Patents

Literature

334 results about "Potassium niobate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium niobate (KNbO₃) is a perovskite ferroelectric crystal. It has nonlinear optical coefficient properties, making it common in the manufacture of lasers. Nanowires of potassium niobate have been used to produce tunable coherent light. The LD₅₀ for potassium niobate is 3000 mg/kg (oral, rat).

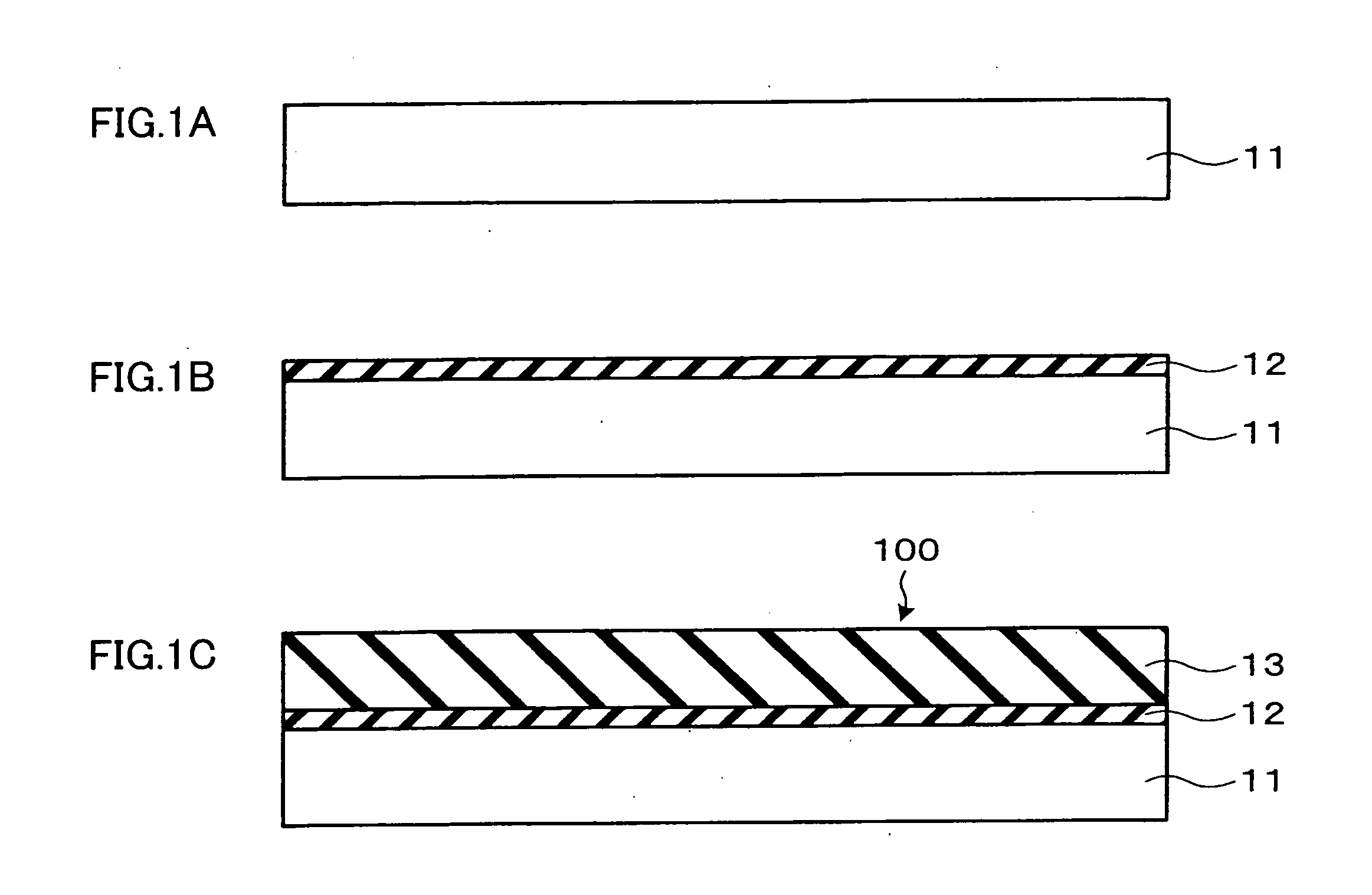

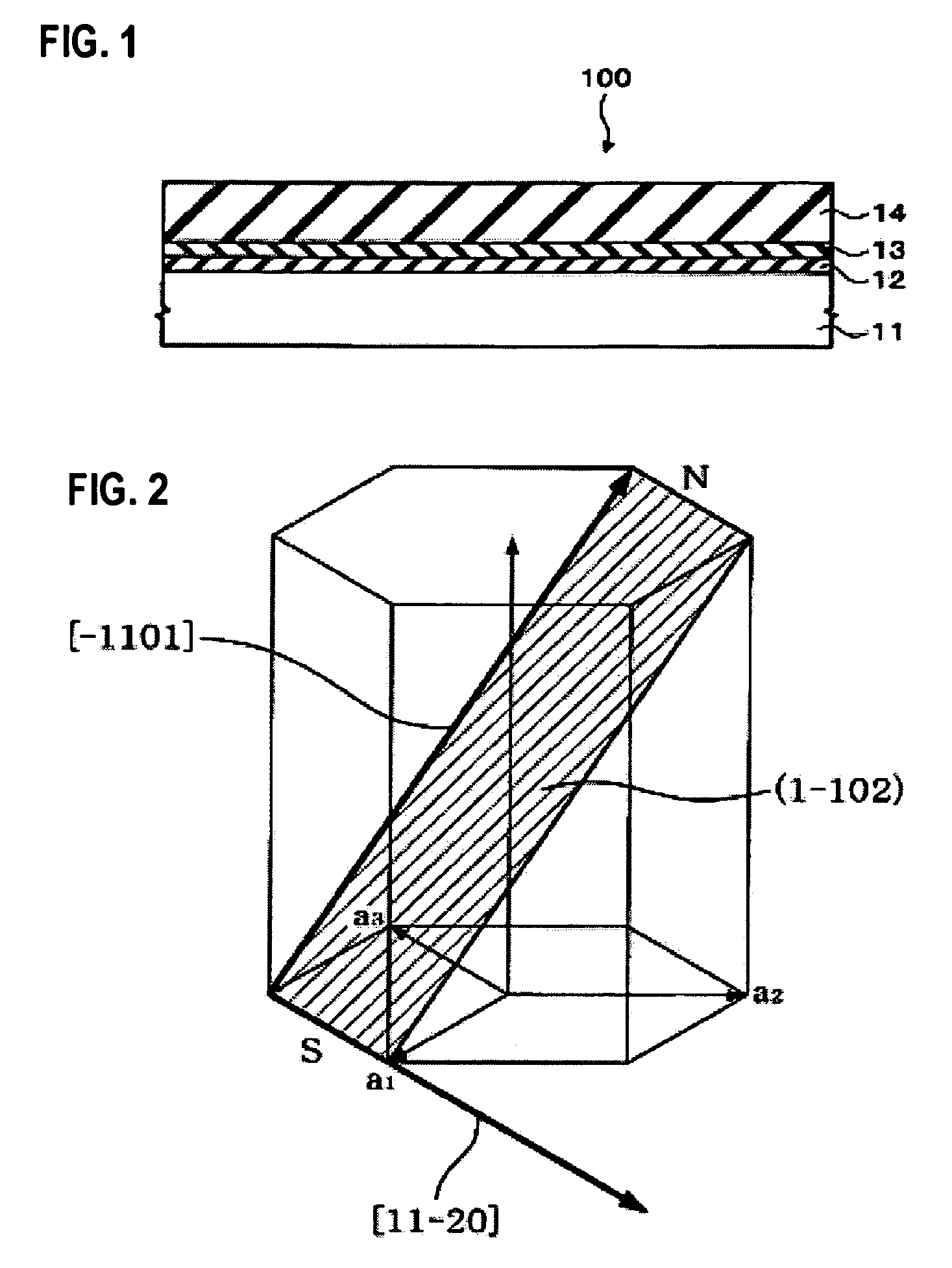

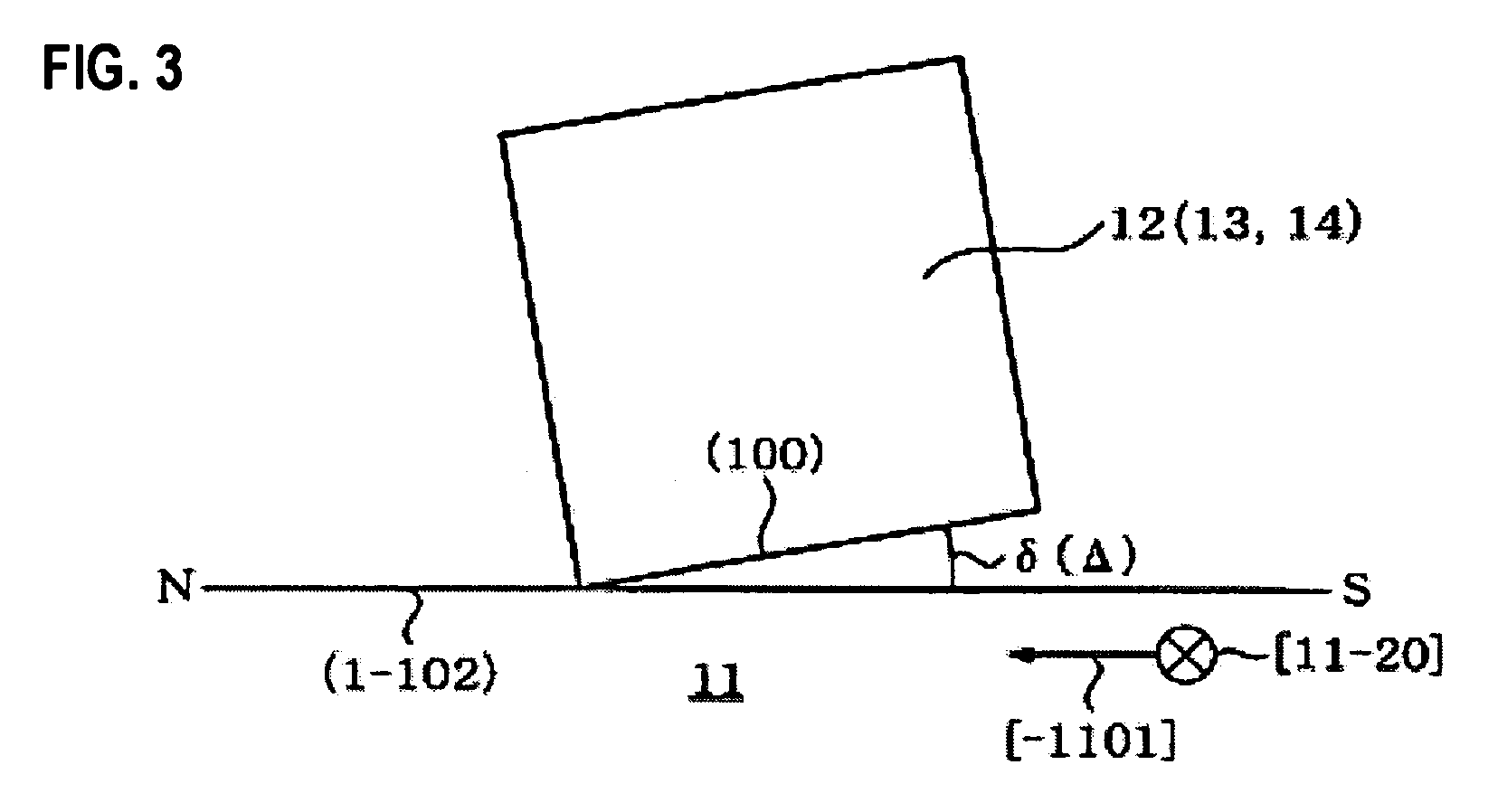

Method of manufacturing potassium niobate single crystal thin film, surface acoustic wave element, frequency filter, frequency oscillator, electric circuit, and electronic apparatus

InactiveUS20040197599A1Piezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthGas phaseSingle crystal

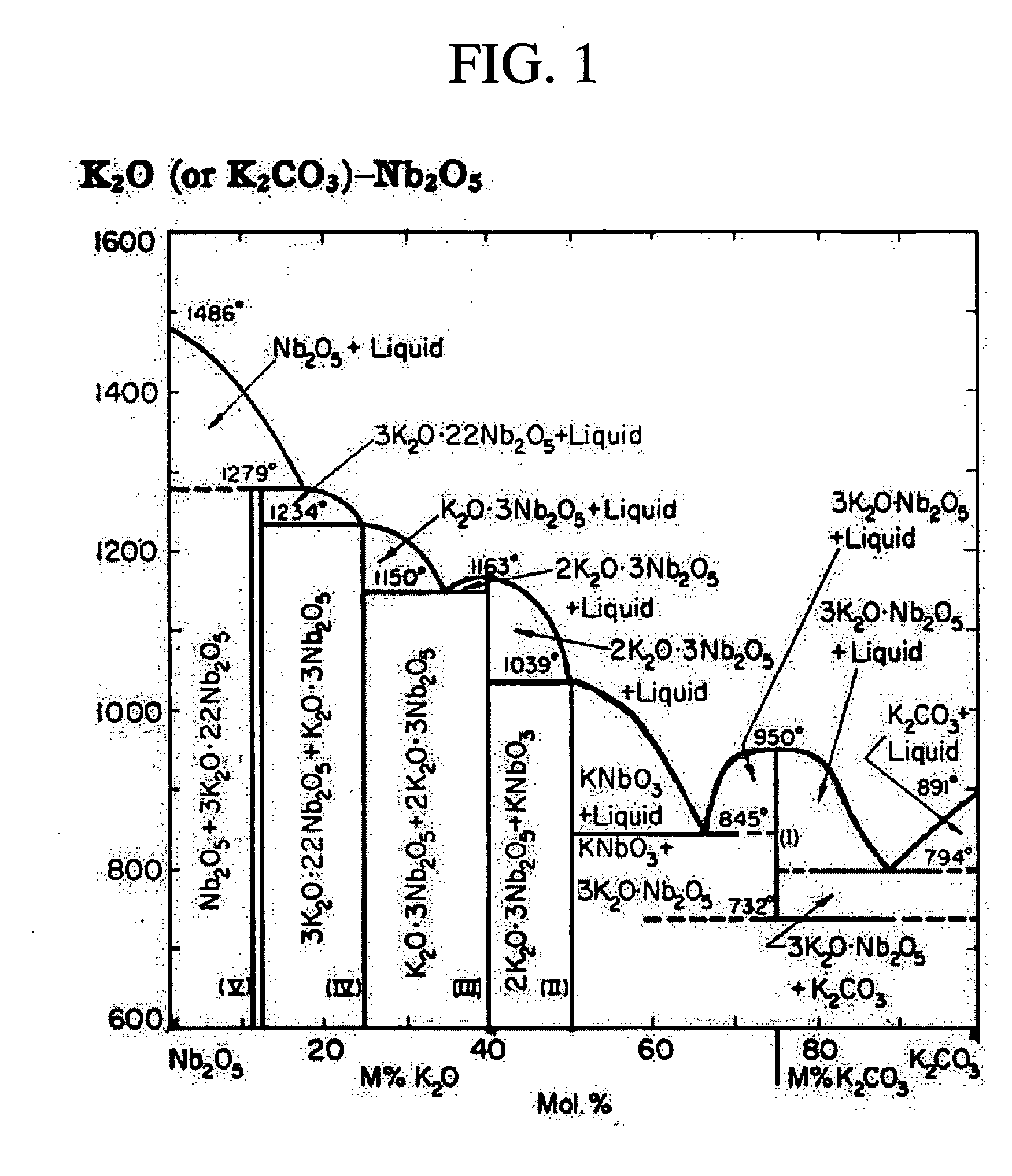

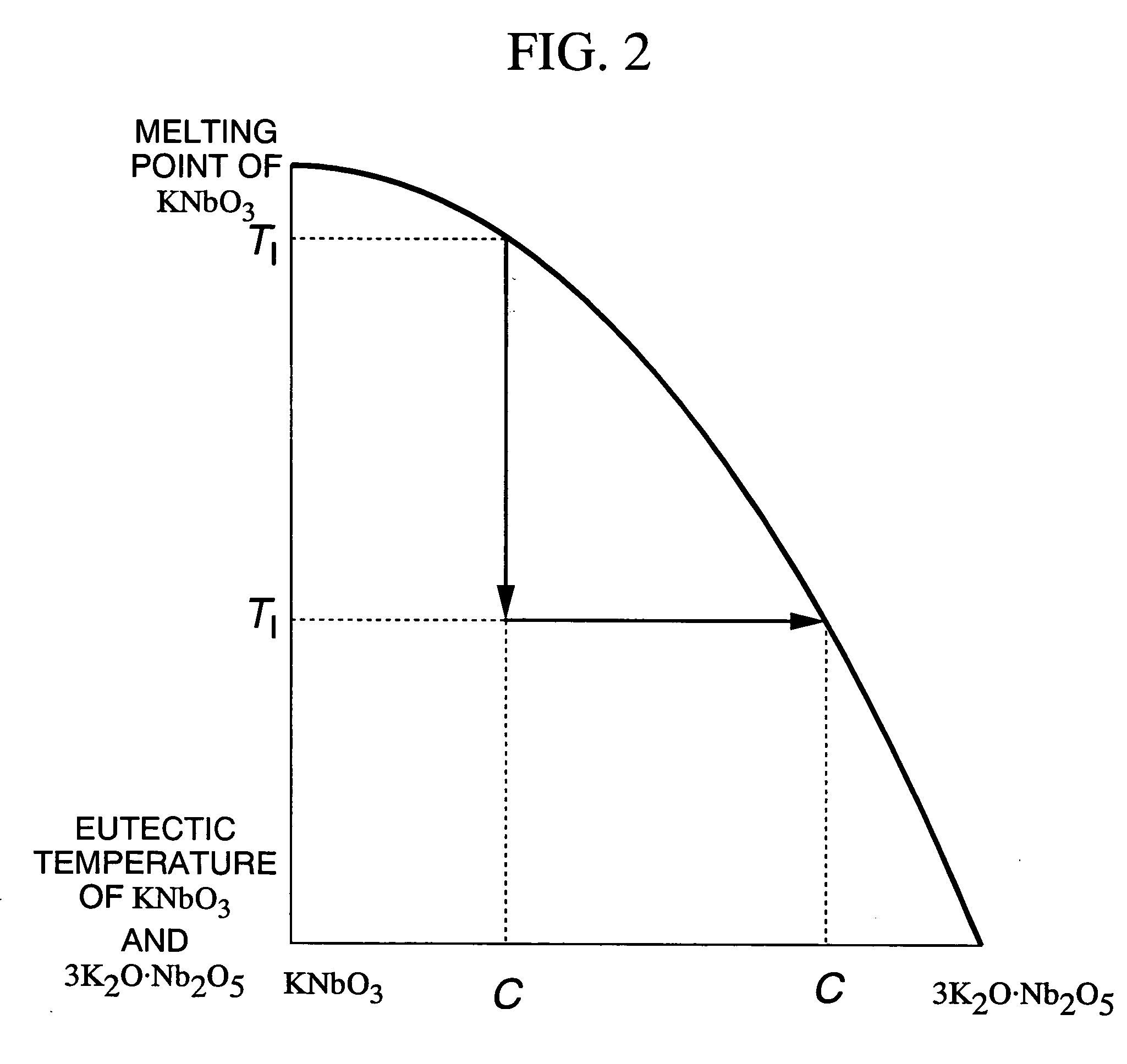

A method of manufacturing a potassium niobate (KNbO3) single crystal thin film, includes the steps of maintaining the substrate under a predetermined oxygen partial pressure; maintaining the substrate within a temperature region which is equal to or higher than an eutectic temperature of KNbO3 and 3K2O.Nb2O5 and is equal to or lower than complete melting temperature of KNbO3 and 3K2O.Nb2O5 so that a solid phase of KNbO3 and a liquid phase can coexist on the substrate; depositing a vapor phase material on the substrate in a state in which a solid phase and a liquid phase coexist; and precipitating KNbO3 on the substrate from the liquid phase as a solid phase to grow a KNbO3 single crystal thin film. The composition of a starting material to be vaporized to generate the vapor phase material is from K2O.Nb2O5=50:50 to K2O.Nb2O5=65:35.

Owner:SEIKO EPSON CORP

Amorphous dielectric capacitors on silicon

InactiveUS6255122B1Improve conformityReduce leakage currentTransistorSemiconductor/solid-state device manufacturingLead zirconate titanateMaterials science

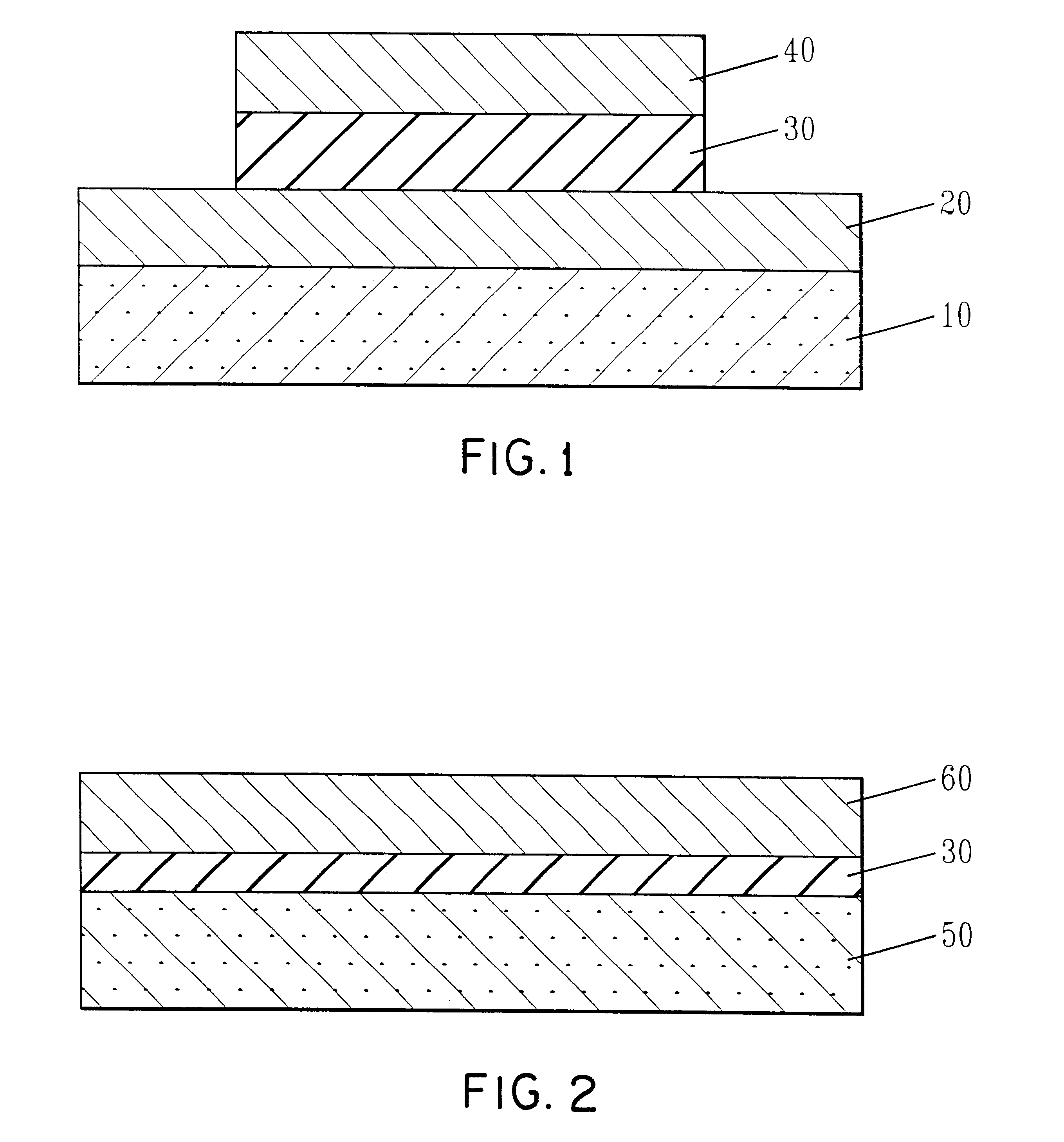

High-capacity capacitors and gate insulators exhibiting moderately high dielectric constants with surprisingly low leakage using amorphous or low temperature films of perovskite type oxides including a titanate system material such as barium titanate, strontium titanate, barium strontium titanate (BST), lead titanate, lead zirconate titanate, lead lanthanum zirconate titanate, barium lanthanum titanate, a niobate, aluminate or tantalate system material such as lead magnesium niobate, lithium niobate lithium tantalate, potassium niobate and potassium tantalum niobate, a tungsten-bronze system material such as barium strontium niobate, lead barium niobate, barium titanium niobate, and Bi-layered perovskite system material such as strontium bismuth tantalate, bismuth titanate deposited directly on a silicon surface at temperatures about 450° C. or less.

Owner:GLOBALFOUNDRIES INC

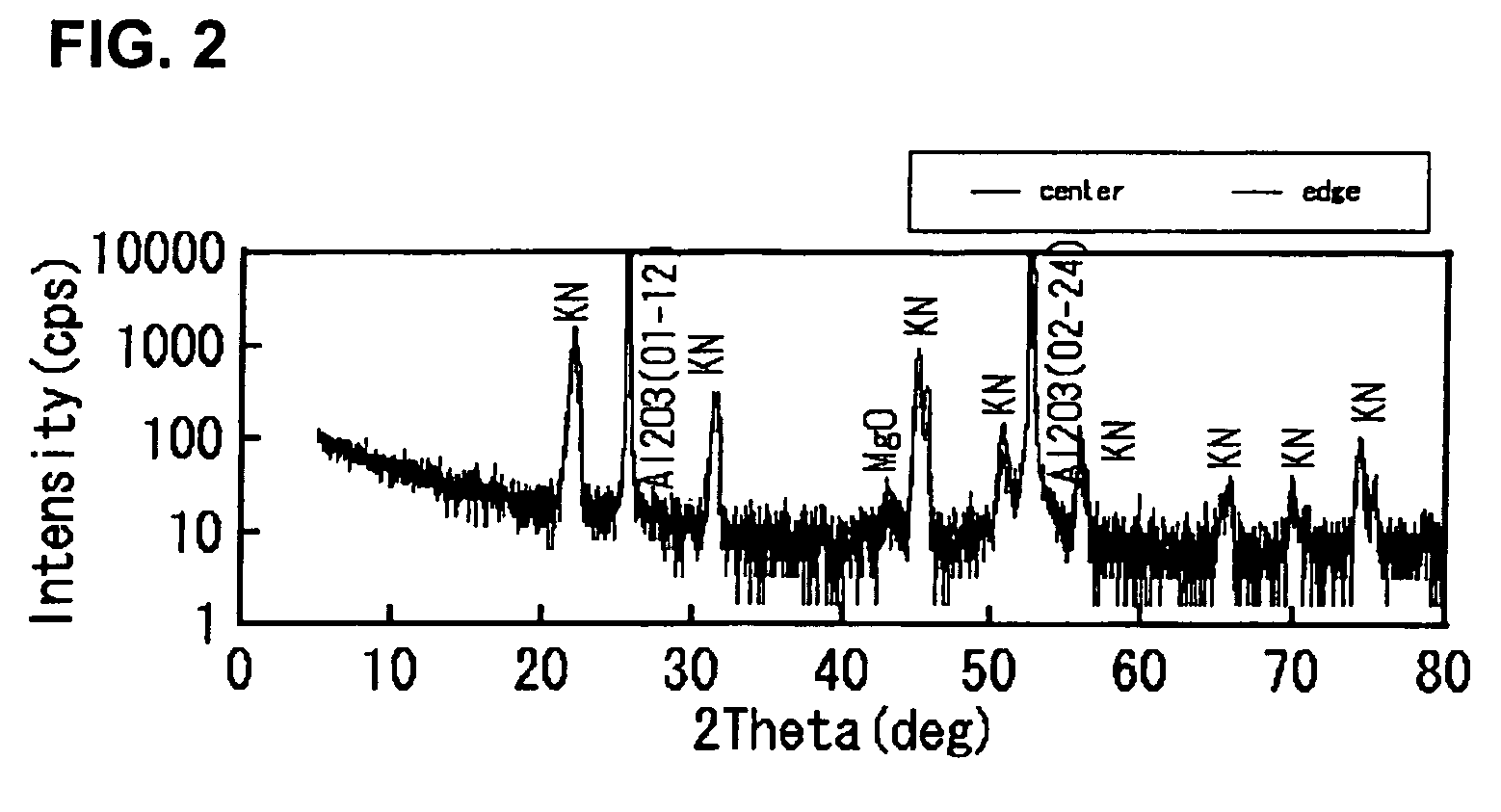

Potassium niobate deposited body, method for manufacturing the same, surface acoustic wave element, frequency filter, frequency oscillator, electronic circuit, and electronic apparatus

InactiveUS20050200235A1High crystallinityPolycrystalline material growthPiezoelectric/electrostrictive device manufacture/assemblyFrequency filteringAcoustic wave

A potassium niobate deposited body includes a sapphire substrate, and a potassium niobate layer formed above the sapphire substrate. The potassium niobate deposited body further includes a buffer layer consisting of a metal oxide formed above the sapphire substrate, wherein the potassium niobate layer is formed above the buffer layer.

Owner:SEIKO EPSON CORP

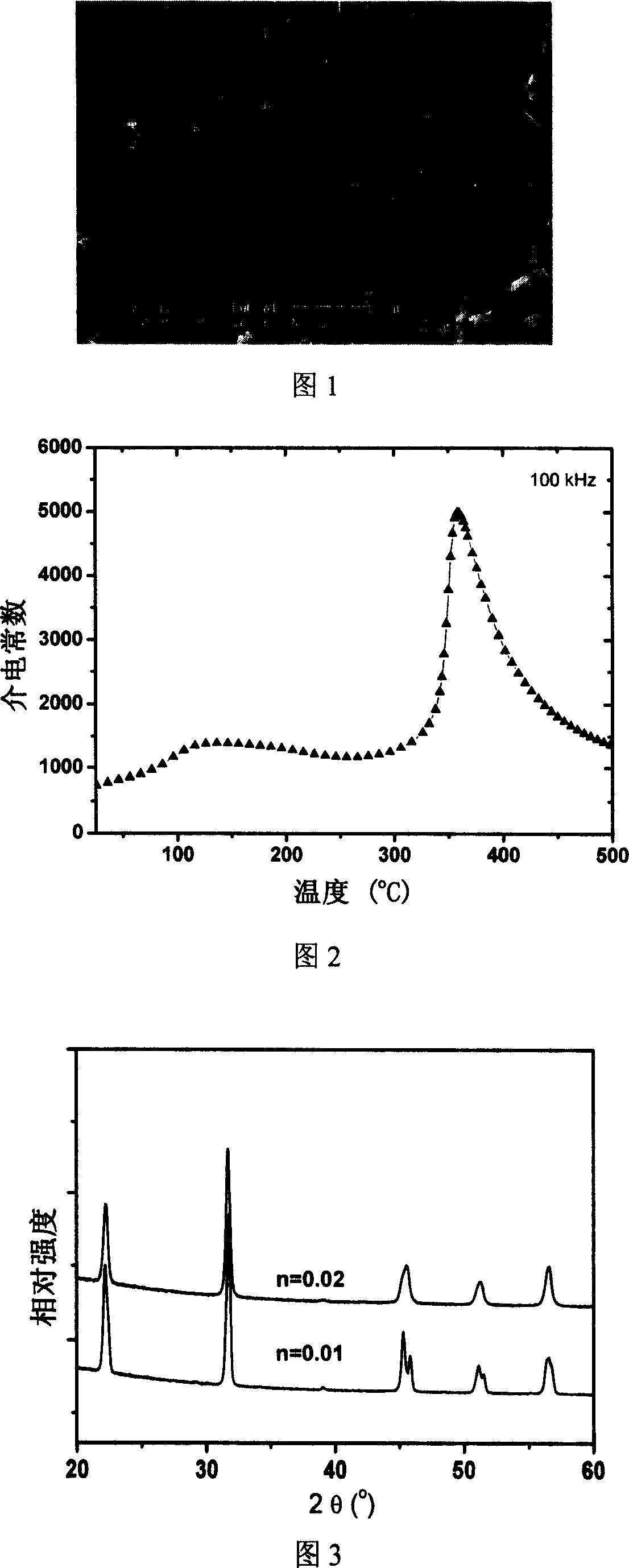

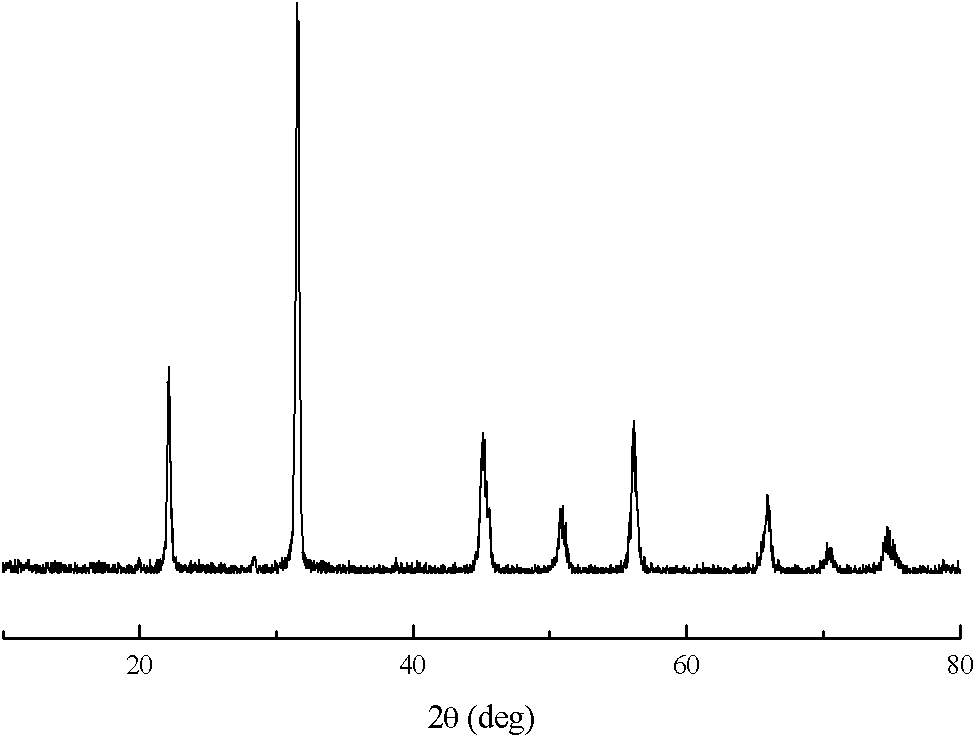

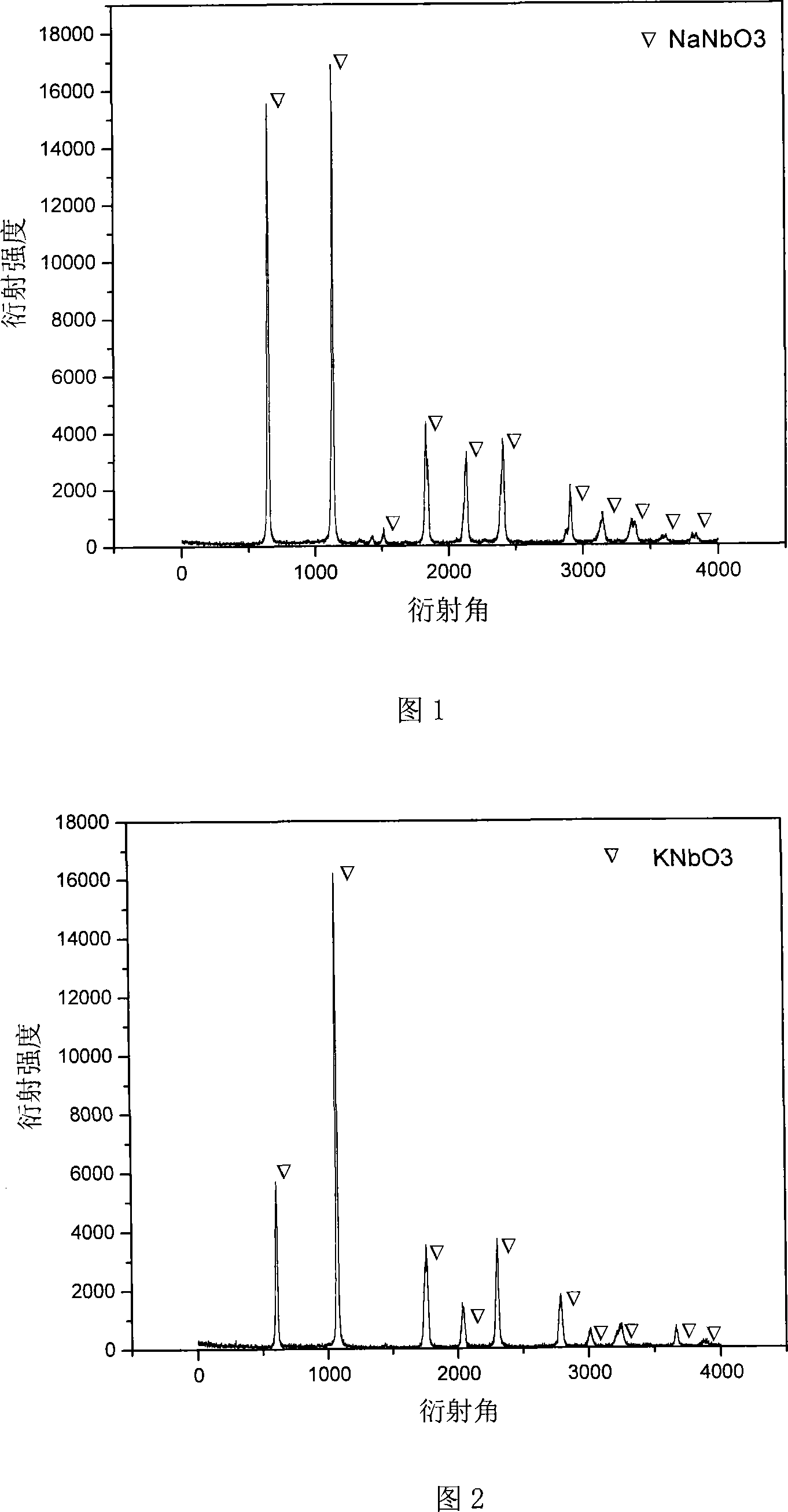

Niobium niobium antimony sodiate potassium leadless piezoelectric ceramic composition

InactiveCN101376594AExcellent piezoelectric propertiesHigh curie temperaturePiezoelectric/electrostrictive/magnetostrictive devicesNiobiumPotassium

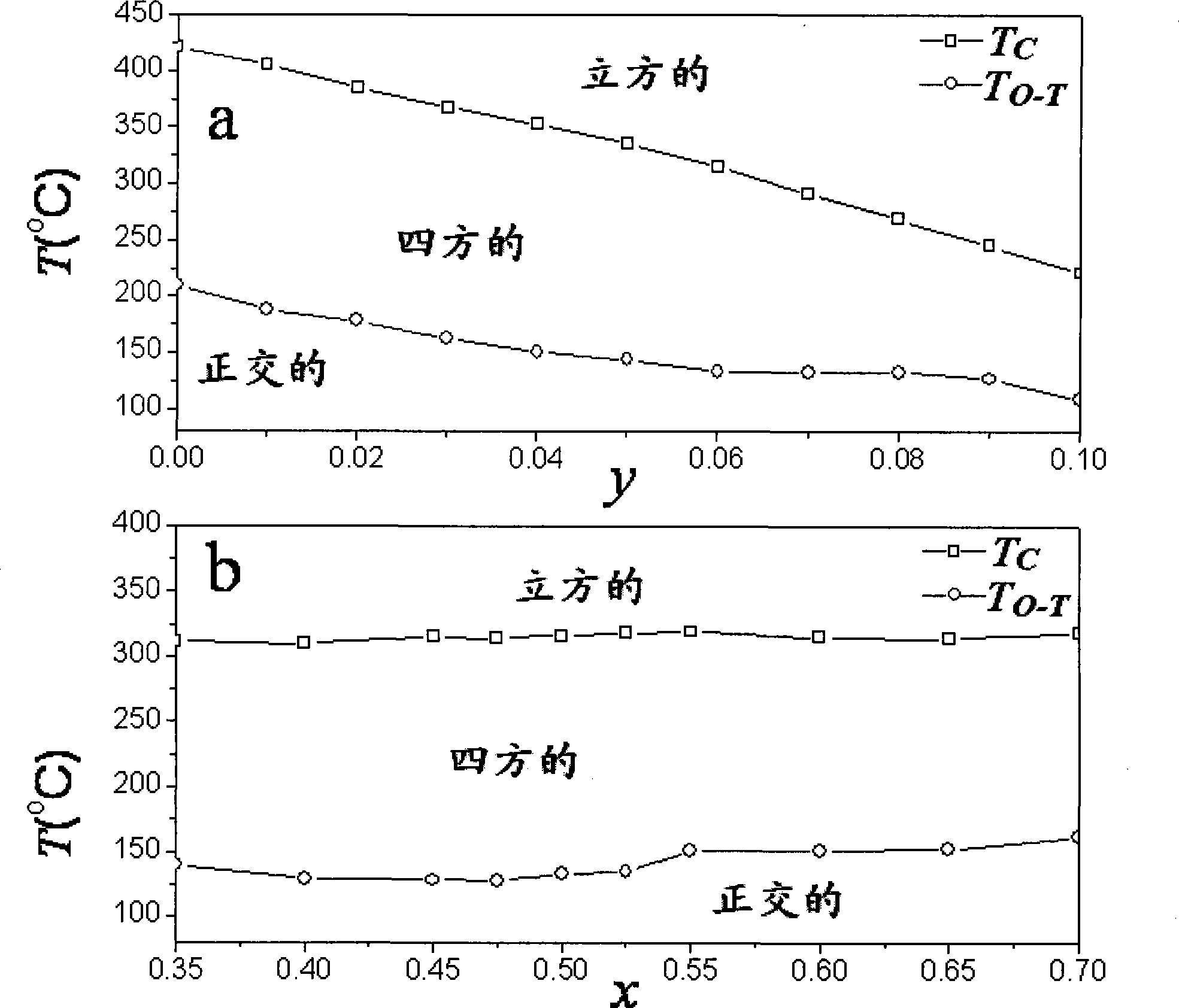

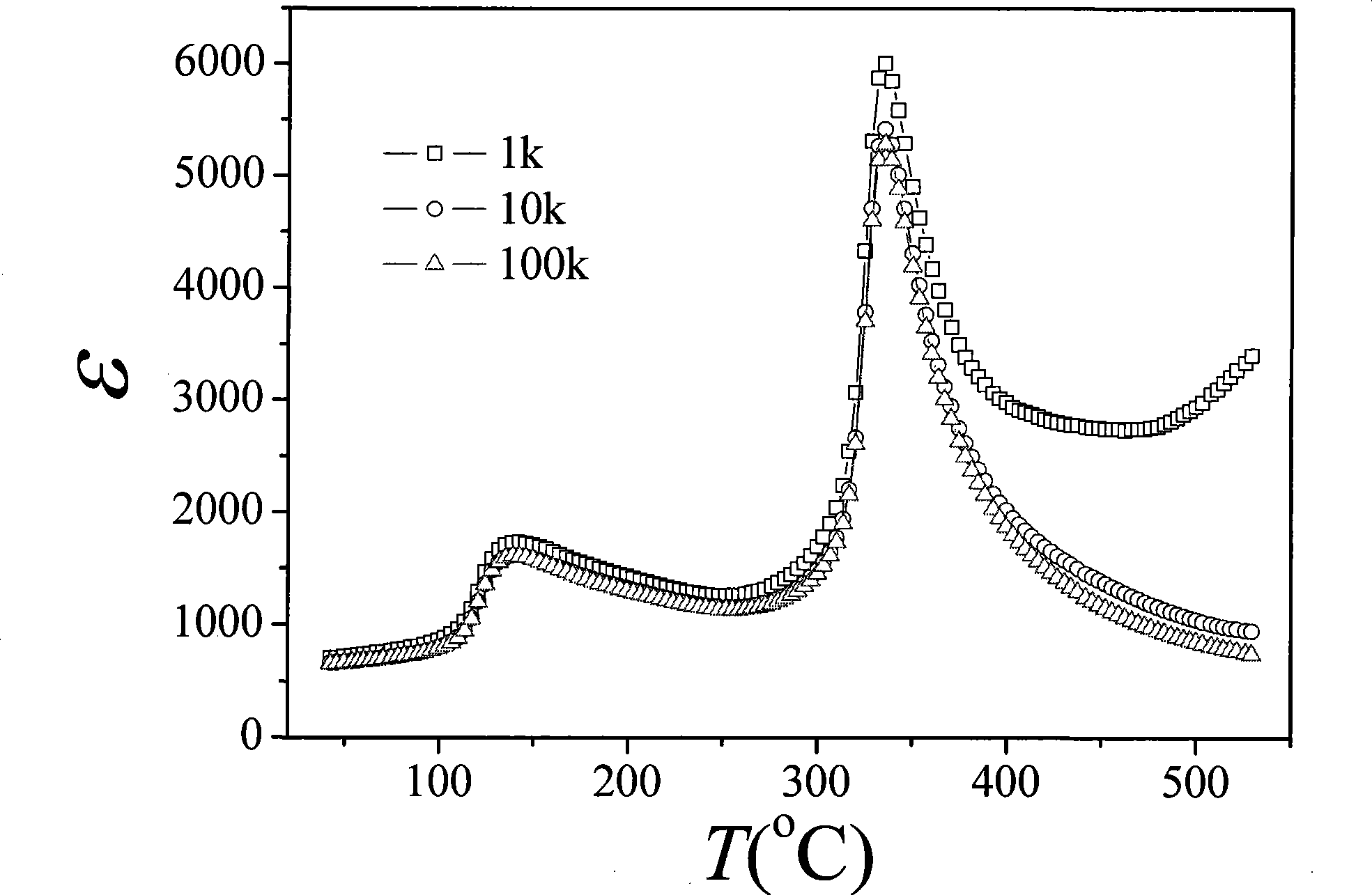

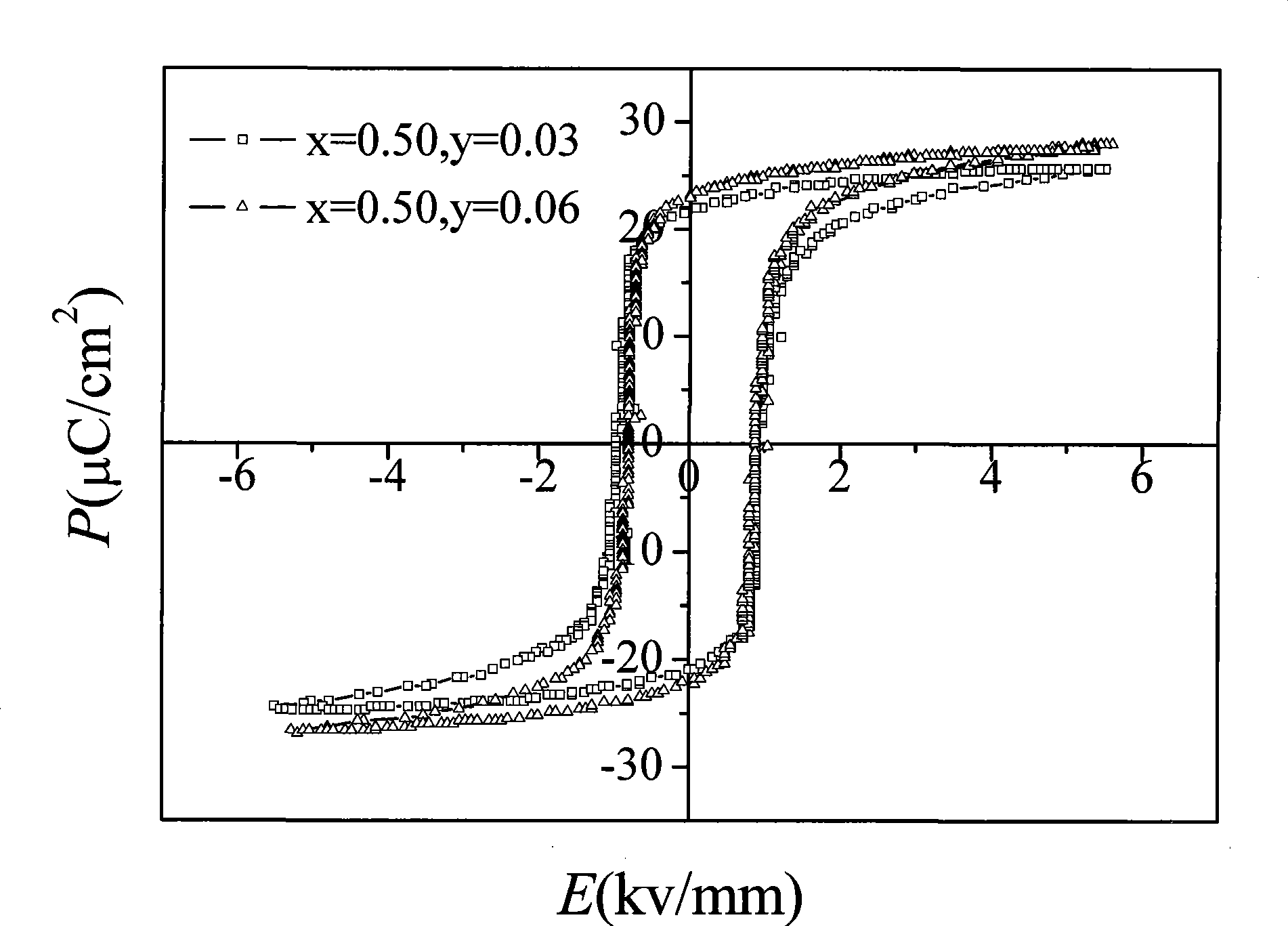

The invention provides lead-free sodium potassium niobate antimonate piezoelectric ceramic composition. The composition is lead-free piezoelectric ceramic solid solution formed by introducing high electronegativity Sb part into the B position of alkali metal niobate ferroelectrics (Na1-xKx) NbO3 with ABO3 type perofskite structure to replace Nb. The lead-free piezoelectric ceramic composition has the advantages that the piezoelectric performance is excellent, the Curie temperature is high, the thermostability of the piezoelectric performance is good, the preparation technique is stable, the composition is obtained by adopting tradition piezoelectric ceramics, the sintering temperature is low, and the compactness is good.

Owner:THE HONG KONG POLYTECHNIC UNIV

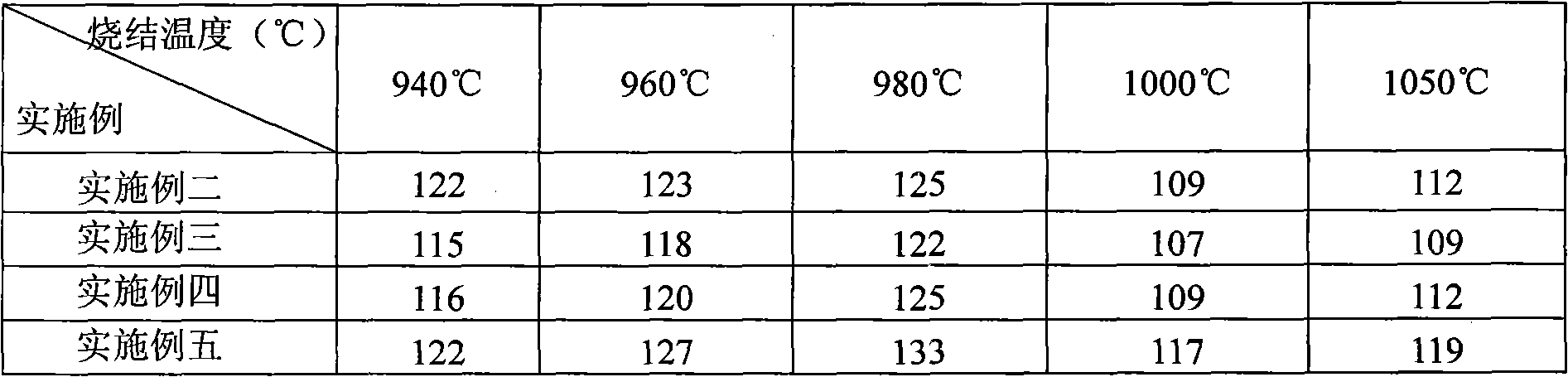

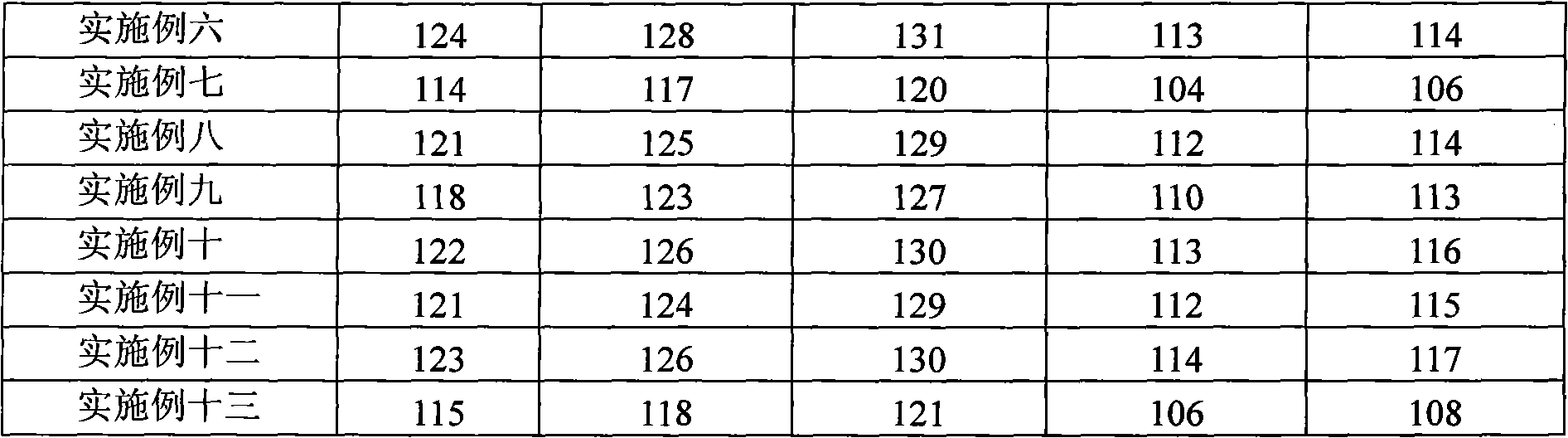

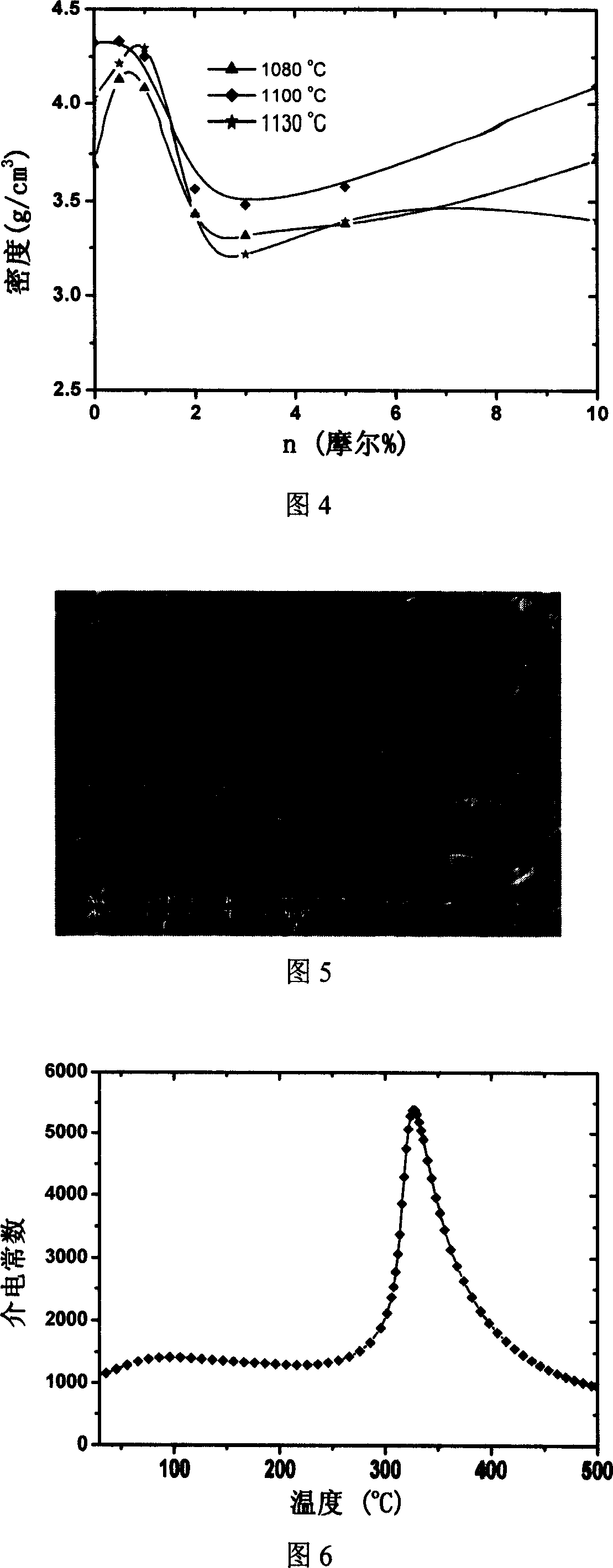

Low-temperature sintered potassium sodium niobate lead-free piezoelectric ceramic and preparation method thereof

InactiveCN102070337ALower sintering temperatureExcellent and stable performancePiezoelectric/electrostrictive/magnetostrictive devicesFritPotassium niobate

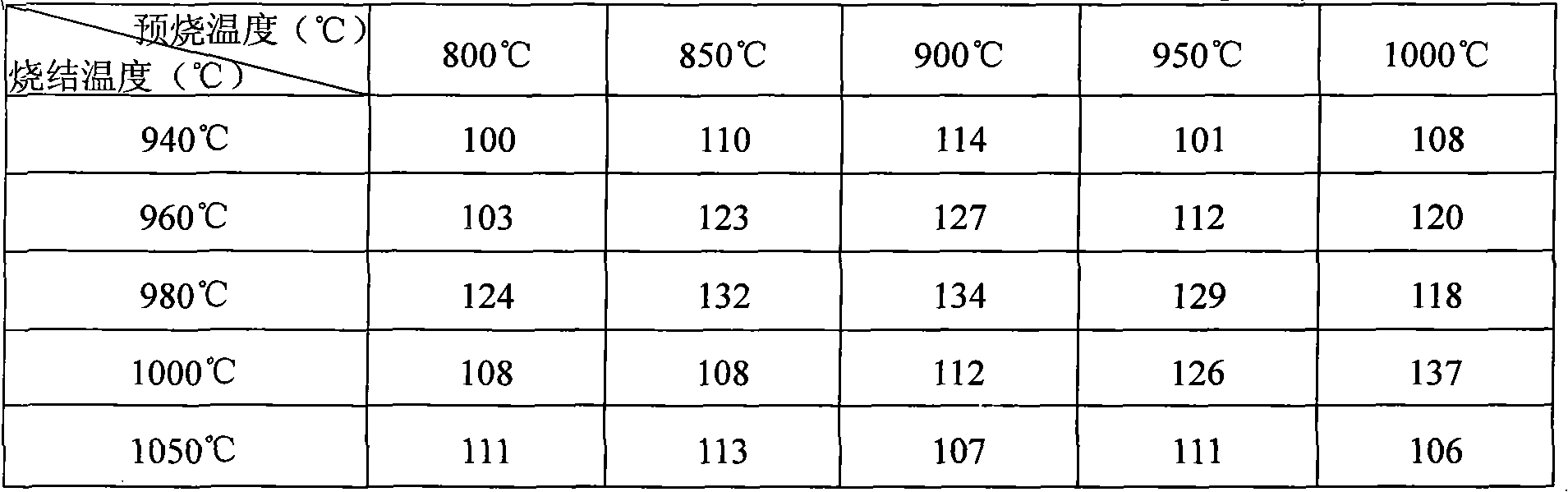

The invention discloses a low-temperature sintered potassium sodium niobate lead-free piezoelectric ceramic, which is expressed by a low-temperature clinker of a general formula KaNabNbO3-x, wherein a and b express molar fractions of elements respectively, the a is more than or equal to 0.3 and less than or equal to 0.7, and the b is more than or equal to 0.3 and less than or equal to 0.7; x expresses weight percentage of the low-temperature clinker in the KaNabNbO3, and x is more than 0 and less than or equal to 15 percent; and the low-temperature clinker consists of one or more of Li2O, Na2O, K2O, B2O3, SiO2, CaO, BaO, ZnO, CuO, MnO2 and MgO. The invention also discloses a preparation method for the potassium sodium niobate lead-free piezoelectric ceramic. Low-temperature sintering is realized by adding the clinker, the firing temperature range is enlarged at the same time of effectively reducing the sintering temperature of potassium sodium niobate, the stoichiometric ratio is controllable, the chemical component fluctuation is low, and a piezoelectric material with excellent and stable performance is obtained.

Owner:JINGDEZHEN CERAMIC INSTITUTE

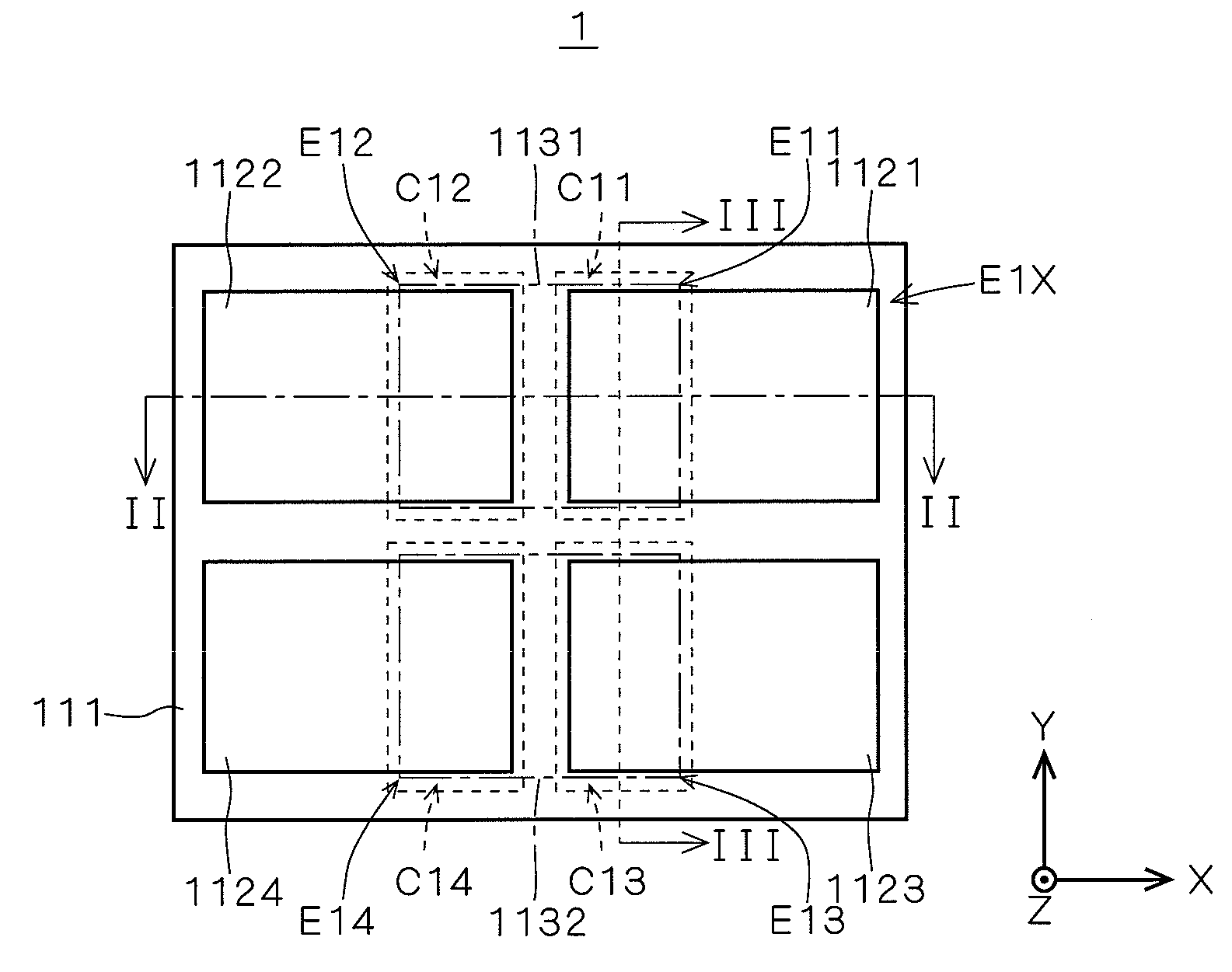

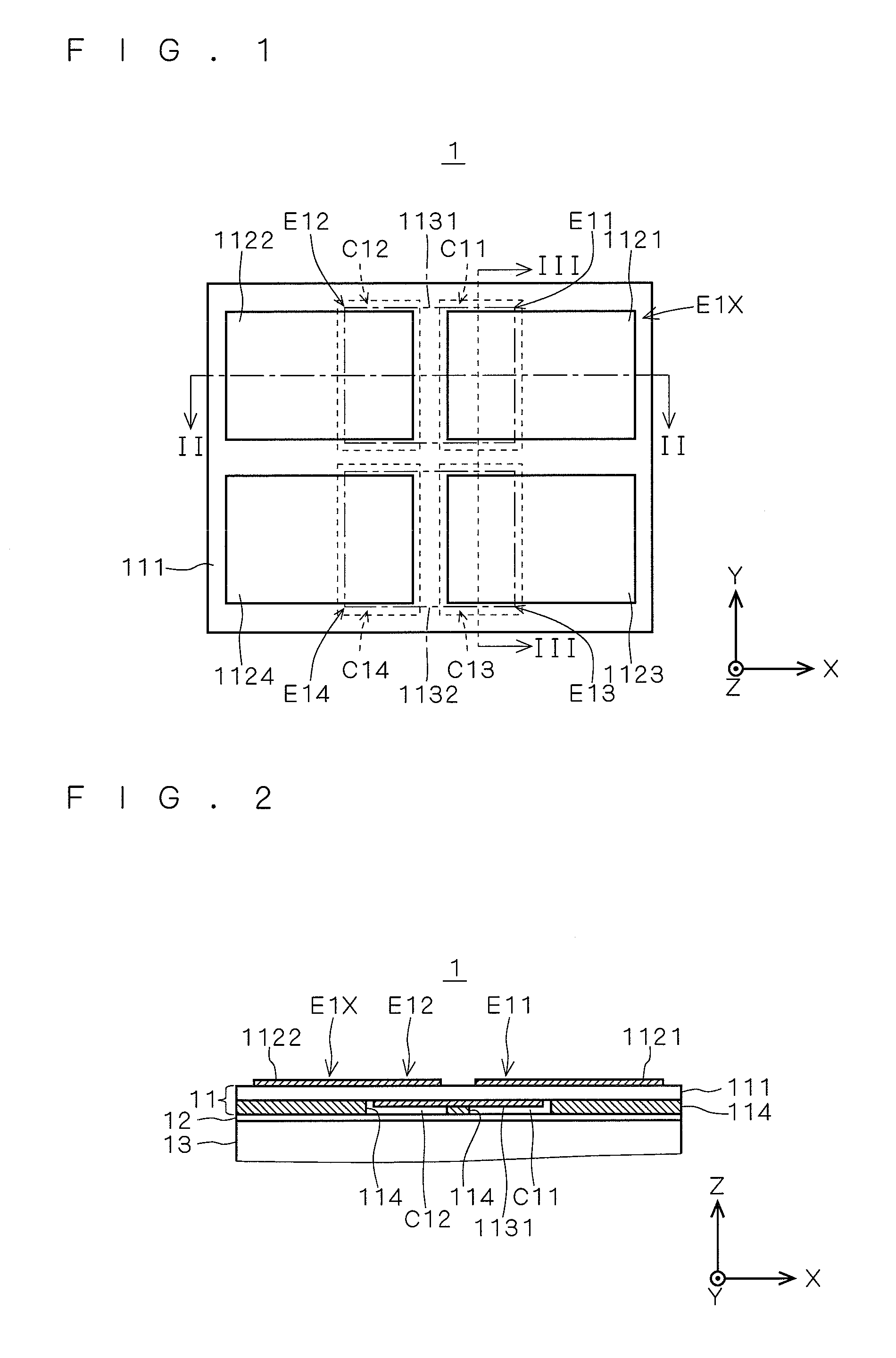

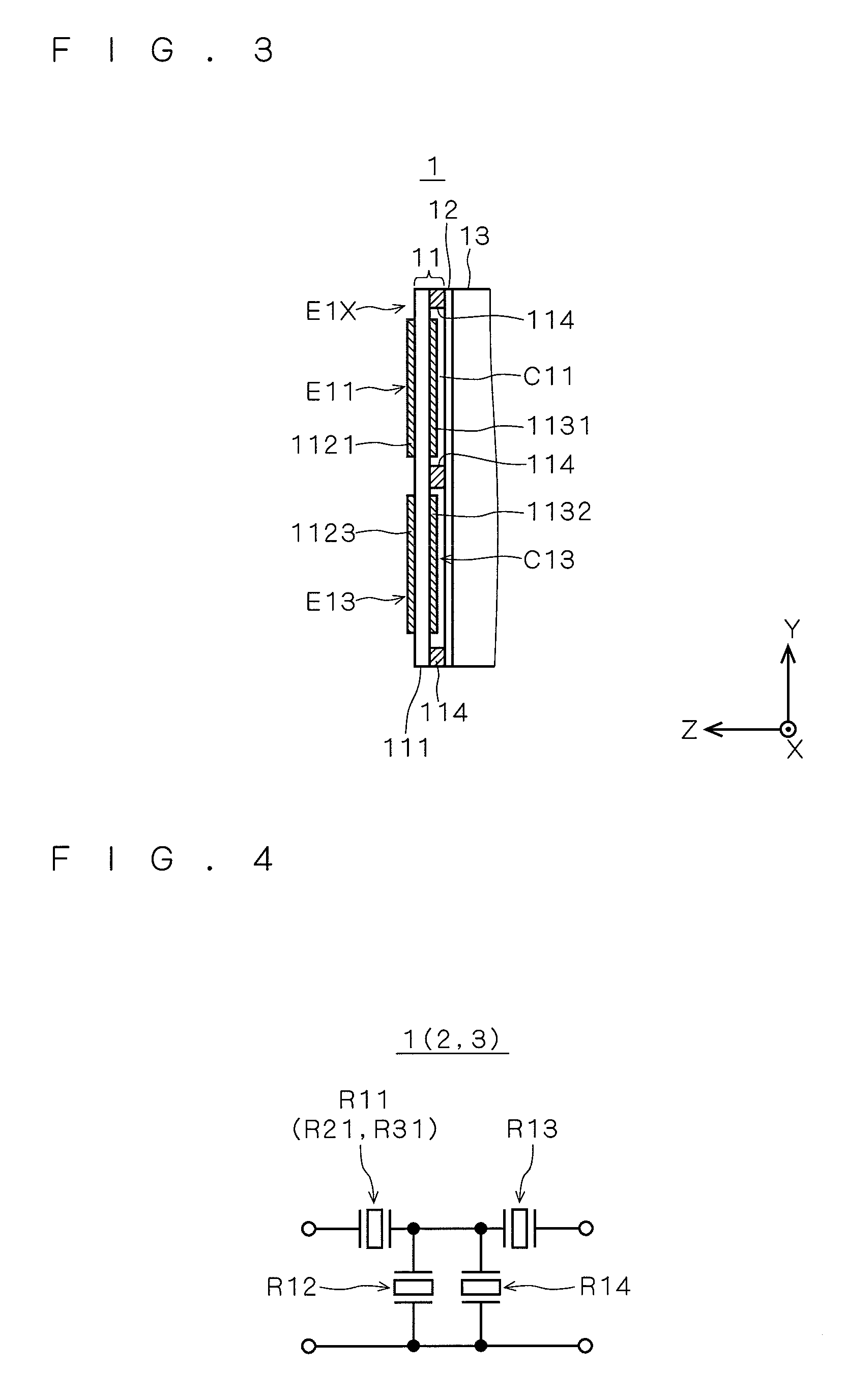

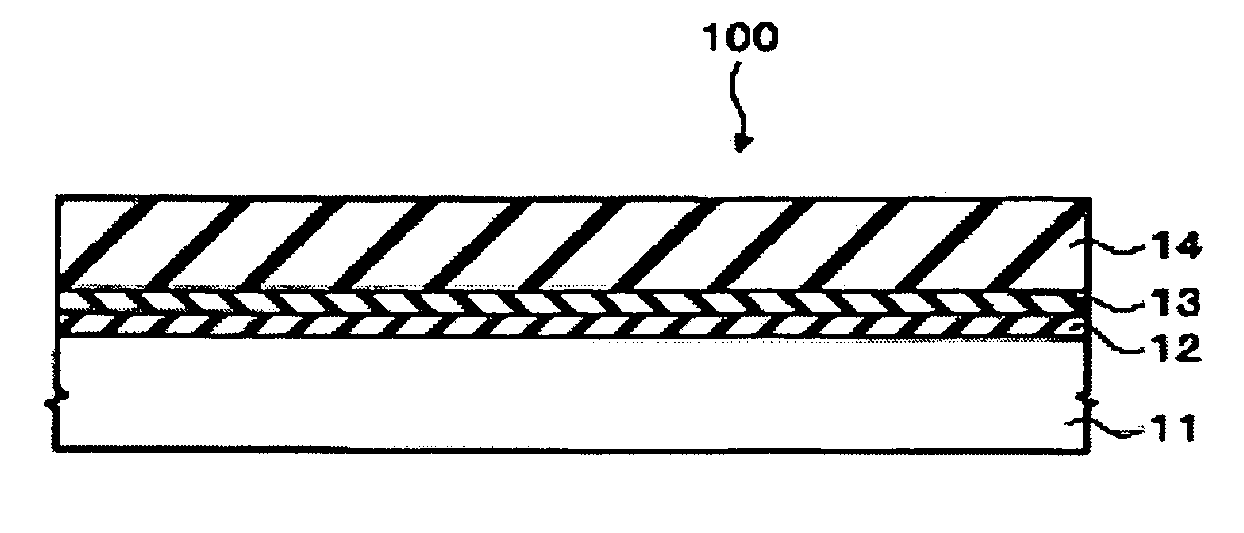

Piezoelectric thin film device

InactiveUS20070200458A1Improve featuresQuality improvementPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesSingle crystalTantalite

The present invention is directed to improving characteristics of a piezoelectric thin film device. A piezoelectric thin film filter including four film bulk acoustic resonators has a configuration where a filter section and a base substrate are bonded to each other via an adhesive layer, the filter section including a piezoelectric thin film which cannot stand up individually under its own weight, the flat base substrate mechanically supporting the filter section. As a piezoelectric material constructing the piezoelectric thin film, it is desirable to use a single-crystal material including no grain boundary, selected from crystal, lithium niobate, lithium tantalite, lithium tetraborate, zinc oxide, potassium niobate, and langasite.

Owner:NGK INSULATORS LTD +1

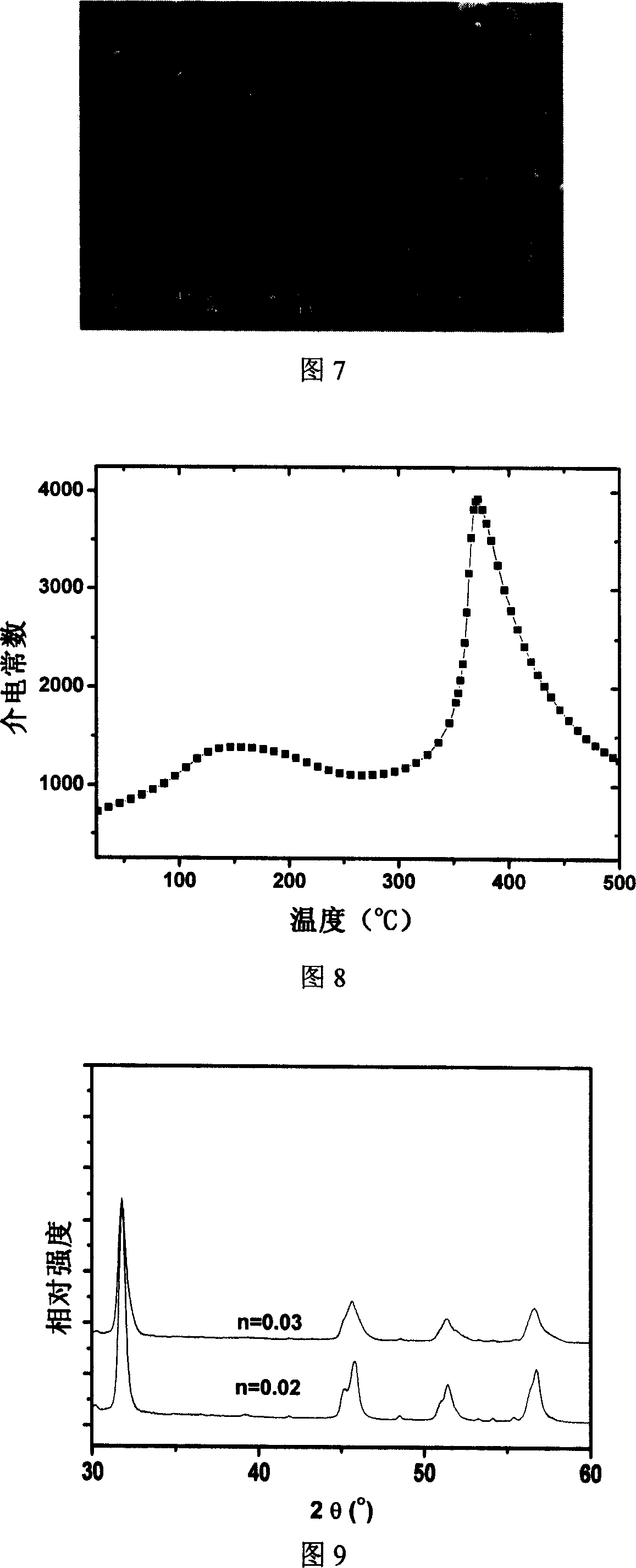

Sodium-potassium niobate series substituted by bismuth-base calcium-titanium ore and preparing method

InactiveCN101024574AImprove performanceLead-free system with good performance has good environmental compatibilityPiezoelectric/electrostrictive/magnetostrictive devicesElectricityManufacturing technology

The invention relates to a potassium niobate natrium series leadless piezoelectric ceramics and the manufacturing method. It is expressed by the general equation: (1-u)[(1-n)(LitNa1-w-t1Kw-t2)(Nb1-g-fTagSbf)O3+nBiMeO3]+uM. The invention has stable manufacturing technology and has great usefulness.

Owner:SENBA SENSING TECH CO LTD

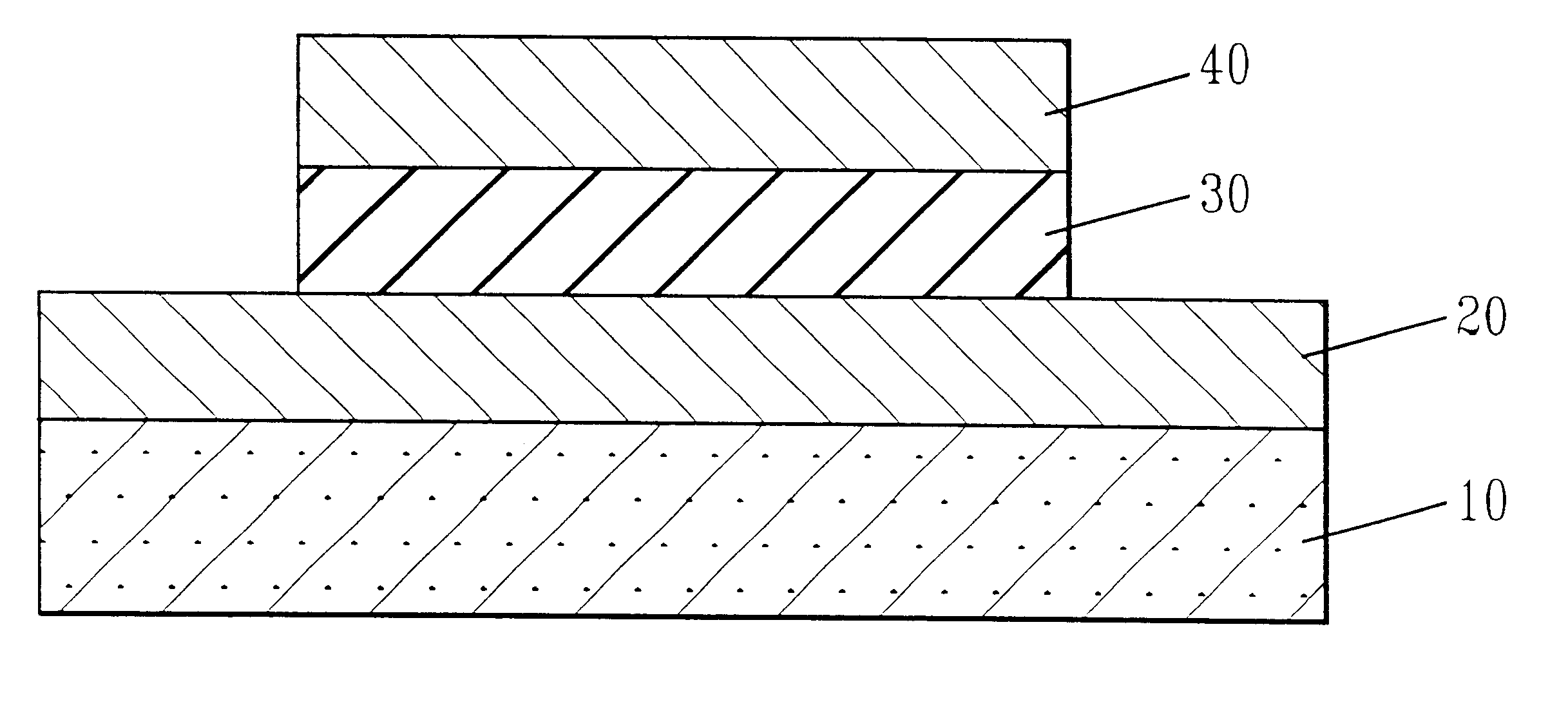

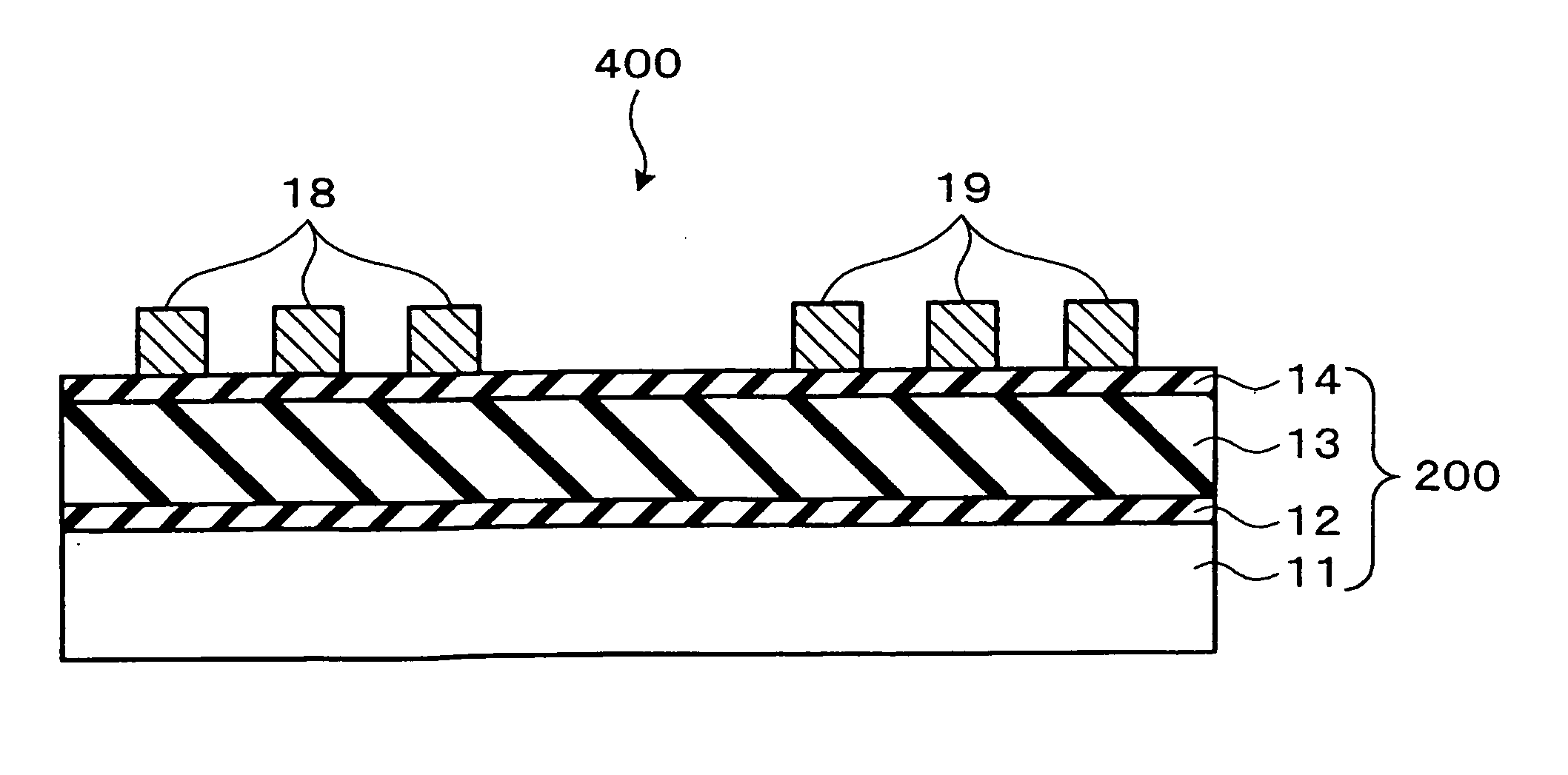

Potassium niobate deposited body and method for manufacturing the same, piezoelectric thin film resonator, frequency filter, oscillator, electronic circuit, and electronic apparatus

InactiveUS20060222872A1Polycrystalline material growthPiezoelectric/electrostrictive device manufacture/assemblyLead zirconate titanatePotassium

A potassium niobate deposited body includes an R-plane sapphire substrate, a buffer layer composed of a metal oxide and formed above the R-plane sapphire substrate, a lead zirconate titanate niobate layer formed above the buffer layer, a potassium niobate layer or a potassium niobate solid solution layer formed above the lead zirconate titanate niobate layer, an electrode layer formed above the potassium niobate layer or the potassium niobate solid solution layer, and another substrate formed above the electrode layer.

Owner:SEIKO EPSON CORP

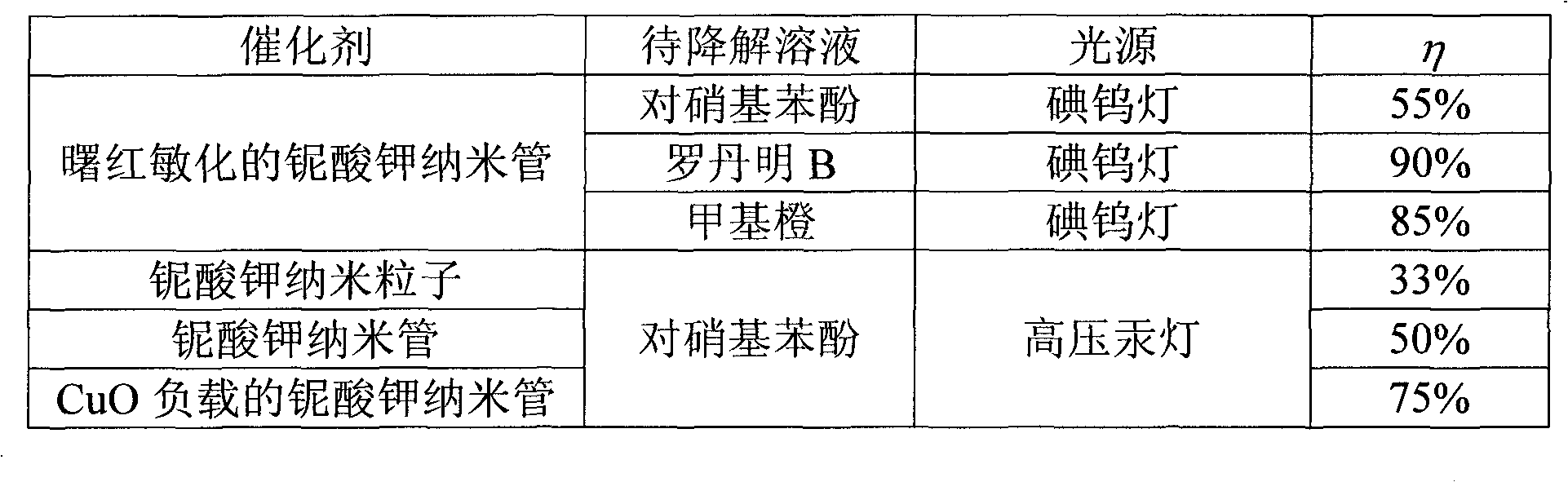

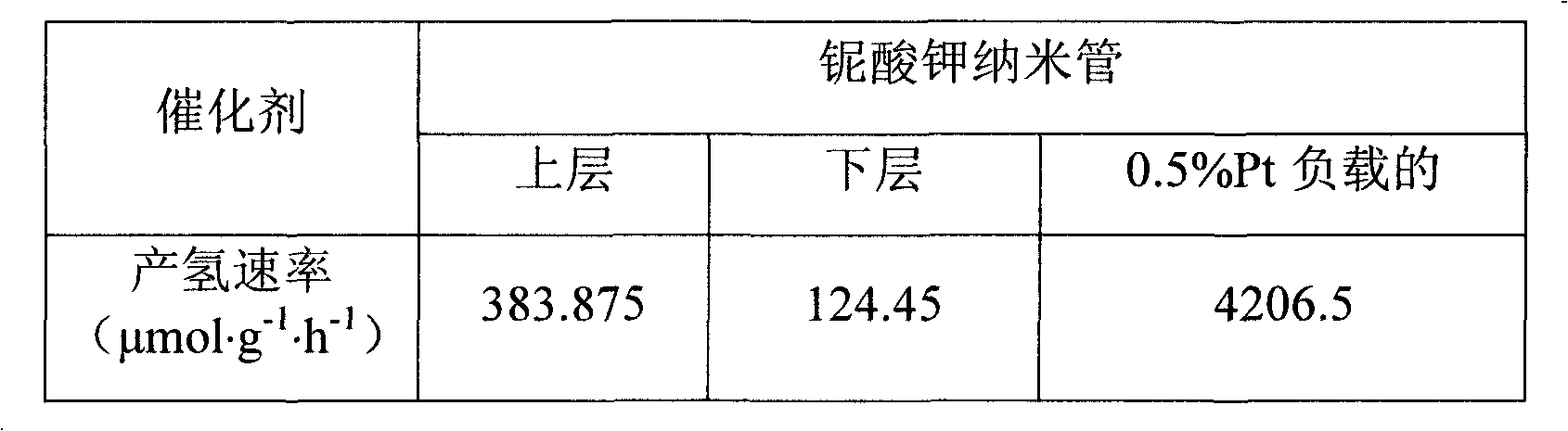

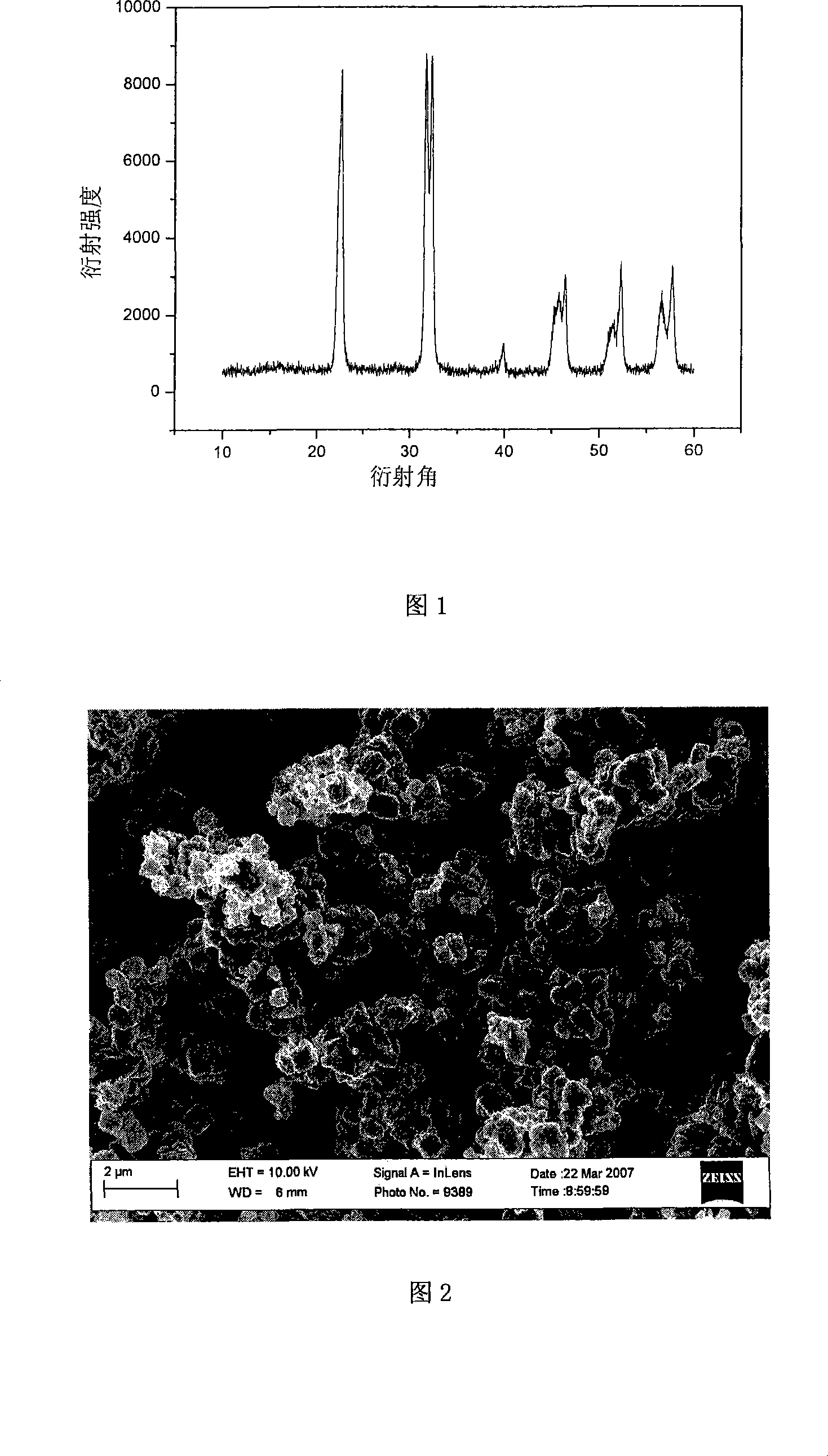

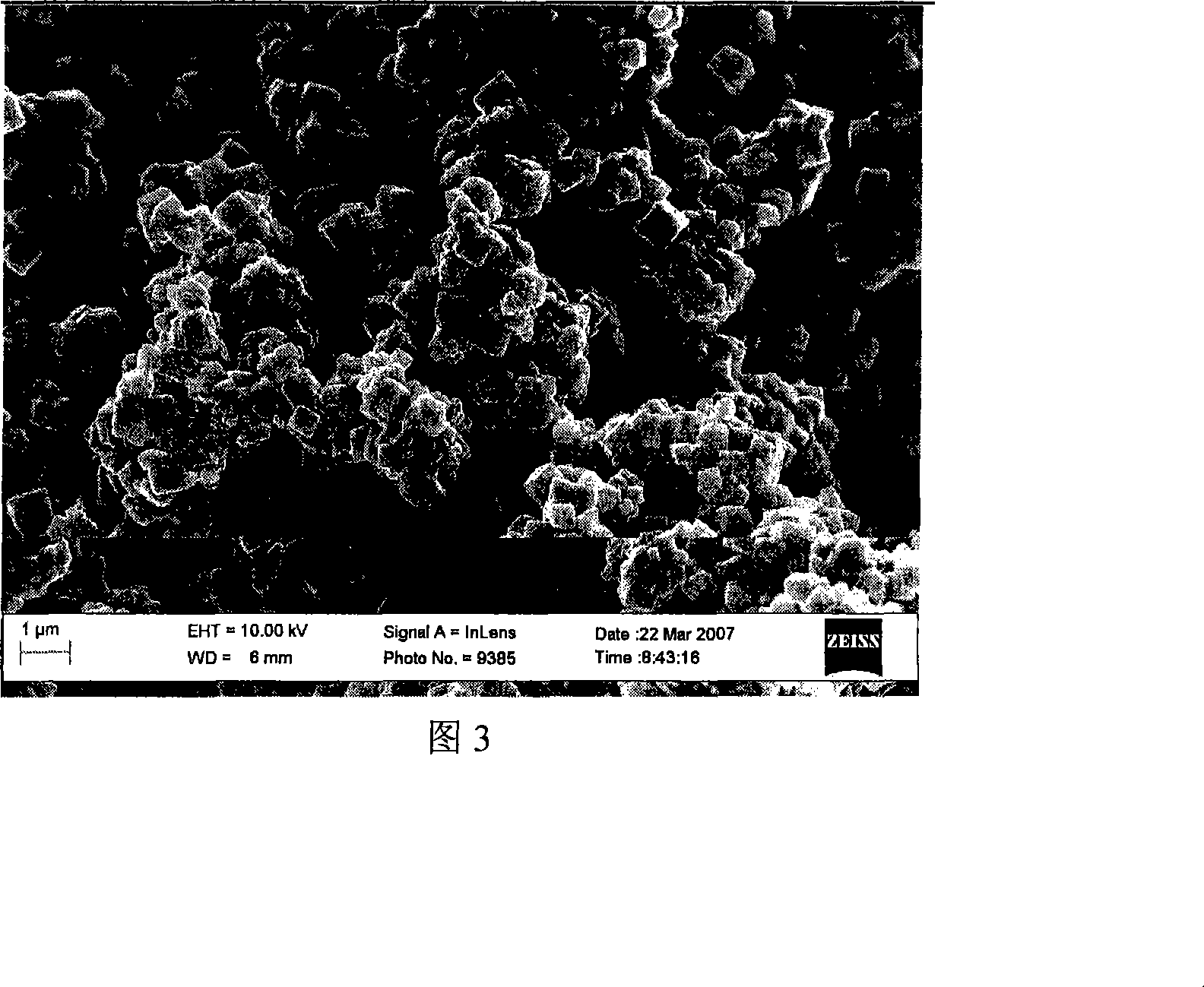

Potassium niobate nanotube photocatalyst and preparation method and application thereof

InactiveCN101811044ALarge specific surface areaImprove performanceOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionNanotubePotassium niobate

The invention discloses a potassium niobate nanotube photocatalyst and a preparation method and application thereof. Potassium niobate nano particle powder is dispersed in dilute acid solution to be filtered and washed to be neutral after being continuously stirred for 3-4 days to obtain acidulated potassium niobate; the acidulated potassium niobate is dispersed in deionized water; alkylamine aqueous solution is dropwise added until pH is 9-10; solution stands for grading after being stirred for 2-3 days to obtain the potassium niobate nanotube photocatalyst; metal, oxide or dyes can be further loaded; and under the condition of ultraviolet or visible light, the aqueous solution is catalyzed and reduced to prepare hydrogen and degrade organic pollutants. The preparation method of the invention has moderate condition, short period and environment protection and can obtain the potassium niobate nanotube photocatalyst with even appearance, narrow pipe diameter distribution and high catalysis efficiency.

Owner:EAST CHINA UNIV OF SCI & TECH

Hydro-thermal synthesis method for tantalum adulterated potassium sodium niobate leadless piezoelectric ceramic powder

InactiveCN101186338APiezoelectric/electrostrictive/magnetostrictive devicesNiobium compoundsCeramic sinteringSynthesis methods

The invention relates to a hydrothermal synthesis method for preparation of sodium-potassium niobate lead-free piezoelectric ceramic powder intermingled with tantalum, which belongs to the functional ceramic material field. The invention is characterized in that sodium hydroxide, potassium hydroxide, niobium pentaoxide and tantalum pentoxide are used as raw materials at the temperature ranging from 200 to 250 DEG C, and K0.5Na0.5NbO3 piezoelectric ceramic powder intermingled with Ta can be achieved by hydrothermal synthesis while preserving the heat for 20 to 36 hours; the molar ratio of the total added amount of niobium pentaoxide and tantalum pentoxide to alkali solution is 1:10 to 1:25, and the molar ratio of the added niobium pentaoxide to tantalum pentoxide is 1:9 to 4:6; the solution mixture ratio of sodium hydroxide to potassium hydroxide is 1:4 to 1:6, and the concentration of alkali solution is 4-10mol / L. The synthesis temperature is low and the powder grain is fine and average with a diameter about hundreds of nanometers in the invention. And the surface activity is great, which is favorable to the ceramic sintering at the latter stage.

Owner:UNIV OF SCI & TECH BEIJING

Multi-element sodium-potassium niobate series lead-free piezoelectric ceramic and preparing method

InactiveCN101024573AImprove performanceLead-free system with good performance has good environmental compatibilityPiezoelectric/electrostrictive/magnetostrictive devicesManufacturing technologyGeneral equation

The invention relates to a multielement potassium niobate natrium series leadless piezoelectric ceramics and the manufacturing method. It is expressed by the general equation: (1-u)[(1-z-n)(LitNa1-w-t1Kw-t2)(Nb1-g-fTagSbf)O3+ z(Bi0.5Na0.5xK0.5 (1-x))TiO3+nBaTiO3]+uM. The invention has stable manufacturing technology and has great usefulness.

Owner:HEFEI UNIV OF TECH

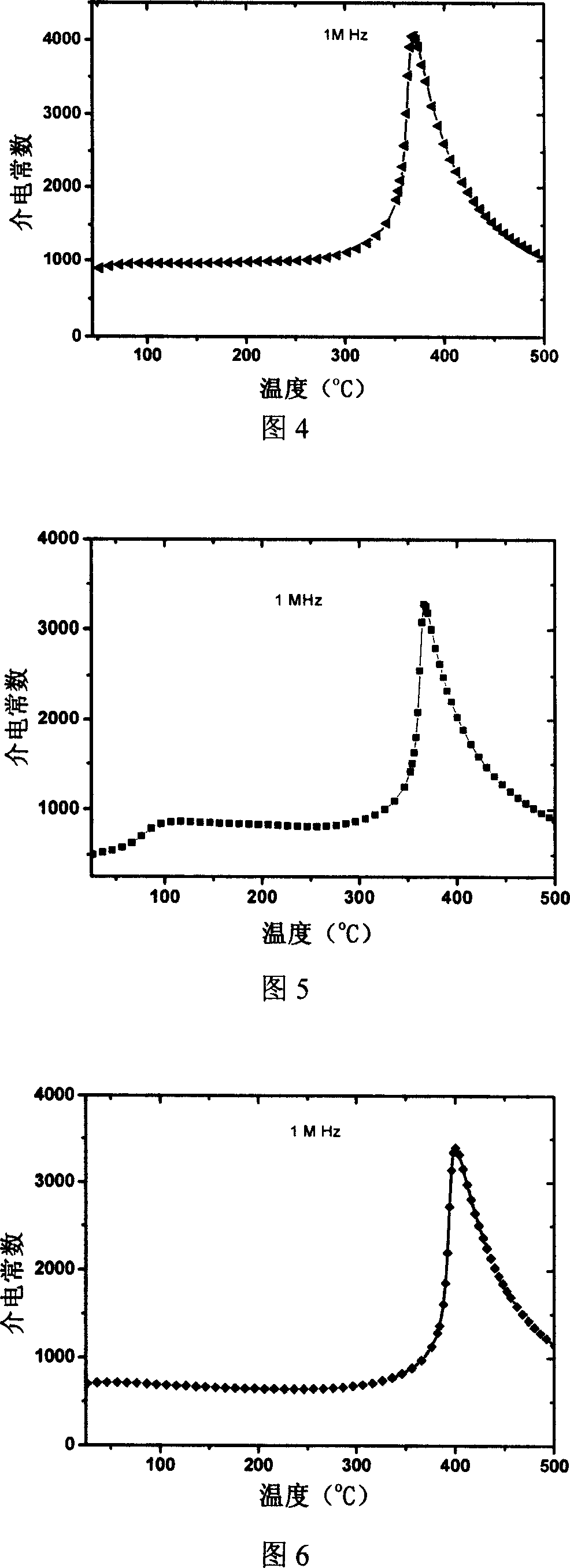

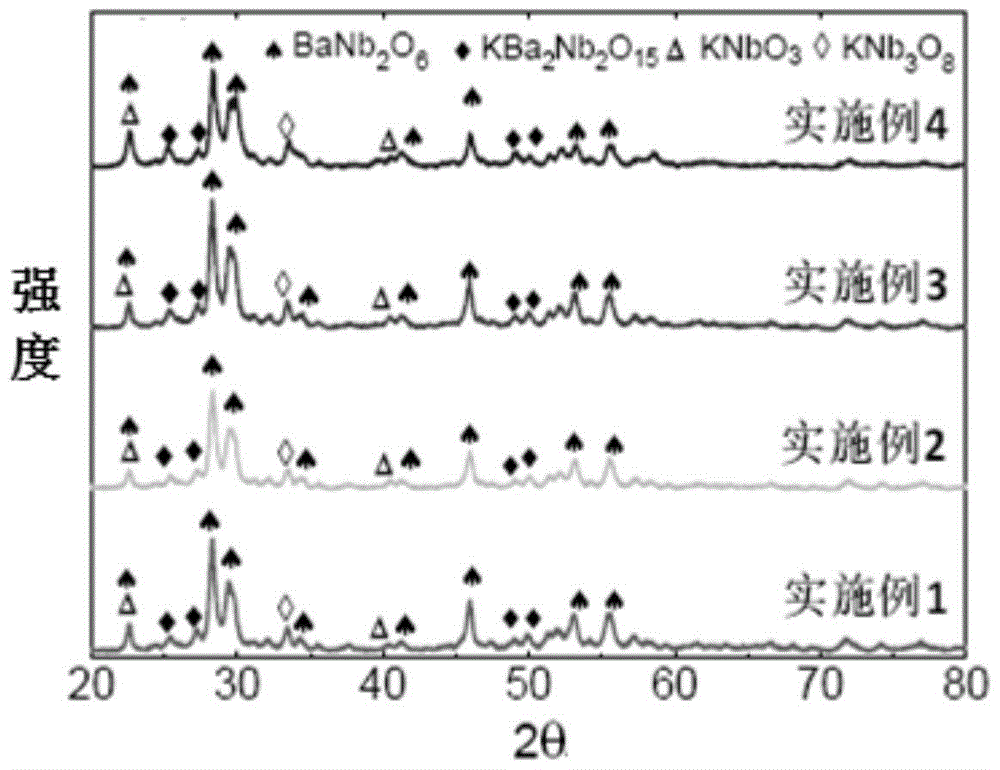

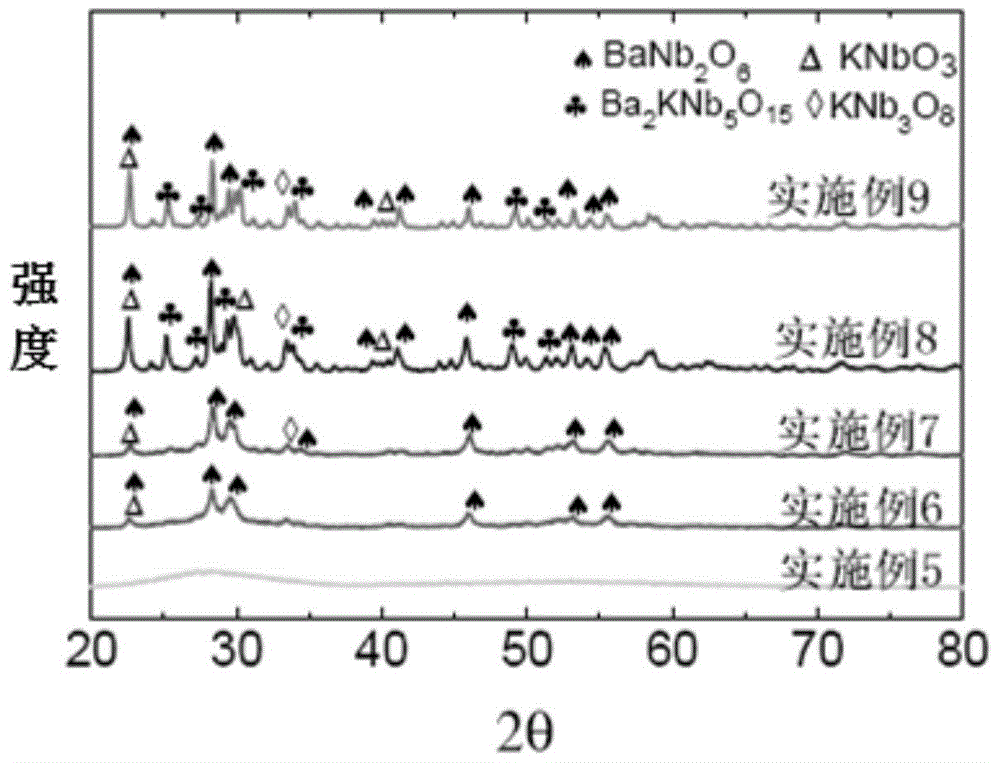

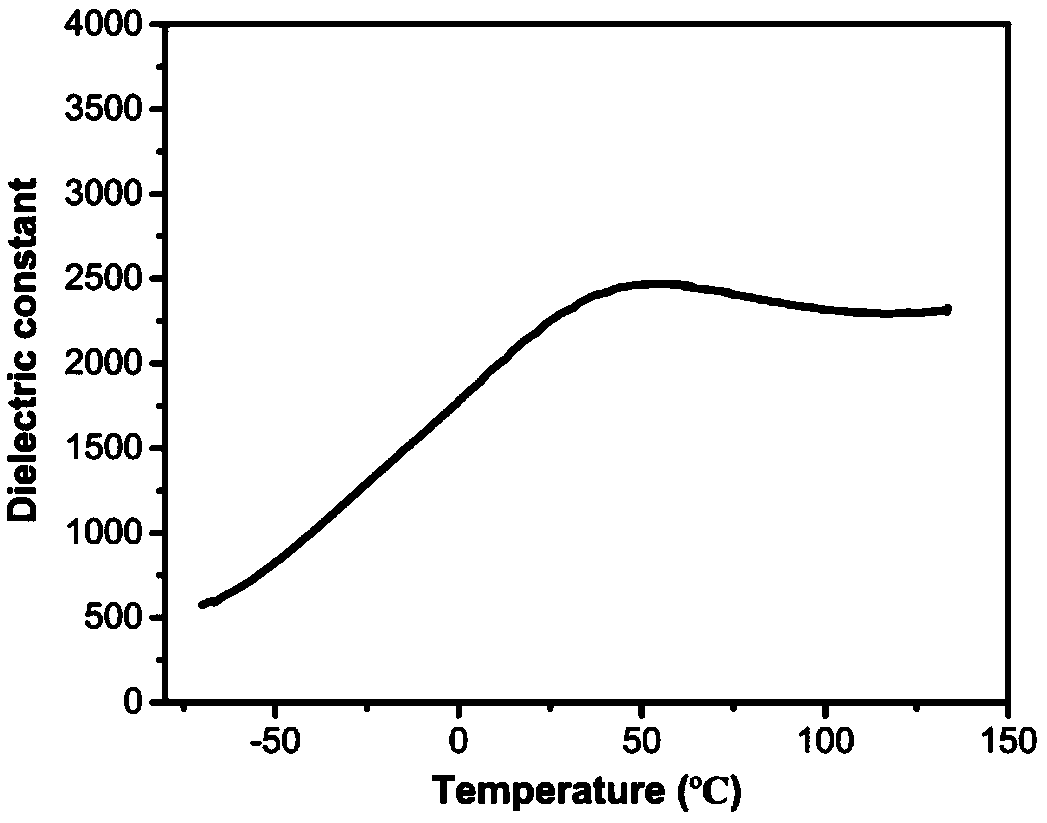

High-energy-storage-density barium potassium niobate based glass ceramic energy storage material and preparation as well as application

The invention relates to a high-energy-storage-density barium potassium niobate based glass ceramic energy storage material and preparation as well as application. The glass ceramic energy storage material is prepared from a SiO2 glass component and a ceramic particle component, wherein the ceramic particle component comprises perovskite-phase KNbO3 and tungsten bronze-phase BaNb2O6 and Ba2KNb5O15; in the glass ceramic energy storage material, all chemical ingredients accord with a chemical general formula: 32xBaO.32(1-x)K2O.32Nb2O5.36SiO2, wherein the value range of x is 0.5 to 0.9; the above energy storage material is prepared through the following steps of (1), weighing BaCO3, K2CO3, Nb2O5 and SiO2, uniformly mixing the BaCO3, the K2CO3, the Nb2O5 and the SiO2, and melting an obtained mixture at a high temperature, so as to prepare a high-temperature melt; (2), pouring the high-temperature melt into a preheated metal mold,stress-relief annealing, the high-temperature melt so as to prepare transparent glass, and slicing the transparent glass to obtain a glass slice; (3), carrying out controlled crystallization on the glass slice, so as to prepare a target product. The barium potassium niobate based glass ceramic energy storage material is used for an energy storage capacitor material. Compared with the prior art, the high-energy-storage-density barium potassium niobate based glass ceramic energy storage material and the preparation as well as the application have the advantages that a preparation process is simple, the energy storage density of the glass ceramic energy storage material is high, and the like.

Owner:TONGJI UNIV

Optical switching method capable of using electronic control quadratic electro-optical effect for deflecting incident light

InactiveCN103605217APolarization direction achievedReduce volumeNon-linear opticsOptical polarizationMaterials science

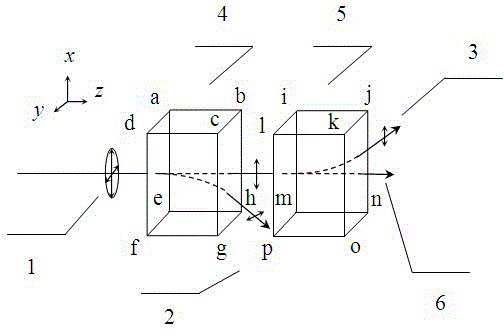

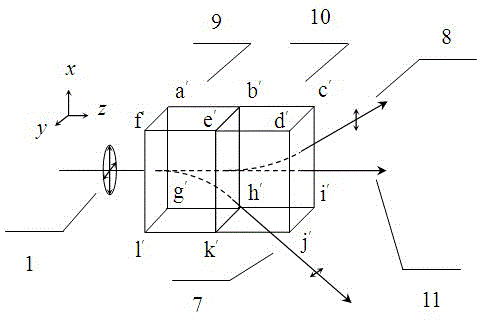

The invention provides an optical switching method capable of using the electronic control quadratic electro-optical effect for deflecting incident light, belongs to the technical field of optics, and aims to solve the problem in the existing optical switching technology that a broadband range and quick responses cannot be realized. The optical switching method specifically comprises the following steps: a quadratic electro-optical effect potassium tantalate niobate crystal is used; when laser radiation is needed, an external electric field is not applied to the crystal, and lasers directly penetrate through the crystal; when laser radiation is not needed, the external electric field is applied to the crystal in the two directions perpendicular to the incident lasers, and the quadratic electro-optical effect is used for making polarized components in the incident lasers be polarized sequentially after the polarized components pass through the crystal, wherein the polarization direction of the polarized components is parallel to the direction of the externally applied electric field; finally, the polarized components deviate from the original propagation direction, and the purpose of switching on and off is achieved. An optical switch manufactured by the adoption of the optical switching method has the advantages of being small in size, low in cost, easy to process, and high in response speed (at a nanosecond level), so that the application prospect of the optical switch is quite broad.

Owner:HARBIN INST OF TECH

Low temperature synthesized no-lead piezoelectric Mg doped sodium potassium niobate ceramic and its prepn process

InactiveCN101066868ALower sintering temperatureImprove performancePiezoelectric/electrostrictive/magnetostrictive devicesRoastingPotassium niobate

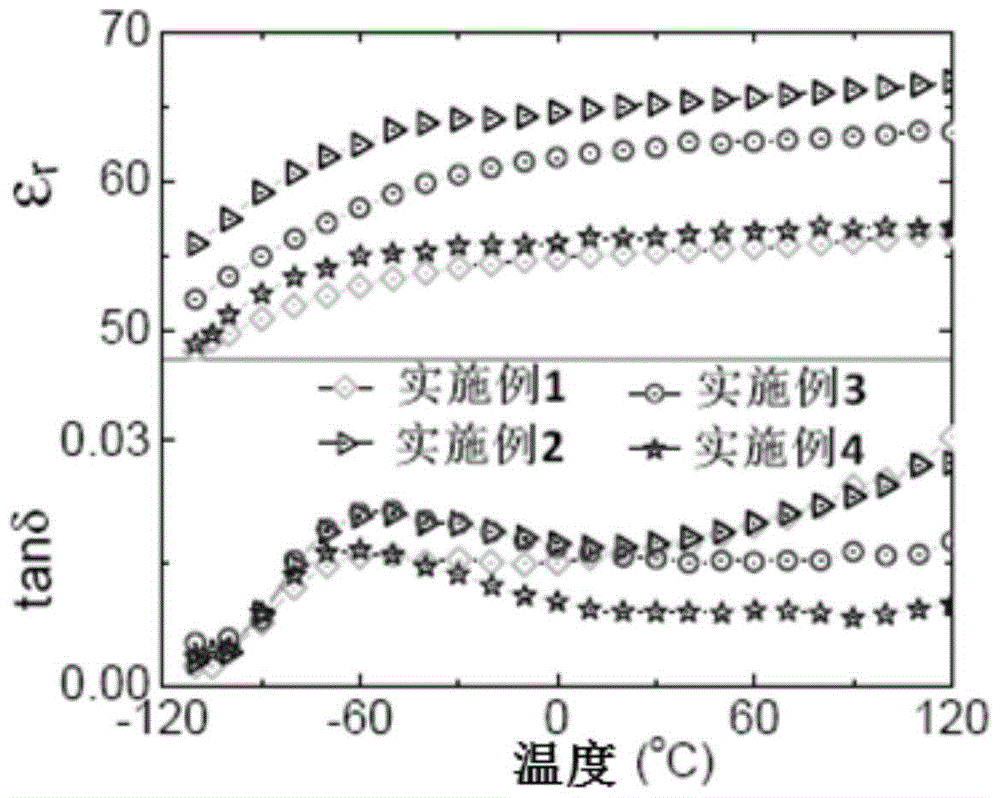

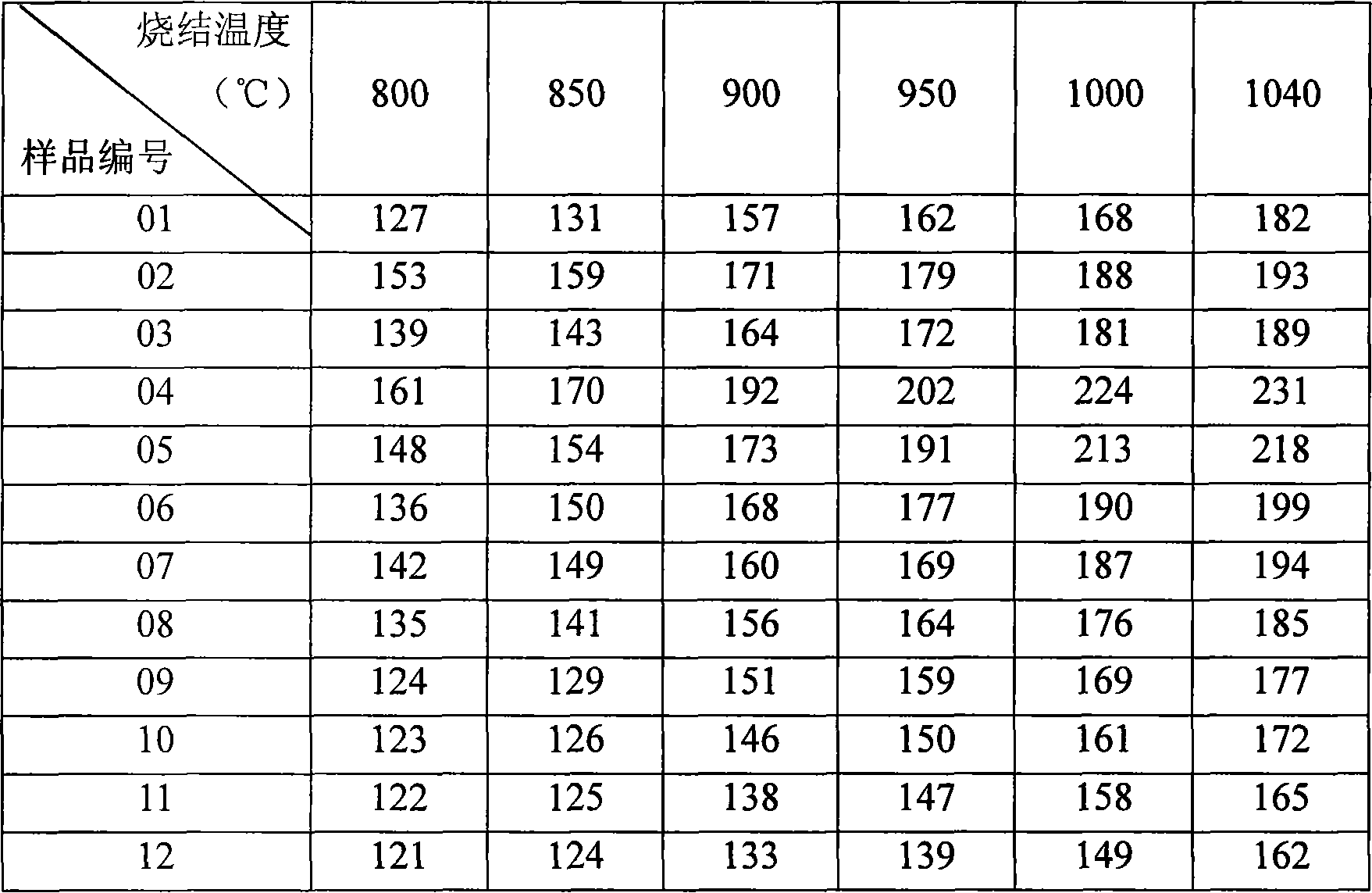

The low temperature synthesized no-lead piezoelectric Mg doped sodium potassium niobate ceramic as one kind of environment friendly material has the composition formula of (NaaKbLic)NbO3+xMgO, where, a, b, c and x are the molar fractions of Na, K, Li, Mg separately, a is 0.20-0.80, b is 0.20-0.80, c is 0.00-0.30, and x is 0.00-0.30. Its preparation process includes the technological steps of mixing material, roasting, forming, sintering, coating silver, polarizing, etc. The low temperature synthesized no-lead piezoelectric Mg doped sodium potassium niobate ceramic of the present invention has the advantages of sintering temperature effectively lowered to 800-1040 deg.c and high performance.

Owner:UNIV OF SCI & TECH BEIJING

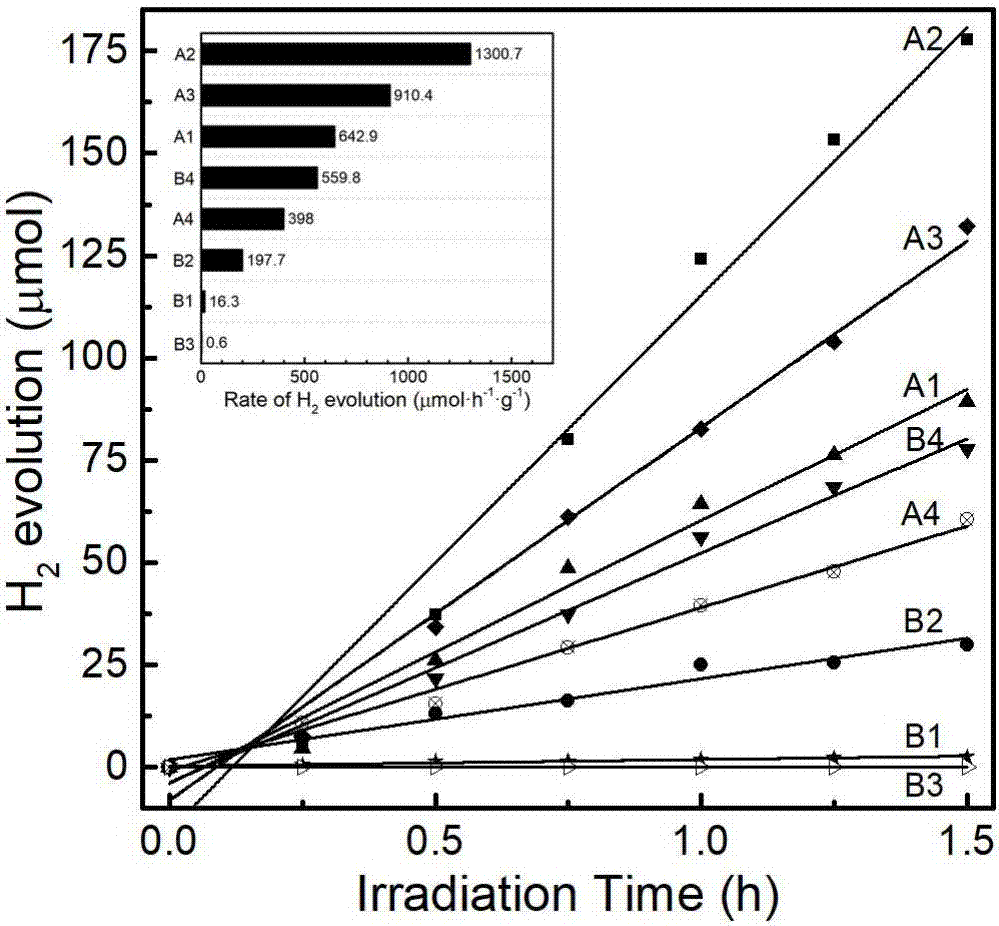

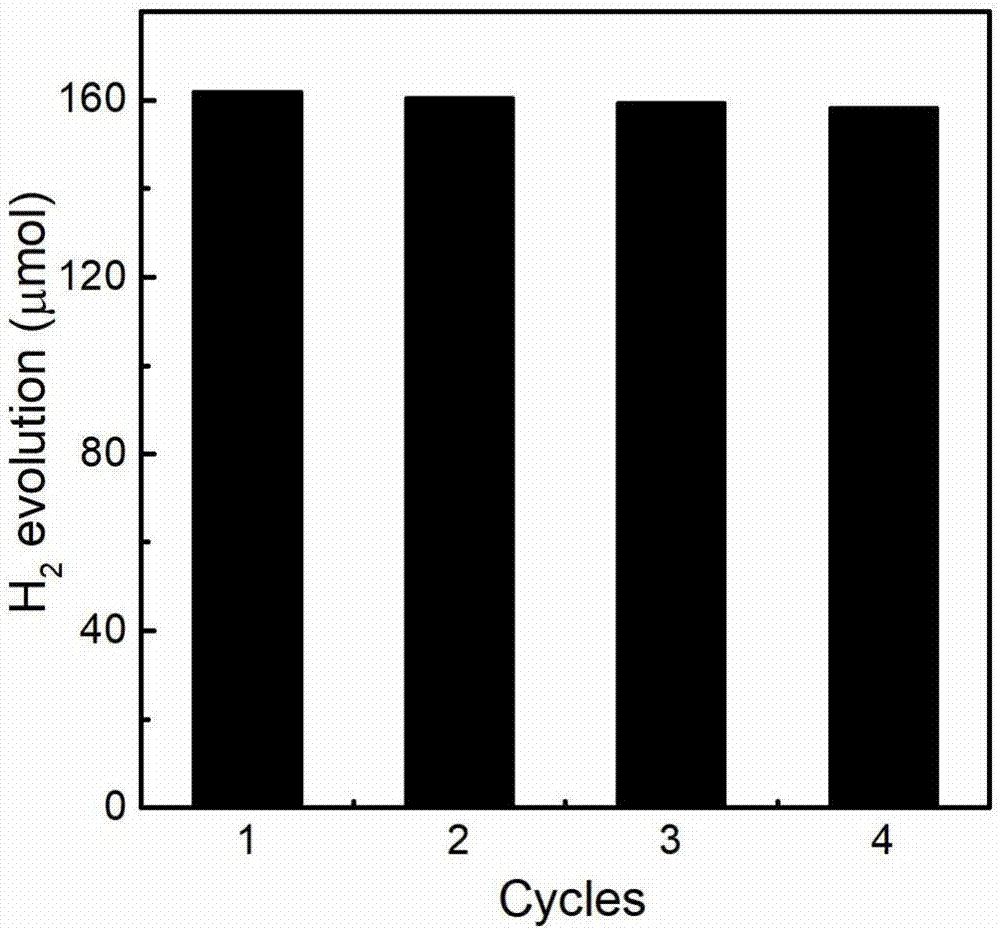

Photocatalytic hydrogen production catalyst and preparation method thereof

ActiveCN107185558AEasy to prepareGood photocatalytic hydrogen production activityCatalyst activation/preparationHydrogen productionSodium molybdateChemical composition

The invention discloses a photocatalytic hydrogen production catalyst and a preparation method thereof. The catalyst is molybdenum disulfide composite carbon-doped potassium niobate, the chemical composition formula of the catalyst is xMoS2 / C-KNbO3, x refers to the molar ratio of molybdenum disulfide to potassium niobate, C-KNbO3 refers to carbon-doped potassium niobate, and 0.001<=x<=0.01. Firstly, niobium pentoxide, glucose and potassium hydroxide are used for preparing the carbon-doped potassium niobate. Secondly, the carbon-doped potassium niobate, sodium molybdate and thiourea are used for preparing the molybdenum disulfide composite carbon-doped potassium niobate. The catalyst has efficient photocatalytic hydrogen production performance and good stability.

Owner:ZHEJIANG NORMAL UNIVERSITY

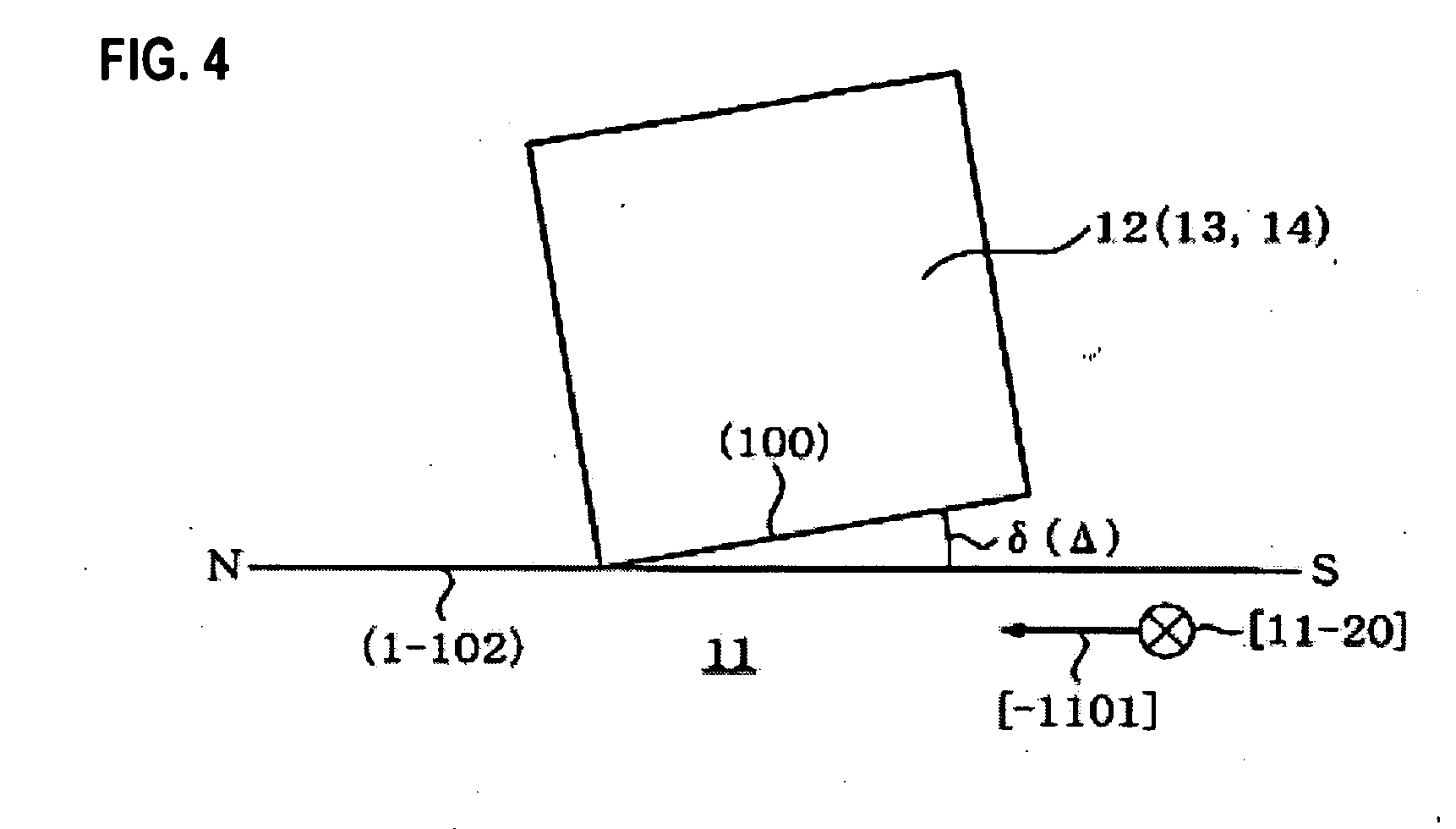

Method for manufacturing a potassium niobate deposited body

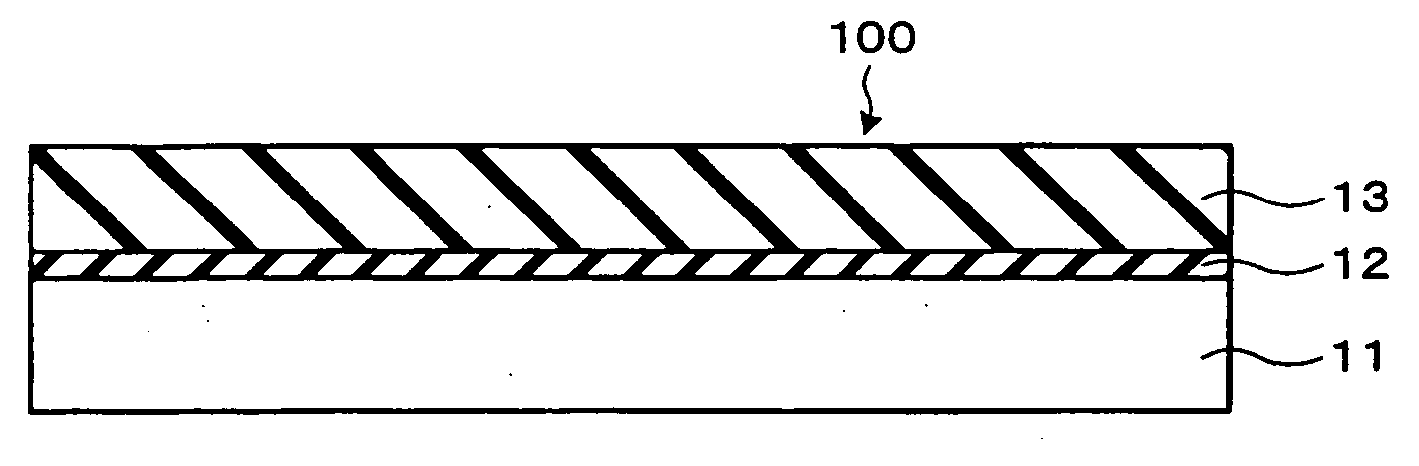

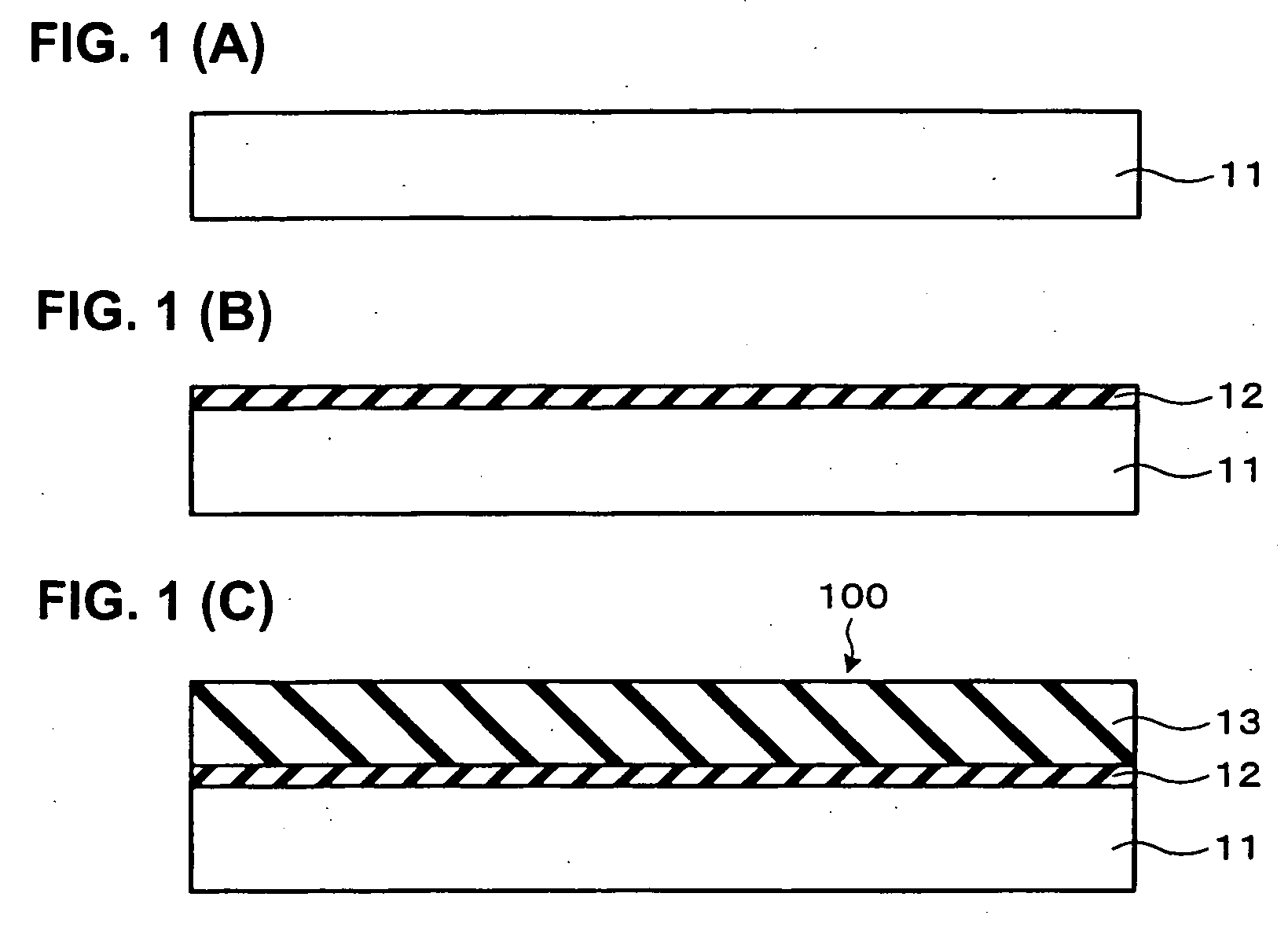

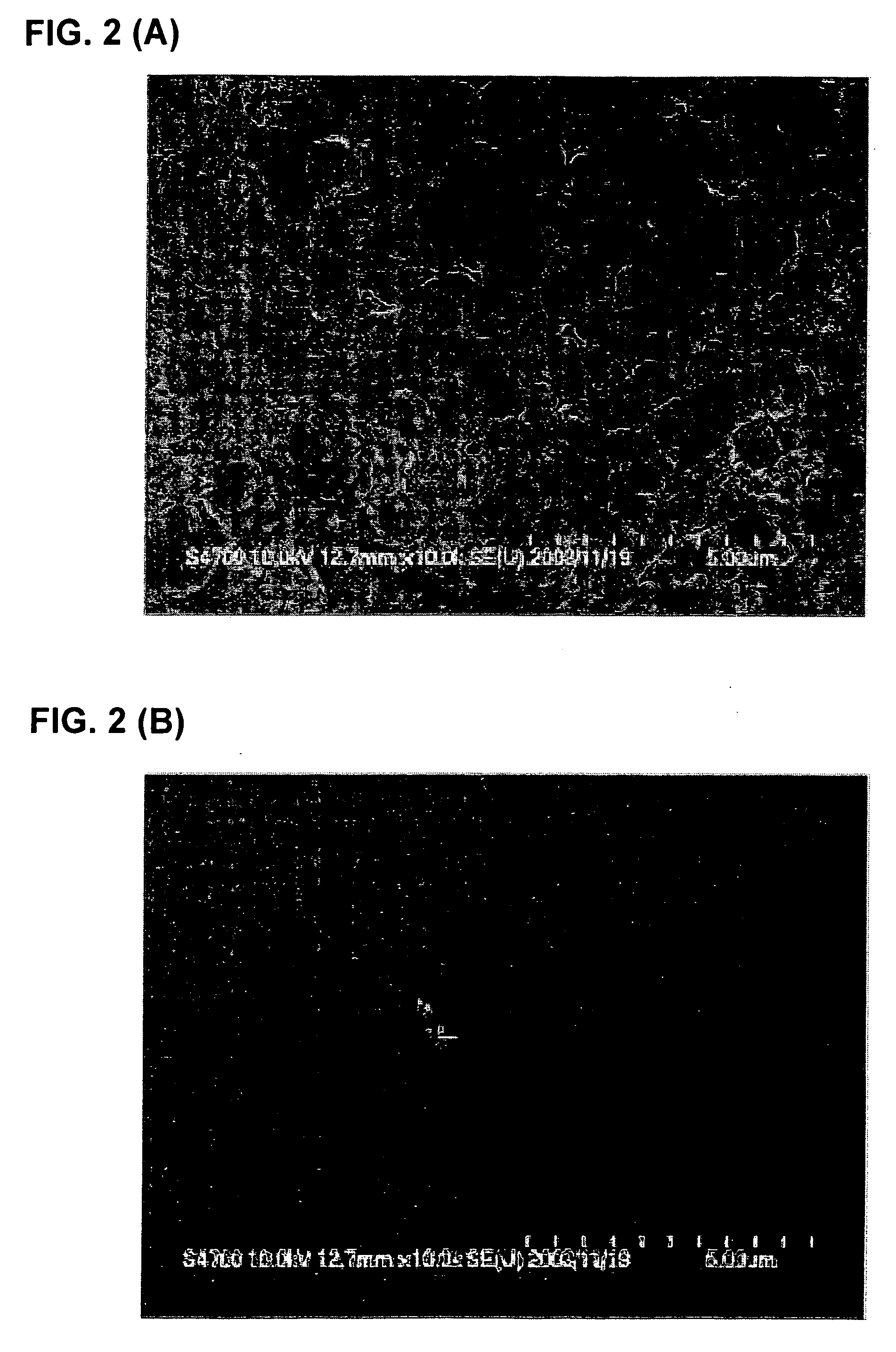

InactiveUS7310874B2High crystallinityPiezoelectric/electrostriction/magnetostriction machinesVacuum evaporation coatingA domainLattice constant

A potassium niobate deposited body includes a substrate, an electrode layer formed above the substrate, and a potassium niobate layer formed above the electrode layer. The potassium niobate layer can include a domain that epitaxially grows in a (110) or (001) orientation, when a lattice constant of orthorhombic potassium niobate is 21 / 2 c<a<b, and a b-axis is a polarization axis.

Owner:SEIKO EPSON CORP

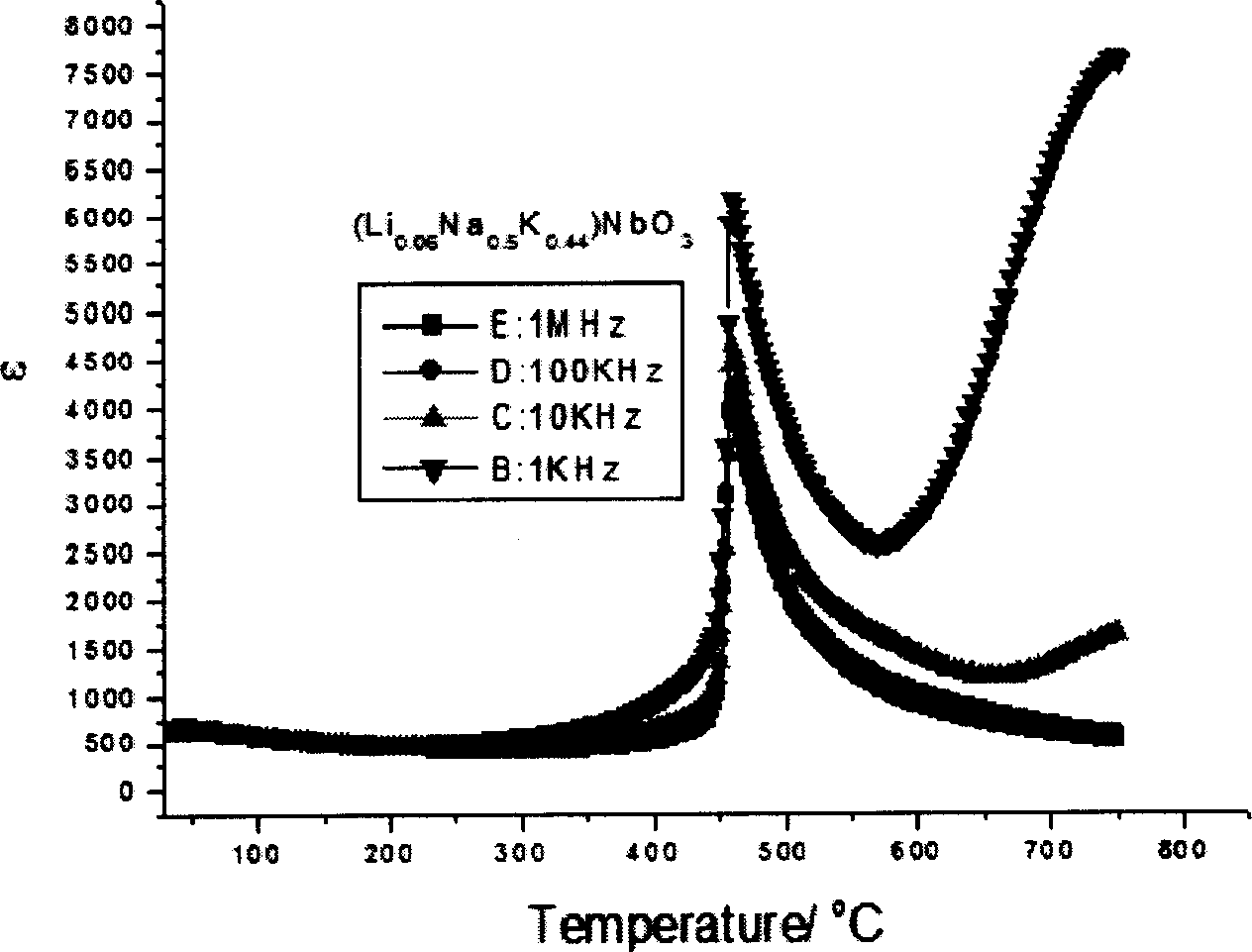

Lead-less lithium sodium potassium niobate piezoelectric ceramic with high curie point and its prepn

InactiveCN1810711AExcellent piezoelectric propertiesOvercoming the Drawbacks of Lead PollutionPiezoelectric/electrostrictive/magnetostrictive devicesLithiumElectricity

The present invention relates to lead-less piezoelectric ceramic composition and is especially one kind of lead-less Li-Na-K niobate piezoelectric ceramic and its preparation process. The lead-less piezoelectric ceramic composition of the present invention is expressed in the general expression of (1-u)[(1-z)(LixNayK1-x-y)NbO3+zMTiO3]+uMnO2, where, x, y and z are atom percentages of corresponding elements, x is 0.01-0.2, y is 0.2-0.7, z is 0.01-0.25, x+y+z=1, u is 0-0.05, and M is one bivalent metal ion selected from Ca, Mg, Ba and Sr. The lead-less piezoelectric ceramic composition is prepared through sintering at relatively low temperature, say, 1190 deg.c or even lower, and has good piezoelectric characteristic, practical plane electromechanical coupling coefficient kp, high Curie point and no lead and lead compound contained.

Owner:SICHUAN UNIV

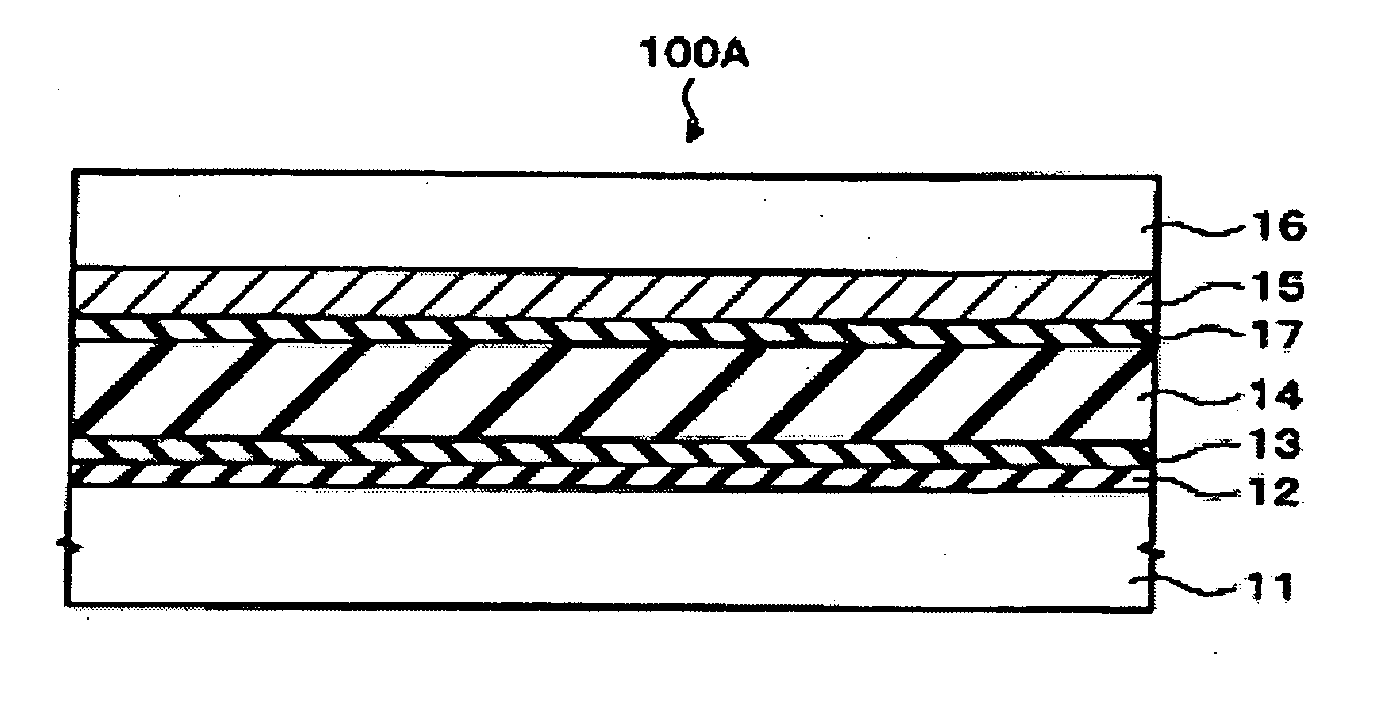

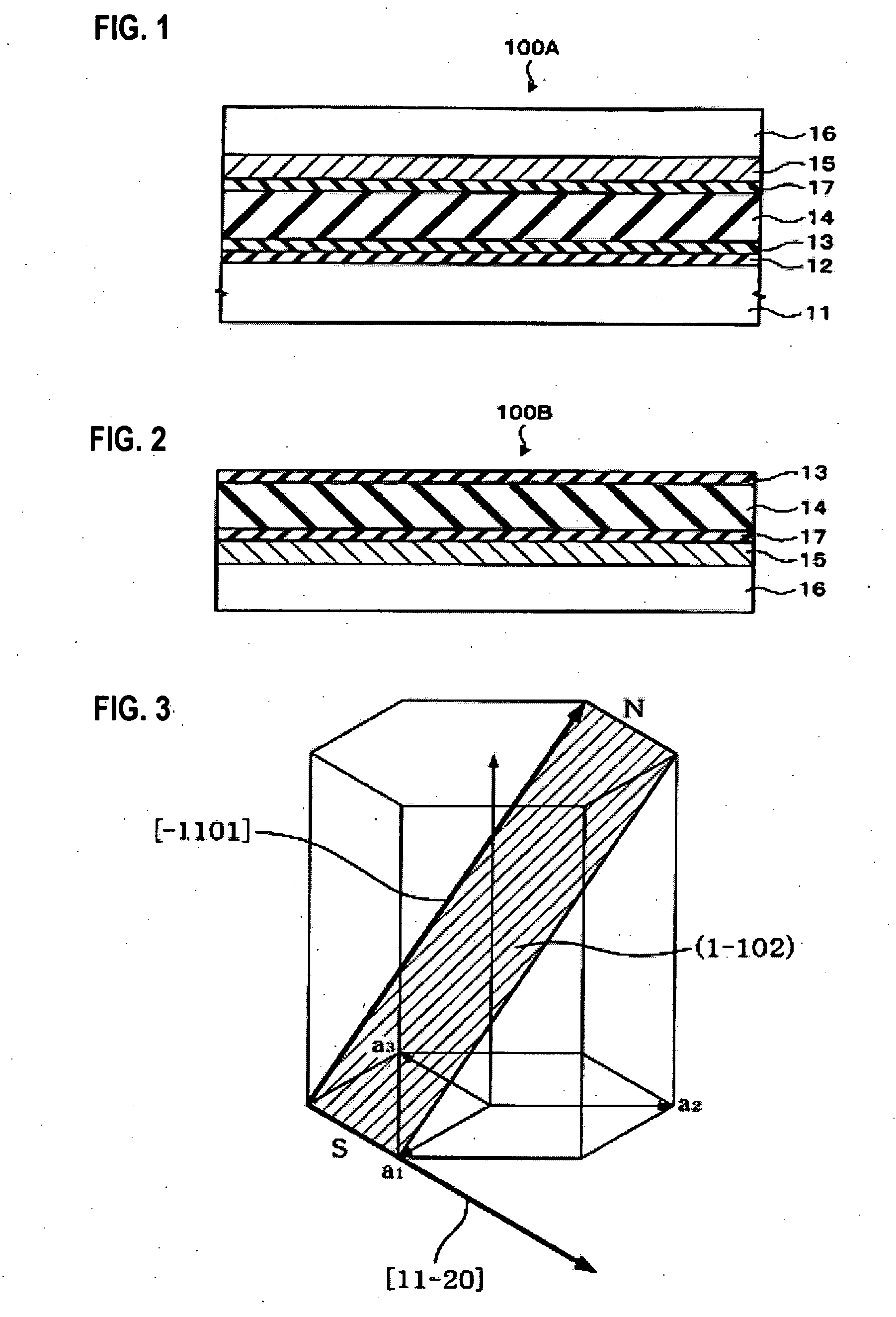

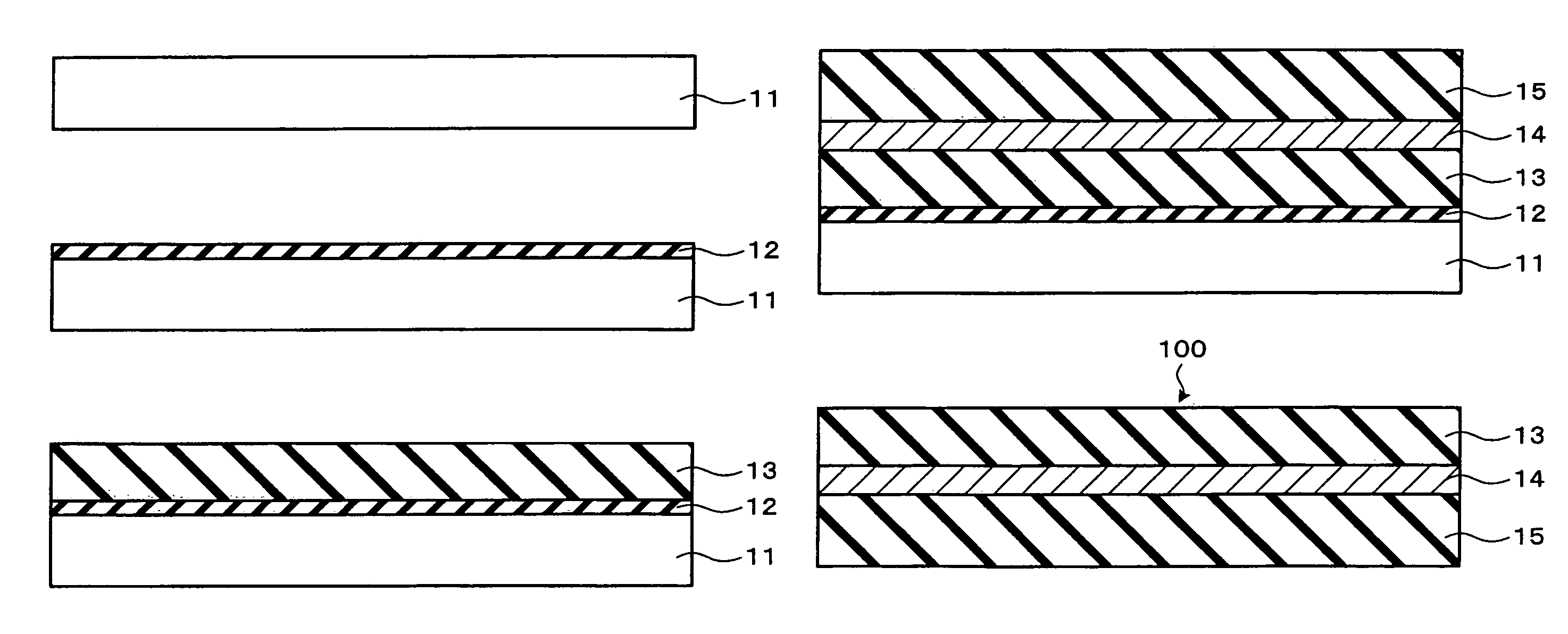

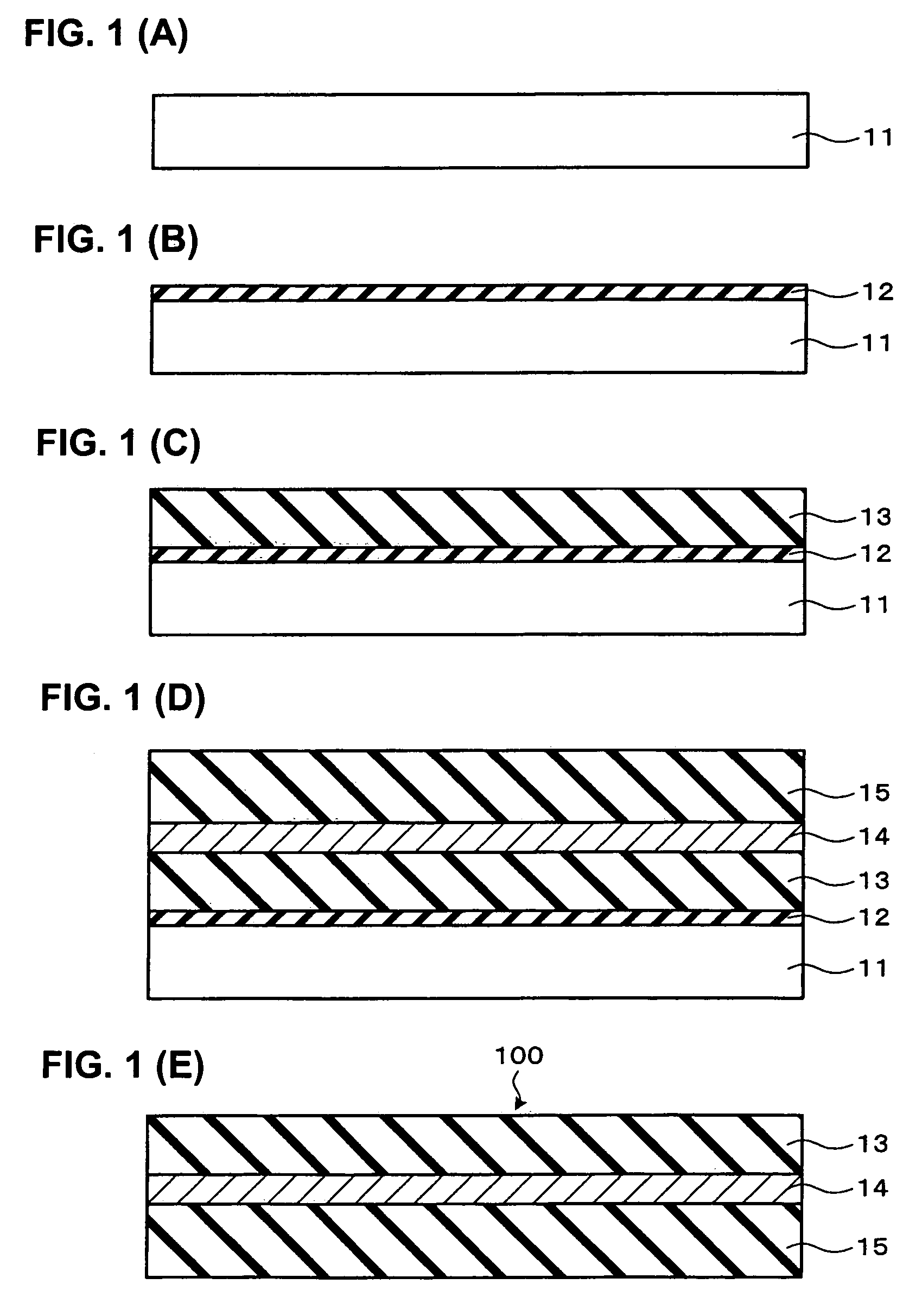

Piezoelectric film laminate and method of manufacturing the same

InactiveUS20060222895A1Impedence networksZirconium compoundsLead zirconate titanatePotassium niobate

A piezoelectric film laminate including a sapphire substrate and a lead zirconate titanate niobate film and a potassium niobate film formed on the sapphire substrate.

Owner:SEIKO EPSON CORP

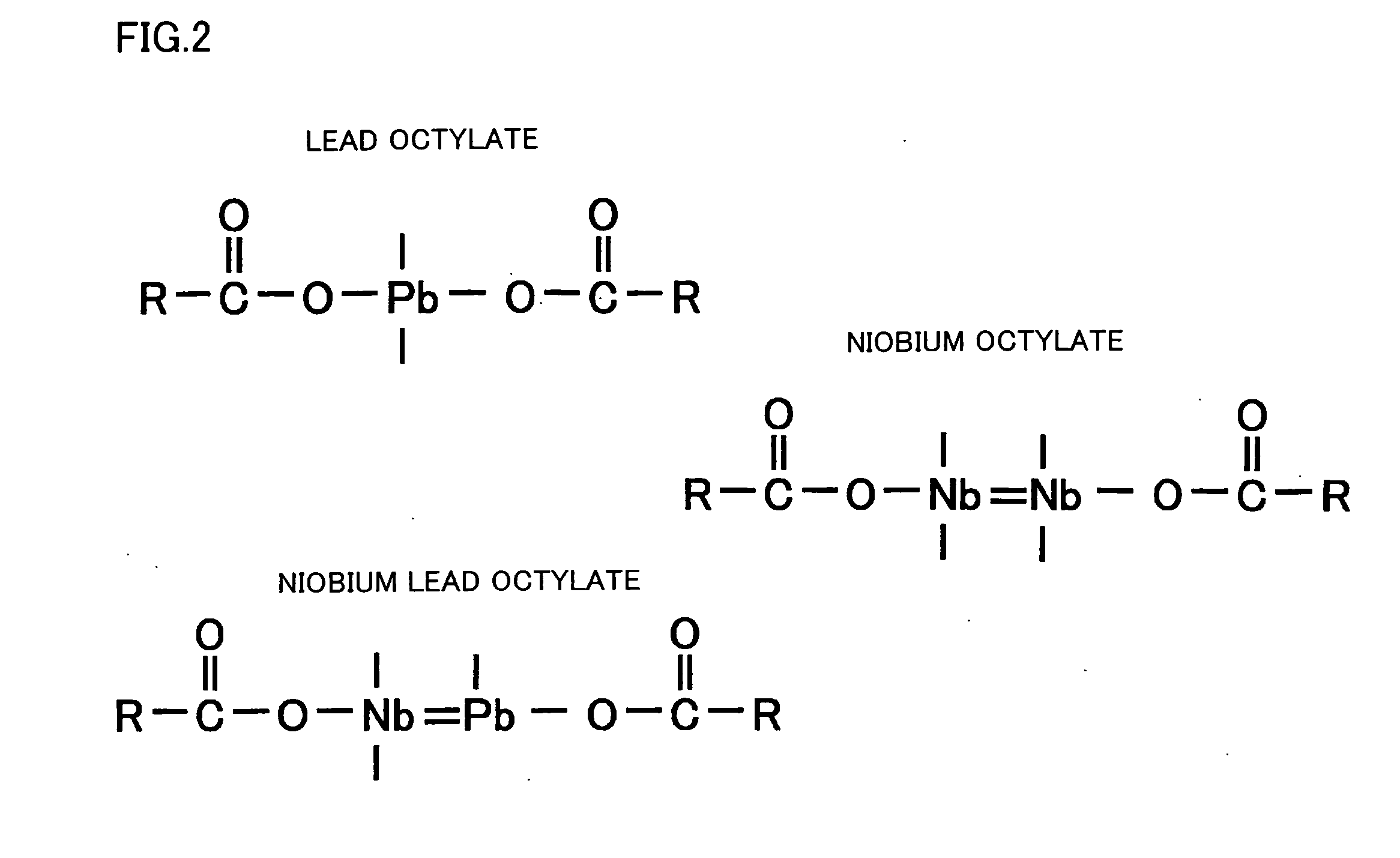

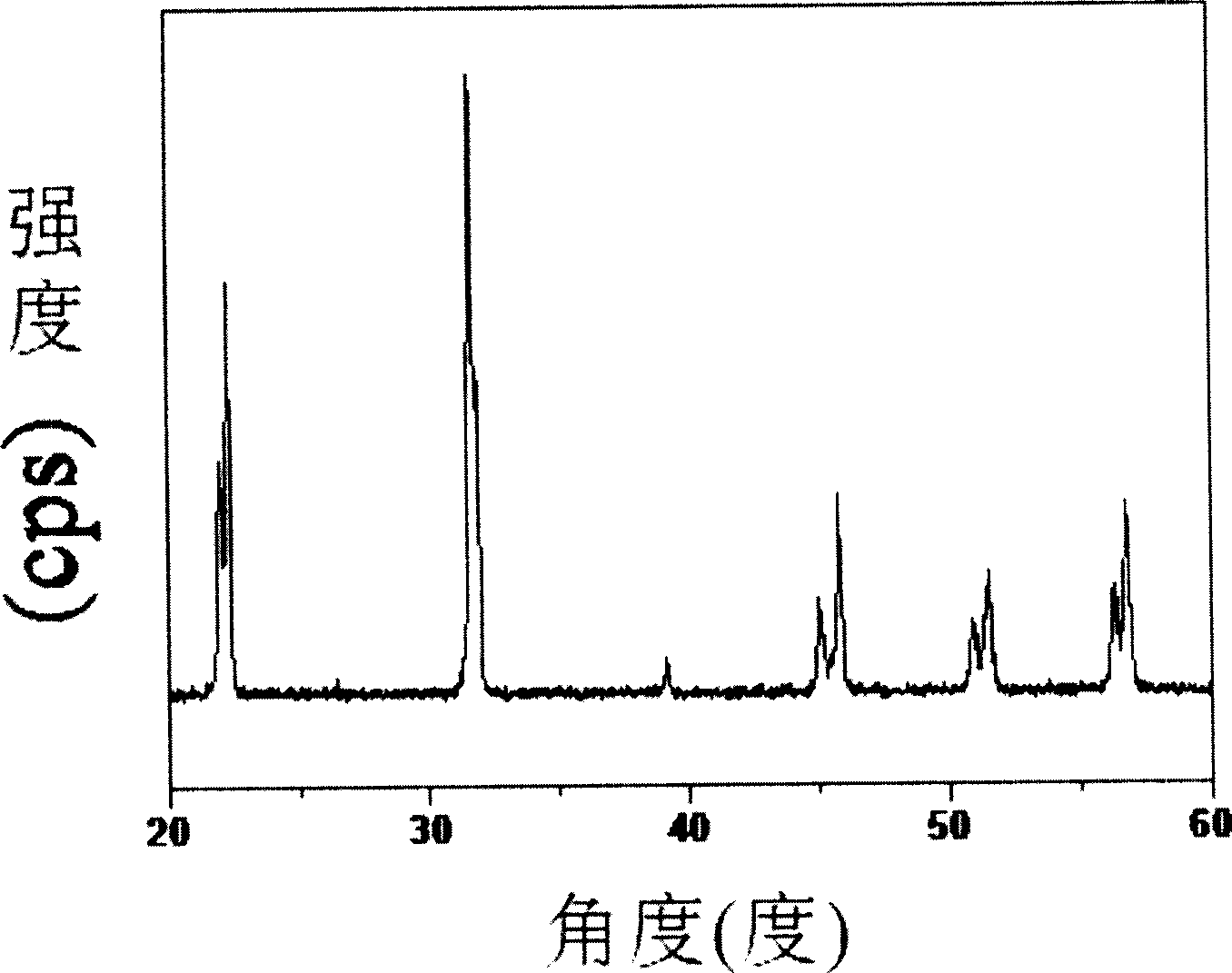

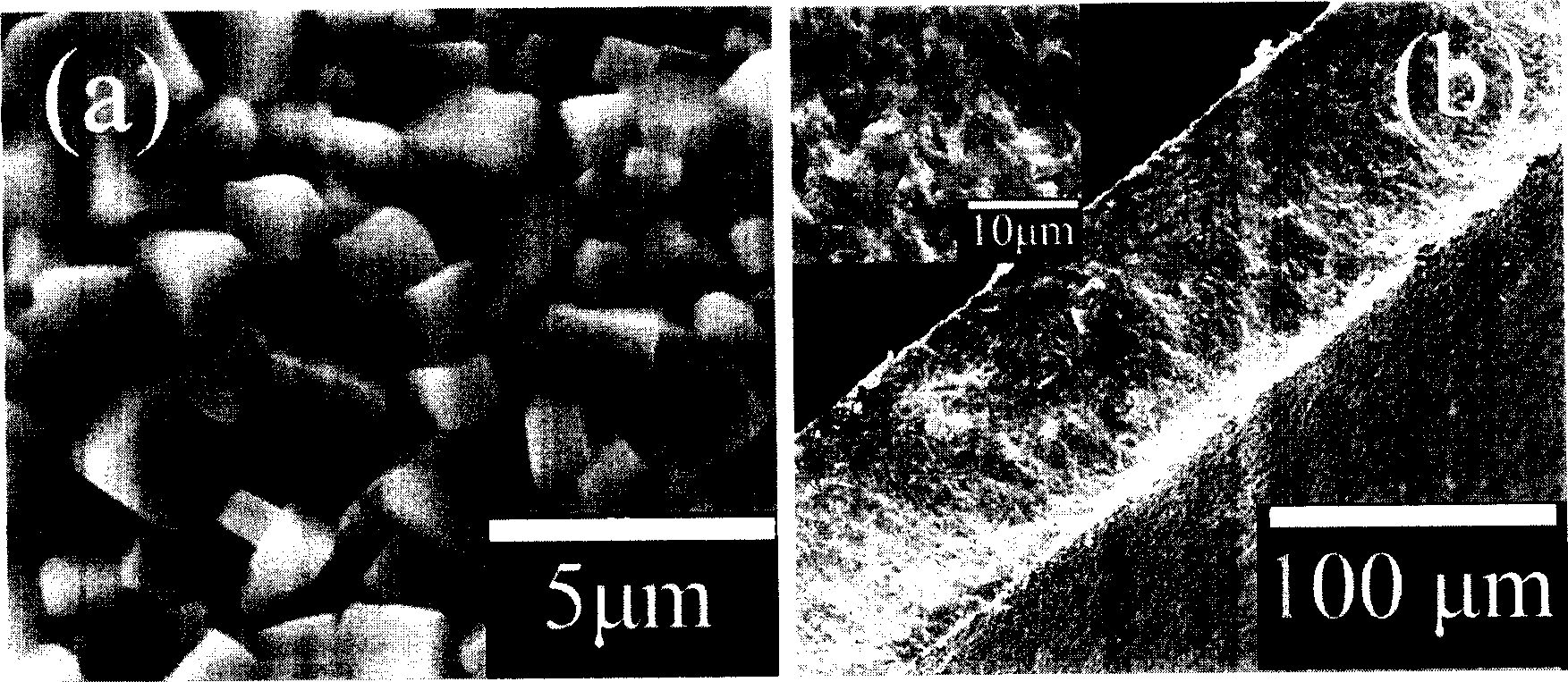

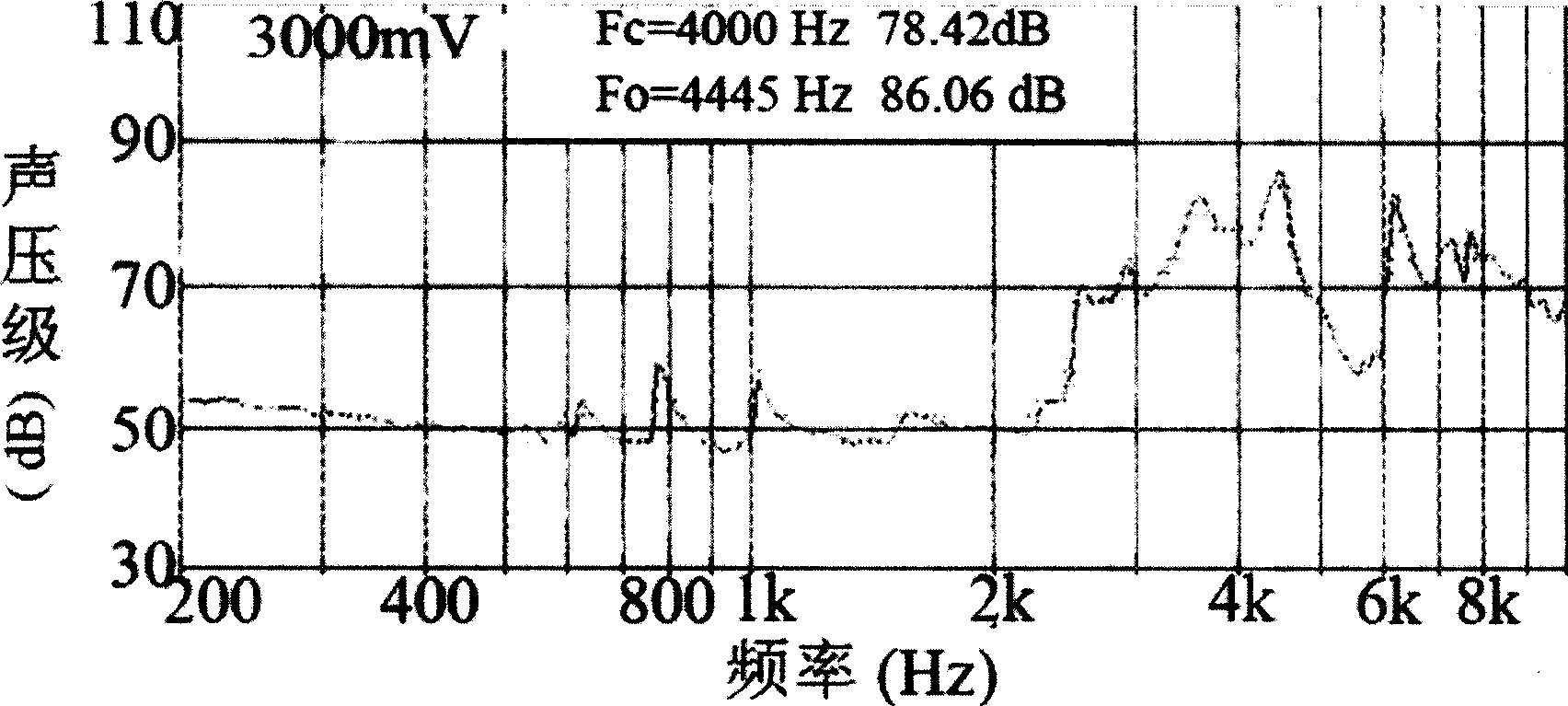

Method for preparing potassium niobate sodium base leadless piezoelectric ceramic thin sheet and application thereof in buzzer

InactiveCN101456733AHigh densityUniform grainSound producing devicesMaterials sciencePotassium niobate

The invention discloses a method for preparing a sodium potassium niobate-based lead-free piezoelectric ceramic sheet expressed by a general formula (K0.44Na0.52Li0.04)(Nb0.80Ta0.20)O3, which consists of process steps of raw material pretreatment, raw material mixing, preburning, pulping, tape casting, sheet punching, binder removal, sintering, silver coating and polarization. Compared with the prior piezoelectric ceramic preparation method, the method adopts the process steps of the pulping and the tape casting to be prepared into the sodium potassium niobate-based lead-free piezoelectric ceramic sheet with a pure perovskite structure, high density, fine crystals, uniform crystal grains, and good electrical property, and the thickness of the sodium potassium niobate-based lead-free piezoelectric ceramic sheet is 0.12mm. The sodium potassium niobate-based lead-free piezoelectric ceramic sheet prepared by the method is prepared into a lead-free piezoelectric buzzer, and the lead-free piezoelectric buzzer has no environmental pollution; the acoustic pressure reaches a maximum value 86.06dB at 4.445kHz when the driving voltage is 3V, and the maximum acoustic pressure ratio is increased to between 91.91 and 95.22dB respectively when the driving voltage is 6V and 9V, thereby showing that the piezoelectric buzzer has good electroacoustic property and achieves the application requirement of an acoustic generation device.

Owner:SHAANXI NORMAL UNIV

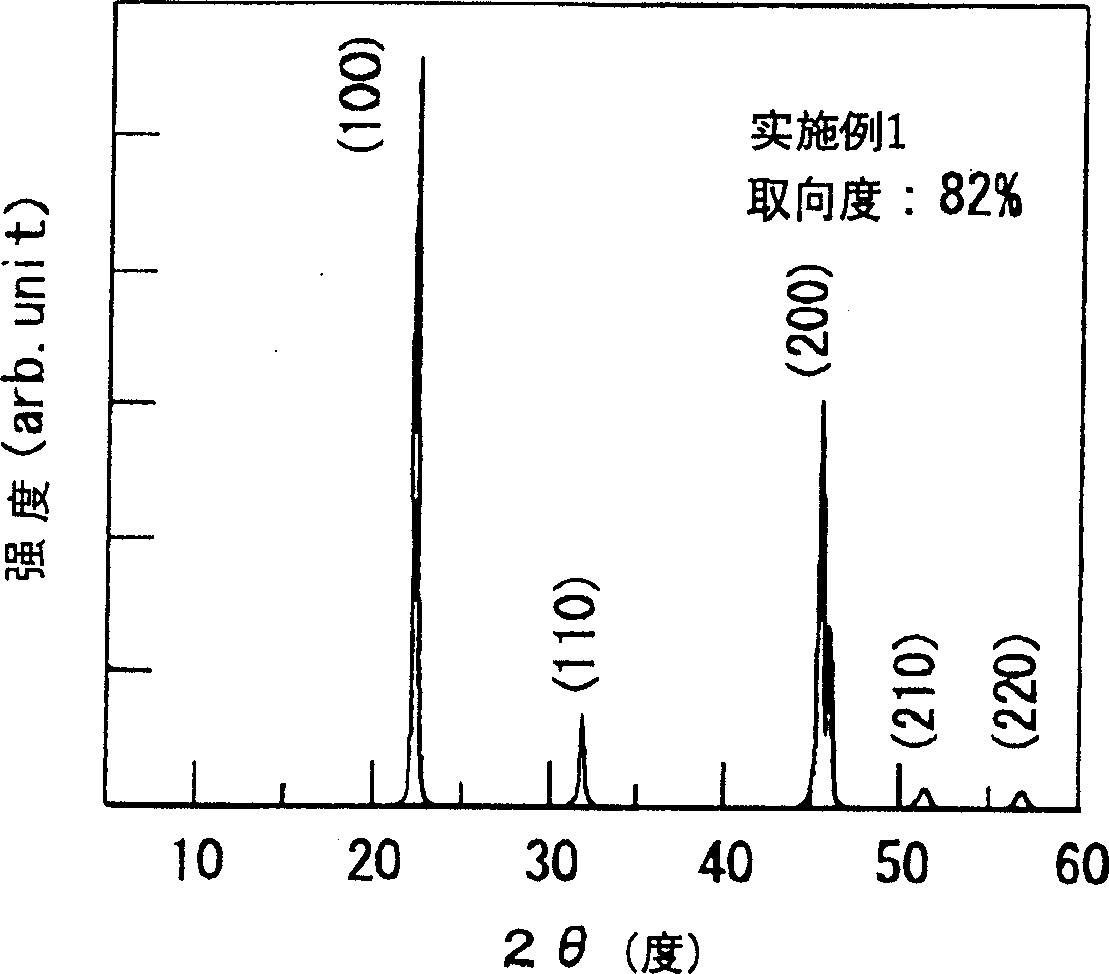

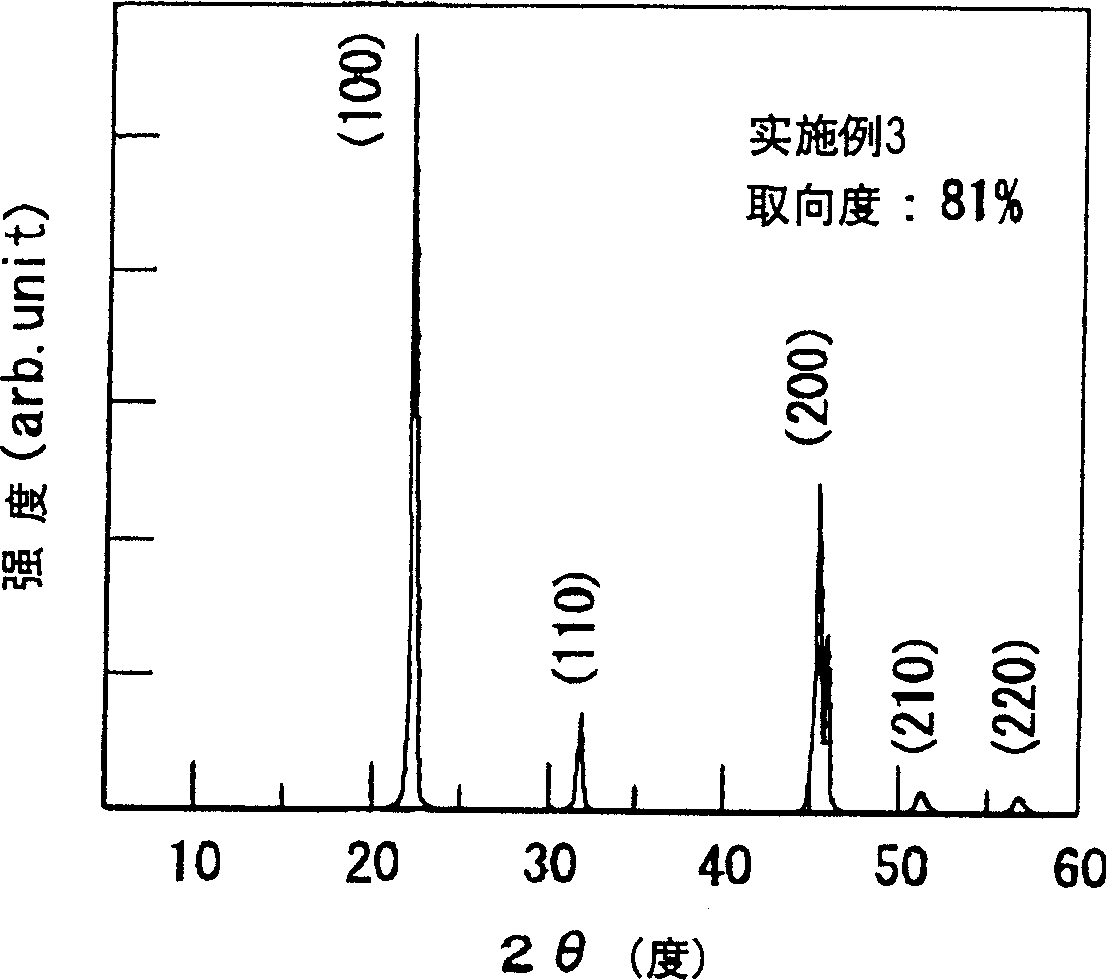

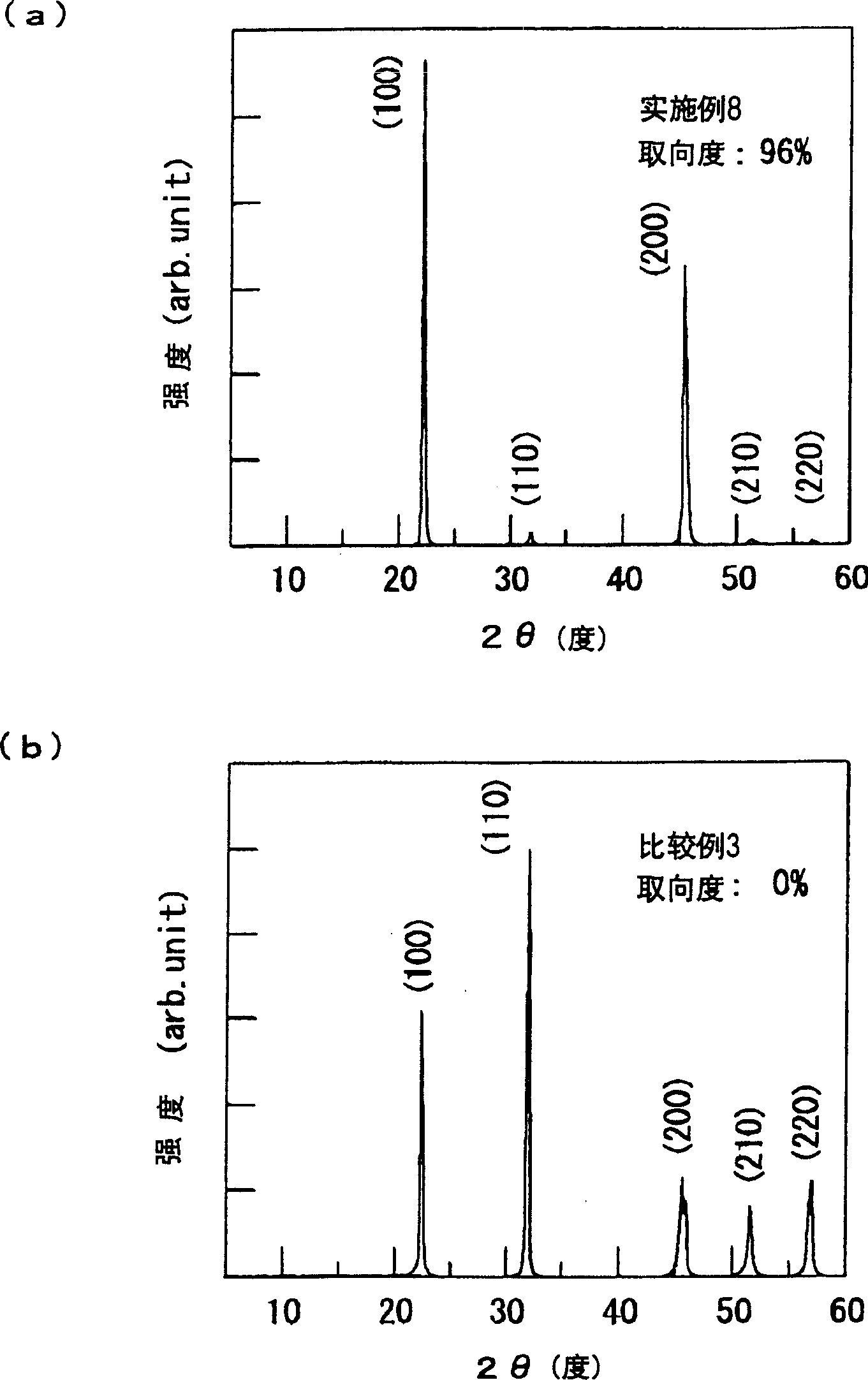

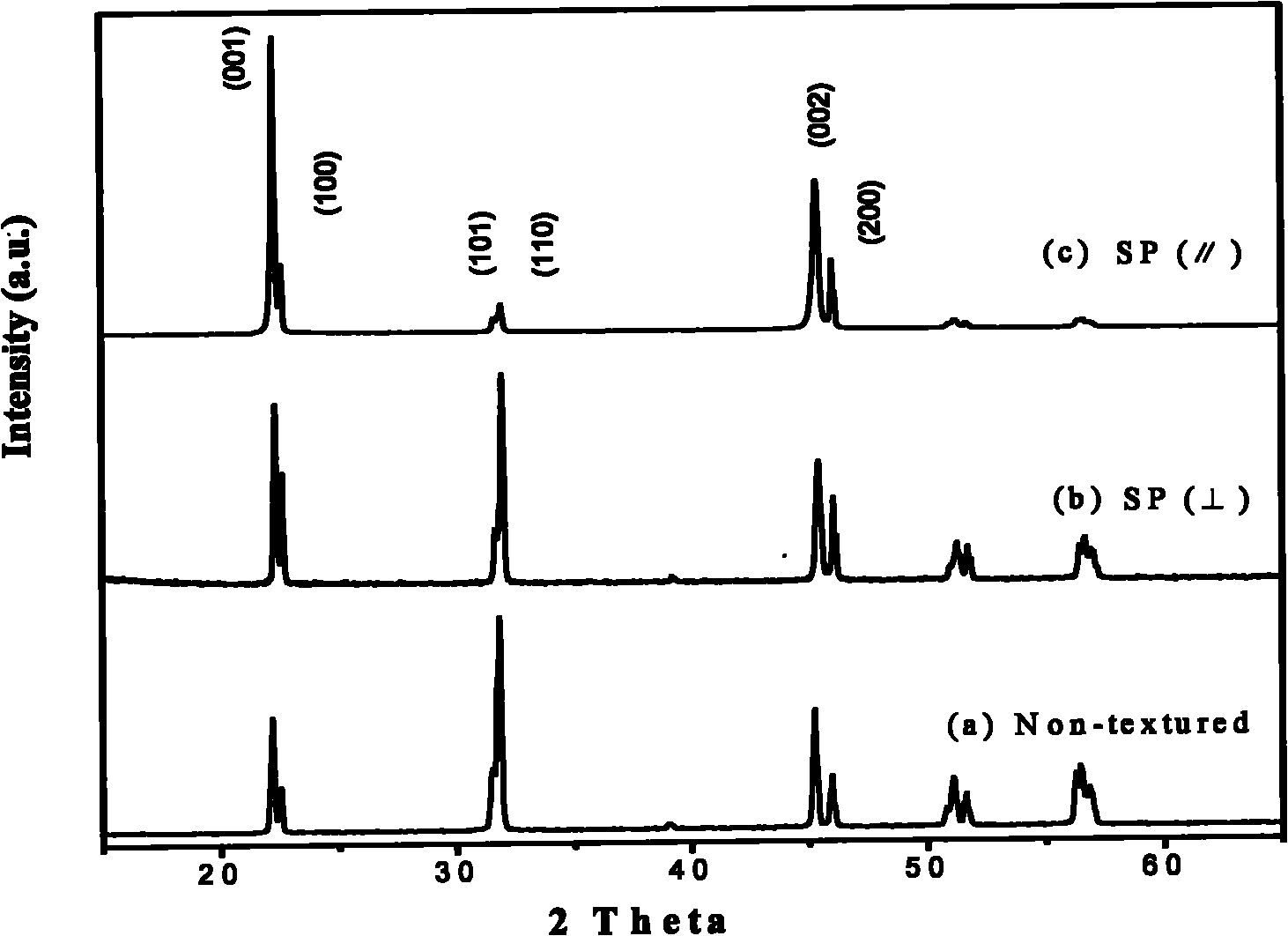

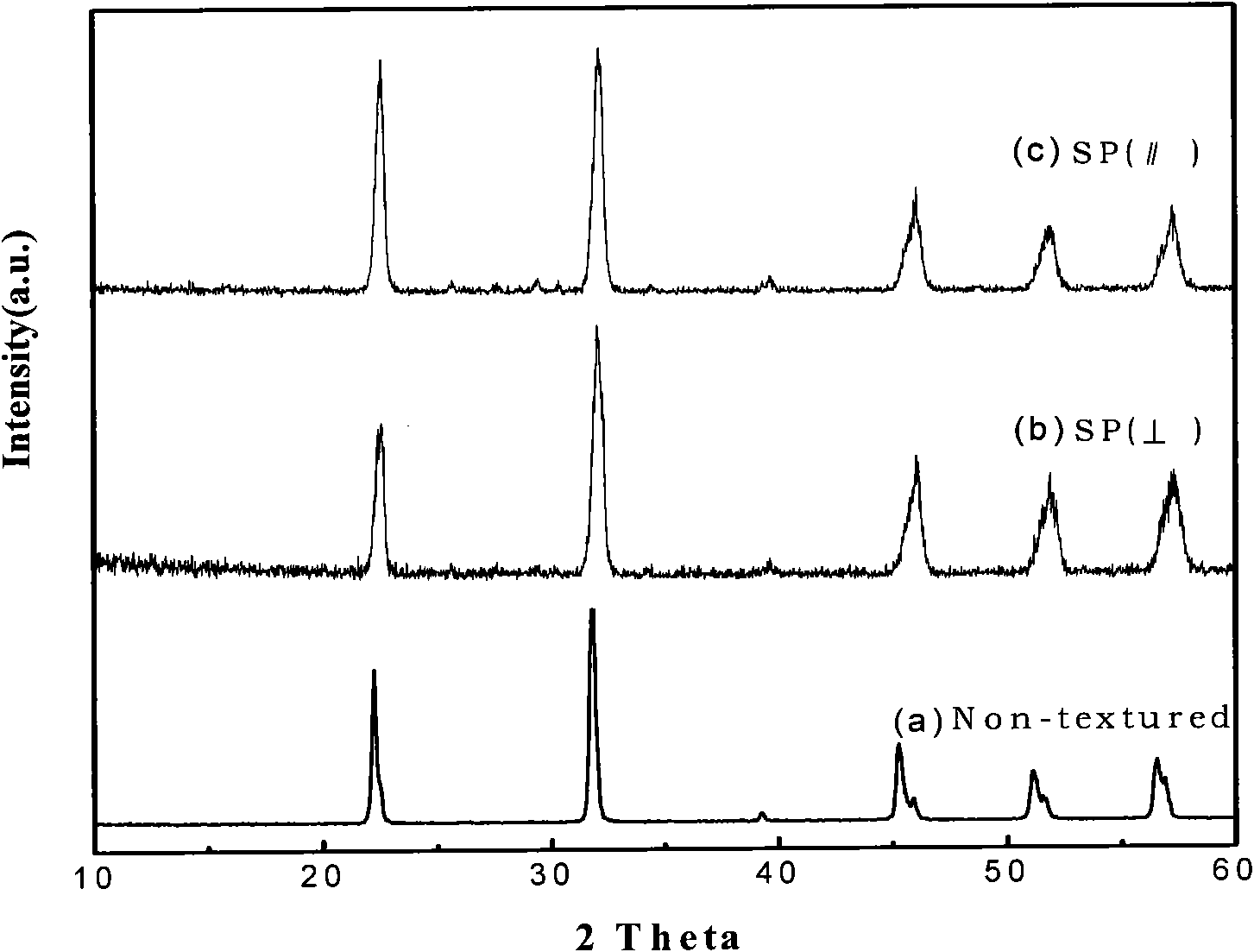

Crystal oriented ceramics and production method of same

InactiveCN1609047ATantalum compoundsPiezoelectric/electrostrictive/magnetostrictive devicesCrystal planeCrystallite

The present invention provides crystal oriented ceramics, and a production method of the same, having a basic composition of isotropic perovskite-based potassium sodium niobate, demonstrating superior piezoelectric characteristics, and having a specific crystal plane oriented to a high degree of orientation. The crystal oriented ceramics as claimed in the present invention is composed of a polycrystalline substance of an isotropic perovskite compound represented by the general formula: {Lix(K1-yNay)1-x}{Nb1-z-wTazSbw}O3 (wherein, 0<=x<=0.2, 0<=y<=1, 0<=z<=0.4, 0<=w<=0.2, x+z+w>0), and a specific crystal plane of each crystal grain that composes said polycrystalline substance is oriented. Such crystal oriented ceramics are obtained by molding a mixture of a first anisotropic shaped powder, for which the growth plane has lattice coherency with a specific crystal plane of the isotropic perovskite compound to be produced, and a first reaction raw material, so that the first anisotropic shaped powder is oriented, followed by heating.

Owner:DENSO CORP

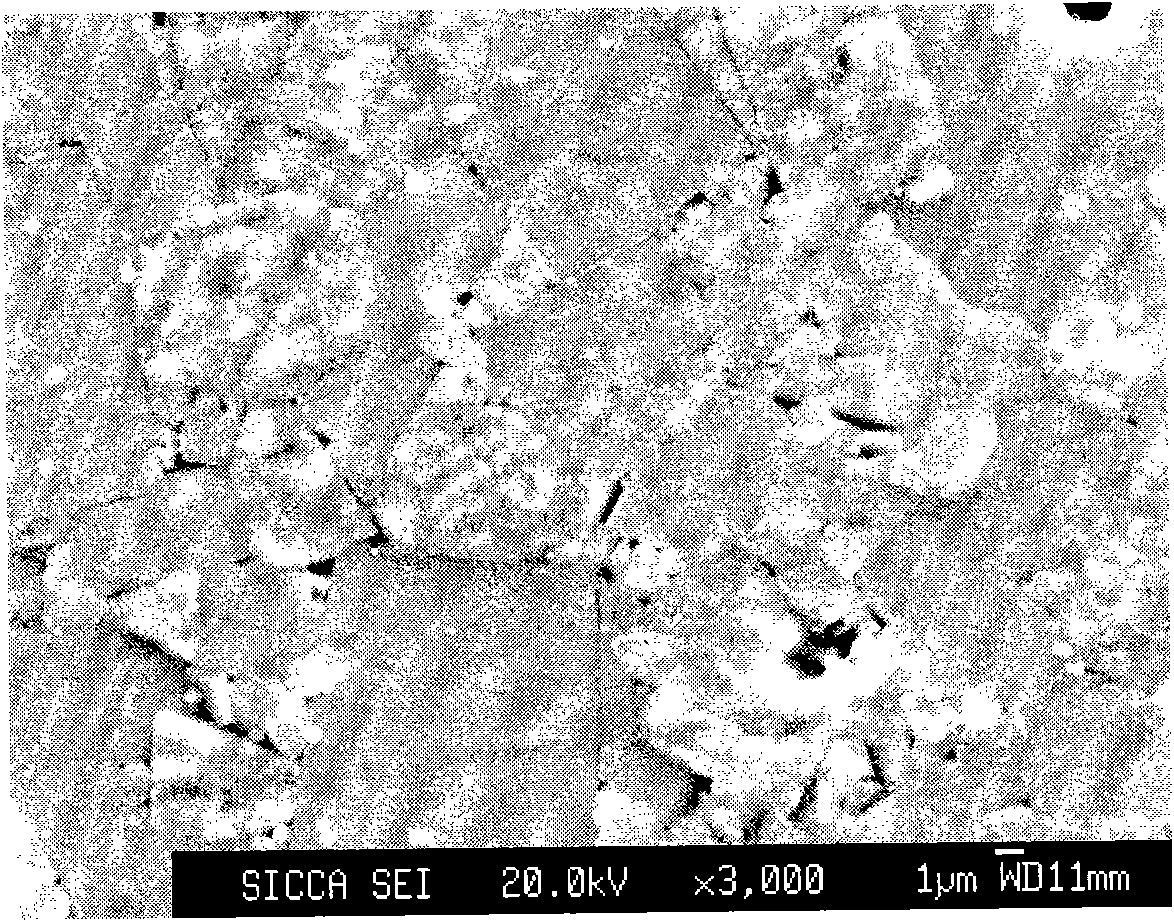

Method for preparing textured potassium niobate sodium-based leadless piezoelectric ceramic

The invention relates to a method for preparing textured potassium niobate sodium-based leadless piezoelectric ceramic and belongs to the field of preparation of leadless piezoelectric ceramic. The method comprises the following steps of: preparing power and obtaining slurry by taking flaky NaNbO3 or flaky KnbO3 as a template or a non-type template and selecting powder of Na2CO3, K2CO3, Li2CO3, Nb2O5, Ta2O5, Sb2O3 according to a chemical formula, namely, [(KmNa1-m)1-xLix](Nb1-y-zTaySbz)O33; laminating and pressing a plurality layers of thick ceramic films obtained by screen printing so as to obtain a biscuit; removing plastic from the biscuit; and sintering the biscuit from which the plastic is removed. A printing process is simple, the textured potassium niobate sodium-based leadless piezoelectric ceramic with a very high degree of orientation can be obtained and the highest degree of orientation factor is up to 90 percent.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

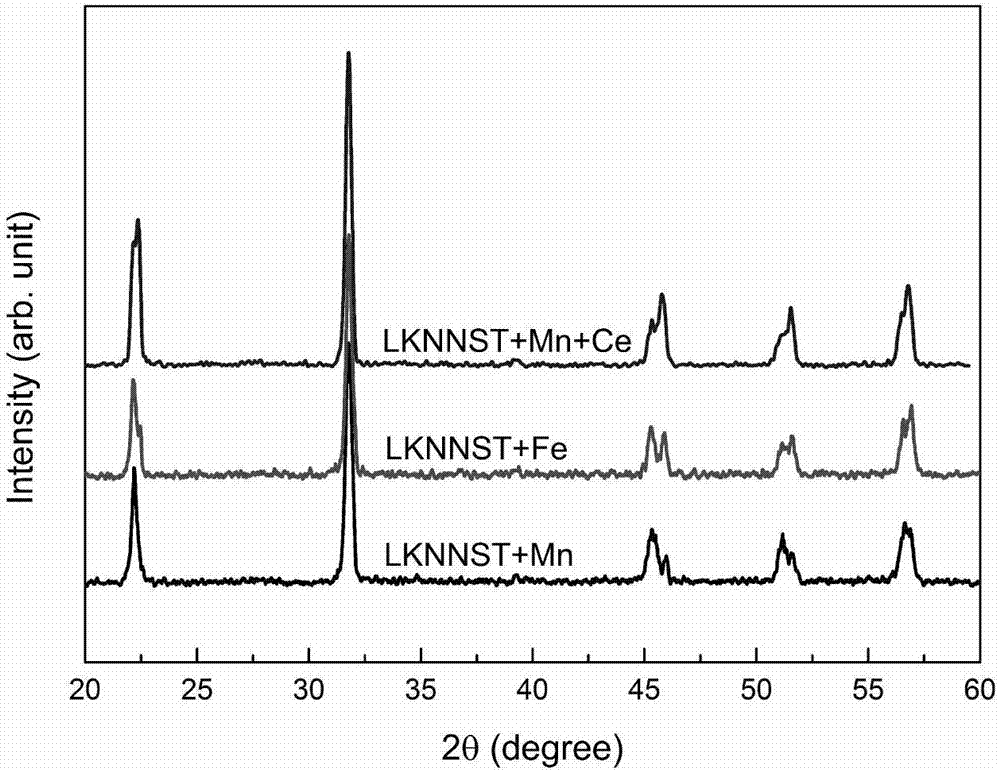

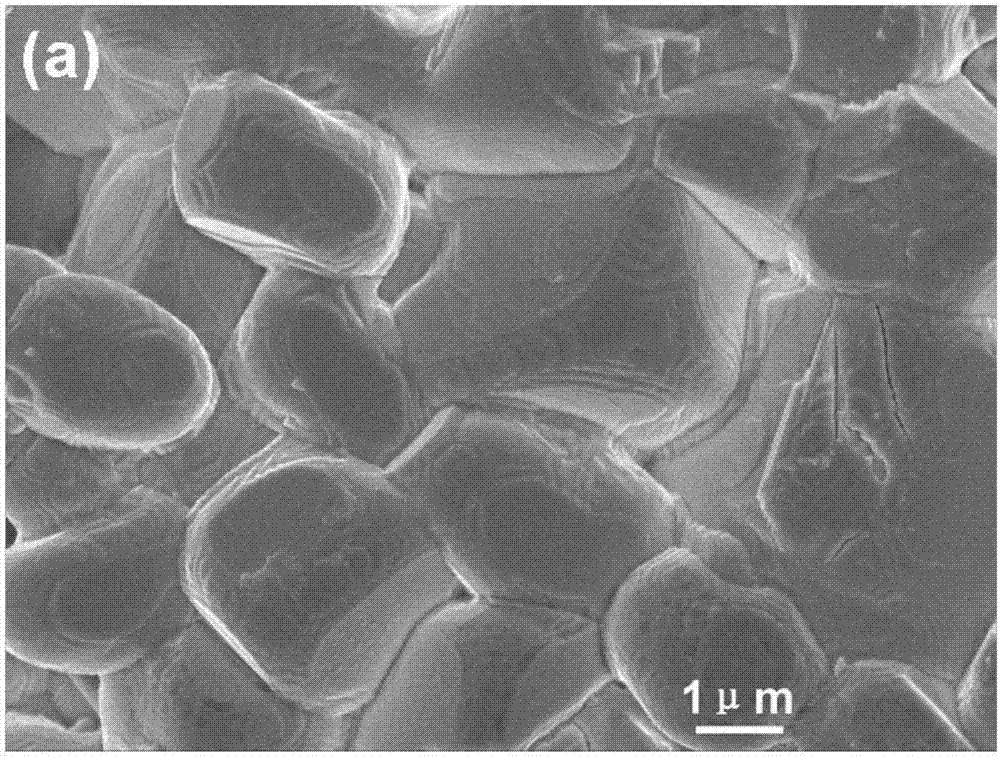

High-mechanical-strength potassium-sodium niobate based lead-free piezoelectric ceramic material, preparation method of material and application of material

InactiveCN107382318ASolve the problem of poor sinterabilityAchieving controllable equipmentPiezoelectric/electrostrictive/magnetostrictive devicesOxidePorosity

The invention provides a high-mechanical-strength potassium-sodium niobate based lead-free piezoelectric ceramic material, a preparation method of the material and an application of the material. The potassium-sodium niobate based lead-free piezoelectric ceramic material comprises [Li0.06(K0.47-xNa0.47+x)][(Nb0.893Sb0.057Ta0.05)O3, TMO (transition metal oxide) and REO (rare earth oxide), wherein the TMO is MnO2, Fe2O3, Ni2O3, CuO, Cr2O3 or Co2O3, and the REO is Ce2O3, Nd2O3 or Yb2O3. Li<+> co-substitutes A-site K<+> and Na<+>, Sb<5+> and Ta<5+> co-substitutes B-site Nb<5+>, synergistic modification is realized by transition / rare-earth metal oxide coping, the sintering property of the potassium-sodium niobate based ceramics is improved, and controllable preparation of low-porosity dense ceramics is realized, so that the potassium-sodium niobate based lead-free piezoelectric ceramic material has good mechanical strength and piezoelectric performance.

Owner:HUBEI UNIV

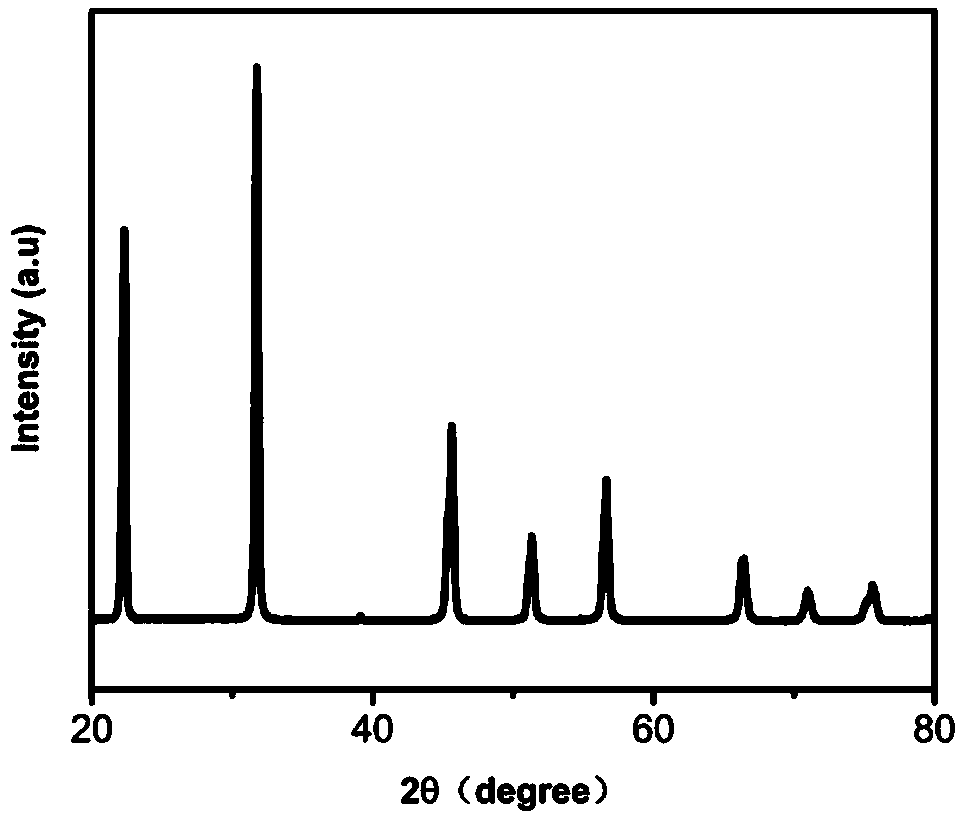

Quadrature-phase lithium tantalum doped potassium sodium niobate based lead-free piezoelectric single crystal and preparation method thereof

ActiveCN102628186AGood electrical propertiesExcellent piezoelectric propertiesPolycrystalline material growthBy pulling from meltSlurrySingle crystal

A quadrature-phase lithium tantalum doped sodium potassium niobate based lead-free piezoelectric single crystal and a preparation method thereof, relate to a functional single crystal material and a preparation method thereof. The preparation method provided in the invention solves the technical problems of growth difficulty, small size and weak piezoelectric property existing in potassium sodium niobate based piezoelectric single crystal. The method compromises the following steps of: firstly, preparing slurry; second, synthesizing polycrystal; thirdly, melting raw materials; fourthly, performing neck-contracting; fifthly, performing shoulder-expanding ; sixthly, performing diameter-equating; and seventhly, performing cooling. The method provided in the invention has the advantages of simple process, a short growth cycle and low cost. The potassium sodium niobate based piezoelectric single crystal produced by the growth method, is characterized by large size, uniform mass and good electrical property with radial size being about 8 mm and length being about 20 mm. the quadrature-phase lithium tantalum doped potassium sodium niobate based piezoelectric single crystal provided in the invention is of a pure perovskite structure, without any other impurity phase. The lithium tantalum doped potassium sodium niobate based piezoelectric single crystal is a quadrature-phase structure at room temperature. The quadrature-phase lithium tantalum doped potassium sodium niobate based piezoelectric single crystal has very good piezoelectric property.

Owner:HARBIN INST OF TECH

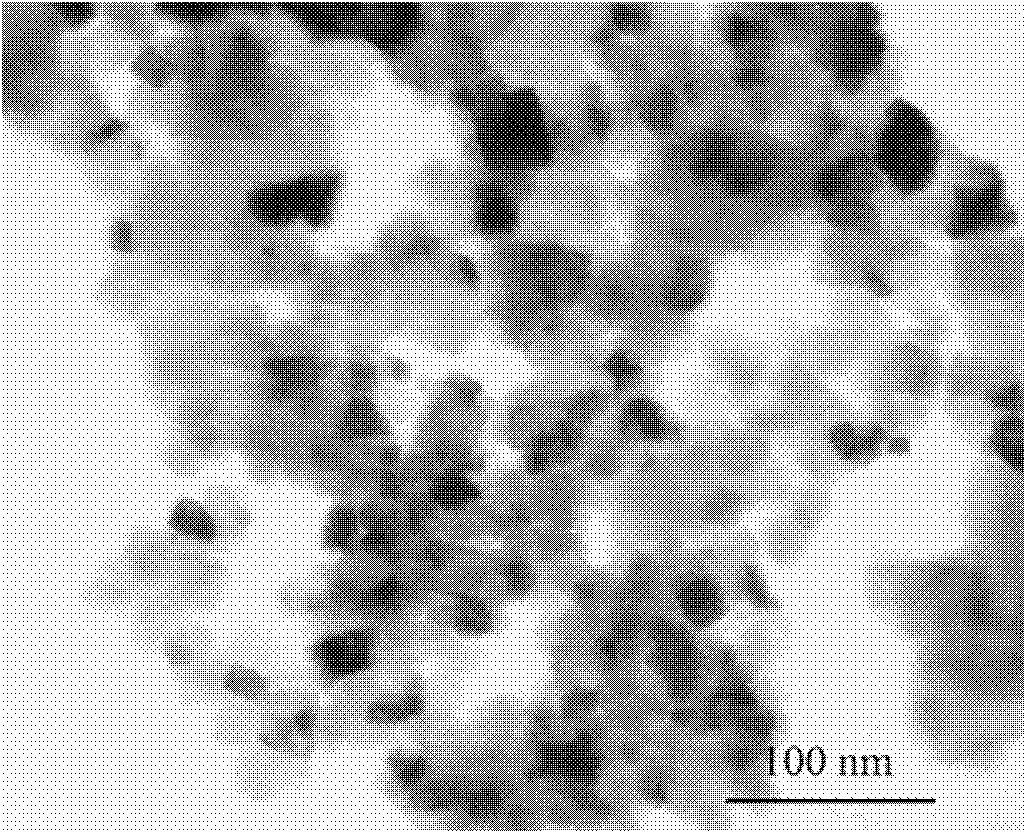

Method for preparing potassium niobate nano powder

InactiveCN102153350ASmall granularityHigh sintering activityNanotechnologyPotassium hydroxidePotassium niobate

The invention relates to a method for preparing potassium niobate nano powder. The single-phase nano KNbO3 powder can be obtained at a low temperature by the method. The method comprises the following steps of: mixing potassium hydroxide and niobium pentaoxide in a molar ratio of 8-12:1, calcining the mixture for 1 to 4 hours at the temperature of between 320 and 400 DEG C, dissolving the obtained solid into deionized water, adding oxalic acid, regulating the pH value of the solution to between 4 and 5, and obtaining white sediment; dissolving the white sediment into aqueous solution of citric acid, adding potassium nitrate according to the component proportion of KNbO3, and obtaining a precursor by sol-gel and burning processes; and calcining the precursor at the temperature of between 600 and 800 DEG C to obtain the potassium niobate powder with grain diameter of between 10 and 70 nanometers and with perovskite structure. The process is simple and quick, the prepared powder has high purity and low granularity, and the cost is reduced.

Owner:DALIAN JIAOTONG UNIVERSITY

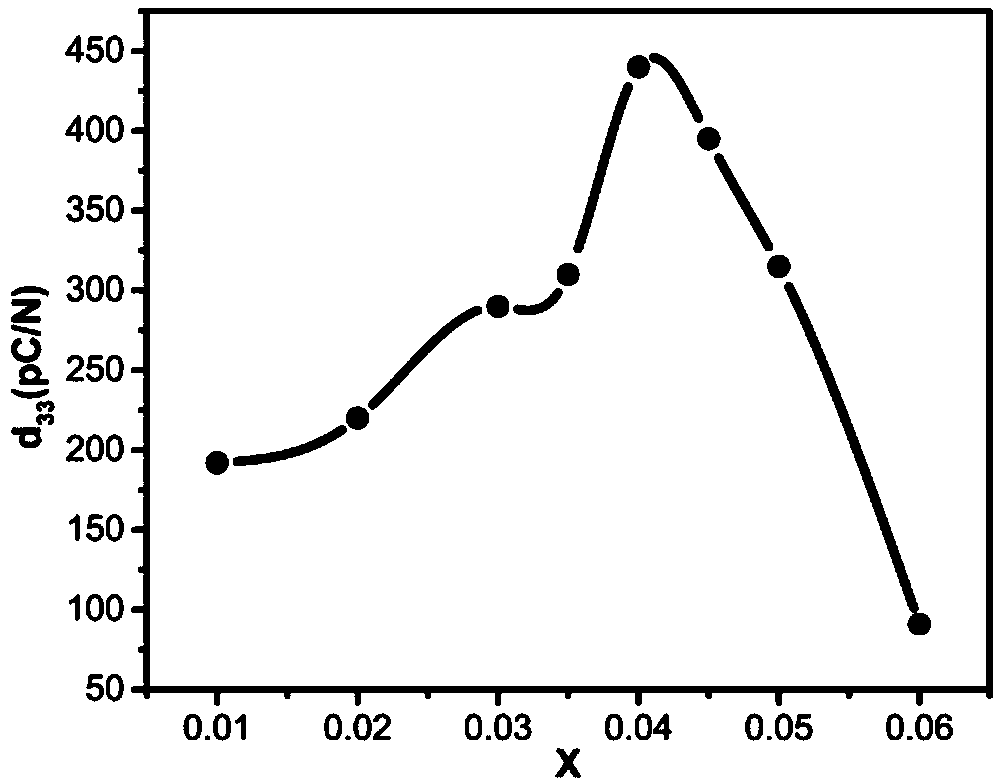

Lead-free piezoelectric ceramic material with high piezoelectricity and high electrogenerated strain and preparation method thereof

ActiveCN109608195ALower the holding temperatureHigh piezoelectric coefficientChemical compositionHigh pressure

The invention relates to a lead-free piezoelectric ceramic material with high piezoelectricity and high electrogenerated strain and a preparation method thereof. The chemical composition of the material accords with the chemical general formula (1-x)(K0.5Na0.5)0.98Ag0.02(Nb0.96Sb0.04) O3-x (Bi0.5Na0.5) ZrO3, wherein x represents the percentage of (Bi0.5Na0.5) ZrO3 in the potassium-sodium niobate-based lead-free piezoelectric ceramic, and x is more than or equal to 0.01 and less than or equal to 0.06. Compared with the prior art, the preparation method has the advantages of simplicity, good stability and low cost. The lead-free piezoelectric ceramic material obtained by the preparation method has excellent piezoelectric performance and electrogenerated strain, the d33 reaches 440 pC / N, thed33* reaches 553 pm / V, good temperature stability is shown, and the lead-free piezoelectric ceramic material can be used for piezoelectric sensors, piezoelectric motors and high-precision displacementcontrollers, the material has good application prospect.

Owner:TONGJI UNIV

Lithium-sulfur battery composite positive electrode material and preparation method thereof

InactiveCN106532016ASimple methodNo complicated operationsCell electrodesLead zirconate titanateBarium titanate

The invention discloses a lithium-sulfur battery composite positive electrode material. Graphene oxide is used as a matrix of the battery positive electrode material, a graphene / ferroelectric composite material is obtained after the graphene oxide and a ferroelectric material are compounded, and then the graphene / ferroelectric composite material is mixed with nano sulfur according to a mass ratio of 3:7 to prepare the lithium-sulfur battery composite positive electrode material; and the ferroelectric material is one of barium titanate, lead titanate, potassium niobate, strontium titanate, lithium niobate or lead zirconate titanate. According to the lithium-sulfur battery composite positive electrode material disclosed by the invention, excellent electrical conductivity and structural stability of the graphene oxide are utilized, and the graphene oxide is used as an excellent conductive network and the positive electrode matrix, so that electrical conductivity of the positive electrode material is improved; and by utilizing strong adsorption of ferroelectricity of the ferroelectric material on polar polysulfide, dissolution and shuttling of the polysulfide in electrolyte are inhibited, so that loss of active substances is reduced, coulombic efficiency of a lithium-sulfur battery is improved and a cycle life of the lithium-sulfur battery is prolonged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

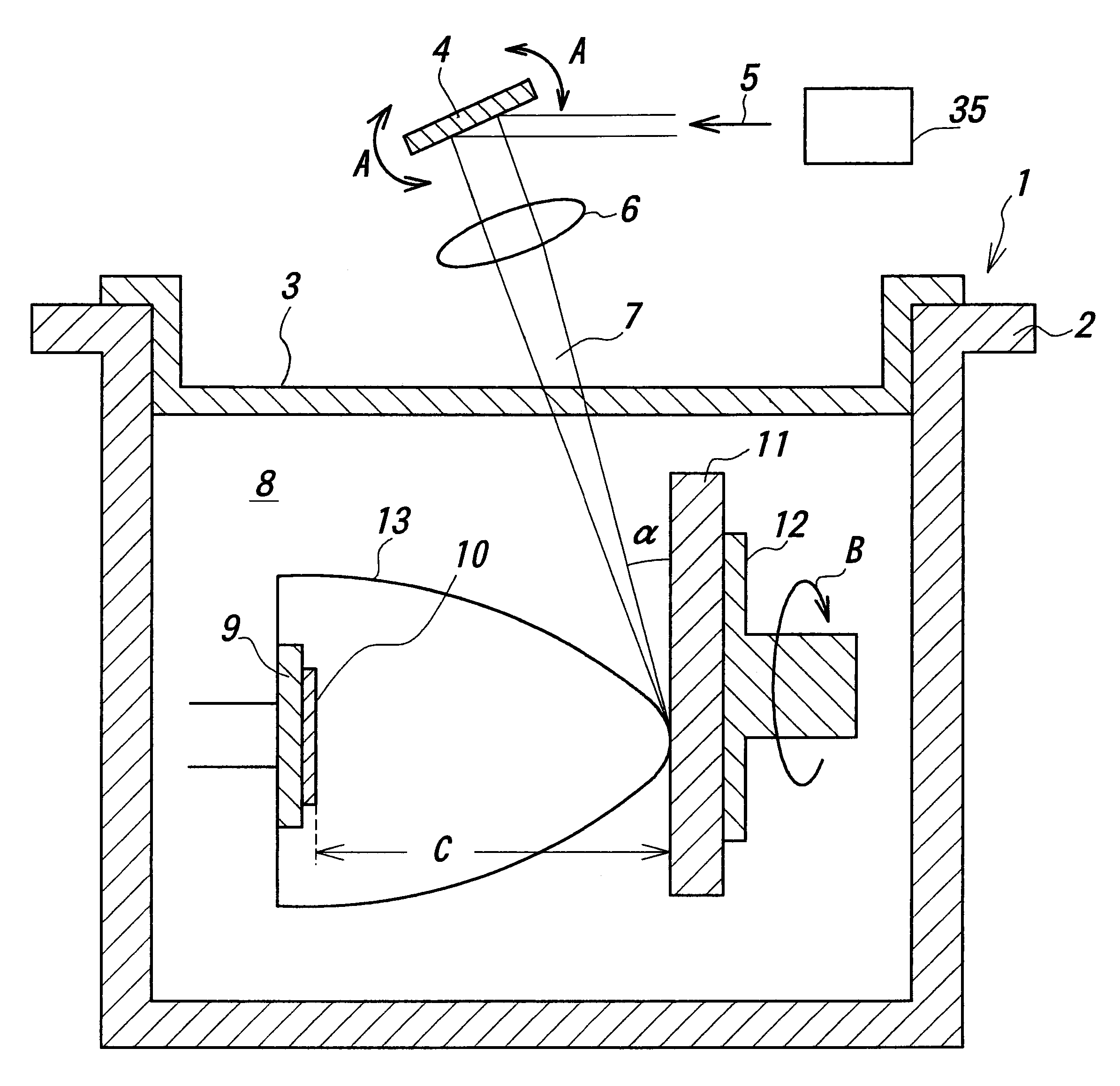

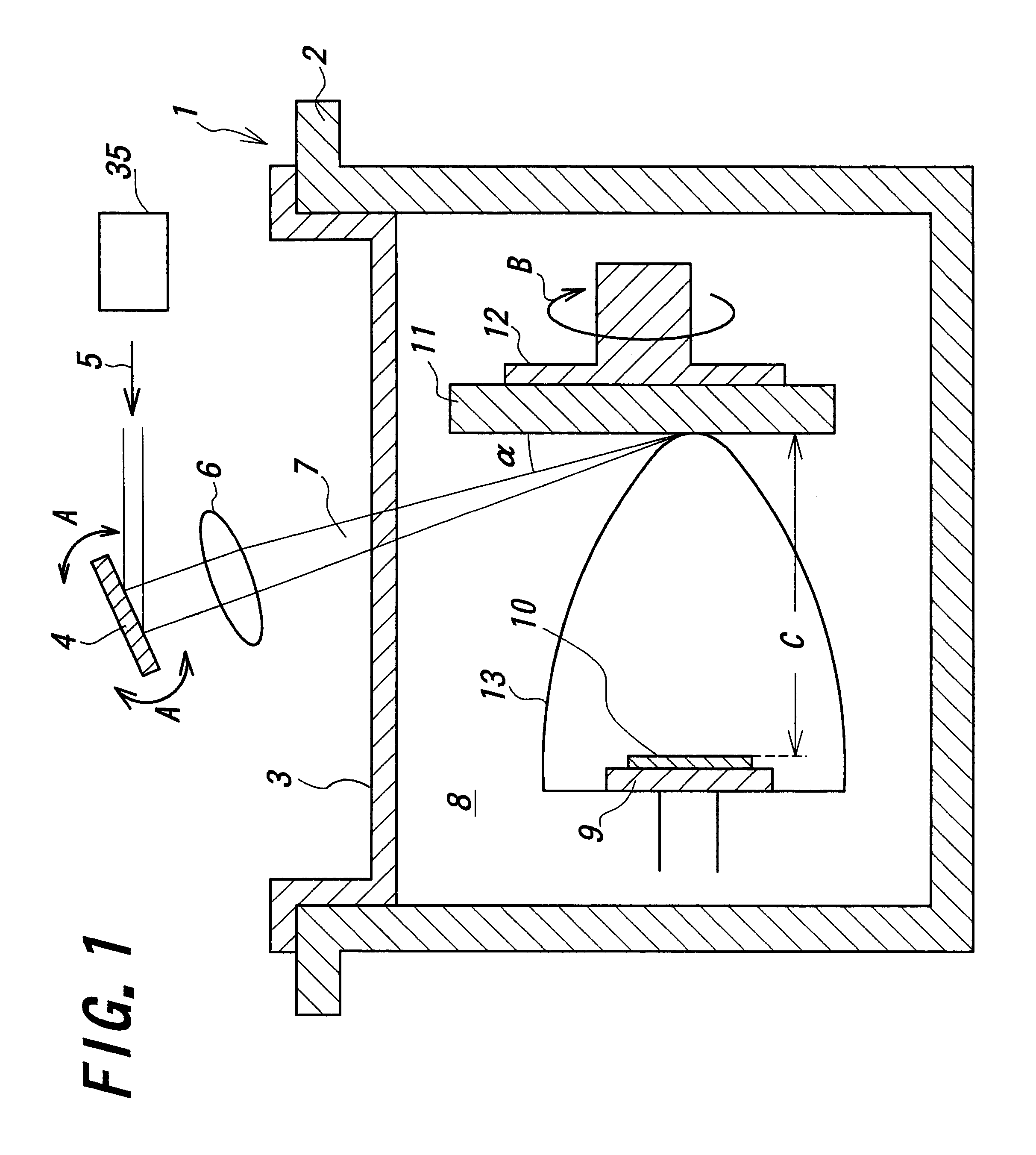

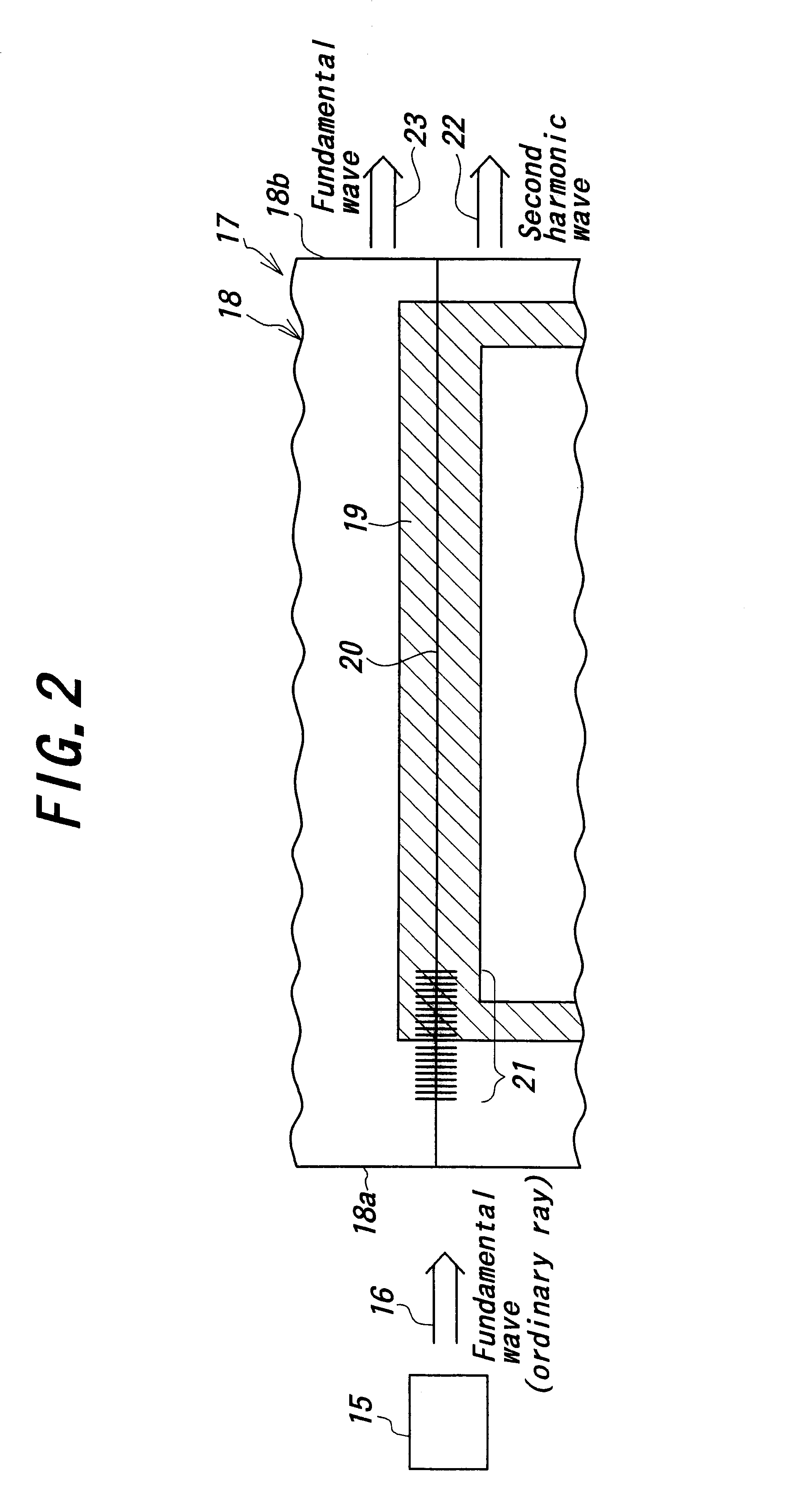

Method for producing a single-crystalline film of KLN or KLNT

InactiveUS6447606B2Improve featuresImprove conversion efficiencyPolycrystalline material growthSemiconductor/solid-state device manufacturingLithiumPotassium

Owner:NGK INSULATORS LTD

Sodium potassium niobate-sodium bismuth zirconate titanate lead-free piezoelectric ceramic

InactiveCN103288451AImprove piezoelectric performanceImprove temperature stabilityElectricityZirconate

The invention belongs to the field of perovskite structure environment-compatible piezoelectric ceramics and particularly relates to a sodium potassium niobate-sodium bismuth zirconate titanate lead-free piezoelectric ceramic. The lead-free piezoelectric ceramic is represented by the general formula (1-x) (KuNav) NbO3-xBi0.5Na0.5Zr1-yTiyO3, wherein x is more than 0 and not more than 0.05, y is not less than 0 and not more than 0.3, u is not less than 0.40 and not more than 0.55, v is not less than 0.45 and not more than 0.60, and u+v=1. The lead-free piezoelectric ceramic provided by the invention has the advantages of higher piezoelectric performance, low price of used raw materials and cost saving, is favorable for promoting the practical process and can be applied to industrial production.

Owner:SICHUAN UNIV

Potassium niobate deposited body and method for manufacturing the same, surface acoustic wave device, frequency filter, oscillator, electronic circuit, and electronic apparatus

InactiveUS7265482B2Piezoelectric/electrostrictive device manufacture/assemblyImpedence networksLead zirconate titanateSurface acoustic wave

A potassium niobate deposited body includes an R-plane sapphire substrate, a buffer layer composed of a metal oxide and formed above the R-plane sapphire substrate, a lead zirconate titanate niobate layer formed above the buffer layer, and a potassium niobate layer or a potassium niobate solid solution layer formed above the lead zirconate titanate niobate layer.

Owner:SEIKO EPSON CORP

Microwave hydro-thermal synthesis method for sodium niobate potassium niobate leadless piezoelectric ceramic powder

InactiveCN101186339ASimple processLow costPiezoelectric/electrostrictive/magnetostrictive devicesNiobium compoundsMicrowaveSynthesis methods

The invention relates to a microwave hydrothermal synthesis method for preparation of sodium-potassium and niobate-potassium lead-free piezoelectric ceramic powder, which belongs to the functional material field. The invention is characterized in that: NaOH or KOH solution and Nb2O5 are used as reactants; NaNbO3 or KNbO3 ceramic powder is synthesized by microwave hydrothermal technology; the concentration of NaOH or KOH is 4-8mol / L while the input amount of the Nb2O5 is 0.01 to 0.02 mol; and the reaction temperature is 110 to 150 DEG C and the heat is preserved for 2 to 6 hours. The microwave hydrothermal synthesis method for preparation of sodium-potassium and niobate-potassium lead-free piezoelectric ceramic powder combines the unique heating features of a microwave and the advantage of the hydrothermal method, thus having simple technique, low cost, low consumption and very wide application prospect.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com