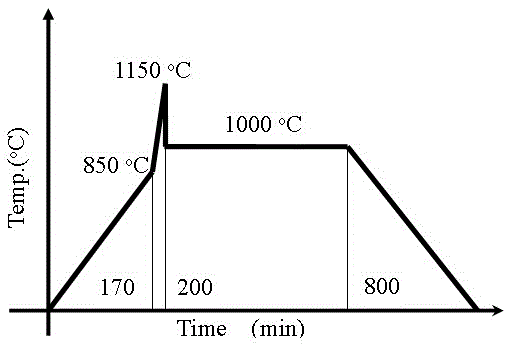

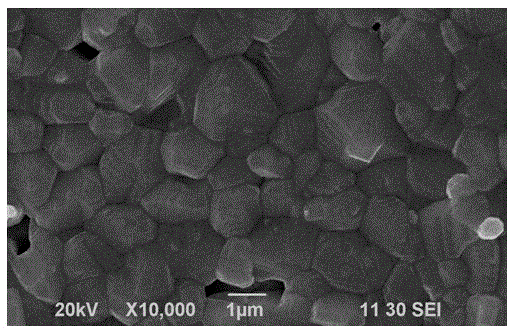

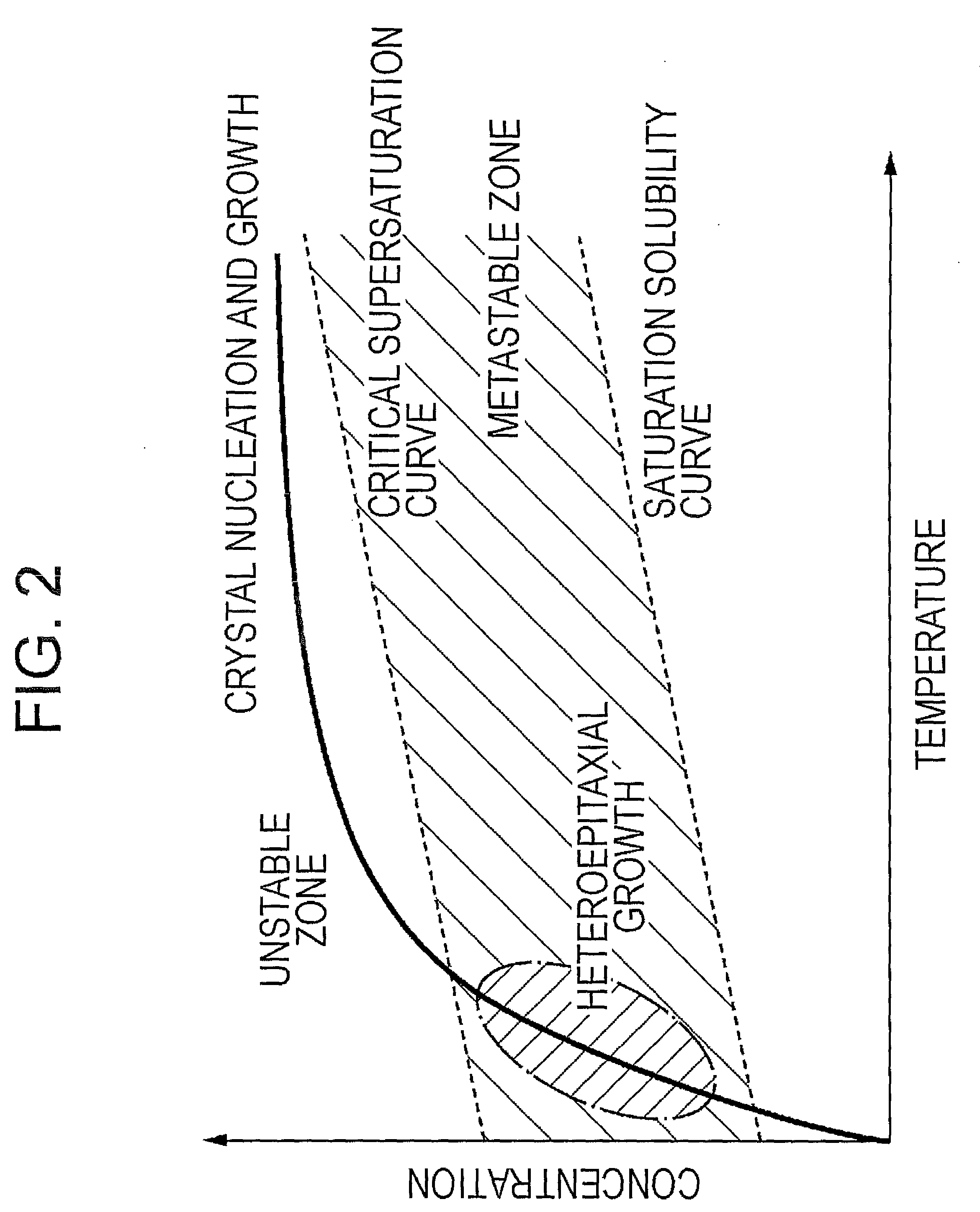

Sodium niobate powder, method for producing the same, method for producing ceramic, and piezoelectric element

ActiveUS20150062257A1Reduce moisture contentPiezoelectric/electrostriction/magnetostriction machinesCeramic shaping apparatusSolid componentPhysical chemistry

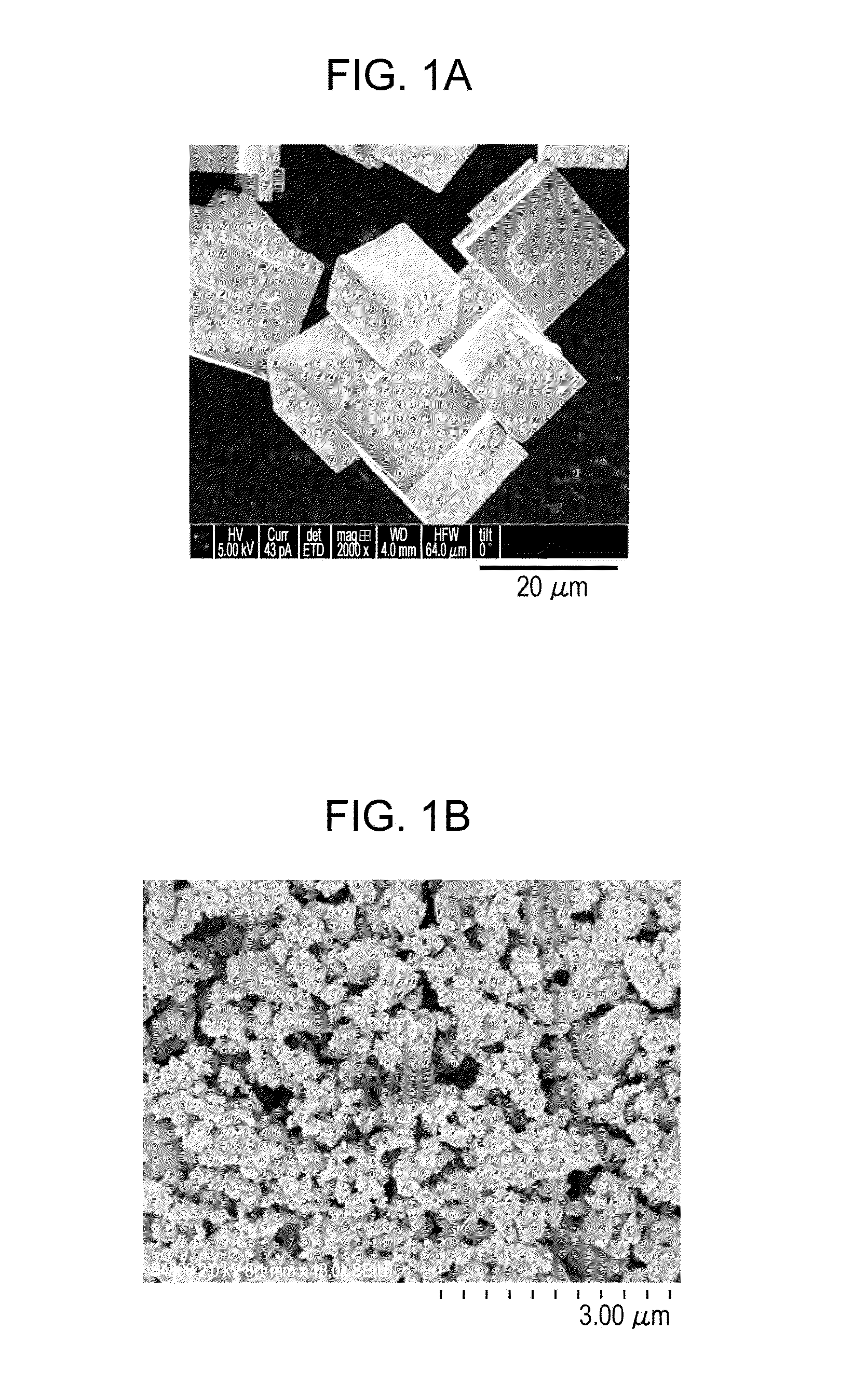

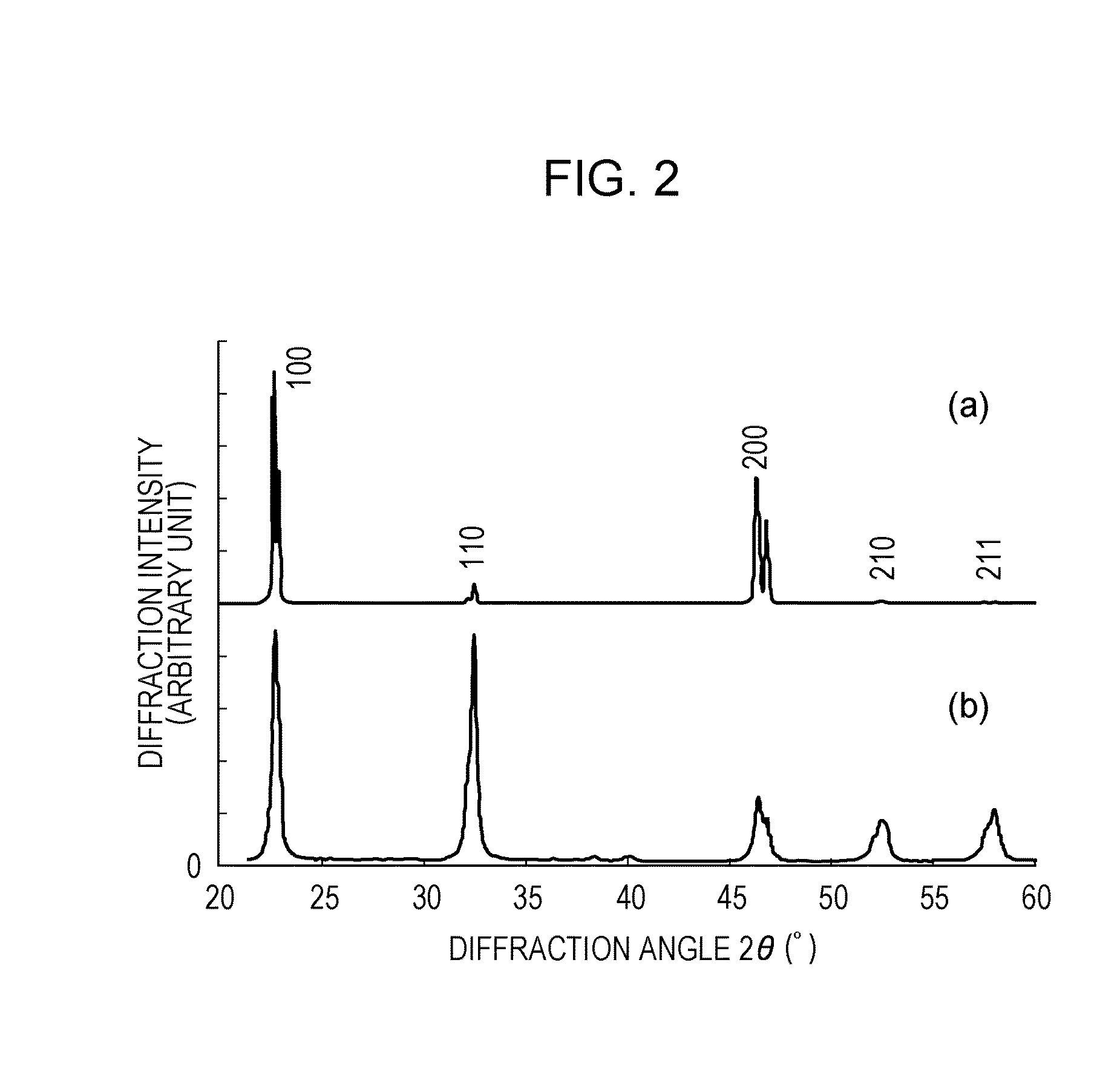

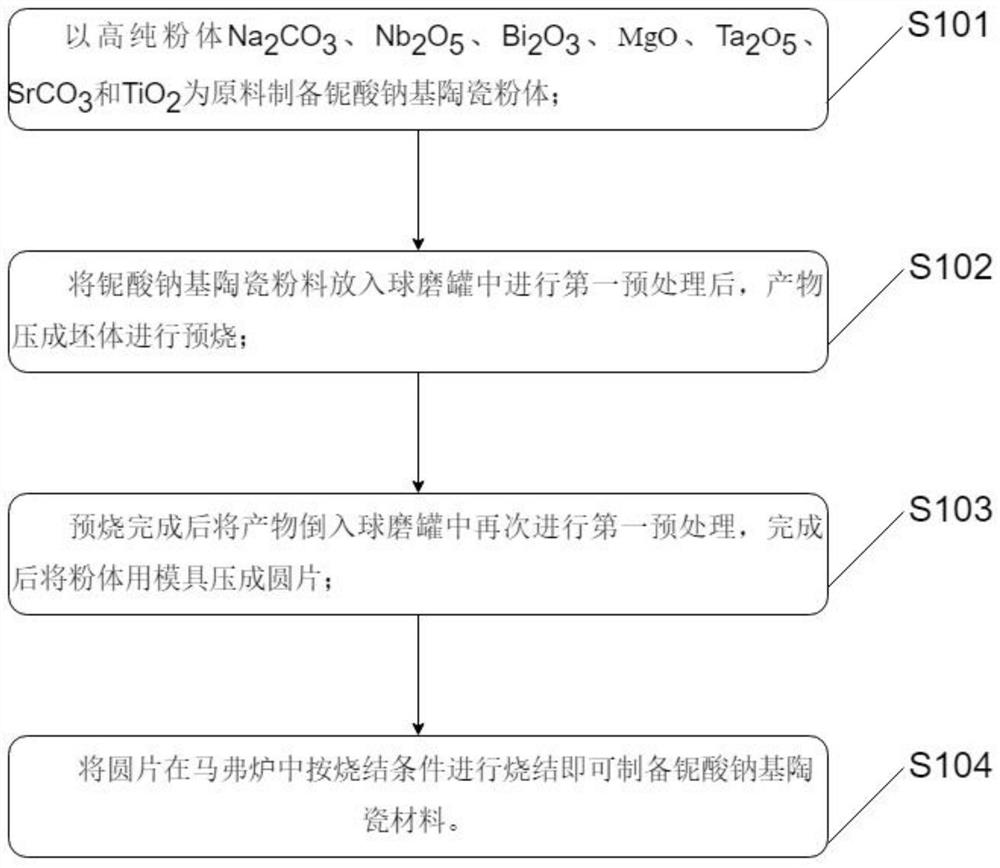

A sodium niobate powder includes sodium niobate particles having a shape of a cuboid and having a side average length of 0.1 μm or more and 100 μm or less, wherein at least one face of each of the sodium niobate particles is a (100) plane in the pseudocubic notation and a moisture content of the sodium niobate powder is 0.15 mass % or less. A method for producing a ceramic using the sodium niobate powder is provided. A method for producing a sodium niobate powder includes a step of holding an aqueous alkali dispersion liquid containing a niobium component and a sodium component at a pressure exceeding 0.1 MPa, a step of isolating a solid matter from the aqueous dispersion liquid after the holding, and a step of heat treating the solid matter at 500° C. to 700° C.

Owner:CANON KK

Novel high-energy-storage and high-efficiency sodium niobate-based ceramic material and preparation method thereof

ActiveCN112174664AHigh strengthHigh breakdown field strengthCeramic shaping apparatusDielectric ceramicsSodium niobate

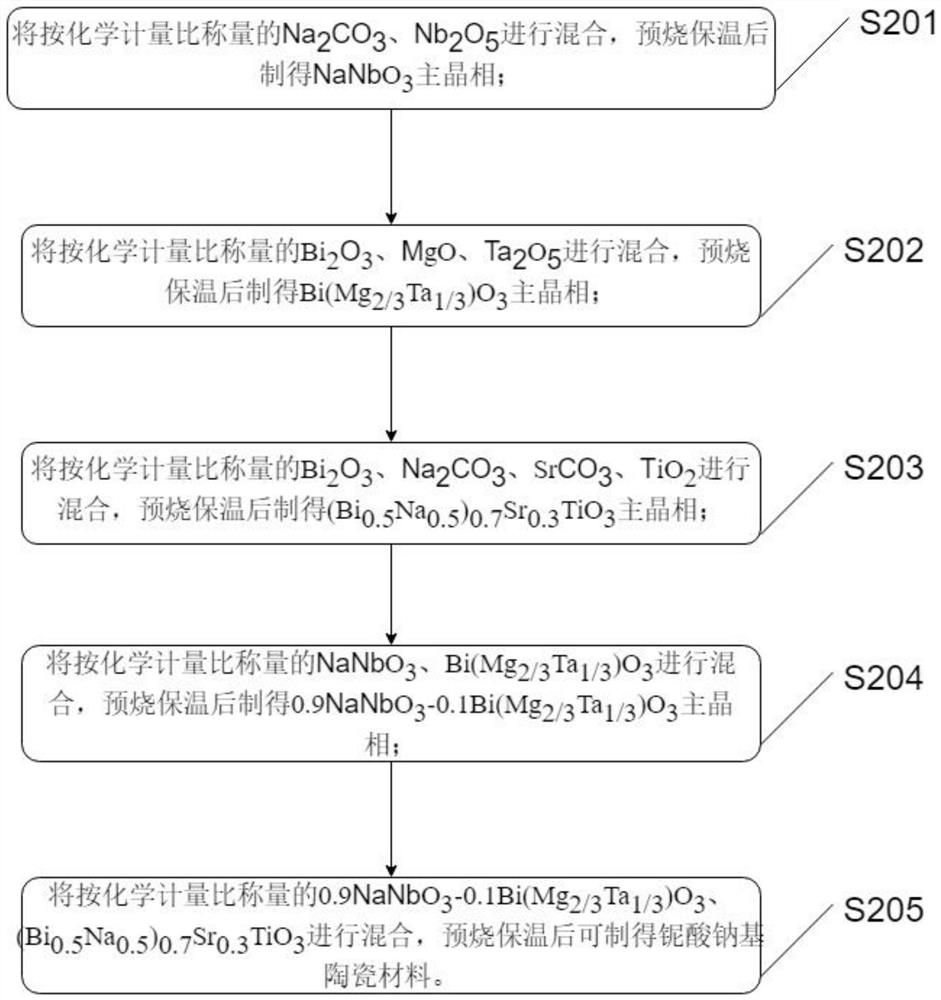

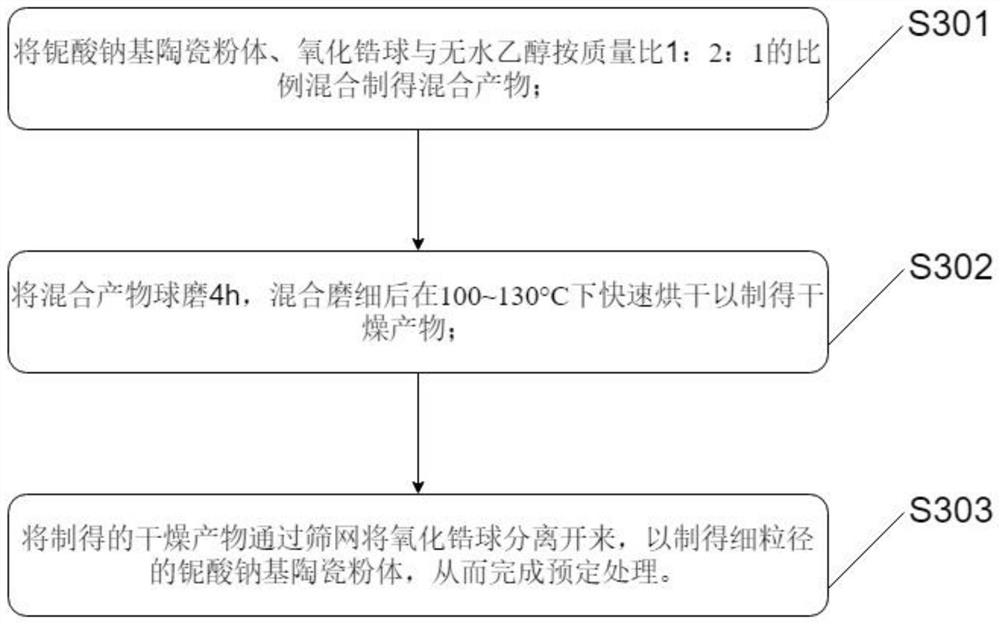

The invention discloses a novel high-energy-storage and high-efficiency sodium niobate-based ceramic material of which the composition formula is (1x)[0.9 NaNbO3-0.1Bi(Mg2 / 3Ta1 / 3)O3]x(Bi0.5Na0.5)0.7Sr0.3TiO3, x is the molar percentage, and x is more than or equal to 0 and less than or equal to 0.40. The invention also discloses a preparation method of the sodium niobate-based ceramic material, which includes the novel high-energy storage and high-efficiency sodium niobate-based ceramic material, and further comprises the following steps: preparing sodium niobate-based ceramic powder; putting the sodium niobate-based ceramic powder into a ball milling tank for predetermined treatment, and pressing a product into a green body for presintering; pouring a product into the ball-milling tank after pre-sintering is completed, carrying out predetermined treatment again, and pressing the powder into a wafer by using a mold after pre-sintering is completed; sintering the wafer in a muffle furnace according to sintering conditions to prepare the sodium niobate-based ceramic material, and introducing strong ferroelectric Bi(Mg2 / 3Ta1 / 3)O3 and (Bi0.5Na0.5)0.7 Sr0.3TiO3 to form a uniform solid solution with NaNbO3 antiferroelectric so that the maximum polarization strength and breakdown field strength of the ceramic material are improved, wherein the energy storage density of the dielectric ceramic material is improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

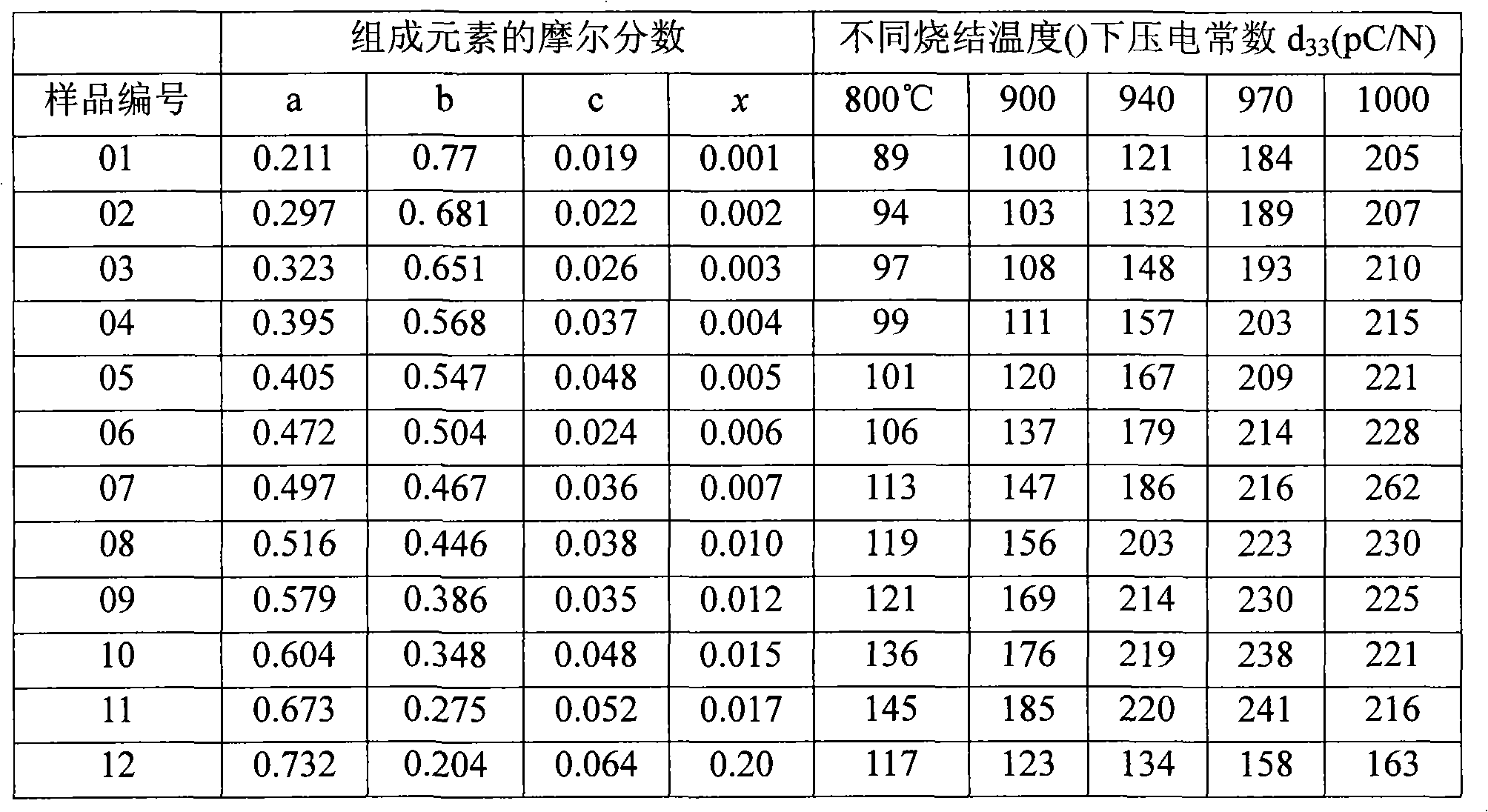

Sodion compensating potassium and sodium niobate based leadless piezoelectric ceramics and method for preparing same

InactiveCN101289318ALower sintering temperatureImprove performancePiezoelectric/electrostrictive/magnetostrictive devicesLithiumChemical composition

The invention relates to Na<+> compensatory potassium-sodium niobate lithium base leadless piezoelectric ceramics and a low-temperature sintering method thereof, which belongs to the filed of functional ceramic materials. The general formula of chemical composition can be represented as (Naa+xKbLic)NbO3; wherein, a, b, and c represent the molar fraction of the components such as Na, K, Li respectively; and a plus b plus c equals to 1; x represent the molar fraction of the compensatory Na<+>; the value range of each parameter is that: a is more than 0.20 and less than 0.80, b is more than 0.20 and less than 0.80, c is more than 0.00 and less than 0.30, and x is more than 0.00 and equal or less than 0.20. The preparation method of the ceramics system comprises the processing steps of mixing raw materials, baking, molding, sintering, baking sliver and polarization, etc. The Na<+> compensatory potassium-sodium niobate lithium base leadless piezoelectric ceramics and the low-temperature sintering method of the invention have the advantages of effectively reducing the baking temperature of potassium-sodium niobate lithium base leadless piezoelectric ceramics by the compensation of Na<+> and preparing leadless piezoelectric ceramics with good property material at the low temperature of 800 to 1000 DEG C.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for sodium columbate ceramic material with stable antiferroelectricity and low dielectric loss

InactiveCN105523760AStable antiferroelectric phaseMeet high-quality ceramic requirementsNanotechnologyElectricityAlcohol

The invention provides a preparation method for a sodium columbate ceramic material with stable antiferroelectricity and low dielectric loss, belonging to the field of dielectric ceramic materials. With the method, stability of an antiferroelectric phase in pure sodium columbate ceramic is realized; ferroelectric phase induced by an electric field does not occure in a 100 kv / cm high electric field; and the material has low dielectric loss (less than 2%). The preparation method comprises the following steps: weighing Na2CO3 and Nb2O5 according to a mol stoichiometric ratio of Na to Nb of 1: 1 and putting the two raw materials into a ball milling tank for ball milling, with absolute ethyl alcohol as a ball milling medium; and subjecting powder obtained after batch mixing to dry grinding through a high-energy ball milling method so as to obtain nanometer sodium columbate powder, directly pressurizing and molding the obtained nanometer powder without addition of any binder and then carrying out sintering at 1350 to 1375 DEG C so as to obtain a ceramic body. Determination of a stable antiferroelectric phase is realized through electric performance testing. The preparation method provided by the invention is simple and has low energy consumption. The prepared sodium columbate ceramic material has stable antiferroelectricity and low dielectric loss.

Owner:BEIJING UNIV OF TECH

Composite piezoelectric ceramic and piezoelectric device

ActiveUS20150249201A1Reduce the amount requiredEasy to producePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionHeterojunctionBarium titanate

A composite piezoelectric ceramic includes a compact of crystal particles including at least one of potassium niobate (KNbO3) and sodium niobate (NaNbO3) and optionally further including lithium niobate (LiNbO3), and a layer containing barium titanate (BaTiO3) that is disposed on the surface of the compact while forming a heterojunction with the compact. A piezoelectric device includes the composite piezoelectric ceramic.

Owner:TDK CORPARATION

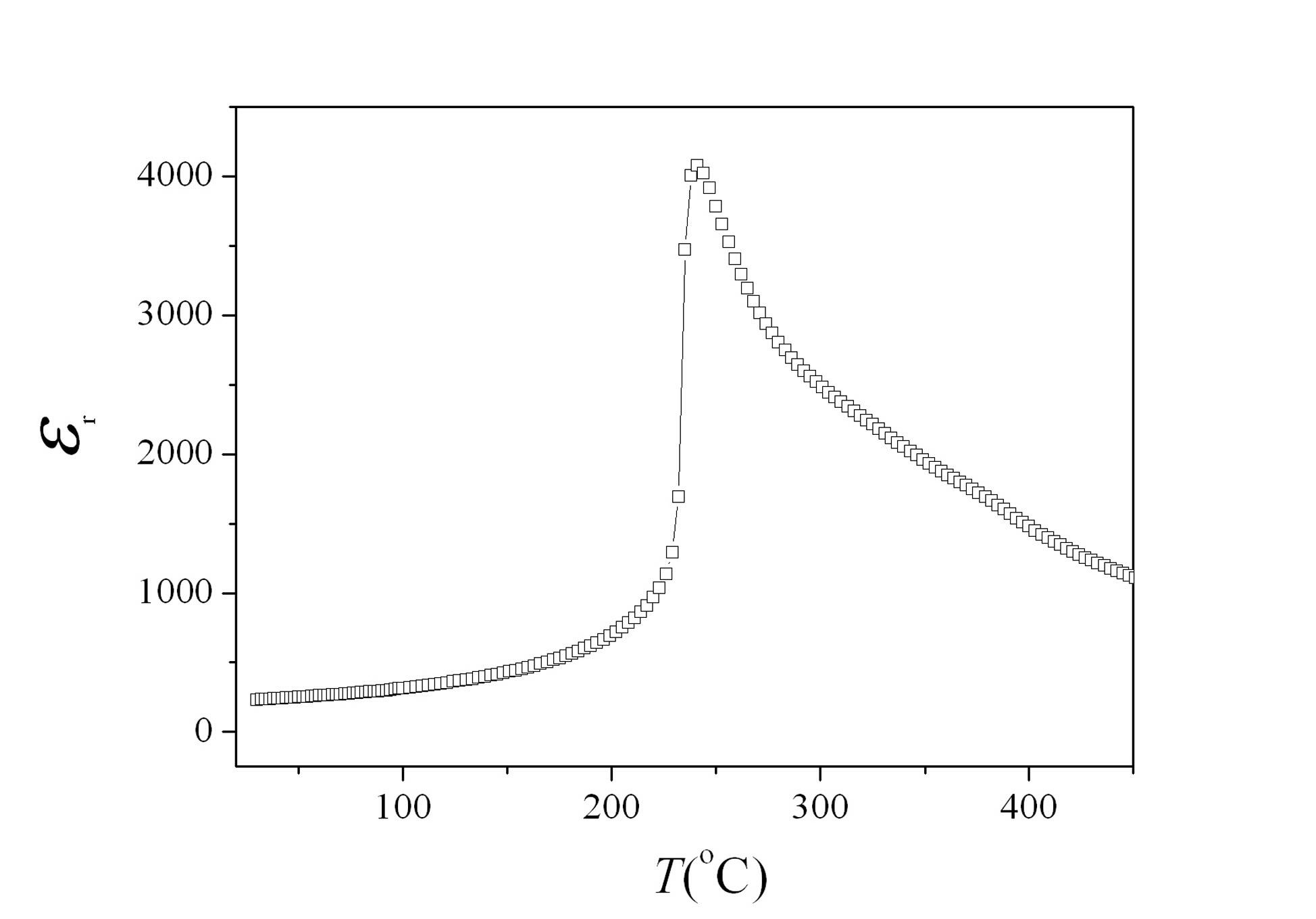

Sodium niobate/bismuth titanate lithium system leadless piezoelectric ceramic composition

InactiveCN102531599AExcellent piezoelectric ferroelectric propertiesHigh curie temperatureElectricityLithium

The invention relates to a novel sodium niobate / bismuth titanate lithium system leadless piezoelectric ceramic composition containing perovskite antiferroelectric NaNbO3 and ABO3 compound Bi0.5Li0.5TiO3 with a general formula expressed as (1-x)NaNbO3-xBi0.5Li0.5TiO3, wherein x is great than or equal to 0.025 and less than or equal to 0.25. The leadless piezoelectric ceramic composition can also contain one or more oxides with a general formula of (1-x)NaNbO3-xBi0.5Li0.5TiO3((100-a) mol%)+MalphaObeta (a mol%), wherein MalphaObeta is one or more oxides, the molar ratio of the content a of MalphaObeta to the main component (1-x)NaNbO3-xBi0.5Li0.5TiO3 is 0-3%, M is an element with (+1)-(-6) valence and can be combined with oxygen to form a solid oxide, and alpha and beta are used for respectively expressing the atom numbers of the corresponding element M and oxygen in the related oxide. The system leadless piezoelectric ceramic composition obtained by adopting traditional piezoelectric ceramic preparing technology is characterized in that the optimal value d33 can be up to more than 50pC / N and the kp can be up to more than 15%, and has the advantages of high Curie temperature, good heat stability, good compactness and stable process.

Owner:SICHUAN NORMAL UNIVERSITY

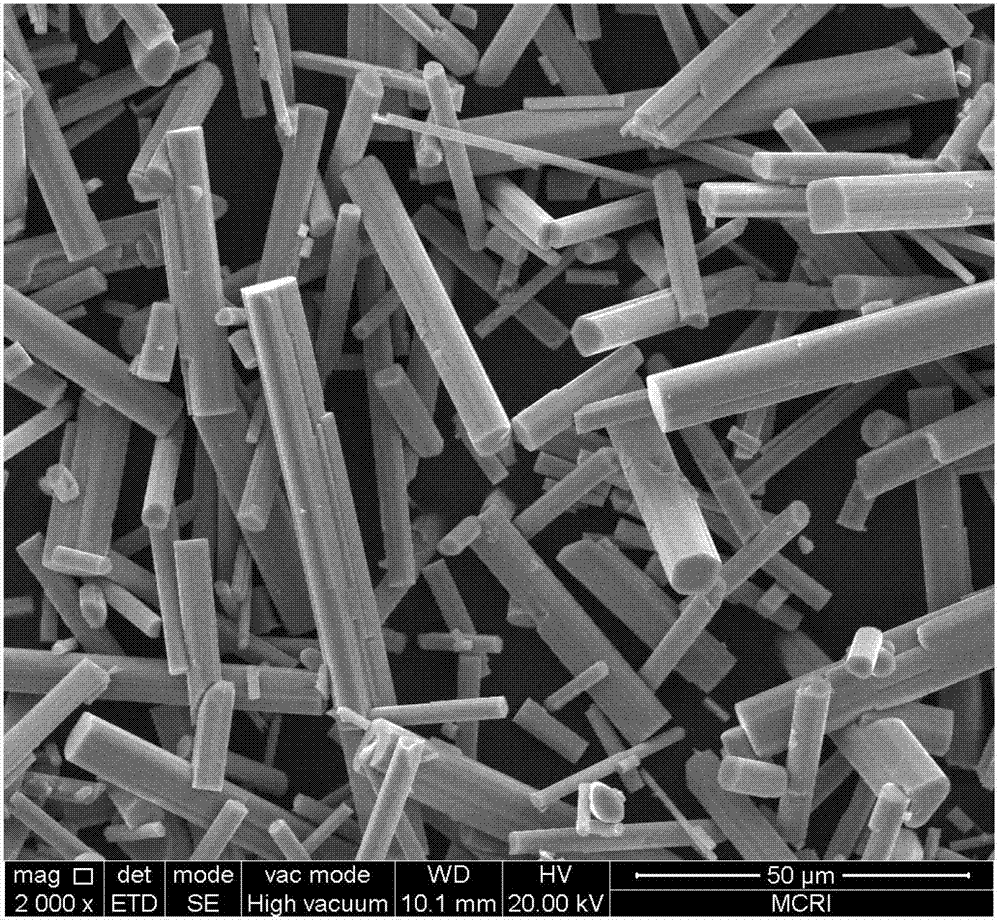

Preparation method of cylindrical strontium sodium niobate crystallite powder

Disclosed is a preparation method of cylindrical strontium sodium niobate crystallite powder. The strontium sodium niobate crystallite powder is prepared by a one-step molten salt method. The preparation method includes firstly, synthesizing strontium potassium niobate crystallite powder having anisotropic shapes; and secondly, exchanging sodium ion with potassium ion to obtain final product cylindrical strontium sodium niobate crystallite powder. The obtained strontium sodium niobate crystallite powder has no other impurities, is single-phase crystallite powder in square tungsten bronze structure, has cylindrical appearance with anisotropic shapes, is about 11-87micrometers in length and about 3-9micrometers in diameter and is not adhered to one another, particle is even and dispersibility is high. The preparation method is simple and convenient, the obtained product is high in purity, size is controllable, agglomeration is avoided, the requirement for anisotropic template is met, mechanical pollution is small, deviation of a formula is small, process is easy to control, reproducibility and stability of the strontium sodium niobate crystallite powder are high, and industrialization is facilitated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

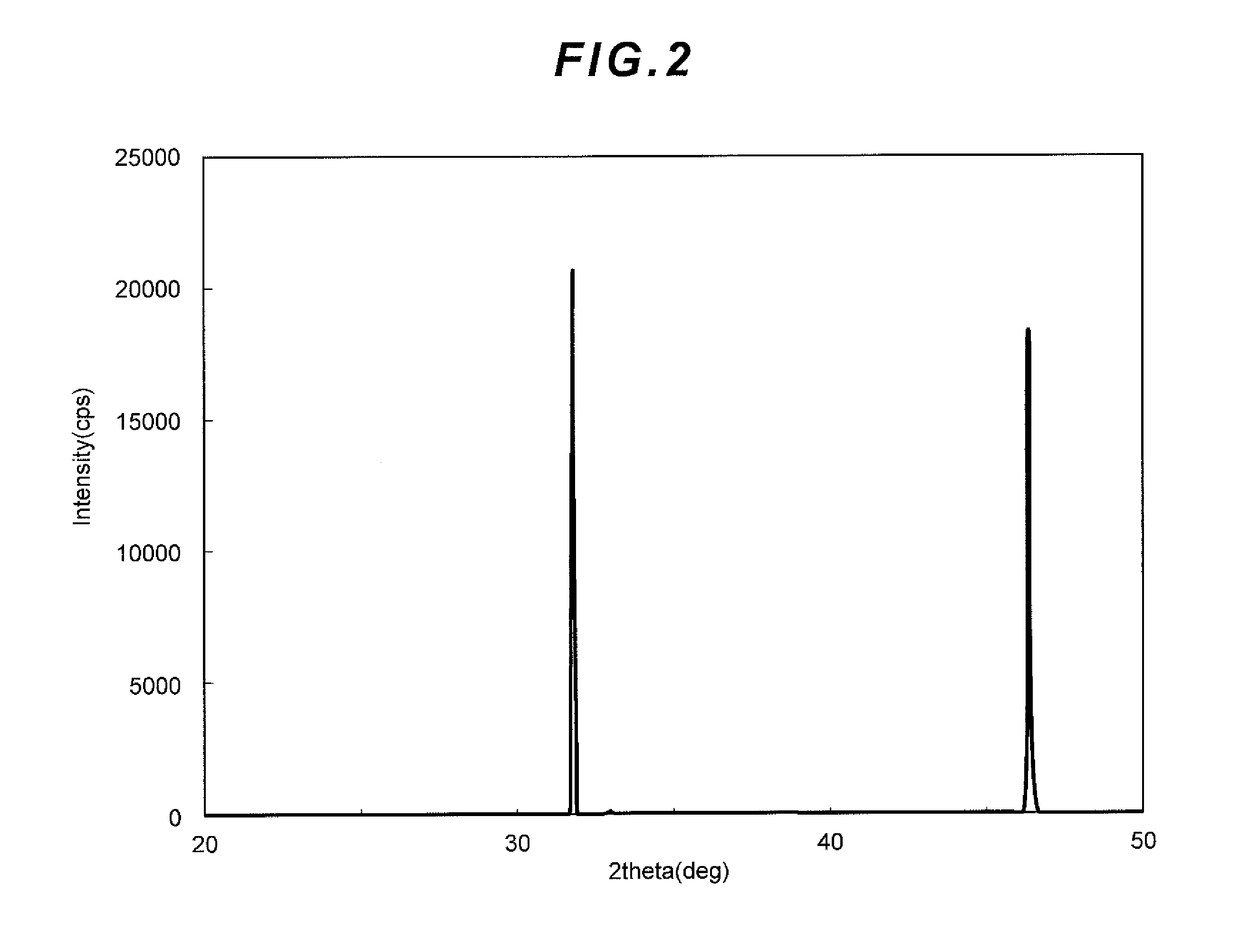

Piezoelectric device, piezoelectric actuator, piezoelectric sensor, hard disk drive, and inkjet printer apparatus

ActiveUS20150364670A1Improve piezoelectric characteristicImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionHard disc driveComputer printing

A piezoelectric element exhibiting a small leakage current density and high reliability as compared with a KNN thin film piezoelectric element in the related art is provided. The piezoelectric element is characterized by including a lower electrode, a piezoelectric layer primarily made from potassium-sodium niobate, which is a perovskite type compound represented by a general formula ABO3, and an upper electrode, wherein the piezoelectric layer is present between the lower electrode and the upper electrode, and the piezoelectric layer has the value determined by dividing the maximum value of intensity of a diffraction peak, where the angle of 2θ is within the range of 21.1°≦2θ≦23.4° in the X-ray diffraction pattern (2θ / θ), by the intensity of a diffraction peak, where 2θ is within the range of 30.1°≦2θ≦33.3°, of 0.04 or less.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com