Method for preparing potassium niobate nano powder

A technology of nano-powder and potassium niobate, which is applied in the field of preparation of potassium niobate nano-powder, can solve the problems of high requirements on instruments and equipment, waste of raw materials, strict requirements on the use environment, etc., and achieves high sintering activity, easy process control, The effect of small powder particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] ① Mix potassium hydroxide and niobium pentoxide with a molar ratio of 8:1 and then calcinate at 350°C for 2 hours; dissolve the calcined product in water, filter to remove insoluble impurities, add oxalic acid to adjust the pH value of the solution to 5, and the solution A large amount of white precipitates were produced in the medium; after filtration, the white precipitates were washed repeatedly with deionized water to remove potassium ions and oxalate ions in the precipitates.

[0021] ② Add the white precipitate to the citric acid aqueous solution, and the molar ratio of niobium ions and citric acid is 1:4 to obtain a transparent niobium-containing citric acid solution; Stir in a water bath at 60°C to obtain a transparent sol, then continue to stir in a water bath at 80°C to obtain a light yellow transparent gel.

[0022] ③Heat the above gel to 180°C and keep it warm for 15 minutes, the gel undergoes redox reaction to form a fluffy precursor.

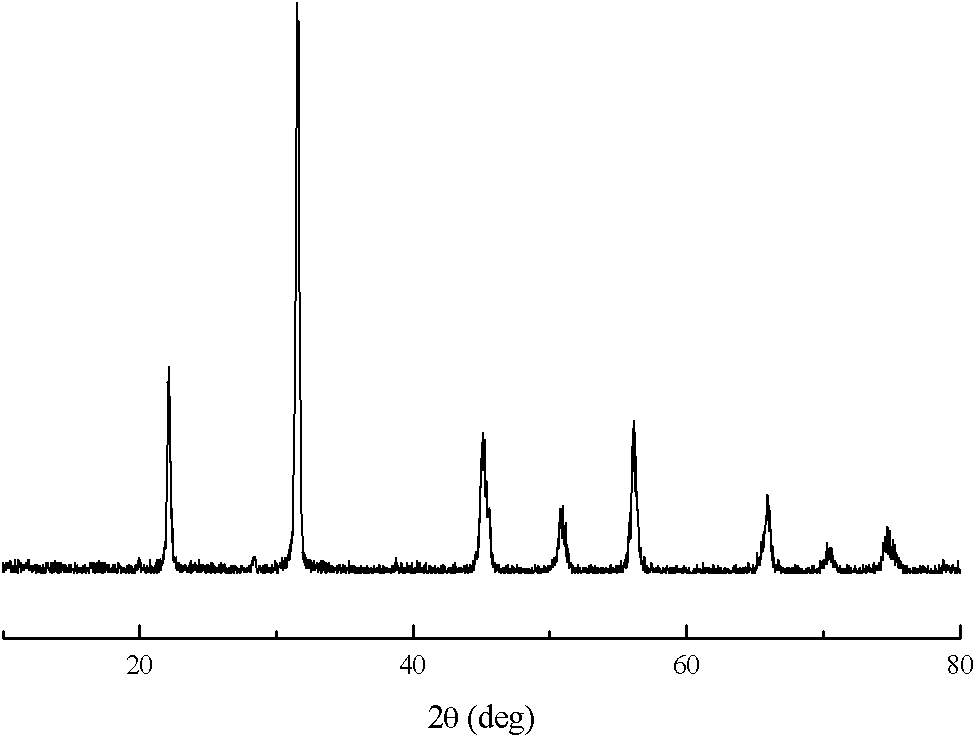

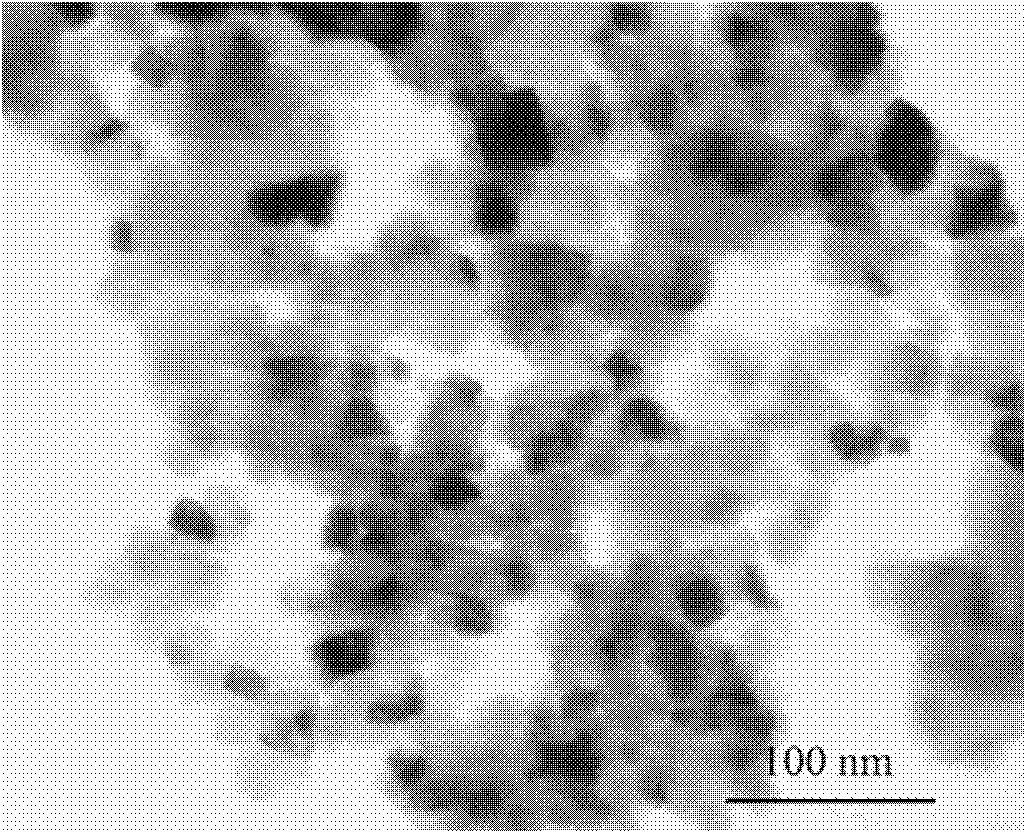

[0023] ④The pulveri...

example 2

[0026] Mix potassium hydroxide and niobium pentoxide with a molar ratio of 10:1 and calcinate at 320°C for 4 hours, dissolve the calcined product in water, remove insoluble impurities, add oxalic acid to the solution to adjust the pH to 4, and A large number of white precipitates are produced; when the gel is heated to 150°C and kept for 20 minutes, a fluffy precursor is formed. KNbO with a particle size of 40 nm was obtained by annealing the precursor at 800 °C for 2 h after grinding 3 Nano powder (all the other conditions are with example 1).

example 3

[0028] Mix potassium hydroxide and niobium pentoxide with a molar ratio of 8:1, and then calcinate at 400°C for 1 hour, dissolve the calcined product in water, remove insoluble impurities, and then add oxalic acid to the solution to adjust the pH value to 4. A white precipitate is produced; the white precipitate is added to the citric acid aqueous solution, and the molar ratio of niobium ions and citric acid is 1:6 to obtain a transparent niobium-containing citric acid solution; after adding potassium nitrate, stir in a water bath at 70°C to obtain a transparent sol, Then continue stirring in a 90°C water bath to obtain a light yellow transparent gel. The above gel was heated to 200° C. and kept for 30 minutes to form a light yellow fluffy precursor. KNbO with a particle size of 50 nm was obtained by annealing at 900 °C for 2 h after precursor grinding 3 Nano powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com