Microwave hydro-thermal synthesis method for sodium niobate potassium niobate leadless piezoelectric ceramic powder

A microwave hydrothermal and ceramic powder technology, applied in chemical instruments and methods, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problems of high sintering temperature, high energy consumption, high heat treatment temperature, etc. Achieve the effect of wide application prospect, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

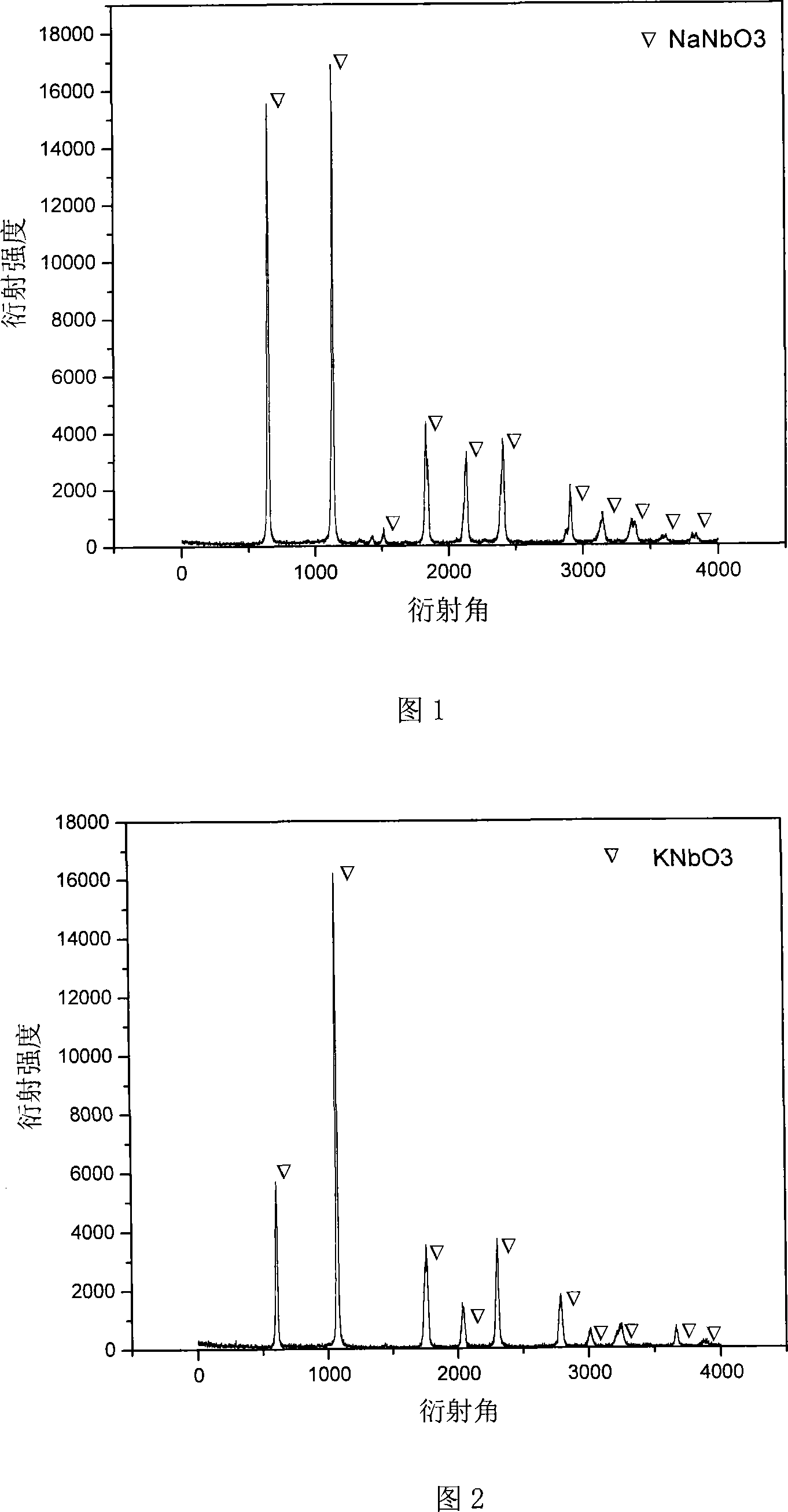

Embodiment 1

[0020] The process flow is as follows:

[0021] 1. Configure a sodium hydroxide solution with a concentration of 6mol / L, and the volume of the solution is 60ml;

[0022] 2. Weigh 3.75 grams (0.0141mol) Nb 2 o 5 Powder;

[0023] 3. Add Nb 2 o 5 Mix the powder with potassium hydroxide solution and put it into a polytetrafluoroethylene hydrothermal kettle, keep the filling degree of 50%, and stir for 1 hour until the mixture is uniform;

[0024] 4. Put the hydrothermal kettle into the microwave oven, adjust the power knob, control the reaction temperature at 110-150°C, and keep it warm for 2-6h.;

[0025] 5. After the reaction is complete, a white precipitate can be seen on the bottom of the inner substrate. In order to detect whether there is soluble niobate in the solution, pour the supernatant in the inner lining into a beaker and add hydrochloric acid dropwise until neutral;

[0026] 6. Use deionized water to centrifuge the white sediment at the bottom of the inner subs...

Embodiment 2

[0030] The process flow is as follows:

[0031] 1. Configure a potassium hydroxide solution with a concentration of 6mol / L, and the volume of the solution is 60ml;

[0032] 2. Weigh 3.75 grams (0.0141mol) Nb 2 o 5 Powder;

[0033] 3. Add Nb 2 o 5 Mix the powder with KOH solution and put it into a polytetrafluoroethylene hydrothermal kettle, keep the filling degree of 50%, and stir for 1 hour until the mixture is uniform;

[0034] 4. Put the hydrothermal kettle into the microwave oven, adjust the power knob, control the reaction temperature at 110-150°C, and keep it warm for 10-24h;

[0035] 5. After the reaction is complete, a white precipitate can be seen on the bottom of the inner substrate. In order to detect whether there is soluble niobate in the solution, pour the supernatant in the inner lining into a beaker and add hydrochloric acid dropwise until neutral;

[0036] 6. Use deionized water to centrifuge the white sediment at the bottom of the inner substrate severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com